ECU FORD FESTIVA 1991 Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 9 of 454

Black/White and Black wire terminals of relay. Check continuity of relay across 2 Black/Yellow wire terminals of relay. Continuity should

exist when relay is energized. When relay is de-energized, continuity should not exist.

FILAMENT TESTING

1. To locate breaks in grid wire filaments, attach a voltmeter to middle portion of each filament. Attach other meter probe to vertical

section of window grid.

2. If a grid is broken, meter will register either zero volt or battery voltage, depending on if grid is broken between or outside test leads. If

wire is not broken, meter will register about one half of battery voltage. To locate break, move probe along wire until meter needle

mo ves ab ru p t l y.

REMOVAL & INSTALLATION

REAR DEFOGGER SWITCH

Removal & Installation (Capri)

1. Disconnect negative battery cable. Pull out center storage compartment. Remove 2 nuts, 2 lower screws, and heater/radio bezel. Pull

outward and remove 2 trim covers, one located on each side of steering column.

2. Remove instrument panel bezel retaining screws and pull instrument bezel from dash. Disconnect electrical connector from rear

defogger switch. Depress tangs on both sides of switch and remove switch. To install, reverse removal procedure.

Removal & Installation (Festiva)

Disconnect negative battery cable. Remove steering column covers. Remove screws securing instrument panel bezel to instrument panel. Pull

instrument bezel away from instrument panel. Disconnect electrical connectors from switches in bezel. Compress rear defogger switch lock

tabs and remove switch from bezel. To install, reverse removal procedure.

WIRING DIAGRAMS

See appropriate chassis wiring diagram in the WIRING DIAGRAMS Section.

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00028302

Page 3 of 3 MITCHELL 1 ARTICLE - DEFOGGER - REAR WINDOW 1991 ACCESSORIES & SAFETY EQUIPMENT Rear Window D

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 10 of 454

Back To Article

1990-92 ACCESSORIES & EQUIPMENT

Power Mirrors - Festiva

DESCRIPTION & OPERATION

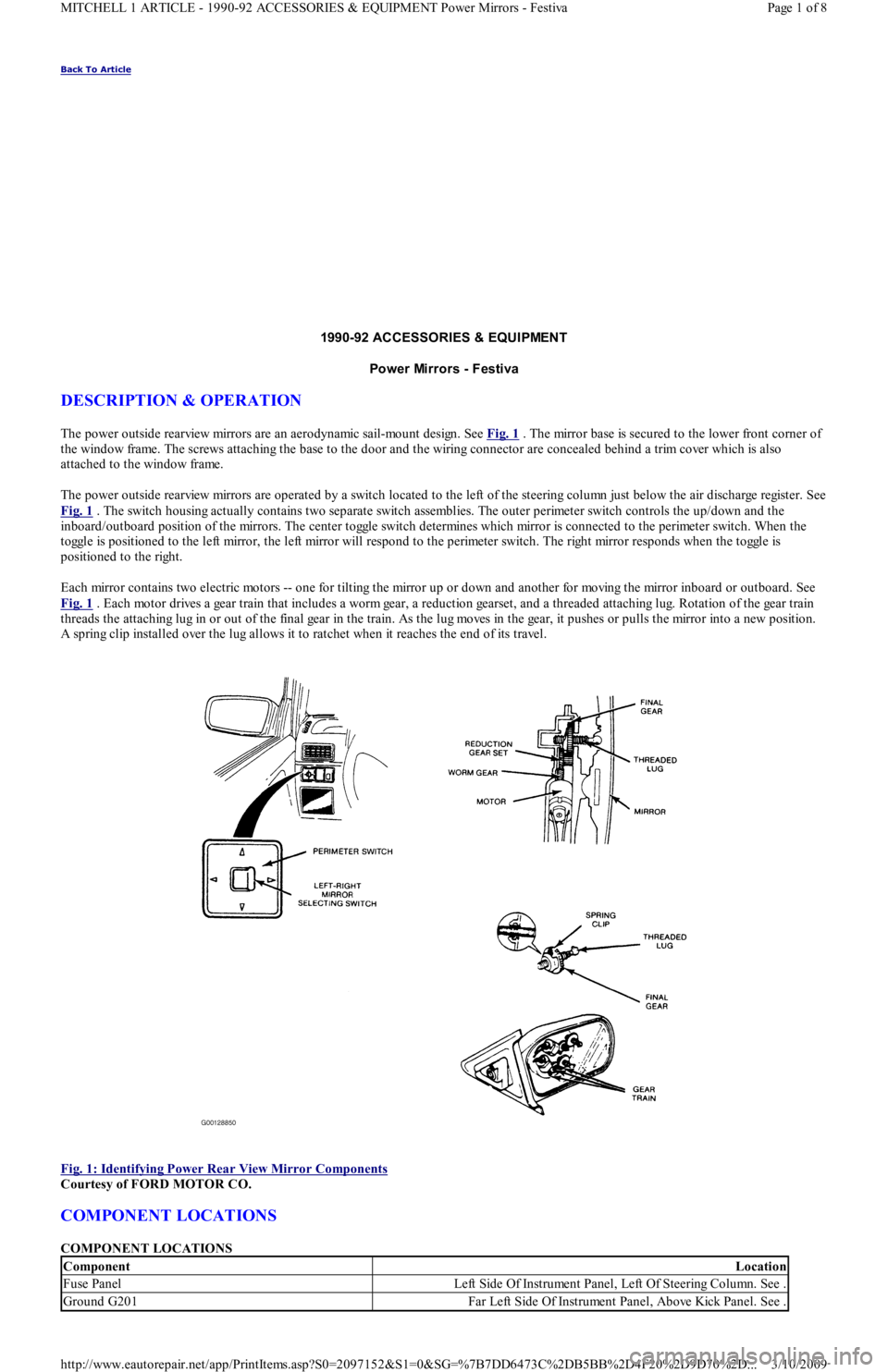

The power outside rearview mirrors are an aerodynamic sail-mount design. See Fig. 1 . The mirror base is secured to the lower front corner of

the window frame. The screws attaching the base to the door and the wiring connector are concealed behind a trim cover which is also

attached to the window frame.

