check engine FORD F650/750 2023 Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2023, Model line: F650/750, Model: FORD F650/750 2023Pages: 378, PDF Size: 5.65 MB

Page 263 of 378

Follow the tire manufacturer's

recommended cold inflation pressure for

the tire size, load range (ply rating) and

steer axle loading typical for their operation

(each steer axle tire equals ½ steer axle

loading).

Special applications may warrant a setting

based on experience with the type of tire

operating loads and conditions. Radial tires

are more sensitive to toe-in setting than

bias ply tires. Fine tuning school bus

alignment to line-haul truck standards

does not drastically improve tire tread life.

STEERING SYSTEM

INSPECTION

WARNING: Failure to maintain the

steering system in proper condition can

cause reduced steering ability resulting

in property damage, personal injury or

death.

Note:Have any steering problems

immediately corrected by a qualified service

technician.

Ask your service technician to examine the

steering mechanism. Only minor

adjustments may be necessary.

Regular inspections should include:

• Checking the tie rod, drag link end

clamp bolts and ball joints for proper

tightness.

• Checking for installation and spread of

cotter pins and tightness of nuts at

both ends of the tie rod and drag link.

• Checking that the pitman arm (steering

arm at steering gear) mounting is tight

and locked. Check system for leaks or

hose chafing. Repair immediately, if

necessary.• Maintaining proper steering gear and

power steering pump lubricant levels.

• Checking steering column joint bolts

and steering linkage, particularly for

body-to-chassis clearance.

Steering Column Joint Bolts

As a good maintenance practice, check

steering column joint bolt tightness every

60,000 mi (96,000 km) or annually,

whichever occurs first. Do not overtighten

the bolts.

Hydraulic System

Whenever draining and refilling the power

steering's hydraulic system for any reason,

bleed air from the system before returning

the vehicle to service. Failure to bleed the

hydraulic system properly can result in

degradation of power system performance.

Consult an authorized dealer who is aware

of the proper procedures for filling and

bleeding the system.

SUSPENSION SYSTEM

INSPECTION

Note:Do not adjust air suspension height

to any setting other than the specified

setting. Altering the height setting changes

the driveline angle and may result in

unwarrantable component damage, such

as transmission component damage.

Verify drive axle air suspension height and

height control valve performance at engine

oil change intervals.

Periodically check:

• Condition of spring leaves for evidence

of fatigue, bending or breakage.

• Condition of suspension mounting

brackets and bushings.

• Torque rod mounting fasteners for

tightness.

259

Maintenance

Page 264 of 378

• For proper suspension alignment.

Maintain proper alignment at all times.

• U-bolts. After the chassis has been

operating under load for 1,000 mi

(1,600 km) or six months (whichever

comes first), the U-bolt nuts must be

re-torqued. Re-torque the U-bolt nuts

every 37,000 mi (60,000 km)

thereafter. Clean and lubricate the

U-bolt and nut threads and seats to

make sure a like new condition when

re-torqueing. See Spring U-Bolt

Check (page 260).

FRAME AND TOW HOOK

INSPECTION

Your vehicle's chassis is manufactured

with frame rails of either HSLA steel or

heat-treated steel. Handle each in a

specific manner to make sure maximum

service life. Consult the service manual or

an authorized dealer before attempting

frame repair or modification.

It is important, particularly on vehicles that

use tow hooks frequently, to inspect the

front and rear tow hooks for damage or a

loose mounting.

REAR AXLE FLUID CHECK

Your rear axle may have an optional

synthetic lubricant that allows the use of

extended service intervals. A tag on the

filler plug identifies the use of the synthetic

lubricant.

Only use a lubricant that meets

manufacturer specifications. Use of a

non-approved rear axle lubricant may

cause internal axle component damage.

See Rear Axle Fluid Capacity and

Specification (page 305).

Checking the Fluid Level

1. Park your vehicle on level ground.2. Set the parking brake and shift into

position neutral (N) or park (P). Turn

the engine off.

3. Clean any dirt from around the axle

filler plug.

4. Remove the filler plug and inspect the

lubricant level. It should be at the

bottom of the filler plug opening.

5. Add lubricant, if necessary, through the

filler plug opening.

6. Clean and install the filler plug securely.

Changing the Fluid

Note:Drain the rear axle while the lubricant

is warm.

1. Park your vehicle on level ground.

2. Set the parking brake and shift into

position neutral (N) or park (P). Turn

the engine off.

3. Clean any dirt from around the axle

filler and drain plugs.

4. Remove the filler and drain plugs. Drain

the lubricant into a suitable container.

Dispose of all used automotive fluids

in a responsible manner following your

local authorized standards.

5. Clean and install the drain plug

securely.

6. Add lubricant through the filler plug

opening.

7. Clean and install the filler plug securely.

SPRING U-BOLT CHECK

Check and tighten the U-bolt nuts after

your vehicle has been operated under load

for 1,000 mi (1,600 km) or six months,

whichever occurs first.

Check and tighten the U-bolt nuts every

37,000 mi (60,000 km).

Check and tighten the U-bolt nuts with

your vehicle at curb height and unloaded.

260

Maintenance

Page 272 of 378

• With your foot on the brake, shift

through all the gears while the engine

is running.

