FORD F750 2015 13.G Owners Manual

Manufacturer: FORD, Model Year: 2015, Model line: F750, Model: FORD F750 2015 13.GPages: 384, PDF Size: 4.95 MB

Page 201 of 384

Special applications may warrant a setting based on experience with the

type of tire operating loads and conditions. Radial tires are more

sensitive to toe-in setting than bias ply tires. Fine tuning school bus

alignment to line-haul truck standards does not drastically improve tire

tread life.

Rear Axle

Regular inspections should include:

•Checking for proper tightness of axle mounting U-bolt nuts, attaching

or mounting bolts and nuts. SeeSpring U-bolt checkslater in this

chapter.

•Checking the axle for damage, binding, worn parts and adequate

lubrication.

NoSpin Detroit Locker Positive Locking Differential

Vehicles equipped with this type differential have the operator’s manual

supplied with the vehicle. See that manual for maintenance inspections.

Brake System

Note:People handling brake linings should follow all precautions listed

below:

200Maintenance

2015 F-650/750(f67)

Owners Guide gf(ownloose), 1st Printing, December 2013

Canadian_French(fr_can)

Page 202 of 384

WARNING:

1. Always wear a respirator approved by the National Institute of

Occupational Studies of Health (NIOSH) or Mine Safety and Appliance

(MSA) during all brake service procedures. Wear the respirator from

removal of the wheels through assembly.

2.Neveruse compressed air or dry brushing to clean brake parts or

assemblies.

3. Clean brake parts and assemblies in open air. During assembly,

carefully place all parts on the floor to avoid getting dust in the air. Use

an industrial vacuum cleaner with a HEPA filter system to clean dust

from the brake drums, backing plates and other brake parts. After using

the vacuum, remove any remaining dust with a rag soaked in water and

wrung until nearly dry.

4.Neveruse compressed air or dry sweeping to clean the work area.

Use an industrial vacuum cleaner with a HEPA filter system and rags

soaked in water and wrung until nearly dry. Dispose of used rags with

care to avoid getting dust in the air. Use an approved respirator when

emptying vacuum cleaners and handling used rags.

5.Worker clean-up:Wash your hands before eating, drinking or

smoking. Vacuum your work clothes after use and then launder them

separately, without shaking them, to prevent fiber dust getting into the

air.

Your vehicle is equipped with non-asbestos brake linings. However,

exposure to excessive amounts of brake material (whether asbestos or

non-asbestos, fiberglass, mineral wool, aramid or carbon) may be a

serious health hazard.

Air Brakes

WARNING:Do not manually adjust the automatic slack adjusters

to correct excessive push rod stroke as it may result in reduced

brake effectiveness and a vehicle crash. Excessive push rod stroke

indicates that a problem exists with the automatic adjuster, with the

installation of the adjuster, or with foundation brake components that

manual adjustment does not remedy. Seek service from a qualified

facility for excessive push rod stroke.

Maintenance201

2015 F-650/750(f67)

Owners Guide gf(ownloose), 1st Printing, December 2013

Canadian_French(fr_can)

Page 203 of 384

Inspection and adjustment:Establish a regular schedule for periodic

cleaning, lubrication and adjustment inspection based on vehicle use.

Exact maintenance intervals are difficult to predetermine due to vehicle

applications and operating conditions. If you are uncertain of the proper

schedule for your vehicle, contact an authorized dealer.

Regular inspections should include:

•Periodic checking (every service interval) of push rod travel or brake

adjustment. This is essential for effective braking. Brake chamber

push rods on original equipment chambers now incorporate an orange

paint marker near the base of the push rod as a stroke indicator to

aid in adjustment checks. If the push rod is clean and the brakes are

out of adjustment, you can see the orange marker protruding from

the chamber when the brakes are applied.

•Checking the brake lining (every service interval). When brake lining

or blocks wear within 1/16th inch (1.6 millimeters) of rivets, replace

the brake linings. A qualified technician should perform this

inspection and keep to instructions provided by the service manual.

