FORD F650 2006 11.G Owners Manual

Manufacturer: FORD, Model Year: 2006, Model line: F650, Model: FORD F650 2006 11.GPages: 272, PDF Size: 1.86 MB

Page 211 of 272

1. Slide inner rear or front tire and wheel in position over studs and push

it back as far as possible. Use care so that the threads on studs are not

damaged.

2. Position the outer rear tire and wheel in place over the studs and

push it back as far as possible. Use care so that the threads on studs are

not damaged.

3. Run the nuts on the studs until they contact the wheel(s). Rotate the

wheel assembly a half-turn to permit the parts to seat.

4. Draw up the nuts alternately following the crisscross sequence

illustrated underInstallation, tightening and alignment. Do not fully

tighten the nuts. This will allow uniform seating of the nuts and ensure

even face-to-face contact of the wheel and hub.

5. Continue tightening the nuts to the torque specifications in the torque

chart using the same crisscross sequence shown.

6. After operating the vehicle approximately 50 miles (80 km), check the

nuts for tightness. Some natural seating of parts may be encountered

and the torque on the nuts will drop. Retighten all nuts to specifications.

Once a week, inspect and retighten the wheel stud nuts.

2006 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

211

Page 212 of 272

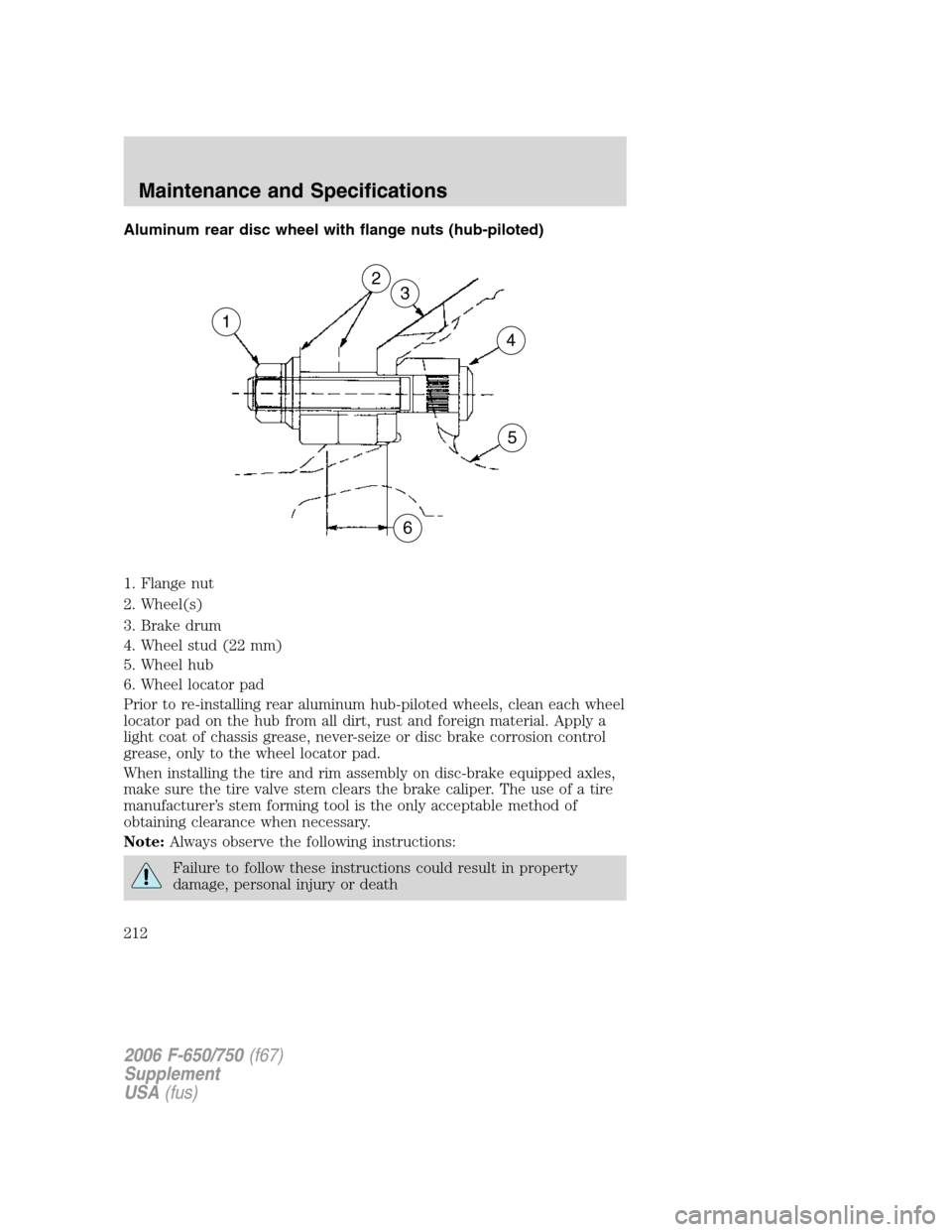

Aluminum rear disc wheel with flange nuts (hub-piloted)

1. Flange nut

2. Wheel(s)

3. Brake drum

4. Wheel stud (22 mm)

5. Wheel hub

6. Wheel locator pad

Prior to re-installing rear aluminum hub-piloted wheels, clean each wheel

locator pad on the hub from all dirt, rust and foreign material. Apply a

light coat of chassis grease, never-seize or disc brake corrosion control

grease, only to the wheel locator pad.

