light FORD F650 2010 12.G Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2010, Model line: F650, Model: FORD F650 2010 12.GPages: 274, PDF Size: 1.51 MB

Page 118 of 274

ANTI-LOCK BRAKE SYSTEM (ABS)

A noise from the hydraulic pump motor and pulsation in the pedal may

be observed during ABS braking events. Pedal pulsation coupled with

noise while braking under panic conditions or on loose gravel, bumps,

wet or snowy roads is normal and indicates proper functioning of the

vehicle’s ABS. If the vehicle has continuous vibration or shudder in the

steering wheel while braking, the vehicle should be inspected by a

qualified service technician.

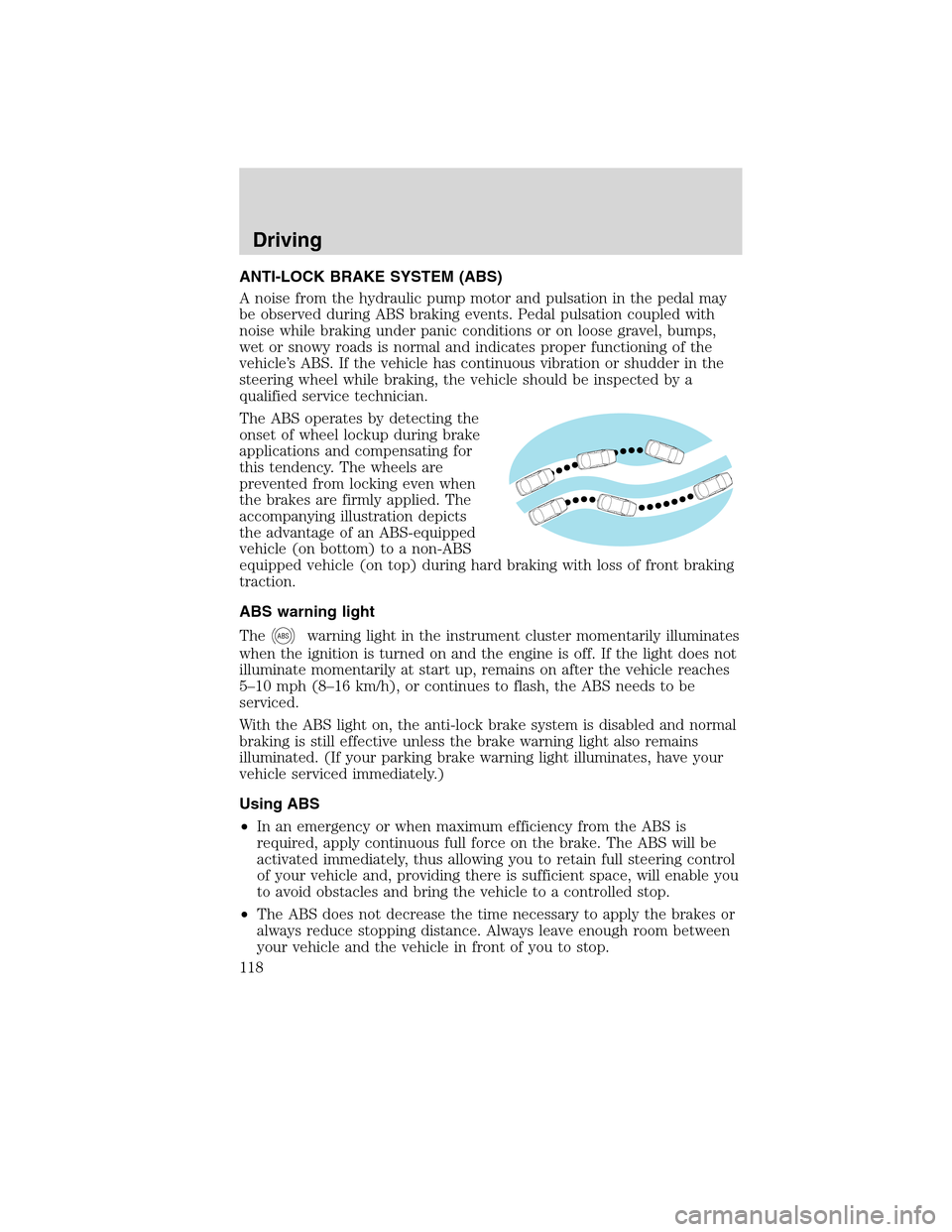

The ABS operates by detecting the

onset of wheel lockup during brake

applications and compensating for

this tendency. The wheels are

prevented from locking even when

the brakes are firmly applied. The

accompanying illustration depicts

the advantage of an ABS-equipped

vehicle (on bottom) to a non-ABS

equipped vehicle (on top) during hard braking with loss of front braking

traction.

ABS warning light

The

ABSwarning light in the instrument cluster momentarily illuminates

when the ignition is turned on and the engine is off. If the light does not

illuminate momentarily at start up, remains on after the vehicle reaches

5–10 mph (8–16 km/h), or continues to flash, the ABS needs to be

serviced.

With the ABS light on, the anti-lock brake system is disabled and normal

