belt FORD FESTIVA 1991 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 230 of 454

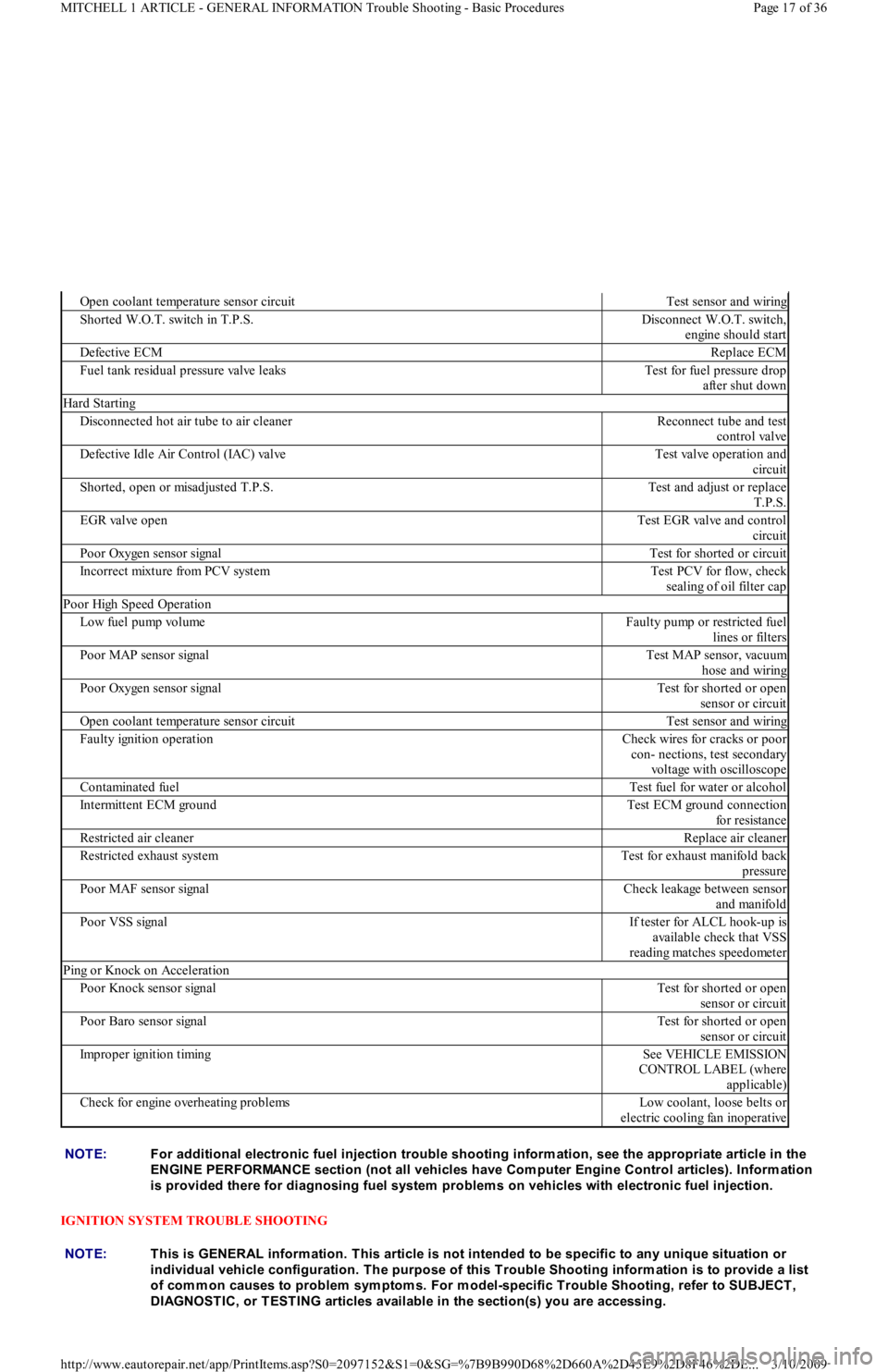

IGNITION SYSTEM TROUBLE SHOOTING

Open coolant temperature sensor circuitTest sensor and wiring

Shorted W.O.T. switch in T.P.S.Disconnect W.O.T. switch,

engine should start

Defective ECMReplace ECM

Fuel tank residual pressure valve leaksTest for fuel pressure drop

after shut down

Hard Starting

Disconnected hot air tube to air cleanerReconnect tube and test

control valve

Defective Idle Air Control (IAC) valveTest valve operation and

circuit

Shorted, open or misadjusted T.P.S.Test and adjust or replace

T.P.S.

EGR valve openTest EGR valve and control

circuit

Poor Oxygen sensor signalTest for shorted or circuit

Incorrect mixture from PCV systemTest PCV for flow, check

sealing of oil filter cap

Poor High Speed Operation

Low fuel pump volumeFaulty pump or restricted fuel

lines or filters

Poor MAP sensor signalTest MAP sensor, vacuum

hose and wiring

Poor Oxygen sensor signalTest for shorted or open

sensor or circuit

Open coolant temperature sensor circuitTest sensor and wiring

Faulty ignition operationCheck wires for cracks or poor

con- nections, test secondary

voltage with oscilloscope

Contaminated fuelTest fuel for water or alcohol

Intermittent ECM groundTest ECM ground connection

for resistance

Restricted air cleanerReplace air cleaner

Restricted exhaust systemTest for exhaust manifold back

pressure

Poor MAF sensor signalCheck leakage between sensor

and manifold

Poor VSS signalIf tester for ALCL hook-up is

available check that VSS

reading matches speedometer

Ping or Knock on Acceleration

Poor Knock sensor signalTest for shorted or open

sensor or circuit

Poor Baro sensor signalTest for shorted or open

sensor or circuit

Improper ignition timingSee VEHICLE EMISSION

CONTROL LABEL (where

applicable)

Check for engine overheating problemsLow coolant, loose belts or

electric cooling fan inoperative

NOTE:For additional electronic fuel injection trouble shooting inform ation, see the appropriate article in the

ENGINE PERFORMANCE section (not all vehicles have Com puter Engine Control articles). Inform ation

is provided there for diagnosing fuel system problem s on vehicles with electronic fuel injection.

NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to SUBJECT ,

DIAGNOST IC, or T EST ING articles available in the section(s) you are accessing.