When installing the tire and rim assembly on disc-brake equipped axles,

make sure the tire valve stem clears the brake caliper. The use of a tire

manufacturer’s stem forming tool is the only acceptable method of

obtaining clearance when necessary.

Note:Always observe the following instructions:

Failure to follow these instructions could result in property

damage, personal injury or death

1

6

5

4

32

2006 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

212

Page 213 of 272

•Always loosen rim clamps before complete removal of nut from stud

(cast spoke wheels). With loosened nuts on stud, strike clamps with a

heavy hammer and be sure each clamp is loose.

•Always deflate tires completely before removing locks or side rings.

•Always inflate tires in a safety cage.

•Never mix rim side rings or lock rings of different types,

manufacturers or sizes.

•Never use cracked, bent or badly rusted parts.

•Never re-inflate flat tires on-vehicle; use the spare tire.

•Never add air until each side ring or lock ring is fully seated.

•Never hammer side ring or lock ring on a partially- or fully-inflated

tire.

Proper torque

It is important to tighten and maintain wheel and rim mounting nuts to

the proper torque. Loose nuts or over-tightened nuts can lead to

premature wear and possible failure of the wheel and/or mounting

hardware.

Changing wheel types

Consult your dealer or wheel/rim distributor before attempting any wheel

or fastener changes.

Use only the same type and style wheels and mounting hardware

to replace original parts. Failure to do so may result in an

assembly that looks fine, but does not fit together properly. This could

possibly cause wheel or fastener failures which could result in property

damage, personal injury or death.

Note:Do not attempt to mix stud-piloted wheels or fasteners with

hub-piloted wheels or fasteners.

Note:Do not change from aluminum wheels to steel wheels or

vice-versa without changing the mounting hardware required or, with

flange-nut mounting systems, changing the hub and stud assembly.