The power outside rearview mirrors are operated by a switch located to the left of the steering column just below the air discharge register. See

Fig. 1

. The switch housing actually contains two separate switch assemblies. The outer perimeter switch controls the up/down and the

inboard/outboard position of the mirrors. The center toggle switch determines which mirror is connected to the perimeter switch. When the

toggle is positioned to the left mirror, the left mirror will respond to the perimeter switch. The right mirror responds when the toggle is

positioned to the right.

Each mirror contains two electric motors -- one for tilting the mirror up or down and another for moving the mirror inboard or outboard. See

Fig. 1

. Each motor drives a gear train that includes a worm gear, a reduction gearset, and a threaded attaching lug. Rotation of the gear train

threads the attaching lug in or out of the final gear in the train. As the lug moves in the gear, it pushes or pulls the mirror into a new position.

A spring clip installed over the lug allows it to ratchet when it reaches the end of its travel.

Fig. 1: Identifying Power Rear View Mirror Components

Courtesy of FORD MOTOR CO.

COMPONENT LOCATIONS

COMPONENT LOCATIONS

ComponentLocation

Fuse PanelLeft Side Of Instrument Panel, Left Of Steering Column. See .

Ground G201Far Left Side Of Instrument Panel, Above Kick Panel. See .

Page 1 of 8 MITCHELL 1 ARTICLE - 1990-92 ACCESSORIES & EQUIPMENT Power Mirrors - Festiva

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 20 of 454

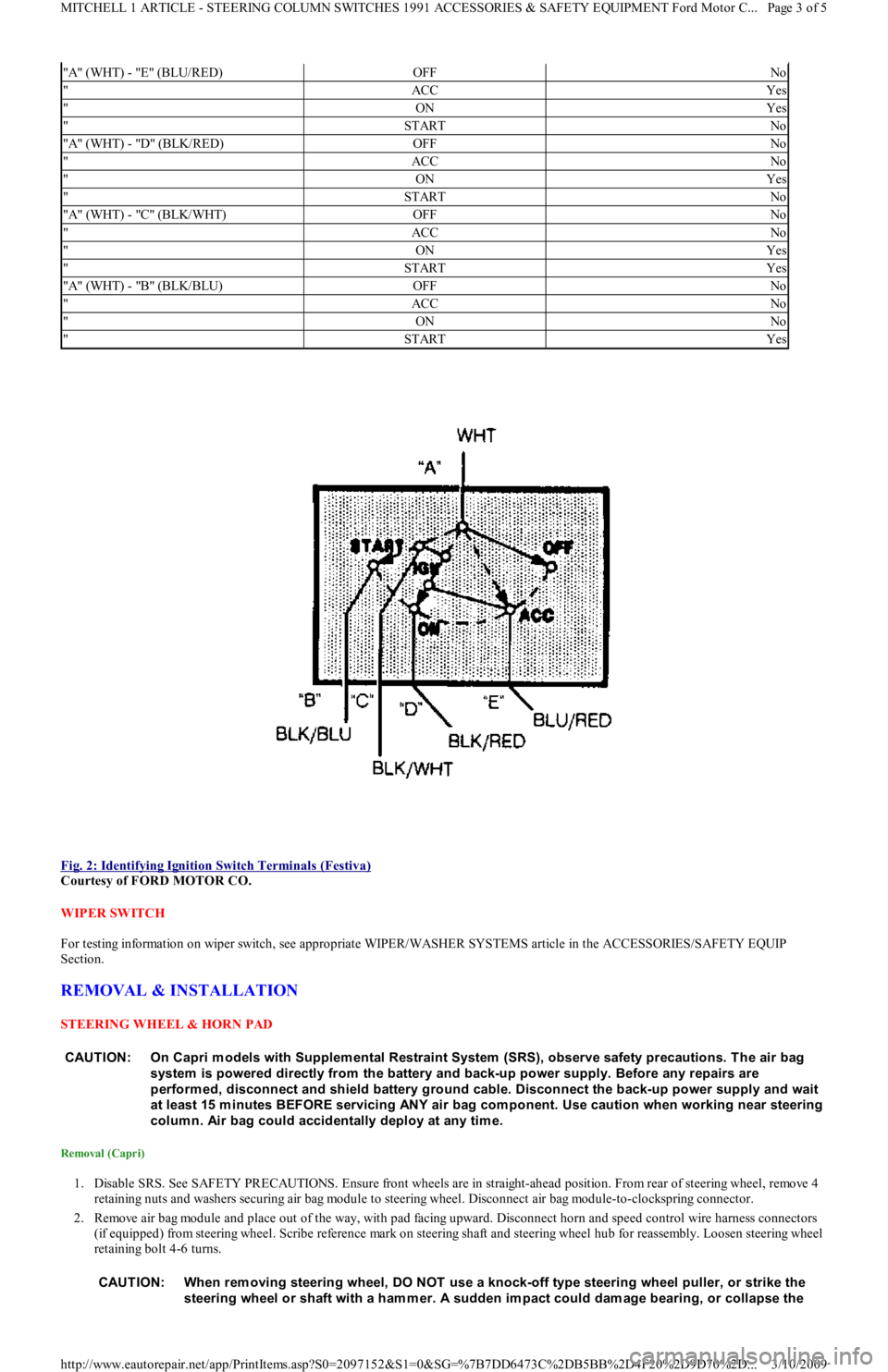

Fig. 2: Identifying Ignition Switch Terminals (Festiva)

Courtesy of FORD MOTOR CO.

WIPER SWITCH

For testing information on wiper switch, see appropriate WIPER/WASHER SYSTEMS article in the ACCESSORIES/SAFETY EQUIP

Section.

REMOVAL & INSTALLATION

STEERING WHEEL & HORN PAD

Removal (Capri)

1. Disable SRS. See SAFETY PRECAUTIONS. Ensure front wheels are in straight-ahead position. From rear of steering wheel, remove 4

retaining nuts and washers securing air bag module to steering wheel. Disconnect air bag module-to-clockspring connector.

2. Remove air bag module and place out of the way, with pad facing upward. Disconnect horn and speed control wire harness connectors

(if equipped) from steering wheel. Scribe reference mark on steering shaft and steering wheel hub for reassembly. Loosen steering wheel

retaining bolt 4-6 turns.

