power steering FORD FESTIVA 1991 Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 111 of 454

bearing oil seal. To complete installation, reverse removal procedure.

WATER PUMP

Removal & Installation (1.3L)

Remove timing belt. Drain cooling system. Remove lower radiator hose and heater return hose from water pump. Remove water pump

retaining bolts and water pump. Clean gasket mounting surface and replace gasket. To install, reverse removal procedure.

Removal (1.6L)

1. Remove timing belt. See TIMING BELT . Drain cooling system. Remove timing belt tensioner and idler pulleys. Remove oil dipstick

bracket retaining bolt.

2. Remove power steering pump from retaining bracket, leaving hoses attached. Remove power steering bracket and position power

steering pump to one side. Remove water pump outlet. Remove water pump retaining bolts and water pump.

Installation (1.6L)

1. Clean all gasket surfaces. Transfer rubber belt cover seal to new water pump (if required). Position water pump with new gasket and

install retaining bolts. Install pump outlet with new gasket and "O" ring. See TORQUE SPECIFICATIONS

table at end of article.

2. Install oil dipstick retaining bolt. Install timing belt tensioner and idler pulleys. Install power steering pump bracket. Install power

steering pump. Tighten all bolts and nuts to specification. See TORQUE SPECIFICATIONS

table at end of article.

3. Install timing belt. Fill cooling system. Start engine and check for leaks and proper system function.

OIL PAN

Removal (1.3L)

Disconnect battery ground cable. Raise vehicle and drain engine oil. Remove flywheel housing dust cover. Remove oil pan retaining bolts,

nuts and stiffeners. Rotate crankshaft while removing oil pan. Remove baffle plate from oil pan. Clean gasket mating surfaces thoroughly.

Installation (1.3L)

Ensure gasket surfaces are clean. Apply oil resistant sealer to front and rear engine covers and across joint line of cylinder block.

Removal (1.6L)

1. Raise vehicle and drain engine oil. Remove frame brace retaining bolt. Loosen RH "A" arm front bolt, and pivot brace downward.

Disconnect front exhaust pipe from exhaust manifold (or turbocharger). Remove exhaust pipe bracket retaining bolts. Loosen rubber

exhaust hangers at catalytic converter.

2. Allow exhaust to hang supported by mechanic's wire. Disconnect turbocharger oil return hose (if equipped). Remove oil pan retaining

bolts. Carefully pry oil pan loose from cylinder block.

Installation (1.6L)

1. Clean pan and block gasket surfaces. Apply Gasket Sealant (E3AZ-19562-A) to new front and rear pan seals. Install seals to cylinder

block. Apply Gasket Sealant (E3AZ-19562-A) to oil pan gasket surface. See Fig. 8

. Install oil pan and tighten pan retaining bolts to

specification. See TORQUE SPECIFICATIONS

table at end of article.

2. Connect turbocharger oil return hose (if equipped). Install rubber exhaust hanger to brackets. Install new gasket and connect fro n t

exhaust pipe to exhaust manifold (or turbocharger). Install front exhaust pipe bracket. Tighten nuts and bolts to specification.

3. Pivot frame brace into position. Tighten retaining bolt to crossmember and RH "A" arm front retaining bolt to specification. Lower

vehicle, fill with oil and start engine. Check for oil leaks and system operation. NOTE:Raise engine slightly with floor jack, if required, to gain clearance for water pum p rem oval.

CAUT ION: DO NOT force a pry tool between cylinder block and oil pan.

Page 11 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 128 of 454

Crankshaft Pulley Bolts10-13 (12-17)

Crankshaft Sprocket Bolt80-87 (108-118)

Power Steering Adjuster Nut27-38 (37-52)

Timing Belt Tensioner Adjuster Bolt14-19 (19-26)

Water Pump Pulley Bolts36-45 (49-61)

INCH Lbs. (N.m)

Camshaft Cover71-97 (8-11)

Timing Belt Cover Bolt71-97 (8-11)

Valve Cover Bolt44-79 (5-9)

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00155957

Page 3 of 3 MITCHELL 1 ARTICLE - FORD 1.3L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 148 of 454

Removal

Drain radiator and remove negative battery cable. Disconnect throttle cable. Remove air duct from throttle body. Disconnect throttle position

sensor/switch connector. Mark all coolant and vacuum hoses for reassembly reference and remove from throttle body. See Fig. 4

. Remove

intake plenum bolts and remove intake plenum and gasket.

Installation

To install, reverse removal procedure. Use NEW intake plenum-to-intake manifold gasket. Tighten bolts to specification, see TORQUE

SPECIFICATIONS at end of article.

OXYGEN (O2) SENSOR

Removal & Installation

Disconnect negative battery cable. Disconnect wire harness connector, and remove oxygen sensor. If exhaust sensor is difficult to remove, use

rust penetrant to avoid possible damage to exhaust threads. If new sensor is not pre-coated with anti-seize, apply anti-seize compound to

sensor threads. DO NOT remove anti-seize from sensor. To install, tighten sensor and attach wire harness connector.

THROTTLE BODY

Removal & Installation

Drain radiator and remove negative battery cable. Remove resonance chamber. Disconnect throttle cable. Remove air duct. Mark all coolant

and vacuum hoses for reassembly reference and remove from throttle body. Disconnect throttle position sensor/switch connector. Remove

throttle body nuts and bolts. Remove throttle body and gasket. To install, reverse removal procedure using NEW throttle body-to-intake

plenum gasket.

THROTTLE POSITION SENSOR/SWITCH

Removal & Installation

Disconnect negative battery cable. Disconnect throttle position sensor/switch connector. Remove attaching bolts. Remove sensor/switch from

throttle body. To install, reverse removal procedure.

TURBOCHARGER

Removal

1. Drain radiator and remove negative battery cable. Remove throttle body air intake tube. Disconnect intercooler hose from turbocharger

assembly. Disconnect O2 sensor. Remove lower heat shield retaining bolts and lower heat shield from turbocharger. Remove upper heat

shield retaining bolts and upper heat shield from exhaust manifold.

2. Slide O2 sensor wire and guide through upper heat shield. Remove side heat shield retaining bolts from turbocharger, and remove sid e

heat shield. Remove power steering belt. Remove power steering pump through bolt and adjuster nuts and bolts. Disconnect lower

radiator hose from water pump.

3. Pull pump from bracket, and position pump to access mounting bracket retaining nut and bolts. Remove mounting bracket-to-engine nut

and bolts and remove bracket. Remove air cleaner duct retaining screws. Loosen clamp at turbocharger and move duct tube out of way.

Disconnect coolant supply hose at turbocharger.