braking is still effective unless the brake warning light also remains

illuminated. (If your parking brake warning light illuminates, have your

vehicle serviced immediately.)

Using ABS

•In an emergency or when maximum efficiency from the ABS is

required, apply continuous full force on the brake. The ABS will be

activated immediately, thus allowing you to retain full steering control

of your vehicle and, providing there is sufficient space, will enable you

to avoid obstacles and bring the vehicle to a controlled stop.

•The ABS does not decrease the time necessary to apply the brakes or

always reduce stopping distance. Always leave enough room between

your vehicle and the vehicle in front of you to stop.

Driving

118

2010 F-650/750(f67)

Supplement(supplement), 1st Printing

USA(fus)

Page 119 of 274

•We recommend that you familiarize yourself with this braking

technique. However, avoid taking any unnecessary risks.

TRACTION CONTROL™ (IF EQUIPPED)

Your vehicle may be equipped with a Traction Control™ system. This

system helps you maintain the stability and steerability of your vehicle,

especially on slippery road surfaces such as snow- or ice-covered roads

and gravel roads, by reducing engine power and/or selectively applying

the rear brakes. The system will allow your vehicle to make better use of

available traction in these conditions.

Note:The traction control system will not apply the brakes when the

vehicle speed is above 25 mph (40 km/h).