Page 17 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 236 of 454

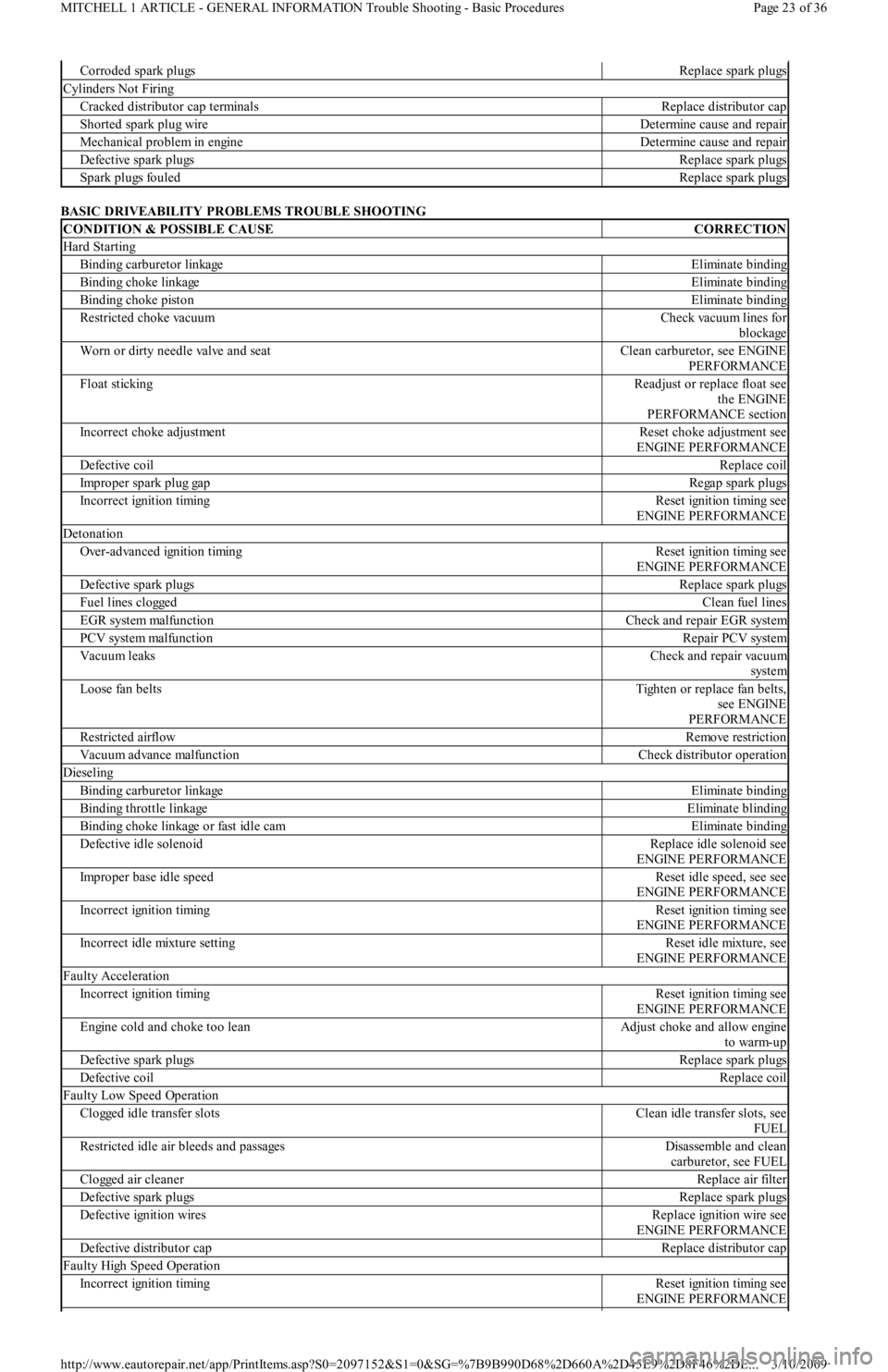

BASIC DRIVEABILITY PROBLEMS TROUBLE SHOOTING

Corroded spark plugsReplace spark plugs

Cylinders Not Firing

Cracked distributor cap terminalsReplace distributor cap

Shorted spark plug wireDetermine cause and repair

Mechanical problem in engineDetermine cause and repair

Defective spark plugsReplace spark plugs

Spark plugs fouledReplace spark plugs

CONDITION & POSSIBLE CAUSECORRECTION

Hard Starting

Binding carburetor linkageEliminate binding

Binding choke linkageEliminate binding

Binding choke pistonEliminate binding

Restricted choke vacuumCheck vacuum lines for

blockage

Worn or dirty needle valve and seatClean carburetor, see ENGINE

PERFORMANCE

Float stickingReadjust or replace float see

the ENGINE

PERFORMANCE section

Incorrect choke adjustmentReset choke adjustment see

ENGINE PERFORMANCE

Defective coilReplace coil

Improper spark plug gapRegap spark plugs

Incorrect ignition timingReset ignition timing see

ENGINE PERFORMANCE

Detonation

Over-advanced ignition timingReset ignition timing see

ENGINE PERFORMANCE

Defective spark plugsReplace spark plugs

Fuel lines cloggedClean fuel lines

EGR system malfunctionCheck and repair EGR system

PCV system malfunctionRepair PCV system

Vacuum leaksCheck and repair vacuum

system

Loose fan beltsTighten or replace fan belts,

see ENGINE

PERFORMANCE

Restricted airflowRemove restriction

Vacuum advance malfunctionCheck distributor operation

Dieseling

Binding carburetor linkageEliminate binding

Binding throttle linkageEliminate blinding

Binding choke linkage or fast idle camEliminate binding

Defective idle solenoidReplace idle solenoid see

ENGINE PERFORMANCE

Improper base idle speedReset idle speed, see see

ENGINE PERFORMANCE

Incorrect ignition timingReset ignition timing see

ENGINE PERFORMANCE

Incorrect idle mixture settingReset idle mixture, see

ENGINE PERFORMANCE

Faulty Acceleration

Incorrect ignition timingReset ignition timing see

ENGINE PERFORMANCE

