transmission fluid FORD F650/750 2019 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2019, Model line: F650/750, Model: FORD F650/750 2019Pages: 387, PDF Size: 4.78 MB

Page 183 of 387

Engine starting (with parking brake applied)

Check the gauge (diesel engine) or indicator light (gasoline

engine) to verify the alternator is charging.

Voltmeter

Inspect for excessive free play in the steering linkages. The

steering wheel should have less than 2 in (5 cm) of free play

at its rim.

Steering linkage free play

Verify the parking brake holds the vehicle by gently trying to

pull forward with the parking brake applied.

Parking brake

Verify operation using the following procedure. Chock the

wheels, if necessary. Push in the parking brake and, on

tractors, push in the tractor parking brake knob:

Air brakes

1. Verify the air compressor or governor cutout pressure is

approximately 120 psi (827 kPa).

2. Turn off the engine, and then turn the key back to the on

position (without starting the engine).

3. Without the brake pedal applied, note the air pressure drop

for one minute. It should be less than 2 psi (14 kPa) for single

vehicles and

3 psi (21 kPa) for combination vehicles.

4. Press and hold the brake pedal with

90 psi (621 kPa) or

more. Make sure there is no more than a 3 psi (21 kPa) per

minute leak for single vehicles and a 4 psi (28 kPa) minute

leak for combination vehicles.

5. Pump the brake pedal to deplete the system of air pressure.

The warning light and tone should turn on at 57 psi (393 kPa).

6. Pump the brake pedal and make sure the parking brake

and trailer parking brake knobs pop out at

20 psi (138 kPa)

or higher.

Verify that the fluid level is in the proper operating range. See

Automatic Transmission Fluid Check

(page 204).

Automatic transmission

fluid Front of vehicle

Verify all exterior lights illuminate and are clean.

Lights

Check headlights function on high and low beam.

Verify reflectors are clean, unbroken and of proper color (red

on rear, amber elsewhere).

180

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Vehicle Inspection Guide

Page 189 of 387

Inspect the transmission fluid level and

shift linkage for proper operation.

186

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Vehicle Inspection Guide

Page 193 of 387

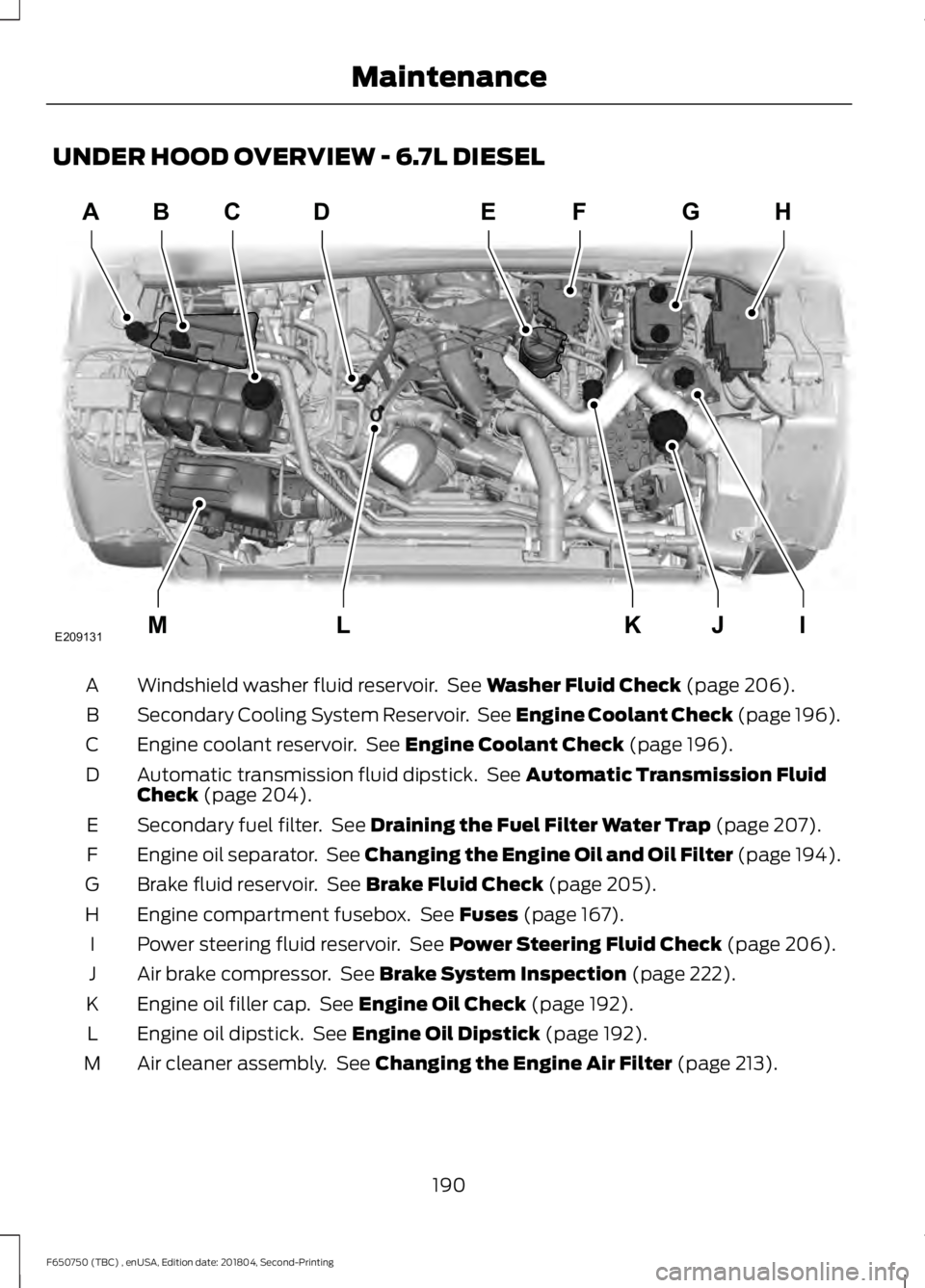

UNDER HOOD OVERVIEW - 6.7L DIESEL

Windshield washer fluid reservoir. See Washer Fluid Check (page 206).