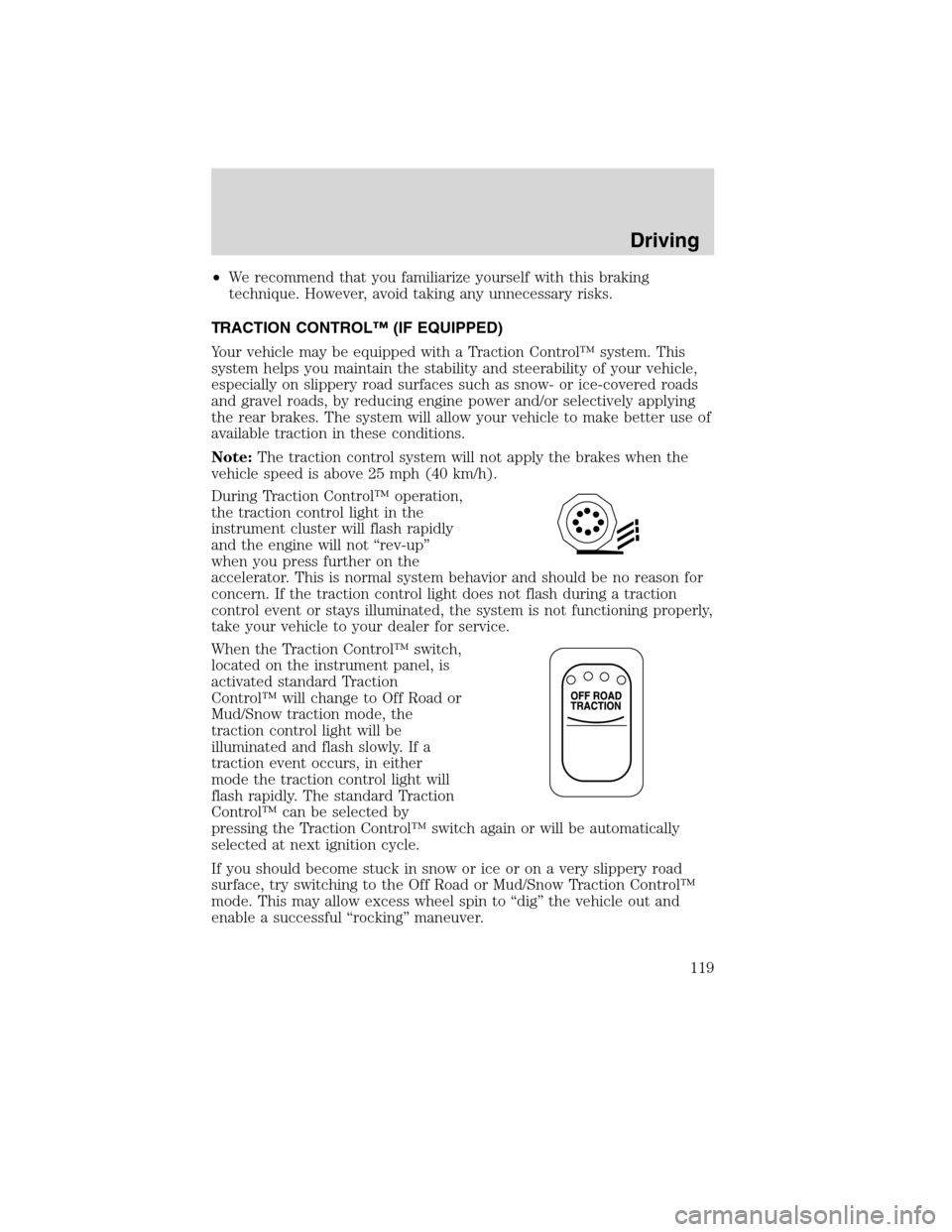

During Traction Control™ operation,

the traction control light in the

instrument cluster will flash rapidly

and the engine will not “rev-up”

when you press further on the

accelerator. This is normal system behavior and should be no reason for

concern. If the traction control light does not flash during a traction

control event or stays illuminated, the system is not functioning properly,

take your vehicle to your dealer for service.

When the Traction Control™ switch,

located on the instrument panel, is

activated standard Traction

Control™ will change to Off Road or

Mud/Snow traction mode, the

traction control light will be

illuminated and flash slowly. If a

traction event occurs, in either

mode the traction control light will

flash rapidly. The standard Traction

Control™ can be selected by

pressing the Traction Control™ switch again or will be automatically

selected at next ignition cycle.

If you should become stuck in snow or ice or on a very slippery road

surface, try switching to the Off Road or Mud/Snow Traction Control™

mode. This may allow excess wheel spin to “dig” the vehicle out and

enable a successful “rocking” maneuver.

Driving

119

2010 F-650/750(f67)

Supplement(supplement), 1st Printing

USA(fus)

Page 121 of 274

Tractor-trailer connections

WARNING:To reduce the risk of personal injury, use extreme

caution when making brake and light connections. Inclement

weather and accumulated road contamination deposits on handhold

and stepping surfaces require extra care to avoid slip and falls. Provide

adequate lighting of working areas.

WARNING:Do not climb on the back of the tractor unless it

has been provided with a deck plate and handholds. Use a

three-point stance when climbing up and down from a deck plate. Do

not jump from the vehicle. Whenever possible, make all connections

while standing on the ground.

Connecting and disconnecting a trailer with air suspension

When connecting to a trailer:

•Press the lower portion of the switch and air will exhaust from the air

suspension system.

•After making the connection to the trailer, press the upper portion of

the switch, then raise the landing gear.

When disconnecting the trailer:

•Lower the landing gear, then press the lower portion of the switch.

