belt FORD FESTIVA 1991 Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 349 of 454

Back To Article

1991 AIR CONDIT IONING & HEAT

MANUAL A/C

A/C SYSTEM SPECIFICATIONS

SPECIFICATIONS

DESCRIPTION

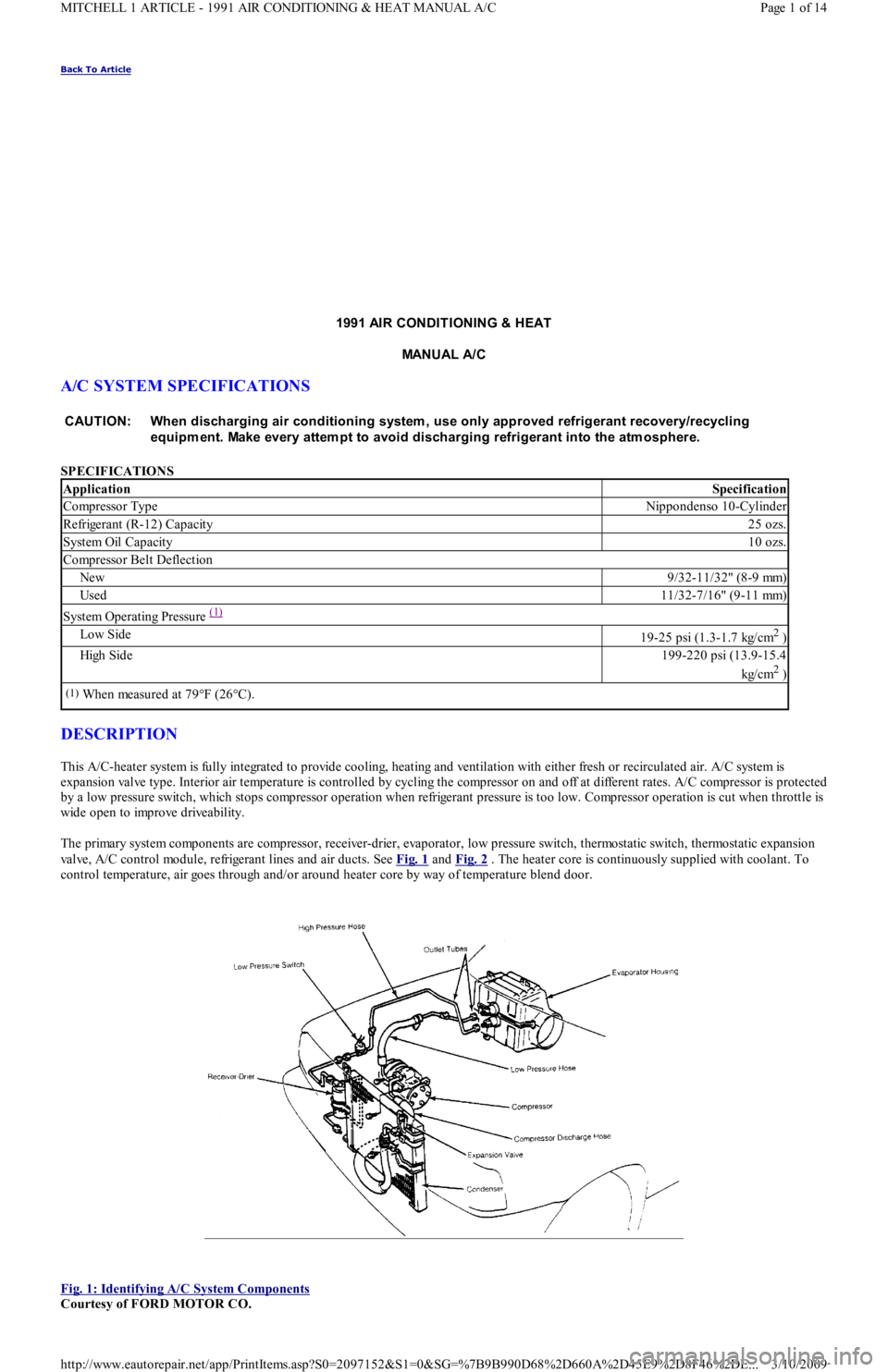

This A/C-heater system is fully integrated to provide cooling, heating and ventilation with either fresh or recirculated air. A/C system is

expansion valve type. Interior air temperature is controlled by cycling the compressor on and off at different rates. A/C compressor is protected

by a low pressure switch, which stops compressor operation when refrigerant pressure is too low. Compressor operation is cut when throttle is

wide open to improve driveability.

The primary system components are compressor, receiver-drier, evaporator, low pressure switch, thermostatic switch, thermostatic expansion

valve, A/C control module, refrigerant lines and air ducts. See Fig. 1

and Fig. 2 . The heater core is continuously supplied with coolant. To

control temperature, air goes through and/or around heater core by way of temperature blend door.

Fig. 1: Identifying A/C System Components

Courtesy of FORD MOTOR CO. CAUT ION: When discharging air conditioning system , use only approved refrigerant recovery/recycling

equipm ent. Make every attem pt to avoid discharging refrigerant into the atm osphere.

ApplicationSpecification

Compressor TypeNippondenso 10-Cylinder

Refrigerant (R-12) Capacity25 ozs.

System Oil Capacity10 ozs.

Compressor Belt Deflection

New9/32-11/32" (8-9 mm)

Used11/32-7/16" (9-11 mm)

System Operating Pressure (1)

Low Side19-25 psi (1.3-1.7 kg/cm2 )

High Side199-220 psi (13.9-15.4

kg/cm

2 )

(1)When measured at 79°F (26°C).

