belt FORD FESTIVA 1991 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 128 of 454

Crankshaft Pulley Bolts10-13 (12-17)

Crankshaft Sprocket Bolt80-87 (108-118)

Power Steering Adjuster Nut27-38 (37-52)

Timing Belt Tensioner Adjuster Bolt14-19 (19-26)

Water Pump Pulley Bolts36-45 (49-61)

INCH Lbs. (N.m)

Camshaft Cover71-97 (8-11)

Timing Belt Cover Bolt71-97 (8-11)

Valve Cover Bolt44-79 (5-9)

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00155957

Page 3 of 3 MITCHELL 1 ARTICLE - FORD 1.3L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 132 of 454

Back To Article

A - ENGINE/VIN ID

1991 ENGINE PERFORMANCE Ford/Mercury - Introduction

APPLICATION

MODEL COVERAGE

VIN DEFINITION

Numbers preceding the explanations in the legend below refer to the sequence of characters as listed on VIN identification label.

SAMPLE VIN

Digit #: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17.

(VIN) K N J P T O 6 H 9 L 6 1 0 0 0 0 0.

VIN Definition

1-3 - Indicates Nation of Origin.

4 - Indicates Restraint System.

5 - Indicates Carline Code.

6-7 - Indicates Body Type.

8 - Indicates Engine Type.

9 - Indicates Check Digit.

10 - Indicates Model Year.

11 - Indicates Assembly Plant.

12-17 - Vehicle Serial Number.

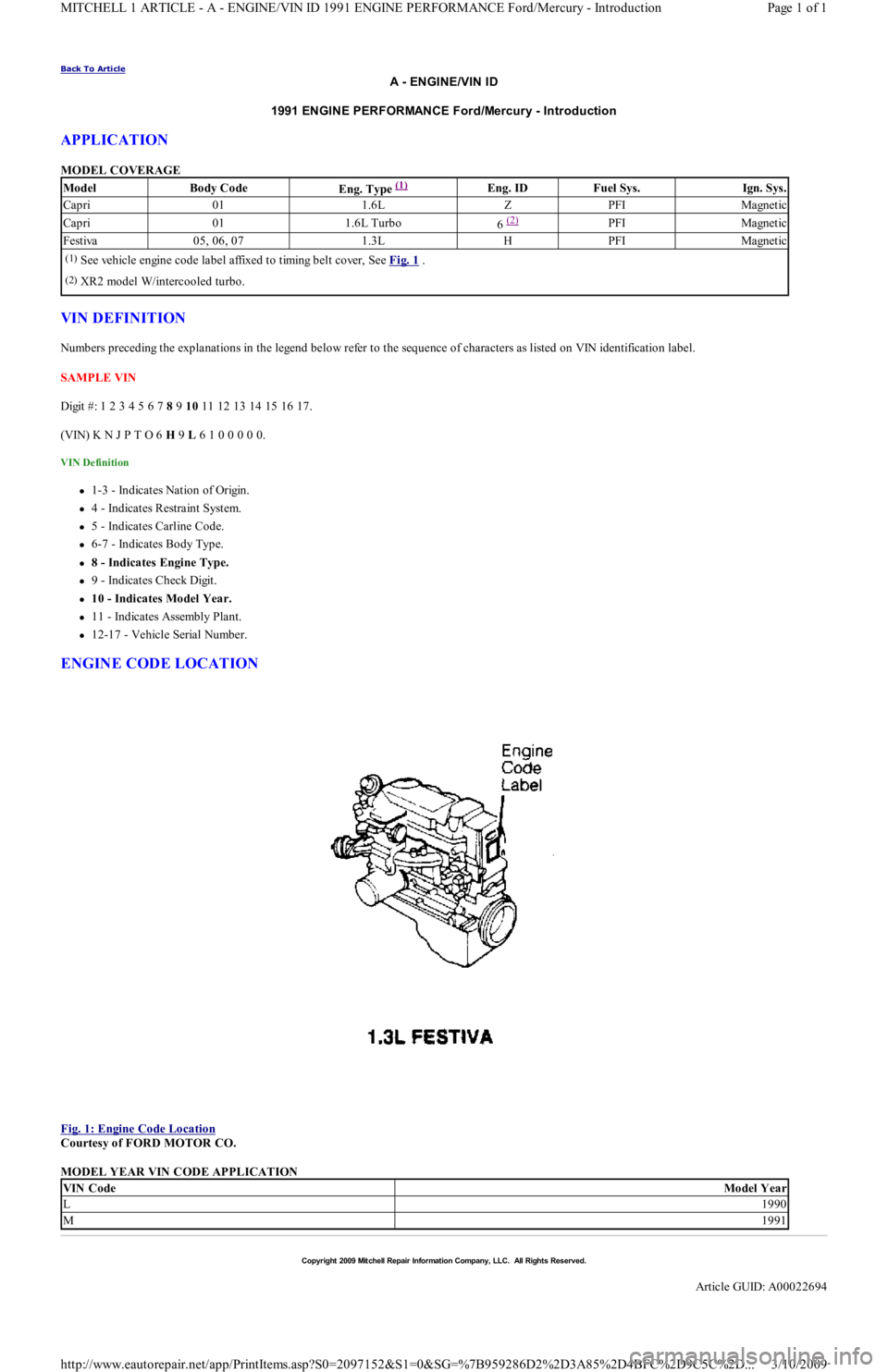

ENGINE CODE LOCATION

Fig. 1: Engine Code Location

Courtesy of FORD MOTOR CO.

MODEL YEAR VIN CODE APPLICATION

ModelBody CodeEng. Type (1) Eng. IDFuel Sys.Ign. Sys.

Capri011.6LZPFIMagnetic

Capri011.6L Turbo6 (2) PFIMagnetic

Festiva05, 06, 071.3LHPFIMagnetic

(1)See vehicle engine code label affixed to timing belt cover, See Fig. 1 .

(2)XR2 model W/intercooled turbo.

VIN CodeModel Year

L1990

M1991

Copyr ight 2009 Mit chell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00022694

Page 1 of 1 MITCHELL 1 ARTICLE - A - ENGINE/VIN ID 1991 ENGINE PERFORMANCE Ford/Mercury - Introduction

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 148 of 454

Removal

Drain radiator and remove negative battery cable. Disconnect throttle cable. Remove air duct from throttle body. Disconnect throttle position

sensor/switch connector. Mark all coolant and vacuum hoses for reassembly reference and remove from throttle body. See Fig. 4

. Remove

intake plenum bolts and remove intake plenum and gasket.

Installation

To install, reverse removal procedure. Use NEW intake plenum-to-intake manifold gasket. Tighten bolts to specification, see TORQUE

SPECIFICATIONS at end of article.

OXYGEN (O2) SENSOR

Removal & Installation

Disconnect negative battery cable. Disconnect wire harness connector, and remove oxygen sensor. If exhaust sensor is difficult to remove, use

rust penetrant to avoid possible damage to exhaust threads. If new sensor is not pre-coated with anti-seize, apply anti-seize compound to

sensor threads. DO NOT remove anti-seize from sensor. To install, tighten sensor and attach wire harness connector.

