FORD F650 2008 11.G Owners Manual

Manufacturer: FORD, Model Year: 2008, Model line: F650, Model: FORD F650 2008 11.GPages: 273, PDF Size: 1.71 MB

Page 181 of 273

Calculating fuel economy

1. Fill the fuel tank(s) completely and record the initial odometer

reading (in miles or kilometers).

2. Each time you fill the tank(s), record the amount of fuel added (in

gallons or liters).

3. After at least three to five tank fill-ups, fill the fuel tank(s) and record

the current odometer reading.

4. Subtract your initial odometer reading from the current odometer

reading.

5. Follow one of the simple calculations in order to determine fuel

economy:

•Divide total miles traveled by total gallons used.

•Multiply liters used by 100, then divide by total kilometers traveled.

Keep a record for at least one month and record the type of driving (city

or highway). This will provide an accurate estimate of the vehicle’s fuel

economy under current driving conditions. Additionally, keeping records

during summer and winter will show how temperature impacts fuel

economy. In general, lower temperatures give lower fuel economy.

Driving style - good driving and fuel economy habits

Give consideration to the lists that follow and you may be able to change

a number of variables and improve your fuel economy.

Habits

•Smooth, moderate operation can yield up to 10% savings in fuel.

•Steady speeds without stopping will usually give the best fuel

economy.

•Anticipate stopping; slowing down may eliminate the need to stop.

•Sudden or hard accelerations may reduce fuel economy.

•Slow down gradually.

•Driving at reasonable speeds (traveling at 55 mph [88 km/h] uses 15%

less fuel than traveling at 65 mph [105 km/h]).

•Using the air conditioner or defroster may reduce fuel economy.

•Resting your foot on the brake pedal while driving may reduce fuel

economy.

2008 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

180

Page 182 of 273

Conditions

•Carrying unnecessary weight may reduce fuel economy.

•Fuel economy may decrease with lower temperatures during the first

8–10 miles (12–16 km) of driving.

•Flat terrain driving improves fuel economy over hilly roads.

•Transmissions give their best fuel economy when operated in the top

cruise gear and with steady pressure on the accelerator.

•Close windows for highway driving.

DIESEL PARTICULATE FILTER (DPF)

Your vehicle is equipped with a diesel particulate filter (DPF), as part of

the after-treatment exhaust system, to trap soot and other large particles

produced by the engine combustion process. The soot that accumulates

in the filter must be periodically reduced to ash to prevent excessive

exhaust restriction. The soot reduction process, also known as “filter

regeneration,” is generally performed automatically by your engine and

after-treatment system.

The normal operating temperature of the exhaust system is very

high. Never work around, or attempt to repair, any part of the

exhaust system until it has cooled. Use special care when working

around the diesel particulate filter. The DPF heats up to a high

temperature after only a short period of engine operation, and can

remain hot even after the engine is turned off. Failure to follow these

instructions may result in personal injury.

Diesel particulate filter regeneration (Caterpillar engine only)

DPF regeneration requires no operator interaction and may occur at any

time. A small increase in engine sound-level during filter regeneration is

normal and should be no reason for concern.

A separate fuel injector/nozzle, which requires periodic cleaning, is used

in the regeneration process. Refer to Caterpillar’sOperation and

Maintenance Manualfor details regarding cleaning requirements.

