FORD F650/750 2023 Owners Manual

Manufacturer: FORD, Model Year: 2023, Model line: F650/750, Model: FORD F650/750 2023Pages: 378, PDF Size: 5.65 MB

Page 231 of 378

• Sustained, high-speed driving at the

gross vehicle weight rating.

• Use of fuels with sulfur content other

than ultra-low sulfur diesel (ULSD).

• Use of high-sulfur diesel fuel.

Only use engine oil that meets our

specifications. See Capacities and

Specifications (page 288).

OIL CHANGE INDICATOR

RESET

Base Cluster

Use the information display controls on

the steering wheel to reset the oil change

indicator.

From the main menu scroll to:

Action and Description Message

Press the right arrow button,

then from this menu scroll

to the following message. Settings

Press the down arrow

button, then from this menu

scroll to the following

message. Vehicle

Press the right arrow button,

then from this menu scroll

to the following message. Oil Life

Reset

Press and hold the OK

button until the instrument

cluster displays the

following message. Oil Life

Hold to

Reset

Press and hold the OK

button until the instrument

cluster displays the

following message. Oil Life

Hold OK

to Reset

Action and Description Message

Reset Complete

If the instrument cluster

displays the following

message, repeat the

process.

Reset Cancelled

High Series Cluster

Use the information display controls on

the steering wheel to reset the oil change

indicator.

From the main menu scroll to:

Action and Description Message

Press the down arrow

button, then from this menu

scroll to the following

message. Truck Info

Press the OK button. Mainten-

ance

Monitor

Press the down arrow

button, then from this menu

scroll to the following

message. Oil Life:

xxx%

Press the OK button. Oil Life

Press and hold the OK

button until the instrument

cluster displays the

following message. Oil Life

Hold OK to

Reset

Oil Life: 100%

When the oil change indic-

ator resets, the instrument

cluster displays 100%.

Repeat the process if the oil

change indicator does not

reset.

227

Maintenance

Page 232 of 378

CHANGING THE ENGINE AIR

FILTER - 6.7L DIESEL

Air Filter Restriction Gauge

WARNING: To reduce the risk of

vehicle damage and personal burn

injuries, do not start your engine with the

air cleaner removed and do not remove

it while the engine is running.

Note:Operating your vehicle in heavy

snowfall or extreme rain conditions may

allow excessive amounts of snow or water

into the air intake system. This could plug

or soak the air filter and cause the engine to

lose power or shut down.