Do not back off or disconnect the front brakes so that they are less

effective, letting the rear brakes do all the stopping of your vehicle. Do

not overlook the brakes on the trailer either. Brake condition on the

trailer is just as important as the tractor. Proper brake balance on trucks

and tractor-trailers is essential for effective braking.

Once a year, inspect the entire brake system:

•Rubber components for deterioration. A qualified technician should

inspect these components and replace them as necessary.

Replacement intervals vary according to the severity and length of

vehicle service.

•Condition of brake drums, brake chambers and slack adjusters.

•System for air leaks.

•Hose or pipes for rust, damage and deterioration.

•Operation of service and parking brakes.

Periodically inspect parts such as air brake chamber diaphragm, air

compressor and air cleaner. Replace any parts if you can consider them

unserviceable.

Air dryer:Climactic conditions affect performance of desiccant or

after-cooler type air dryers. You must establish a maintenance schedule

for each specific operation.

The use of an air dryer on a vehicle does not eliminate the need to drain

the air reservoirs periodically.

202Maintenance

2015 F-650/750(f67)

Owners Guide gf(ownloose), 1st Printing, December 2013

Canadian_French(fr_can)

Page 204 of 384

Desiccant air dryer:Inspect for moisture in the air system by opening

reservoirs, draincocks or valves and checking for presence of water. The

presence of small amounts of water due to condensation is normal and is

not an indication that the dryer is not functioning properly.

Replace or rebuild the desiccant cartridge when you determine that the

desiccant is contaminated and does not have adequate water absorption

capacity. The desiccant change interval may vary. A general

recommendation is to replace the desiccant every 12 months (yearly). If

experience has shown that extended or shortened life has resulted for a

particular installation, then the yearly interval can be increased or

decreased accordingly.

Draining the air brake reservoir:

Completely drain all the air brake

reservoirs daily by opening the

draincock at the ends of the tanks.

(Where accessible. Pull-chains are

used when the drains are undercab

or otherwise inaccessible.) Close the

draincock after draining. Manually

drain any air tanks equipped with

automatic moisture ejector valves,

as required, to maintain a dry air

system. Contact an authorized dealer if you are unsure of the air

reservoir locations or the draining procedure.

WARNING:Failure to drain air brake reservoirs can result in a

reduction or loss of braking ability due to fluid accumulation in

the reservoir and/or possible freeze-up during cold weather.

Hydraulic Brakes

Establish a regular schedule for periodic cleaning, lubrication and

adjustment inspection based on vehicle use. Exact maintenance intervals

are difficult to predetermine due to vehicle applications and operating

conditions. If you are uncertain of the proper schedule for your vehicle,

contact an authorized dealer.

Regular inspections should include:

•Checking the brake lining (every service interval). Establish

inspection intervals that provide for lining replacement before damage

to the disc occurs. Excessive lining wear may expose the backing

plate to the disc causing scoring of the disc faces. A qualified

technician should perform this inspection and keep to instructions

Maintenance203

2015 F-650/750(f67)

Owners Guide gf(ownloose), 1st Printing, December 2013

Canadian_French(fr_can)

Page 205 of 384

provided by the service manual. Hydraulic brake systems are

power-assisted. There is a great reduction in braking capabilities

without engine assist.

•Proper fluid level. The level should be at the bottom edge of the ring

on each reservoir fill port. Do not fill the master cylinder to the top of

the reservoir. If fluid level requires attention to maintain a proper

master cylinder level, this is an indication of either severe operation

(pad wear) or fluid leakage. A more frequent and thorough brake

inspection is required.

•Brake lines, hoses and fittings. Repair or replace brake line tubes,

hoses or fittings as required. Inspect these components every

4000 miles (6000 kilometers):

•Lines for kinks, dents, corrosion or rupture.