• We recommend that you change the

engine oil before you use your vehicle

again.

Fuel system

• Fill the fuel tank with high-quality fuel

until the first automatic shutoff of the

fuel pump nozzle.

Cooling system

• Protect against freezing temperatures.

• When removing your vehicle from

storage, check coolant fluid level.

Confirm that there are no cooling

system leaks and that fluid is at the

recommended level.

Disconnecting Your 12 Volt Battery

• Check and recharge as necessary. Keep

connections clean.

• If storing your vehicle for more than 30

days without recharging the battery,

we recommend that you disconnect

the battery cables to maintain battery

charge for quick starting.

Note:It is necessary to reset memory

features if you disconnect the battery

cables.

Brakes

• Make sure the brakes and parking brake

release fully.

Tires

• Maintain recommended air pressure.

Miscellaneous

• Make sure all linkages, cables, levers

and pins under your vehicle are covered

with grease to prevent rust.

• Move vehicles at least 25 ft (7.5 m)

every 15 days to lubricate working parts

and prevent corrosion.

Removing Vehicle From Storage

When your vehicle is ready to come out of

storage, do the following:

• Wash your vehicle to remove any dirt

or grease film build-up on window

surfaces.

• Check windshield wipers for any

deterioration.

• Check under the hood for any foreign

material that may have collected

during storage such as mice or squirrel

nests.

• Check the exhaust for any foreign

material that may have collected

during storage.

• Check tire pressures and set tire

inflation per the Tire Label.

• Check brake pedal operation. Drive

your vehicle 15 ft (4.5 m) back and

forth to remove rust build-up.

• Check fluid levels (including coolant,

oil and gas) to make sure there are no

leaks, and fluids are at recommended

levels.

• If you remove the battery, clean the

battery cable ends and check for

damage.

Contact an authorized dealer if you have

any concerns or issues.