E163372

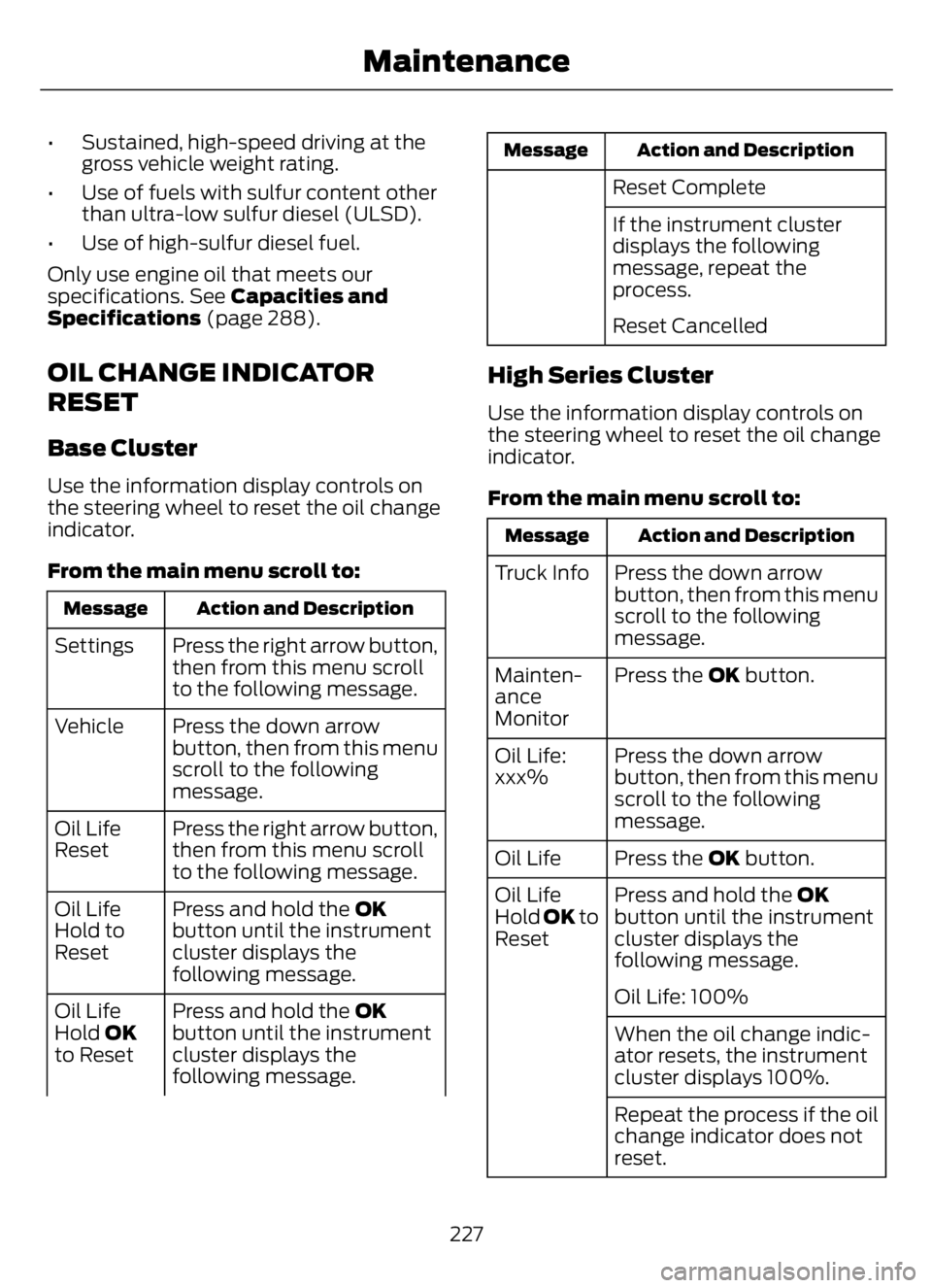

The restriction gauge, on the upper housing

of the air filter assembly, measures the

vacuum inside the air filter. The more the

air filter is dirty or clogged, the higher the

vacuum reading.

Check the air filter restriction gauge

whenever you open the hood to perform

general engine maintenance or at least

every 7,500 mi (12,000 km). If you operate

your vehicle in extremely dusty conditions,

check and reset the gauge at least every

500 mi (800 km), or two weeks, whichevercomes first. Change the air filter when the

restriction gauge reads near the change

filter line and the gauge is yellow. If you

allow the restriction gauge to reach

maximum restriction, you can affect your

engine performance and fuel economy.

Note:Do not blow out the air filter element

with compressed air since the compressed

air could damage the filter paper.

Note:Do not rely on filter appearance

alone. A filter which appears to be dirty may

have several thousand miles (kilometers)

of life remaining.

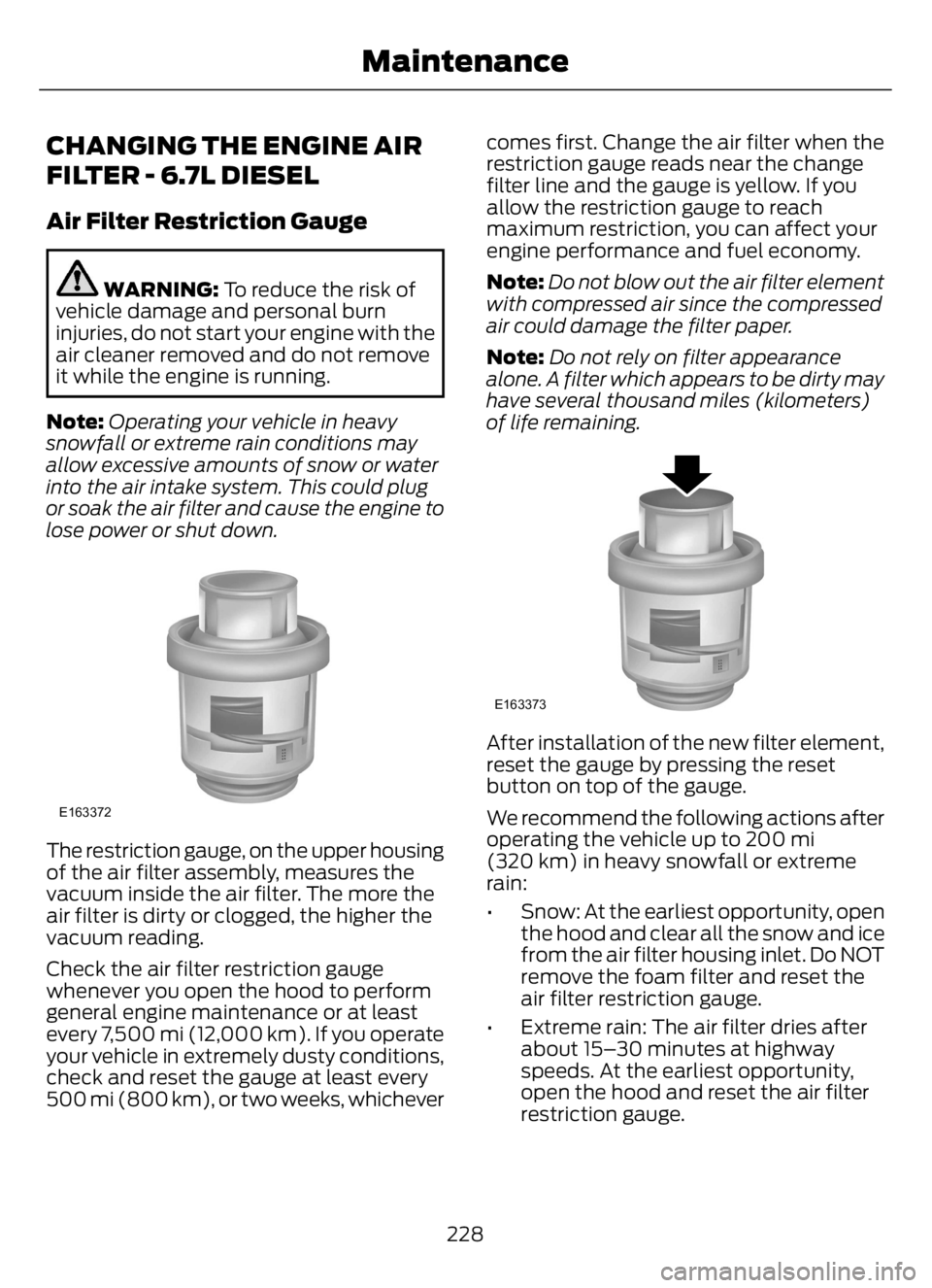

E163373

After installation of the new filter element,

reset the gauge by pressing the reset

button on top of the gauge.