A

Secondary Cooling System Reservoir. See Engine Coolant Check (page 196).

B

Engine coolant reservoir. See

Engine Coolant Check (page 196).

C

Automatic transmission fluid dipstick. See

Automatic Transmission Fluid

Check (page 204).

D

Secondary fuel filter. See

Draining the Fuel Filter Water Trap (page 207).

E

Engine oil separator. See

Changing the Engine Oil and Oil Filter (page 194).

F

Brake fluid reservoir. See

Brake Fluid Check (page 205).

G

Engine compartment fusebox. See

Fuses (page 167).

H

Power steering fluid reservoir. See

Power Steering Fluid Check (page 206).

I

Air brake compressor. See

Brake System Inspection (page 222).

J

Engine oil filler cap. See

Engine Oil Check (page 192).

K

Engine oil dipstick. See

Engine Oil Dipstick (page 192).

L

Air cleaner assembly. See

Changing the Engine Air Filter (page 213).

M

190

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing MaintenanceABD

IJKLM

FEGH

E209131C

Page 194 of 387

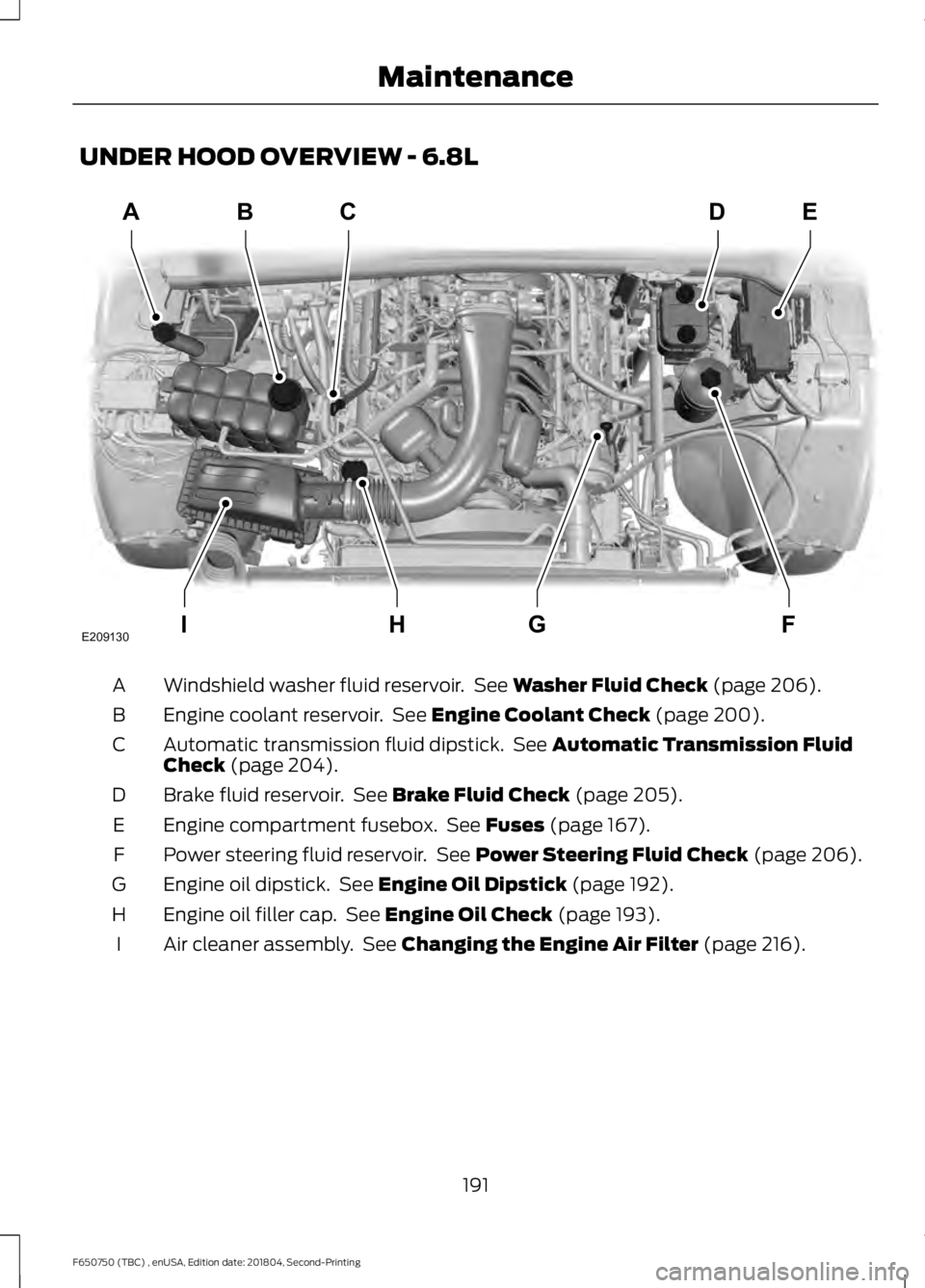

UNDER HOOD OVERVIEW - 6.8L

Windshield washer fluid reservoir. See Washer Fluid Check (page 206).

