height FORD EXPLORER 2015 5.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2015, Model line: EXPLORER, Model: FORD EXPLORER 2015 5.GPages: 596, PDF Size: 6.32 MB

Page 102 of 596

DAYTIME RUNNING LAMPS (IF EQUIPPED)

WARNING:Always remember to turn on your headlamps at

dusk or during inclement weather. The Daytime Running Lamp

(DRL) system does not activate the tail lamps and generally may not

provide adequate lighting during these conditions. Failure to activate

your headlamps under these conditions may result in a collision.

The system turns the headlamps on with a reduced output.

To activate:

•the ignition must be in the on position and

•the lighting control is in the off, autolamp, or parking lamp position

and

•the transmission is not in PARK.

AUTOMATIC HIGH BEAM CONTROL (IF EQUIPPED)

The system will automatically turn on your high beams if it is dark

enough and no other traffic is present. When it detects an approaching

vehicle’s headlights, a preceding vehicle’s tail lamps or street lighting, the

system will turn off the high beams (low beams remain on) before they

distract other drivers.

Note:If it appears that automatic control of the high beams is not

functioning properly, check the windshield in front of the camera for

blockage. A clear view of the road is required for proper system

operation. Any windshield damage in the area of the camera field-of-view

should be repaired.

Note:If a blockage is detected (e.g. bird dropping, bug splatter, snow, or

ice) and no changes are observed, the system will go into low beam

mode until the blockage is cleared. A message may also appear in the

instrument cluster display noting the front camera is blocked.

Note:Typical road dust, dirt and water spots will not affect the

automatic high beam system’s performance. However, in cold or

inclement weather conditions, the automatic high beam system’s

availability may be decreased. If the driver wants to change the beam

state independently of the system, the driver may turn the high beams

on or off using the multifunction switch stalk. Automatic control will

resume when conditions are correct.

Note:Modification of the vehicle ride height (e.g. using much larger

tires) may degrade feature performance.

Lighting101

2015 Explorer(exp)

Owners Guide gf, 2nd Printing, September 2014

USA(fus)

Page 278 of 596

2. To reinstall the cover, insert the

four plastic tabs on top of the cover

into the corresponding slots (B),

and push the cover into the bumper

trim.

3. Hold the cover against the bumper trim and reinstall the two

1�4-turn

fasteners by turning them clockwise.

Hitches

Do not use a hitch that clamps onto your vehicle’s bumper. Use a

load-carrying hitch.

You must distribute the load in your trailer so that 10–15% of the total

weight of the trailer is on the tongue. Do not to exceed the maximum

tongue load of 500 pounds (227 kilograms) on a Class III receiver.

Weight-Distributing Hitch

WARNING:Do not adjust a weight-distributing hitch to any

position where the rear bumper of the vehicle is higher than it

was before attaching the trailer. Doing so will defeat the function of the

weight-distributing hitch, which may cause unpredictable handling, and

could result in serious personal injury.

When hooking-up a trailer using a weight-distributing hitch, always use

the following procedure:

1. Park your vehicle, without the trailer, on a level surface.

2. Measure the height of the top of your vehicle’s front wheel opening

on the fender. This is H1.

3. Attach the trailer to your vehicle without the weight-distributing bars

connected.

4. Measure the height of the top of your vehicle’s front wheel opening

on the fender a second time. This is H2.

5. Install and adjust the tension in the weight distributing bars so that

the height of the front fender is approximately halfway between H1

and H2.

6. Check that the trailer is level. If not level, adjust the ball height

accordingly and repeat Steps 3–6.

BBBB

Towing277

2015 Explorer(exp)

Owners Guide gf, 2nd Printing, September 2014

USA(fus)

Page 334 of 596

7. Lower the driver’s side of the cover and slide the

three tabs on the cover into the three slots in the

housing.

8. Lower the passenger’s side of the cover. Engage

the two clamps to secure the cover to the housing.

ADJUSTING THE HEADLAMPS

The headlamps on your vehicle are properly aimed at the assembly plant.

If your vehicle has been in an accident, an authorized dealer should

check the alignment of your headlamps.

Vertical Aim Adjustment

The headlamps on your vehicle can only be vertically adjusted. Your

vehicle does not require horizontal aim adjustments.