We recommend the following actions after

operating the vehicle up to 200 mi

(320 km) in heavy snowfall or extreme

rain:

• Snow: At the earliest opportunity, open

the hood and clear all the snow and ice

from the air filter housing inlet. Do NOT

remove the foam filter and reset the

air filter restriction gauge.

• Extreme rain: The air filter dries after

about 15–30 minutes at highway

speeds. At the earliest opportunity,

open the hood and reset the air filter

restriction gauge.

228

Maintenance

Page 233 of 378

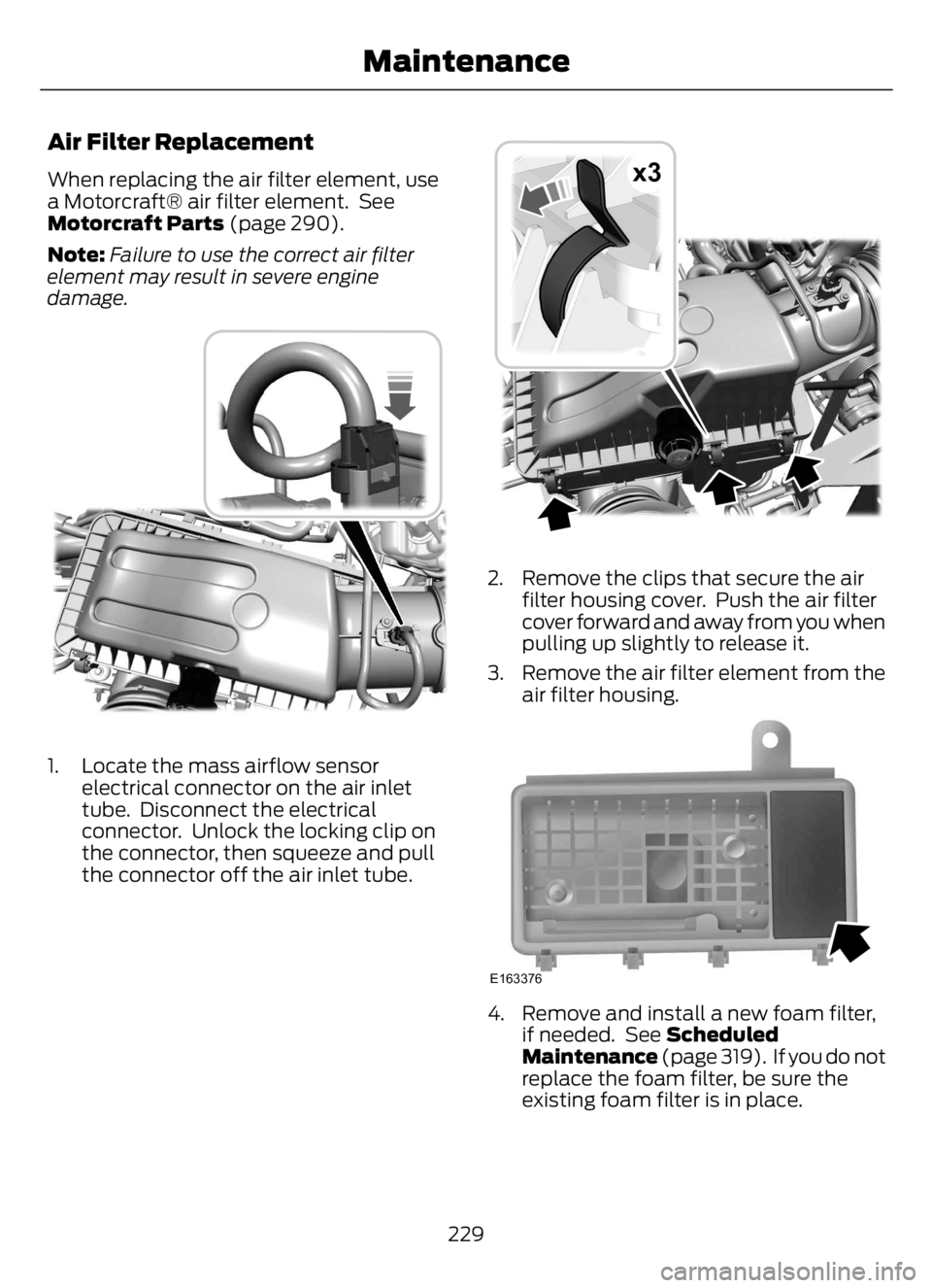

Air Filter Replacement

When replacing the air filter element, use

a Motorcraft® air filter element. See

Motorcraft Parts (page 290).

Note:Failure to use the correct air filter

element may result in severe engine

damage.

E317651E317651

1. Locate the mass airflow sensor

electrical connector on the air inlet

tube. Disconnect the electrical

connector. Unlock the locking clip on

the connector, then squeeze and pull

the connector off the air inlet tube.

E317652

x3

2. Remove the clips that secure the air

filter housing cover. Push the air filter

cover forward and away from you when

pulling up slightly to release it.

3. Remove the air filter element from the

air filter housing.

E163376

4. Remove and install a new foam filter,

if needed. See Scheduled

Maintenance (page 319). If you do not

replace the foam filter, be sure the

existing foam filter is in place.