A

Engine coolant reservoir. See

Engine Coolant Check (page 200).

B

Automatic transmission fluid dipstick. See

Automatic Transmission Fluid

Check (page 204).

C

Brake fluid reservoir. See

Brake Fluid Check (page 205).

D

Engine compartment fusebox. See

Fuses (page 167).

E

Power steering fluid reservoir. See

Power Steering Fluid Check (page 206).

F

Engine oil dipstick. See

Engine Oil Dipstick (page 192).

G

Engine oil filler cap. See

Engine Oil Check (page 193).

H

Air cleaner assembly. See

Changing the Engine Air Filter (page 216).

I

191

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing MaintenanceABC

FGHI

DE

E209130

Page 207 of 387

AUTOMATIC TRANSMISSION

FLUID CHECK

The transmission does not consume fluid.

However, the fluid level should be checked

if the transmission is not working properly,

for example if the transmission slips, shifts

slowly or if there are signs of fluid loss.

The transmission fluid and filter on your

vehicle must be replaced at the specified

service interval. See Scheduled

Maintenance (page 322).

Automatic transmission fluid expands

when warmed. To check the fluid level

consistently and accurately, do the

following:

1. Drive the vehicle until it reaches normal

operating temperature. This may take

up to

20 mi (30 km).

2. Make sure that your vehicle is on level ground.

3. With the engine running, parking brake

engaged and your foot on the brake

pedal, move the gearshift lever through

all of the gear ranges. Allow sufficient

time for each gear to engage.

4. Make sure the parking brake is on. Make

sure the transmission is in park (P) or

neutral (N) and leave the engine

running.

5. Open the hood. See

Opening and

Closing the Hood (page 188).

6. Remove the dipstick and wipe it with a clean, lint-free cloth. See

Under

Hood Overview (page 191).