Engine cold and choke too leanAdjust choke and allow engine

to warm-up

Defective spark plugsReplace spark plugs

Defective coilReplace coil

Faulty Low Speed Operation

Clogged idle transfer slotsClean idle transfer slots, see

FUEL

Restricted idle air bleeds and passagesDisassemble and clean

carburetor, see FUEL

Clogged air cleanerReplace air filter

Defective spark plugsReplace spark plugs

Defective ignition wiresReplace ignition wire see

ENGINE PERFORMANCE

Defective distributor capReplace distributor cap

Faulty High Speed Operation

Incorrect ignition timingReset ignition timing see

ENGINE PERFORMANCE

Page 23 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 244 of 454

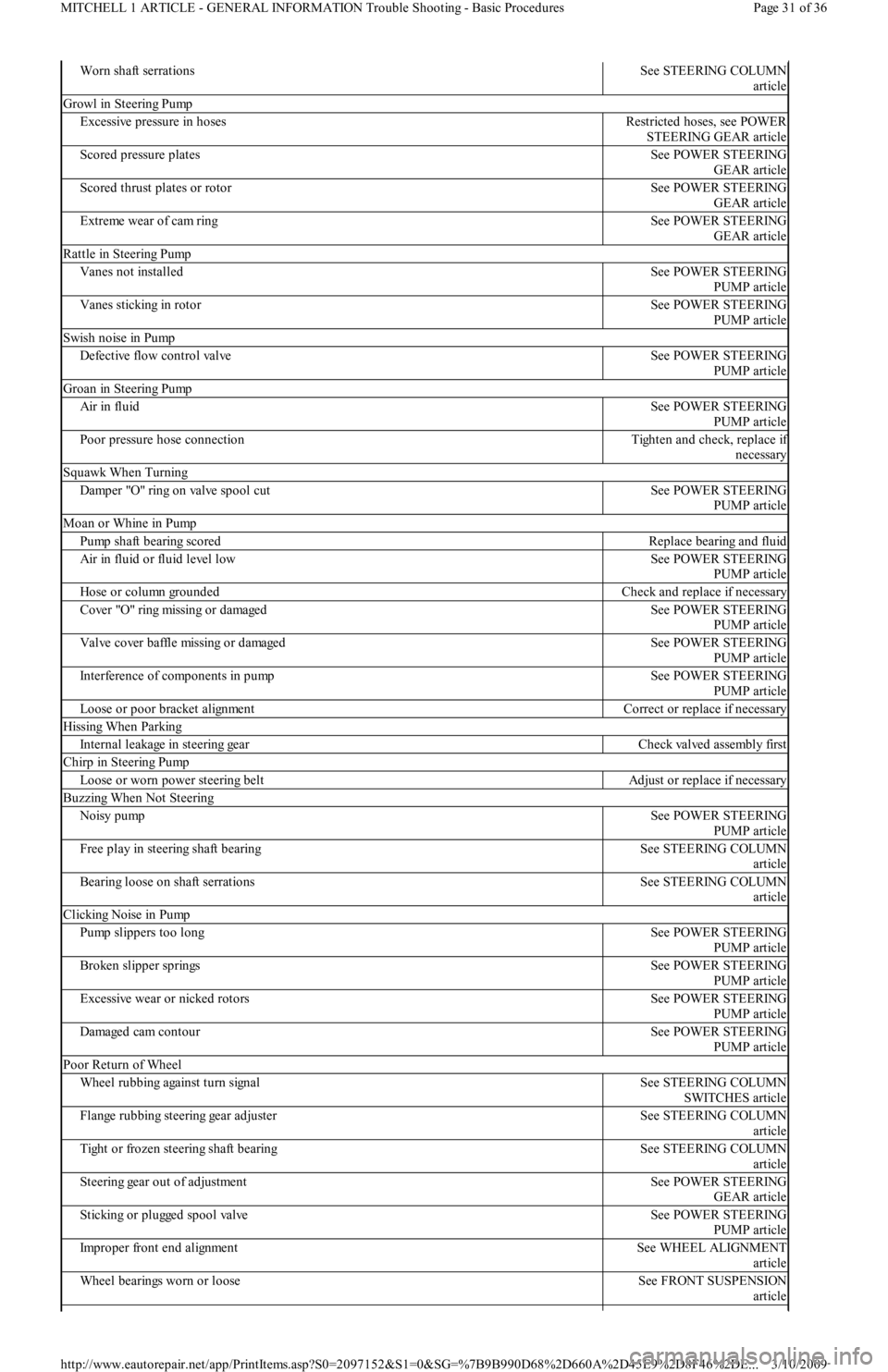

Worn shaft serrationsSee STEERING COLUMN

article

Growl in Steering Pump

Excessive pressure in hosesRestricted hoses, see POWER

STEERING GEAR article

Scored pressure platesSee POWER STEERING

GEAR article

Scored thrust plates or rotorSee POWER STEERING

GEAR article

Extreme wear of cam ringSee POWER STEERING

GEAR article

Rattle in Steering Pump

Vanes not installedSee POWER STEERING

PUMP article

Vanes sticking in rotorSee POWER STEERING

PUMP article

Swish noise in Pump

Defective flow control valveSee POWER STEERING

PUMP article

Groan in Steering Pump

Air in fluidSee POWER STEERING

PUMP article

Poor pressure hose connectionTighten and check, replace if

necessary

Squawk When Turning

Damper "O" ring on valve spool cutSee POWER STEERING

PUMP article

Moan or Whine in Pump

Pump shaft bearing scoredReplace bearing and fluid

Air in fluid or fluid level lowSee POWER STEERING

PUMP article

Hose or column groundedCheck and replace if necessary

Cover "O" ring missing or damagedSee POWER STEERING

PUMP article

Valve cover baffle missing or damagedSee POWER STEERING

PUMP article

Interference of components in pumpSee POWER STEERING

PUMP article

Loose or poor bracket alignmentCorrect or replace if necessary

Hissing When Parking

Internal leakage in steering gearCheck valved assembly first

Chirp in Steering Pump