•Hoses for abrasions, kinks, soft spots or rupture, collapse, cracks,

twists or loose frame supports. When replacing a hose, be sure

there is adequate clearance to the hose to avoid an abrasion to the

new hose.

•All connections for leaks.

Driveline Parking Brake

WARNING:Use wheel chocks and exercise caution when

inspecting under the vehicle. A vehicle roll-away could result in

property damage, personal injury or death.

A qualified technician should adjust the parking brake and keep to the

instructions in the service manual.

Steering System

WARNING:Failure to maintain the steering system in proper

condition can cause reduced steering ability resulting in property

damage, personal injury or death.

Note:Have any steering problems immediately corrected by a qualified

service technician.

Ask your service technician to examine the steering mechanism. Only

minor adjustments may be necessary. Regular inspections should include:

•Checking the tie rod, drag link end clamp bolts and ball joints for

proper tightness.

•Checking for installation and spread of cotter pins and tightness of

nuts at both ends of the tie rod and drag link.

204Maintenance

2015 F-650/750(f67)

Owners Guide gf(ownloose), 1st Printing, December 2013

Canadian_French(fr_can)

Page 206 of 384

•Checking that the pitman arm (steering arm at steering gear)

mounting is tight and locked. Check system for leaks or hose chafing.

Repair immediately, if necessary.

•Maintaining proper steering gear and power steering pump lubricant

levels.

•Checking steering column joint bolts and steering linkage, particularly

for body-to-chassis clearance.

Steering Column Joint Bolts

As a good maintenance practice, check steering column joint bolt

tightness every 60000 miles (96000 kilometers) or annually, whichever

occurs first. Do not overtighten the bolts.

Hydraulic System

Whenever draining and refilling the power steering’s hydraulic system for

any reason, bleed air from the system before returning the vehicle to

service. Failure to bleed the hydraulic system properly can result in

degradation of power system performance.

Consult an authorized dealer who is aware of the proper procedures for

filling and bleeding the system.

Catalytic Converter (Diesel Engine)

Note:If your vehicle is equipped with a catalytic converter or muffler,

do not blend waste oil with diesel fuel. Operate only on ultra-low sulfur

(less than 15 parts per million sulfur) diesel fuel with a cetane value of

45 or higher.

If your diesel engine is equipped with a catalytic converter, it is

important to review the maintenance schedule to make sure proper

functioning of the catalytic converter. Also, take precautions not to

damage the catalytic converter when servicing your engine or storing

your vehicle.

Diesel Exhaust Fluid (DEF), Diesel Particulate Filter (DPF) and

Select Catalyst Reduction (SCR) System

See your engine operator’s manual for information about DEF, DPF and

SCR system service

Air Induction System

WARNING:When performing maintenance to any turbocharged

engine with engine air inlet piping disconnected, keep loose

clothing, jewelry and long hair away from the engine air inlet piping. A

turbocharger compressor air inlet protective shield should be installed

over the turbocharger air inlet to reduce the risk of personal injury or

death.

Maintenance205

2015 F-650/750(f67)

Owners Guide gf(ownloose), 1st Printing, December 2013

Canadian_French(fr_can)

Page 207 of 384

Perform a complete inspection of the air induction system annually.

In areas where road salt is used, disassemble the joints of each aluminum

component and inspect for salt build-up and presence of chlorine that

can cause aluminum particles to flake off and enter the engine

combustion chambers. If evidence of corrosion is found (usually at the

pipe connections), use a wire brush to clean the inside of the pipes and

inside the rubber hoses.

If pitting is evident at the joint ends of the intake pipes, use Motorcraft

Silicone Gasket and Sealant TA-30 to seal the joints. Make sure no

excess material, which can pull into the engine, is on the inside of the

pipes. If the service condition of the pipes, hoses or clamps is

questionable, replace the defective part(s).

Make sure to clean all dust and debris out of the pipes and couplings

with a clean, damp rag before reassembly.

Chassis-mounted Charge Air Cooler

Visually inspect the core assembly for debris and clogging of external fins

with the engine off. Before engine operation, remove any debris blocking

the core.

