FORD F650/750 2023 Owners Manual

Manufacturer: FORD, Model Year: 2023, Model line: F650/750, Model: FORD F650/750 2023Pages: 378, PDF Size: 5.65 MB

Page 261 of 378

Air Dryer

Climactic conditions affect performance

of desiccant or after-cooler type air dryers.

You must establish a maintenance

schedule for each specific operation.

The use of an air dryer on a vehicle does

not eliminate the need to drain the air

reservoirs periodically.

Inspect for moisture in the air system by

opening reservoirs, draincocks or valves

and checking for presence of water. The

presence of small amounts of water due

to condensation is normal and is not an

indication that the dryer is not functioning

properly.

Replace or rebuild the desiccant cartridge

when you determine that the desiccant is

contaminated and does not have adequate

water absorption capacity. The desiccant

change interval may vary. A general

recommendation is to replace the

desiccant every 12 months (yearly). If

experience has shown that extended or

shortened life has resulted for a particular

installation, then the yearly interval can be

increased or decreased accordingly.

Draining the Air Brake Reservoir

WARNING: Failure to drain air

brake reservoirs can result in a reduction

or loss of braking ability due to fluid

accumulation in the reservoir and/or

possible freeze-up during cold weather.

Completely drain all the air brake reservoirs

daily by opening the draincock at the ends

of the tanks. (Where accessible.

Pull-chains are used when the drains are

undercab or otherwise inaccessible.) Close

the draincock after draining. Manually drainany air tanks equipped with automatic

moisture ejector valves, as required, to

maintain a dry air system. Contact an

authorized dealer if you are unsure of the

air reservoir locations or the draining

procedure.

Hydraulic Brakes

Establish a regular schedule for periodic

cleaning, lubrication and adjustment

inspection based on vehicle use. Exact

maintenance intervals are difficult to

predetermine due to vehicle applications

and operating conditions. If you are

uncertain of the proper schedule for your

vehicle, contact an authorized dealer.

Regular inspections should include:

• Checking the brake lining (every service

interval). Establish inspection intervals

that provide for lining replacement

before damage to the disc occurs.

Excessive lining wear may expose the

backing plate to the disc causing

scoring of the disc faces. A qualified

technician should perform this

257

Maintenance

Page 262 of 378

inspection and keep to instructions

provided by the service manual.

Hydraulic brake systems are

power-assisted. There is a great

reduction in braking capabilities

without engine assist.

• Proper fluid level. The level should be

at the bottom edge of the ring on each

reservoir fill port. Do not fill the master

cylinder to the top of the reservoir. If

fluid level requires attention to

maintain a proper master cylinder level,

this is an indication of either severe

operation (pad wear) or fluid leakage.

A more frequent and thorough brake

inspection is required.

• Brake lines, hoses and fittings. Repair

or replace brake line tubes, hoses or

fittings as required. Inspect these

components every 4,000 mi

(6,000 km) for the following.

• Lines for kinks, dents, corrosion or

rupture.

• Hoses for abrasions, kinks, soft

spots or rupture, collapse, cracks,

twists or loose frame supports.

When replacing a hose, be sure

there is adequate clearance to the

hose to avoid an abrasion to the

new hose.

• All connections for leaks.

Driveline Parking Brake

WARNING: Use wheel chocks and

exercise caution when inspecting under

the vehicle. A vehicle roll-away could

result in property damage, personal injury

or death.

A qualified technician should adjust the

parking brake and keep to the instructions

in the service manual.

AXLE INSPECTION

Front Axle

Maintaining the front axle alignment to

specifications is very important. A qualified

technician should check and maintain the

alignment.

Regular inspections should include:

• Toe-in inspection and adjustment (if

necessary), particularly with radial

tires.

• Checking for proper tightness of axle

mounting U-bolt nuts, attaching or

mounting bolts and nuts.

• Checking the axle for damage, binding,

worn parts and adequate lubrication.

• Checking the kingpins for excessive

wear. Also, perform this check during

other scheduled maintenance, for

example as tire rotation or service,

wheel bearing service and alignment.

See the workshop manual for proper

procedures.

Toe-in

It is essential to maintain correct toe-in

and tire pressure for optimum tire wear.

Inspecting steer axle tires in the first

3,000–10,000 mi (5,000–16,000 km)

generally shows if tires are wearing

normally.