Page 1 of 14 MITCHELL 1 ARTICLE - 1991 AIR CONDITIONING & HEAT MANUAL A/C

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 360 of 454

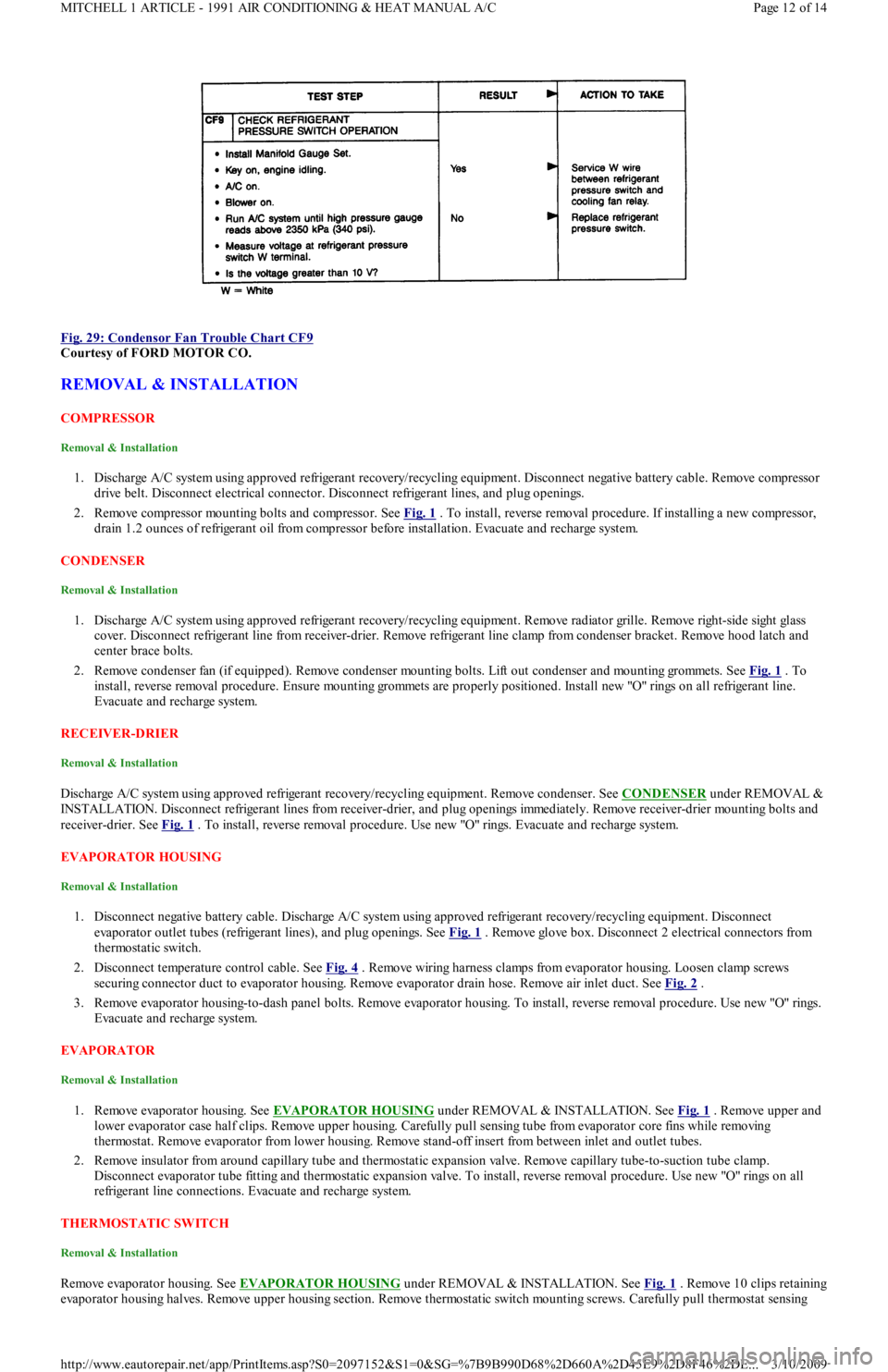

Fig. 29: Condensor Fan Trouble Chart CF9

Courtesy of FORD MOTOR CO.

REMOVAL & INSTALLATION

COMPRESSOR

Removal & Installation

1. Discharge A/C system using approved refrigerant recovery/recycling equipment. Disconnect negative battery cable. Remove compressor

drive belt. Disconnect electrical connector. Disconnect refrigerant lines, and plug openings.

2. Remove compressor mounting bolts and compressor. See Fig. 1

. To install, reverse removal procedure. If installing a new compressor,

drain 1.2 ounces of refrigerant oil from compressor before installation. Evacuate and recharge system.

CONDENSER

Removal & Installation

1. Discharge A/C system using approved refrigerant recovery/recycling equipment. Remove radiator grille. Remove right-side sight glass

cover. Disconnect refrigerant line from receiver-drier. Remove refrigerant line clamp from condenser bracket. Remove hood latch and

center brace bolts.

2. Remove condenser fan (if equipped). Remove condenser mounting bolts. Lift out condenser and mounting grommets. See Fig. 1

. To

install, reverse removal procedure. Ensure mounting grommets are properly positioned. Install new "O" rings on all refrigerant line.

Evacuate and recharge system.

RECEIVER-DRIER

Removal & Installation

Discharge A/C system using approved refrigerant recovery/recycling equipment. Remove condenser. See CONDENSER under REMOVAL &

INSTALLATION. Disconnect refrigerant lines from receiver-drier, and plug openings immediately. Remove receiver-drier mounting bolts and

receiver-drier. See Fig. 1

. To install, reverse removal procedure. Use new "O" rings. Evacuate and recharge system.

EVAPORATOR HOUSING

Removal & Installation

1. Disconnect negative battery cable. Discharge A/C system using approved refrigerant recovery/recycling equipment. Disconnect

evaporator outlet tubes (refrigerant lines), and plug openings. See Fig. 1

. Remove glove box. Disconnect 2 electrical connectors from

thermostatic switch.