"A" (WHT) - "E" (BLU/RED)OFFNo

"ACCYes

"ONYes

"STARTNo

"A" (WHT) - "D" (BLK/RED)OFFNo

"ACCNo

"ONYes

"STARTNo

"A" (WHT) - "C" (BLK/WHT)OFFNo

"ACCNo

"ONYes

"STARTYes

"A" (WHT) - "B" (BLK/BLU)OFFNo

"ACCNo

"ONNo

"STARTYes

CAUTION: On Capri m odels with Supplem ental Restraint System (SRS), observe safety precautions. T he air bag

system is powered directly from the battery and back-up power supply. Before any repairs are

perform ed, disconnect and shield battery ground cable. Disconnect the back-up power supply and wait

at least 15 m inutes BEFORE servicing ANY air bag com ponent. Use caution when working near steering

colum n. Air bag could accidentally deploy at any tim e.

CAUT ION: When rem oving steering wheel, DO NOT use a knock-off type steering wheel puller, or strike the

steering wheel or shaft with a ham m er. A sudden im pact could dam age bearing, or collapse the

Page 3 of 5 MITCHELL 1 ARTICLE - STEERING COLUMN SWITCHES 1991 ACCESSORIES & SAFETY EQUIPMENT Ford Motor C

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 21 of 454

3. Position Steering Wheel Remover (T67L-3600-A) on steering wheel. Tighten bolt on remover until steering wheel is loose. Remove

steering wheel puller, steering wheel retaining bolt, and steering wheel.

Installation

1. Ensure front wheels are in straight-ahead position. Route clockspring wiring harness through steering wheel opening. Position steering

wheel on steering shaft and align reference marks.

2. Ensure clockspring wire is not pinched when positioning steering wheel. Install new steering wheel retaining bolt and tighten to

specification. See TORQUE SPECIFICATIONS table at end of article. Connect horn and speed control wiring connectors (if equipped)

to steering wheel.

3. Connect air bag module-to-clockspring connector. Install air bag module. Tighten air bag module retaining nuts to specification.

Activate SRS. See SAFETY PRECAUTIONS. Check AIR BAG light to ensure system is functioning properly.

Removal (Festiva)

From back of steering wheel, remove 2 screws securing horn pad. Disconnect horn wire from horn pad and remove pad. Remove steering

wheel nut. Scribe reference mark on steering shaft and steering wheel hub for reassembly. Using Steering Wheel Puller (T67L-3600-A),

remove steering wheel.

Installation

Position steering wheel on steering shaft and align reference marks. Be sure cutouts in rear cover engage turn signal canceling cam. To

complete installation, reverse removal procedure.

COMBINATION SW ITCH

Removal (Capri)

1. Disconnect negative battery cable. Remove lower steering column cover. Remove center access panel and trim cover under steering

column. Remove left side defroster connector tube. Remove steering column upper retaining bolts. Column will pivot downward and

rest on instrument panel brace.

2. Remove 2 switch retaining screws and remove switch. Grasp switch and lever and pull lever out of switch. Disconnect switch electrical

connectors and remove switch.

Installation

Align key with slot and install lever in switch assembly. Position switch on steering column and install retaining screws. To complete

installation, reverse removal procedure.

Removal (Festiva)

1. Disconnect negative battery cable. Remove steering wheel. See STEERING WHEEL & HORN PAD under REMOVAL &

INSTALLATION. Remove 4 screws from upper half of lower steering column cover and remove cover. Remove upper steering column

cover. Remove 5 clips from lower half of lower steering column cover and remove cover.

2. Release wiring harness clip and unplug 4 harness connectors from back of combination switch. From below steering column, loosen

band clamp securing switch hub to steering column jacket. Pull switch assembly from steering column.

Installation

Slide combination switch assembly onto steering column. Make sure switch assembly is seated and level against end of column jacket. To

complete installation, reverse removal procedure.

HEADLIGHT SWITCH

Removal & Installation (Capri)

1. Headlight off/on switch is located on left side of instrument panel bezel. Disconnect negative battery cable. Pull out center storage

compartment. Remove 2 upper screws, 2 lower screws and heater/radio bezel. Pull outward and remove trim covers located on both

sides of steering column.

2. Remove retaining screws and carefully pull instrument panel bezel partially away from dash. Disconnect electrical connector from

headlight switch. Depress tangs on both sides of switch and remove switch from bezel. To install, reverse removal procedure.

IGNITION SWITCH & LOCK CYLINDER

Removal (Capri)

1. Disconnect negative battery cable. Remove lower steering column cover. Remove center access panel and trim cover under steering

column. Remove left side defroster connector tube. Remove steering column upper retaining bolts. Column will pivot downward and

rest on instrument panel brace. steering colum n.

CAUT ION: Rem ove steering wheel carefully to avoid dam aging clockspring wiring, air bag m odule connector, or

accidentally turning clockspring. After steering wheel rem oval, tape clockspring in position to prevent

dam age and keep it from being turned accidentally.

CAUTION: Ensure that no wiring is pinched beneath steering colum n when lowered.

Page 4 of 5 MITCHELL 1 ARTICLE - STEERING COLUMN SWITCHES 1991 ACCESSORIES & SAFETY EQUIPMENT Ford Motor C

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 22 of 454

2. With ignition key inserted in lock assembly, rotate tumbler while pushing release pin with a .125" (3.17 mm) drift punch. Pull tumbler

assembly out of housing. Remove upper column cover. Remove column lock shield. Disconnect ignition switch electrical connector.

Remove switch retaining screws and remove switch.

Installation

Position ignition switch on column lock assembly. Make sure actuator pin of lock assembly fits into slot in ignition switch. To complete

installation, reverse removal procedure.

Removal & Installation (Festiva)

1. Disconnect negative battery cable. Remove 4 screws from upper half of lower steering column cover and remove cover. Remove upper

steering column cover. Remove 5 clips from lower half of lower steering column cover and remove cover.

2. Remove 4 steering column shield nuts and remove shield. Remove 2 shield bracket bolts and remove bracket. Remove air discharge duct

from below steering column. Remove steering column attaching nuts then lower steering column mounting bracket.