Loose or worn power steering beltAdjust or replace if necessary

Buzzing When Not Steering

Noisy pumpSee POWER STEERING

PUMP article

Free play in steering shaft bearingSee STEERING COLUMN

article

Bearing loose on shaft serrationsSee STEERING COLUMN

article

Clicking Noise in Pump

Pump slippers too longSee POWER STEERING

PUMP article

Broken slipper springsSee POWER STEERING

PUMP article

Excessive wear or nicked rotorsSee POWER STEERING

PUMP article

Damaged cam contourSee POWER STEERING

PUMP article

Poor Return of Wheel

Wheel rubbing against turn signalSee STEERING COLUMN

SWITCHES article

Flange rubbing steering gear adjusterSee STEERING COLUMN

article

Tight or frozen steering shaft bearingSee STEERING COLUMN

article

Steering gear out of adjustmentSee POWER STEERING

GEAR article

Sticking or plugged spool valveSee POWER STEERING

PUMP article

Improper front end alignmentSee WHEEL ALIGNMENT

article

Wheel bearings worn or looseSee FRONT SUSPENSION

article

Page 31 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 245 of 454

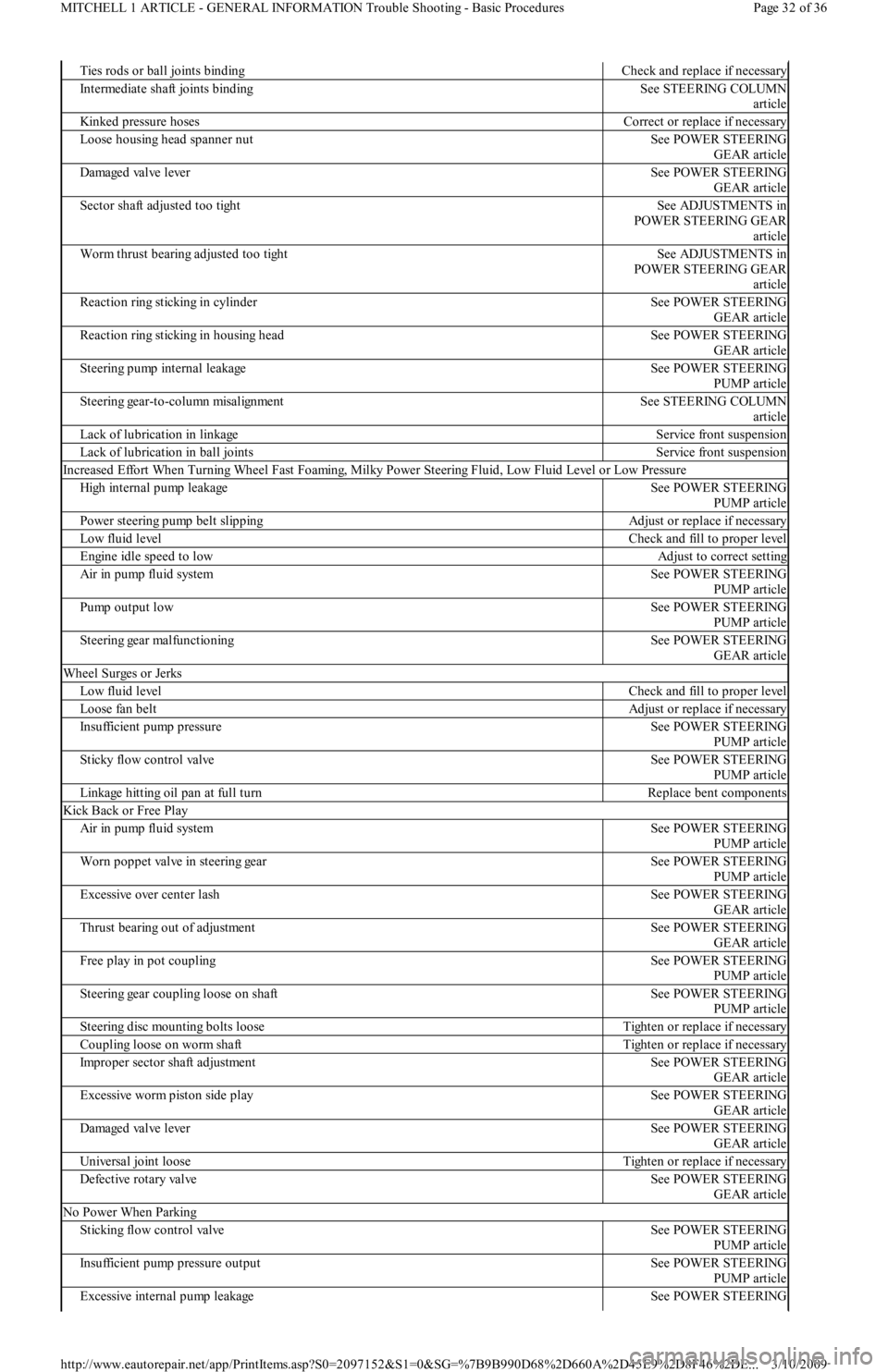

Ties rods or ball joints bindingCheck and replace if necessary

Intermediate shaft joints bindingSee STEERING COLUMN

article

Kinked pressure hosesCorrect or replace if necessary

Loose housing head spanner nutSee POWER STEERING

GEAR article

Damaged valve leverSee POWER STEERING

GEAR article

Sector shaft adjusted too tightSee ADJUSTMENTS in

POWER STEERING GEAR

article

Worm thrust bearing adjusted too tightSee ADJUSTMENTS in

POWER STEERING GEAR

article

Reaction ring sticking in cylinderSee POWER STEERING

GEAR article

Reaction ring sticking in housing headSee POWER STEERING

GEAR article

Steering pump internal leakageSee POWER STEERING

PUMP article

Steering gear-to-column misalignmentSee STEERING COLUMN

article

Lack of lubrication in linkageService front suspension

Lack of lubrication in ball jointsService front suspension

Increased Effort When Turning Wheel Fast Foaming, Milky Power Steering Fluid, Low Fluid Level or Low Pressure