THROTTLE BODY

Removal & Installation

Drain radiator and remove negative battery cable. Remove resonance chamber. Disconnect throttle cable. Remove air duct. Mark all coolant

and vacuum hoses for reassembly reference and remove from throttle body. Disconnect throttle position sensor/switch connector. Remove

throttle body nuts and bolts. Remove throttle body and gasket. To install, reverse removal procedure using NEW throttle body-to-intake

plenum gasket.

THROTTLE POSITION SENSOR/SWITCH

Removal & Installation

Disconnect negative battery cable. Disconnect throttle position sensor/switch connector. Remove attaching bolts. Remove sensor/switch from

throttle body. To install, reverse removal procedure.

TURBOCHARGER

Removal

1. Drain radiator and remove negative battery cable. Remove throttle body air intake tube. Disconnect intercooler hose from turbocharger

assembly. Disconnect O2 sensor. Remove lower heat shield retaining bolts and lower heat shield from turbocharger. Remove upper heat

shield retaining bolts and upper heat shield from exhaust manifold.

2. Slide O2 sensor wire and guide through upper heat shield. Remove side heat shield retaining bolts from turbocharger, and remove sid e

heat shield. Remove power steering belt. Remove power steering pump through bolt and adjuster nuts and bolts. Disconnect lower

radiator hose from water pump.

3. Pull pump from bracket, and position pump to access mounting bracket retaining nut and bolts. Remove mounting bracket-to-engine nut

and bolts and remove bracket. Remove air cleaner duct retaining screws. Loosen clamp at turbocharger and move duct tube out of way.

Disconnect coolant supply hose at turbocharger.

4. Remove bolt and sealing washers attaching oil supply line at engine block. Raise vehicle on hoist. Remove nuts and washers from

exhaust pipe flange. Remove bolts attaching exhaust hanger to engine block. Slide rubber exhaust hangers from catalytic converter. Pull

exhaust pipe downward and to left side of vehicle. Disconnect oil return hose from turbocharger. Disconnect coolant return hose fro m

turbocharger.

5. Remove turbocharger support bracket retaining bolts. Remove coolant by-pass tube outlet-to-water pump bolts. Lower vehicle. Loosen

retaining clamp bolt on coolant by-pass tube at rear of cylinder head. Remove 11 retaining nuts from exhaust manifold. Position coolant

by-pass tube out of way after pulling bracket from exhaust stud.

6. Remove exhaust manifold by pulling off studs and moving assembly towards right side of engine compartment, clearing cooling fan.

With assembly removed from vehicle, remove turbocharger-to-exhaust manifold nuts. Separate assembly and discard gasket.

Installation

1. Install NEW gasket on exhaust manifold and install turbocharger onto studs. Install turbocharger-to-exhaust manifold nuts. Remo ve o il

supply line from turbocharger. Install NEW exhaust gasket on cylinder head. Install turbocharger and exhaust manifold assembly onto

studs. Install coolant by-pass tube bracket onto exhaust stud. Install 11 retaining nuts onto exhaust manifold.

2. Securely tighten heater tube clamp bolt. Raise vehicle. Install coolant by-pass tube outlet-to-water pump bolts. Install turbocharger

support bracket retaining bolts. Connect coolant return hose to turbocharger. Connect oil return hose to turbocharger. Install exhaust

pipe onto turbocharger, and hand tighten nuts and washers. Install bolts attaching exhaust hanger to engine block.

3. Slide rubber exhaust hangers onto catalytic converter. Tighten exhaust pipe nuts and washers. Lower vehicle. Install bolt and sealing

washers attaching oil supply line at engine block. Install oil supply line onto turbocharger. To complete installation, reverse removal

procedure. Tighten bolts and nuts to specification, see TORQUE SPECIFICATIONS

at end of article. NOTE:T o prevent dust and dirt from entering intake m anifold ports, cover ports with clean cloth after

rem oving intake plenum .

WARNING:DO NOT rem ove oxygen sensor when engine is hot.

NOTE:Clean throttle body exterior before rem oval.

CAUT ION: Before installing turbocharger, put .8 oz. (25 m l) engine oil into turbocharger oil inlet.

Page 4 of 5 MITCHELL 1 ARTICLE - N - REMOVE/INSTALL/OVERHAUL 1991 ENGINE PERFORMANCE Ford/Mercury Removal, O