•Disconnect the brake hoses, trailer-side and rear light connectors,

then pull the release lever on the fifth wheel.

The upper portion of the switch must be pressed before operating with a

trailer or operating in the bobtail mode.

Suspension conversions

It is not recommended, or approved, that suspension conversions be

performed. However, it is understood that, on occasion, aftermarket

add-on suspensions are installed by others on the truck chassis which

allow operator control for weight transfer from other axles (i.e., air lift

axles).

WARNING:When operating a loaded vehicle, the driver must

keep all adjustable axles on the ground at all times, supporting

their share of the vehicle’s load. Failure to do so can overload other

axles, tires, wheels, springs, steering components, brakes and frames,

resulting in early component failure, loss of vehicle control, possible

property damage and personal injury.

Driving

121

2010 F-650/750(f67)

Supplement(supplement), 1st Printing

USA(fus)

Page 126 of 274

Clutch brake (vehicles equipped with a non-synchronized

transmission) - Vehicle stationary

A clutch brake is used to stop transmission input shaft rotation so that

the initial 1 (First) or R (Reverse) gear selection can be accomplished

when the vehicle is stationary and the engine is running at idle speed.

Clutch brake application occurs in the last inch (25 mm) of clutch pedal

travel.

When using the clutch brake, fully press the clutch pedal and shift the

transmission into 1 (First) or R (Reverse). If the transmission won’t go

into one of these gears, slowly release the clutch pedal while applying

light pressure on the transmission shift lever until it shifts into gear.

Note:After engagement of 1 (First) gear,do notuse the clutch brake

for upshifting or downshifting. If you do, clutch brake life will shorten

and gear selection shift efforts may increase.

Double-clutch procedures - vehicles equipped with a

non-synchronized transmission

In order to properly upshift or downshift, perform the following steps:

1. Press the clutch pedal to disengage the clutch.

2. Shift the transmission into neutral.

3. Release the clutch pedal.

If upshifting, wait until the engine speed matches the transmission

speed of the gear you are selecting.

If downshifting,accelerate the engine until the engine speed matches

the input speed of the gear you are selecting. Press the clutch pedal

immediately and shift into the desired gear, then release the clutch

pedal.

MANUAL TRANSMISSION OPERATION (IF EQUIPPED)

Note:Continued use of a damaged or worn clutch, prolonged clutch

slippage or downshifting at excessive speeds can result in a failure of the

engine, transmission or clutch components.

Note:To avoid premature clutch wear and failure, do not drive with

your foot resting on the clutch pedal or use it to hold the vehicle at a

standstill on an upgrade as when waiting for a traffic light.

Driving

126

2010 F-650/750(f67)

Supplement(supplement), 1st Printing

USA(fus)

Page 127 of 274

Manual transmission shift patterns

are displayed on either the shift

lever knob or the sun visor.

Study this information carefully before you drive the vehicle even though

you may be familiar with similar units. Do not attempt to drive the

vehicle without knowing the exact shift pattern of the transmission.

Consult your authorized dealer if any questions exist as to the shifting

instructions posted in your vehicle.

WARNING:Do not coast the vehicle with the clutch pedal

pressed or with the transmission in neutral. This practice could

result in loss of vehicle control.

Driving hints

The following driving hints are provided as a brief, general guide in

operating the different manual transmissions used in your vehicle.

•When shifting into 1 (First) or R (Reverse) with vehicle standing still,

quickly release and press the clutch pedal (if necessary to complete

gear engagement).

•Always use the lowest (or most appropriate) gear to start the vehicle.

•Always use a gear ratio low enough to allow the engine to operate

above the minimum engine operation speed range.

•Do not lug the engine.

•Do not slam or jerk the gearshift lever into gear.

•When more power is required, shift to a lower gear and accelerate the

engine near the governed speed.