3. Remove tie strap securing key warning buzzer switch wires. Remove ignition switch attaching screw. Pull switch loose from switch

housing. Remove switch harness from routing clip and disconnect electrical connectors. Remove switch. To install, reverse removal

procedure.

TURN SIGNAL SWITCH

See COMBINATION SWITCH under REMOVAL & INSTALLATION.

WIPER SWITCH

Removal & Installation (Capri)

Remove center trim panel and lower steering column cover. Disconnect wiper switch electrical connector and pull wiring from routing clip.

Firmly grasp switch and lever and pull out to remove. To install, reverse removal procedure.

Removal & installation (Festiva)

See COMBINATION SWITCH under REMOVAL & INSTALLATION.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS CAUTION: Ensure that no wiring is pinched beneath steering colum n when it is lowered.

ApplicationFt. Lbs. (N.m)

Capri

Column Lock Shield Screw & Nut11-14 (15-19)

Ignition Lock Housing Bolt12-13 (16-18)

Steering Wheel Bolt23-33 (31-45)

Upper Column Retaining Bolts17-23 (23-31)

Festiva

Steering Wheel Nut29-36 (39-49)

Upper Column Retaining Bolts23-34 (31-46)

INCH Lbs. (N.m)

Capri

Ign it io n Swit ch Screw50-70 (5.6-7.9)

Capri & Festiva

Air Bag Module-To-Steering Wheel Nuts35-53 (4-6)

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00028303

Page 5 of 5 MITCHELL 1 ARTICLE - STEERING COLUMN SWITCHES 1991 ACCESSORIES & SAFETY EQUIPMENT Ford Motor C

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 26 of 454

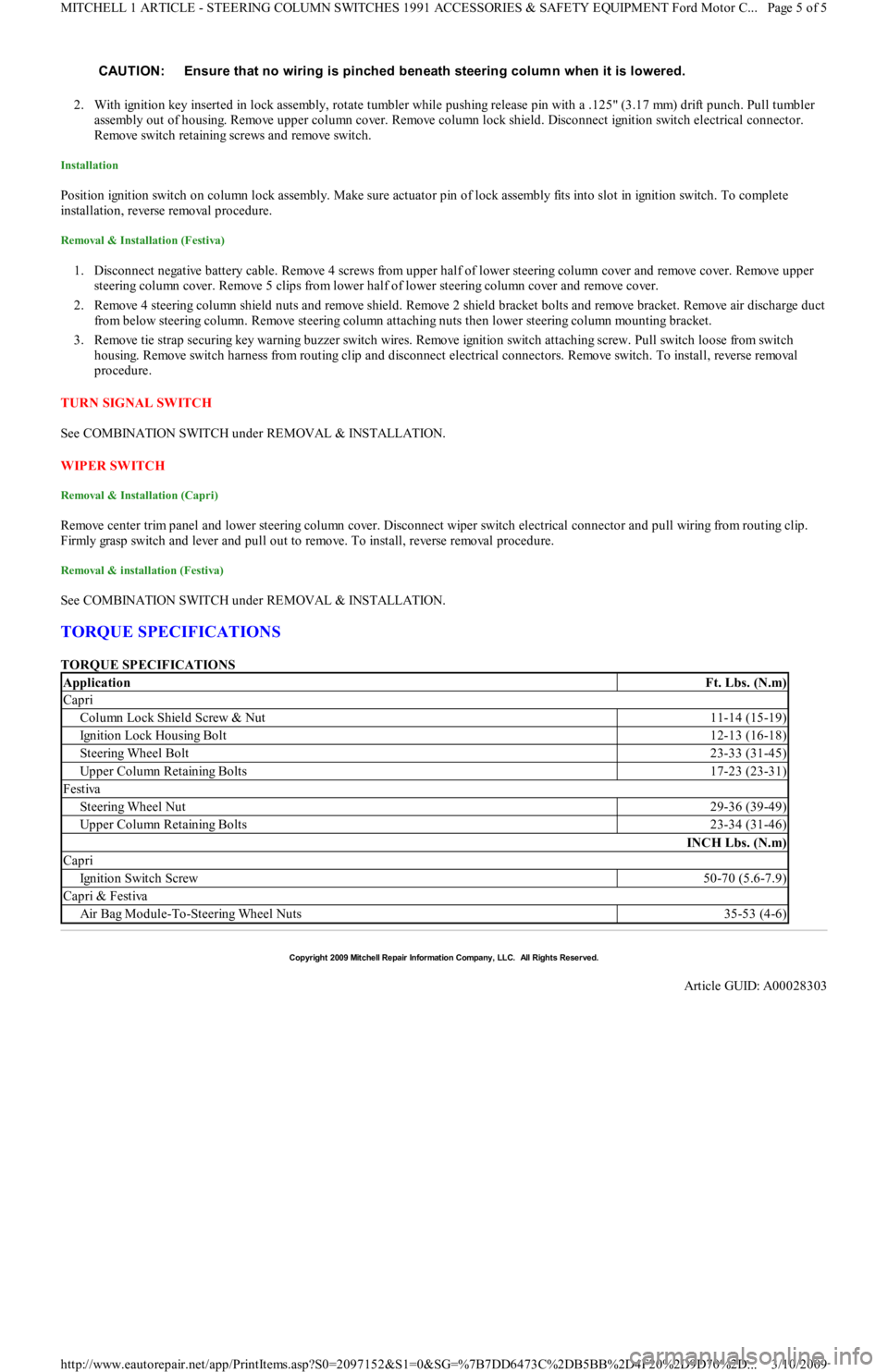

Fig. 3: Identifying Rear Wiper/Washer Switch Terminals (Festiva)

Courtesy of FORD MOTOR CO.

REAR WASHER MOTOR TEST

See FRONT WASHER MOTOR TEST under TESTING.

REMOVAL & INSTALLATION

FRONT WIPER MOTOR

Removal

Disconnect negative battery cable. On Capri, gently pry linkage off ball socket at wiper motor arm. On Festiva, remove access plate then gently

pry linkage off ball socket at wiper motor arm. On all models, disconnect wiper motor electrical connector. Remove 4 mounting bolts and

rubber insulators and remove wiper motor.

Installation

Position wiper motor on firewall. Install 4 rubber insulators and mounting screws and tighten to 62-89 INCH lbs. (7-10 N.m). Reverse removal

procedure to complete installation. Check wipers for proper operation.