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 153 of 454

Back To Article

C - SPECIFICATIONS

1991 ENGINE PERFORMANCE Ford/Mercury - Service & Adjustm ent Specifications

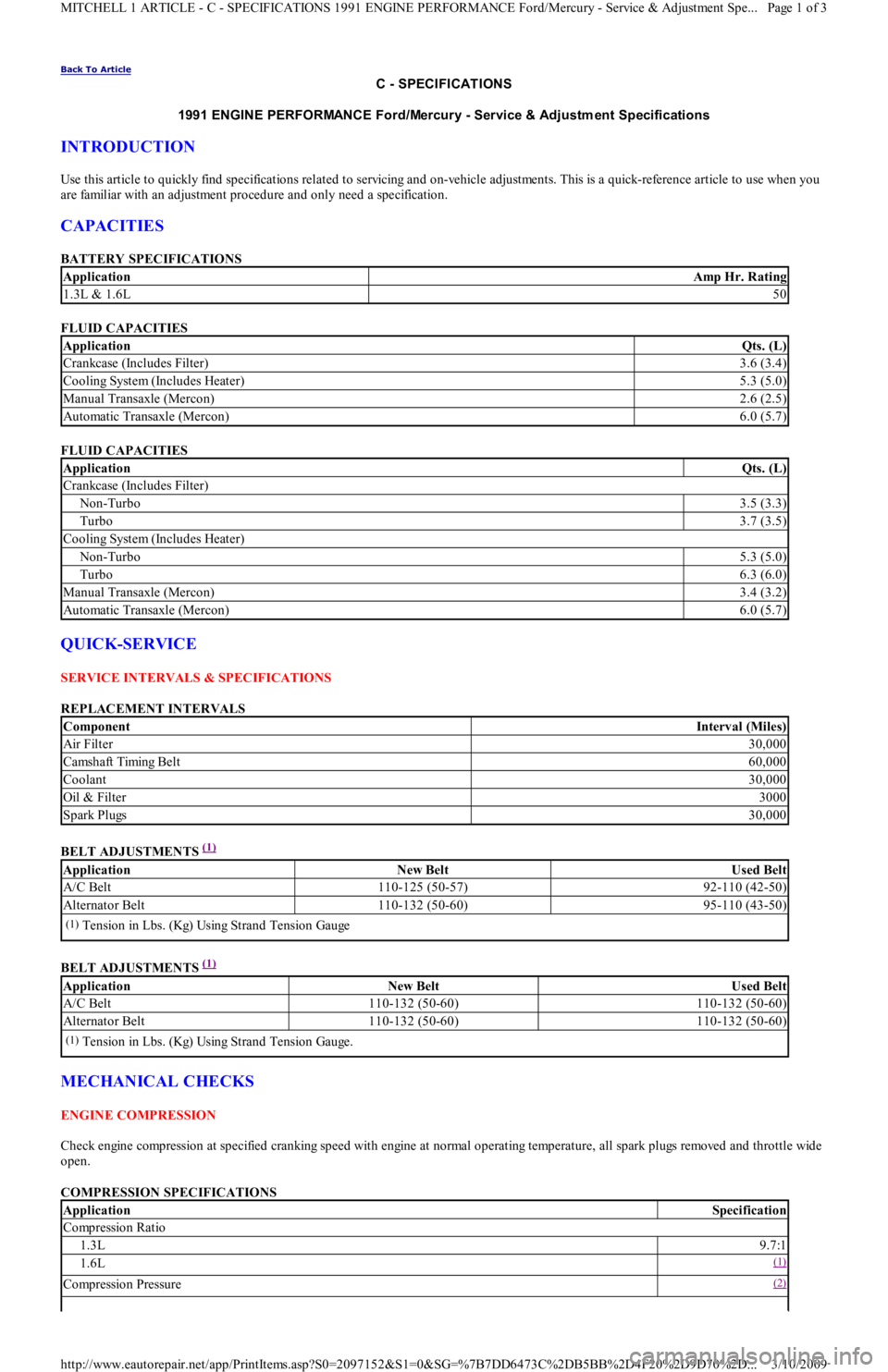

INTRODUCTION

Use this article to quickly find specifications related to servicing and on-vehicle adjustments. This is a quick-reference article to use when you

are familiar with an adjustment procedure and only need a specification.

CAPACITIES

BATTERY SPECIFICATIONS

FLUID CAPACITIES

FLUID CAPACITIES

QUICK-SERVICE

SERVICE INTERVALS & SPECIFICATIONS

REPLACEMENT INTERVALS

BELT ADJUSTMENTS

(1)

BELT ADJUSTMENTS

(1)

MECHANICAL CHECKS

ENGINE COMPRESSION

Check engine compression at specified cranking speed with engine at normal operating temperature, all spark plugs removed and throttle wide

open.

COMPRESSION SPECIFICATIONS

ApplicationAmp Hr. Rating

1.3L & 1.6L50

ApplicationQts. (L)

Crankcase (Includes Filter)3.6 (3.4)

Cooling System (Includes Heater)5.3 (5.0)

Manual Transaxle (Mercon)2.6 (2.5)

Automatic Transaxle (Mercon)6.0 (5.7)

ApplicationQts. (L)

Crankcase (Includes Filter)

Non-Turbo3.5 (3.3)

Turbo3.7 (3.5)

Cooling System (Includes Heater)

Non-Turbo5.3 (5.0)

Turbo6.3 (6.0)

Manual Transaxle (Mercon)3.4 (3.2)

Automatic Transaxle (Mercon)6.0 (5.7)

ComponentInterval (Miles)

Air Filter30,000

Camsh aft Timin g Bel t60,000

Coolant30,000

Oil & Filter3000

Spark Plugs30,000

ApplicationNew BeltUsed Belt

A/C Belt110-125 (50-57)92-110 (42-50)

Alternator Belt110-132 (50-60)95-110 (43-50)

(1)Tension in Lbs. (Kg) Using Strand Tension Gauge

ApplicationNew BeltUsed Belt

A/C Belt110-132 (50-60)110-132 (50-60)

Alternator Belt110-132 (50-60)110-132 (50-60)

(1)Tension in Lbs. (Kg) Using Strand Tension Gauge.

ApplicationSpecification

Compression Ratio

1.3L9.7:1

1.6L(1)

Compression Pressure(2)

Page 1 of 3 MITCHELL 1 ARTICLE - C - SPECIFICATIONS 1991 ENGINE PERFORMANCE Ford/Mercury - Service & Adjustment Spe