4. Remove bolt and sealing washers attaching oil supply line at engine block. Raise vehicle on hoist. Remove nuts and washers from

exhaust pipe flange. Remove bolts attaching exhaust hanger to engine block. Slide rubber exhaust hangers from catalytic converter. Pull

exhaust pipe downward and to left side of vehicle. Disconnect oil return hose from turbocharger. Disconnect coolant return hose fro m

turbocharger.

5. Remove turbocharger support bracket retaining bolts. Remove coolant by-pass tube outlet-to-water pump bolts. Lower vehicle. Loosen

retaining clamp bolt on coolant by-pass tube at rear of cylinder head. Remove 11 retaining nuts from exhaust manifold. Position coolant

by-pass tube out of way after pulling bracket from exhaust stud.

6. Remove exhaust manifold by pulling off studs and moving assembly towards right side of engine compartment, clearing cooling fan.

With assembly removed from vehicle, remove turbocharger-to-exhaust manifold nuts. Separate assembly and discard gasket.

Installation

1. Install NEW gasket on exhaust manifold and install turbocharger onto studs. Install turbocharger-to-exhaust manifold nuts. Remo ve o il

supply line from turbocharger. Install NEW exhaust gasket on cylinder head. Install turbocharger and exhaust manifold assembly onto

studs. Install coolant by-pass tube bracket onto exhaust stud. Install 11 retaining nuts onto exhaust manifold.

2. Securely tighten heater tube clamp bolt. Raise vehicle. Install coolant by-pass tube outlet-to-water pump bolts. Install turbocharger

support bracket retaining bolts. Connect coolant return hose to turbocharger. Connect oil return hose to turbocharger. Install exhaust

pipe onto turbocharger, and hand tighten nuts and washers. Install bolts attaching exhaust hanger to engine block.

3. Slide rubber exhaust hangers onto catalytic converter. Tighten exhaust pipe nuts and washers. Lower vehicle. Install bolt and sealing

washers attaching oil supply line at engine block. Install oil supply line onto turbocharger. To complete installation, reverse removal

procedure. Tighten bolts and nuts to specification, see TORQUE SPECIFICATIONS

at end of article. NOTE:T o prevent dust and dirt from entering intake m anifold ports, cover ports with clean cloth after

rem oving intake plenum .

WARNING:DO NOT rem ove oxygen sensor when engine is hot.

NOTE:Clean throttle body exterior before rem oval.

CAUT ION: Before installing turbocharger, put .8 oz. (25 m l) engine oil into turbocharger oil inlet.

Page 4 of 5 MITCHELL 1 ARTICLE - N - REMOVE/INSTALL/OVERHAUL 1991 ENGINE PERFORMANCE Ford/Mercury Removal, O

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 149 of 454

VANE AIRFLOW (VAF) METER

Removal

1. Disconnect negative battery cable. On Capri, disconnect primary and secondary wires from coil. On Festiva, disconnect VAF wire

harness connector. Remove air duct.

2. On Capri, remove retaining bolt and ground wire from air cleaner cover. Remove air cleaner cover bolts and air cleaner cover. From

inside of air cleaner cover, remove VAF meter retaining nuts. On Festiva, remove attaching bolt and 4 nuts. Remove vane airflow met er.

Installation

To install, reverse removal procedure. Position new gasket over VAF mounting studs. Tighten bolts and nuts to specification, see TORQUE

SPECIFICATIONS at end of article.

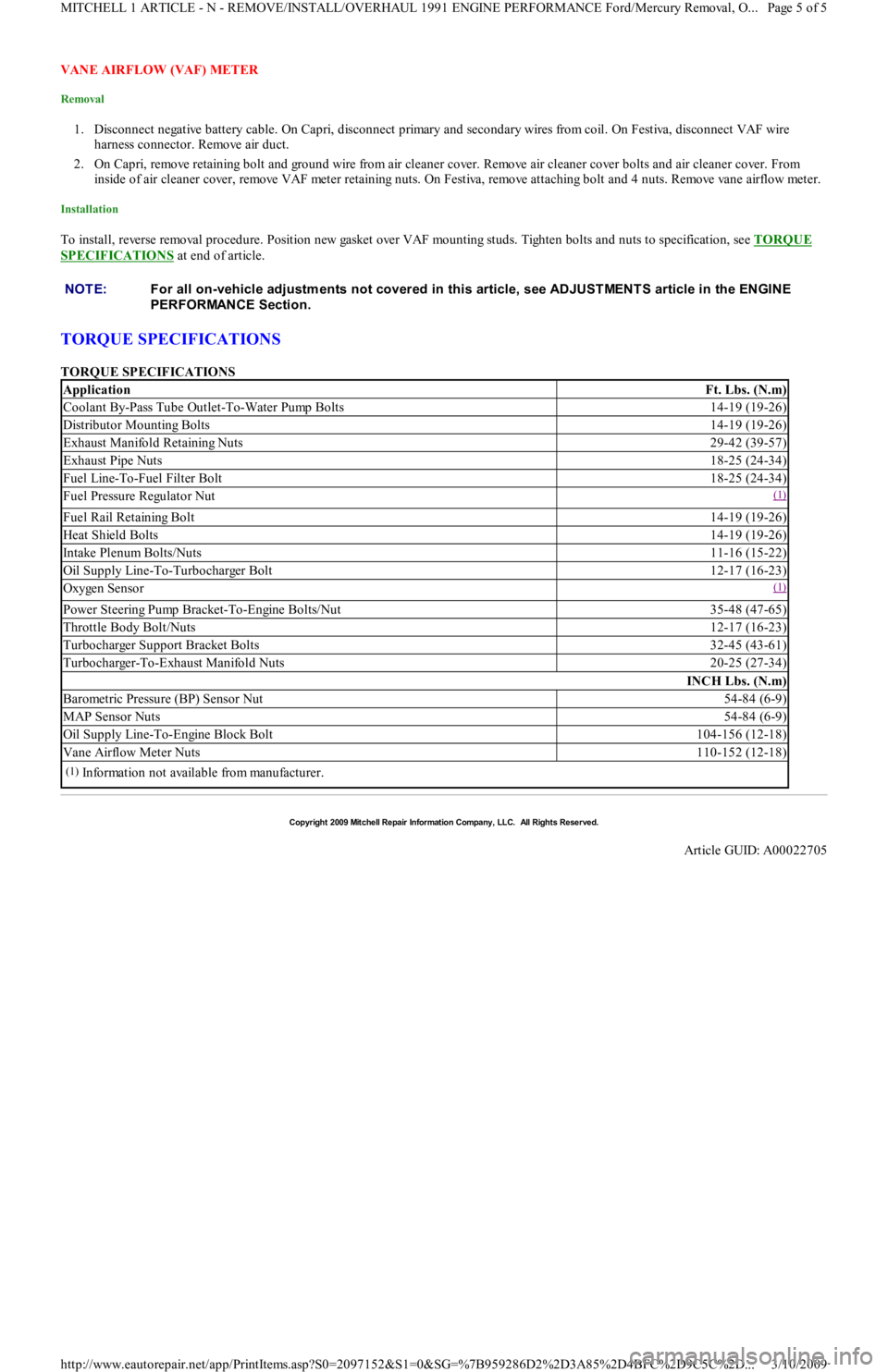

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS NOTE:For all on-vehicle adjustm ents not covered in this article, see ADJUST MENT S article in the ENGINE

PERFORMANCE Section.