High internal pump leakageSee POWER STEERING

PUMP article

Power steering pump belt slippingAdjust or replace if necessary

Low fluid levelCheck and fill to proper level

Engine idle speed to lowAdjust to correct setting

Air in pump fluid systemSee POWER STEERING

PUMP article

Pump output lowSee POWER STEERING

PUMP article

Steering gear malfunctioningSee POWER STEERING

GEAR article

Wheel Surges or Jerks

Low fluid levelCheck and fill to proper level

Loose fan beltAdjust or replace if necessary

Insufficient pump pressureSee POWER STEERING

PUMP article

Sticky flow control valveSee POWER STEERING

PUMP article

Linkage hitting oil pan at full turnReplace bent components

Kick Back or Free Play

Air in pump fluid systemSee POWER STEERING

PUMP article

Worn poppet valve in steering gearSee POWER STEERING

PUMP article

Excessive over center lashSee POWER STEERING

GEAR article

Thrust bearing out of adjustmentSee POWER STEERING

GEAR article

Free play in pot couplingSee POWER STEERING

PUMP article

Steering gear coupling loose on shaftSee POWER STEERING

PUMP article

Steering disc mounting bolts looseTighten or replace if necessary

Coupling loose on worm shaftTighten or replace if necessary

Improper sector shaft adjustmentSee POWER STEERING

GEAR article

Excessive worm piston side playSee POWER STEERING

GEAR article

Damaged valve leverSee POWER STEERING

GEAR article

Universal joint looseTighten or replace if necessary

Defective rotary valveSee POWER STEERING

GEAR article

No Power When Parking

Sticking flow control valveSee POWER STEERING

PUMP article

Insufficient pump pressure outputSee POWER STEERING

PUMP article

Excessive internal pump leakageSee POWER STEERING

Page 32 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 246 of 454

STEERING COLUMN TROUBLE SHOOTING

BASIC STEERING COLUMN TROUBLE SHOOTING CHART

PUMP article

Excessive internal gear leakageSee POWER STEERING

PUMP article

Flange rubs against gear adjust plugSee STEERING COLUMN

article

Loose pump beltAdjust or replace if necessary

Low fluid levelCheck and add proper amount

of fluid

Engine idle too lowAdjust to correct setting

Steering gear-to-column misalignedSee STEERING COLUMN

article

No Power, Left Turn

Left turn reaction seal "O" ring wornSee POWER STEERING

GEAR article

Left turn reaction seal damaged/missingSee POWER STEERING

GEAR article

Cylinder head "O" ring damagedSee POWER STEERING

PUMP article

No Power, Right Turns

Column pot coupling bottomedSee STEERING COLUMN

article

Right turn reaction seal "O" ring wornSee POWER STEERING

GEAR article

Right turn reaction seal damagedSee POWER STEERING

GEAR article

Internal leakage through piston end plugSee POWER STEERING

GEAR article

Internal leakage through side plugsSee POWER STEERING

GEAR article

Lack of Effort in Turning

Left and/or right reaction seal sticking in cylinder headReplace, see POWER

STEERING GEAR article

Wanders to One Side

Front end alignment incorrectSee WHEEL ALIGNMENT

article

Unbalanced steering gear valveSee POWER STEERING

GEAR article

Low Pressure Due to Steering Pump

Flow control valve stuck or inoperativeSee POWER STEERING

PUMP article

Pressure plate not flat against cam ringSee POWER STEERING

PUMP article

Extreme wear of cam ringReplace and check

adjustments

Scored plate, thrust plate or rotorSee POWER STEERING

PUMP article

Vanes not installed properlySee POWER STEERING

PUMP article

Vanes sticking in rotor slotsSee POWER STEERING

PUMP article

Cracked/broken thrust or pressure plateSee POWER STEERING

PUMP article

NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to SUBJECT ,

DIAGNOST IC, or T EST ING articles available in the section(s) you are accessing.

CONDITION & POSSIBLE CAUSECORRECTION

Noise in Steering

Coupling pulled apartSee STEERING COLUMNS

article

Column not correctly alignedSee STEERING COLUMNS

article

Broken lower jointReplace joint

Horn contact ring notSee STEERING COLUMN

article

Bearing not lubricatedSee STEERING COLUMN

article

Shaft snap ring not properly seatedReseat or replace snap ring

Plastic spherical joint not lubricatedSee STEERING COLUMN

Page 33 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 249 of 454

Mismatched tiresSee WHEEL ALIGNMENT

Broken or sagging springSee SUSPENSION section

Broken torsion barSee SUSPENSION section

Power steering valve not centeredSee STEERING section

Front alignment out of toleranceSee WHEEL ALIGNMENT

section

Defective wheel bearingSee WHEEL BEARINGS in

SUSPENSION section

Uneven sway bar linksSee SUSPENSION section

Frame bentCheck for frame damage

Steering system bushing wornSee STEERING section

Hard Steering

Idler arm bushing too tightSee STEERING LINKAGE in

STEERING section

Ball joint tight or seizedSee SUSPENSION section

Steering linkage too tightSee STEERING LINKAGE in

STEERING section

Power steering fluid lowAdd proper amount of fluid

Power steering drive belt looseSee STEERING section

Power steering pump defectiveSee STEERING section

Steering gear out of adjustmentSee STEERING section

Incorrect wheel alignmentSee WHEEL ALIGNMENT

Damaged steering gearSee STEERING section

Damaged suspensionSee SUSPENSION section

Bent steering knuckle or supportsSee SUSPENSION section

Vehicle "Wanders"

Strut rod or control arm bushing wornSee SUSPENSION section

Loose or worn wheel bearingsSee WHEEL BEARINGS in

SUSPENSION section

Improper tire inflationCheck tire pressure

Stabilizer bar missing or defectiveSee SUSPENSION section

Wheel alignment out of toleranceSee Adjustment in WHEEL

ALIGNMENT section

Broken springSee SUSPENSION section

Defective shock absorberReplace shock absorbers

Worn steering & suspension componentsSee SUSPENSION section

Front End Shimmy

Tire out of balance/roundCheck tire balance

Excessive wheel runoutSee WHEEL ALIGNMENT

Insufficient or improper casterSee WHEEL ALIGNMENT

section

Worn suspension or steering componentsSee SUSPENSION section

Defective shock absorbersReplace shock absorber

Wheel bearings worn or looseSee WHEEL BEARING ADJ.

in SUSPENSION section

Power steering reaction Bracket looseSee STEERING section

Steering gear box (rack) mounting looseSee STEERING section

Steering gear adjustment looseSee STEERING section

Worn spherical jointsSee SUSPENSION section

Toe-In Not Adjustable

Lower control arm bentSee SUSPENSION section

Frame bentCheck frame for damage

Camber Not Adjustable

Control arm bentSee SUSPENSION section

Frame bentCheck frame for damage

Hub & bearing not seated properlySee SUSPENSION section

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00027342

Page 36 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 250 of 454

Back To Article

GENERAL INFORMATION

T ROUBLE SHOOT ING

* PLEASE READ THIS FIRST *

ENGINE PERFORMANCE

TUNE-UP TROUBLE SHOOTING NOTE:T his article is generic in nature and all inform ation does not apply to all vehicles. For vehicle specific

inform ation, see the appropriate articles in the ENGINE PERFORMANCE category.