2. Disconnect temperature control cable. See Fig. 4

. Remove wiring harness clamps from evaporator housing. Loosen clamp screws

securing connector duct to evaporator housing. Remove evaporator drain hose. Remove air inlet duct. See Fig. 2

.

3. Remove evaporator housing-to-dash panel bolts. Remove evaporator housing. To install, reverse removal procedure. Use new "O" rings.

Evacuate and recharge system.

EVAPORATOR

Removal & Installation

1. Remove evaporator housing. See EVAPORATOR HOUSING under REMOVAL & INSTALLATION. See Fig. 1 . Remove upper and

lower evaporator case half clips. Remove upper housing. Carefully pull sensing tube from evaporator core fins while removing

thermostat. Remove evaporator from lower housing. Remove stand-off insert from between inlet and outlet tubes.

2. Remove insulator from around capillary tube and thermostatic expansion valve. Remove capillary tube-to-suction tube clamp.

Disconnect evaporator tube fitting and thermostatic expansion valve. To install, reverse removal procedure. Use new "O" rings on all

refrigerant line connections. Evacuate and recharge system.

THERMOSTATIC SW ITCH

Removal & Installation

Remove evaporator housing. See EVAPORATOR HOUSING under REMOVAL & INSTALLATION. See Fig. 1. Remove 10 clips retaining

evaporator housing halves. Remove upper housing section. Remove thermostatic switch mounting screws. Carefully pull thermostat sensing

Page 12 of 14 MITCHELL 1 ARTICLE - 1991 AIR CONDITIONING & HEAT MANUAL A/C

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 363 of 454

Back To Article

1971-96 MAINT ENANCE & SERVICE INFORMAT ION

Interference Verification Check For OHC Engine - T im ing Belt Inform ation

TIMING BELT INTERFERENCE VERIFICATION INFORMATION

TIMING BELT INTERFERENCE CAUTION

Crack Or Tears In Belt Surface

Missing, Damaged, Cracked Or Rounded Teeth

Oil Contamination

Damaged Or Faulty Tensioners

Incorrect Tension Adjustment

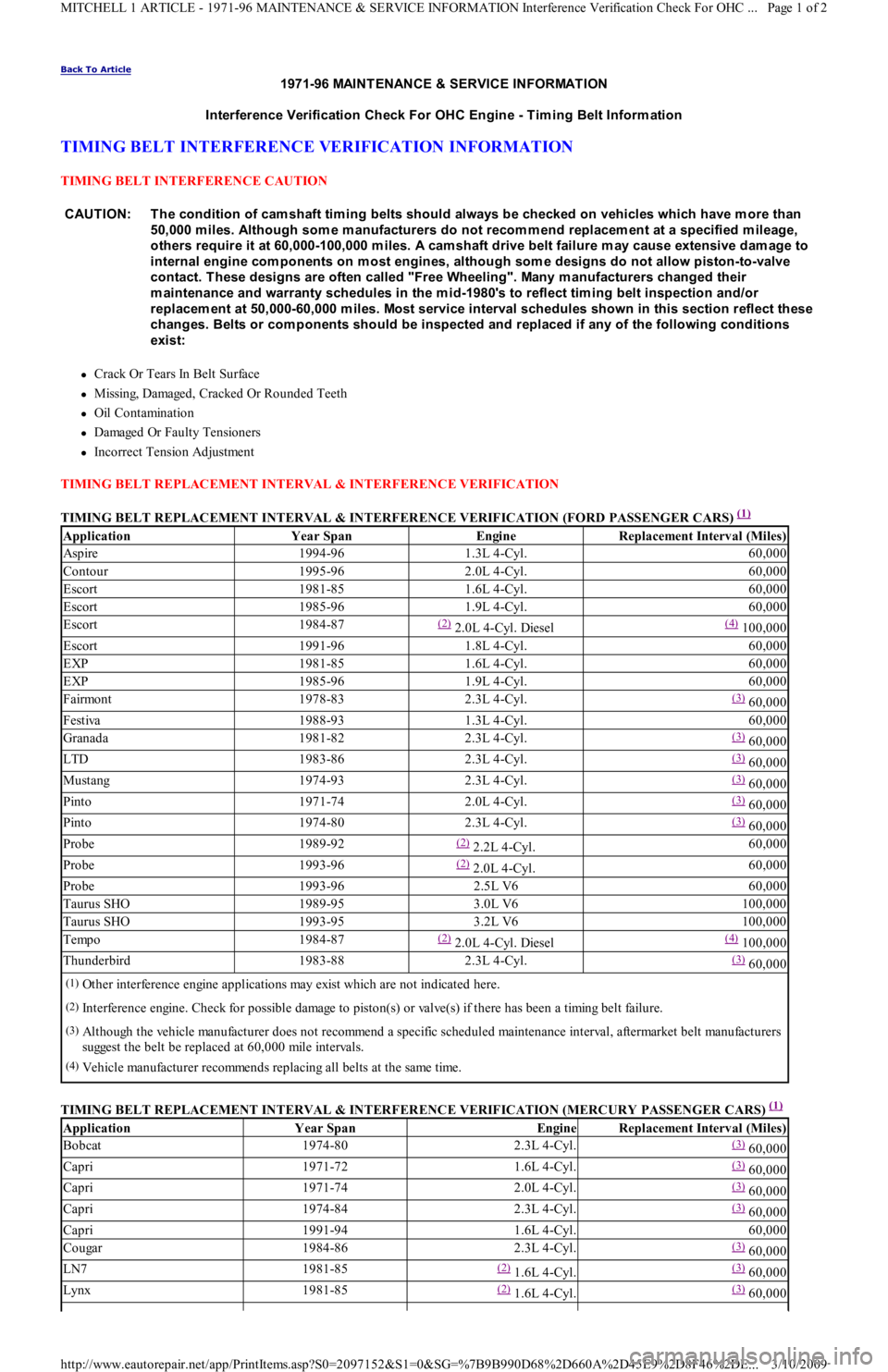

TIMING BELT REPLACEMENT INTERVAL & INTERFERENCE VERIFICATION

TIMING BELT REPLACEMENT INTERVAL & INTERFERENCE VERIFICATION (FORD PASSENGER CARS)