ApplicationFt. Lbs. (N.m)

Coolant By-Pass Tube Outlet-To-Water Pump Bolts14-19 (19-26)

Distributor Mounting Bolts14-19 (19-26)

Exhaust Manifold Retaining Nuts29-42 (39-57)

Exhaust Pipe Nuts18-25 (24-34)

Fuel Line-To-Fuel Filter Bolt18-25 (24-34)

Fuel Pressure Regulator Nut(1)

Fuel Rail Retaining Bolt14-19 (19-26)

Heat Shield Bolts14-19 (19-26)

Intake Plenum Bolts/Nuts11-16 (15-22)

Oil Supply Line-To-Turbocharger Bolt12-17 (16-23)

Oxygen Sensor(1)

Power Steering Pump Bracket-To-Engine Bolts/Nut35-48 (47-65)

Throttle Body Bolt/Nuts12-17 (16-23)

Turbocharger Support Bracket Bolts32-45 (43-61)

Turbocharger-To-Exhaust Manifold Nuts20-25 (27-34)

INCH Lbs. (N.m)

Barometric Pressure (BP) Sensor Nut54-84 (6-9)

MAP Sensor Nuts54-84 (6-9)

Oil Supply Line-To-Engine Block Bolt104-156 (12-18)

Vane Airflow Meter Nuts110-152 (12-18)

(1)Information not available from manufacturer.

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00022705

Page 5 of 5 MITCHELL 1 ARTICLE - N - REMOVE/INSTALL/OVERHAUL 1991 ENGINE PERFORMANCE Ford/Mercury Removal, O

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 163 of 454

POWER STEERING PRESSURE SWITCH

1. Start engine and run it at idle. Remove connector from switch. Connect ohmmeter to switch terminals. Turn steering wheel from side to

side while observing ohmmeter.

2. Replace power steering switch if continuity does not exist with front wheels turned, or if continuity exists with wheels straight ahead.

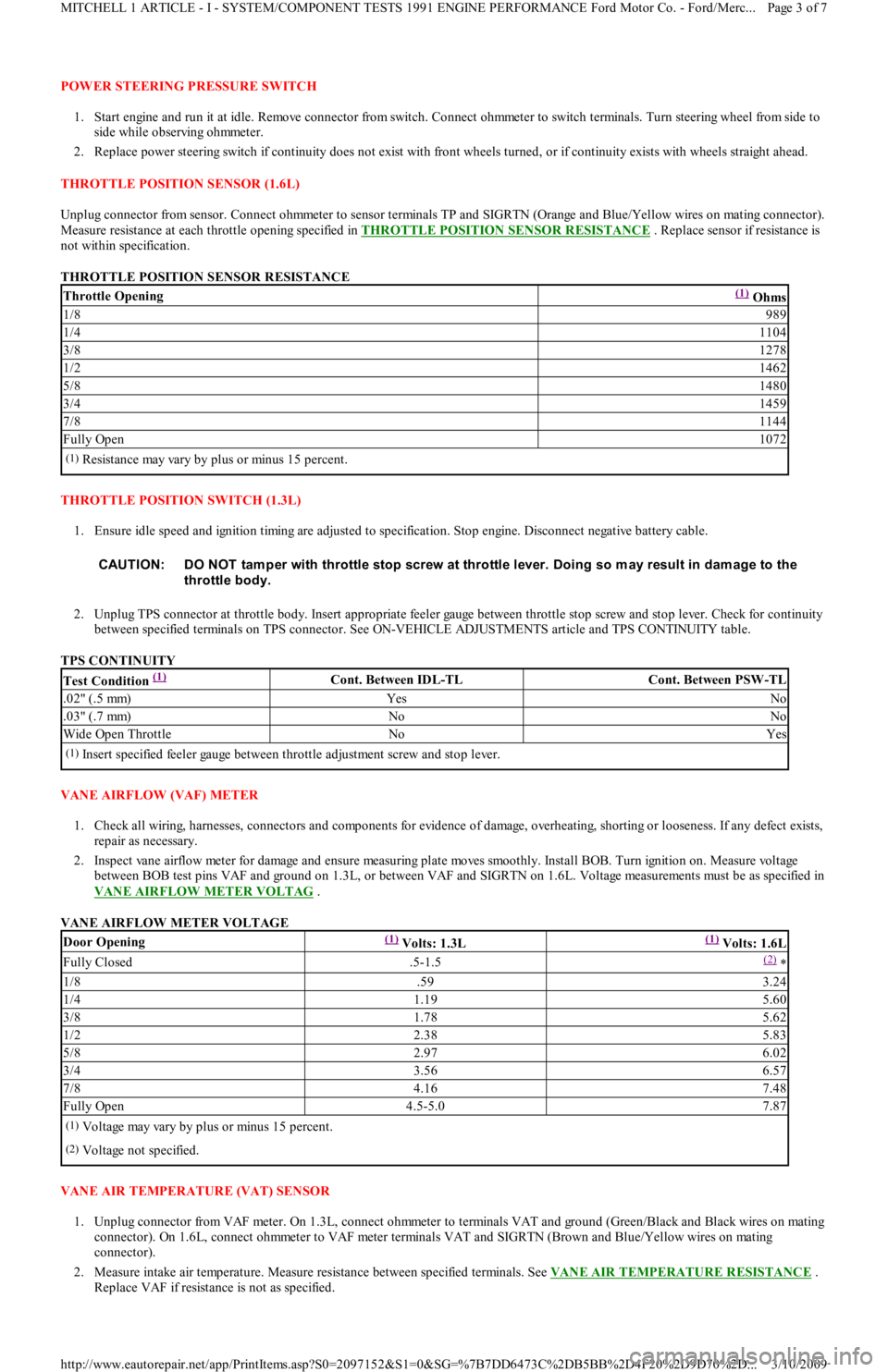

THROTTLE POSITION SENSOR (1.6L)

Unplug connector from sensor. Connect ohmmeter to sensor terminals TP and SIGRTN (Orange and Blue/Yellow wires on mating connector).