268

Vehicle Care

Page 311 of 378

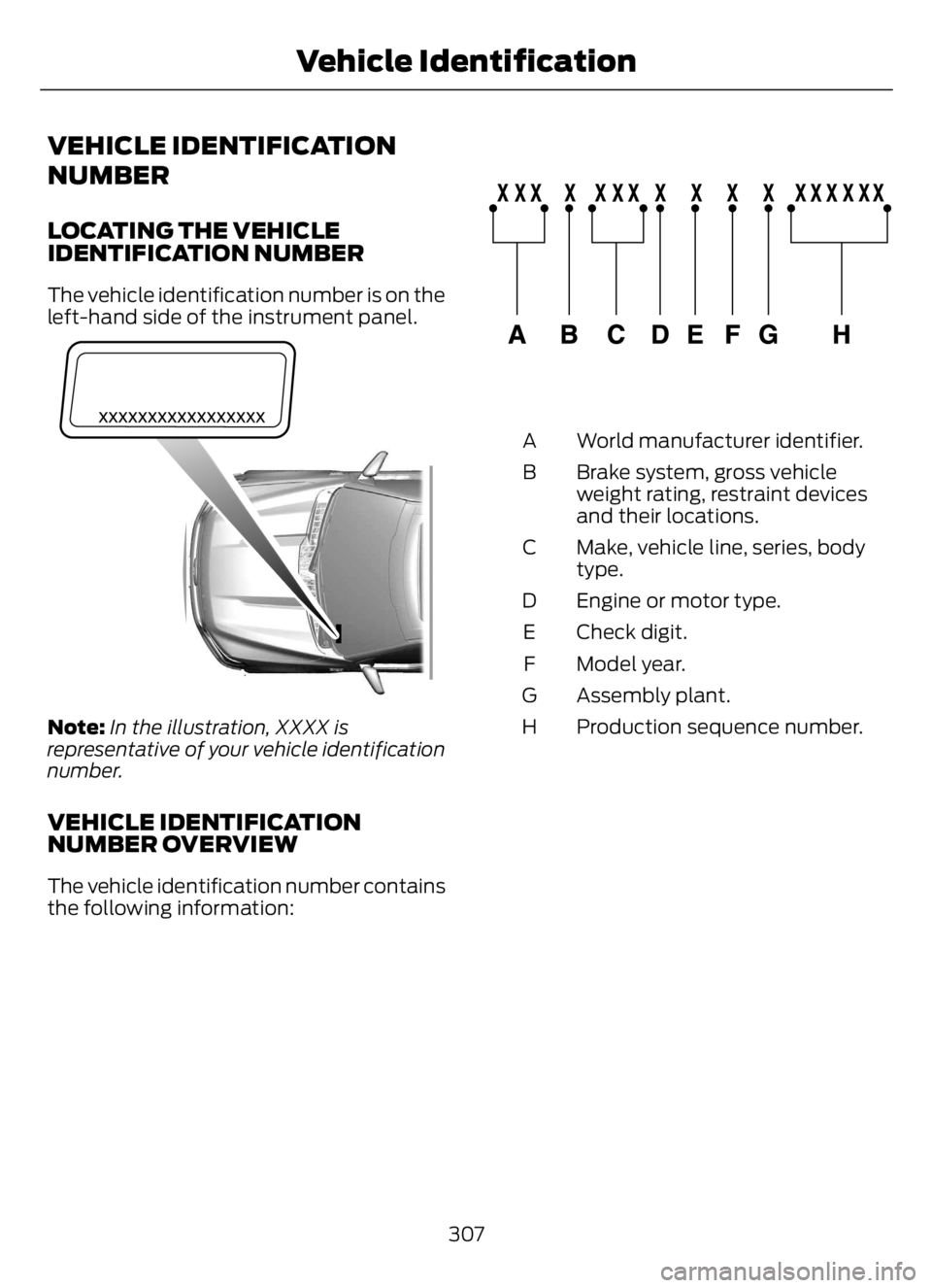

VEHICLE IDENTIFICATION

NUMBER

LOCATING THE VEHICLE

IDENTIFICATION NUMBER

The vehicle identification number is on the

left-hand side of the instrument panel.

E311767

Note:In the illustration, XXXX is

representative of your vehicle identification

number.

VEHICLE IDENTIFICATION

NUMBER OVERVIEW

The vehicle identification number contains

the following information:

E142477

World manufacturer identifier. A

Brake system, gross vehicle

weight rating, restraint devices

and their locations. B

Make, vehicle line, series, body

type. C

Engine or motor type. D

Check digit. E

Model year. F

Assembly plant. G

Production sequence number. H

307

Vehicle Identification

Page 322 of 378

Less Cost to Properly Maintain Your

Vehicle

Ford Protect extended service plan also

offers a Premium Maintenance Plan that

covers all scheduled maintenance, and

selected wear items. The coverage is

prepaid, so you never have to worry about

the cost of your vehicle’s maintenance.

Covered maintenance includes:

• Windshield wiper blades.

• Spark plugs.

• The clutch disc (if equipped).

• Brake pads and linings.

• Shock absorbers.

• Struts.

• Engine belts.

• Engine coolant hoses, clamps and

O-rings.

• Diesel exhaust fluid replenishment (if

equipped).

• Cabin air filter replacement every

20,000 mi (32,000 km) (electric

vehicles only).

Interest Free Finance Options

Just a 5% down payment will provide you

with an affordable, no interest, no fee

payment program allowing you all the

security and benefits Ford Protect

extended service plan has to offer while

paying over time. You are pre-approved

with no credit check or hassles. To learn

more, call our Ford Protect extended

service plan specialists at 800-367-3377.

Ford Protect Extended Service Plan

P.O. Box 321067

Detroit, MI 48232Ford Protect Extended Service

Plan (CANADA ONLY)

You can get more protection for your

vehicle by purchasing a Ford Protect

extended service plan. Ford Protect

extended service plan is the only service

contract backed by Ford Motor Company

of Canada, Limited. Depending on the plan

you purchase, Ford Protect extended

service plan provides benefits such as:

• Rental reimbursement.

• Coverage for certain maintenance and

wear items.

• Protection against repair costs after

your New Vehicle Limited Warranty

Coverage expires.

• Roadside Assistance benefits.

There are several Ford Protect extended

service plans available in various time,

distance and deductible combinations.

Each plan is tailored to fit your own driving

needs, including reimbursement for towing

and rental. When you purchase Ford

Protect extended service plan, you receive

added peace-of-mind protection

throughout Canada, the United States and

Mexico, provided by a network of

participating authorized Ford Motor

Company dealers.

Note:Repairs performed outside of Canada

and the United States are not eligible for

Ford Protect extended service plan

coverage.

This information is subject to change. For

more information; visit your local Ford of

Canada dealer or www.ford.ca to find the

Ford Protect extended service plan that is

right for you.