Shifting with a synchronized transmission

With the clutch pedal pressed in, use 2 (Second) gear synchronizer to

stop the clutch disc rotation; this allows smooth engagement of 1 (First)

or R (Reverse). To complete the gear engagement, it may be necessary

to apply light pressure to the gearshift lever during initial engagement of

the clutch. It takes a second or two to match gear speeds; steady

R 1 3 5

4

6 2

Driving

127

2010 F-650/750(f67)

Supplement(supplement), 1st Printing

USA(fus)

Page 128 of 274

pressure on the gearshift lever will help the synchronizer perform its job

more quickly. If the gearshift lever is forced into position, this action

defeats the purpose of the synchronizer by causing gear clash.

Shifting with a non-synchronized transmission

Refer toClutch brakeandDouble clutch proceduresin theClutch

section of this chapter.

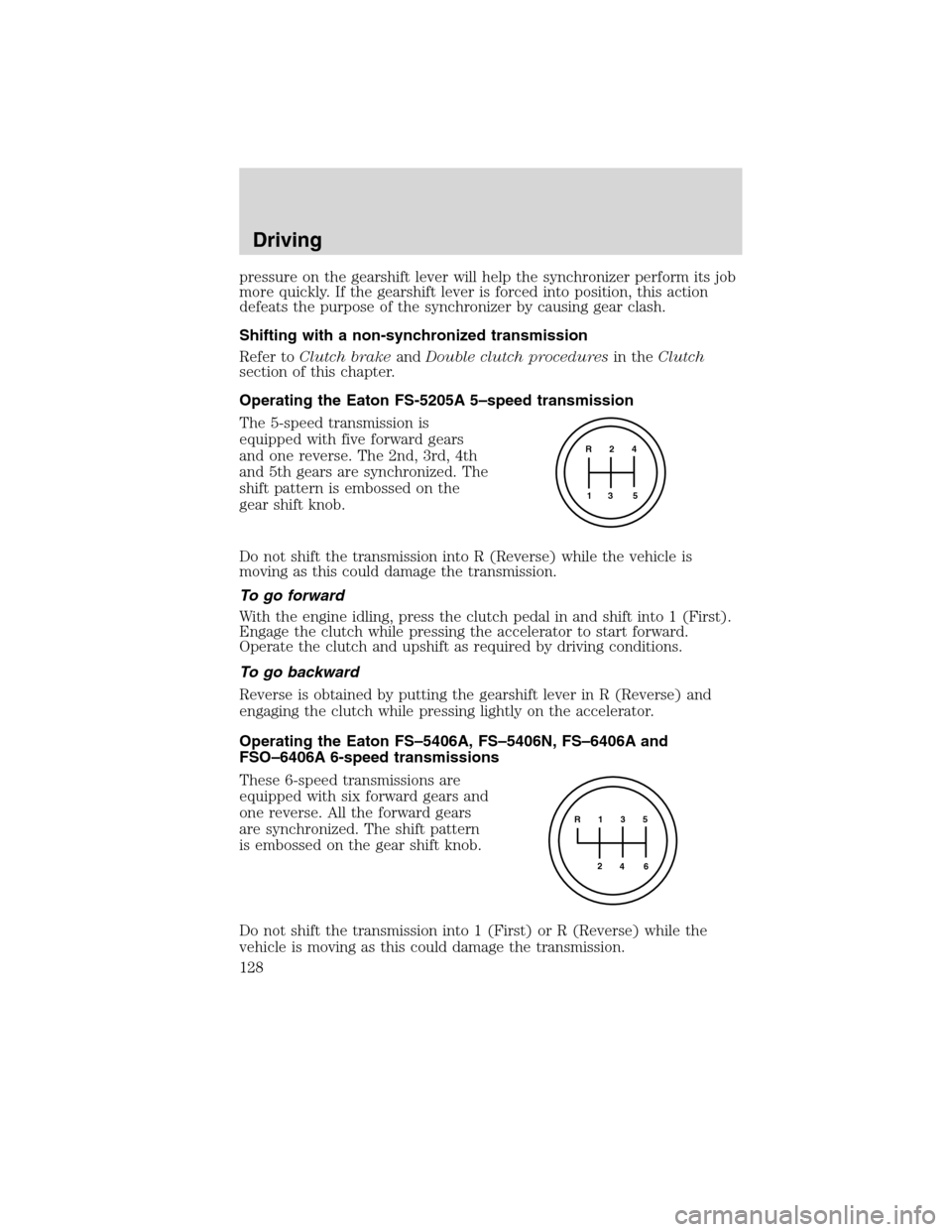

Operating the Eaton FS-5205A 5–speed transmission

The 5-speed transmission is

equipped with five forward gears

and one reverse. The 2nd, 3rd, 4th

and 5th gears are synchronized. The

shift pattern is embossed on the

gear shift knob.