Measure resistance at each throttle opening specified in THROTTLE POSITION SENSOR RESISTANCE

. Replace sensor if resistance is

not within specification.

THROTTLE POSITION SENSOR RESISTANCE

THROTTLE POSITION SWITCH (1.3L)

1. Ensure idle speed and ignition timing are adjusted to specification. Stop engine. Disconnect negative battery cable.

2. Unplug TPS connector at throttle body. Insert appropriate feeler gauge between throttle stop screw and stop lever. Check for continuity

between specified terminals on TPS connector. See ON-VEHICLE ADJUSTMENTS article and TPS CONTINUITY table.

TPS CONTINUITY

VANE AIRFLOW (VAF) METER

1. Check all wiring, harnesses, connectors and components for evidence of damage, overheating, shorting or looseness. If any defect exists,

repair as necessary.

2. Inspect vane airflow meter for damage and ensure measuring plate moves smoothly. Install BOB. Turn ignition on. Measure voltage

between BOB test pins VAF and ground on 1.3L, or between VAF and SIGRTN on 1.6L. Voltage measurements must be as specified in

VANE AIRFLOW METER VOLTAG

.

VANE AIRFLOW METER VOLTAGE

VANE AIR TEMPERATURE (VAT) SENSOR

1. Unplug connector from VAF meter. On 1.3L, connect ohmmeter to terminals VAT and ground (Green/Black and Black wires on mating

connector). On 1.6L, connect ohmmeter to VAF meter terminals VAT and SIGRTN (Brown and Blue/Yellow wires on mating

connector).

2. Measure intake air temperature. Measure resistance between specified terminals. See VANE AIR TEMPERATURE RESISTANCE

.

Replace VAF if resistance is not as specified.

Throttle Opening(1) Ohms

1/8989

1/41104

3/81278

1/21462

5/81480

3/41459

7/81144

Fully Open1072

(1)Resistance may vary by plus or minus 15 percent.

CAUT ION: DO NOT tam per with throttle stop screw at throttle lever. Doing so m ay result in dam age to the

throttle body.

Test Condition (1) Cont. Between IDL-TLCont. Between PSW-TL

.02" (.5 mm)YesNo

.03" (.7 mm)NoNo

Wide Open ThrottleNoYes

(1)Insert specified feeler gauge between throttle adjustment screw and stop lever.

Door Opening(1) Volts: 1.3L(1) Volts: 1.6L

Fully Closed.5-1.5(2) *

1/8.593.24

1/41.195.60

3/81.785.62

1/22.385.83

5/82.976.02

3/43.566.57

7/84.167.48

Fully Open4.5-5.07.87

(1)Voltage may vary by plus or minus 15 percent.

(2)Voltage not specified.

Page 3 of 7 MITCHELL 1 ARTICLE - I - SYSTEM/COMPONENT TESTS 1991 ENGINE PERFORMANCE Ford Motor Co. - Ford/Merc

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 192 of 454

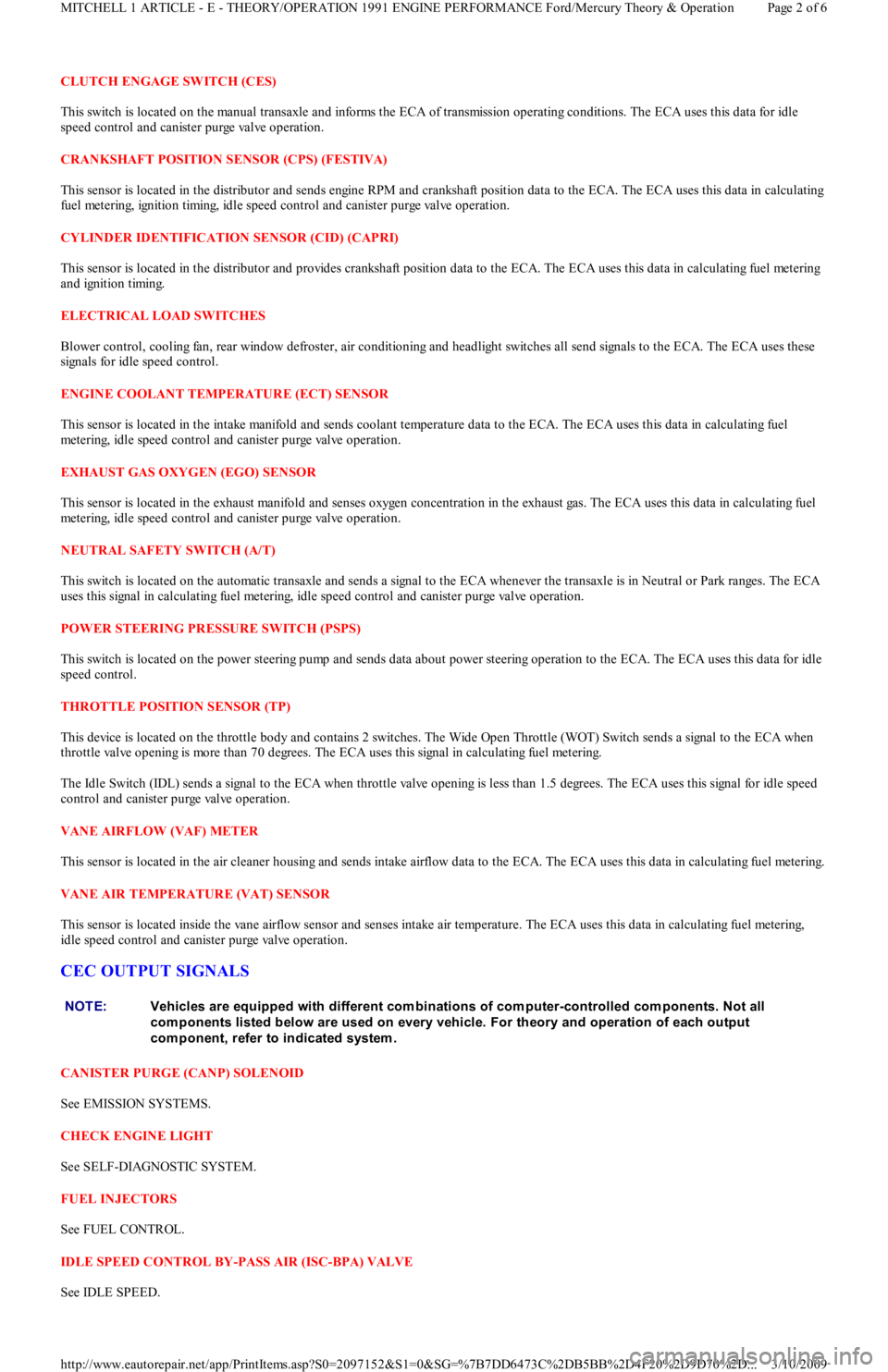

CLUTCH ENGAGE SWITCH (CES)

This switch is located on the manual transaxle and informs the ECA of transmission operating conditions. The ECA uses this data fo r id l e

speed control and canister purge valve operation.