Rapid outside shoulder wear on both tires

indicates too much toe-in.

Rapid inside shoulder wear on both tires

indicates too much toe-out.

In P&D-type service, there can be a

left-to-right steer tire tread life differential

up to 40% depending on routes and other

variables.

258

Maintenance

Page 263 of 378

Follow the tire manufacturer's

recommended cold inflation pressure for

the tire size, load range (ply rating) and

steer axle loading typical for their operation

(each steer axle tire equals ½ steer axle

loading).

Special applications may warrant a setting

based on experience with the type of tire

operating loads and conditions. Radial tires

are more sensitive to toe-in setting than

bias ply tires. Fine tuning school bus

alignment to line-haul truck standards

does not drastically improve tire tread life.

STEERING SYSTEM

INSPECTION

WARNING: Failure to maintain the

steering system in proper condition can

cause reduced steering ability resulting

in property damage, personal injury or

death.

Note:Have any steering problems

immediately corrected by a qualified service

technician.

Ask your service technician to examine the

steering mechanism. Only minor

adjustments may be necessary.

Regular inspections should include:

• Checking the tie rod, drag link end

clamp bolts and ball joints for proper

tightness.

• Checking for installation and spread of

cotter pins and tightness of nuts at

both ends of the tie rod and drag link.

• Checking that the pitman arm (steering

arm at steering gear) mounting is tight

and locked. Check system for leaks or

hose chafing. Repair immediately, if

necessary.• Maintaining proper steering gear and

power steering pump lubricant levels.

• Checking steering column joint bolts

and steering linkage, particularly for

body-to-chassis clearance.

Steering Column Joint Bolts

As a good maintenance practice, check

steering column joint bolt tightness every

60,000 mi (96,000 km) or annually,

whichever occurs first. Do not overtighten

the bolts.

Hydraulic System

Whenever draining and refilling the power

steering's hydraulic system for any reason,

bleed air from the system before returning

the vehicle to service. Failure to bleed the

hydraulic system properly can result in

degradation of power system performance.

Consult an authorized dealer who is aware

of the proper procedures for filling and

bleeding the system.

SUSPENSION SYSTEM

INSPECTION

Note:Do not adjust air suspension height

to any setting other than the specified

setting. Altering the height setting changes

the driveline angle and may result in

unwarrantable component damage, such

as transmission component damage.

Verify drive axle air suspension height and

height control valve performance at engine

oil change intervals.

Periodically check:

• Condition of spring leaves for evidence

of fatigue, bending or breakage.

• Condition of suspension mounting

brackets and bushings.

• Torque rod mounting fasteners for

tightness.

259

Maintenance

Page 264 of 378

• For proper suspension alignment.

Maintain proper alignment at all times.

• U-bolts. After the chassis has been

operating under load for 1,000 mi

(1,600 km) or six months (whichever

comes first), the U-bolt nuts must be

re-torqued. Re-torque the U-bolt nuts

every 37,000 mi (60,000 km)

thereafter. Clean and lubricate the

U-bolt and nut threads and seats to

make sure a like new condition when

re-torqueing. See Spring U-Bolt

Check (page 260).

FRAME AND TOW HOOK

INSPECTION

Your vehicle's chassis is manufactured

with frame rails of either HSLA steel or

heat-treated steel. Handle each in a

specific manner to make sure maximum

service life. Consult the service manual or

an authorized dealer before attempting

frame repair or modification.

It is important, particularly on vehicles that

use tow hooks frequently, to inspect the

front and rear tow hooks for damage or a

loose mounting.

REAR AXLE FLUID CHECK

Your rear axle may have an optional

synthetic lubricant that allows the use of

extended service intervals. A tag on the

filler plug identifies the use of the synthetic

lubricant.

Only use a lubricant that meets

manufacturer specifications. Use of a

non-approved rear axle lubricant may

cause internal axle component damage.

See Rear Axle Fluid Capacity and

Specification (page 305).

Checking the Fluid Level

1. Park your vehicle on level ground.2. Set the parking brake and shift into

position neutral (N) or park (P). Turn

the engine off.

3. Clean any dirt from around the axle

filler plug.

4. Remove the filler plug and inspect the

lubricant level. It should be at the

bottom of the filler plug opening.