FRONT WIPER/WASHER SWITCH

Removal & Installation (Capri)

Remove center trim panel and access cover under steering column. Remove 2 screws and remove lower steering column shroud. Disconnect

wiper/washer switch electrical connector and pull wiring from routing clip. Firmly grasp switch and lever and remove from mounting. To

install, reverse removal procedure.

Removal & Installation (Festiva)

1. Disconnect negative battery cable. From back of steering wheel, remove 2 screws securing horn pad. Disconnect horn wire from horn

pad and remove pad. Remove steering wheel nut. Scribe reference mark on steering shaft and steering wheel hub for reassembly. Using

Steering Wheel Puller (T67L-3600-A), remove steering wheel.

2. Remove 4 screws from upper half of lower steering column cover. Remove cover. Remove upper steering column cover. Remove 5 clips

from lower half of lower steering column cover. Remove cover.

3. Release wiring harness clip and unplug 4 harness connectors from back of combination switch. From below steering column, loosen

band clamp securing switch hub to steering column jacket. Pull switch assembly from steering column.

4. To install, slide combination switch assembly onto steering column. Make sure switch assembly is seated and level against end of

column jacket. To complete installation, reverse removal procedure.

FRONT WASHER MOTOR & RESERVOIR

Removal & Installation (Capri)

Drain reservoir if necessary. Remove 2 bolts securing reservoir to inner finder. Disconnect electrical connector from washer pump mo t o r.

NOTE:Disconnect linkage from wiper m otor arm ball socket NOT by rem oving nut and wiper m otor arm . This

will elim inate the need to retim e wiper m otor and linkage. Replacem ent m otors are supplied with arm

attached. Manufacturer does not give procedure for tim ing m otor arm to wiper park position.

Page 4 of 5 MITCHELL 1 ARTICLE - WIPER/WASHER SYSTEM 1991 ACCESSORIES & SAFETY EQUIPMENT Ford Motor Co. Wip

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 27 of 454

Disconnect fluid lines and remove reservoir. To install, reverse removal procedure.

Removal & Installation (Festiva)

1. Disconnect negative battery cable. Remove washer reservoir filler neck attaching bolt. Remove coolant expansion reservoir. Disconnect

washer pump electrical connector. Remove left front splash shield.

2. Disconnect washer pump fluid lines and detach lines from reservoir clips. Remove reservoir attaching nuts and bolt. Detach washer

reservoir from filler neck and remove reservoir. To install, reverse removal procedure.

REAR WIPER MOTOR

Removal & Installation (Festiva)

Remove rear wiper arm and blade assembly. Remove boot from outer bushing attaching nut. Remove outer bushing attaching nut and remove

outer bushing. Remove liftgate trim panel. Disconnect wiper motor electrical connector. Remove 4 wiper motor mounting bolts and remove

motor. To install, reverse removal procedure.

REAR WIPER/WASHER SWITCH

Removal & Installation (Festiva)

Disconnect negative battery cable. Remove steering column covers. Remove screws securing instrument panel bezel to instrument panel. Pull

instrument bezel away from instrument panel. Disconnect electrical connectors from switches in bezel. Compress wiper/washer switch lock

tabs and remove switch from bezel. To install, reverse removal procedure.

REAR WASHER MOTOR & RESERVOIR

Removal & Installation (Festiva)

Open liftgate and detach reservoir cap. Remove rear quarter trim panel. Remove reservoir mounting bolts. Disconnect electrical connector

from washer pump. Disconnect fluid lines. Remove reservoir. To install, reverse removal procedure.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

WIRING DIAGRAMS

See appropriate chassis wiring diagram in the WIRING DIAGRAMS Section.

ApplicationINCH Lbs. (N.m)

Front Wiper Arm Retaining Nut89-124 (10-14)

Front Wiper Motor Mounting Bolts62-89 (7-10)

Rear Outer Bushing Retaining Nut27-44 (3-5)

Rear Wiper Arm Nut53-62 (6-7)

Rear Wiper Motor Mounting Bolts71-97 (8-11)

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00028304

Page 5 of 5 MITCHELL 1 ARTICLE - WIPER/WASHER SYSTEM 1991 ACCESSORIES & SAFETY EQUIPMENT Ford Motor Co. Wip

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 29 of 454

Power brake push rod length is not adjustable.