CRANKSHAFT POSITION SENSOR (CPS) (FESTIVA)

This sensor is located in the distributor and sends engine RPM and crankshaft position data to the ECA. The ECA uses this data in calculating

fuel metering, ignition timing, idle speed control and canister purge valve operation.

CYLINDER IDENTIFICATION SENSOR (CID) (CAPRI)

This sensor is located in the distributor and provides crankshaft position data to the ECA. The ECA uses this data in calculating fuel metering

and ignition timing.

ELECTRICAL LOAD SWITCHES

Blower control, cooling fan, rear window defroster, air conditioning and headlight switches all send signals to the ECA. The ECA uses these

signals for idle speed control.

ENGINE COOLANT TEMPERATURE (ECT) SENSOR

This sensor is located in the intake manifold and sends coolant temperature data to the ECA. The ECA uses this data in calculating fuel

metering, idle speed control and canister purge valve operation.

EXHAUST GAS OXYGEN (EGO) SENSOR

This sensor is located in the exhaust manifold and senses oxygen concentration in the exhaust gas. The ECA uses this data in calculating fuel

metering, idle speed control and canister purge valve operation.

NEUTRAL SAFETY SWITCH (A/T)

This switch is located on the automatic transaxle and sends a signal to the ECA whenever the transaxle is in Neutral or Park ranges. The ECA

uses this signal in calculating fuel metering, idle speed control and canister purge valve operation.

POWER STEERING PRESSURE SWITCH (PSPS)

This switch is located on the power steering pump and sends data about power steering operation to the ECA. The ECA uses this data for idle

speed control.

THROTTLE POSITION SENSOR (TP)

This device is located on the throttle body and contains 2 switches. The Wide Open Throttle (WOT) Switch sends a signal to the ECA when

throttle valve opening is more than 70 degrees. The ECA uses this signal in calculating fuel metering.

The Idle Switch (IDL) sends a signal to the ECA when throttle valve opening is less than 1.5 degrees. The ECA uses this signal for idle speed

control and canister purge valve operation.

VANE AIRFLOW (VAF) METER

This sensor is located in the air cleaner housing and sends intake airflow data to the ECA. The ECA uses this data in calculating fuel metering.

VANE AIR TEMPERATURE (VAT) SENSOR

This sensor is located inside the vane airflow sensor and senses intake air temperature. The ECA uses this data in calculating fu el met erin g,

idle speed control and canister purge valve operation.

CEC OUTPUT SIGNALS

CANISTER PURGE (CANP) SOLENOID

See EMISSION SYSTEMS.

CHECK ENGINE LIGHT

See SELF-DIAGNOSTIC SYSTEM.

FUEL INJECTORS

See FUEL CONTROL.

IDLE SPEED CONTROL BY-PASS AIR (ISC-BPA) VALVE

See IDLE SPEED. NOTE:Vehicles are equipped with different com binations of com puter-controlled com ponents. Not all

com ponents listed below are used on every vehicle. For theory and operation of each output

com ponent, refer to indicated system .

Page 2 of 6 MITCHELL 1 ARTICLE - E - THEORY/OPERATION 1991 ENGINE PERFORMANCE Ford/Mercury Theory & Operation