2006 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

213

Page 214 of 272

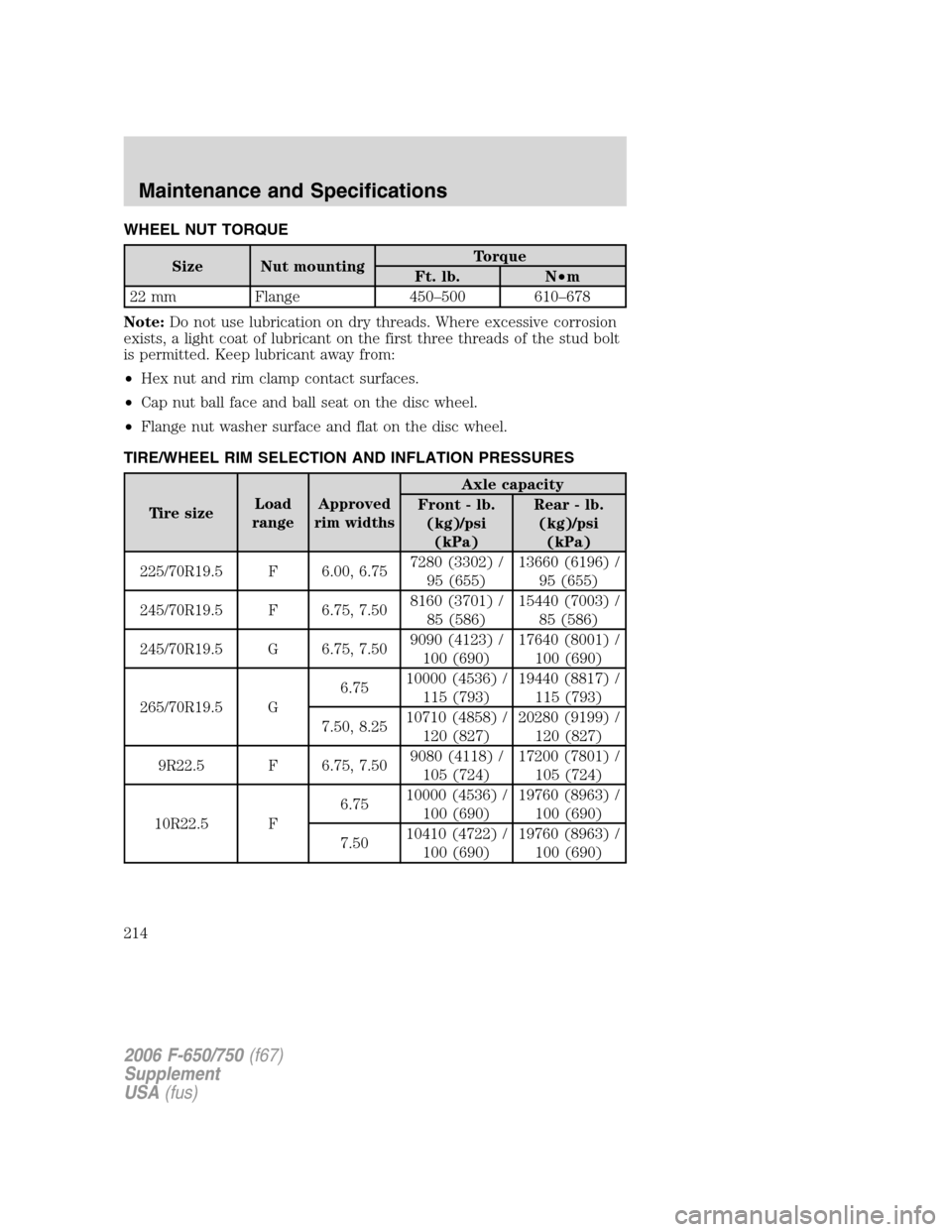

WHEEL NUT TORQUE

Size Nut mountingTorque

Ft. lb. N•m

22 mm Flange 450–500 610–678

Note:Do not use lubrication on dry threads. Where excessive corrosion

exists, a light coat of lubricant on the first three threads of the stud bolt

is permitted. Keep lubricant away from:

•Hex nut and rim clamp contact surfaces.

•Cap nut ball face and ball seat on the disc wheel.

•Flange nut washer surface and flat on the disc wheel.

TIRE/WHEEL RIM SELECTION AND INFLATION PRESSURES

Tire sizeLoad

rangeApproved

rim widthsAxle capacity

Front - lb.

(kg)/psi

(kPa)Rear - lb.

(kg)/psi

(kPa)

225/70R19.5 F 6.00, 6.757280 (3302) /

95 (655)13660 (6196) /

95 (655)

245/70R19.5 F 6.75, 7.508160 (3701) /

85 (586)15440 (7003) /

85 (586)

245/70R19.5 G 6.75, 7.509090 (4123) /

100 (690)17640 (8001) /

100 (690)

265/70R19.5 G6.7510000 (4536) /

115 (793)19440 (8817) /

115 (793)

7.50, 8.2510710 (4858) /

120 (827)20280 (9199) /

120 (827)

9R22.5 F 6.75, 7.509080 (4118) /

105 (724)17200 (7801) /

105 (724)

10R22.5 F6.7510000 (4536) /

100 (690)19760 (8963) /

100 (690)

7.5010410 (4722) /

100 (690)19760 (8963) /

100 (690)