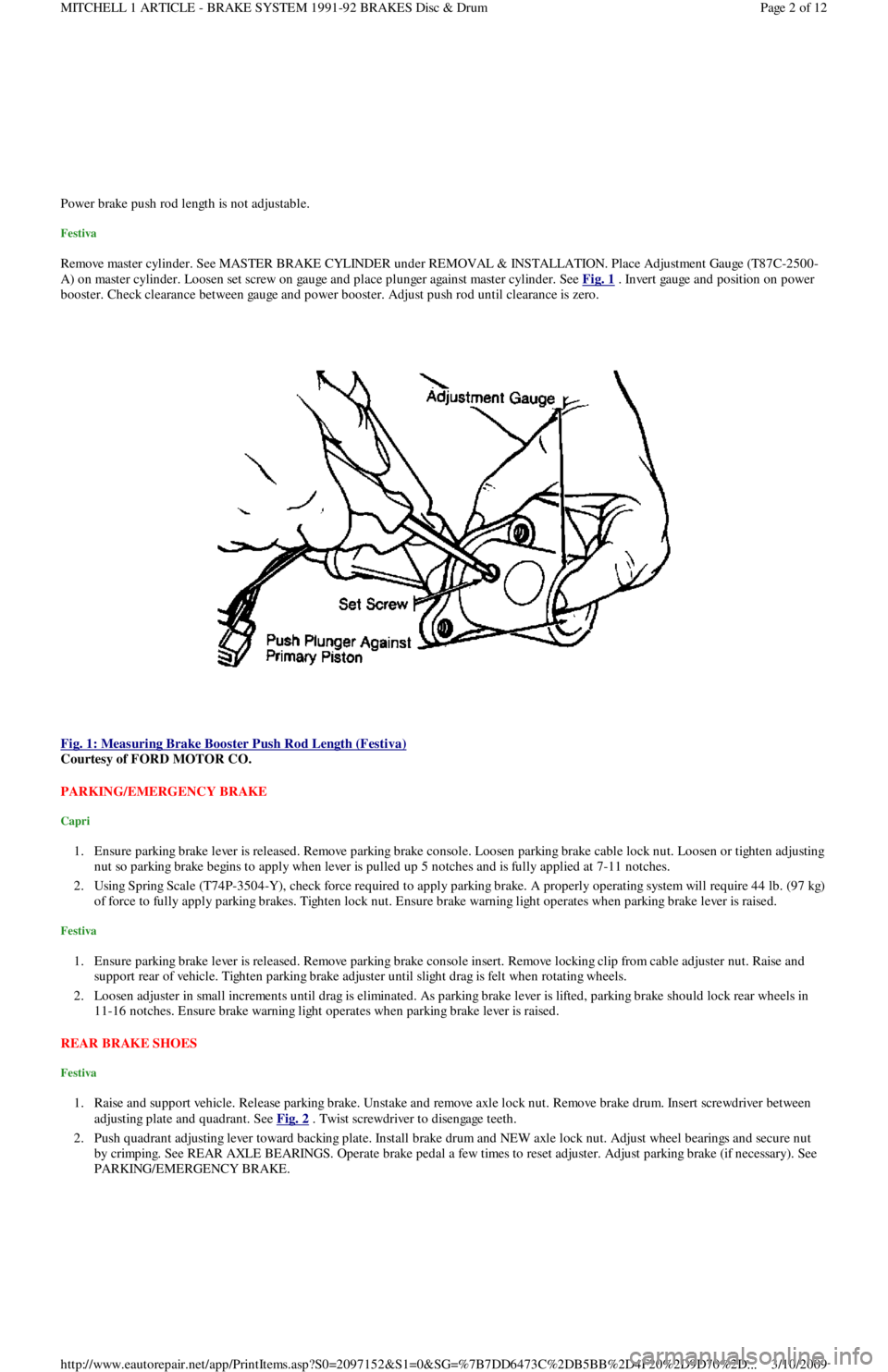

Festiva

Remove master cylinder. See MASTER BRAKE CYLINDER under REMOVAL & INSTALLATION. Place Adjustment Gauge (T87C-2500-

A) on master cylinder. Loosen set screw on gauge and place plunger against master cylinder. See Fig. 1

. Invert gauge and position on power

booster. Check clearance between gauge and power booster. Adjust push rod until clearance is zero.

Fig. 1: Measuring Brake Booster Push Rod Length (Festiva)

Courtesy of FORD MOTOR CO.

PARKING/EMERGENCY BRAKE

Capri

1. Ensure parking brake lever is released. Remove parking brake console. Loosen parking brake cable lock nut. Loosen or tighten adjusting

nut so parking brake begins to apply when lever is pulled up 5 notches and is fully applied at 7-11 notches.

2. Using Spring Scale (T74P-3504-Y), check force required to apply parking brake. A properly operating system will require 44 lb. (97 kg)

of force to fully apply parking brakes. Tighten lock nut. Ensure brake warning light operates when parking brake lever is raised.

Festiva

1. Ensure parking brake lever is released. Remove parking brake console insert. Remove locking clip from cable adjuster nut. Raise and

support rear of vehicle. Tighten parking brake adjuster until slight drag is felt when rotating wheels.

2. Loosen adjuster in small increments until drag is eliminated. As parking brake lever is lifted, parking brake should lock rear wheels in

11-16 notches. Ensure brake warning light operates when parking brake lever is raised.