229

Maintenance

Page 234 of 378

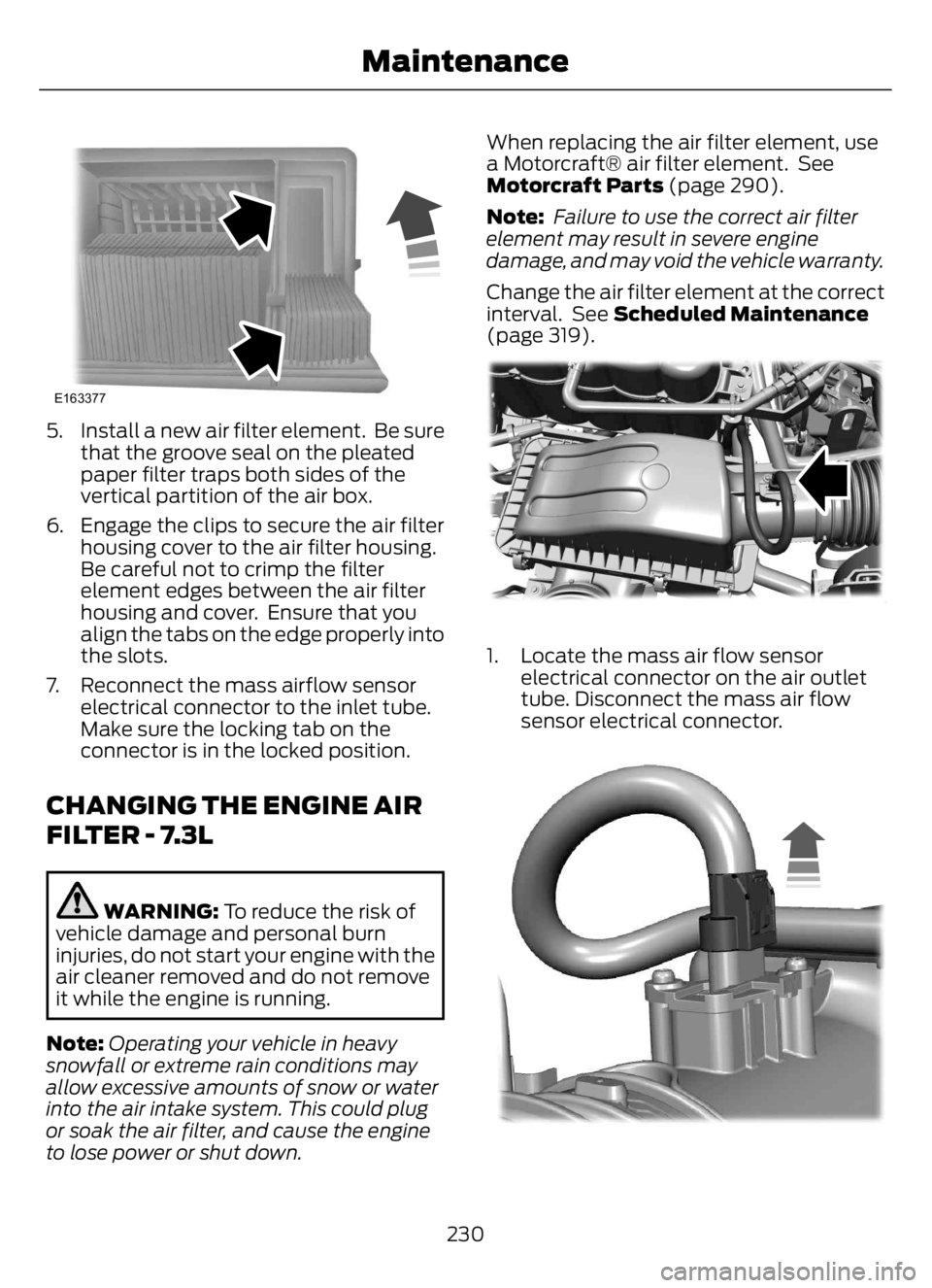

E163377

5. Install a new air filter element. Be sure

that the groove seal on the pleated

paper filter traps both sides of the

vertical partition of the air box.

6. Engage the clips to secure the air filter

housing cover to the air filter housing.

Be careful not to crimp the filter

element edges between the air filter

housing and cover. Ensure that you

align the tabs on the edge properly into

the slots.

7. Reconnect the mass airflow sensor

electrical connector to the inlet tube.

Make sure the locking tab on the

connector is in the locked position.

CHANGING THE ENGINE AIR

FILTER - 7.3L

WARNING: To reduce the risk of

vehicle damage and personal burn

injuries, do not start your engine with the

air cleaner removed and do not remove

it while the engine is running.

Note:Operating your vehicle in heavy

snowfall or extreme rain conditions may

allow excessive amounts of snow or water

into the air intake system. This could plug

or soak the air filter, and cause the engine

to lose power or shut down.When replacing the air filter element, use

a Motorcraft® air filter element. See

Motorcraft Parts (page 290).

Note: Failure to use the correct air filter

element may result in severe engine

damage, and may void the vehicle warranty.

Change the air filter element at the correct

interval. See Scheduled Maintenance

(page 319).

E317615E317615

1. Locate the mass air flow sensor

electrical connector on the air outlet

tube. Disconnect the mass air flow

sensor electrical connector.