318

Ford Protect

Page 325 of 378

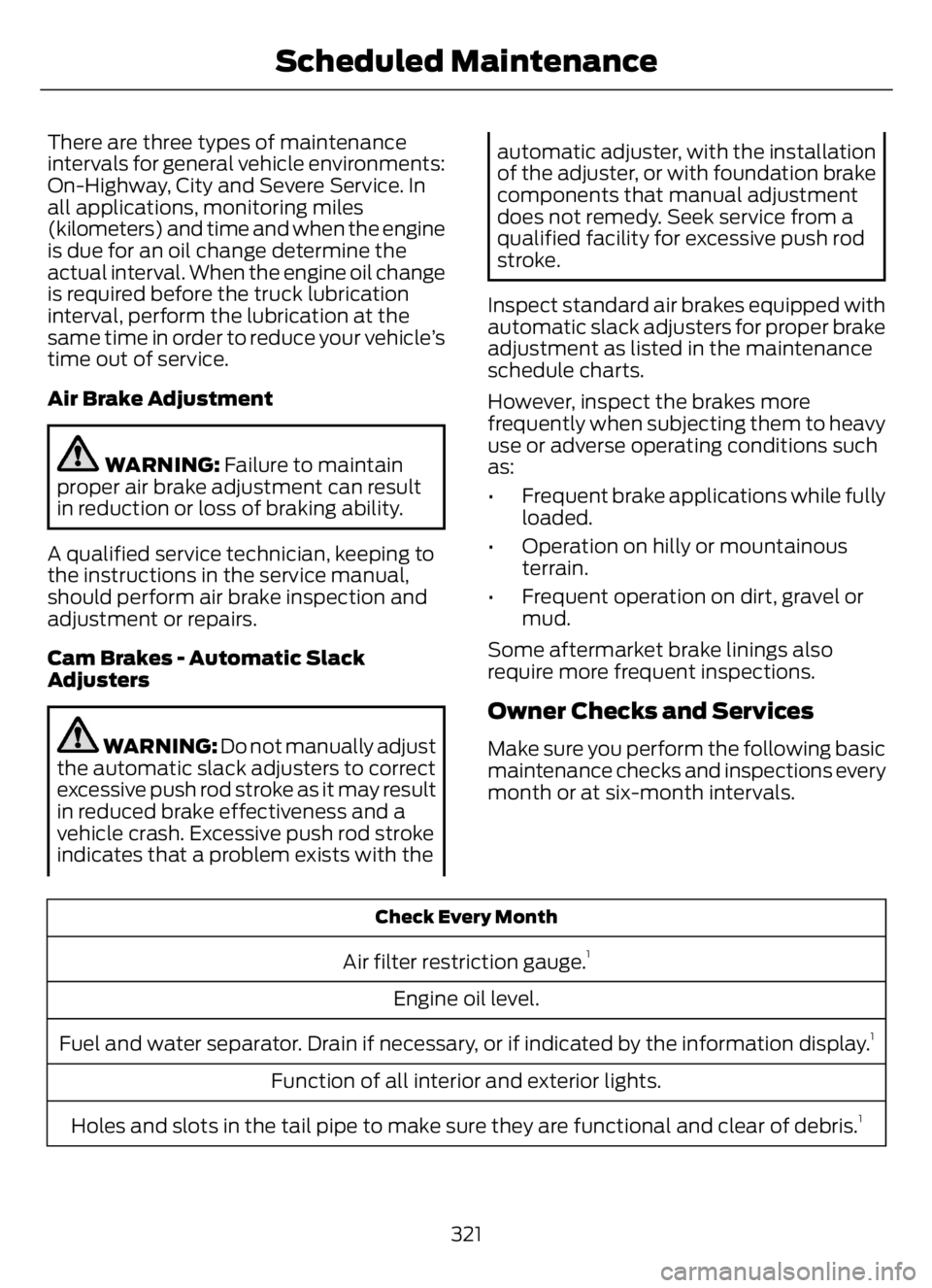

There are three types of maintenance

intervals for general vehicle environments:

On-Highway, City and Severe Service. In

all applications, monitoring miles

(kilometers) and time and when the engine

is due for an oil change determine the

actual interval. When the engine oil change

is required before the truck lubrication

interval, perform the lubrication at the

same time in order to reduce your vehicle’s

time out of service.

Air Brake Adjustment

WARNING: Failure to maintain

proper air brake adjustment can result

in reduction or loss of braking ability.

A qualified service technician, keeping to

the instructions in the service manual,

should perform air brake inspection and

adjustment or repairs.

Cam Brakes - Automatic Slack

Adjusters

WARNING: Do not manually adjust

the automatic slack adjusters to correct

excessive push rod stroke as it may result

in reduced brake effectiveness and a

vehicle crash. Excessive push rod stroke

indicates that a problem exists with the

automatic adjuster, with the installation

of the adjuster, or with foundation brake

components that manual adjustment

does not remedy. Seek service from a

qualified facility for excessive push rod

stroke.

Inspect standard air brakes equipped with

automatic slack adjusters for proper brake

adjustment as listed in the maintenance

schedule charts.

However, inspect the brakes more

frequently when subjecting them to heavy

use or adverse operating conditions such

as:

• Frequent brake applications while fully

loaded.

• Operation on hilly or mountainous

terrain.

• Frequent operation on dirt, gravel or

mud.

Some aftermarket brake linings also

require more frequent inspections.

Owner Checks and Services

Make sure you perform the following basic

maintenance checks and inspections every

month or at six-month intervals.

Check Every Month

Air filter restriction gauge.1

Engine oil level.

Fuel and water separator. Drain if necessary, or if indicated by the information display.

1

Function of all interior and exterior lights.

Holes and slots in the tail pipe to make sure they are functional and clear of debris.