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 210 of 454

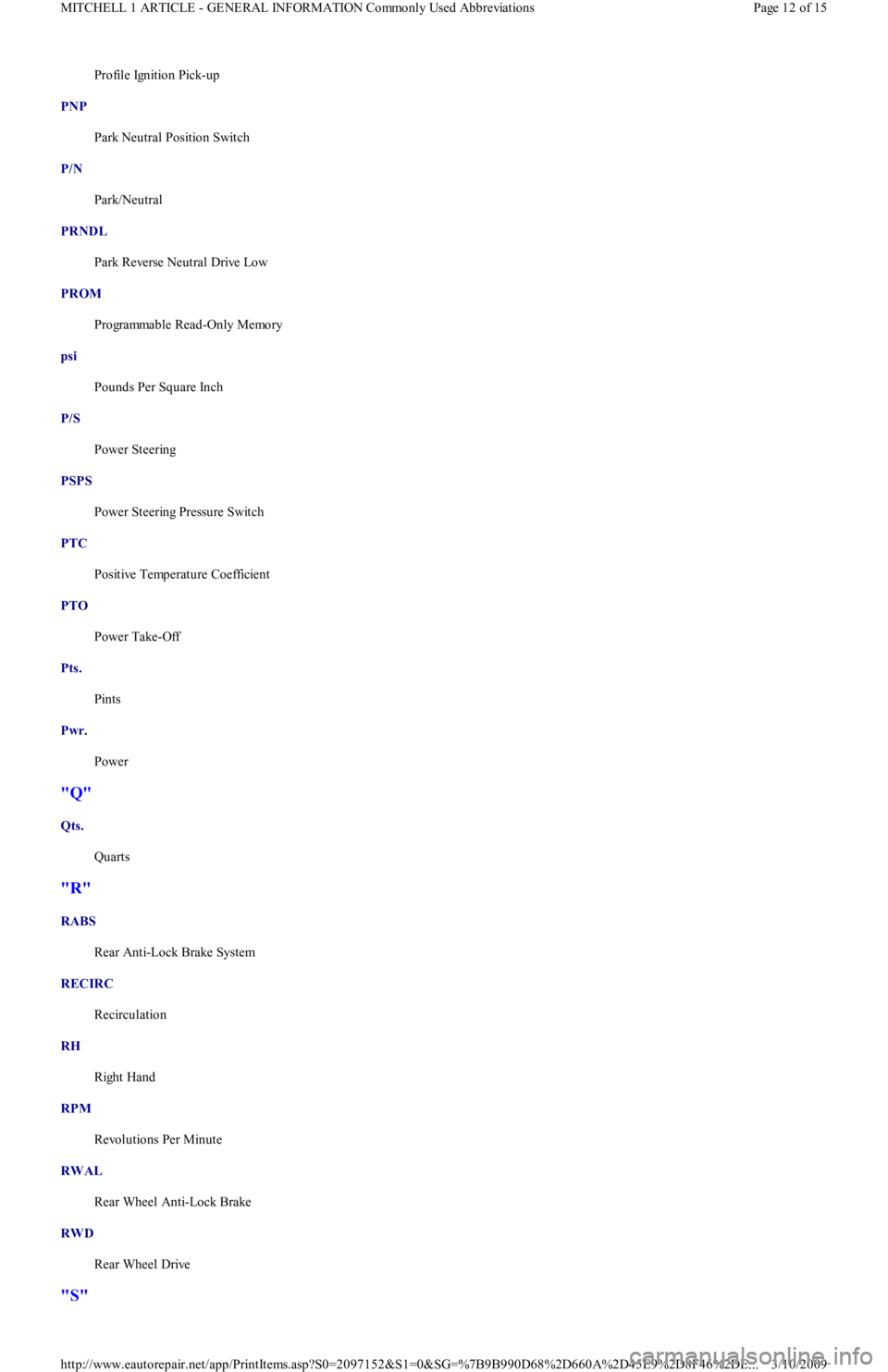

Profile Ignition Pick-up

PNP

Park Neutral Position Switch

P/N

Park/Neutral

PRNDL

Park Reverse Neutral Drive Low

PROM

Programmable Read-Only Memory

psi

Pounds Per Square Inch

P/S

Power Steering

PSPS

Power Steering Pressure Switch

PTC

Positive Temperature Coefficient

PTO

Power Take-Off

Pts.

Pints

Pwr.

Power

"Q"

Qts.

Quarts

"R"

RABS

Rear Anti-Lock Brake System

RECIRC

Recirculation

RH

Right Hand

RPM

Revolutions Per Minute

RWAL

Rear Wheel Anti-Lock Brake

RWD

Rear Wheel Drive

"S"

Page 12 of 15 MITCHELL 1 ARTICLE - GENERAL INFORMATION Commonly Used Abbreviations

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 212 of 454

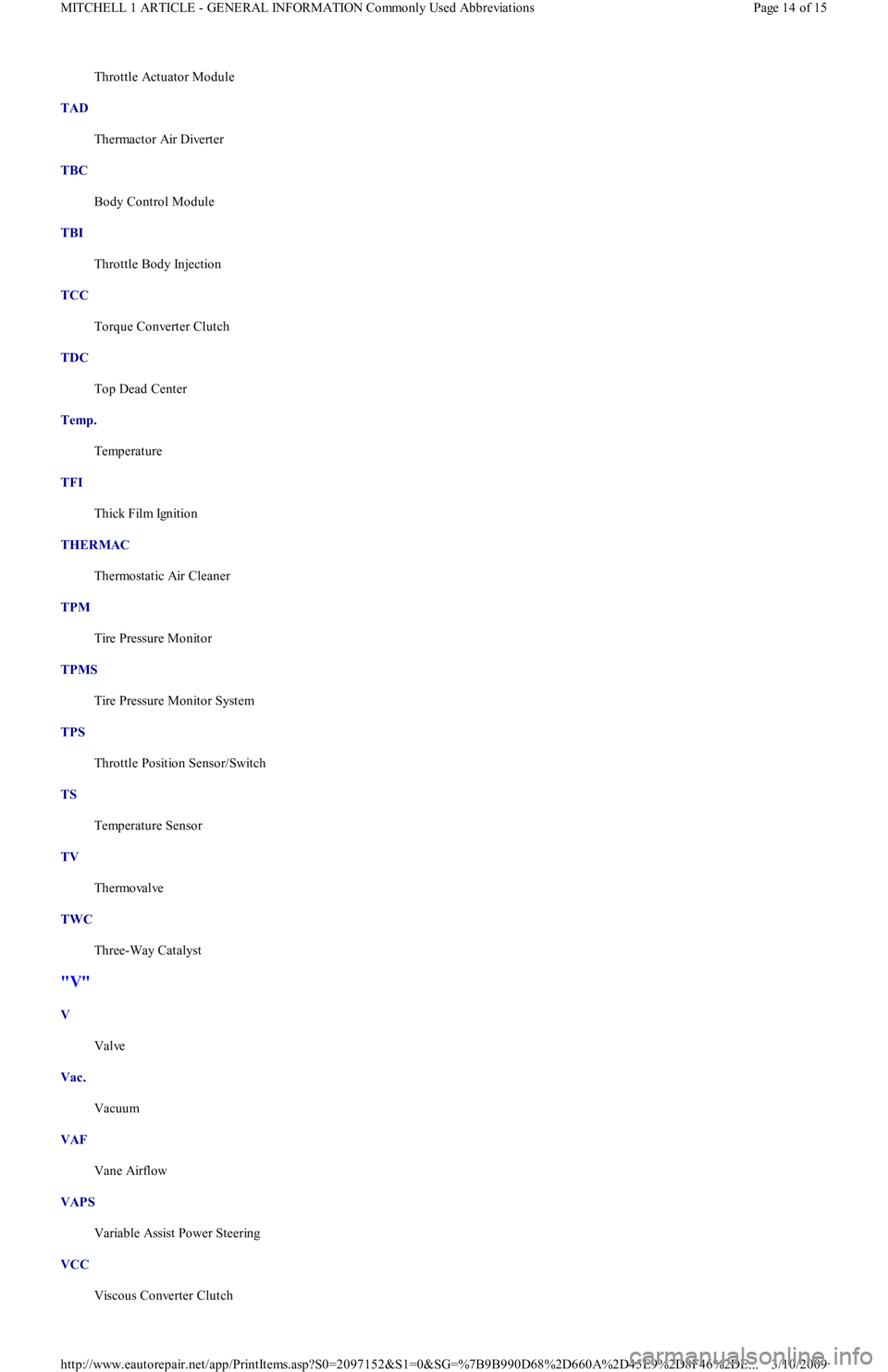

Throttle Actuator Module

TAD

Thermactor Air Diverter

TBC

Body Control Module

TBI

Throttle Body Injection

TCC

Torque Converter Clutch

TDC

Top Dead Center

Temp.

Temperature

TFI

Thick Film Ignition

THERMAC

Thermostatic Air Cleaner

TPM

Tire Pressure Monitor

TPMS

Tire Pressure Monitor System

TPS

Throttle Position Sensor/Switch

TS

Temperature Sensor

TV

Thermovalve

TWC

Three-Way Catalyst

"V"

V

Valve

Vac.