•Turbocharger-to-charge air cooler

•Charge air cooler-to-intake manifold pipe

•Mounting bracket

•Chassis-mounted charge air cooler core

Inspect air intake piping:

•Check for accumulation of salt deposits (where applicable). If

present, disassemble and clean the complete air intake piping system.

If pitting is evident on the intake piping, use Motorcraft Silicone

Gasket and Sealant TA-30 to seal joints against leakage.

•Check for loose hoses and clamps.

•Check for ruptured or collapsed hoses.

•Check air cleaner housing for cracks.

Suspension Inspection

Note:Do not adjust air suspension height to any setting other than the

specified setting. Altering the height setting changes the driveline angle

and may result in unwarrantable component damage, such as

transmission component damage.

Verify drive axle air suspension height and height control valve

performance at engine oil change intervals.

206Maintenance

2015 F-650/750(f67)

Owners Guide gf(ownloose), 1st Printing, December 2013

Canadian_French(fr_can)

Page 208 of 384

Periodically check:

•Condition of spring leaves for evidence of fatigue, bending or

breakage.

•Condition of suspension mounting brackets and bushings.

•Torque rod mounting fasteners for tightness.

•For proper suspension alignment. Maintain proper alignment at all

times.

•U-bolts. After the chassis has been operating under load for

1000 miles (1600 kilometers) or six months (whichever comes first),

the U-bolt nuts must be re-torqued. Re-torque the U-bolt nuts every

36000 miles (60000 kilometers) thereafter. Clean and lubricate the

U-bolt and nut threads and seats to make sure a like new condition

when re-torqueing.

Note:SeeSpring U-bolt checklater in this chapter.

Supporting Your Vehicle for Service

WARNING:Do not use a jack when working under a vehicle. It

may give way, causing the vehicle to fall and result in property

damage, personal injury or death. Always use floor stands to support

the vehicle.

Prepare your vehicle for service repairs by doing the following:

1. Park your vehicle on a level, concrete floor.

2. Set the parking brake and block the wheels to prevent your vehicle

from moving.

3. Select a jack with a rated capacity sufficient to lift and hold up your

vehicle.

4. Raise your vehicle with the jack applied to the axle(s). Do not use

the bumper as a lifting point.

5. Support your vehicle with floor stands under the axle(s). When

servicing the axle or the suspension, support your vehicle with floor

stands under the frame side-members, preferably between the axles.

Frame and Tow Hooks

Your vehicle’s chassis is manufactured with frame rails of either HSLA

steel or heat-treated steel. Handle each in a specific manner to make

sure maximum service life. Consult the service manual or an authorized

dealer before attempting frame repair or modification.

It is important, particularly on vehicles that use tow hooks frequently, to

inspect the front and rear tow hooks for damage or a loose mounting.

Maintenance207

2015 F-650/750(f67)

Owners Guide gf(ownloose), 1st Printing, December 2013

Canadian_French(fr_can)

Page 209 of 384

OPENING AND CLOSING THE HOOD

WARNING:The parking brake must be fully set before opening

the hood or possible personal injury may occur.

WARNING:To reduce the risk of the possibility of personal

injury, never stand beneath the hood when it is being raised or

lowered.

WARNING:If you must leave the engine running while checking

under the hood, do not allow any loose clothing, jewelry, hair or

other items to get near moving engine components or possible personal

injury may occur.

A latch located on each fender holds the hood and fenders in position.

Before opening the hood, set the parking brake, shift into positionN

(automatic transmission) or first (manual transmission) and turn the

engine off.