Do not shift the transmission into R (Reverse) while the vehicle is

moving as this could damage the transmission.

To go forward

With the engine idling, press the clutch pedal in and shift into 1 (First).

Engage the clutch while pressing the accelerator to start forward.

Operate the clutch and upshift as required by driving conditions.

To go backward

Reverse is obtained by putting the gearshift lever in R (Reverse) and

engaging the clutch while pressing lightly on the accelerator.

Operating the Eaton FS–5406A, FS–5406N, FS–6406A and

FSO–6406A 6-speed transmissions

These 6-speed transmissions are

equipped with six forward gears and

one reverse. All the forward gears

are synchronized. The shift pattern

is embossed on the gear shift knob.

Do not shift the transmission into 1 (First) or R (Reverse) while the

vehicle is moving as this could damage the transmission.

R 2 4

3 5 1

R 1 3 5

4

6 2

Driving

128

2010 F-650/750(f67)

Supplement(supplement), 1st Printing

USA(fus)

Page 129 of 274

To go forward

With the engine idling, press the clutch pedal in and shift into 1 (First).

Engage the clutch while pressing the accelerator to start forward.

Operate the clutch and upshift as required by driving conditions.

To go backward

Reverse is obtained by putting the gearshift lever in R (Reverse) and

engaging the clutch while pressing lightly on the accelerator.