5. Add lubricant, if necessary, through the

filler plug opening.

6. Clean and install the filler plug securely.

Changing the Fluid

Note:Drain the rear axle while the lubricant

is warm.

1. Park your vehicle on level ground.

2. Set the parking brake and shift into

position neutral (N) or park (P). Turn

the engine off.

3. Clean any dirt from around the axle

filler and drain plugs.

4. Remove the filler and drain plugs. Drain

the lubricant into a suitable container.

Dispose of all used automotive fluids

in a responsible manner following your

local authorized standards.

5. Clean and install the drain plug

securely.

6. Add lubricant through the filler plug

opening.

7. Clean and install the filler plug securely.

SPRING U-BOLT CHECK

Check and tighten the U-bolt nuts after

your vehicle has been operated under load

for 1,000 mi (1,600 km) or six months,

whichever occurs first.

Check and tighten the U-bolt nuts every

37,000 mi (60,000 km).

Check and tighten the U-bolt nuts with

your vehicle at curb height and unloaded.

260

Maintenance

Page 265 of 378

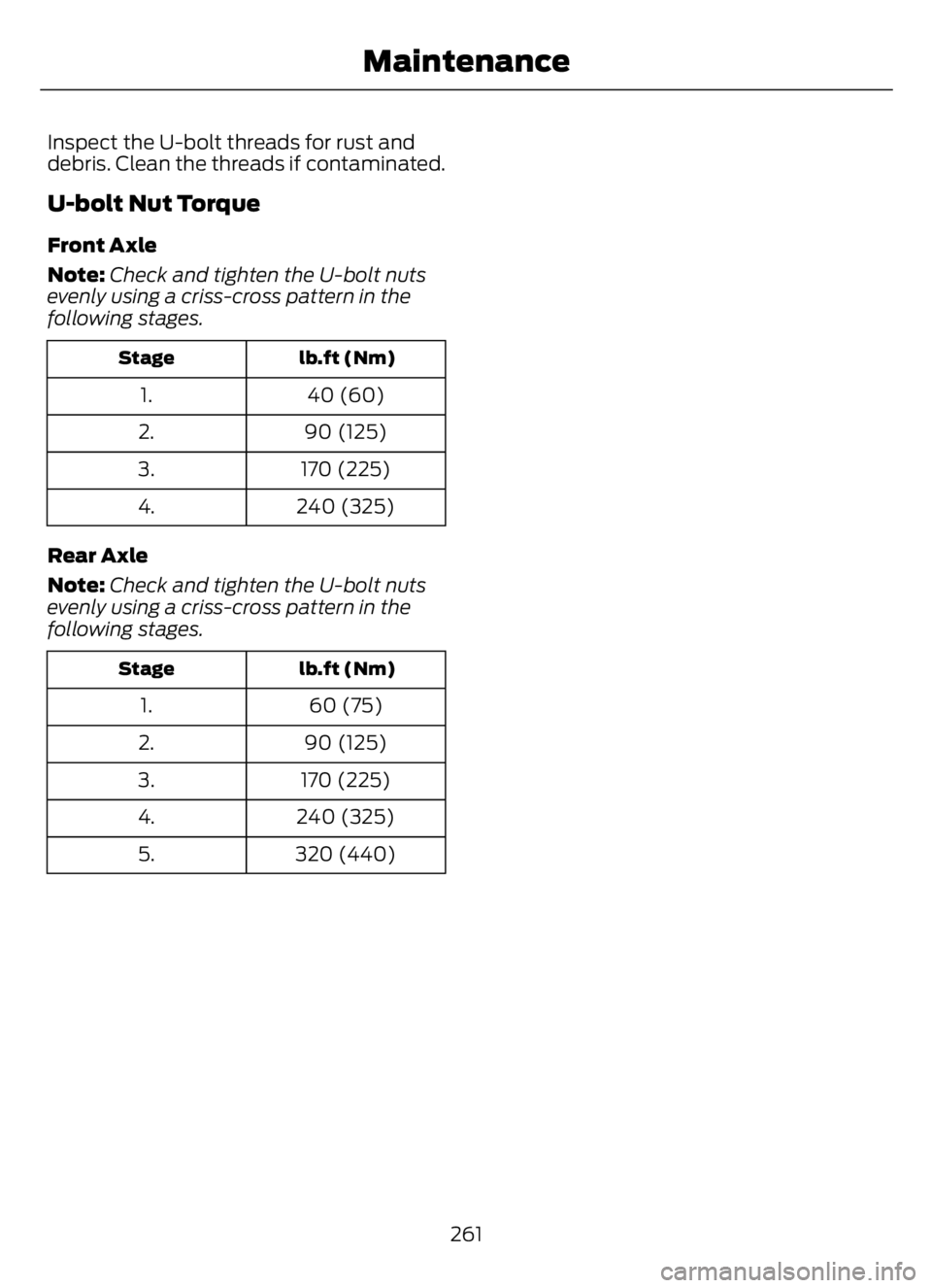

Inspect the U-bolt threads for rust and

debris. Clean the threads if contaminated.

U-bolt Nut Torque

Front Axle

Note:Check and tighten the U-bolt nuts

evenly using a criss-cross pattern in the

following stages.

lb.ft (Nm) Stage

40 (60) 1.

90 (125) 2.

170 (225) 3.

240 (325) 4.

Rear Axle

Note:Check and tighten the U-bolt nuts

evenly using a criss-cross pattern in the

following stages.

lb.ft (Nm) Stage

60 (75) 1.

90 (125) 2.

170 (225) 3.

240 (325) 4.

320 (440) 5.