2006 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

214

Page 215 of 272

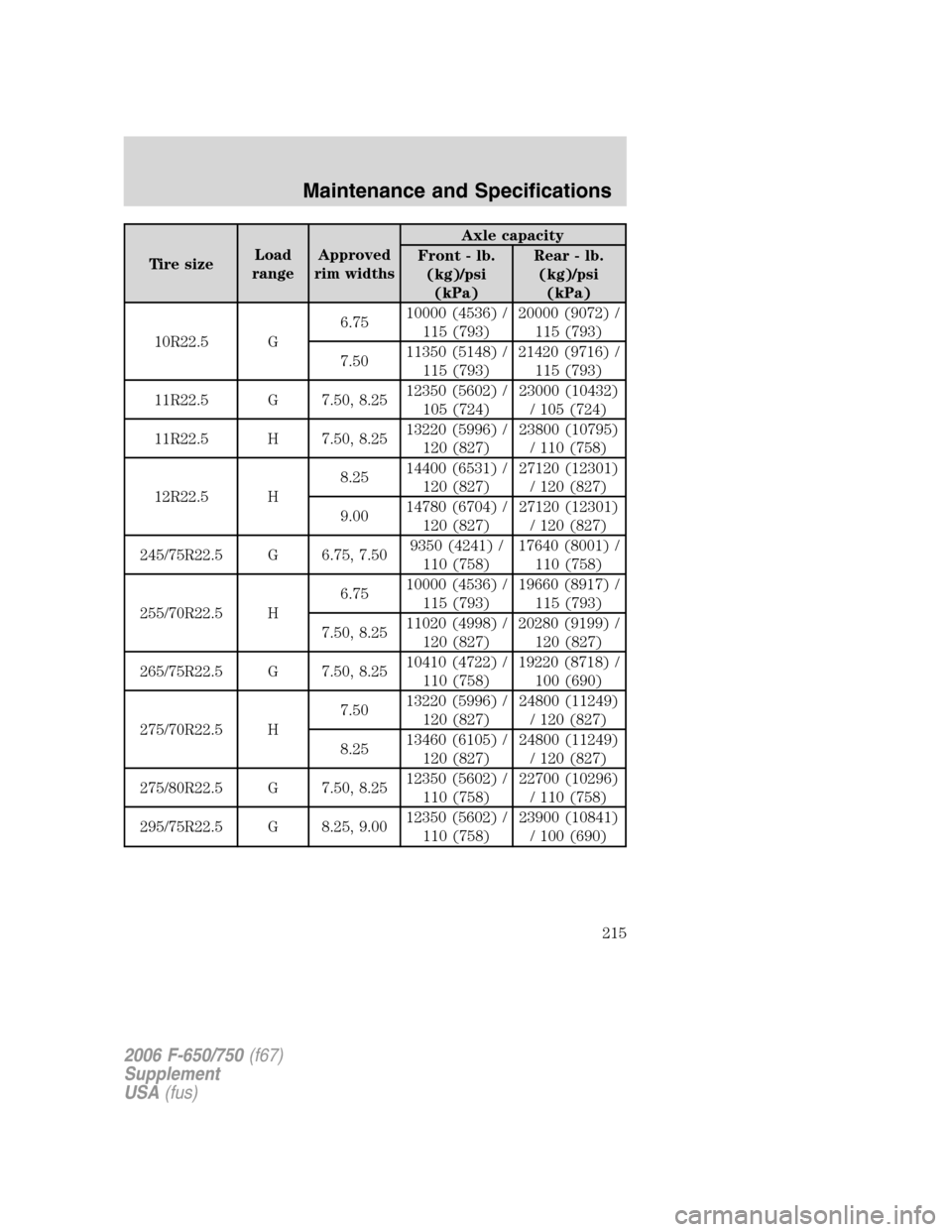

Tire sizeLoad

rangeApproved

rim widthsAxle capacity

Front - lb.

(kg)/psi

(kPa)Rear - lb.

(kg)/psi

(kPa)

10R22.5 G6.7510000 (4536) /

115 (793)20000 (9072) /

115 (793)

7.5011350 (5148) /

115 (793)21420 (9716) /

115 (793)

11R22.5 G 7.50, 8.2512350 (5602) /

105 (724)23000 (10432)

/ 105 (724)

11R22.5 H 7.50, 8.2513220 (5996) /

120 (827)23800 (10795)

/ 110 (758)

12R22.5 H8.2514400 (6531) /

120 (827)27120 (12301)

/ 120 (827)

9.0014780 (6704) /

120 (827)27120 (12301)

/ 120 (827)

245/75R22.5 G 6.75, 7.509350 (4241) /

110 (758)17640 (8001) /

110 (758)

255/70R22.5 H6.7510000 (4536) /

115 (793)19660 (8917) /

115 (793)

7.50, 8.2511020 (4998) /

120 (827)20280 (9199) /

120 (827)

265/75R22.5 G 7.50, 8.2510410 (4722) /

110 (758)19220 (8718) /

100 (690)

275/70R22.5 H7.5013220 (5996) /

120 (827)24800 (11249)

/ 120 (827)

8.2513460 (6105) /

120 (827)24800 (11249)

/ 120 (827)

275/80R22.5 G 7.50, 8.2512350 (5602) /

110 (758)22700 (10296)

/ 110 (758)

295/75R22.5 G 8.25, 9.0012350 (5602) /

110 (758)23900 (10841)

/ 100 (690)

2006 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

215

Page 216 of 272

Tire sizeLoad

rangeApproved

rim widthsAxle capacity

Front - lb.

(kg)/psi

(kPa)Rear - lb.

(kg)/psi

(kPa)

295/80R22.5 H8.2514400 (6531) /

120 (827)27760 (12591)

/ 120 (827)

9.0014780 (6704) /

120 (827)27760 (12591)

/ 120 (827)

Tire inflation information

All tires with Steel Carcass Plies (if equipped):

This type of tire utilizes steel cords in the sidewalls. As such, they

cannot be treated like normal light truck tires. Tire service, including

adjusting the air pressure, must be performed by personnel trained,

supervised and equipped according to Federal Occupational Safety and

Health Administration (OSHA) regulations. For example, during any

procedure involving tire inflation, the technician or individual must

utilize a remote inflation device, and ensure that all persons are clear of

the trajectory area.

WARNINGAn inflated tire and rim can be very dangerous if

improperly used, serviced or maintained. To avoid serious injury,

never attempt to re-inflate a tire which has been run flat or seriously

under-inflated without first removing the tire from the wheel assembly

for inspection. Do not attempt to add air to tires or replace tires or

wheels without first taking precautions to protect persons and

property.