2008 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

181

Page 183 of 273

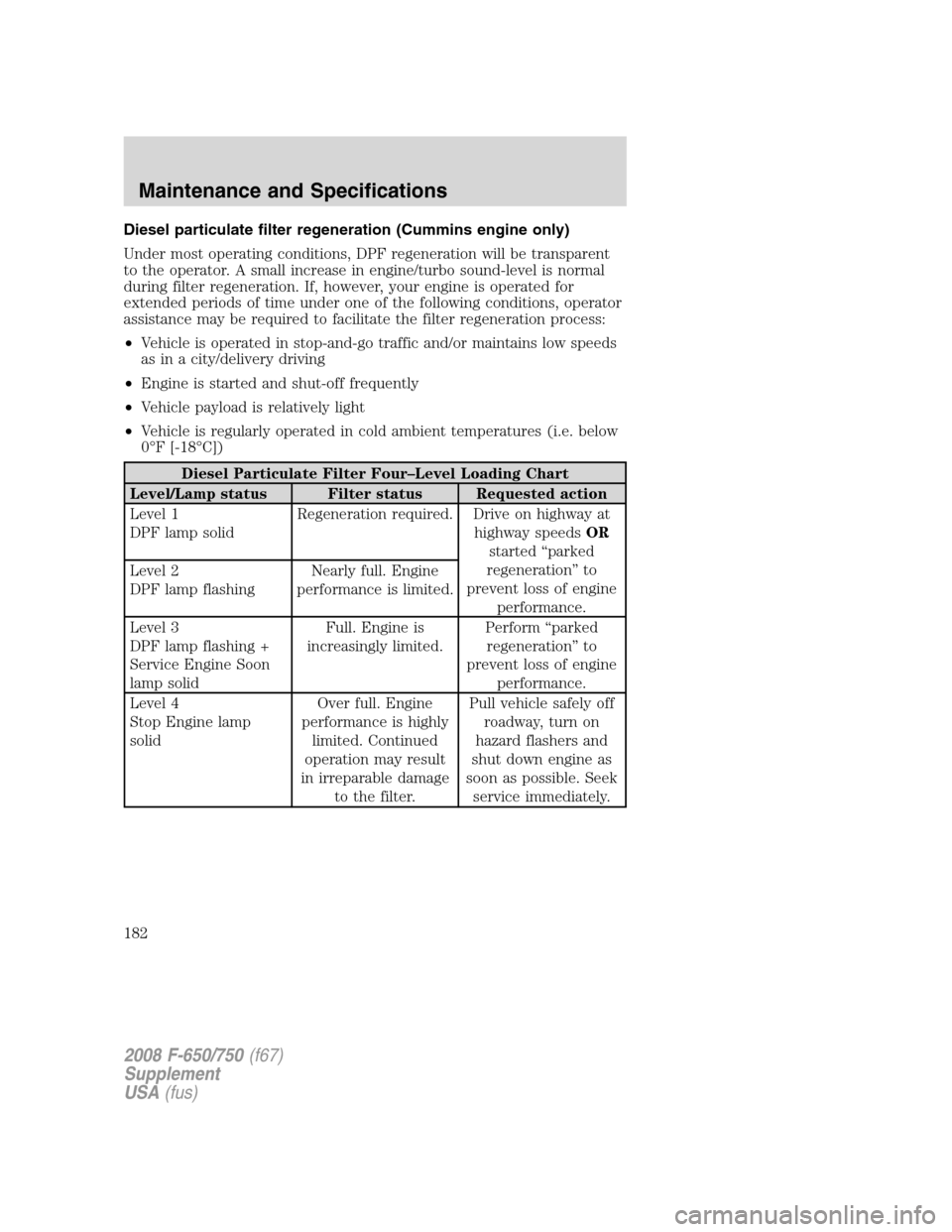

Diesel particulate filter regeneration (Cummins engine only)

Under most operating conditions, DPF regeneration will be transparent

to the operator. A small increase in engine/turbo sound-level is normal

during filter regeneration. If, however, your engine is operated for

extended periods of time under one of the following conditions, operator

assistance may be required to facilitate the filter regeneration process:

•Vehicle is operated in stop-and-go traffic and/or maintains low speeds

as in a city/delivery driving

•Engine is started and shut-off frequently

•Vehicle payload is relatively light

•Vehicle is regularly operated in cold ambient temperatures (i.e. below

0°F [-18°C])

Diesel Particulate Filter Four–Level Loading Chart

Level/Lamp status Filter status Requested action

Level 1

DPF lamp solidRegeneration required. Drive on highway at

highway speedsOR

started “parked

regeneration” to

prevent loss of engine

performance. Level 2

DPF lamp flashingNearly full. Engine

performance is limited.

Level 3

DPF lamp flashing +

Service Engine Soon

lamp solidFull. Engine is

increasingly limited.Perform “parked

regeneration” to

prevent loss of engine

performance.

Level 4

Stop Engine lamp

solidOver full. Engine

performance is highly

limited. Continued

operation may result

in irreparable damage

to the filter.Pull vehicle safely off

roadway, turn on

hazard flashers and

shut down engine as

soon as possible. Seek

service immediately.

2008 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

182

Page 184 of 273

Instrument cluster lamp(s) will

illuminate and/or flash when

operator assistance is required. In

addition, engine performance will

become increasingly limited above

Level 1.