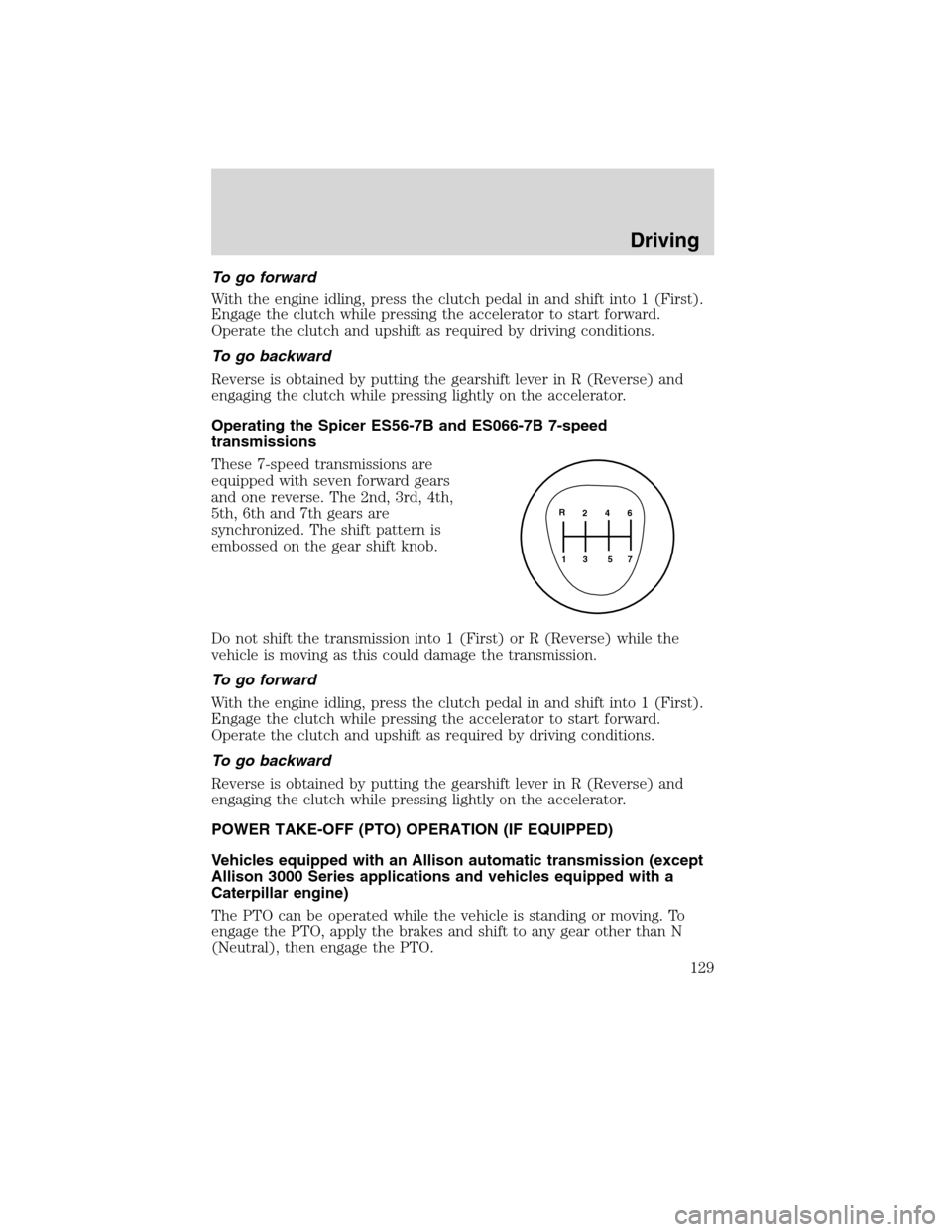

Operating the Spicer ES56-7B and ES066-7B 7-speed

transmissions

These 7-speed transmissions are

equipped with seven forward gears

and one reverse. The 2nd, 3rd, 4th,

5th, 6th and 7th gears are

synchronized. The shift pattern is

embossed on the gear shift knob.

Do not shift the transmission into 1 (First) or R (Reverse) while the

vehicle is moving as this could damage the transmission.

To go forward

With the engine idling, press the clutch pedal in and shift into 1 (First).

Engage the clutch while pressing the accelerator to start forward.

Operate the clutch and upshift as required by driving conditions.

To go backward

Reverse is obtained by putting the gearshift lever in R (Reverse) and

engaging the clutch while pressing lightly on the accelerator.

POWER TAKE-OFF (PTO) OPERATION (IF EQUIPPED)

Vehicles equipped with an Allison automatic transmission (except

Allison 3000 Series applications and vehicles equipped with a

Caterpillar engine)

The PTO can be operated while the vehicle is standing or moving. To

engage the PTO, apply the brakes and shift to any gear other than N

(Neutral), then engage the PTO.

2 4 6

3 5 71 R

Driving

129

2010 F-650/750(f67)

Supplement(supplement), 1st Printing

USA(fus)

Page 130 of 274

If engagement is prevented by the gear teeth not meshing properly,

release the brakes and allow the vehicle to creep slightly or shift the

selector to N (Neutral) and then back into gear. The PTO should never

be engaged by clashing the gear teeth as this may damage the PTO unit

and the transmission PTO drive gear teeth. This could result in further

damage to the transmission and PTO.

PTO operation with vehicle stationary

Stop the vehicle, idle the engine and set the parking brake. Make sure

the gear selector is in any forward drive range, then engage the PTO.

After the PTO is engaged, move the range selector to N (Neutral).

Increase the engine speed until the desired power take-off operation

speed is obtained. To disengage the PTO after operation with the vehicle

standing, release the throttle, allow the drive equipment to come to a

stop, and then disengage the PTO.

WARNING:When the PTO is operated with the vehicle

stationary, the transmission must be placed in N (Neutral) with

the parking brake set. If the transmission is not in N (Neutral) and is

equipped with a remote throttle control, an increase in engine speed

can overpower the parking brake and cause the vehicle to move,

possibly resulting in personal injury and/or property damage.