7. Replace the dipstick and remove it again to check the fluid level.

8. If the fluid level is correct, replace the dipstick and make sure it is fully seated.

Note: If the fluid level is between the

maximum and minimum marks, the fluid

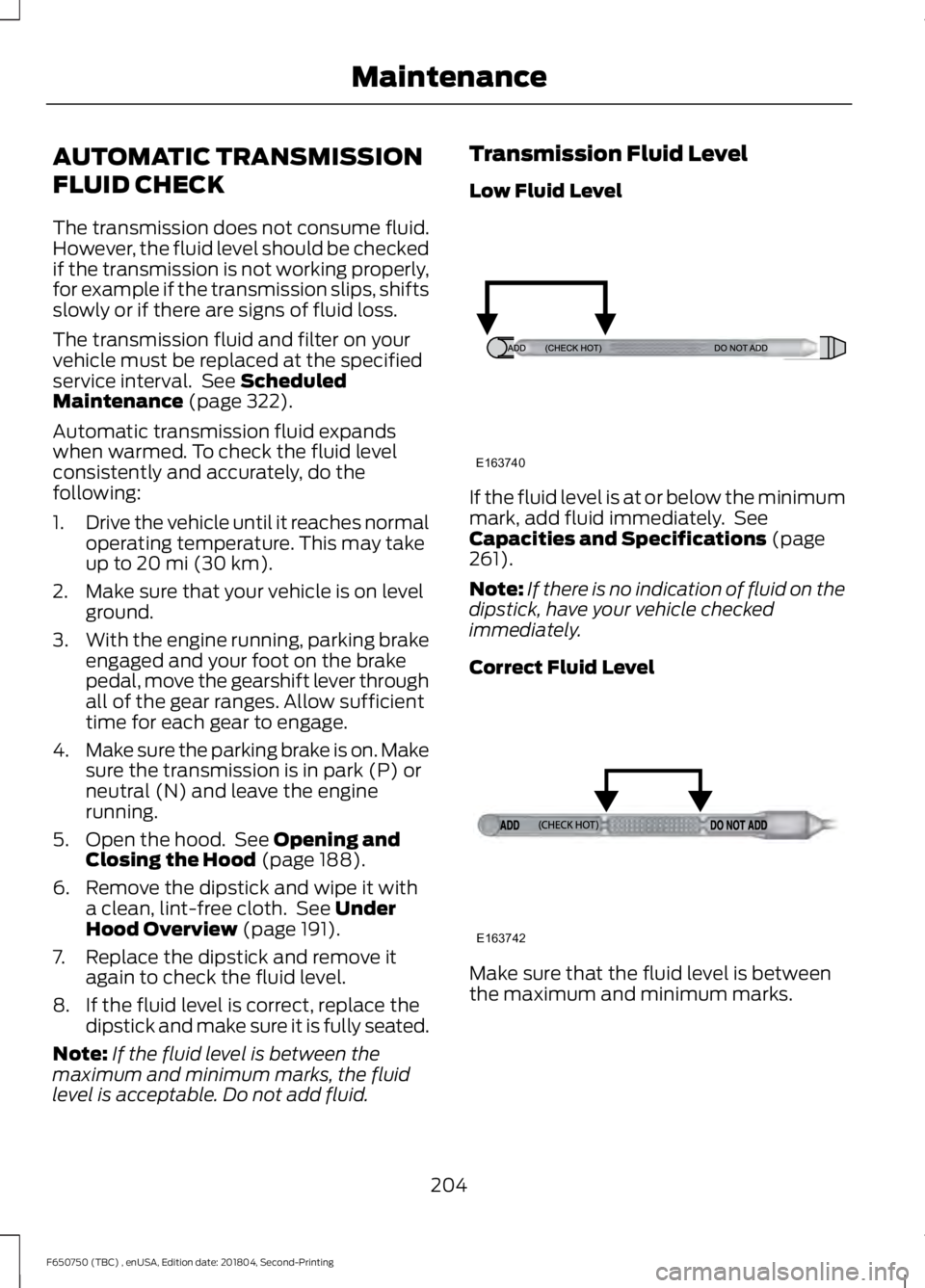

level is acceptable. Do not add fluid. Transmission Fluid Level

Low Fluid Level

If the fluid level is at or below the minimum

mark, add fluid immediately. See

Capacities and Specifications

(page

261).

Note: If there is no indication of fluid on the

dipstick, have your vehicle checked

immediately.

Correct Fluid Level Make sure that the fluid level is between

the maximum and minimum marks.

204

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing MaintenanceE163740 E163742

Page 208 of 387

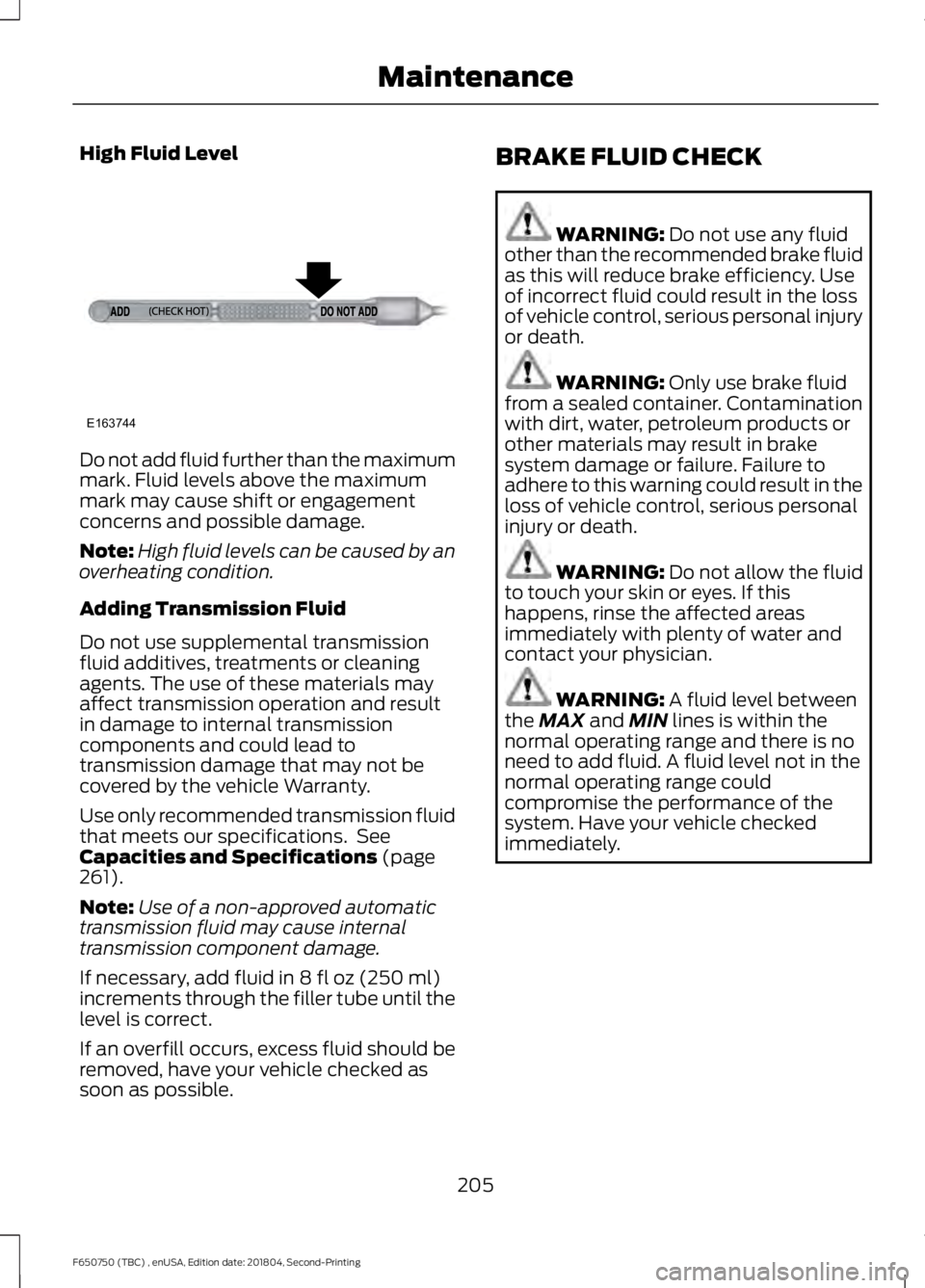

High Fluid Level

Do not add fluid further than the maximum

mark. Fluid levels above the maximum

mark may cause shift or engagement

concerns and possible damage.