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 214 of 454

Back To Article

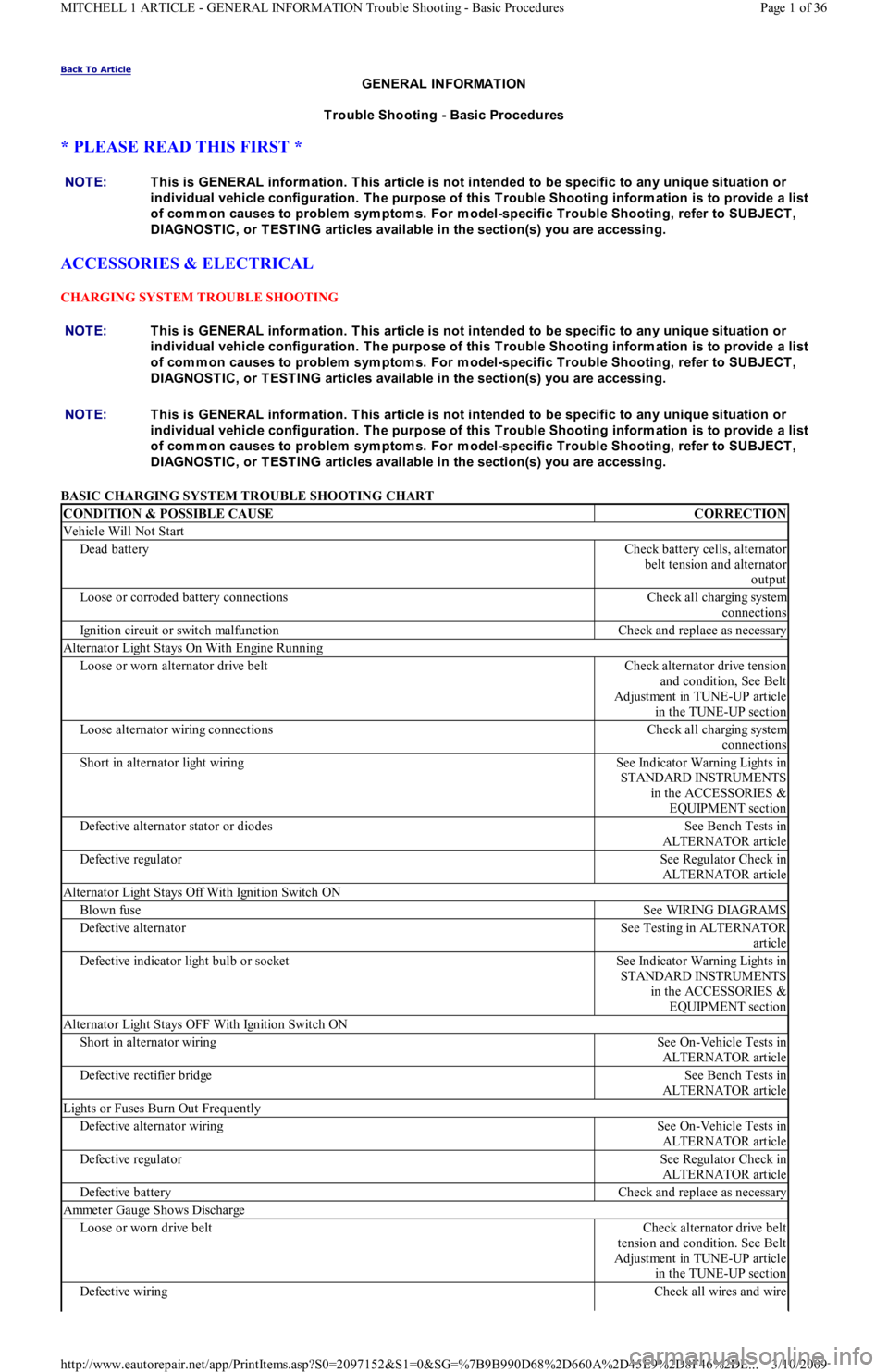

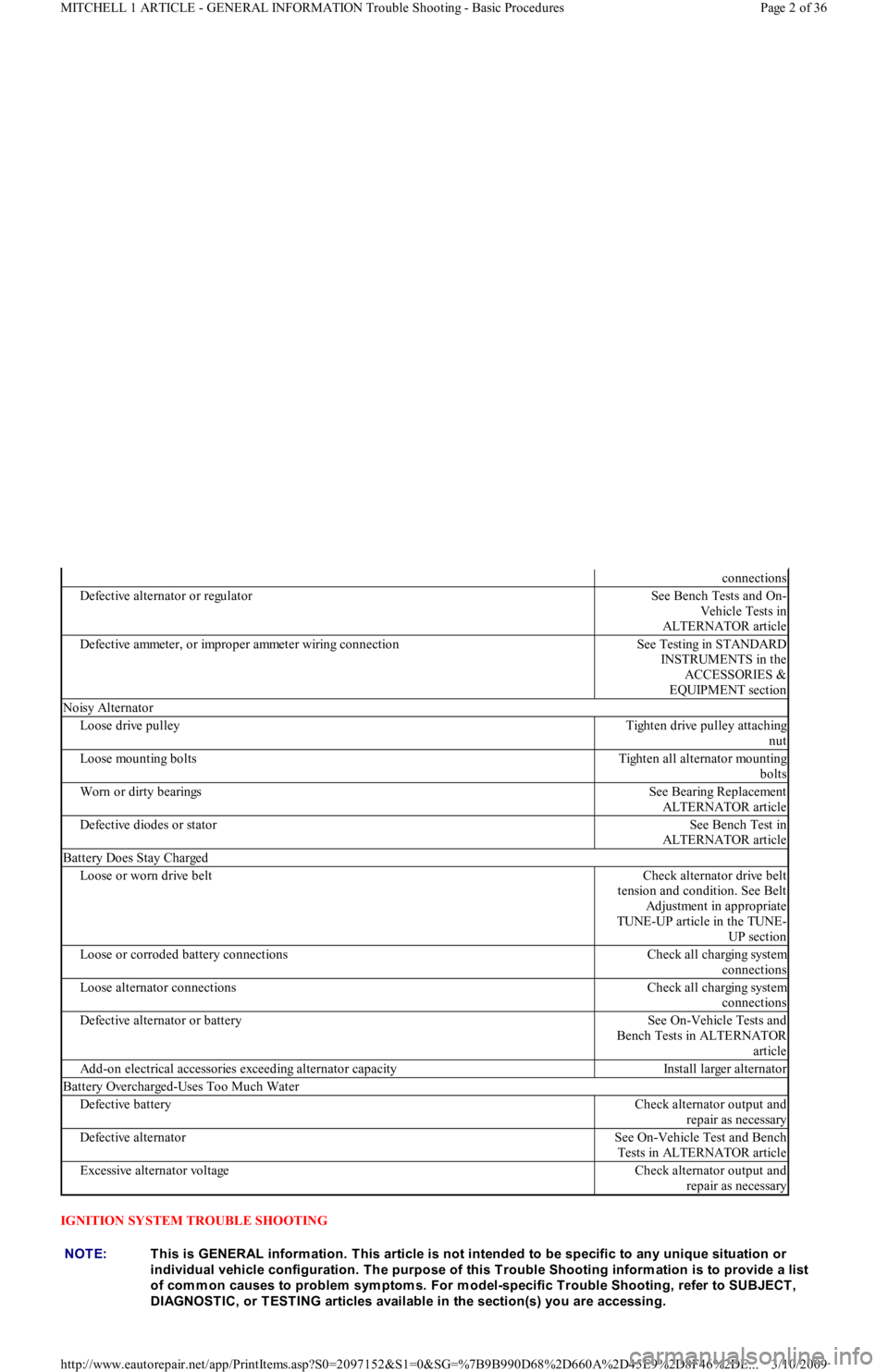

GENERAL INFORMATION

T rouble Shooting - Basic Procedures

* PLEASE READ THIS FIRST *

ACCESSORIES & ELECTRICAL

CHARGING SYSTEM TROUBLE SHOOTING

BASIC CHARGING SYSTEM TROUBLE SHOOTING CHART NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to SUBJECT ,

DIAGNOST IC, or T EST ING articles available in the section(s) you are accessing.

NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to SUBJECT ,

DIAGNOST IC, or T EST ING articles available in the section(s) you are accessing.

NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to SUBJECT ,

DIAGNOST IC, or T EST ING articles available in the section(s) you are accessing.

CONDITION & POSSIBLE CAUSECORRECTION

Vehicle Will Not Start

Dead batteryCheck battery cells, alternator

belt tension and alternator

output

Loose or corroded battery connectionsCheck all charging system

connections

Ignition circuit or switch malfunctionCheck and replace as necessary

Alternator Light Stays On With Engine Running

Loose or worn alternator drive beltCheck alternator drive tension

and condition, See Belt

Adjustment in TUNE-UP article

in the TUNE-UP section

Loose alternator wiring connectionsCheck all charging system

connections

Short in alternator light wiringSee Indicator Warning Lights in

STANDARD INSTRUMENTS

in the ACCESSORIES &

EQUIPMENT section

Defective alternator stator or diodesSee Bench Tests in

ALTERNATOR article

Defective regulatorSee Regulator Check in

ALTERNATOR article

Alternator Light Stays Off With Ignition Switch ON

Blown fuseSee WIRING DIAGRAMS

Defective alternatorSee Testing in ALTERNATOR

article

Defective indicator light bulb or socketSee Indicator Warning Lights in

STANDARD INSTRUMENTS

in the ACCESSORIES &

EQUIPMENT section

Alternator Light Stays OFF With Ignition Switch ON

Short in alternator wiringSee On-Vehicle Tests in

ALTERNATOR article

Defective rectifier bridgeSee Bench Tests in

ALTERNATOR article

Lights or Fuses Burn Out Frequently

Defective alternator wiringSee On-Vehicle Tests in

ALTERNATOR article

Defective regulatorSee Regulator Check in

ALTERNATOR article

Defective batteryCheck and replace as necessary

Ammeter Gauge Shows Discharge

Loose or worn drive beltCheck alternator drive belt

tension and condition. See Belt

Adjustment in TUNE-UP article

in the TUNE-UP section

Defective wiringCheck all wires and wire

Page 1 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 215 of 454

IGNITION SYSTEM TROUBLE SHOOTING

connections

Defective alternator or regulatorSee Bench Tests and On-

Vehicle Tests in

ALTERNATOR article

Defective ammeter, or improper ammeter wiring connectionSee Testing in STANDARD

INSTRUMENTS in the

ACCESSORIES &

EQUIPMENT section

Noisy Alternator

Loose drive pulleyTighten drive pulley attaching

nut

Loose mounting boltsTighten all alternator mounting

bolts

Worn or dirty bearingsSee Bearing Replacement

ALTERNATOR article

Defective diodes or statorSee Bench Test in

ALTERNATOR article

Battery Does Stay Charged

Loose or worn drive beltCheck alternator drive belt

tension and condition. See Belt

Adjustment in appropriate

TUNE-UP article in the TUNE-

UP section

Loose or corroded battery connectionsCheck all charging system

connections

Loose alternator connectionsCheck all charging system

connections

Defective alternator or batterySee On-Vehicle Tests and

Bench Tests in ALTERNATOR

article

Add-on electrical accessories exceeding alternator capacityInstall larger alternator