E317616E317616

230

Maintenance

Page 235 of 378

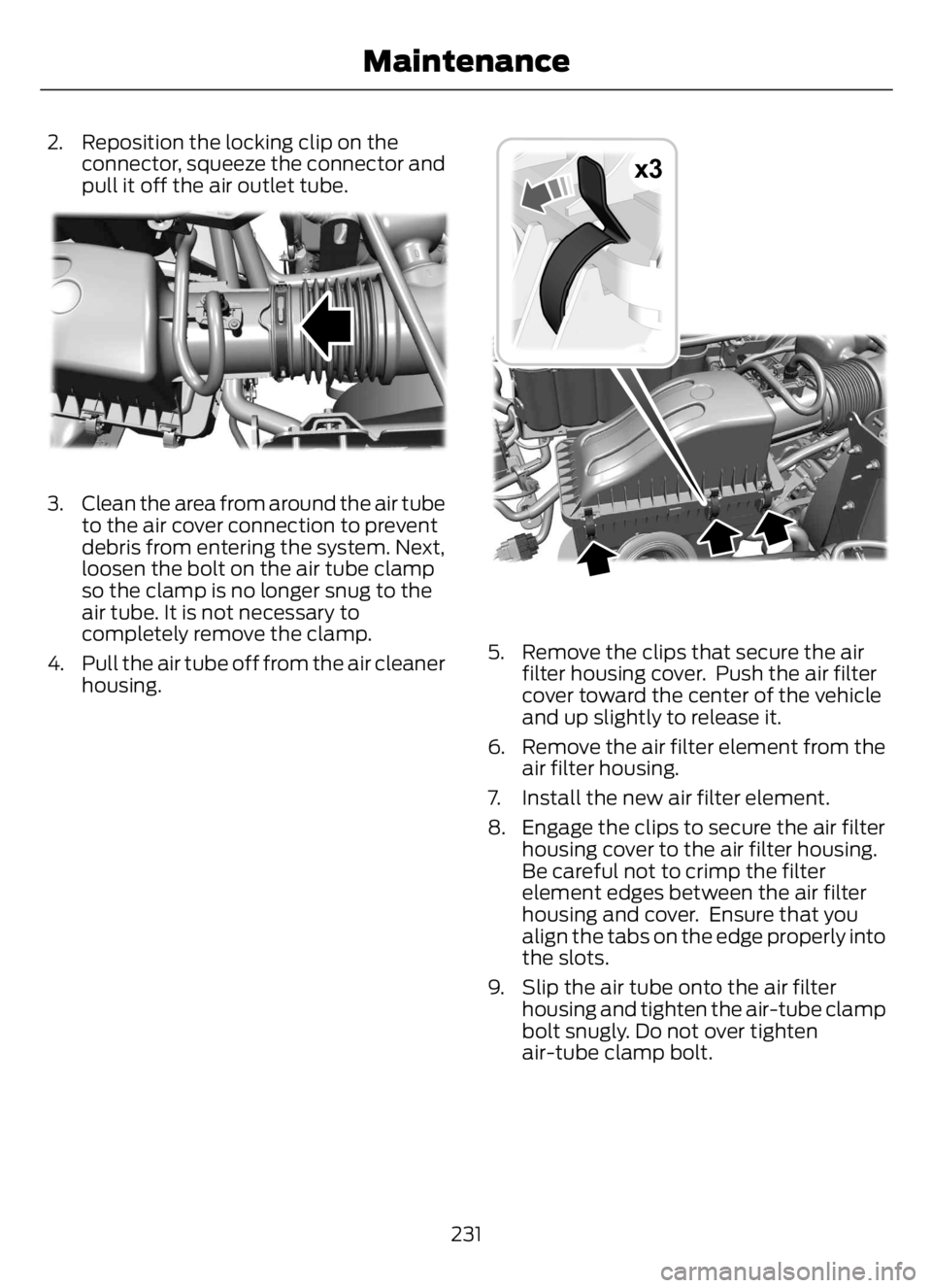

2. Reposition the locking clip on the

connector, squeeze the connector and

pull it off the air outlet tube.

E317617E317617

3. Clean the area from around the air tube

to the air cover connection to prevent

debris from entering the system. Next,

loosen the bolt on the air tube clamp

so the clamp is no longer snug to the

air tube. It is not necessary to

completely remove the clamp.

4. Pull the air tube off from the air cleaner

housing.

E317618

x3

5. Remove the clips that secure the air

filter housing cover. Push the air filter

cover toward the center of the vehicle

and up slightly to release it.

6. Remove the air filter element from the

air filter housing.

7. Install the new air filter element.

8. Engage the clips to secure the air filter

housing cover to the air filter housing.

Be careful not to crimp the filter

element edges between the air filter

housing and cover. Ensure that you

align the tabs on the edge properly into

the slots.

9. Slip the air tube onto the air filter

housing and tighten the air-tube clamp

bolt snugly. Do not over tighten

air-tube clamp bolt.