To adjust the headlamps:

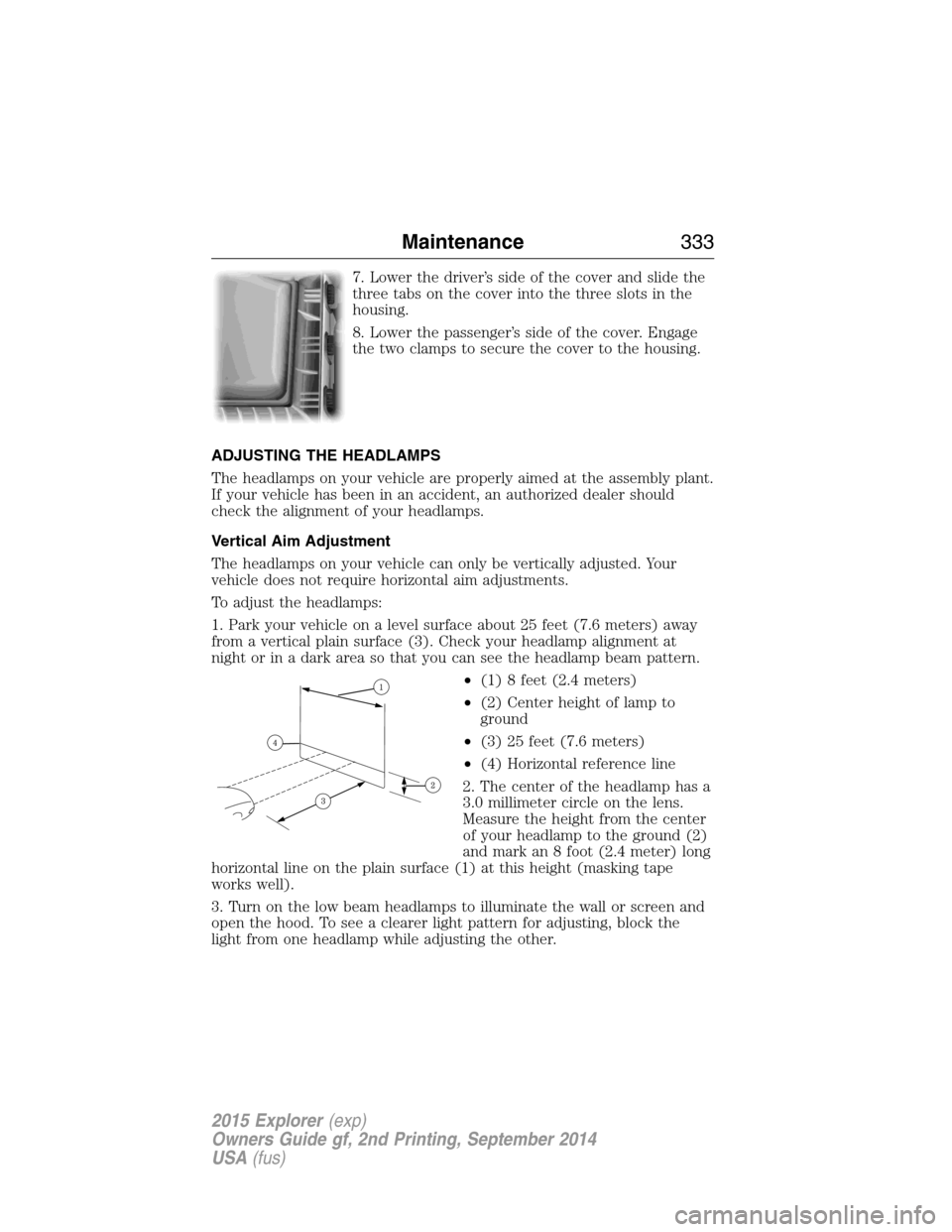

1. Park your vehicle on a level surface about 25 feet (7.6 meters) away

from a vertical plain surface (3). Check your headlamp alignment at

night or in a dark area so that you can see the headlamp beam pattern.

•(1) 8 feet (2.4 meters)

•(2) Center height of lamp to

ground

•(3) 25 feet (7.6 meters)

•(4) Horizontal reference line

2. The center of the headlamp has a

3.0 millimeter circle on the lens.