Battery Overcharged-Uses Too Much Water

Defective batteryCheck alternator output and

repair as necessary

Defective alternatorSee On-Vehicle Test and Bench

Tests in ALTERNATOR article

Excessive alternator voltageCheck alternator output and

repair as necessary

NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to SUBJECT ,

DIAGNOST IC, or T EST ING articles available in the section(s) you are accessing.

Page 2 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 219 of 454

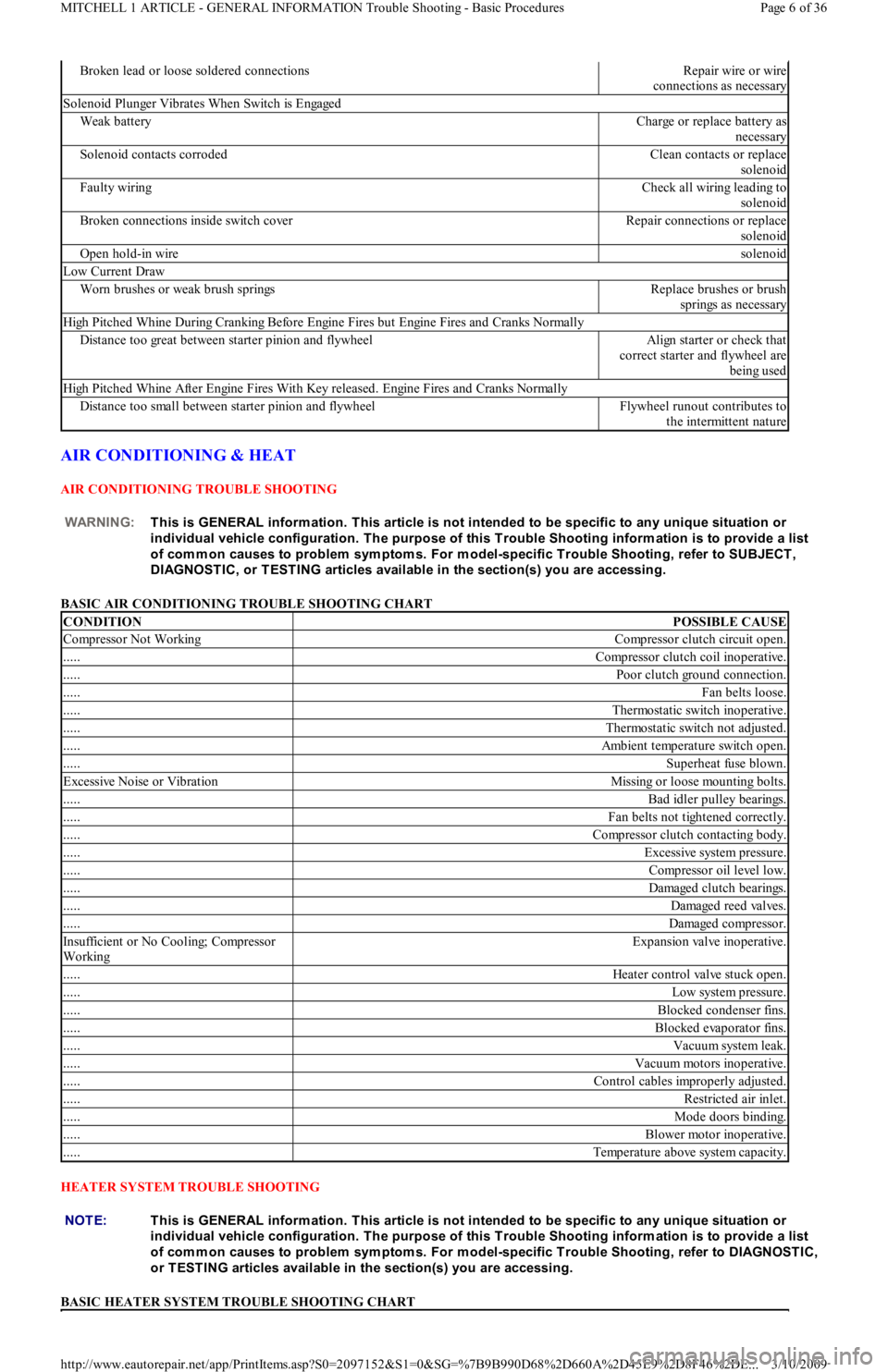

AIR CONDITIONING & HEAT

AIR CONDITIONING TROUBLE SHOOTING

BASIC AIR CONDITIONING TROUBLE SHOOTING CHART

HEATER SYSTEM TROUBLE SHOOTING

BASIC HEATER SYSTEM TROUBLE SHOOTING CHART

Broken lead or loose soldered connectionsRepair wire or wire

connections as necessary

Solenoid Plunger Vibrates When Switch is Engaged

Weak batteryCharge or replace battery as

necessary

Solenoid contacts corrodedClean contacts or replace

solenoid

Faulty wiringCheck all wiring leading to

solenoid

Broken connections inside switch coverRepair connections or replace

solenoid

Open hold-in wiresolenoid

Low Current Draw

Worn brushes or weak brush springsReplace brushes or brush

springs as necessary

High Pitched Whine During Cranking Before Engine Fires but Engine Fires and Cranks Normally

Distance too great between starter pinion and flywheelAlign starter or check that

correct starter and flywheel are

being used

High Pitched Whine After Engine Fires With Key released. Engine Fires and Cranks Normally

Distance too small between starter pinion and flywheelFlywheel runout contributes to

the intermittent nature

WARNING:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to SUBJECT ,

DIAGNOST IC, or T EST ING articles available in the section(s) you are accessing.

CONDITIONPOSSIBLE CAUSE

Compressor Not WorkingCompressor clutch circuit open.

.....Compressor clutch coil inoperative.

.....Poor clutch ground connection.

.....Fan belts loose.

.....Thermostatic switch inoperative.

.....Thermostatic switch not adjusted.

.....Ambient temperature switch open.

.....Superheat fuse blown.

Excessive Noise or VibrationMissing or loose mounting bolts.

.....Bad idler pulley bearings.

.....Fan belts not tightened correctly.