2006 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

216

Page 217 of 272

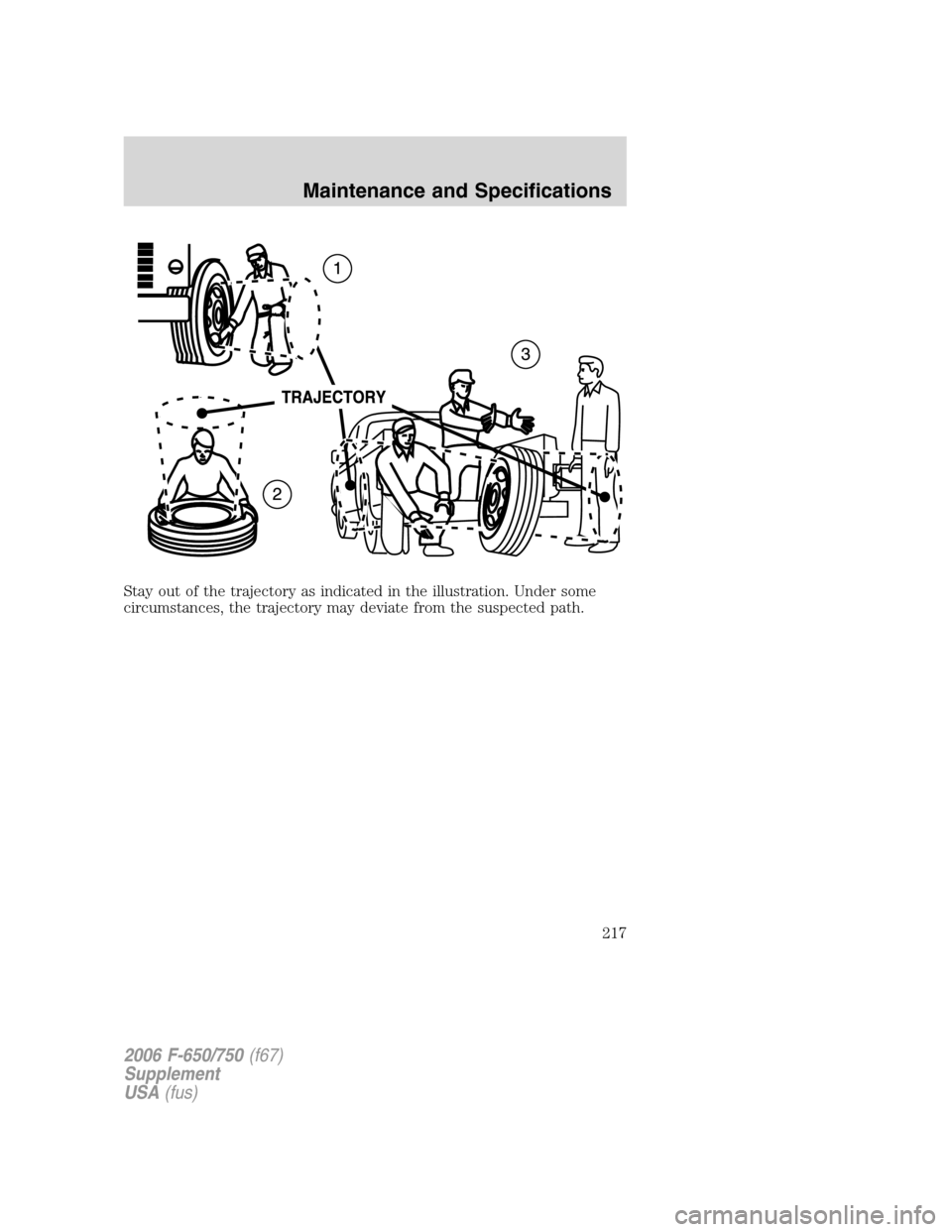

Stay out of the trajectory as indicated in the illustration. Under some

circumstances, the trajectory may deviate from the suspected path.