1

321

Scheduled Maintenance

Page 326 of 378

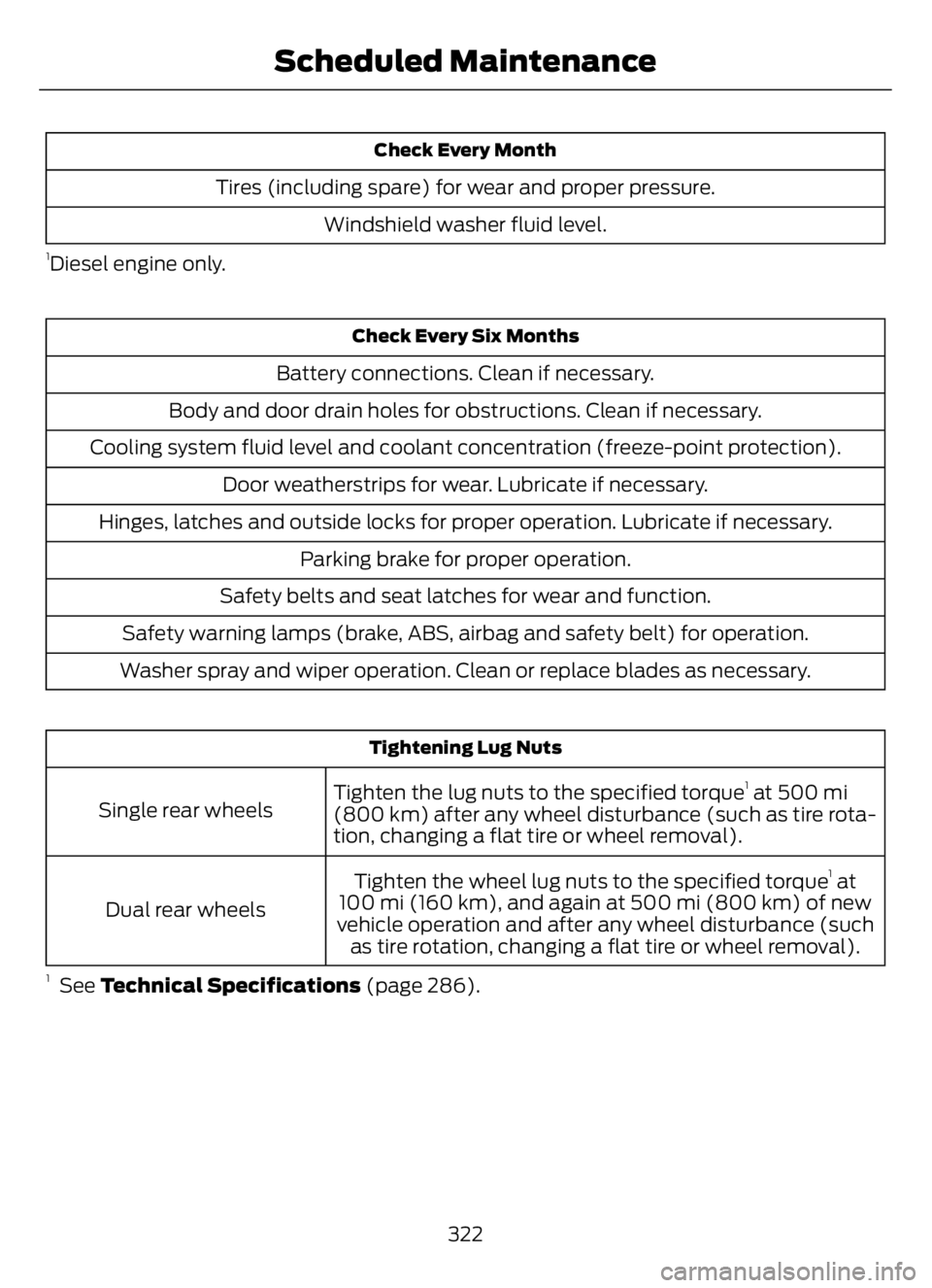

Check Every Month

Tires (including spare) for wear and proper pressure.

Windshield washer fluid level.

1Diesel engine only.

Check Every Six Months

Battery connections. Clean if necessary.

Body and door drain holes for obstructions. Clean if necessary.

Cooling system fluid level and coolant concentration (freeze-point protection).

Door weatherstrips for wear. Lubricate if necessary.

Hinges, latches and outside locks for proper operation. Lubricate if necessary.

Parking brake for proper operation.

Safety belts and seat latches for wear and function.

Safety warning lamps (brake, ABS, airbag and safety belt) for operation.

Washer spray and wiper operation. Clean or replace blades as necessary.