Vacuum

VAF

Vane Airflow

VAPS

Variable Assist Power Steering

VCC

Viscous Converter Clutch

Page 14 of 15 MITCHELL 1 ARTICLE - GENERAL INFORMATION Commonly Used Abbreviations

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 243 of 454

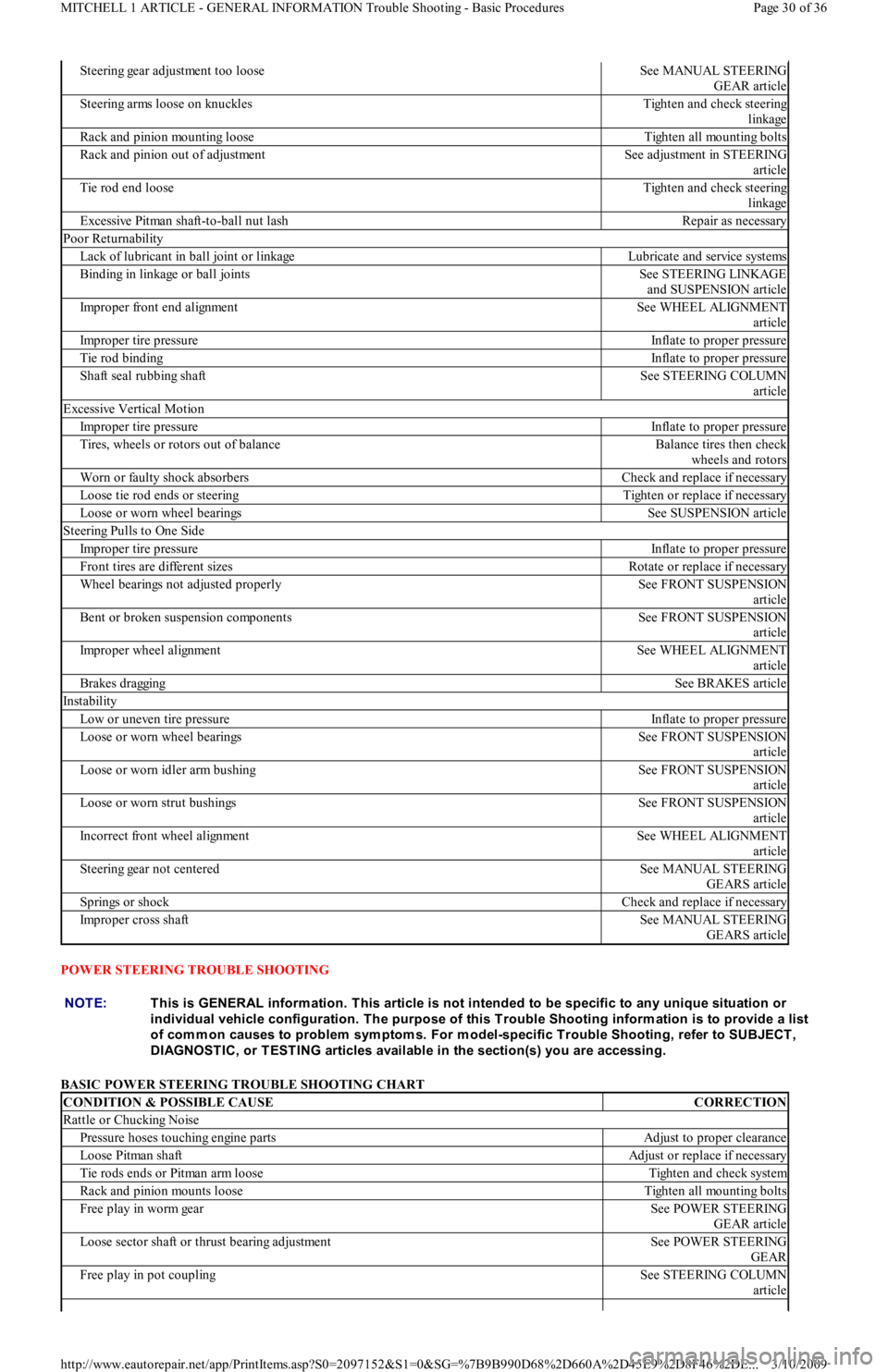

POWER STEERING TROUBLE SHOOTING

BASIC POWER STEERING TROUBLE SHOOTING CHART

Steering gear adjustment too looseSee MANUAL STEERING

GEAR article

Steering arms loose on knucklesTighten and check steering

linkage

Rack and pinion mounting looseTighten all mounting bolts

Rack and pinion out of adjustmentSee adjustment in STEERING

article

Tie rod end looseTighten and check steering

linkage

Excessive Pitman shaft-to-ball nut lashRepair as necessary

Poor Returnability

Lack of lubricant in ball joint or linkageLubricate and service systems

Binding in linkage or ball jointsSee STEERING LINKAGE

and SUSPENSION article

Improper front end alignmentSee WHEEL ALIGNMENT

article

Improper tire pressureInflate to proper pressure

Tie rod bindingInflate to proper pressure

Shaft seal rubbing shaftSee STEERING COLUMN

article

Excessive Vertical Motion

Improper tire pressureInflate to proper pressure

Tires, wheels or rotors out of balanceBalance tires then check

wheels and rotors

Worn or faulty shock absorbersCheck and replace if necessary

Loose tie rod ends or steeringTighten or replace if necessary

Loose or worn wheel bearingsSee SUSPENSION article

Steering Pulls to One Side

Improper tire pressureInflate to proper pressure

Front tires are different sizesRotate or replace if necessary

Wheel bearings not adjusted properlySee FRONT SUSPENSION

article

Bent or broken suspension componentsSee FRONT SUSPENSION

article

Improper wheel alignmentSee WHEEL ALIGNMENT

article

Brakes draggingSee BRAKES article

Instability

Low or uneven tire pressureInflate to proper pressure

Loose or worn wheel bearingsSee FRONT SUSPENSION

article

Loose or worn idler arm bushingSee FRONT SUSPENSION

article

Loose or worn strut bushingsSee FRONT SUSPENSION

article

Incorrect front wheel alignmentSee WHEEL ALIGNMENT

article

Steering gear not centeredSee MANUAL STEERING

GEARS article

Springs or shockCheck and replace if necessary

Improper cross shaftSee MANUAL STEERING

GEARS article

NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to SUBJECT ,

DIAGNOST IC, or T EST ING articles available in the section(s) you are accessing.