.....Compressor clutch contacting body.

.....Excessive system pressure.

.....Compressor oil level low.

.....Damaged clutch bearings.

.....Damaged reed valves.

.....Damaged compressor.

In su fficien t o r No Co o l in g; Co mp resso r

WorkingExpansion valve inoperative.

.....Heater control valve stuck open.

.....Low system pressure.

.....Blocked condenser fins.

.....Blocked evaporator fins.

.....Vacuum system leak.

.....Vacuum motors inoperative.

.....Control cables improperly adjusted.

.....Restricted air inlet.

.....Mode doors binding.

.....Blower motor inoperative.

.....Temperature above system capacity.

NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to DIAGNOST IC,

or T EST ING articles available in the section(s) you are accessing.

Page 6 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

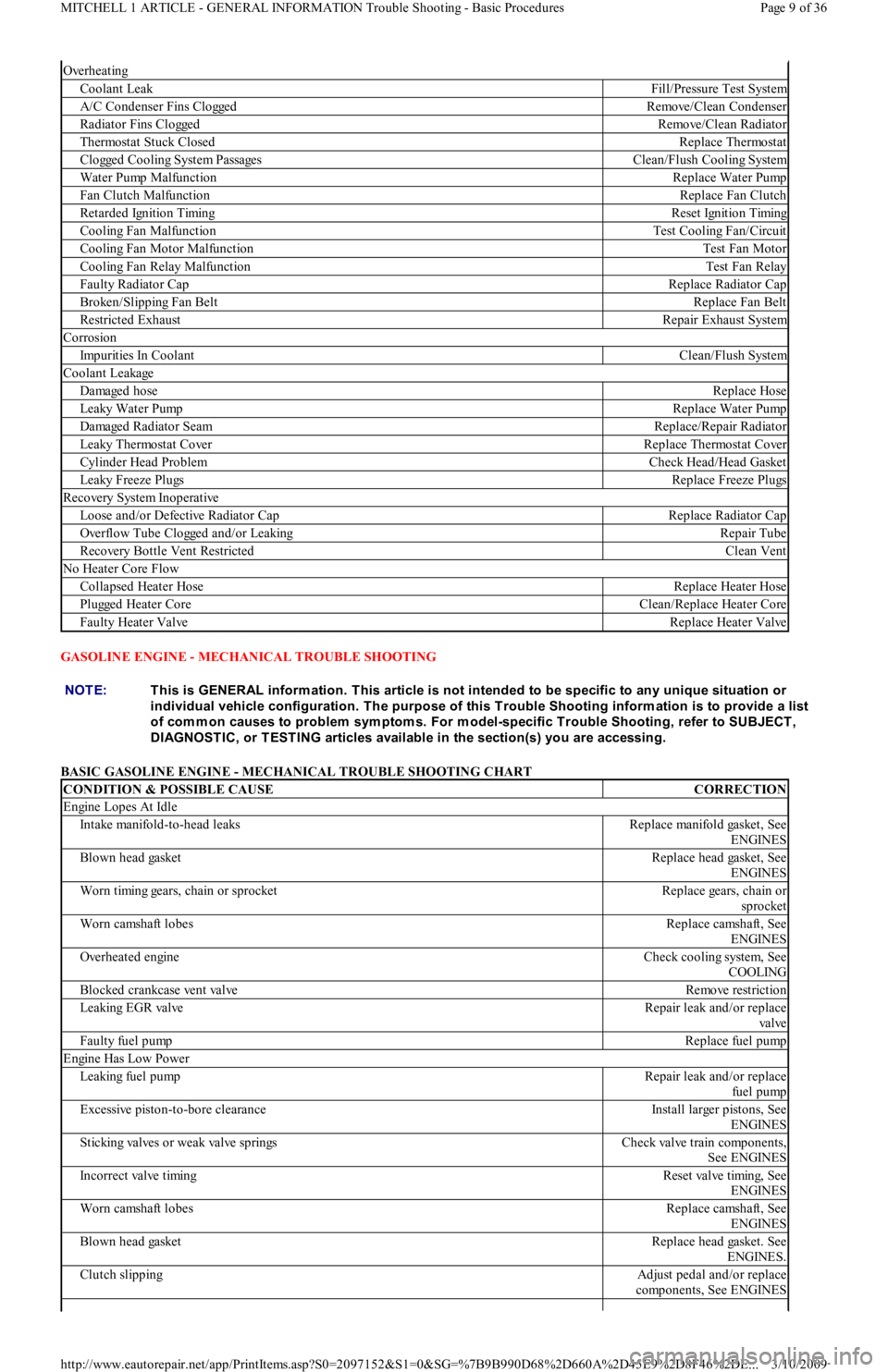

Page 222 of 454

GASOLINE ENGINE - MECHANICAL TROUBLE SHOOTING

BASIC GASOLINE ENGINE - MECHANICAL TROUBLE SHOOTING CHART

Overheating

Coolant LeakFill/Pressure Test System

A/C Condenser Fins CloggedRemove/Clean Condenser

Radiator Fins CloggedRemove/Clean Radiator

Thermostat Stuck ClosedReplace Thermostat

C l o gge d C o o l in g S yst e m P a ssa ge sClean/Flush Cooling System

Water Pump MalfunctionReplace Water Pump

Fan Clutch MalfunctionReplace Fan Clutch

Retarded Ignition TimingReset Ignition Timing

Cooling Fan MalfunctionTest Cooling Fan/Circuit

Cooling Fan Motor MalfunctionTest Fan Motor

Cooling Fan Relay MalfunctionTest Fan Relay

Faulty Radiator CapReplace Radiator Cap

Broken/Slipping Fan BeltReplace Fan Belt

Restricted ExhaustRepair Exhaust System

Corrosion

Impurities In CoolantClean/Flush System

Coolant Leakage

Damaged hoseReplace Hose

Leaky Water PumpReplace Water Pump

Damaged Radiator SeamReplace/Repair Radiator

Leaky Thermostat CoverReplace Thermostat Cover

Cylinder Head ProblemCheck Head/Head Gasket

Leaky Freeze PlugsReplace Freeze Plugs

Recovery System Inoperative

Loose and/or Defective Radiator CapReplace Radiator Cap

Overflow Tube Clogged and/or LeakingRepair Tube

Recovery Bottle Vent RestrictedClean Vent

No Heater Core Flow

Collapsed Heater HoseReplace Heater Hose

Pl u gge d He a t e r C o r eClean/Replace Heater Core

Faulty Heater ValveReplace Heater Valve

NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to SUBJECT ,

DIAGNOST IC, or T EST ING articles available in the section(s) you are accessing.