(1)

TIMING BELT REPLACEMENT INTERVAL & INTERFERENCE VERIFICATION (MERCURY PASSENGER CARS)

(1) CAUT ION: T he condition of cam shaft tim ing belts should always be checked on vehicles which have m ore than

50,000 m iles. Although som e m anufacturers do not recom m end replacem ent at a specified m ileage,

others require it at 60,000-100,000 m iles. A cam shaft drive belt failure m ay cause extensive dam age to

internal engine com ponents on m ost engines, although som e designs do not allow piston-to-valve

contact. T hese designs are often called "Free Wheeling". Many m anufacturers changed their

m aintenance and warranty schedules in the m id-1980's to reflect tim ing belt inspection and/or

replacem ent at 50,000-60,000 m iles. Most service interval schedules shown in this section reflect these

changes. Belts or com ponents should be inspected and replaced if any of the following conditions

exist:

ApplicationYear SpanEngineReplacement Interval (Miles)

Aspire1994-961.3L 4-Cyl.60,000

Contour1995-962.0L 4-Cyl.60,000

Escort1981-851.6L 4-Cyl.60,000

Escort1985-961.9L 4-Cyl.60,000

Escort1984-87(2) 2.0L 4-Cyl. Diesel(4) 100,000

Escort1991-961.8L 4-Cyl.60,000

EXP1981-851.6L 4-Cyl.60,000

EXP1985-961.9L 4-Cyl.60,000

Fairmont1978-832.3L 4-Cyl.(3) 60,000

Festiva1988-931.3L 4-Cyl.60,000

Granada1981-822.3L 4-Cyl.(3) 60,000

LTD1983-862.3L 4-Cyl.(3) 60,000

Mustang1974-932.3L 4-Cyl.(3) 60,000

Pinto1971-742.0L 4-Cyl.(3) 60,000

Pinto1974-802.3L 4-Cyl.(3) 60,000

Probe1989-92(2) 2.2L 4-Cyl.60,000

Probe1993-96(2) 2.0L 4-Cyl.60,000

Probe1993-962.5L V660,000

Taurus SHO1989-953.0L V6100,000

Taurus SHO1993-953.2L V6100,000

Tempo1984-87(2) 2.0L 4-Cyl. Diesel(4) 100,000

Thunderbird1983-882.3L 4-Cyl.(3) 60,000

(1)Other interference engine applications may exist which are not indicated here.

(2)Interference engine. Check for possible damage to piston(s) or valve(s) if there has been a timing belt failure.

(3)Although the vehicle manufacturer does not recommend a specific scheduled maintenance interval, aftermarket belt manufacturers

suggest the belt be replaced at 60,000 mile intervals.

(4)Vehicle manufacturer recommends replacing all belts at the same time.

ApplicationYear SpanEngineReplacement Interval (Miles)

Bobcat1974-802.3L 4-Cyl.(3) 60,000

Capri1971-721.6L 4-Cyl.(3) 60,000

Capri1971-742.0L 4-Cyl.(3) 60,000

Capri1974-842.3L 4-Cyl.(3) 60,000

Capri1991-941.6L 4-Cyl.60,000

Cougar1984-862.3L 4-Cyl.(3) 60,000

LN71981-85(2) 1.6L 4-Cyl.(3) 60,000

Lynx1981-85(2) 1.6L 4-Cyl.(3) 60,000

Page 1 of 2 MITCHELL 1 ARTICLE - 1971-96 MAINTENANCE & SERVICE INFORMATION Interference Verification Check For OHC

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 364 of 454

TIMING BELT REPLACEMENT INTERVAL & INTERFERENCE VERIFICATION (LIGHT TRUCKS) (1)

Lynx1984-871.9L 4-Cyl.(3) 60,000

Lynx1984-872.0L 4-Cyl. Diesel(4) 100,000

Marquis1983-862.3L 4-Cyl.(3) 60,000

Mystique1995-962.0L 4-Cyl.60,000

Topaz1984-86(2) 2.0L 4-Cyl. Diesel(4) 100,000

Tracer1987-901.6L 4-Cyl.60,000

Tracer1991-961.8L 4-Cyl.60,000

Tracer1991-961.9L 4-Cyl.60,000

Tracer (Canadian)1987, 19901.6L 4-Cyl.(3) 60,000

Zephyr1978-832.3L 4-Cyl.(3) 60,000

Villager1993-96(2) 3.0L V6105,000

(1)Other interference engine applications may exist which are not indicated here.

(2)Interference engine. Check for possible damage to piston(s) or valve(s) if there has been a timing belt failure.

(3)Although the vehicle manufacturer does not recommend a specific scheduled maintenance interval, aftermarket belt manufacturers

suggest the belt be replaced at 60,000 mile intervals.

(4)Vehicle manufacturer recommends replacing all belts at the same time.

ApplicationYear SpanEngineReplacement Interval (Miles)

Aerostar1986-872.3L 4-Cyl.(3) 60,000

Courier1977-822.3L 4-Cyl.(3) 60,000

Ranger1986-882.0L 4-Cyl.60,000

Ranger1983-962.3L 4-Cyl.(3) 60,000

Ranger1985-87(2) 2.3L 4-Cyl. Diesel(3) (4) 60,000

(1)Other interference engine applications may exist which are not indicated here.

(2)Interference engine. Check for possible damage to piston(s) or valve(s) if there has been a timing belt failure.

(3)Although the vehicle manufacturer does not recommend a specific scheduled maintenance interval, aftermarket belt manufacturers

suggest the belt be replaced at 60,000 mile intervals.

(4)Vehicle manufacturer recommends replacing all belts at the same time.