261

Maintenance

Page 266 of 378

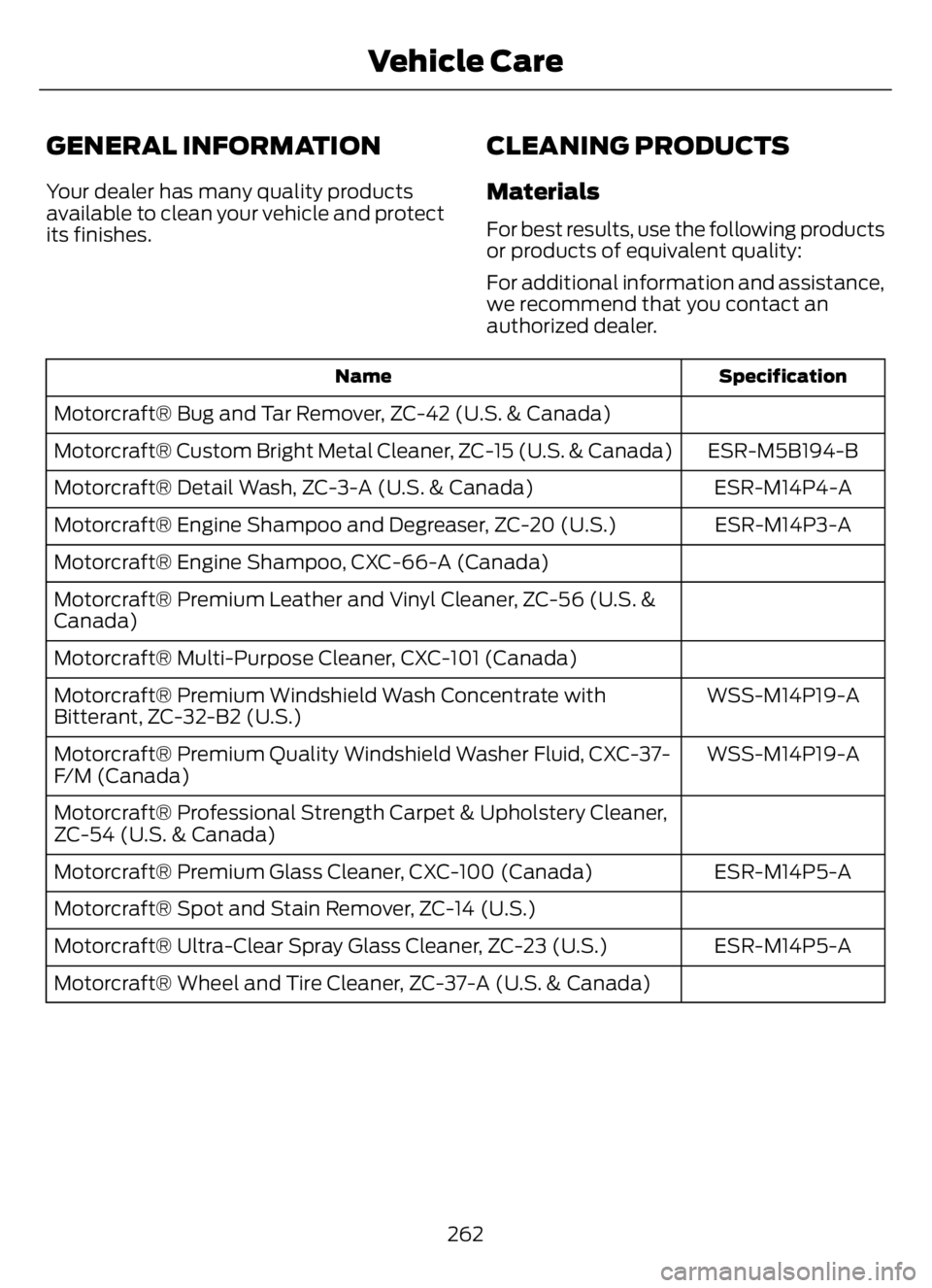

GENERAL INFORMATION

Your dealer has many quality products

available to clean your vehicle and protect

its finishes.

CLEANING PRODUCTS

Materials

For best results, use the following products

or products of equivalent quality:

For additional information and assistance,

we recommend that you contact an

authorized dealer.

Specification Name

Motorcraft® Bug and Tar Remover, ZC-42 (U.S. & Canada)

ESR-M5B194-B Motorcraft® Custom Bright Metal Cleaner, ZC-15 (U.S. & Canada)

ESR-M14P4-A Motorcraft® Detail Wash, ZC-3-A (U.S. & Canada)

ESR-M14P3-A Motorcraft® Engine Shampoo and Degreaser, ZC-20 (U.S.)

Motorcraft® Engine Shampoo, CXC-66-A (Canada)

Motorcraft® Premium Leather and Vinyl Cleaner, ZC-56 (U.S. &

Canada)

Motorcraft® Multi-Purpose Cleaner, CXC-101 (Canada)

WSS-M14P19-A Motorcraft® Premium Windshield Wash Concentrate with

Bitterant, ZC-32-B2 (U.S.)

WSS-M14P19-A Motorcraft® Premium Quality Windshield Washer Fluid, CXC-37-

F/M (Canada)

Motorcraft® Professional Strength Carpet & Upholstery Cleaner,

ZC-54 (U.S. & Canada)

ESR-M14P5-A Motorcraft® Premium Glass Cleaner, CXC-100 (Canada)

Motorcraft® Spot and Stain Remover, ZC-14 (U.S.)

ESR-M14P5-A Motorcraft® Ultra-Clear Spray Glass Cleaner, ZC-23 (U.S.)

Motorcraft® Wheel and Tire Cleaner, ZC-37-A (U.S. & Canada)

262

Vehicle Care

Page 267 of 378

CLEANING THE EXTERIOR