Tightening Lug Nuts

Tighten the lug nuts to the specified torque1 at 500 mi

(800 km) after any wheel disturbance (such as tire rota-

tion, changing a flat tire or wheel removal). Single rear wheels

Tighten the wheel lug nuts to the specified torque

1 at

100 mi (160 km), and again at 500 mi (800 km) of new

vehicle operation and after any wheel disturbance (such

as tire rotation, changing a flat tire or wheel removal). Dual rear wheels

1 See Technical Specifications (page 286).

322

Scheduled Maintenance

Page 327 of 378

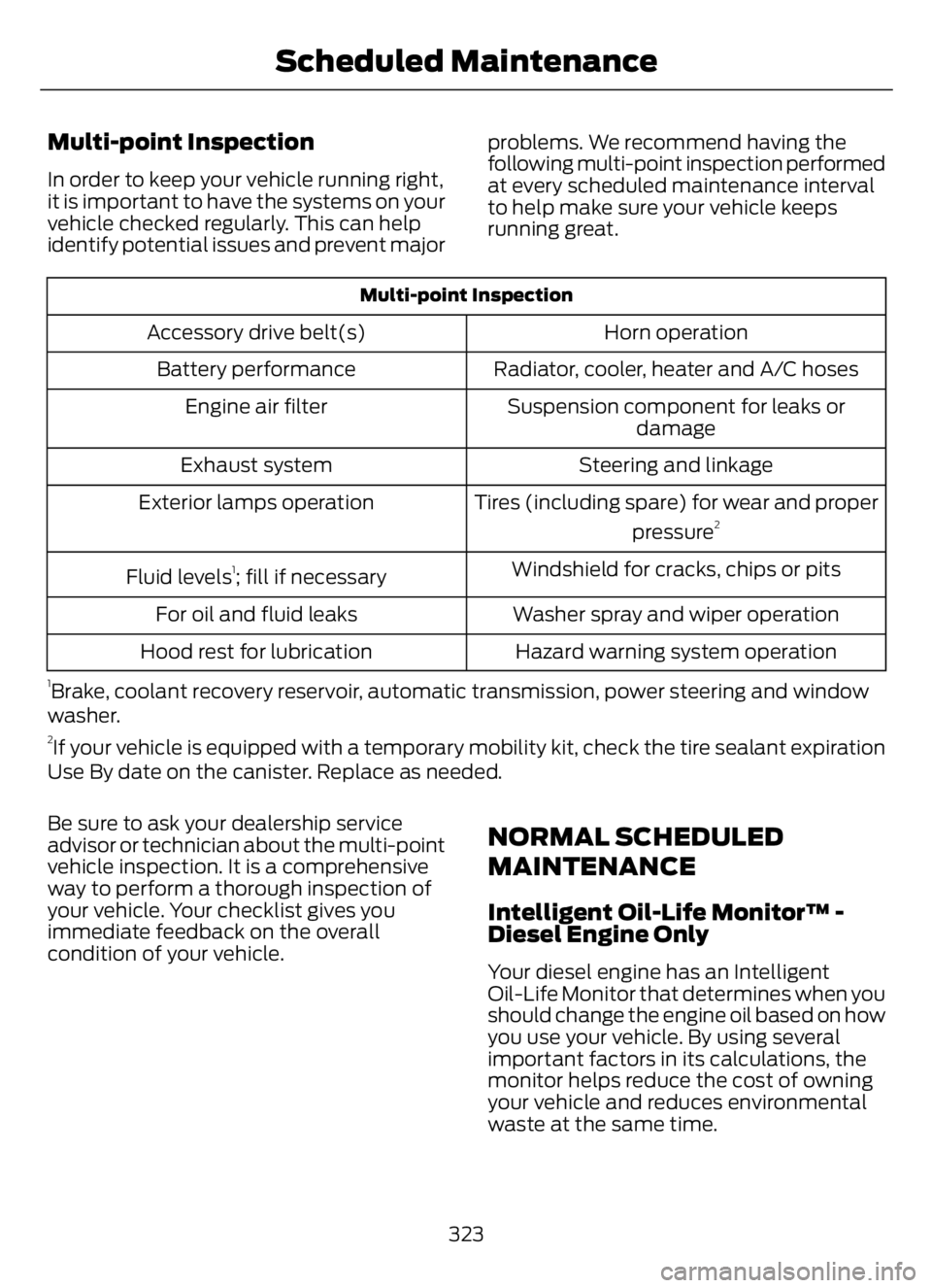

Multi-point Inspection

In order to keep your vehicle running right,

it is important to have the systems on your

vehicle checked regularly. This can help

identify potential issues and prevent majorproblems. We recommend having the

following multi-point inspection performed

at every scheduled maintenance interval

to help make sure your vehicle keeps

running great.

Multi-point Inspection

Horn operation Accessory drive belt(s)

Radiator, cooler, heater and A/C hoses Battery performance

Suspension component for leaks or

damage Engine air filter

Steering and linkage Exhaust system

Tires (including spare) for wear and proper

pressure

2Exterior lamps operation

Windshield for cracks, chips or pits

Fluid levels

1; fill if necessary

Washer spray and wiper operation For oil and fluid leaks

Hazard warning system operation Hood rest for lubrication

1Brake, coolant recovery reservoir, automatic transmission, power steering and window

washer.

2If your vehicle is equipped with a temporary mobility kit, check the tire sealant expiration

Use By date on the canister. Replace as needed.

Be sure to ask your dealership service

advisor or technician about the multi-point

vehicle inspection. It is a comprehensive

way to perform a thorough inspection of

your vehicle. Your checklist gives you

immediate feedback on the overall

condition of your vehicle.

NORMAL SCHEDULED

MAINTENANCE

Intelligent Oil-Life Monitor™ -

Diesel Engine Only

Your diesel engine has an Intelligent

Oil-Life Monitor that determines when you

should change the engine oil based on how

you use your vehicle. By using several

important factors in its calculations, the

monitor helps reduce the cost of owning

your vehicle and reduces environmental

waste at the same time.