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00062912

Page 2 of 2 MITCHELL 1 ARTICLE - 1971-96 MAINTENANCE & SERVICE INFORMATION Interference Verification Check For OHC

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 366 of 454

Driven More Than 10 Miles Daily

No Operating Conditions From Severe Service Schedule

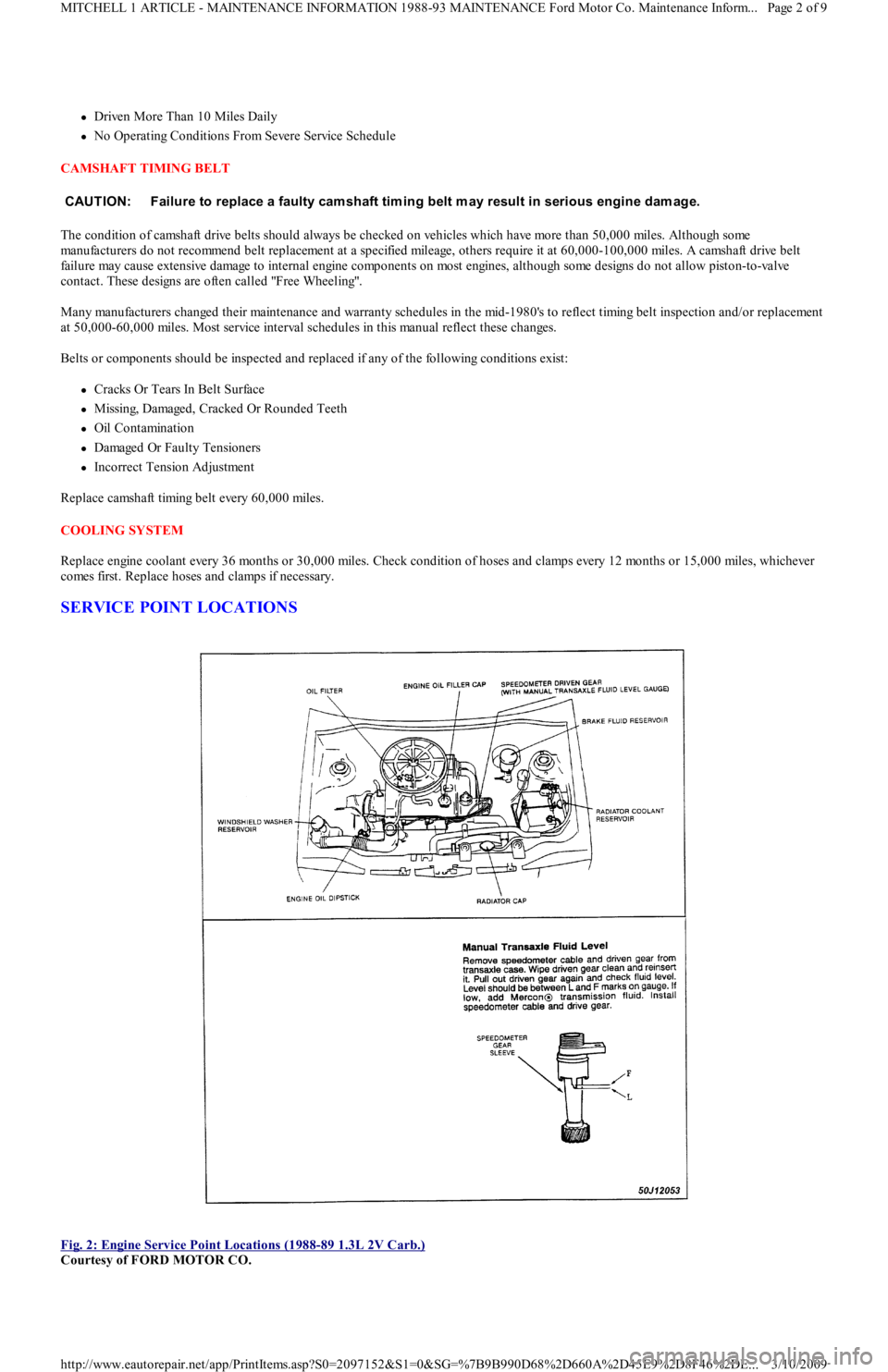

CAMSHAFT TIMING BELT

The condition of camshaft drive belts should always be checked on vehicles which have more than 50,000 miles. Although some

manufacturers do not recommend belt replacement at a specified mileage, others require it at 60,000-100,000 miles. A camshaft drive belt

failure may cause extensive damage to internal engine components on most engines, although some designs do not allow piston-to-va l ve

contact. These designs are often called "Free Wheeling".

Many manufacturers changed their maintenance and warranty schedules in the mid-1980's to reflect timing belt inspection and/or replacement

at 50,000-60,000 miles. Most service interval schedules in this manual reflect these changes.

Belts or components should be inspected and replaced if any of the following conditions exist:

Cracks Or Tears In Belt Surface

Missing, Damaged, Cracked Or Rounded Teeth

Oil Contamination

Damaged Or Faulty Tensioners

Incorrect Tension Adjustment

Replace camshaft timing belt every 60,000 miles.

COOLING SYSTEM

Replace engine coolant every 36 months or 30,000 miles. Check condition of hoses and clamps every 12 months or 15,000 miles, whichever

comes first. Replace hoses and clamps if necessary.

SERVICE POINT LOCATIONS

Fig. 2: Engine Service Point Locations (1988

-89 1.3L 2V Carb.)

Courtesy of FORD MOTOR CO. CAUT ION: Failure to replace a faulty cam shaft tim ing belt m ay result in serious engine dam age.