Wash your vehicle regularly with cool or

lukewarm water and a neutral pH

shampoo, we recommend Motorcraft

Detail Wash.

• Never use strong household detergents

or soap, for example dish washing or

laundry liquid. These products can

discolor and spot painted surfaces.

• Never wash your vehicle when it is hot

to the touch, or during strong or direct

sunlight.

• Dry your vehicle with a chamois or soft

terry cloth towel to eliminate water

spotting.

• Immediately remove fuel spillages, bird

droppings, insect deposits and road tar.

These may cause damage to your

vehicle’s paintwork or trim over time.

We recommend Motorcraft Bug and

Tar Remover.

• Remove any exterior accessories, for

example antennas, before entering a

car wash.

• When filling with AdBlue®, remove any

residue on painted surfaces

immediately.

Note:Suntan lotions and insect repellents

can damage painted surfaces. If these

substances come in contact with your

vehicle, wash the affected area as soon as

possible.

Cleaning the Exterior Precautions

Immediately remove fuel spillages, AdBlue

residuals, bird droppings, insect deposits

and road tar. These may cause damage to

your vehicle’s paintwork or trim over time.

Remove any exterior accessories, for

example antennas, before entering a car

wash.

Cleaning the Exterior Lamps

Note:Do not scrape the exterior lamps

lenses or use abrasives, alcoholic solvents

or chemical solvents to clean them.