323

Scheduled Maintenance

Page 329 of 378

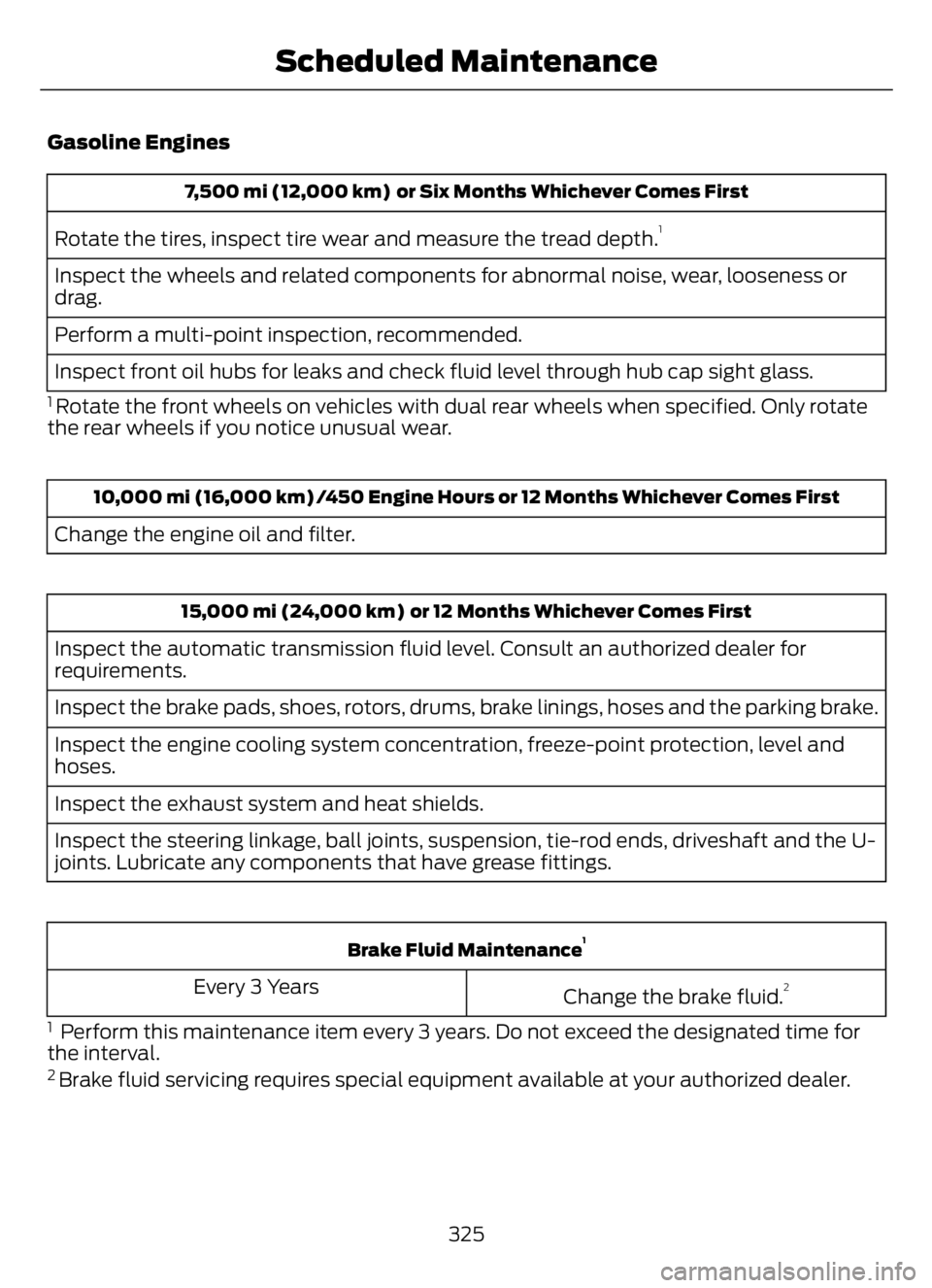

Gasoline Engines

7,500 mi (12,000 km) or Six Months Whichever Comes First

Rotate the tires, inspect tire wear and measure the tread depth.1

Inspect the wheels and related components for abnormal noise, wear, looseness or

drag.

Perform a multi-point inspection, recommended.

Inspect front oil hubs for leaks and check fluid level through hub cap sight glass.

1 Rotate the front wheels on vehicles with dual rear wheels when specified. Only rotate

the rear wheels if you notice unusual wear.

10,000 mi (16,000 km) /450 Engine Hours or 12 Months Whichever Comes First

Change the engine oil and filter.

15,000 mi (24,000 km) or 12 Months Whichever Comes First

Inspect the automatic transmission fluid level. Consult an authorized dealer for

requirements.

Inspect the brake pads, shoes, rotors, drums, brake linings, hoses and the parking brake.

Inspect the engine cooling system concentration, freeze-point protection, level and

hoses.

Inspect the exhaust system and heat shields.

Inspect the steering linkage, ball joints, suspension, tie-rod ends, driveshaft and the U-

joints. Lubricate any components that have grease fittings.

Brake Fluid Maintenance1

Change the brake fluid.2Every 3 Years

1 Perform this maintenance item every 3 years. Do not exceed the designated time for

the interval.