CONDITION & POSSIBLE CAUSECORRECTION

Engine Lopes At Idle

In t ake man ifo l d -t o -h ead l eaksReplace manifold gasket, See

ENGINES

Blown head gasketReplace head gasket, See

ENGINES

Worn timing gears, chain or sprocketReplace gears, chain or

sprocket

Worn camshaft lobesReplace camshaft, See

ENGINES

Overheated engineCheck cooling system, See

COOLING

Blocked crankcase vent valveRemove restriction

Le a kin g E GR va l veRepair leak and/or replace

va l ve

Faulty fuel pumpReplace fuel pump

Engine Has Low Power

Leaking fuel pumpRepair leak and/or replace

fu el p u mp

Excessive piston-to-bore clearanceInstall larger pistons, See

ENGINES

Sticking valves or weak valve springsCheck valve train components,

See ENGINES

Incorrect valve timingReset valve timing, See

ENGINES

Worn camshaft lobesReplace camshaft, See

ENGINES

Blown head gasketReplace head gasket. See

ENGINES.

Clutch slippingAdjust pedal and/or replace

components, See ENGINES

Page 9 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

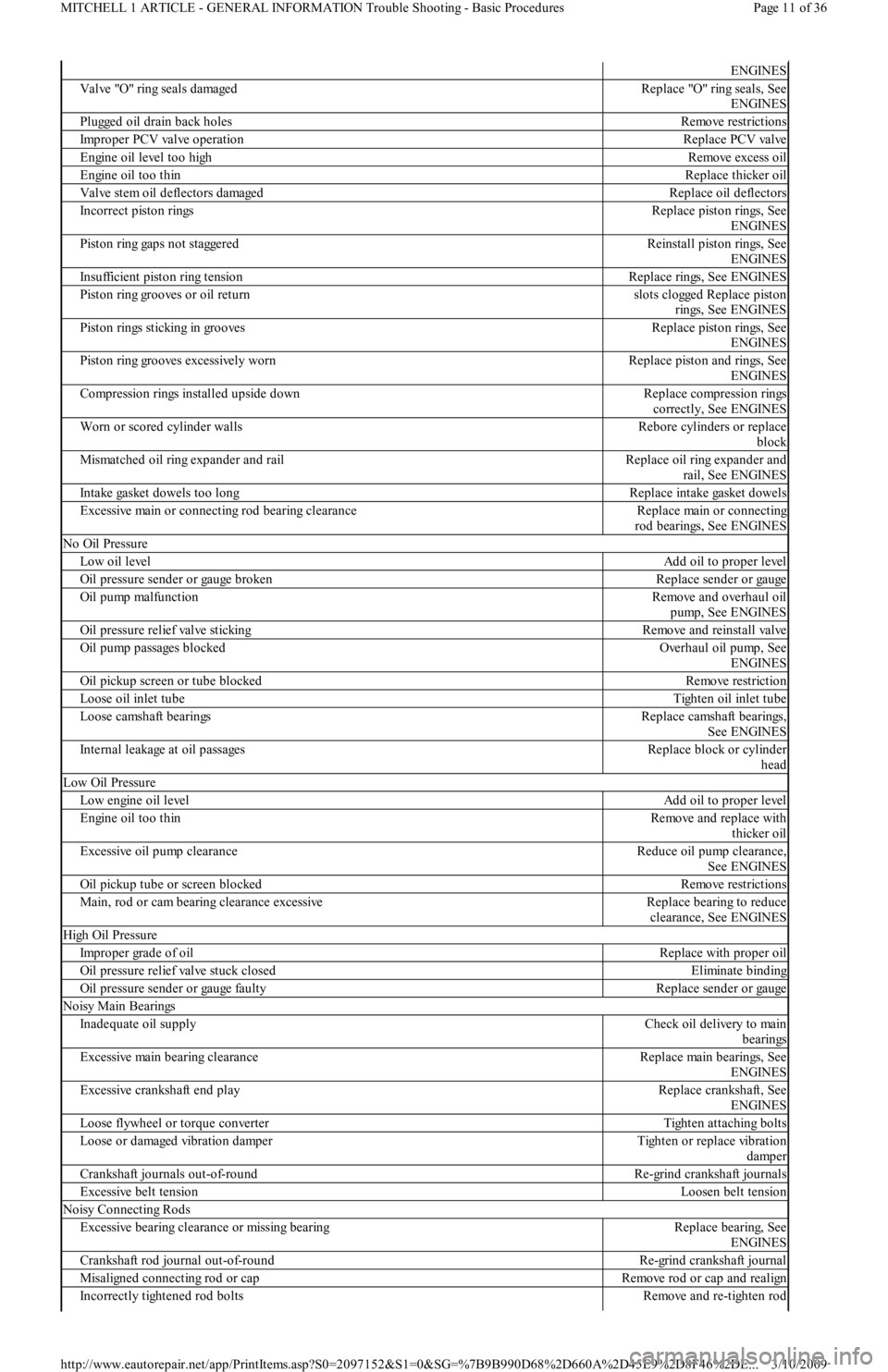

Page 224 of 454

ENGINES

Valve "O" ring seals damagedReplace "O" ring seals, See

ENGINES

Plugged oil drain back holesRemove restrictions

Improper PCV valve operationReplace PCV valve

Engine oil level too highRemove excess oil

Engine oil too thinReplace thicker oil

Valve stem oil deflectors damagedReplace oil deflectors

Incorrect piston ringsReplace piston rings, See

ENGINES

Piston ring gaps not staggeredReinstall piston rings, See

ENGINES

Insufficient piston ring tensionReplace rings, See ENGINES

Piston ring grooves or oil returnslots clogged Replace piston

rings, See ENGINES

Piston rings sticking in groovesReplace piston rings, See

ENGINES

Piston ring grooves excessively wornReplace piston and rings, See

ENGINES

Compression rings installed upside downReplace compression rings

correctly, See ENGINES

Worn or scored cylinder wallsRebore cylinders or replace

block

Mismatched oil ring expander and railReplace oil ring expander and

rail, See ENGINES

Intake gasket dowels too longReplace intake gasket dowels

Excessive main or connecting rod bearing clearanceReplace main or connecting

rod bearings, See ENGINES

No Oil Pressure

Low oil levelAdd oil to proper level

Oil pressure sender or gauge brokenReplace sender or gauge

Oil pump malfunctionRemove and overhaul oil

pump, See ENGINES

Oil pressure relief valve stickingR e mo ve a n d r e in st a l l va l ve

Oil pump passages blockedOverhaul oil pump, See

ENGINES

Oil pickup screen or tube blockedRemove restriction

Loose oil inlet tubeTighten oil inlet tube

Loose camshaft bearingsReplace camshaft bearings,

See ENGINES

Internal leakage at oil passagesReplace block or cylinder

head

Low Oil Pressure

Low engine oil levelAdd oil to proper level

Engine oil too thinRemove and replace with

thicker oil

Excessive oil pump clearanceReduce oil pump clearance,

See ENGINES

Oil pickup tube or screen blockedRemove restrictions

Main, rod or cam bearing clearance excessiveReplace bearing to reduce

clearance, See ENGINES

High Oil Pressure

Improper grade of oilReplace with proper oil

Oil pressure relief valve stuck closedEliminate binding

Oil pressure sender or gauge faultyReplace sender or gauge

Noisy Main Bearings

Inadequate oil supplyCheck oil delivery to main