At Levels 1 and 2, two courses of action may be taken by the operator to

facilitate filter regeneration:

1. The vehicle may be driven on the highway at highway speeds,

2. The operator may perform a parked regeneration by following the

steps inParked regeneration procedure (Cummins engine only).

At Level 3, performing a parked regeneration is the only available course

of action (short of professional servicing) available to the operator for

regenerating the filter. At Level 4, professional servicing is the only way

to regenerate the filter.

Parked regeneration procedure (Cummins engine only)

When performing the parked regeneration procedure, make

certain the vehicle is safely off roadway, and the exhaust system

is away from people, or any flammable materials, vapors, or structures.

Engine speed may increase during parked regeneration.

Note:Parked regeneration is only available when the DPF lamp on the

instrument cluster is illuminated (solid or flashing).

1. Bring the vehicle to a complete stop on level ground and safely off the

road with the exhaust system away from people, flammable materials,

vapors or structures.

2. If your vehicle is equipped with an automatic transmission and a

steering column shift lever, place transmission in P (Park). Otherwise,

place the transmission in N (Neutral).

3. Remove feet from the accelerator pedal and clutch pedal (if

equipped).

4. Set the parking brake.

5.Within 5 seconds of setting the parking brake,remove foot from

the service brake pedal.

2008 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

183

Page 185 of 273

When these steps are performed successfully in the order outlined above,

the DPF lamp will begin flashing at a rate of once every 10 seconds. The

engine speed may also increase slightly. To allow parked regeneration to

continue uninterrupted:

1. The vehicle must remain parked

2. The transmission must remain in P (Park) or N (Neutral) (as

previously described in Step 2).

3. The accelerator pedal, service brake pedal, and clutch pedal (if

equipped) must not be depressed

4. The parking brake must remain set

On average (depending on filter level and other factors), the process will

take 20–30 minutes to complete. The DPF lamp will turn off when the

process is complete. Repeat Steps 1–5, if parked regeneration is

interrupted.

To discontinue parked regeneration (Cummins engine only)

Depress any of the floor pedals to discontinue parked regeneration.

Diesel particulate filter maintenance and service

The DPF is designed to retain a relatively large amount of residual ash

and provide many miles and hours of maintenance-free operation. At

some point, generally beyond 150,000 miles (240,000 km) or 5,000 hours

of operation (whichever comes first), the DPF will require professional

cleaning to remove the accumulated ash

The exact number of miles or hours of operation will vary greatly

depending upon vehicle/engine loading and operating conditions, ash

content of the engine oil, and quality of the diesel fuel used in your

truck. Adhering to your engine manufacturer’s recommended oil and fuel

specifications will maximize the miles and hours of operation before a

DPF professional cleaning is required. Refer to your engine

manufacturer’s owner’s manual for more details regarding recommended

maintenance and service of your DPF.

Exhaust outlet assembly

The normal operating temperature of the exhaust system is very

high. Never work around or attempt to repair any part of the

exhaust system until it has cooled. Failure to follow these instructions

may result in personal injury.

2008 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

184

Page 186 of 273

The exhaust outlet assembly on your vehicle is a uniquely functioning

device that accompanies the DPF assembly. It is designed to help control

the temperature of the exhaust during the DPF regeneration process.Do

not modify or remove this device. Modification of the system

and/or additions of aftermarket devices can reduce the

effectiveness of the system, as well as cause damage to the

exhaust system and/or engine. Any modifications may also

invalidate the vehicle and/or engine warranties. See the vehicle

and engine warranty guides for more information.

The inlet holes in the side of the assembly are functional. These holes

allow outside air to be drawn into the outlet assembly. The holes need to

be kept clear of mud and other foreign material to maintain proper

functionality of the system. One way to keep the holes clear is to spray

the outlet assembly with a hose when washing the vehicle. Failure to

keep the functional holes clear of foreign material may result in the holes

becoming blocked or plugged.Blocked/plugged holes or

modification/removal of the outlet assembly could result in

elevated exhaust temperatures which may result in

vehicle/property damage and/or personal injury.

NOISE EMISSIONS – EXTERIOR

In order to comply with the federal exterior noise regulations, your

vehicle may be equipped with noise emission items. Depending on the

vehicle configuration, it may have all or some of the following items:

Air Intake System

•Air Cleaner:should be inspected and its location should not be

altered. Do not alter inlet and outlet piping.