Note:

High fluid levels can be caused by an

overheating condition.

Adding Transmission Fluid

Do not use supplemental transmission

fluid additives, treatments or cleaning

agents. The use of these materials may

affect transmission operation and result

in damage to internal transmission

components and could lead to

transmission damage that may not be

covered by the vehicle Warranty.

Use only recommended transmission fluid

that meets our specifications. See

Capacities and Specifications (page

261).

Note: Use of a non-approved automatic

transmission fluid may cause internal

transmission component damage.

If necessary, add fluid in

8 fl oz (250 ml)

increments through the filler tube until the

level is correct.

If an overfill occurs, excess fluid should be

removed, have your vehicle checked as

soon as possible. BRAKE FLUID CHECK WARNING:

Do not use any fluid

other than the recommended brake fluid

as this will reduce brake efficiency. Use

of incorrect fluid could result in the loss

of vehicle control, serious personal injury

or death. WARNING:

Only use brake fluid

from a sealed container. Contamination

with dirt, water, petroleum products or

other materials may result in brake

system damage or failure. Failure to

adhere to this warning could result in the

loss of vehicle control, serious personal

injury or death. WARNING:

Do not allow the fluid

to touch your skin or eyes. If this

happens, rinse the affected areas

immediately with plenty of water and

contact your physician. WARNING:

A fluid level between

the MAX and MIN lines is within the

normal operating range and there is no

need to add fluid. A fluid level not in the

normal operating range could

compromise the performance of the

system. Have your vehicle checked

immediately.

205

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing MaintenanceE163744

Page 230 of 387

SUSPENSION SYSTEM

INSPECTION

Note:

Do not adjust air suspension height

to any setting other than the specified

setting. Altering the height setting changes

the driveline angle and may result in

unwarrantable component damage, such

as transmission component damage.

Verify drive axle air suspension height and

height control valve performance at engine

oil change intervals.

Periodically check:

• Condition of spring leaves for evidence

of fatigue, bending or breakage.

• Condition of suspension mounting

brackets and bushings.

• Torque rod mounting fasteners for

tightness.

• For proper suspension alignment.

Maintain proper alignment at all times.

• U-bolts. After the chassis has been

operating under load for 1,000 mi

(1,600 km) or six months (whichever

comes first), the U-bolt nuts must be

re-torqued. Re-torque the U-bolt nuts

every

37,000 mi (60,000 km)

thereafter. Clean and lubricate the

U-bolt and nut threads and seats to

make sure a like new condition when

re-torqueing. See

Spring U-Bolt

Check (page 228).

FRAME AND TOW HOOK

INSPECTION

Your vehicle's chassis is manufactured

with frame rails of either HSLA steel or

heat-treated steel. Handle each in a

specific manner to make sure maximum

service life. Consult the service manual or

an authorized dealer before attempting

frame repair or modification. It is important, particularly on vehicles that

use tow hooks frequently, to inspect the

front and rear tow hooks for damage or a

loose mounting.

REAR AXLE FLUID CHECK

Your rear axle may have an optional

synthetic lubricant that allows the use of

extended service intervals. A tag on the

filler plug identifies the use of the synthetic

lubricant.

Only use a lubricant that meets

manufacturer specifications. Only use a

lubricant that meets manufacturer

specifications. Use of a non-approved rear

axle lubricant may cause internal axle

component damage. See Capacities and

Specifications

(page 261).

Checking the Fluid Level

1. Park your vehicle on level ground.

2. Set the parking brake and shift into position neutral (N) or park (P). Turn

the engine off.

3. Clean any dirt from around the axle filler plug.

4. Remove the filler plug and inspect the lubricant level. It should be at the

bottom of the filler plug opening.

5. Add lubricant, if necessary, through the

filler plug opening.

6. Clean and install the filler plug securely.

Changing the Fluid

Note: Drain the rear axle while the lubricant

is warm.

1. Park your vehicle on level ground.

2. Set the parking brake and shift into position neutral (N) or park (P). Turn

the engine off.