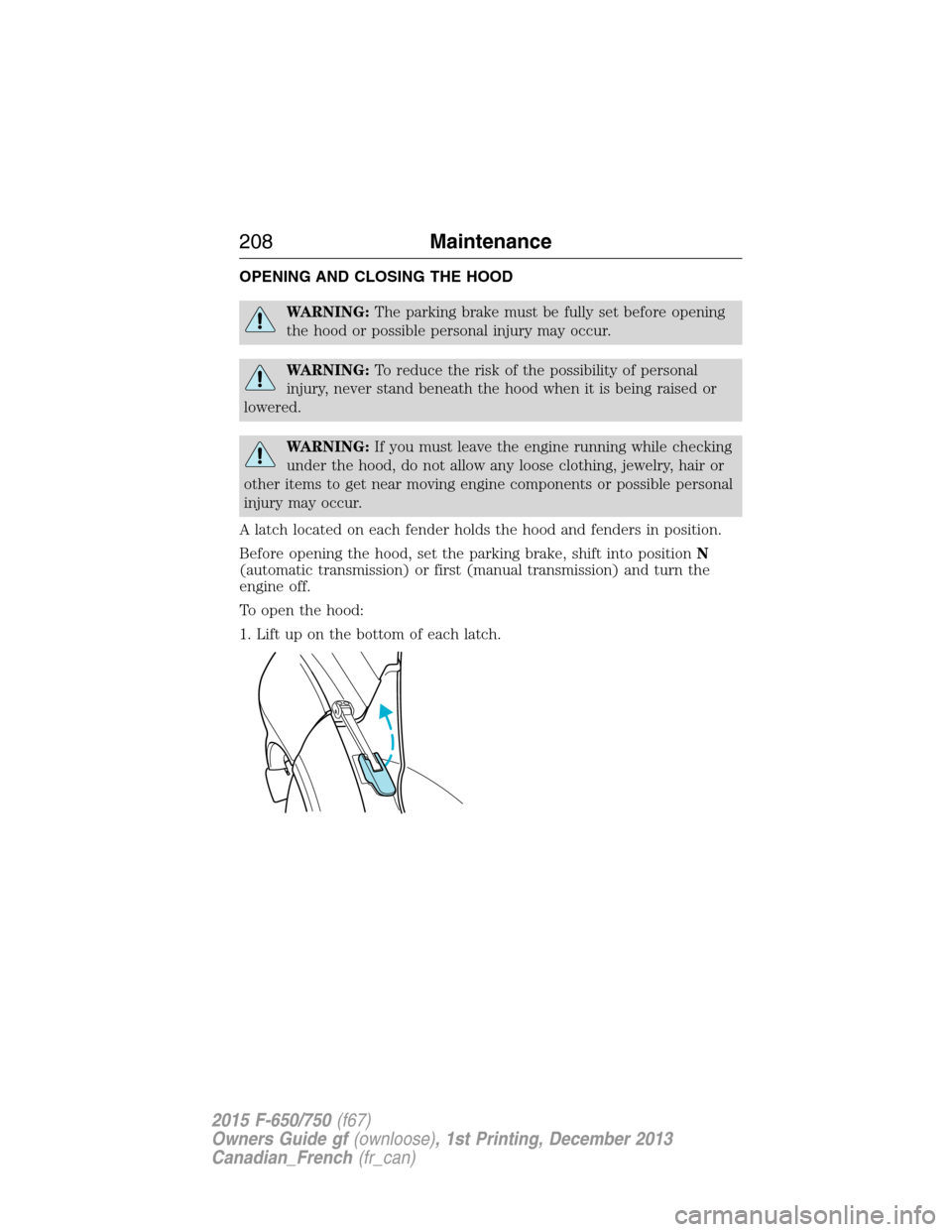

To open the hood:

1. Lift up on the bottom of each latch.

208Maintenance

2015 F-650/750(f67)

Owners Guide gf(ownloose), 1st Printing, December 2013

Canadian_French(fr_can)