2006 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

217

Page 218 of 272

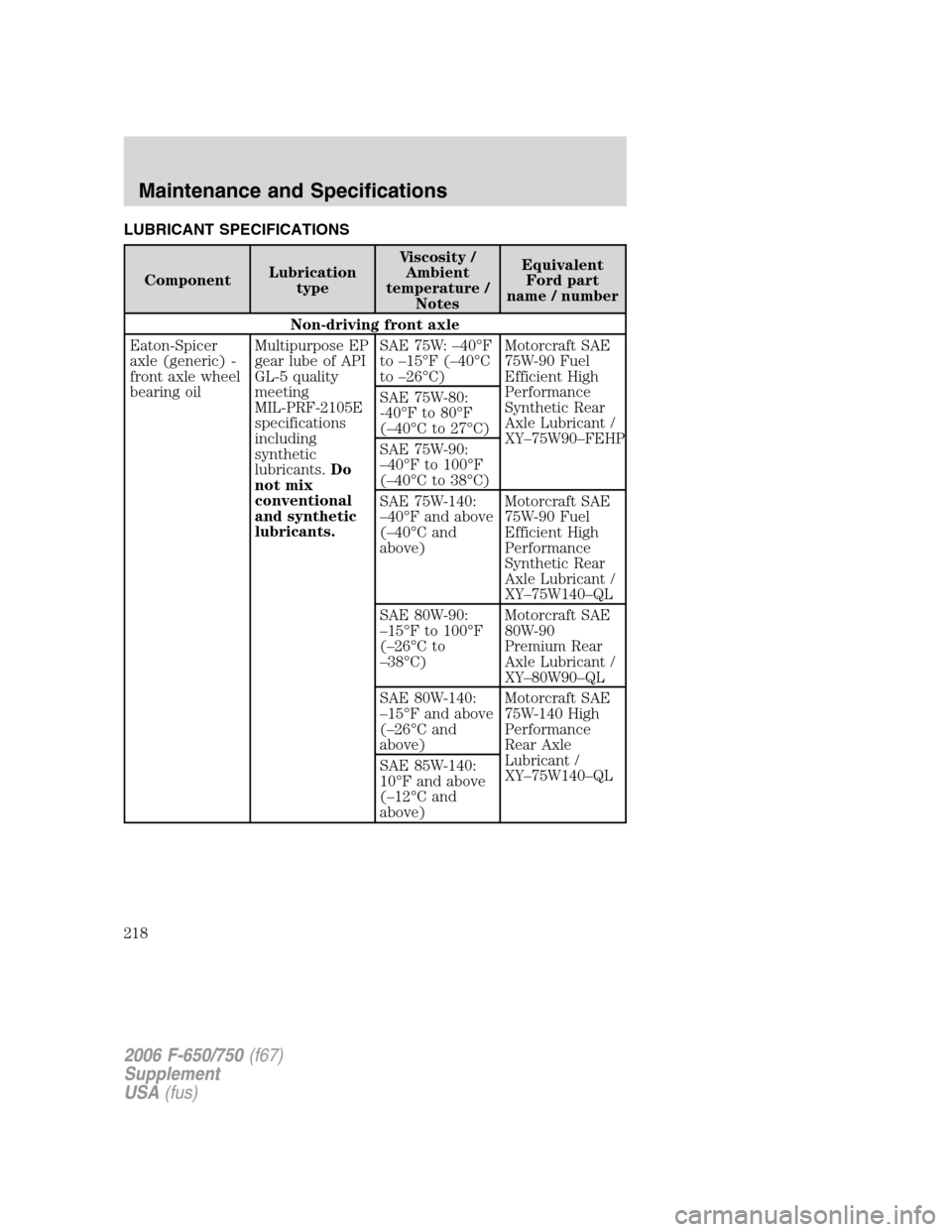

LUBRICANT SPECIFICATIONS

ComponentLubrication

typeViscosity /

Ambient

temperature /

NotesEquivalent

Ford part

name / number

Non-driving front axle

Eaton-Spicer

axle (generic) -

front axle wheel

bearing oilMultipurpose EP

gear lube of API

GL-5 quality

meeting

MIL-PRF-2105E

specifications

including

synthetic

lubricants.Do

not mix

conventional

and synthetic

lubricants.SAE 75W: –40°F

to –15°F (–40°C

to –26°C)Motorcraft SAE

75W-90 Fuel

Efficient High

Performance

Synthetic Rear

Axle Lubricant /

XY–75W90–FEHP SAE 75W-80:

-40°F to 80°F

(–40°C to 27°C)

SAE 75W-90:

–40°F to 100°F

(–40°C to 38°C)

SAE 75W-140:

–40°F and above

(–40°C and

above)Motorcraft SAE

75W-90 Fuel

Efficient High

Performance

Synthetic Rear

Axle Lubricant /

XY–75W140–QL

SAE 80W-90:

–15°F to 100°F

(–26°C to

–38°C)Motorcraft SAE

80W-90

Premium Rear

Axle Lubricant /

XY–80W90–QL

SAE 80W-140:

–15°F and above

(–26°C and

above)Motorcraft SAE

75W-140 High

Performance

Rear Axle

Lubricant /

XY–75W140–QL SAE 85W-140:

10°F and above

(–12°C and

above)