3. Clean any dirt from around the axle filler and drain plugs.

227

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Maintenance

Page 265 of 387

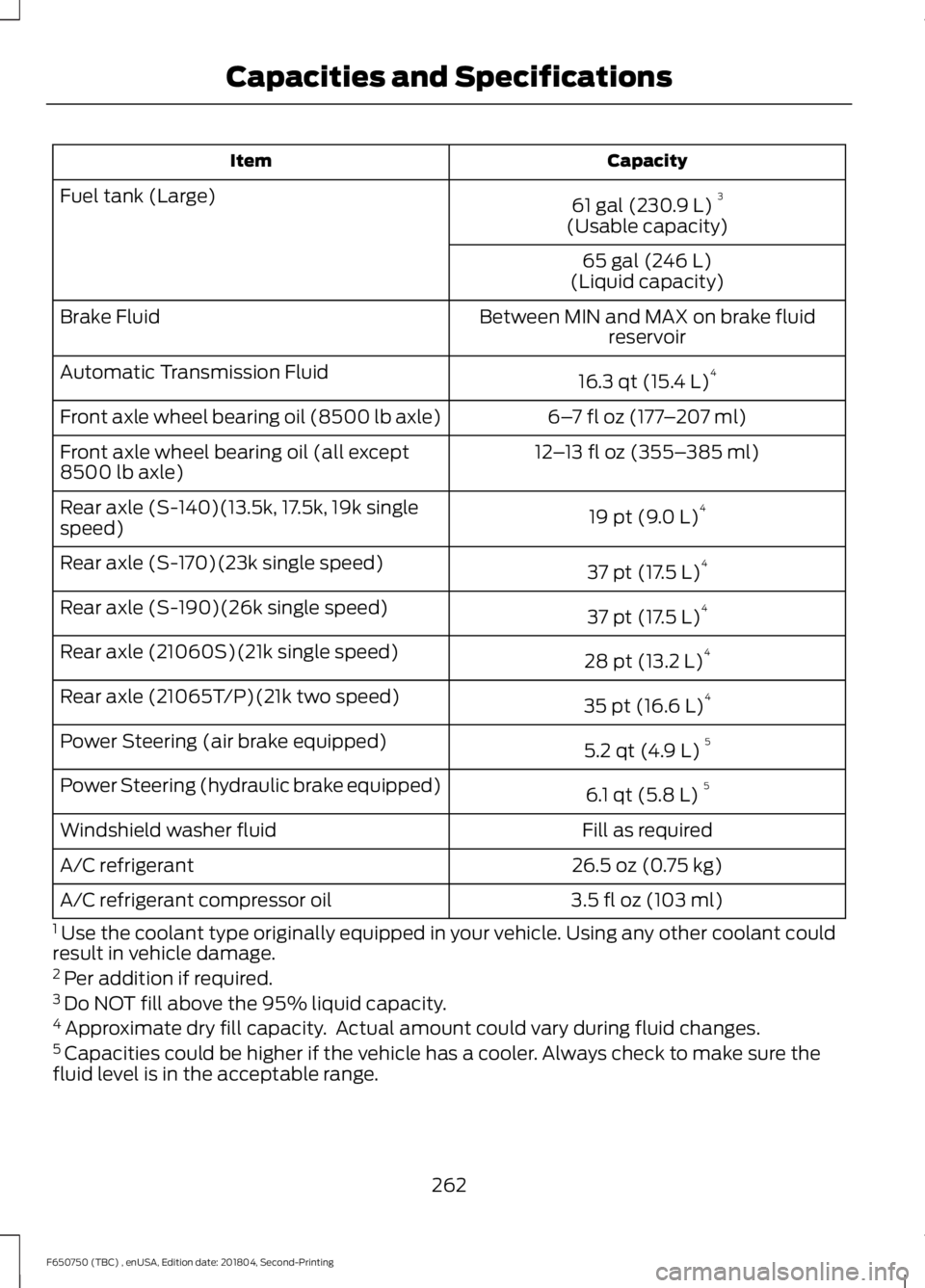

Capacity

Item

61 gal (230.9 L)3

Fuel tank (Large)

(Usable capacity)

65 gal (246 L)

(Liquid capacity)

Between MIN and MAX on brake fluid reservoir

Brake Fluid

16.3 qt (15.4 L)4

Automatic Transmission Fluid

6–7 fl oz (177 –207 ml)

Front axle wheel bearing oil (8500 lb axle)

12–13 fl oz (355– 385 ml)

Front axle wheel bearing oil (all except

8500 lb axle)

19 pt (9.0 L)4

Rear axle (S-140)(13.5k, 17.5k, 19k single

speed)

37 pt (17.5 L)4

Rear axle (S-170)(23k single speed)

37 pt (17.5 L)4

Rear axle (S-190)(26k single speed)

28 pt (13.2 L)4

Rear axle (21060S)(21k single speed)

35 pt (16.6 L)4

Rear axle (21065T/P)(21k two speed)

5.2 qt (4.9 L)5

Power Steering (air brake equipped)

6.1 qt (5.8 L)5

Power Steering (hydraulic brake equipped)

Fill as required

Windshield washer fluid

26.5 oz (0.75 kg)

A/C refrigerant

3.5 fl oz (103 ml)

A/C refrigerant compressor oil

1 Use the coolant type originally equipped in your vehicle. Using any other coolant could

result in vehicle damage.

2 Per addition if required.

3 Do NOT fill above the 95% liquid capacity.

4 Approximate dry fill capacity. Actual amount could vary during fluid changes.

5 Capacities could be higher if the vehicle has a cooler. Always check to make sure the

fluid level is in the acceptable range.

262

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Capacities and Specifications