bearings

Excessive main bearing clearanceReplace main bearings, See

ENGINES

Excessive crankshaft end playReplace crankshaft, See

ENGINES

Loose flywheel or torque converterTighten attaching bolts

Loose or damaged vibration damperTighten or replace vibration

damper

Crankshaft journals out-of-roundRe-grind crankshaft journals

Excessive belt tensionLoosen belt tension

Noisy Connecting Rods

Excessive bearing clearance or missing bearingReplace bearing, See

ENGINES

Crankshaft rod journal out-of-roundRe-grind crankshaft journal

Misaligned connecting rod or capRemove rod or cap and realign

Incorrectly tightened rod boltsRemove and re-tighten rod

Page 11 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 229 of 454

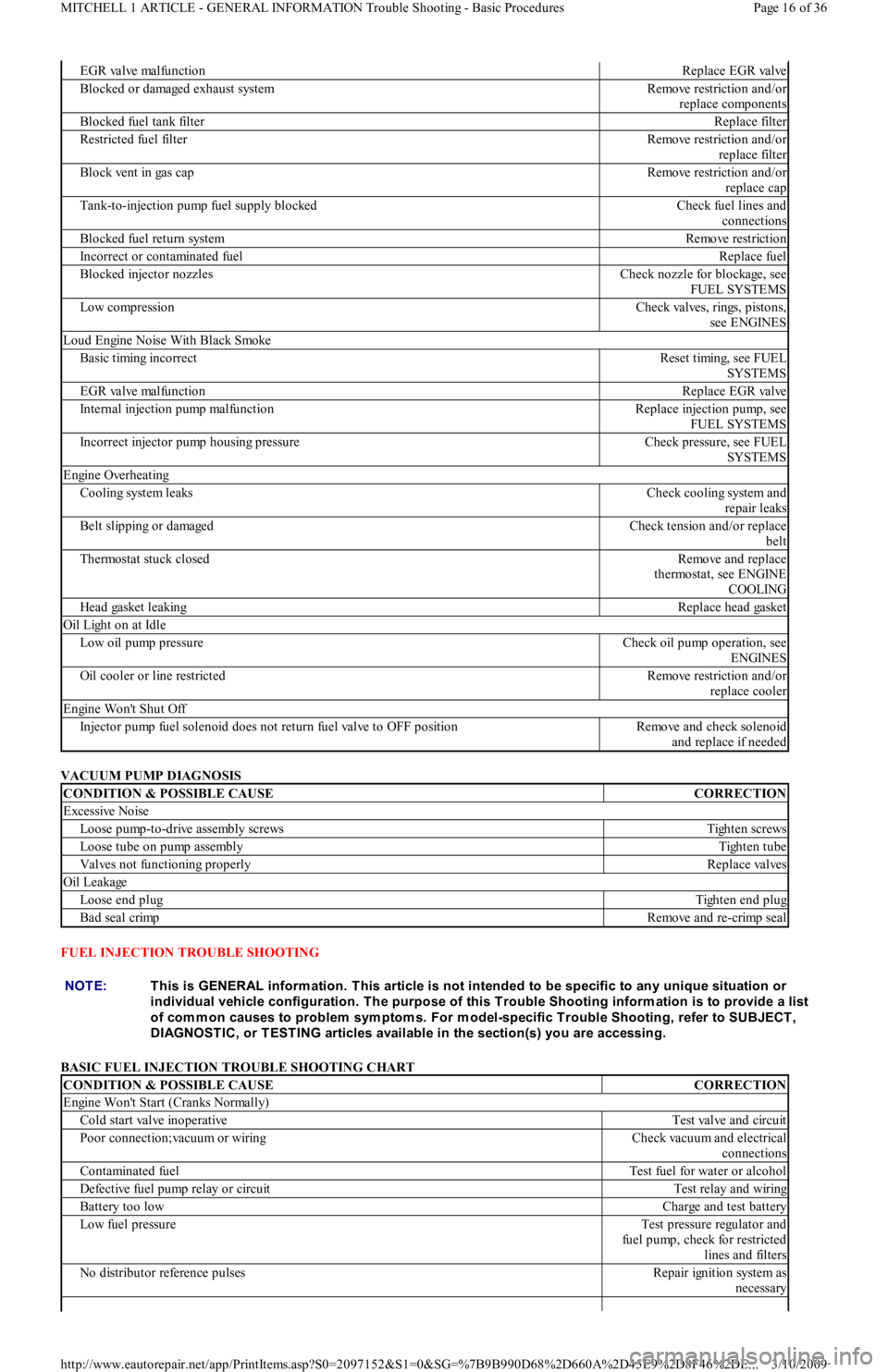

VACUUM PUMP DIAGNOSIS

FUEL INJECTION TROUBLE SHOOTING

BASIC FUEL INJECTION TROUBLE SHOOTING CHART

EGR valve malfunctionReplace EGR valve

Blocked or damaged exhaust systemRemove restriction and/or

replace components

Blocked fuel tank filterReplace filter

Restricted fuel filterRemove restriction and/or

replace filter

Block vent in gas capRemove restriction and/or

replace cap

Tank-to-injection pump fuel supply blockedCheck fuel lines and

connections

Blocked fuel return systemRemove restriction

Incorrect or contaminated fuelReplace fuel

Blocked injector nozzlesCheck nozzle for blockage, see

FUEL SYSTEMS

Low compressionCheck valves, rings, pistons,

see ENGINES

Loud Engine Noise With Black Smoke

Basic timing incorrectReset timing, see FUEL

SYSTEMS

EGR valve malfunctionReplace EGR valve

Internal injection pump malfunctionReplace injection pump, see

FUEL SYSTEMS

Incorrect injector pump housing pressureCheck pressure, see FUEL

SYSTEMS

Engine Overheating

Cooling system leaksCheck cooling system and

repair leaks

Belt slipping or damagedCheck tension and/or replace

belt

Thermostat stuck closedRemove and replace

thermostat, see ENGINE

COOLING

Head gasket leakingReplace head gasket

Oil Light on at Idle

Low oil pump pressureCheck oil pump operation, see

ENGINES

Oil cooler or line restrictedRemove restriction and/or

replace cooler

Engine Won't Shut Off

Injector pump fuel solenoid does not return fuel valve to OFF positionRemove and check solenoid

and replace if needed

CONDITION & POSSIBLE CAUSECORRECTION

Excessive Noise

Loose pump-to-drive assembly screwsTighten screws

Loose tube on pump assemblyTighten tube

Valves not functioning properlyReplace valves

Oil Leakage

Loose end plugTighten end plug

Bad seal crimpRemove and re-crimp seal

NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to SUBJECT ,

DIAGNOST IC, or T EST ING articles available in the section(s) you are accessing.

CONDITION & POSSIBLE CAUSECORRECTION

Engine Won't Start (Cranks Normally)

Cold start valve inoperativeTest valve and circuit

Poor connection;vacuum or wiringCheck vacuum and electrical

connections

Contaminated fuelTest fuel for water or alcohol

Defective fuel pump relay or circuitTest relay and wiring

Battery too lowCharge and test battery

Low fuel pressureTest pressure regulator and

fuel pump, check for restricted

lines and filters

No distributor reference pulsesRepair ignition system as

necessary

Page 16 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...