Measure the height from the center

of your headlamp to the ground (2)

and mark an 8 foot (2.4 meter) long

horizontal line on the plain surface (1) at this height (masking tape

works well).

3. Turn on the low beam headlamps to illuminate the wall or screen and

open the hood. To see a clearer light pattern for adjusting, block the

light from one headlamp while adjusting the other.

Maintenance333

2015 Explorer(exp)

Owners Guide gf, 2nd Printing, September 2014

USA(fus)

Page 358 of 596

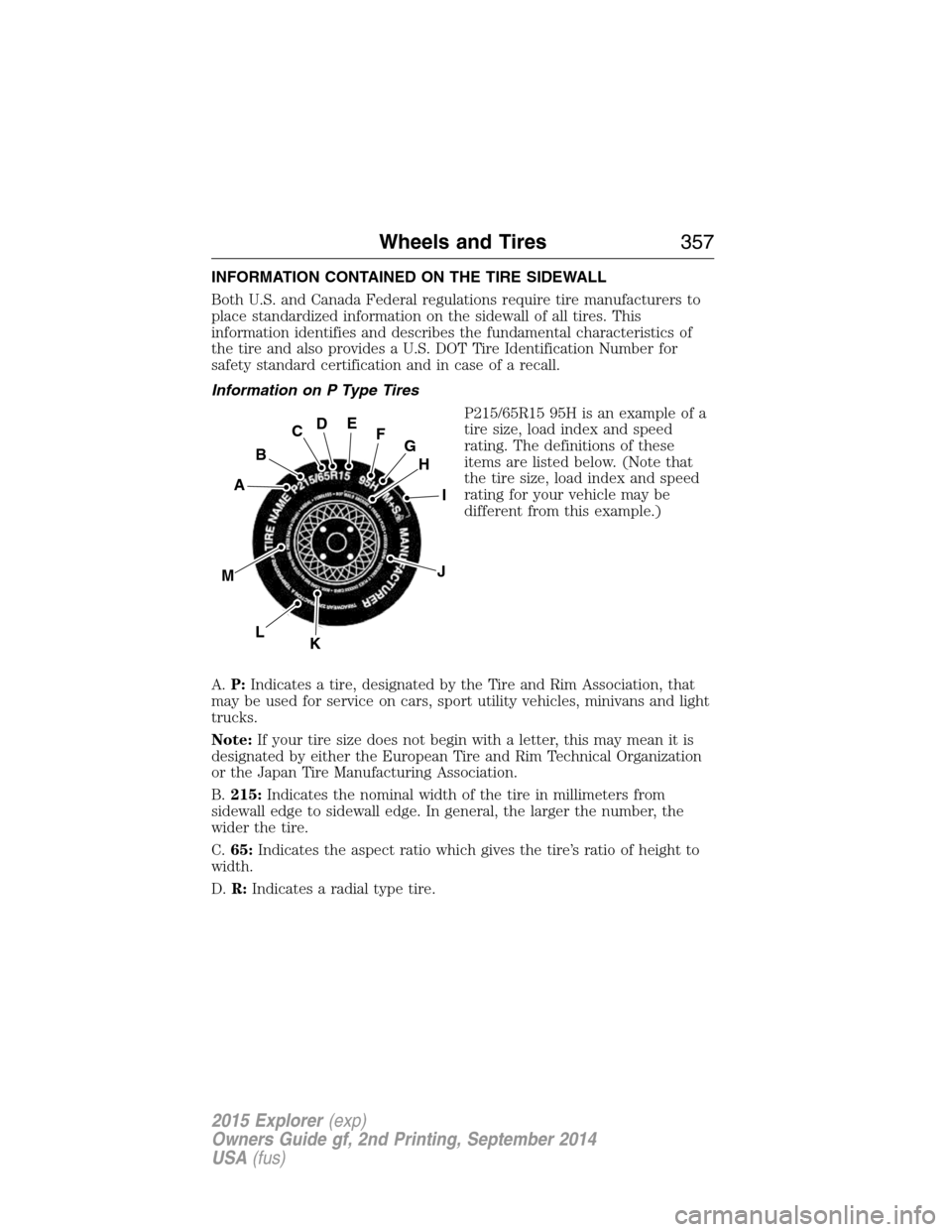

INFORMATION CONTAINED ON THE TIRE SIDEWALL

Both U.S. and Canada Federal regulations require tire manufacturers to

place standardized information on the sidewall of all tires. This

information identifies and describes the fundamental characteristics of

the tire and also provides a U.S. DOT Tire Identification Number for

safety standard certification and in case of a recall.