Note:Do not wipe the exterior lamps when

they are dry.

Exterior Chrome Parts

• Apply a high quality-cleaning product

to bumpers and other chrome parts.

Follow the manufacturer’s instructions.

We recommend Motorcraft Custom

Bright Metal Cleaner.

• Do not apply the cleaning product to

hot surfaces. Do not leave the cleaning

product on chrome surfaces longer

than the time recommended.

• Using non-recommended cleaners can

result in severe and permanent

cosmetic damage.

Note:Never use abrasive materials, for

example steel wool or plastic pads as they

can scratch the chrome surface.

Note:Do not use chrome cleaner, metal

cleaner or polish on wheels or wheel covers.

Exterior Plastic Parts

For routine cleaning we recommend

Motorcraft Detail Wash. If tar or grease

spots are present, we recommend

Motorcraft Bug and Tar Remover.

Stripes or Graphics (If Equipped)

Hand washing your vehicle is preferred

however, pressure washing may be used

under the following conditions:

• Do not use water pressure higher than

2,000 psi (14,000 kPa).

• Do not use water hotter than 179°F

(82°C).

263

Vehicle Care

Page 268 of 378

• Use a spray with a 40 degree wide

spray angle pattern.

• Keep the nozzle at a 12 in (305 mm)

distance and 90 degree angle to your

vehicle's surface.

Note:Holding the pressure washer nozzle

at an angle to the vehicle's surface may

damage graphics and cause the edges to

peel away from the vehicle's surface.

Underbody

Regularly clean the underside of your

vehicle using water. Keep body and door

drain holes free of debris or foreign

material.

Under Hood

For removing black rubber marks from

under the hood we recommend Motorcraft

Wheel and Tire Cleaner or Motorcraft Bug

and Tar Remover.

WAXING

Regular waxing is necessary to protect your

car's paint from the elements. We

recommend that you wash and wax the

painted surface once or twice a year.

When washing and waxing, park your

vehicle in a shaded area out of direct

sunlight. Always wash your vehicle before

applying wax.

• Use a quality wax that does not contain

abrasives.

• Follow the manufacturer’s instructions

to apply and remove the wax.

• Apply a small amount of wax in a

back-and-forth motion, not in circles.• Do not allow wax to come in contact

with any non-body (low-gloss black)

colored trim. The wax will discolor or

stain the parts over time.

• Roof racks.

• Bumpers.

• Grained door handles.

• Side moldings.

• Mirror housings.

• Windshield cowl area.

• Do not apply wax to glass areas.

• After waxing, your car's paint should

feel smooth, and be free of streaks and

smudges.

CLEANING THE ENGINE

Engines are more efficient when they are

clean because grease and dirt buildup keep

the engine warmer than normal.

When washing:

• Take care when using a power washer

to clean the engine. The high-pressure

fluid could penetrate the sealed parts

and cause damage.

• Do not spray a hot engine with cold

water to avoid cracking the engine

block or other engine components.

• Spray Motorcraft Engine Shampoo and

Degreaser on all parts that require

cleaning and pressure rinse clean. In

Canada, use Motorcraft Engine

Shampoo.

Note:If your vehicle has an engine cover

remove the cover before application of

Motorcraft Engine Shampoo and Degreaser.

Immediately rinse away any over spray.

264

Vehicle Care

Page 269 of 378

• Never wash or rinse the engine while it

is hot or running; water in the running

engine may cause internal damage.

• Never wash or rinse any ignition coil,

spark plug wire or spark plug well, or

the area in and around these locations.

• Cover the battery, power distribution

box, and air filter assembly to prevent

water damage when cleaning the

engine.

CLEANING THE WINDOWS AND

WIPER BLADES

Car wash chemicals and environmental

fallout can result in windshield and wiper

blade contamination. Dirty windshield and

wipers will result in poor windshield wiper

operation. Keep the windshield and wiper

blades clean to maintain windshield wiper

performance.

To clean the windshield and wiper blades:

• Clean the windshield with a

non-abrasive glass cleaner. When

cleaning the interior of the windshield,

avoid getting any glass cleaner on the

instrument panel or door panels. Wipe

any glass cleaner off these surfaces

immediately.