Body

•Wheel Well:splash shields, cab shields and under-hood insulation

should be inspected for deterioration, dislocation, and orientation.

Cooling System

•Check the fan for damage to blades; replace, if damaged, with the

recommended parts. Inspect for fan to shroud interference, and any

damage to shroud such as cracks and holes.

•The fan ratio should not be changed and the fan spacer dimensions

and positions should not be altered.

•Inspect the fan clutch for proper operation, make sure that the fan is

disengaged when cooling of the engine is not required.

2008 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

185

Page 187 of 273

•Check for proper operation of radiator shutters, if equipped. The

shutters should be open during normal operating temperatures.

Engine and Driveline System

•Transmission Enclosure:inspect for cracks, holes, and tears. Clean

any deposits such as oil, dirt, and stones.

•Engine valve covers and block covers are made to damp out engine

mechanical noise and, if needed, should be replaced with

recommended parts. Check for mechanical isolations.

Exhaust System

•Inspect the exhaust system for leaks at various joint connections and

tighten the clamps.

•Do a visual inspection for cracks or holes in the muffler and tail pipe.

•Always use the recommended parts when items need to be replaced.

•The tail pipe elbow or offset tail pipe orientation must not be changed

from the standard position as originally received.

•To avoid abnormal changes in vehicle sound levels, it is necessary for

the owner to perform inspections and necessary maintenance at the

intervals shown in theScheduled Maintenance Guidechapter.

POWER STEERING FLUID

Check the power steering fluid level using the following procedure. If

adding fluid is necessary, refer toLubricant Specificationsin this

chapter for the proper fluid type. Refer to theScheduled Maintenance

Guidechapter for the recommended service intervals.

1. Set the parking brake, shift into N (Neutral) (automatic transmission)

or 1 (First) (manual transmission) and turn the engine off.