231

Maintenance

Page 236 of 378

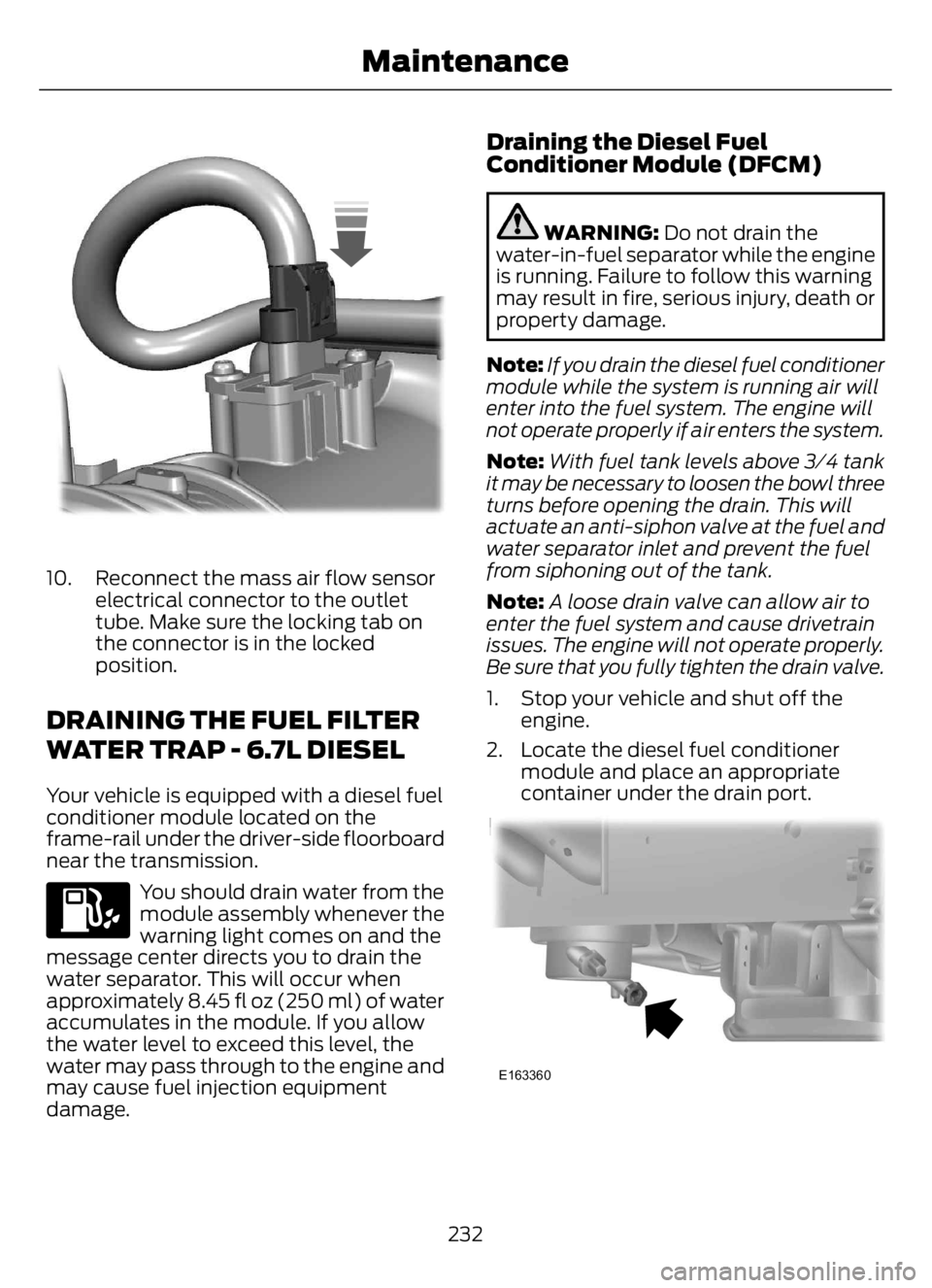

E317619E317619

10. Reconnect the mass air flow sensor

electrical connector to the outlet

tube. Make sure the locking tab on

the connector is in the locked

position.

DRAINING THE FUEL FILTER

WATER TRAP - 6.7L DIESEL

Your vehicle is equipped with a diesel fuel

conditioner module located on the

frame-rail under the driver-side floorboard

near the transmission.

You should drain water from the

module assembly whenever the

warning light comes on and the

message center directs you to drain the

water separator. This will occur when

approximately 8.45 fl oz (250 ml) of water

accumulates in the module. If you allow

the water level to exceed this level, the

water may pass through to the engine and

may cause fuel injection equipment

damage.

Draining the Diesel Fuel

Conditioner Module (DFCM)

WARNING: Do not drain the

water-in-fuel separator while the engine

is running. Failure to follow this warning

may result in fire, serious injury, death or

property damage.

Note:If you drain the diesel fuel conditioner

module while the system is running air will

enter into the fuel system. The engine will

not operate properly if air enters the system.

Note:With fuel tank levels above 3⁄4 tank

it may be necessary to loosen the bowl three

turns before opening the drain. This will

actuate an anti-siphon valve at the fuel and

water separator inlet and prevent the fuel

from siphoning out of the tank.

Note:A loose drain valve can allow air to

enter the fuel system and cause drivetrain

issues. The engine will not operate properly.

Be sure that you fully tighten the drain valve.

1. Stop your vehicle and shut off the

engine.

2. Locate the diesel fuel conditioner

module and place an appropriate

container under the drain port.