Page 2 of 9 MITCHELL 1 ARTICLE - MAINTENANCE INFORMATION 1988-93 MAINTENANCE Ford Motor Co. Maintenance Inform...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 368 of 454

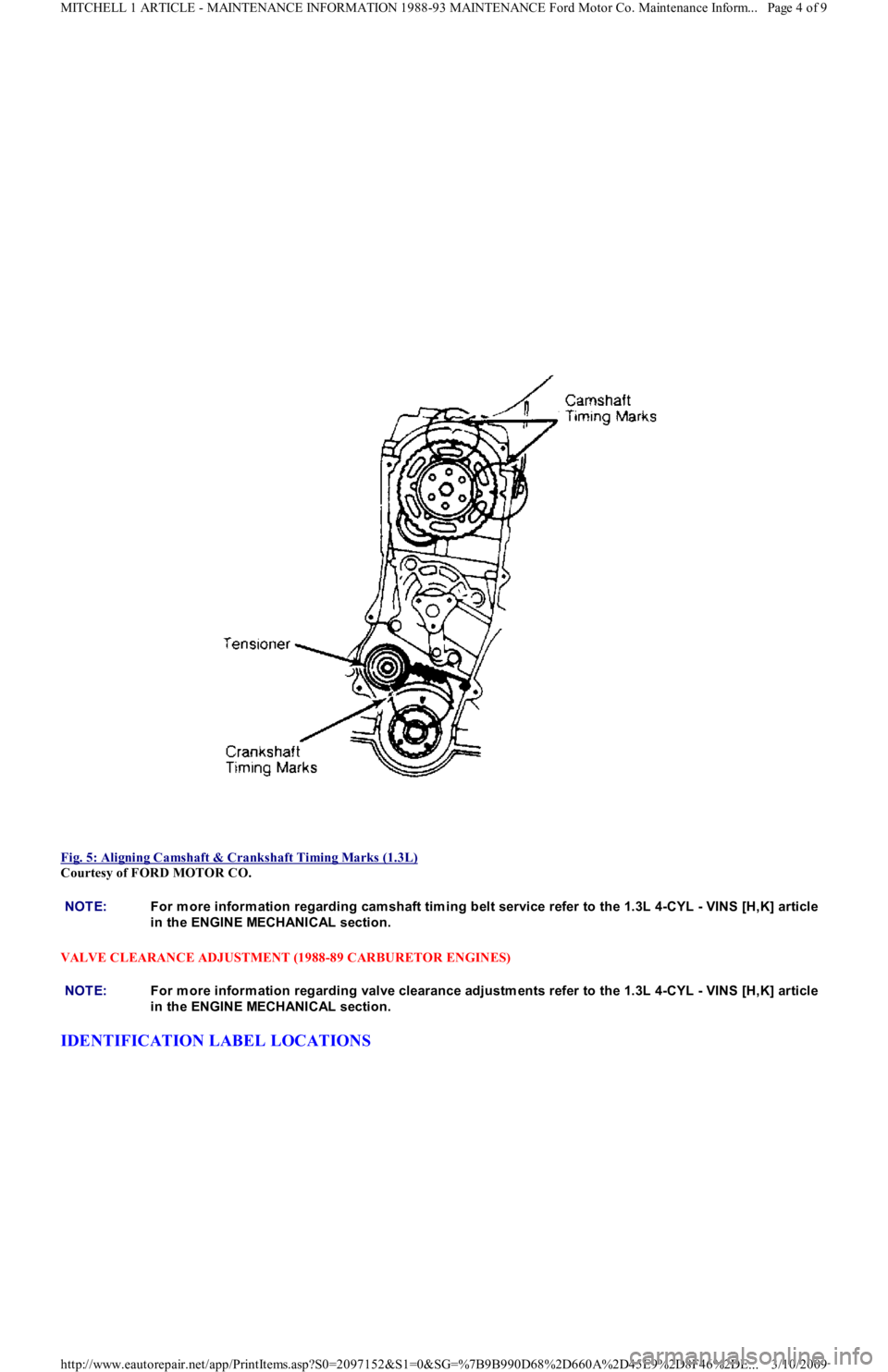

Fig. 5: Aligning Camshaft & Crankshaft Timing Marks (1.3L)

Courtesy of FORD MOTOR CO.

VALVE CLEARANCE ADJUSTMENT (1988-89 CARBURETOR ENGINES)

IDENTIFICATION LABEL LOCATIONS

NOTE:For m ore inform ation regarding cam shaft tim ing belt service refer to the 1.3L 4-CYL - VINS [H,K] article

in the ENGINE MECHANICAL section.

NOTE:For m ore inform ation regarding valve clearance adjustm ents refer to the 1.3L 4-CYL - VINS [H,K] article

in the ENGINE MECHANICAL section.

Page 4 of 9 MITCHELL 1 ARTICLE - MAINTENANCE INFORMATION 1988-93 MAINTENANCE Ford Motor Co. Maintenance Inform...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 372 of 454