2. Open the hood.

3. Clean the top of the power steering fluid reservoir.

4. Remove the dipstick from the reservoir and wipe the dipstick clean.

5. Reinstall the dipstick. Remove it again and check the fluid level.

2008 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

186

Page 188 of 273

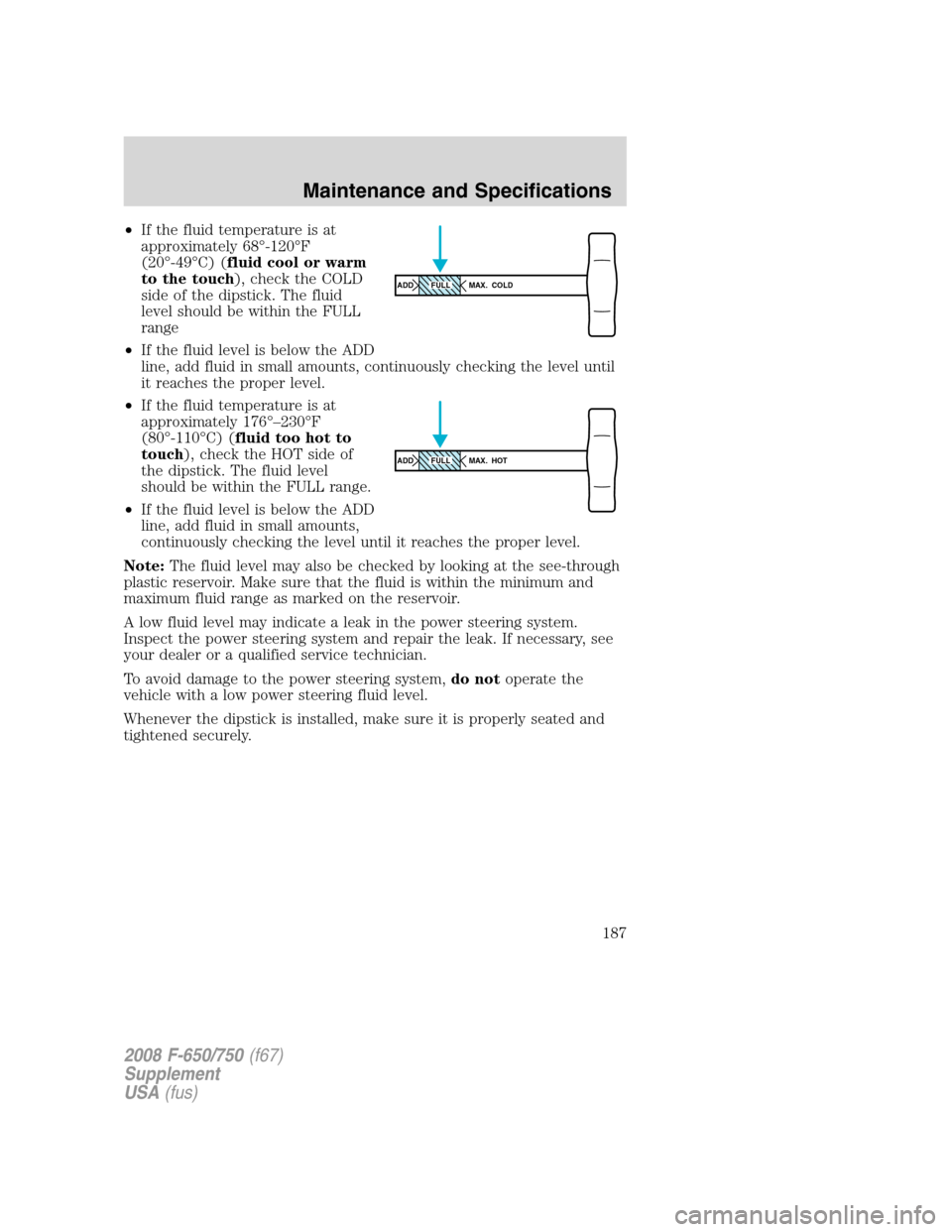

•If the fluid temperature is at

approximately 68°-120°F

(20°-49°C) (fluid cool or warm

to the touch), check the COLD

side of the dipstick. The fluid

level should be within the FULL

range

•If the fluid level is below the ADD

line, add fluid in small amounts, continuously checking the level until

it reaches the proper level.

•If the fluid temperature is at

approximately 176°–230°F

(80°-110°C) (fluid too hot to

touch), check the HOT side of

the dipstick. The fluid level

should be within the FULL range.

•If the fluid level is below the ADD

line, add fluid in small amounts,

continuously checking the level until it reaches the proper level.

Note:The fluid level may also be checked by looking at the see-through

plastic reservoir. Make sure that the fluid is within the minimum and

maximum fluid range as marked on the reservoir.

A low fluid level may indicate a leak in the power steering system.

Inspect the power steering system and repair the leak. If necessary, see

your dealer or a qualified service technician.

To avoid damage to the power steering system,do notoperate the

vehicle with a low power steering fluid level.

Whenever the dipstick is installed, make sure it is properly seated and

tightened securely.