E163360

232

Maintenance

Page 237 of 378

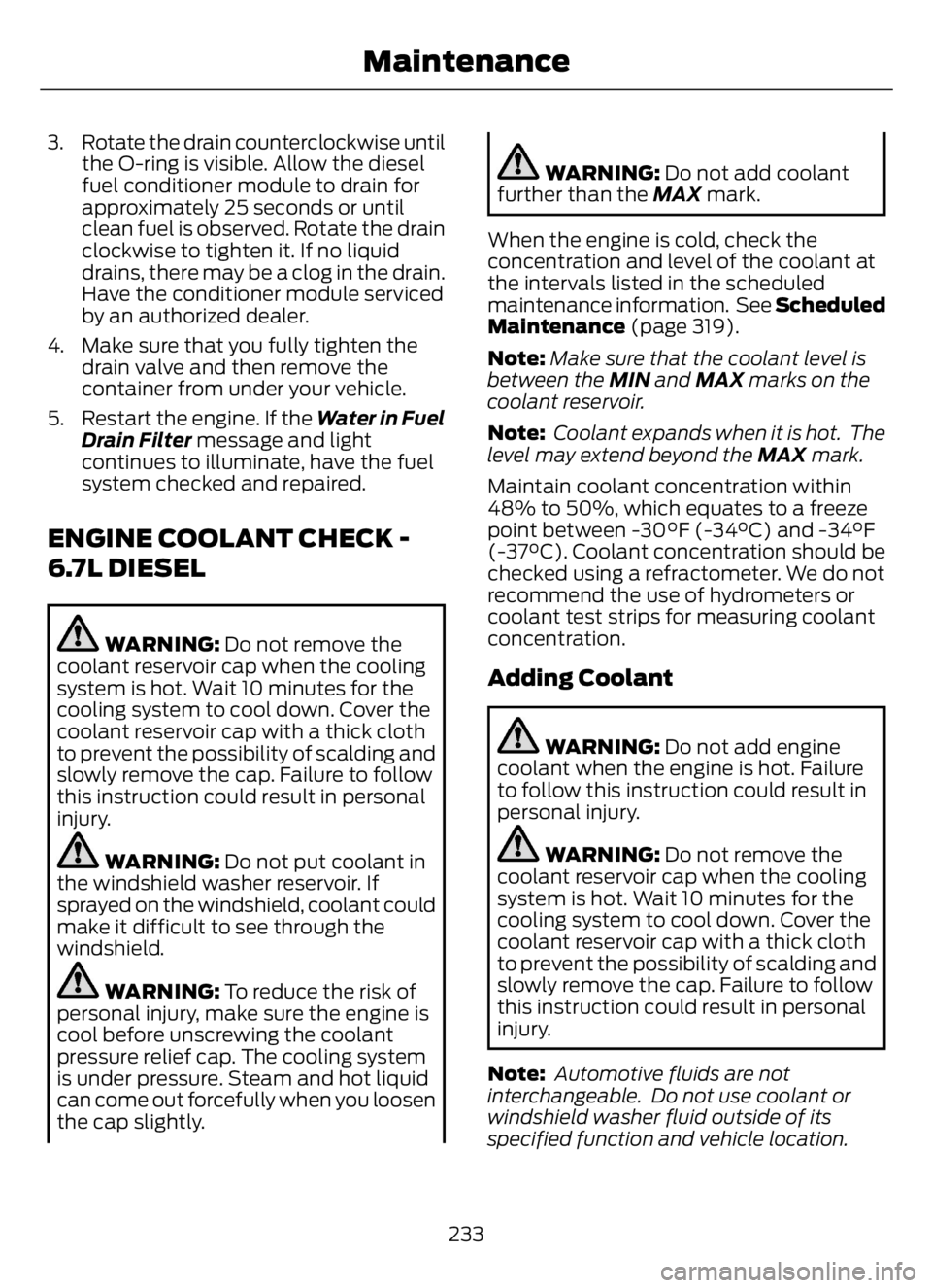

3. Rotate the drain counterclockwise until

the O-ring is visible. Allow the diesel

fuel conditioner module to drain for

approximately 25 seconds or until

clean fuel is observed. Rotate the drain

clockwise to tighten it. If no liquid

drains, there may be a clog in the drain.

Have the conditioner module serviced

by an authorized dealer.

4. Make sure that you fully tighten the

drain valve and then remove the

container from under your vehicle.

5. Restart the engine. If the Water in Fuel

Drain Filter message and light

continues to illuminate, have the fuel

system checked and repaired.

ENGINE COOLANT CHECK -

6.7L DIESEL

WARNING: Do not remove the

coolant reservoir cap when the cooling

system is hot. Wait 10 minutes for the

cooling system to cool down. Cover the

coolant reservoir cap with a thick cloth

to prevent the possibility of scalding and

slowly remove the cap. Failure to follow

this instruction could result in personal

injury.

WARNING: Do not put coolant in

the windshield washer reservoir. If

sprayed on the windshield, coolant could

make it difficult to see through the

windshield.

WARNING: To reduce the risk of

personal injury, make sure the engine is

cool before unscrewing the coolant

pressure relief cap. The cooling system

is under pressure. Steam and hot liquid

can come out forcefully when you loosen

the cap slightly.

WARNING: Do not add coolant

further than the MAX mark.

When the engine is cold, check the

concentration and level of the coolant at

the intervals listed in the scheduled

maintenance information. See Scheduled

Maintenance (page 319).

Note:Make sure that the coolant level is

between the MIN and MAX marks on the

coolant reservoir.

Note: Coolant expands when it is hot. The

level may extend beyond the MAX mark.

Maintain coolant concentration within

48% to 50%, which equates to a freeze

point between -30°F (-34°C) and -34°F

(-37°C). Coolant concentration should be

checked using a refractometer. We do not

recommend the use of hydrometers or

coolant test strips for measuring coolant

concentration.

Adding Coolant

WARNING: Do not add engine

coolant when the engine is hot. Failure

to follow this instruction could result in

personal injury.

WARNING: Do not remove the

coolant reservoir cap when the cooling

system is hot. Wait 10 minutes for the

cooling system to cool down. Cover the

coolant reservoir cap with a thick cloth

to prevent the possibility of scalding and

slowly remove the cap. Failure to follow

this instruction could result in personal

injury.

Note: Automotive fluids are not

interchangeable. Do not use coolant or

windshield washer fluid outside of its

specified function and vehicle location.

233

Maintenance

Page 238 of 378

Note: Do not use stop leak pellets, cooling

system sealants, or non-specified additives

as they can cause damage to the engine

cooling or heating systems. Resulting

component damage may not be covered by

the vehicle Warranty.

It is very important to use prediluted

coolant approved to the correct

specification in order to avoid plugging the

small passageways in the engine cooling

system. See Cooling System Capacity

and Specification (page 297). Do not mix

different colors or types of coolant in your

vehicle. Mixing of engine coolants or using

an incorrect coolant may harm the engine

or cooling system components and may

not be covered by the vehicle Warranty.

Note: Coolants marketed for all makes and

models may not be approved to Ford

specifications and may cause damage to

the cooling system. Resulting component

damage may not be covered by the vehicle

Warranty.

If the coolant level is at or below the

minimum mark, add prediluted coolant

immediately.