2 Brake fluid servicing requires special equipment available at your authorized dealer.

325

Scheduled Maintenance

Page 331 of 378

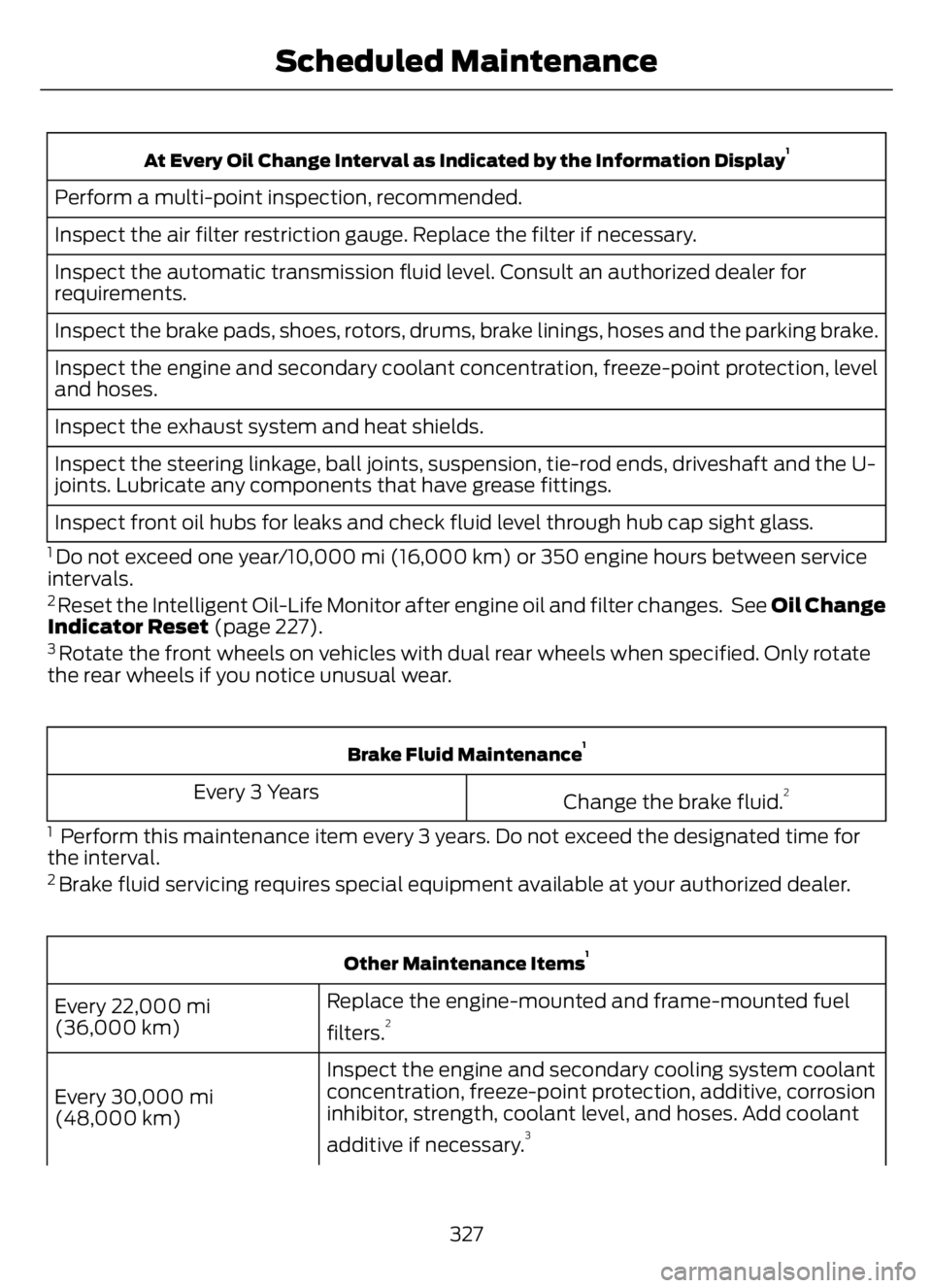

At Every Oil Change Interval as Indicated by the Information Display1

Perform a multi-point inspection, recommended.

Inspect the air filter restriction gauge. Replace the filter if necessary.

Inspect the automatic transmission fluid level. Consult an authorized dealer for

requirements.

Inspect the brake pads, shoes, rotors, drums, brake linings, hoses and the parking brake.

Inspect the engine and secondary coolant concentration, freeze-point protection, level

and hoses.

Inspect the exhaust system and heat shields.

Inspect the steering linkage, ball joints, suspension, tie-rod ends, driveshaft and the U-

joints. Lubricate any components that have grease fittings.

Inspect front oil hubs for leaks and check fluid level through hub cap sight glass.

1 Do not exceed one year/10,000 mi (16,000 km) or 350 engine hours between service

intervals.

2 Reset the Intelligent Oil-Life Monitor after engine oil and filter changes. See Oil Change

Indicator Reset (page 227).

3 Rotate the front wheels on vehicles with dual rear wheels when specified. Only rotate

the rear wheels if you notice unusual wear.

Brake Fluid Maintenance1

Change the brake fluid.2Every 3 Years

1 Perform this maintenance item every 3 years. Do not exceed the designated time for

the interval.

2 Brake fluid servicing requires special equipment available at your authorized dealer.

Other Maintenance Items1

Replace the engine-mounted and frame-mounted fuel

filters.2Every 22,000 mi

(36,000 km)

Inspect the engine and secondary cooling system coolant

concentration, freeze-point protection, additive, corrosion

inhibitor, strength, coolant level, and hoses. Add coolant

additive if necessary.

3

Every 30,000 mi

(48,000 km)

327

Scheduled Maintenance