2006 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

218

Page 219 of 272

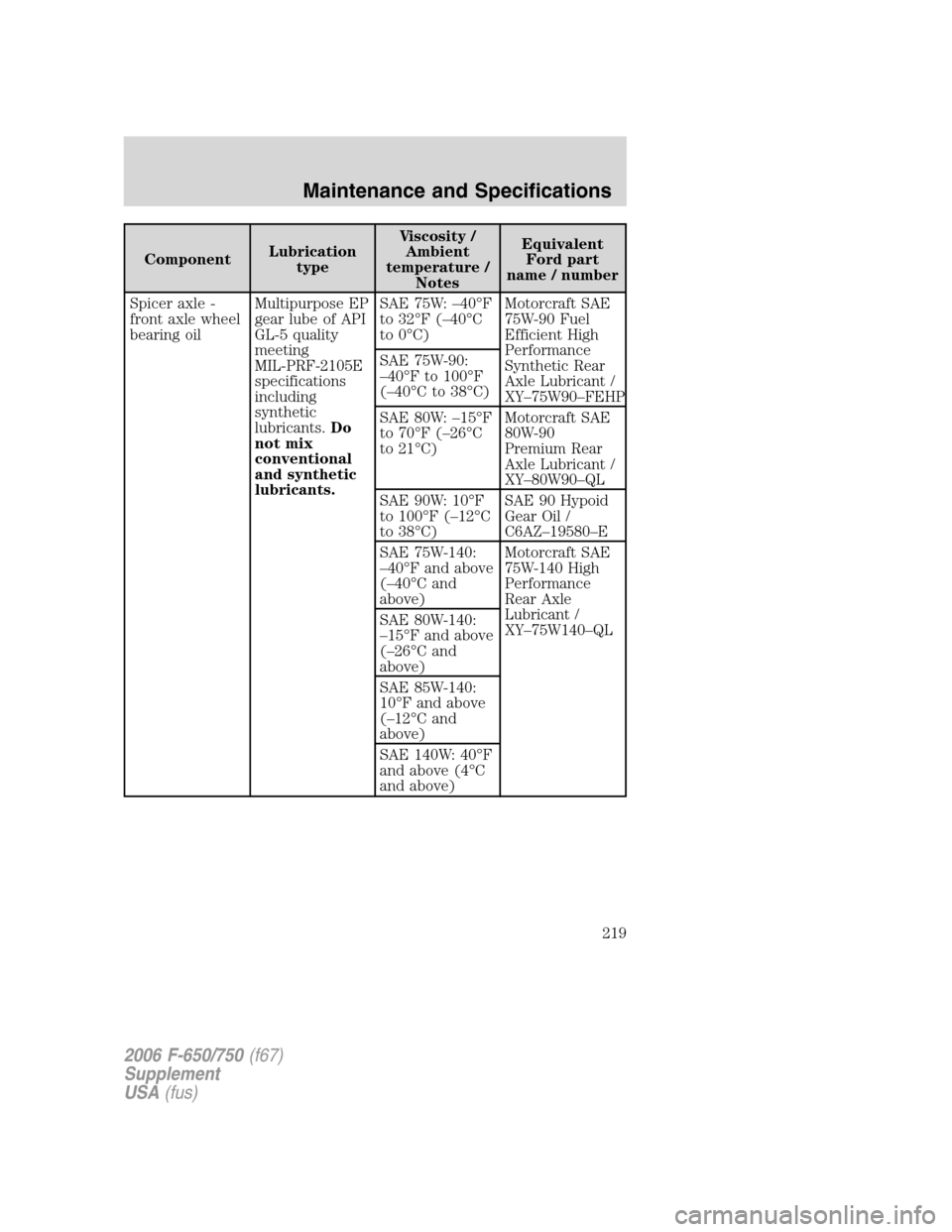

ComponentLubrication

typeViscosity /

Ambient

temperature /

NotesEquivalent

Ford part

name / number

Spicer axle -

front axle wheel

bearing oilMultipurpose EP

gear lube of API

GL-5 quality

meeting

MIL-PRF-2105E

specifications

including

synthetic

lubricants.Do

not mix

conventional

and synthetic

lubricants.SAE 75W: –40°F

to 32°F (–40°C

to 0°C)Motorcraft SAE

75W-90 Fuel

Efficient High

Performance

Synthetic Rear

Axle Lubricant /

XY–75W90–FEHP SAE 75W-90:

–40°F to 100°F

(–40°C to 38°C)

SAE 80W: –15°F

to 70°F (–26°C

to 21°C)Motorcraft SAE

80W-90

Premium Rear

Axle Lubricant /

XY–80W90–QL

SAE 90W: 10°F

to 100°F (–12°C

to 38°C)SAE 90 Hypoid

Gear Oil /

C6AZ–19580–E

SAE 75W-140:

–40°F and above

(–40°C and

above)Motorcraft SAE

75W-140 High

Performance

Rear Axle

Lubricant /

XY–75W140–QL SAE 80W-140:

–15°F and above

(–26°C and

above)

SAE 85W-140:

10°F and above

(–12°C and

above)

SAE 140W: 40°F

and above (4°C

and above)