NOTE:T his article is generic in nature and all inform ation does not apply to all vehicles. For vehicle specific

inform ation, see the appropriate articles in the ENGINE PERFORMANCE category.

Problem & Possible CauseAction

Carbon Fouled Plugs

C l o gge d Air Fil t e rReplace Air Filter

Incorrect Idle SpeedReset Idle Speed

Faulty Ignition WiringReplace Ignition Wiring

Sticky Valves/Worn Valve SealCheck Valve Train

Fuel Injection OperationCheck Fuel Injection

Wet/Oil Fouled Plugs

Worn Rings/PistonsOverhaul/Replace Engine

Excessive Cylinder WearOverhaul/Replace Engine

Plug Gap Bridged

Combustion Chamber Carbon DepositsClean Combustion

Chamber

Blistered Electrode

Engine OverheatingCheck Cooling System

Loose Spark PlugsClean/Torque Plugs

Over-Advanced TimingReset Timing

Wrong Plug Heat RangeInstall Correct Plug

Melted Electrodes

Incorrect TimingReset Timing

Burned ValvesReplace Valves

Engine OverheatingCheck Cooling System

Wrong Plug Heat RangeInstall Correct Plug

Engine Won't Start

Loose ConnectionsCheck Connections

No PowerCheck Fuses/Battery

Loose/Worn Timing Belt/Chain/GearsCheck Belt/Chain/Gears

Engine Runs Rough

Leaky/Clogged Fuel InjectorsRepair Fuel Injectors

Leaky/Clogged Fuel LinesRepair Fuel Lines

Clogged Fuel FilterReplace Fuel Filter

Incorrect TimingReset Timing/Check

Advance

Faulty Plugs/WiresReplace Plugs/Wires

Uneven CompressionOverhaul/Replace Engine

Poor Acceleration

Incorrect Ignition TimingReset Timing

Leaky ValvesCheck Compression

Component Failure

Spark ArcingReplace Faulty Part

Defective Pick-Up CoilReplace Pick-Up Coil

Defective Ignition CoilReplace Ignition Coil

Defective Control UnitReplace Control Unit

Ignition Diagnosis By Scope Pattern

All Firing Lines Abnormally High

Retarded Ignition TimingReset Ignition Timing

Lean Air/Fuel MixtureAdjust Fuel Mixture

High Secondary ResistanceRepair Secondary

Ign it io n

All Firing Lines Abnormally Low

Rich Air/Fuel MixtureAdjust Air/Fuel Mixture

Arcing Coil WireReplace Coil Wire

Cracked CoilReplace Coil

Low Coil OutputReplace Coil

Low CompressionCheck/Repair Engine

Page 1 of 3 MITCHELL 1 ARTICLE - GENERAL INFORMATION TROUBLE SHOOTING

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 270 of 454

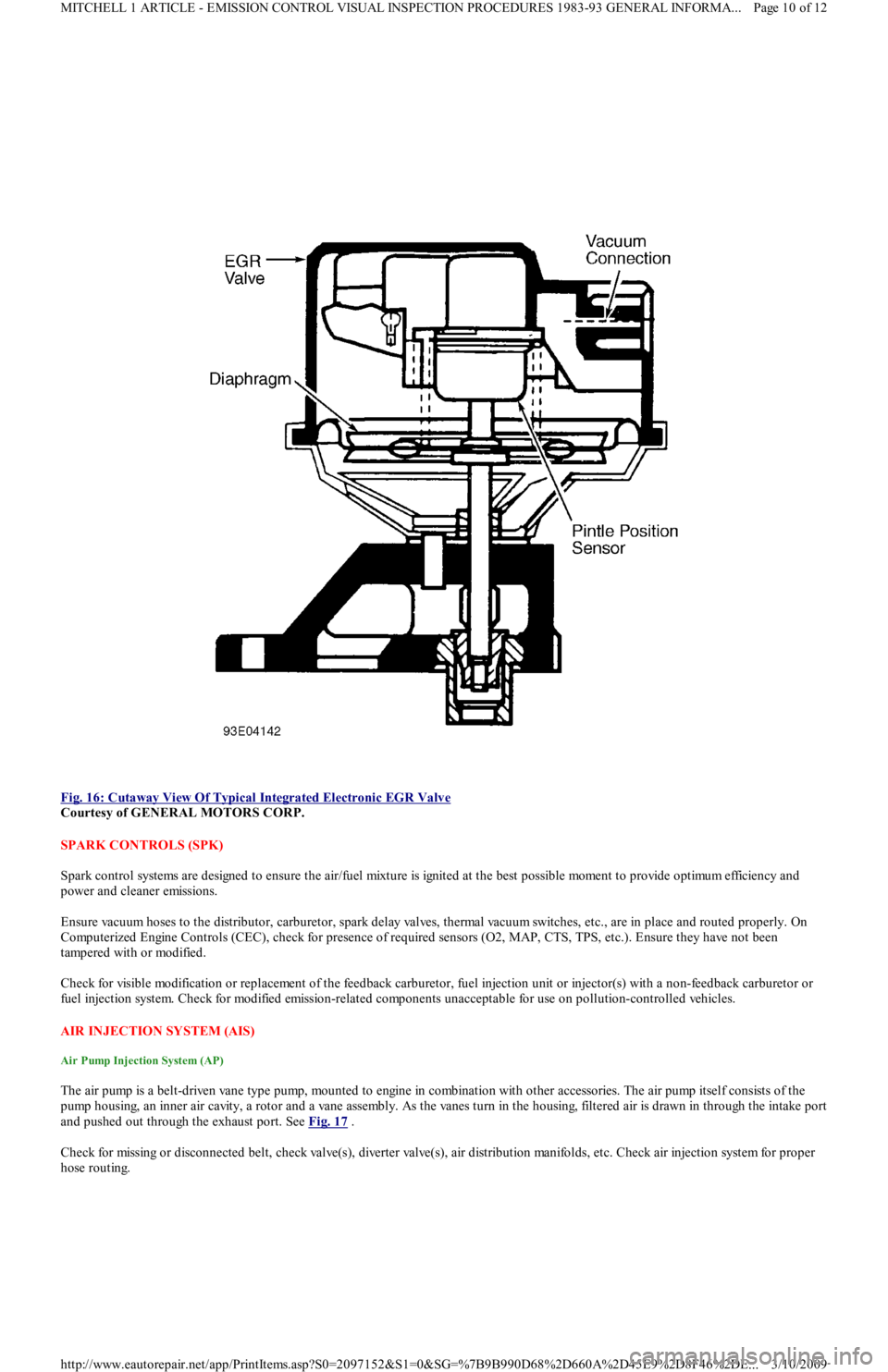

Fig. 16: Cutaway View Of Typical Integrated Electronic EGR Valve

Courtesy of GENERAL MOTORS CORP.