ADD MAX. COLDFULL

ADD MAX. HOTFULL

2008 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

187

Page 189 of 273

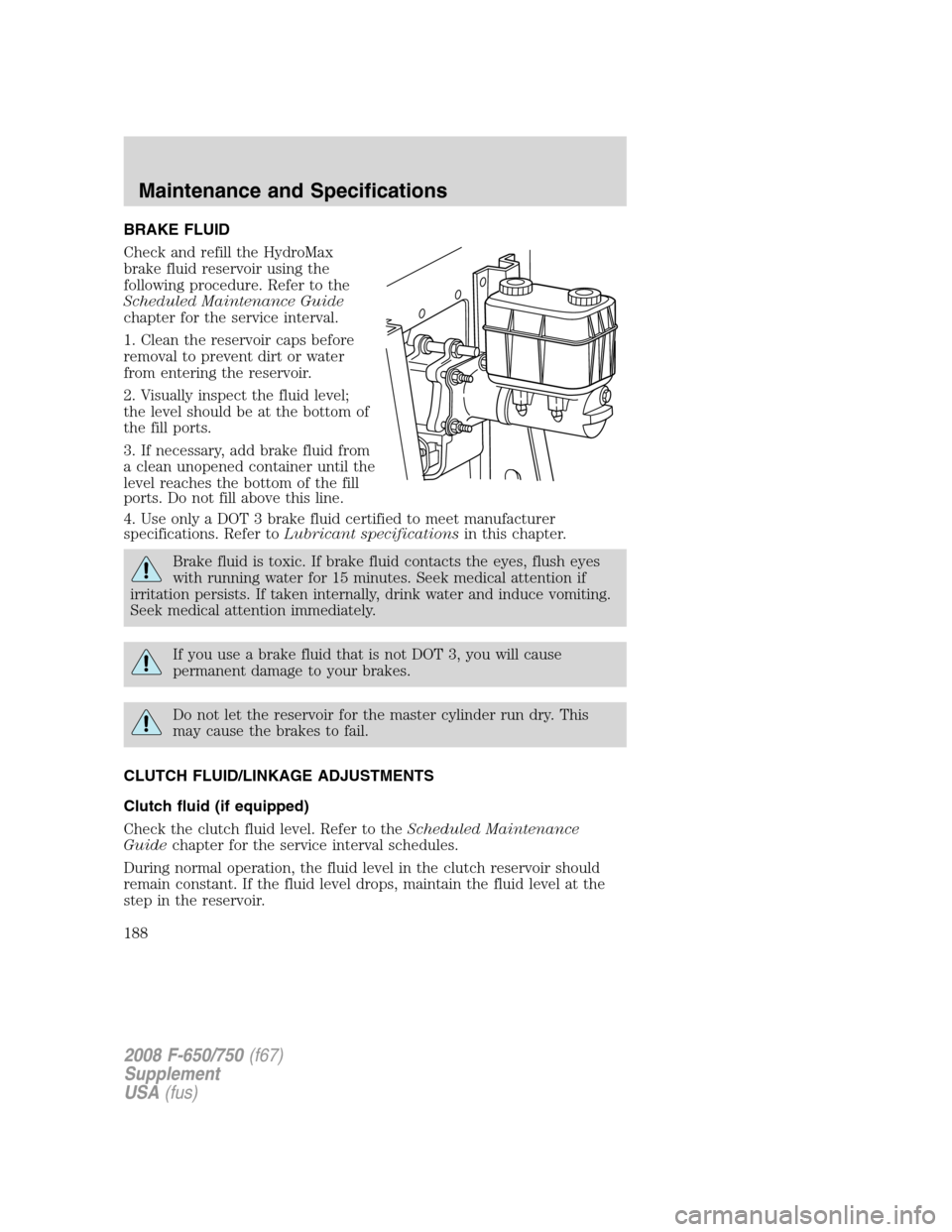

BRAKE FLUID

Check and refill the HydroMax

brake fluid reservoir using the

following procedure. Refer to the

Scheduled Maintenance Guide

chapter for the service interval.

1. Clean the reservoir caps before

removal to prevent dirt or water

from entering the reservoir.

2. Visually inspect the fluid level;

the level should be at the bottom of

the fill ports.

3. If necessary, add brake fluid from

a clean unopened container until the

level reaches the bottom of the fill

ports. Do not fill above this line.

4. Use only a DOT 3 brake fluid certified to meet manufacturer

specifications. Refer toLubricant specificationsin this chapter.

Brake fluid is toxic. If brake fluid contacts the eyes, flush eyes

with running water for 15 minutes. Seek medical attention if

irritation persists. If taken internally, drink water and induce vomiting.

Seek medical attention immediately.

If you use a brake fluid that is not DOT 3, you will cause

permanent damage to your brakes.

Do not let the reservoir for the master cylinder run dry. This

may cause the brakes to fail.

CLUTCH FLUID/LINKAGE ADJUSTMENTS

Clutch fluid (if equipped)

Check the clutch fluid level. Refer to theScheduled Maintenance

Guidechapter for the service interval schedules.

During normal operation, the fluid level in the clutch reservoir should

remain constant. If the fluid level drops, maintain the fluid level at the

step in the reservoir.

2008 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

188

Page 190 of 273

Use only a DOT 3 brake fluid designed to meet manufacturer

specifications. Refer toLubricant specificationsin this chapter.

Carefully read cautionary information on product label. For

MEDICAL EMERGENCY INFORMATION, contact a physician or

Poison Control Center immediately; on Ford-Motorcraft products call:

1-800-959-3673 (FORD). Failure to follow these instructions may result

in personal injury.