CONDITION & POSSIBLE CAUSECORRECTION

Rattle or Chucking Noise

Pressure hoses touching engine partsAdjust to proper clearance

Loose Pitman shaftAdjust or replace if necessary

Tie rods ends or Pitman arm looseTighten and check system

Rack and pinion mounts looseTighten all mounting bolts

Free play in worm gearSee POWER STEERING

GEAR article

Loose sector shaft or thrust bearing adjustmentSee POWER STEERING

GEAR

Free play in pot couplingSee STEERING COLUMN

article

Page 30 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 244 of 454

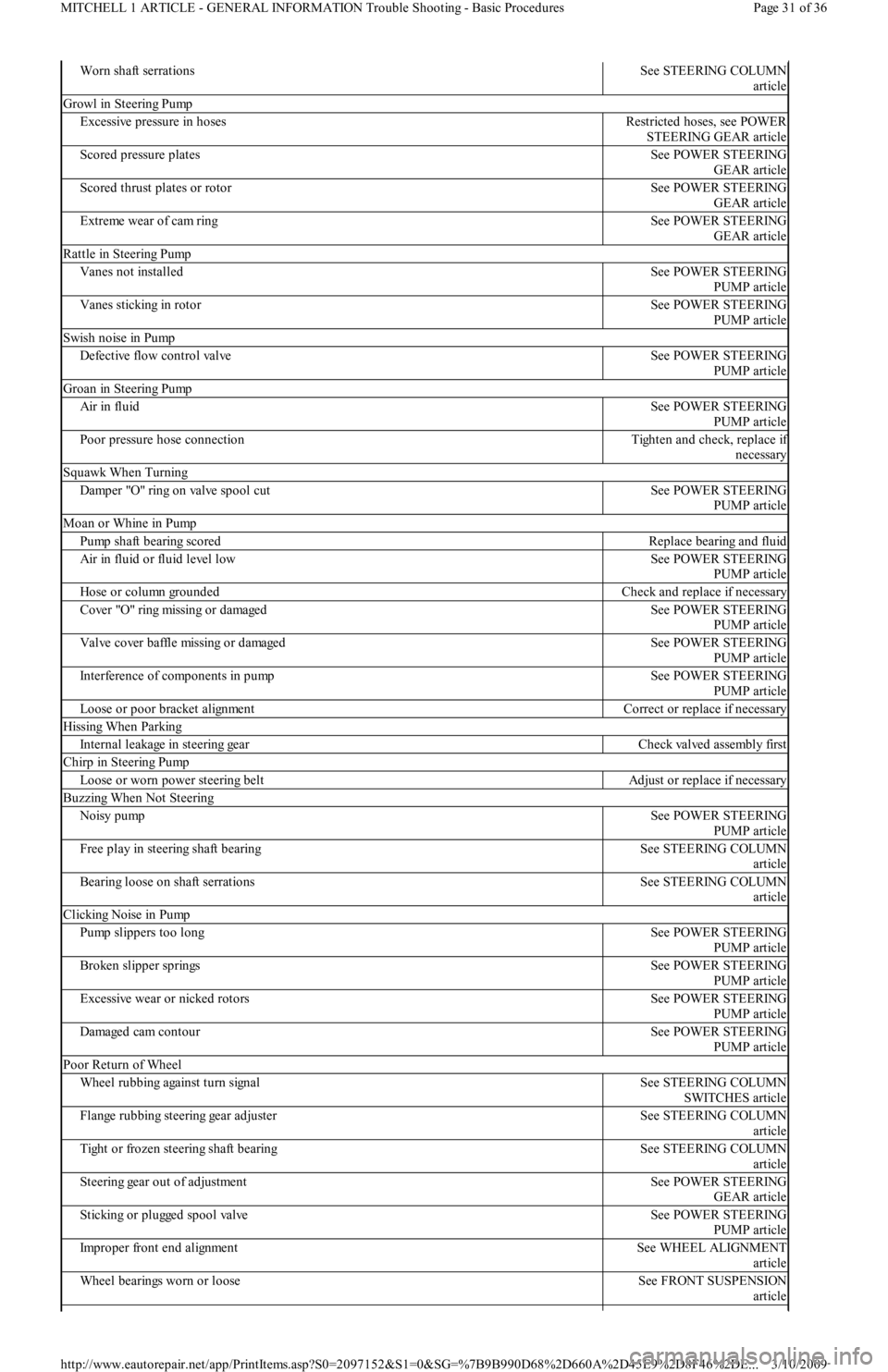

Worn shaft serrationsSee STEERING COLUMN

article

Growl in Steering Pump

Excessive pressure in hosesRestricted hoses, see POWER

STEERING GEAR article

Scored pressure platesSee POWER STEERING

GEAR article

Scored thrust plates or rotorSee POWER STEERING

GEAR article

Extreme wear of cam ringSee POWER STEERING

GEAR article

Rattle in Steering Pump

Vanes not installedSee POWER STEERING

PUMP article

Vanes sticking in rotorSee POWER STEERING

PUMP article

Swish noise in Pump

Defective flow control valveSee POWER STEERING

PUMP article

Groan in Steering Pump

Air in fluidSee POWER STEERING

PUMP article

Poor pressure hose connectionTighten and check, replace if

necessary

Squawk When Turning

Damper "O" ring on valve spool cutSee POWER STEERING

PUMP article

Moan or Whine in Pump

Pump shaft bearing scoredReplace bearing and fluid

Air in fluid or fluid level lowSee POWER STEERING

PUMP article

Hose or column groundedCheck and replace if necessary

Cover "O" ring missing or damagedSee POWER STEERING

PUMP article

Valve cover baffle missing or damagedSee POWER STEERING

PUMP article

Interference of components in pumpSee POWER STEERING

PUMP article

Loose or poor bracket alignmentCorrect or replace if necessary

Hissing When Parking

Internal leakage in steering gearCheck valved assembly first

Chirp in Steering Pump

Loose or worn power steering beltAdjust or replace if necessary

Buzzing When Not Steering

Noisy pumpSee POWER STEERING

PUMP article

Free play in steering shaft bearingSee STEERING COLUMN

article

Bearing loose on shaft serrationsSee STEERING COLUMN

article

Clicking Noise in Pump

Pump slippers too longSee POWER STEERING

PUMP article

Broken slipper springsSee POWER STEERING

PUMP article

Excessive wear or nicked rotorsSee POWER STEERING

PUMP article

Damaged cam contourSee POWER STEERING

PUMP article

Poor Return of Wheel

Wheel rubbing against turn signalSee STEERING COLUMN

SWITCHES article

Flange rubbing steering gear adjusterSee STEERING COLUMN

article

Tight or frozen steering shaft bearingSee STEERING COLUMN

article

Steering gear out of adjustmentSee POWER STEERING

GEAR article

Sticking or plugged spool valveSee POWER STEERING

PUMP article

Improper front end alignmentSee WHEEL ALIGNMENT

article

Wheel bearings worn or looseSee FRONT SUSPENSION

article

Page 31 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...