Information on P Type Tires

P215/65R15 95H is an example of a

tire size, load index and speed

rating. The definitions of these

items are listed below. (Note that

the tire size, load index and speed

rating for your vehicle may be

different from this example.)

A.P:Indicates a tire, designated by the Tire and Rim Association, that

may be used for service on cars, sport utility vehicles, minivans and light

trucks.

Note:If your tire size does not begin with a letter, this may mean it is

designated by either the European Tire and Rim Technical Organization

or the Japan Tire Manufacturing Association.

B.215:Indicates the nominal width of the tire in millimeters from

sidewall edge to sidewall edge. In general, the larger the number, the

wider the tire.

C.65:Indicates the aspect ratio which gives the tire’s ratio of height to

width.

D.R:Indicates a radial type tire.

H

I

J

KL

M

A

B

CDEFG

Wheels and Tires357

2015 Explorer(exp)

Owners Guide gf, 2nd Printing, September 2014

USA(fus)

Page 362 of 596

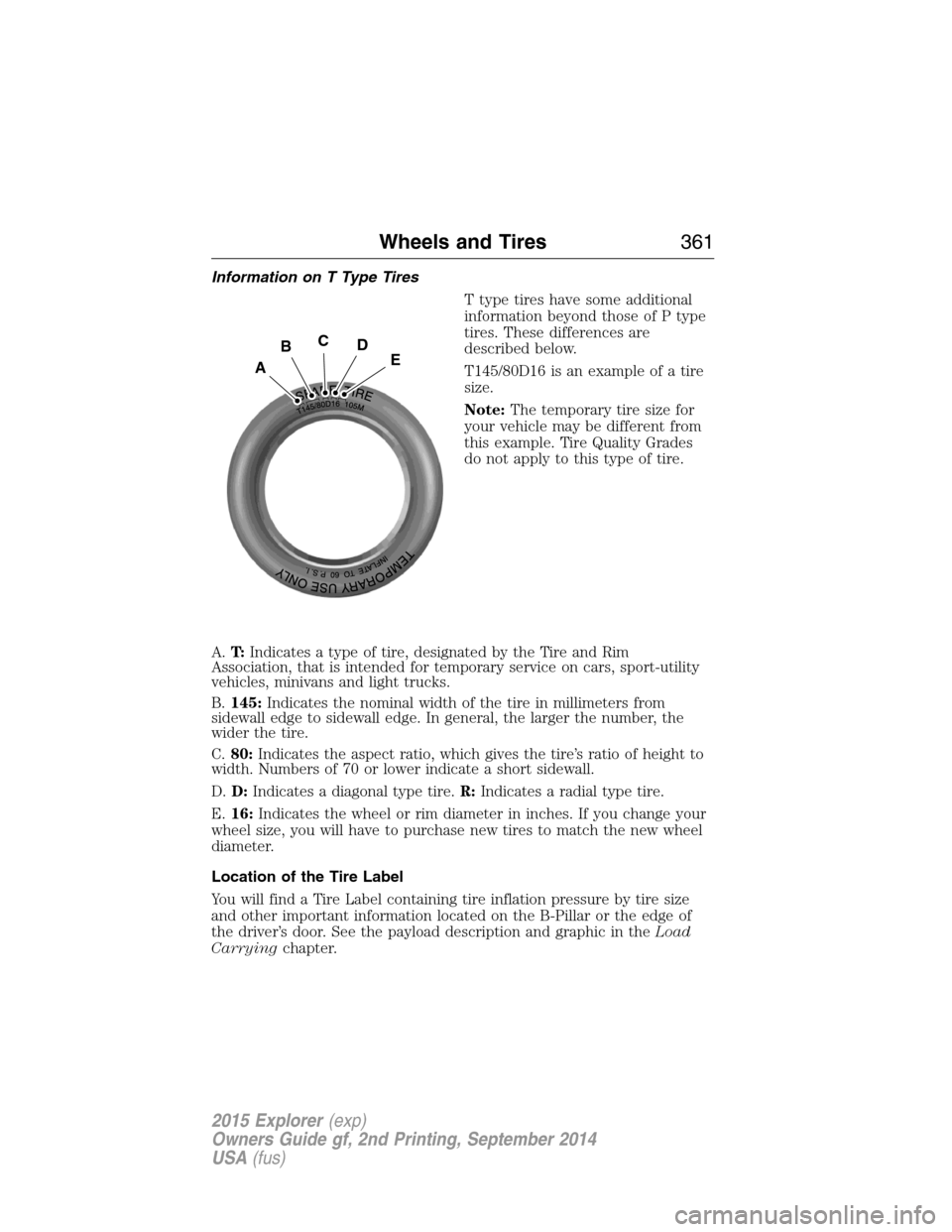

Information on T Type Tires

T type tires have some additional

information beyond those of P type

tires. These differences are

described below.

T145/80D16 is an example of a tire

size.

Note:The temporary tire size for

your vehicle may be different from

this example. Tire Quality Grades

do not apply to this type of tire.

A.T:Indicates a type of tire, designated by the Tire and Rim

Association, that is intended for temporary service on cars, sport-utility

vehicles, minivans and light trucks.

B.145:Indicates the nominal width of the tire in millimeters from

sidewall edge to sidewall edge. In general, the larger the number, the

wider the tire.

C.80:Indicates the aspect ratio, which gives the tire’s ratio of height to