REAR BRAKE SHOES

Festiva

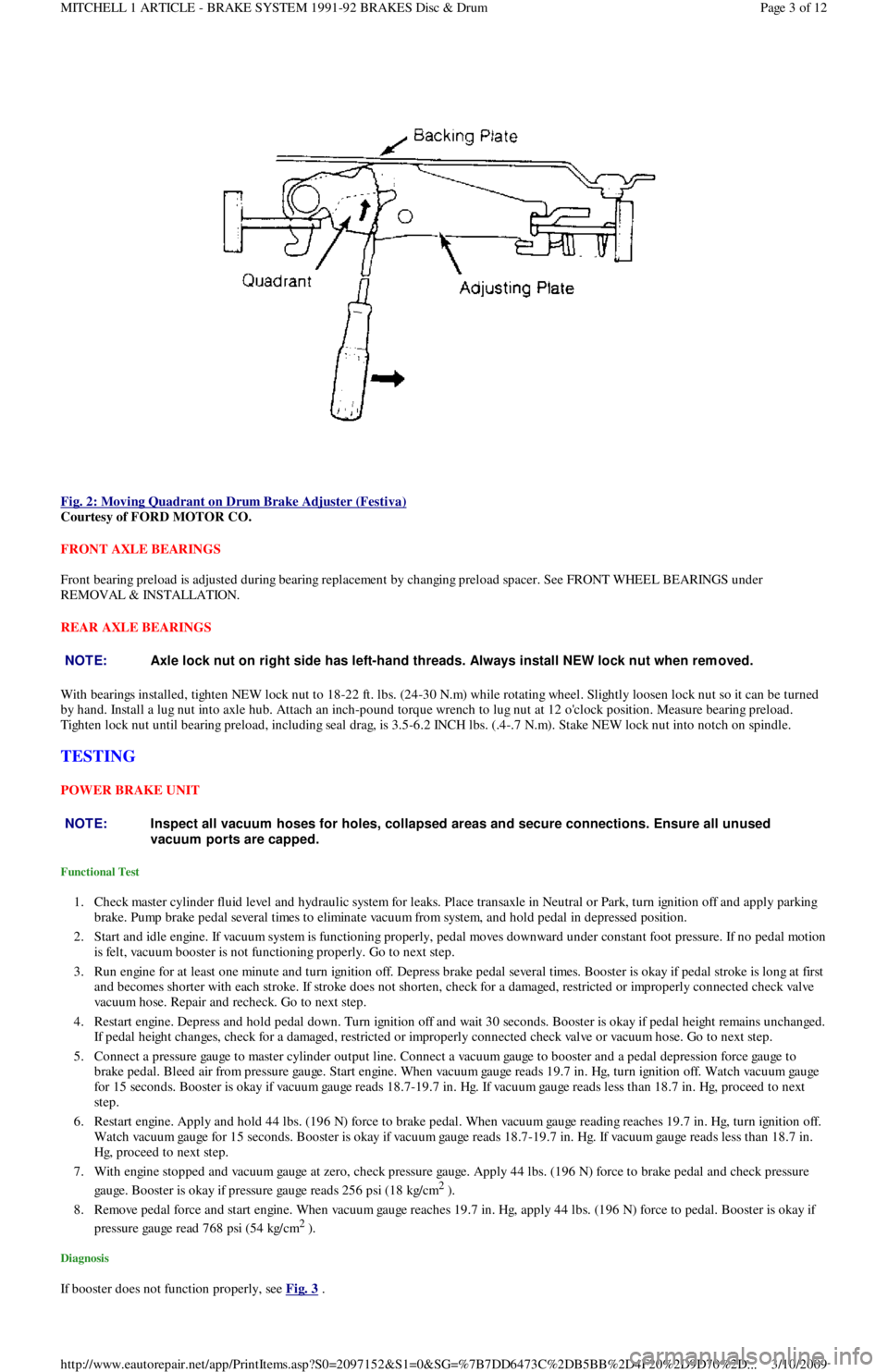

1. Raise and support vehicle. Release parking brake. Unstake and remove axle lock nut. Remove brake drum. Insert screwdriver between

adjusting plate and quadrant. See Fig. 2

. Twist screwdriver to disengage teeth.

2. Push quadrant adjusting lever toward backing plate. Install brake drum and NEW axle lock nut. Adjust wheel bearings and secure nut

by crimping. See REAR AXLE BEARINGS. Operate brake pedal a few times to reset adjuster. Adjust parking brake (if necessary). See

PARKING/EMERGENCY BRAKE.

Page 2 of 12 MITCHELL 1 ARTICLE - BRAKE SYSTEM 1991-92 BRAKES Disc & Drum

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 30 of 454

Fig. 2: Moving Quadrant on Drum Brake Adjuster (Festiva)

Courtesy of FORD MOTOR CO.

FRONT AXLE BEARINGS

Front bearing preload is adjusted during bearing replacement by changing preload spacer. See FRONT WHEEL BEARINGS under

REMOVAL & INSTALLATION.

REAR AXLE BEARINGS

With bearings installed, tighten NEW lock nut to 18-22 ft. lbs. (24-30 N.m) while rotating wheel. Slightly loosen lock nut so it can be turned

by hand. Install a lug nut into axle hub. Attach an inch-pound torque wrench to lug nut at 12 o'clock position. Measure bearing preload.

Tighten lock nut until bearing preload, including seal drag, is 3.5-6.2 INCH lbs. (.4-.7 N.m). Stake NEW lock nut into notch on spindle.

TESTING

POWER BRAKE UNIT

Functional Test

1. Check master cylinder fluid level and hydraulic system for leaks. Place transaxle in Neutral or Park, turn ignition off and apply parking

brake. Pump brake pedal several times to eliminate vacuum from system, and hold pedal in depressed position.

2. Start and idle engine. If vacuum system is functioning properly, pedal moves downward under constant foot pressure. If no pedal motion

is felt, vacuum booster is not functioning properly. Go to next step.

3. Run engine for at least one minute and turn ignition off. Depress brake pedal several times. Booster is okay if pedal stroke is long at first

and becomes shorter with each stroke. If stroke does not shorten, check for a damaged, restricted or improperly connected check va l ve

vacuum hose. Repair and recheck. Go to next step.

4. Restart engine. Depress and hold pedal down. Turn ignition off and wait 30 seconds. Booster is okay if pedal height remains unchanged.

If pedal height changes, check for a damaged, restricted or improperly connected check valve or vacuum hose. Go to next step.

5. Connect a pressure gauge to master cylinder output line. Connect a vacuum gauge to booster and a pedal depression force gauge to

brake pedal. Bleed air from pressure gauge. Start engine. When vacuum gauge reads 19.7 in. Hg, turn ignition off. Watch vacuum ga u ge

for 15 seconds. Booster is okay if vacuum gauge reads 18.7-19.7 in. Hg. If vacuum gauge reads less than 18.7 in. Hg, proceed to next

step.

6. Restart engine. Apply and hold 44 lbs. (196 N) force to brake pedal. When vacuum gauge reading reaches 19.7 in. Hg, turn ignition off.

Watch vacuum gauge for 15 seconds. Booster is okay if vacuum gauge reads 18.7-19.7 in. Hg. If vacuum gauge reads less than 18.7 in.

Hg, proceed to next step.

7. With engine stopped and vacuum gauge at zero, check pressure gauge. Apply 44 lbs. (196 N) force to brake pedal and check pressure

gauge. Booster is okay if pressure gauge reads 256 psi (18 kg/cm

2 ).

8. Remove pedal force and start engine. When vacuum gauge reaches 19.7 in. Hg, apply 44 lbs. (196 N) force to pedal. Booster is okay if

pressure gauge read 768 psi (54 kg/cm

2 ).

Diagnosis

If booster does not function properly, see Fig. 3 .

NOTE:Axle lock nut on right side has left-hand threads. Always install NEW lock nut when rem oved.

NOTE:Inspect all vacuum hoses for holes, collapsed areas and secure connections. Ensure all unused

vacuum ports are capped.

Page 3 of 12 MITCHELL 1 ARTICLE - BRAKE SYSTEM 1991-92 BRAKES Disc & Drum

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 40 of 454

Back To Article

AXLE SHAFT S - FRONT

1988-93 Drive Axles - FWD Axle Shafts

DESCRIPTION & OPERATION

Axle shafts transfer power from transaxle to driving wheels. All axle shafts consist of a shaft with a flexible Constant Velocity (CV) joint at

each end. Inner CV joint is coupled to transaxle by splines. Outer CV joint is splined to hub assembly and secured by axle shaft nut.

Three different types of axle shaft CV joints are used: Double Offset Joint (DOJ) or Rzeppa type, Birfield Joint (BJ) and the Tripot Joint (TJ).