Page 210 of 384

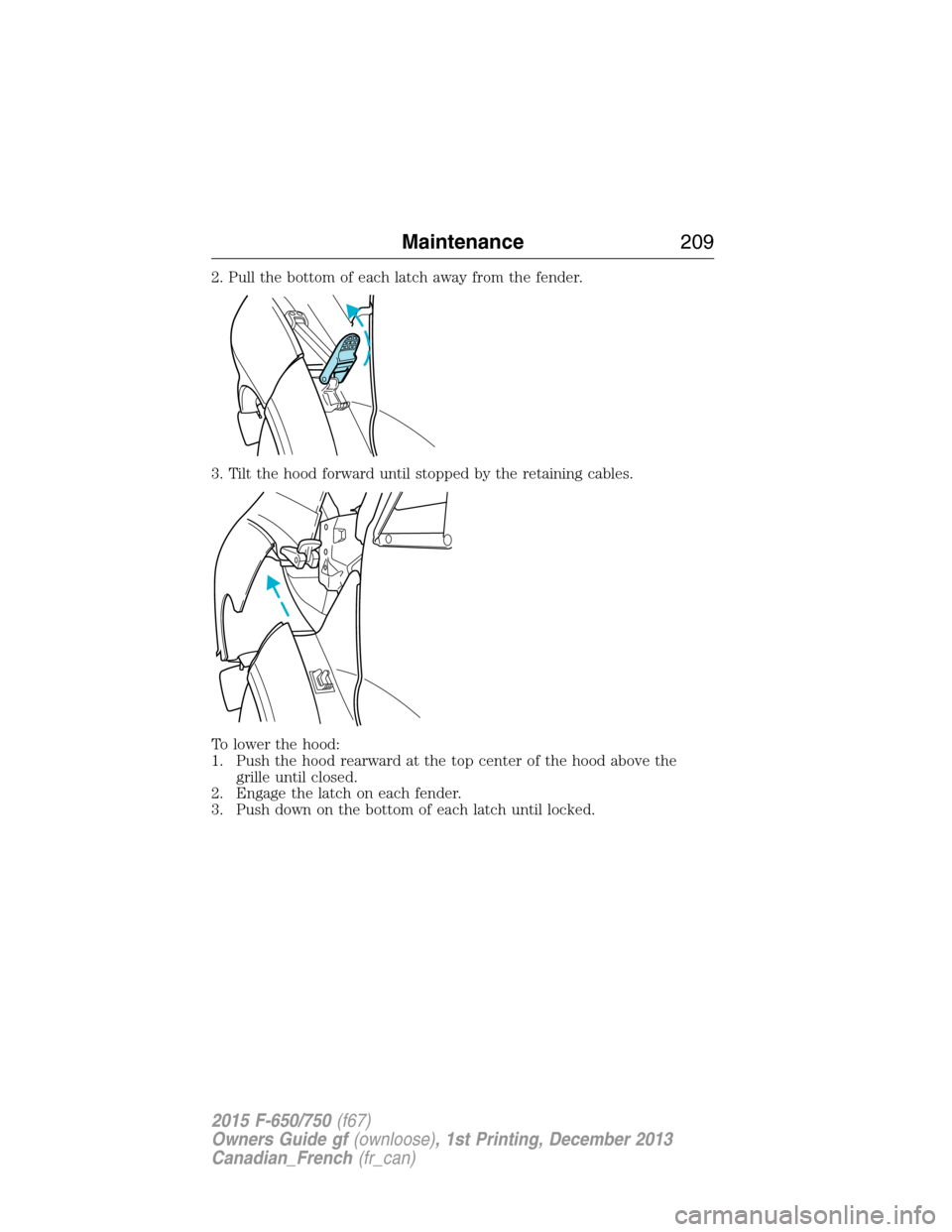

2. Pull the bottom of each latch away from the fender.

3. Tilt the hood forward until stopped by the retaining cables.

To lower the hood:

1. Push the hood rearward at the top center of the hood above the

grille until closed.

2. Engage the latch on each fender.

3. Push down on the bottom of each latch until locked.

Maintenance209

2015 F-650/750(f67)

Owners Guide gf(ownloose), 1st Printing, December 2013

Canadian_French(fr_can)