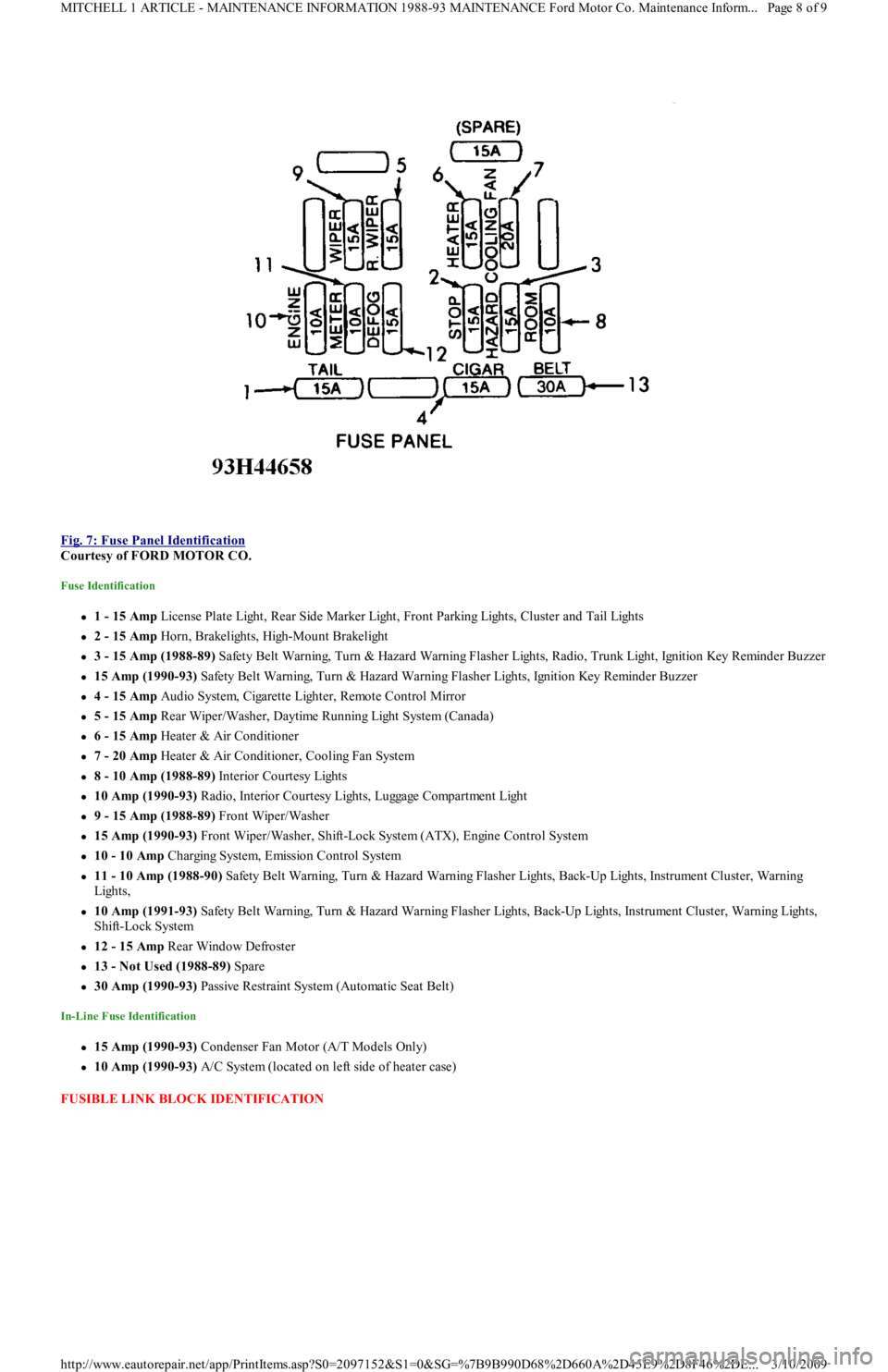

Fig. 7: Fuse Panel Identification

Courtesy of FORD MOTOR CO.

Fuse Identification

1 - 15 Amp License Plate Light, Rear Side Marker Light, Front Parking Lights, Cluster and Tail Lights

2 - 15 Amp Horn, Brakelights, High-Mount Brakelight

3 - 15 Amp (1988-89) Safety Belt Warning, Turn & Hazard Warning Flasher Lights, Radio, Trunk Light, Ignition Key Reminder Buzzer

15 Amp (1990-93) Safety Belt Warning, Turn & Hazard Warning Flasher Lights, Ignition Key Reminder Buzzer

4 - 15 Amp Audio System, Cigarette Lighter, Remote Control Mirror

5 - 15 Amp Rear Wiper/Washer, Daytime Running Light System (Canada)

6 - 15 Amp Heater & Air Conditioner

7 - 20 Amp Heater & Air Conditioner, Cooling Fan System

8 - 10 Amp (1988-89) Interior Courtesy Lights

10 Amp (1990-93) R a d io , In t e r io r C o u r t e sy Ligh t s, Lu gga ge C o mp a r t me n t Ligh t

9 - 15 Amp (1988-89) Front Wiper/Washer

15 Amp (1990-93) Front Wiper/Washer, Shift-Lock System (ATX), Engine Control System

10 - 10 Amp Charging System, Emission Control System

11 - 10 Amp (1988-90) Safety Belt Warning, Turn & Hazard Warning Flasher Lights, Back-Up Lights, Instrument Cluster, Warning

Lights,

10 Amp (1991-93) Safety Belt Warning, Turn & Hazard Warning Flasher Lights, Back-Up Lights, Instrument Cluster, Warning Lights,

Shift-Lock System

12 - 15 Amp Rear Window Defroster

13 - Not Used (1988-89) Spare

30 Amp (1990-93) Passive Restraint System (Automatic Seat Belt)

In-Line Fuse Identification

15 Amp (1990-93) Condenser Fan Motor (A/T Models Only)

10 Amp (1990-93) A/C System (located on left side of heater case)

FUSIBLE LINK BLOCK IDENTIFICATION

Page 8 of 9 MITCHELL 1 ARTICLE - MAINTENANCE INFORMATION 1988-93 MAINTENANCE Ford Motor Co. Maintenance Inform...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 378 of 454

Back To Article

ST EERING SYST EM - POWER

1991-92 ST EERING Ford Motor Co. - Steering - Power Rack & Pinion

DESCRIPTION & OPERATION

Power steering system consists of a rack and pinion steering gear, valve body, power steering pump, fluid reservoir and interconnecting

hydraulic lines. Pressure and return lines from pump are connected to valve body. A vane-type power steering pump draws fluid from the

steering reservoir. Fluid is compressed by rotor and vanes inside steering pump and sent to steering gear. Pressure is monitored and controlled

by a pressure switch and a control valve located inside of steering pump.

TROUBLE SHOOTING

Refer to TROUBLE SHOOTING - BASIC PROCEDURES article in the GENERAL TROUBLE SHOOTING section.