CV joint boots protect CV joints by maintaining proper lubrication and preventing contaminants from entering joint. Boots must be replaced

when signs of leakage or cracks are present. Inner CV joint may be disassembled and serviced. Outer CV joint boot may be replaced, but outer

Birfield CV joint must NOT be disassembled. It must be replaced as an assembly, if faulty.

To prevent torsional vibration and torque steer on turbocharged Capri vehicles, an intermediate shaft and conventional axle shaft are used on

the right side. Both shafts are of similar length and are supported by a bearing, which is attached to engine.

CV JOINT IDENTIFICATION

TROUBLE SHOOTING

REMOVAL, DISASSEMBLY, REASSEMBLY & INSTALLATION

FWD AXLE SHAFTS

Removal

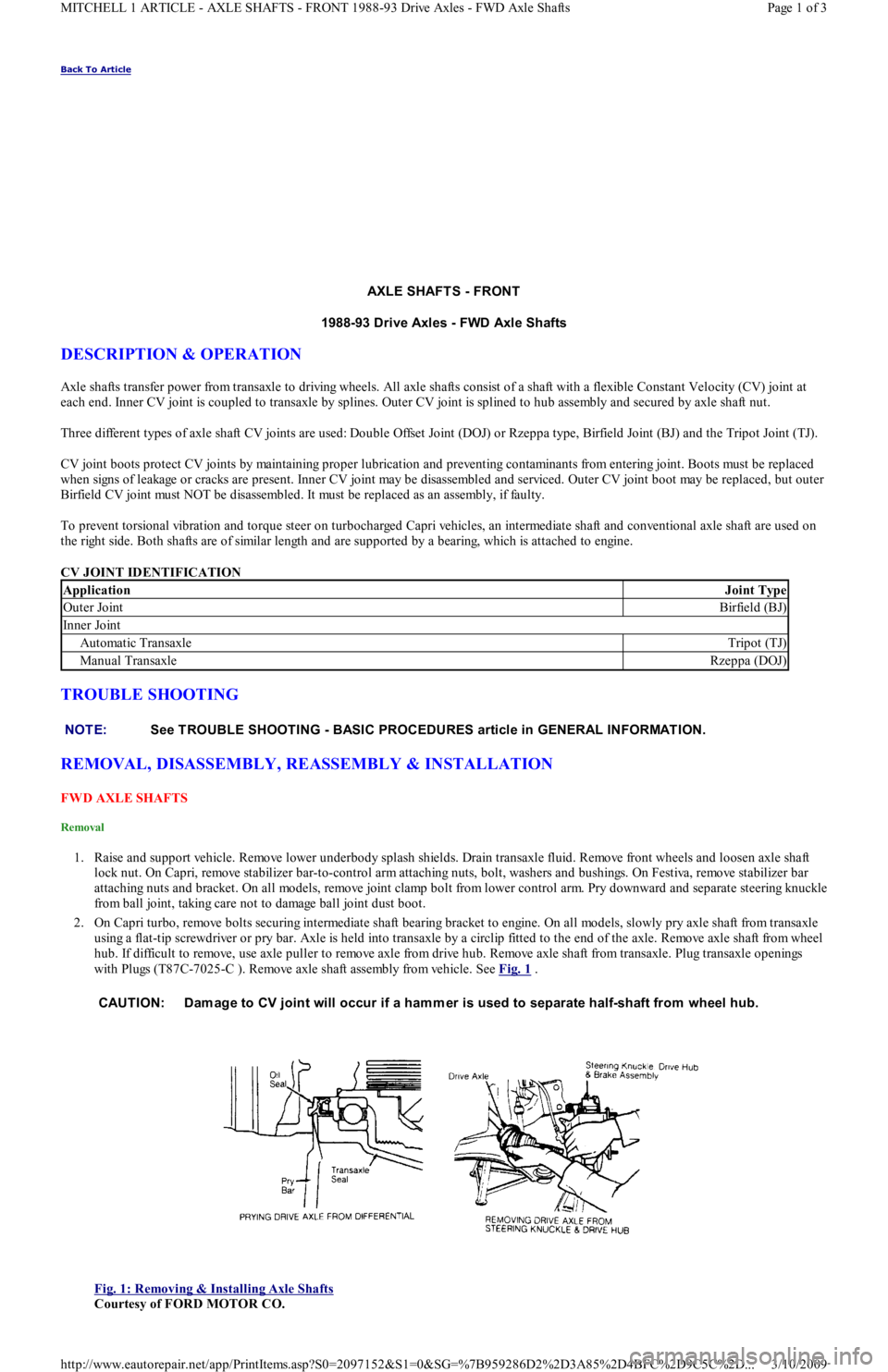

1. Raise and support vehicle. Remove lower underbody splash shields. Drain transaxle fluid. Remove front wheels and loosen axle shaft

lock nut. On Capri, remove stabilizer bar-to-control arm attaching nuts, bolt, washers and bushings. On Festiva, remove stabilizer bar

attaching nuts and bracket. On all models, remove joint clamp bolt from lower control arm. Pry downward and separate steering knuckle

from ball joint, taking care not to damage ball joint dust boot.

2. On Capri turbo, remove bolts securing intermediate shaft bearing bracket to engine. On all models, slowly pry axle shaft from transaxle

using a flat-tip screwdriver or pry bar. Axle is held into transaxle by a circlip fitted to the end of the axle. Remove axle shaft from wheel

hub. If difficult to remove, use axle puller to remove axle from drive hub. Remove axle shaft from transaxle. Plug transaxle openings

with Plugs (T87C-7025-C ). Remove axle shaft assembly from vehicle. See Fig. 1

.

Fig. 1: Removing & Installing Axle Shafts

Courtesy of FORD MOTOR CO.

ApplicationJoint Type

Outer JointBirfield (BJ)

In n er Jo in t

Automatic TransaxleTripot (TJ)

Manual TransaxleRzeppa (DOJ)

NOTE:See TROUBLE SHOOTING - BASIC PROCEDURES article in GENERAL INFORMATION.

CAUTION: Dam age to CV joint will occur if a ham mer is used to separate half-shaft from wheel hub.

Page 1 of 3 MITCHELL 1 ARTICLE - AXLE SHAFTS - FRONT 1988-93 Drive Axles - FWD Axle Shafts

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...