For vehicles with overflow coolant systems

with a non-pressurized cap on the coolant

recovery system, add coolant to the

coolant recovery reservoir when the engine

is cool. Add prediluted coolant to the

maximum level. For all vehicles which have

a coolant degas system with a pressurized

cap, or if it is necessary to remove the

coolant pressure relief cap on the radiator,

follow these steps to add engine coolant:

1. Turn the engine off and let it cool.

2. Unscrew the cap slowly. Any pressure

escapes as you unscrew the cap.

3. Fill the coolant reservoir slowly with

prediluted engine coolant to within the

minimum and maximum range on the

engine coolant reservoir. If you

removed the radiator cap in an

overflow system, fill the radiator untilthe coolant is visible and the radiator

is almost full. If coolant is added to

bring the level within the minimum and

maximum range when the engine is not

cold, the system may remain under

filled.

4. Replace the coolant reservoir cap, turn

it clockwise until you feel a strong

resistance.

5. Check the coolant level in the coolant

reservoir the next few times you drive

your vehicle. If necessary, add enough

prediluted engine coolant to bring the

coolant level to the proper level.

Note:If prediluted coolant is not available,

use the approved antifreeze concentrate

diluting it to 50/50 with distilled water. See

Cooling System Capacity and

Specification (page 297). Using water that

has not been deionized may contribute to

deposit formation, corrosion or plugging of

the small cooling system passageways.

If you have to add more than 1.1 qt (1 L) of

engine coolant per month, have your

vehicle checked as soon as possible.

Operating an engine with a low level of

coolant can result in engine overheating

and possible engine damage.

Note:During normal vehicle operation, the

coolant may change color from orange to

pink or light red. As long as the coolant is

clear and uncontaminated, this color change

does not indicate the coolant has degraded

nor does it require the coolant to be drained,

the system to be flushed, or the coolant to

be replaced.

In case of emergency, you can add a large

amount of water without prediluted

coolant in order to reach a vehicle service

location. On arrival do the following:

1. Drain the cooling system.

2. Chemically clean the cooling system.

We recommend Motorcraft Premium

Cooling System Flush.

234

Maintenance

Page 239 of 378

3. Refill with prediluted coolant as soon

as possible.

Water alone, without prediluted coolant,

can cause engine damage from corrosion,

overheating or freezing.

Do not use the following as a coolant

substitute:

• Alcohol.

• Methanol.

• Brine.

• Any coolant mixed with alcohol or

methanol antifreeze.

Alcohol and other liquids can cause engine

damage from overheating or freezing.

Do not add extra inhibitors or non-specified

additives to the coolant. These can be

harmful and compromise the corrosion

protection of the coolant.

Engine and Secondary Cooling

System Refill Procedure

The following procedure should be used

when refilling the engine or secondary

cooling systems after it has been drained

or become extremely low:

1. Before you remove the cap, turn the

engine off and let it cool.

2. When the engine is cool, wrap a thick

cloth around the cap. Slowly turn cap

counterclockwise until pressure begins

to release.

3. Step back when the pressure releases.

4. When you are sure that all the pressure

has been released, use the cloth to turn

the cap counterclockwise and then

remove it.

5. Slowly add prediluted engine coolant

to the coolant reservoir until the

coolant level is within the minimum

and maximum range as listed on the

reservoir.

6. Reinstall the pressure relief cap.7. Start and run the engine at 2000 rpm

for 2 minutes.

8. Shut engine off, and remove the

pressure relief cap as previously

outlined.

9. If required, add prediluted engine

coolant to the coolant reservoir until

the coolant level is within the minimum

and maximum range as listed on the

reservoir.

10. Engine cooling system: Repeat steps

5 through 9 until the coolant level has

stabilized (is no longer dropping after

each step) and the upper radiator

hose at the radiator is warm to the

touch (indicating that the engine

thermostat is open and coolant is

flowing through the radiator).

11. Check the secondary cooling system.

Repeat steps 1 through 10 until the

coolant level has stabilized (is no

longer dropping after each step) and

the lower passenger side of the

secondary radiator is warm to the

touch (indicating secondary

thermostat is open and coolant is

flowing through the entire system).

12. Check the coolant level in both

systems before you drive your vehicle

the next few times.

13. If necessary, add prediluted engine

coolant to the coolant reservoirs until

the coolant level is within the

minimum and maximum range as

listed on the reservoir. After any

coolant has been added, check the

coolant concentration.

Recycled Coolant

We do not recommend the use of recycled

coolant as an approved recycling process

is not yet available.

235

Maintenance

Page 240 of 378

Dispose of used engine coolant in an

appropriate manner. Follow your

community’s regulations and standards

for recycling and disposing of automotive

fluids.

Severe Climates

If you drive in extremely cold climates:

• It may be necessary to increase the

coolant concentration above 50%.

• A coolant concentration of 60%

provides improved freeze point

protection. Coolant concentrations

above 60% decrease the overheat

protection characteristics of the

coolant and may cause engine

damage.

If you drive in extremely hot climates:

• You can decrease the coolant

concentration to 40%.

• Coolant concentrations below 40%

decrease the freeze and corrosion

protection characteristics of the

coolant and may cause engine

damage.

Vehicles driven year-round in non-extreme

climates should use prediluted engine

coolant for optimum cooling system and

engine protection.

Checking Coolant Corrosion

Inhibitor Additive Strength

At specific mileage intervals as listed in the

scheduled maintenance information

chapter, the coolant corrosion inhibitor

additive should be checked. An information

message may display in the optional

information display at this time. The

purpose of checking is to verify the correct

engine coolant concentration (freeze point

protection) and corrosion inhibitor additive

level (strength) of the coolant for

maximum engine performance and

protection.Three products are available to confirm

the life and health of the coolant, one tool,

a test kit and a coolant inhibitor additive:

236

Maintenance