width. Numbers of 70 or lower indicate a short sidewall.

D.D:Indicates a diagonal type tire.R:Indicates a radial type tire.

E.16:Indicates the wheel or rim diameter in inches. If you change your

wheel size, you will have to purchase new tires to match the new wheel

diameter.

Location of the Tire Label

You will find a Tire Label containing tire inflation pressure by tire size

and other important information located on the B-Pillar or the edge of

the driver’s door. See the payload description and graphic in theLoad

Carryingchapter.

A

BCDE

Wheels and Tires361

2015 Explorer(exp)

Owners Guide gf, 2nd Printing, September 2014

USA(fus)

Page 365 of 596

6. Visually inspect the tires to make sure there are no nails or other

objects embedded that could poke a hole in the tire and cause an air

leak.

7. Check the sidewalls to make sure there are no gouges, cuts or bulges.

Inspecting Your Tires and Wheel Valve Stems

Periodically inspect the tire treads for uneven or excessive wear and

remove objects such as stones, nails or glass that may be wedged in the

tread grooves. Check the tire and valve stems for holes, cracks, or cuts

that may permit air leakage and repair or replace the tire and replace

the valve stem. Inspect the tire sidewalls for cracking, cuts, bruises and

other signs of damage or excessive wear. If internal damage to the tire is

suspected, have the tire demounted and inspected in case it needs to be

repaired or replaced. For your safety, tires that are damaged or show

signs of excessive wear should not be used because they are more likely

to blow out or fail.

Improper or inadequate vehicle maintenance can cause tires to wear

abnormally. Inspect all your tires, including the spare, frequently, and

replace them if one or more of the following conditions exist:

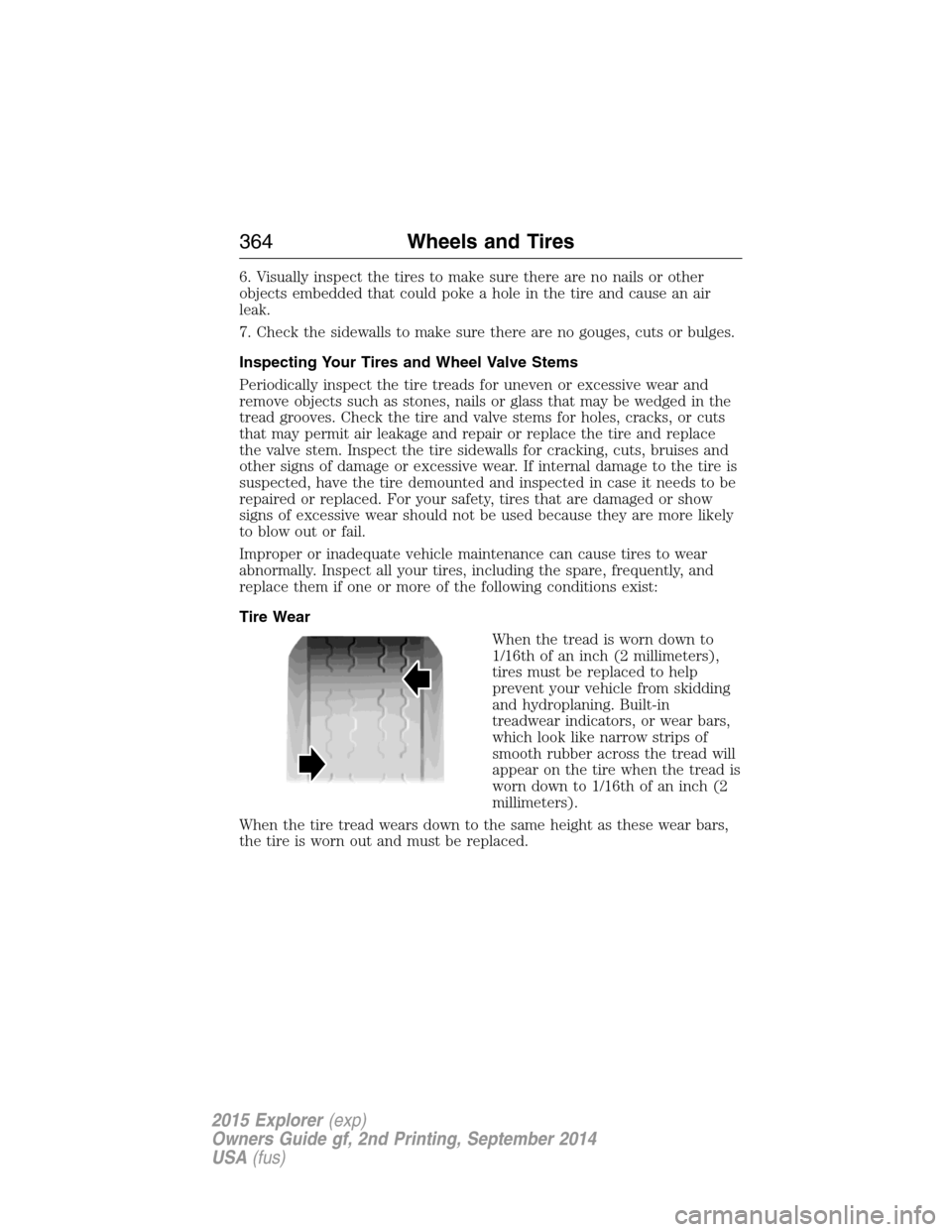

Tire Wear

When the tread is worn down to

1/16th of an inch (2 millimeters),

tires must be replaced to help

prevent your vehicle from skidding

and hydroplaning. Built-in

treadwear indicators, or wear bars,

which look like narrow strips of

smooth rubber across the tread will

appear on the tire when the tread is

worn down to 1/16th of an inch (2

millimeters).

When the tire tread wears down to the same height as these wear bars,

the tire is worn out and must be replaced.

364Wheels and Tires

2015 Explorer(exp)

Owners Guide gf, 2nd Printing, September 2014

USA(fus)