2006 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

219

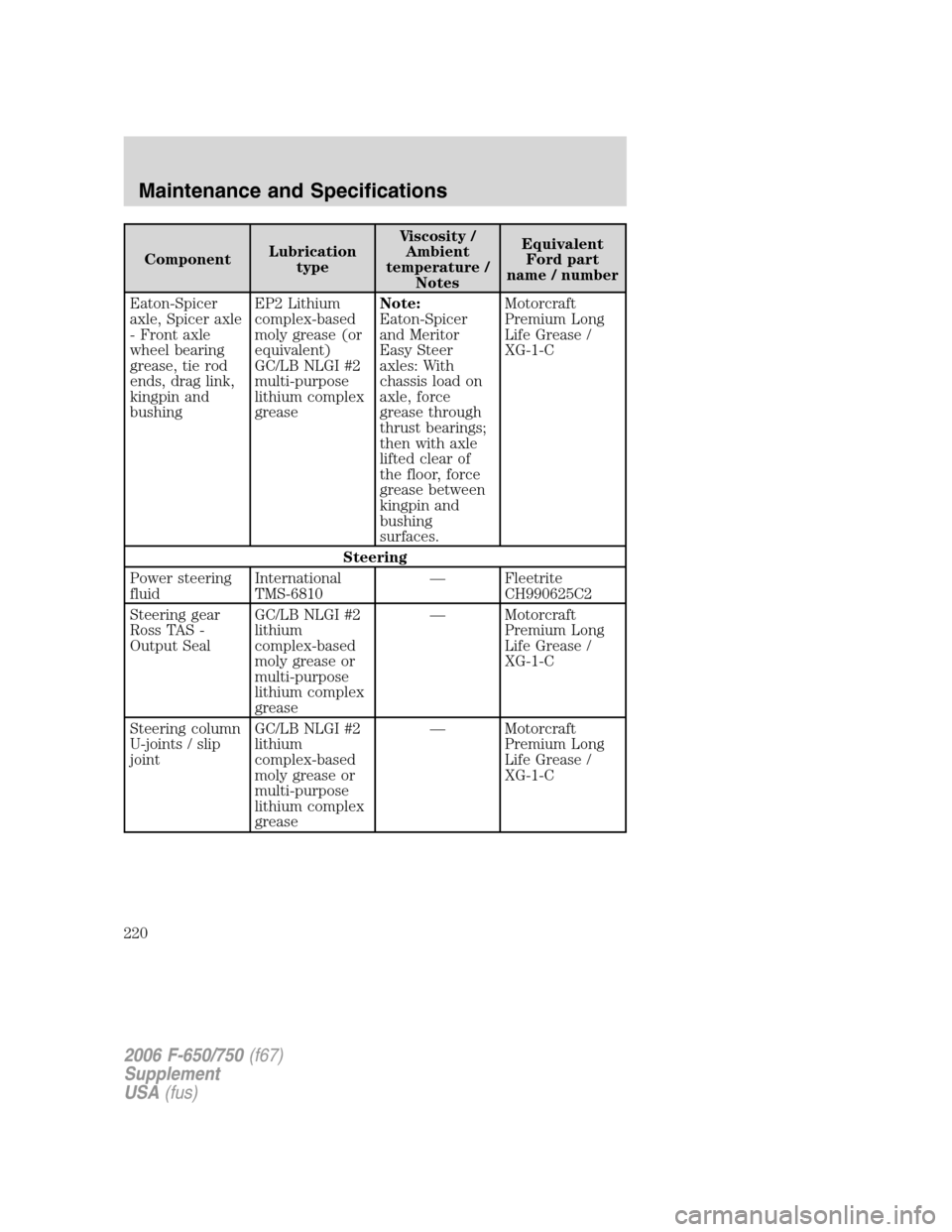

Page 220 of 272

ComponentLubrication

typeViscosity /

Ambient

temperature /

NotesEquivalent

Ford part

name / number

Eaton-Spicer

axle, Spicer axle

- Front axle

wheel bearing

grease, tie rod

ends, drag link,

kingpin and

bushingEP2 Lithium

complex-based

moly grease (or

equivalent)

GC/LB NLGI #2

multi-purpose

lithium complex

greaseNote:

Eaton-Spicer

and Meritor

Easy Steer

axles: With

chassis load on

axle, force

grease through

thrust bearings;

then with axle

lifted clear of

the floor, force

grease between

kingpin and

bushing

surfaces.Motorcraft

Premium Long

Life Grease /

XG-1-C

Steering

Power steering

fluidInternational

TMS-6810— Fleetrite

CH990625C2

Steering gear

Ross TAS -

Output SealGC/LB NLGI #2

lithium

complex-based

moly grease or

multi-purpose

lithium complex

grease— Motorcraft

Premium Long

Life Grease /

XG-1-C

Steering column

U-joints / slip

jointGC/LB NLGI #2

lithium

complex-based

moly grease or

multi-purpose

lithium complex

grease— Motorcraft

Premium Long

Life Grease /

XG-1-C

2006 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

220