Page 267 of 387

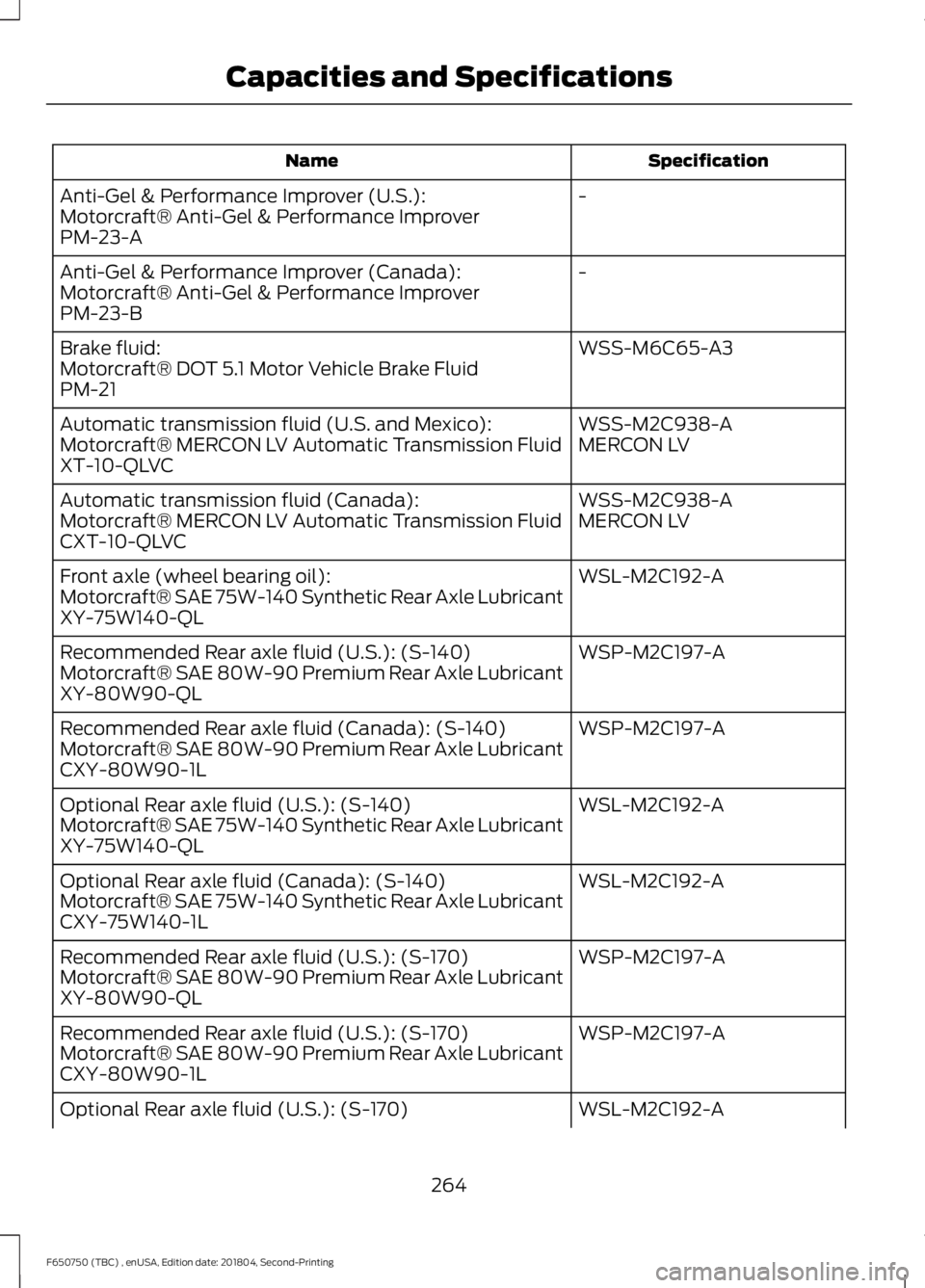

Specification

Name

-

Anti-Gel & Performance Improver (U.S.):

Motorcraft® Anti-Gel & Performance Improver

PM-23-A

-

Anti-Gel & Performance Improver (Canada):

Motorcraft® Anti-Gel & Performance Improver

PM-23-B

WSS-M6C65-A3

Brake fluid:

Motorcraft® DOT 5.1 Motor Vehicle Brake Fluid

PM-21

WSS-M2C938-A

Automatic transmission fluid (U.S. and Mexico):

MERCON LV

Motorcraft® MERCON LV Automatic Transmission Fluid

XT-10-QLVC

WSS-M2C938-A

Automatic transmission fluid (Canada):

MERCON LV

Motorcraft® MERCON LV Automatic Transmission Fluid

CXT-10-QLVC

WSL-M2C192-A

Front axle (wheel bearing oil):

Motorcraft® SAE 75W-140 Synthetic Rear Axle Lubricant

XY-75W140-QL

WSP-M2C197-A

Recommended Rear axle fluid (U.S.): (S-140)

Motorcraft® SAE 80W-90 Premium Rear Axle Lubricant

XY-80W90-QL

WSP-M2C197-A

Recommended Rear axle fluid (Canada): (S-140)

Motorcraft® SAE 80W-90 Premium Rear Axle Lubricant

CXY-80W90-1L

WSL-M2C192-A

Optional Rear axle fluid (U.S.): (S-140)

Motorcraft® SAE 75W-140 Synthetic Rear Axle Lubricant

XY-75W140-QL

WSL-M2C192-A

Optional Rear axle fluid (Canada): (S-140)

Motorcraft® SAE 75W-140 Synthetic Rear Axle Lubricant

CXY-75W140-1L

WSP-M2C197-A

Recommended Rear axle fluid (U.S.): (S-170)

Motorcraft® SAE 80W-90 Premium Rear Axle Lubricant

XY-80W90-QL

WSP-M2C197-A

Recommended Rear axle fluid (U.S.): (S-170)

Motorcraft® SAE 80W-90 Premium Rear Axle Lubricant

CXY-80W90-1L

WSL-M2C192-A

Optional Rear axle fluid (U.S.): (S-170)

264

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Capacities and Specifications