Page 382 of 596

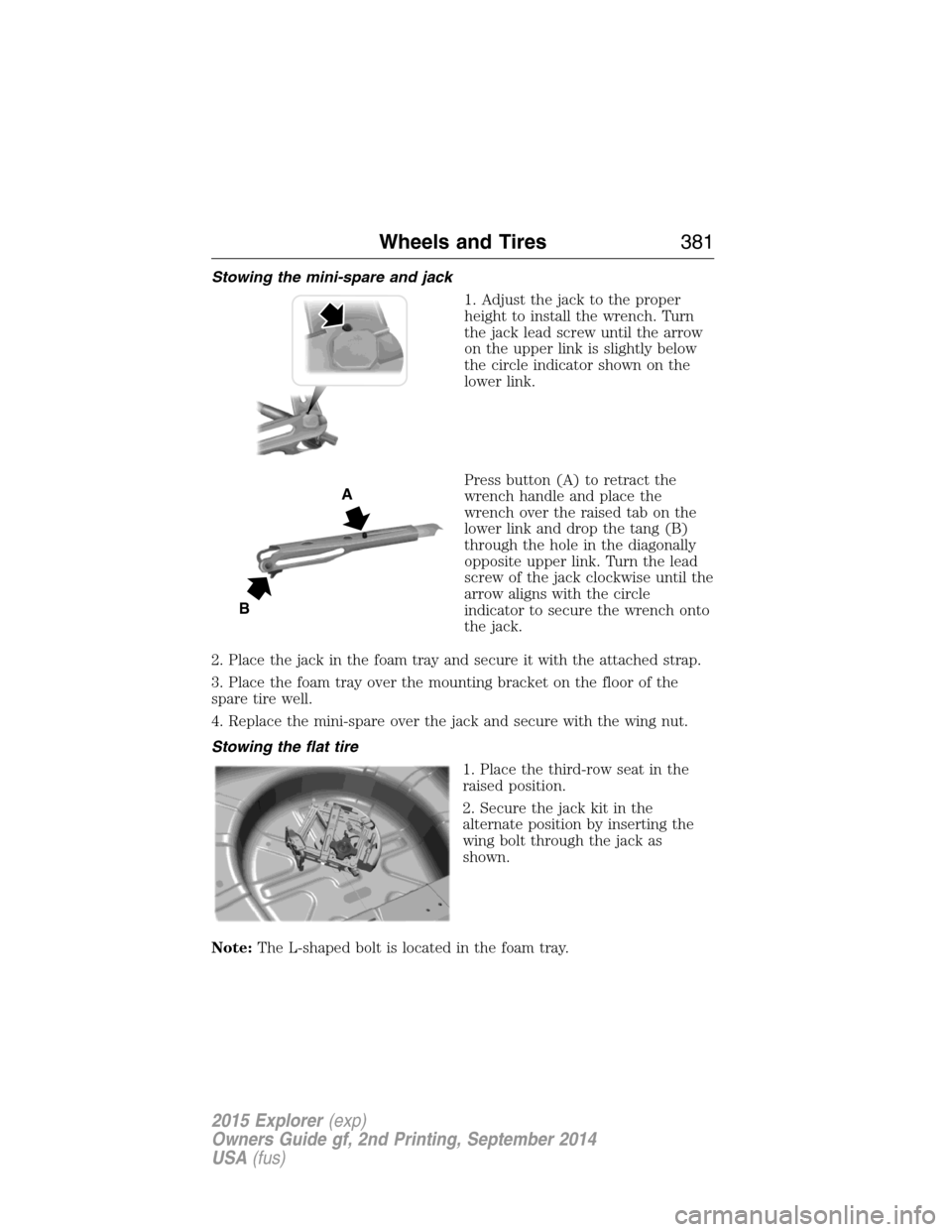

Stowing the mini-spare and jack

1. Adjust the jack to the proper

height to install the wrench. Turn

the jack lead screw until the arrow

on the upper link is slightly below

the circle indicator shown on the

lower link.

Press button (A) to retract the

wrench handle and place the

wrench over the raised tab on the

lower link and drop the tang (B)

through the hole in the diagonally

opposite upper link. Turn the lead

screw of the jack clockwise until the

arrow aligns with the circle

indicator to secure the wrench onto

the jack.

2. Place the jack in the foam tray and secure it with the attached strap.

3. Place the foam tray over the mounting bracket on the floor of the

spare tire well.

4. Replace the mini-spare over the jack and secure with the wing nut.

Stowing the flat tire

1. Place the third-row seat in the

raised position.

2. Secure the jack kit in the

alternate position by inserting the

wing bolt through the jack as

shown.

Note:The L-shaped bolt is located in the foam tray.

A

B

Wheels and Tires381

2015 Explorer(exp)

Owners Guide gf, 2nd Printing, September 2014

USA(fus)