SPARK CONTROLS (SPK)

Spark control systems are designed to ensure the air/fuel mixture is ignited at the best possible moment to provide optimum efficiency and

power and cleaner emissions.

Ensure vacuum hoses to the distributor, carburetor, spark delay valves, thermal vacuum switches, etc., are in place and routed properly. On

Computerized Engine Controls (CEC), check for presence of required sensors (O2, MAP, CTS, TPS, etc.). Ensure they have not been

tampered with or modified.

Check for visible modification or replacement of the feedback carburetor, fuel injection unit or injector(s) with a non-feedback carburetor or

fuel injection system. Check for modified emission-related components unacceptable for use on pollution-controlled vehicles.

AIR INJECTION SYSTEM (AIS)

Air Pump Injection System (AP)

The air pump is a belt-driven vane type pump, mounted to engine in combination with other accessories. The air pump itself consists of the

pump housing, an inner air cavity, a rotor and a vane assembly. As the vanes turn in the housing, filtered air is drawn in through the intake port

and pushed out through the exhaust port. See Fig. 17

.

Check for missing or disconnected belt, check valve(s), diverter valve(s), air distribution manifolds, etc. Check air injection system for proper

hose routing.

Page 10 of 12 MITCHELL 1 ARTICLE - EMISSION CONTROL VISUAL INSPECTION PROCEDURES 1983-93 GENERAL INFORMA...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 309 of 454

article. Drain oil from compressor through suction and discharge ports. Measure amount of oil drained. If amount drained is more than

2.4 ounces, fill with same amount using new oil. If amount drained is less than 2.4 ounces, fill with 2.4 ounces. Install compressor and

recharge.

3. If A/C components are replaced, add refrigerant oil to system. Add 1.4 ounces if condenser is replaced. Add 2 ounces if the evaporator

is replaced. Oil does not need to be added if receiver-drier is replaced.

SANDEN SCROLL DRAIN & REFILL

Discharge system. Remove compressor from vehicle. Drain oil from compressor through inlet and outlet holes. Refill compressor with 2.8

ounces of oil through suction port. When replacing condenser, add .5 ounce. When replacing evaporator, add 1.7 ounces. When replacing

other A/C components, add .5 ounce per component replaced.

SANDEN 5-CYL DRAIN & REFILL

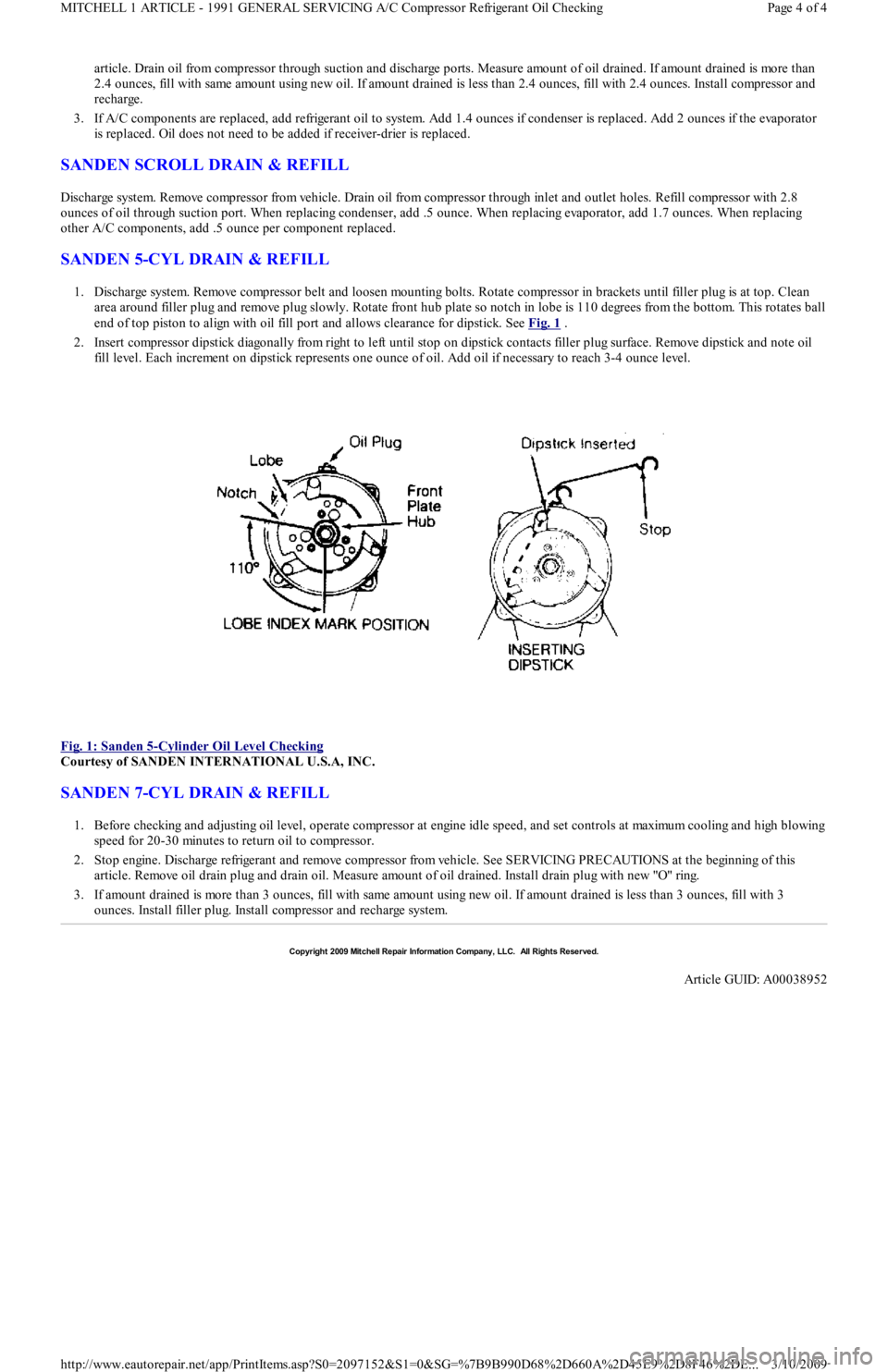

1. Discharge system. Remove compressor belt and loosen mounting bolts. Rotate compressor in brackets until filler plug is at top. Clean

area around filler plug and remove plug slowly. Rotate front hub plate so notch in lobe is 110 degrees from the bottom. This rotates ball

end of top piston to align with oil fill port and allows clearance for dipstick. See Fig. 1

.