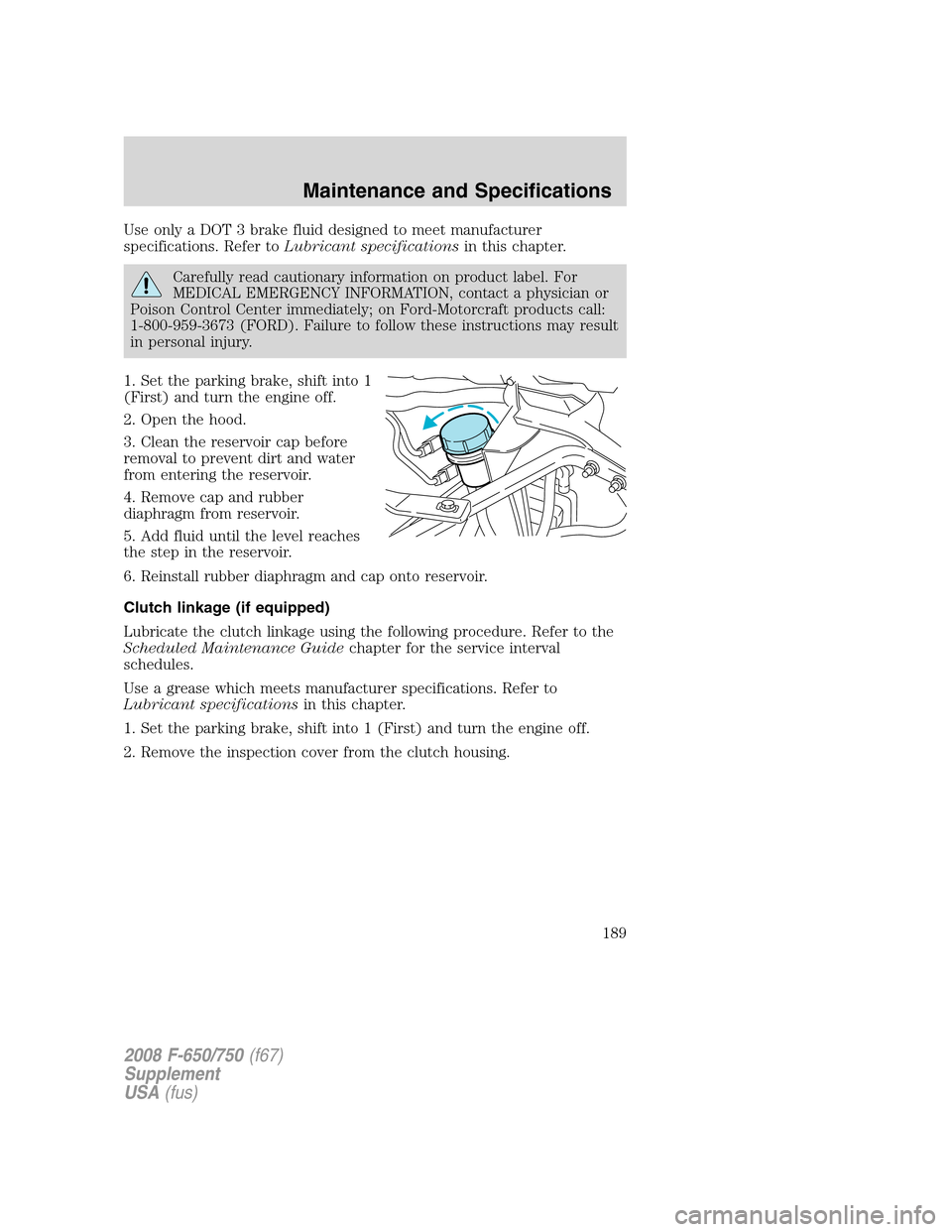

1. Set the parking brake, shift into 1

(First) and turn the engine off.

2. Open the hood.

3. Clean the reservoir cap before

removal to prevent dirt and water

from entering the reservoir.

4. Remove cap and rubber

diaphragm from reservoir.

5. Add fluid until the level reaches

the step in the reservoir.

6. Reinstall rubber diaphragm and cap onto reservoir.

Clutch linkage (if equipped)

Lubricate the clutch linkage using the following procedure. Refer to the

Scheduled Maintenance Guidechapter for the service interval

schedules.

Use a grease which meets manufacturer specifications. Refer to

Lubricant specificationsin this chapter.

1. Set the parking brake, shift into 1 (First) and turn the engine off.

2. Remove the inspection cover from the clutch housing.

2008 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

189