LUBRICATION

CAPACITY

Information is not available.

FLUID TYPE

Use Dexron-II ATF type fluid.

FLUID LEVEL CHECK

Check fluid level before engine is started, while fluid is still cool. Remove reservoir cap fluid indicator on steering pump. Check fluid level.

Fluid should be between the "L" and "H" marks on the level gauge dipstick. If fluid is needed, fill to the "L" mark on dipstick. Run engine until

warm and turn steering wheel fully in both directions about 10 times. Return steering to straight-ahead position and shut engine off. Ensure

fluid level is between "L" and "H" marks. Add fluid if necessary.

HYDRAULIC FLUID BLEEDING

1. Raise and support front of vehicle. Ensure pump reservoir is filled to specified level. With ignition coil wire disconnected, crank engine

and add fluid to steering pump until fluid level remains constant. While cranking engine, rotate steering from stop to stop. Recheck and

add fluid as necessary.

2. Start engine and allow to idle for several minutes. Turn steering wheel completely lock-to-lock several times. Check fluid level. Add

fluid as necessary. Continue this procedure until there is no bubbling or decrease in fluid level.

ADJUSTMENTS

BELT TENSION

On Festiva, remove air duct and air cleaner. On all models, loosen steering pump mounting pivot bolt and the adjusting bolt lock nut. Using

Belt Tension Gauge (021-0028A), fit gauge to longest available belt span for testing. Adjust belt to specification. See BELT TENSION

SPECIFICATIONS . Tighten adjuster lock nut to 32-45 ft. lbs. (43-61 N.m) on Capri or 27-38 ft. lbs. (37-52 N.m) on Festiva.

BELT TENSION SPECIFICATIONS

REMOVAL & INSTALLATION

STEERING GEAR

Removal

1. Disconnect negative battery cable. On Capri, mark and loosen intermediate lower U-joint. On Festiva, mark and remove steering gear

intermediate shaft connecting steering gear to column shaft. On all models, disconnect high pressure and return lines and plug them.

Loosen front wheel lug nuts.

2. Raise vehicle. Remove front wheels. Remove tie rod end cotter pins and nuts. Separate tie rod ends from steering knuckles using Tie

Rod Remover (T85M-3395-A). Remove tie rod end splash shields. Remove right fender splash shield. Remove front catalytic converter

nuts and separate converter from inlet pipe.

3. Place reference marks on tie rod end and tie rod for reassembly reference. Loosen tie rod jam nut and remove right tie rod end. Remove

steering gear mounting bolts and washers. Slide steering gear to the left and pull right tie rod through fender opening. Remove steering

gear by sliding it to the right.

Installation

Application

(1) Deflection: In.

(mm)Gauge Tension:

Lbs. (kg)

New Belt

Capri & Festiva.31-.35 (8-9)110-132 (50-60)

Used Belt

Capri.31-.35 (8-9)110-132 (50-60)

Festiva.35-.39 (9-10)95-110 (43-50)

(1)Apply approximately 22 lbs. (9.9 kg) of pressure.

Page 1 of 9 MITCHELL 1 ARTICLE - STEERING SYSTEM - POWER 1991-92 STEERING Ford Motor Co. - Steering - Power Rack & Pi

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 379 of 454

1. Position steering gear in its mounting position. Attach intermediate shaft to steering gear pinion and tighten clamp bolt to 13-20 ft. lbs.

(18-26 N.m). Guide intermediate shaft into steering column hole. Lower vehicle.

2. Lift steering gear and align intermediate shaft with universal joint and install clamp bolt. Raise vehicle. Install steering gear mounting

bolts and tighten to 23-34 ft. lbs. (31-46 N.m). Install right tie rod end, using marks made during removal for installation reference.

Attach tie rod ends to steering knuckles. Install tie rod end nuts and tighten to 22-33 ft. lbs. (29-44 N.m).

3. Install tie rod end cotter pins. Attach catalytic converter to inlet pipe and install attaching nuts. Tighten nuts to 23-34 ft. lbs. (31-46

N.m). Install tie rod end splash shields. Install right fender splash shield. install front wheels. Lower vehicle.

4. Connect high pressure and return lines. Connect negative battery cable. Add power steering fluid and bleed air from system and check

for leaks. See HYDRAULIC FLUID BLEEDING

under LUBRICATION.

POWER STEERING PUMP

Removal (Capri)

1. Remove right radiator support and brace. Remove pump drive belt. Disconnect intercooler outlet hose at throttle intake (if equipped).

R e mo ve gr o u n d wir e fr o m e n gin e l ift in g e ye .

2. Remove pressure and return hoses and plug. Remove wire from pressure switch. Remove adjusting screw, nut and block from pump

bracket. Remove pivot bolt. Remove bracket retaining bolts then remove pump.

Removal (Festiva)

Remove air duct and air cleaner. Disconnect electrical connector from fluid pressure switch on power steering pump. Disconnect and plug

return and pressure lines. Remove adjustment bolt. Remove lock nut, washer and bracket bolt. Loosen mounting bolt and disconnect drive

belt. Remove mounting bolt. Remove power steering pump.

Installation (Capri & Festiva)

To install pump, reverse removal procedure. Adjust steering belt tension. Tighten all nuts and bolts to specification. See TORQUE

SPECIFICATIONS . Add power steering fluid and bleed air from system and check for leaks. See HYDRAULIC FLUID BLEEDING

under LUBRICATION.

OVERHAUL

STEERING GEAR

Disassembly (Capri)

1. Remove steering gear and place in soft-jawed vise. Remove external hydraulic lines. See Fig. 1 . Remove mount brackets and rubber

mount bushings. Remove brass tubing seats using a self-tapping screw and 2 screwdrivers.

Page 2 of 9 MITCHELL 1 ARTICLE - STEERING SYSTEM - POWER 1991-92 STEERING Ford Motor Co. - Steering - Power Rack & Pi

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...