2. Insert compressor dipstick diagonally from right to left until stop on dipstick contacts filler plug surface. Remove dipstick and note oil

fill level. Each increment on dipstick represents one ounce of oil. Add oil if necessary to reach 3-4 ounce level.

Fig. 1: Sanden 5

-Cylinder Oil Level Checking

Courtesy of SANDEN INTERNATIONAL U.S.A, INC.

SANDEN 7-CYL DRAIN & REFILL

1. Before checking and adjusting oil level, operate compressor at engine idle speed, and set controls at maximum cooling and high blowing

speed for 20-30 minutes to return oil to compressor.

2. Stop engine. Discharge refrigerant and remove compressor from vehicle. See SERVICING PRECAUTIONS at the beginning of this

article. Remove oil drain plug and drain oil. Measure amount of oil drained. Install drain plug with new "O" ring.

3. If amount drained is more than 3 ounces, fill with same amount using new oil. If amount drained is less than 3 ounces, fill with 3

ounces. Install filler plug. Install compressor and recharge system.

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00038952

Page 4 of 4 MITCHELL 1 ARTICLE - 1991 GENERAL SERVICING A/C Compressor Refrigerant Oil Checking

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 346 of 454

5. Check blower motor fan switch continuity. Resistance should not exceed 4 ohms. See BLOWER MOTOR FAN SWITCH

CONTINUITY table. If continuity is not present, replace fan switch. If continuity is okay, repair open in Black wire from blower motor

switch to ground.

BLOWER MOTOR FAN SWITCH CONTINUITY

REMOVAL & INSTALLATION

CONTROL PANEL

1. Remove bezel screws and accessory bezel. Remove radio. Remove 4 screws securing control panel to instrument panel. Remove glove

box attaching screws and glove box. Remove the retaining clip and disconnect fresh/recirculation air door cable from mode door lever.

2. Disconnect mode select cable at mode control door lever. Disconnect temperature control cable at temperature control mode door lever.

Pull control panel away from instrument panel. Disconnect blower motor switch connector. Disconnect illumination electrical

connector. Remove control panel. To install, reverse removal procedure. Adjust control cables. See ADJUSTMENTS in this article.

BLOWER MOTOR FAN SWITCH

Remove control panel. See CONTROL PANEL R & I

. Remove blower motor fan switch knob. Remove attaching nut. To install, reverse

removal procedure.

HEATER CORE

1. Disconnect negative battery cable. Remove steering wheel by prying out center trim insert and removing steering wheel retaining nut.

Remove 2 steering wheel cover retaining screws and remove cover. Using a steering wheel puller, remove steering wheel.

2. Remove 5 screws and remove lower and upper steering column covers. Disconnect electrical connections and remove multifunction

switch. Remove 5 screws and pull instrument cluster hood rearward. Disconnect electrical connections and remove instrument cluster

hood.

3. Disconnect speedometer cable at transaxle. Remove 4 instrument cluster screws. Pull instrument cluster rearward and disconnect

speedometer cable and electrical connections. Remove instrument cluster.

4. Remove 2 center bracket mounting bolts under steering column and remove bracket. Remove glove box attaching screws and remove

glove box. Remove left and right heater ducts. Remove fuse panel cover. Remove 2 screws securing fuse panel and push fuse panel

inward. DO NOT remove fuse panel.

5. Slide both seats to most forward position. Remove 2 console attaching screws, located in front of seat belt anchors. Slide both seats to

rearmost position. Remove parking brake console insert. Using a Phillips screwdriver, remove push retainer insert, located at front lower

edge of parking brake console. Pull back on parking brake lever and remove parking brake console.

6. Remove gearshift knob. Remove screws and remove shift console. Remove radio/heater control panel bezel screws and remove bezel.

Remove 4 radio attaching screws. Pull radio out and disconnect antenna lead and electrical connections. Disconnect radio ground lead

and remove radio.

7. Remove 4 screws attaching heater control panel. Disconnect control cables and electrical connections. Remove control panel, while

pulling cables through opening.

8. Pry out bolt cover trim inserts in top corners of dash. Remove bolts located under trim panels. Remove 7 instrument panel attaching

bolts and 2 nuts. Pull instrument panel rearward. Disconnect any harness connectors and clips. Remove instrument panel.

9. Disconnect electrical connections at blower and resistor. Remove harness from routing brackets on heater box. Loosen clamp screw

securing air inlet housing. Remove attaching nuts at top and bottom of heater box. Disconnect defroster ducts and remove heater

assembly.

10. Disconnect link connecting 2 defroster doors. Remove attaching screw just above and to right of blower resistor. Turn heater assembly

around and remove screw just to left of blower motor opening. Remove clips securing 2 halves of heater assembly. Separate halves. Lift

out heater core.

11. To install, reverse removal procedure. Ensure all heater control cables are routed and adjusted properly. See ADJUSTMENTS in this

article. Fill cooling system. Check for leaks.

BLOWER MOTOR & RESISTOR

Disconnect negative battery cable. Remove instrument panel spacer brace located below steering column. Remove airflow duct below steering

column. Disconnect blower motor or resistor wiring. Remove 3 blower motor attaching screws or 2 resistor attaching screws and remove

component. To install, reverse removal procedure.

Switch PositionContinuity Between Wire Colors

1Black-to-Blue/White

2Black-to-Blue/Yellow & Blue/Yellow-to-Blue/Red

3Black-to-Blue/Black & Blue/Black-to-Blue/Red

Page 2 of 4 MITCHELL 1 ARTICLE - HEATER SYSTEM 1990-92 HEATER SYSTEMS Ford Motor Co.

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...