Page 269 of 387

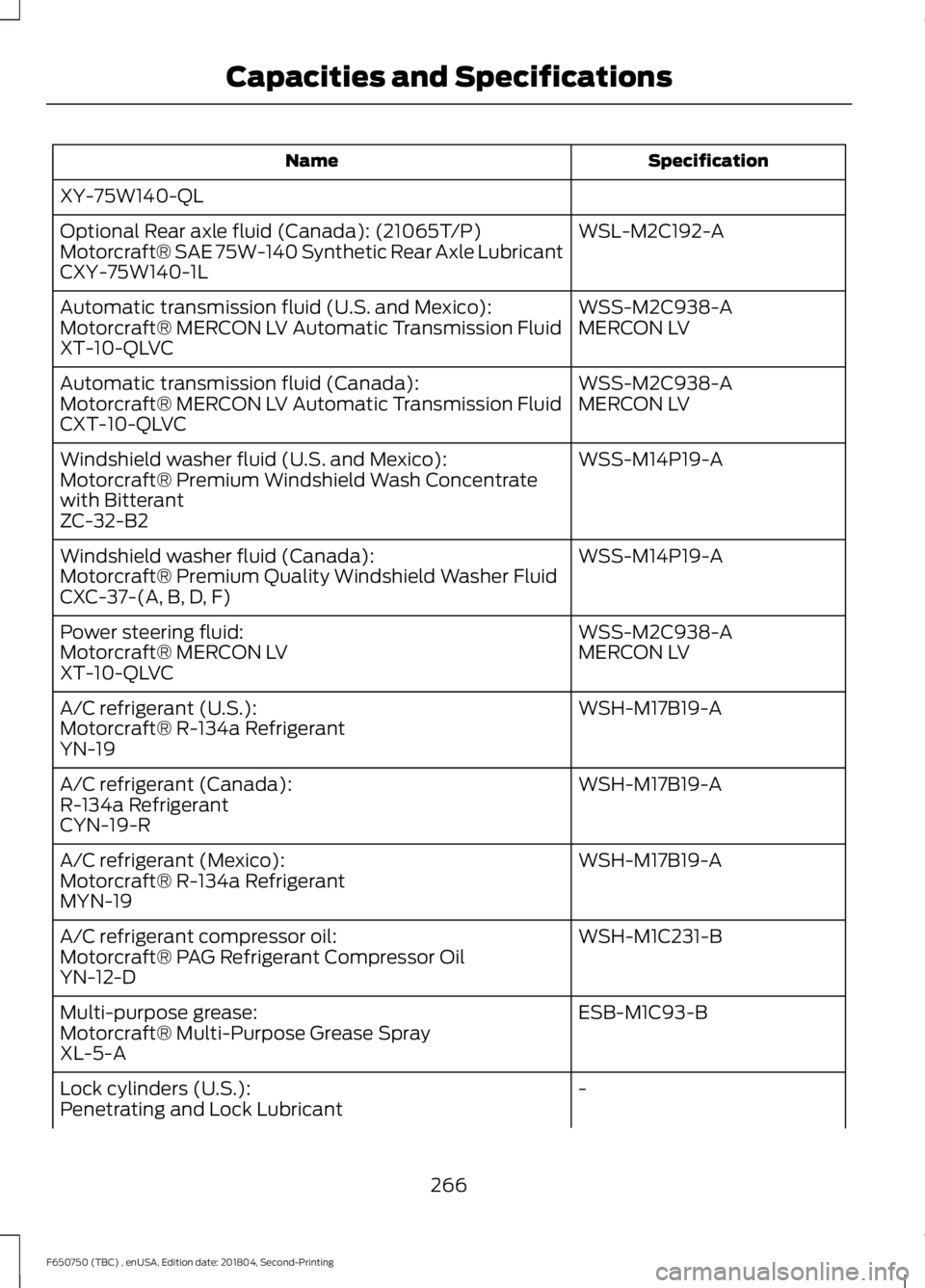

Specification

Name

XY-75W140-QL WSL-M2C192-A

Optional Rear axle fluid (Canada): (21065T/P)

Motorcraft® SAE 75W-140 Synthetic Rear Axle Lubricant

CXY-75W140-1L

WSS-M2C938-A

Automatic transmission fluid (U.S. and Mexico):

MERCON LV

Motorcraft® MERCON LV Automatic Transmission Fluid

XT-10-QLVC

WSS-M2C938-A

Automatic transmission fluid (Canada):

MERCON LV

Motorcraft® MERCON LV Automatic Transmission Fluid

CXT-10-QLVC

WSS-M14P19-A

Windshield washer fluid (U.S. and Mexico):

Motorcraft® Premium Windshield Wash Concentrate

with Bitterant

ZC-32-B2

WSS-M14P19-A

Windshield washer fluid (Canada):

Motorcraft® Premium Quality Windshield Washer Fluid

CXC-37-(A, B, D, F)

WSS-M2C938-A

Power steering fluid:

MERCON LV

Motorcraft® MERCON LV

XT-10-QLVC

WSH-M17B19-A

A/C refrigerant (U.S.):

Motorcraft® R-134a Refrigerant

YN-19

WSH-M17B19-A

A/C refrigerant (Canada):

R-134a Refrigerant

CYN-19-R

WSH-M17B19-A

A/C refrigerant (Mexico):

Motorcraft® R-134a Refrigerant

MYN-19

WSH-M1C231-B

A/C refrigerant compressor oil:

Motorcraft® PAG Refrigerant Compressor Oil

YN-12-D

ESB-M1C93-B

Multi-purpose grease:

Motorcraft® Multi-Purpose Grease Spray

XL-5-A

-

Lock cylinders (U.S.):

Penetrating and Lock Lubricant

266

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Capacities and Specifications