• For windshields contaminated with

tree sap, chemicals, wax or bugs, clean

the entire windshield using steel wool

(no greater than 0000 grade) in a

circular motion and rinse with water.

• Clean the wiper blades with isopropyl

rubbing alcohol or windshield washer

concentrate.

Note: Do not use razor blades or other

sharp objects to clean or remove decals

from the inside of the heated rear window.

The vehicle warranty does not cover

damage caused to the heated rear window

grid lines.

CLEANING THE INTERIOR

WARNING: Do not use cleaning

solvents, bleach or dye on the vehicle's

seatbelts, as these actions may weaken

the belt webbing.

WARNING: On vehicles equipped

with seat-mounted airbags, do not use

chemical solvents or strong detergents.

Such products could contaminate the

side airbag system and affect

performance of the side airbag in a crash.

For fabric, carpets, cloth seats and seats

equipped with side airbags:

• Remove dust and loose dirt with a

vacuum cleaner.

• Remove light stains and soil with

Motorcraft Professional Strength

Carpet & Upholstery Cleaner.

• If grease or tar is present on the

material, spot-clean the area first with

Motorcraft Spot and Stain Remover. In

Canada, use Motorcraft Multi-Purpose

Cleaner.

• If a ring forms on the fabric after spot

cleaning, clean the entire area

immediately (but do not oversaturate)

or the ring will set.

• Do not use household cleaning

products or glass cleaners, which can

stain and discolor the fabric and affect

the flame retardant abilities of the seat

materials.

Mirrors

Do not clean the housing or glass of any

mirror with harsh abrasives, fuel or other

petroleum or ammonia-based cleaning

products.

265

Vehicle Care

Page 270 of 378

CLEANING THE INSTRUMENT

PANEL AND INSTRUMENT

CLUSTER LENS

WARNING: Do not use chemical

solvents or strong detergents when

cleaning the steering wheel or

instrument panel to avoid contamination

of the airbag system.

Note:Follow the same procedure as

cleaning leather seats for cleaning leather

instrument panels and leather interior trim

surfaces.

Clean the instrument panel and cluster

lens with a clean, damp and soft cloth,

then use a clean, dry and soft cloth to dry

these areas.

• Avoid cleaners or polishes that increase

the gloss of the upper portion of the

instrument panel. The dull finish in this

area helps protect you from

undesirable windshield reflection.

• Do not use any household cleaning

products or glass cleaners as these

may damage the finish of the

instrument panel, interior trim and

cluster lens.

• Wash or wipe your hands clean if you

have been in contact with certain

products such as insect repellent and

suntan lotion to avoid possible damage

to the interior painted surfaces.

• Do not allow air fresheners and hand

sanitizers to spill onto interior surfaces.

If a spill occurs, wipe off immediately.

Your warranty may not cover these

damages.

If a staining liquid like coffee or juice has

been spilled on the instrument panel or on

interior trim surfaces:

1. Wipe up spilled liquid using a clean,

soft cloth as quickly as possible.2. Use Motorcraft Premium Leather and

Vinyl Cleaner or a commercially

available leather cleaning product for

automotive interiors. Test any cleaner

or stain remover on an inconspicuous

area.

3. Alternatively, wipe the surface with a

clean, soft cloth and a mild soap and

water solution. Dry the area with a

clean, soft cloth.

4. If necessary, apply more soap and

water solution or cleaning product to

a clean, soft cloth and press it onto the

soiled area. Allow this to set at room

temperature for 30 minutes.

5. Remove the soaked cloth, then with a

clean, damp cloth, use a rubbing

motion for 60 seconds on the soiled

area.

6. Dry the area with a clean, soft cloth.

REPAIRING MINOR PAINT

DAMAGE

Authorized dealers have touch-up paint to

match your vehicle’s color. Your vehicle

color code is printed on a sticker on the

front, left-hand side door jamb. Take your

color code to your authorized dealer to

make sure you get the correct color.

Before repairing minor paint damage, use

a cleaner to remove particles such as bird

droppings, tree sap, insect deposits, tar

spots, road salt and industrial fallout.

Read the instructions before using cleaning

products.

CLEANING THE WHEELS

1. Regularly clean them with a wheel

cleaner. We recommend that you use

Ford approved wheel cleaner if

available.

266

Vehicle Care