PTO operation while vehicle is moving

After the PTO is engaged for driven vehicle operation, shift to the

desired range and drive the vehicle. The speed of the PTO, during this

period of operation, will always maintain direct relation to vehicle speed.

PTO speed will decrease in relation to vehicle (transmission output)

speed as shifts to a higher gear occur. When operating the PTO while the

vehicle is moving, the PTO may be disengaged whenever it is no longer

required. When there is no load on the PTO gear, it can be pulled out of

engagement.

Vehicles equipped with an Eaton UltraShift transmission

Refer to the operationTransmission Power Take Offsection of the

UltraShift Driver Instructions Manual.

Driving

130

2010 F-650/750(f67)

Supplement(supplement), 1st Printing

USA(fus)

Page 133 of 274

When the differential is locked, the vehicle’s turning radius will increase

(vehicle will “under-steer”)

The differential can be locked or unlocked when the vehicle is moving at

a constant speed of less than 25 mph (40 km/h) and while the wheels

are not slipping. The differential must not be locked when the vehicle is

traveling down steep grades and traction is minimal.

Note:Never use the differential lock at vehicle speeds above 25 mph

(40 km/h).

The differential lock and differential lock light will automatically

disengage at speeds above 25 mph (40 km/h). The differential lock will

remain off until either the vehicle is restarted or the differential lock

switch is turned off then back on.

Axle conversions

It is not recommended, or approved, for axle conversions to be

performed. However, it is understood that, on occasion, aftermarket

add-on axles are installed by others on the truck chassis which allow

operator control for weight transfer from other axles (i.e., air lift axles).

WARNING:When operating a loaded vehicle, the driver must

keep all adjustable axles on the ground at all times, supporting

their share of the vehicle’s load. Failure to do so can overload other

axles, tires, wheels, springs, steering components, brakes and frames,

resulting in early component failure, loss of vehicle control, possible

property damage and personal injury.

TWO-SPEED REAR AXLE (IF EQUIPPED)

A two-speed rear axle allows the driver to select a LO range for greater

pulling power and a HI range for greater road speed and fuel economy.

These ranges can also be used to provide additional steps between

transmission shifts when driving on steep grades and/or fuel economy

may be factors.

Note:Do not shift between ranges when the speed control is on.

WARNING:Never shift a two-speed axle when descending a

steep grade as this may cause loss of vehicle control and result

in personal injury.

Driving

133

2010 F-650/750(f67)

Supplement(supplement), 1st Printing

USA(fus)

Page 134 of 274

Axle shifting

Manual transmissions:

•To downshift,select the next lower gear, release and press the

accelerator pedal rapidly, or while holding the accelerator pedal down,

release and engage the clutch rapidly.Note:The clutch method is

recommended when driving at slower speeds.

•To upshift,keep the accelerator pedal down, select the next higher

gear, release the accelerator and pause until the axle upshifts.Note:

De-clutch for smoother axle upshifts when driving at slower speeds.

Automatic transmissions:

•Use LO range for when you drive

a fully loaded vehicle on a severe

grade or in congested traffic. To

activate LO range, press the

upper portion of the switch.

•Use HI range for all normal

driving conditions with a lightly

loaded or partially loaded vehicle.

To activate HI range, press the

lower portion of the switch.

Note:You cannot split-shift with an automatic transmission. Also,

downshifting above 40 mph (64 km/h) may result in transmission or axle

damage.

Shifting the axle from LO to HI range - vehicle stopped

Place the transmission in N (Neutral), then press the lower part of the

switch.

Shifting the axle from LO to HI range - vehicle moving

Accelerate to approximately 35 mph (56 km/h), press the lower part of

the switch while the transmission is in N (Neutral), then release and

apply the accelerator.

Shifting the axle from HI to LO range - vehicle stopped

Place the transmission in N (Neutral), then press the upper part of the

switch.

Note:Do not shift the axle to LO range with the vehicle in motion.

LOW

2SPD

Driving

134

2010 F-650/750(f67)

Supplement(supplement), 1st Printing

USA(fus)