coolant temperature FORD FESTIVA 1991 Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 6 of 454

2. Lift access plate and disconnect sending unit wiring. To relieve fuel pressure, start engine and run it until engine stalls. Turn ignition off.

Disconnect and plug fuel lines at sending unit. Remove sending u n it a t t a c h in g sc r e ws. R e mo ve se n d in g u n it . To in st a l l , r e ve r se removal

procedure.

TACHOMETER

Removal & Installation

Remo ve in st ru men t p an el . See INSTRUMENT PANEL under REMOVAL & INSTALLATION. Disassemble panel and remove tachometer.

To install tachometer, reverse removal procedure. On Capri, the tachometer/speedometer/boost gauge assembly must be replaced as an

assembly.

TEMPERATURE GAUGE

Removal & Installation

Remo ve in st ru men t p an el . See INSTRUMENT PANEL under REMOVAL & INSTALLATION. Disassemble panel and remove temperature

gauge. To install gauge, reverse removal procedure. On Capri, the temperature/oil pressure gauge assembly must be replaced as an assembly.

TEMPERATURE SENDING UNIT

Removal

Disconnect sending unit wire, located on side of block below thermostat housing (Festiva) or cylinder head (Capri). Remove radiator cap to

relieve cooling system pressure. Position drain pan below sending unit. Remove temperature sending unit.

Installation

To install, apply Pipe Sealant With Teflon (D8AZ-19554-A) to threads of sending unit. Reverse removal procedure to complete installation.

Fill cooling system to proper level. Start engine and check for coolant leaks at sending unit.

WIRING DIAGRAMS

CAUT ION: T achom eter is calibrated at factory. Rough handling could disturb calibration.

NOTE:Refer to the appropriate WIRING DIAGRAMS article in the WIRING DIAGRAMS section.

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00028301

Page 5 of 5 MITCHELL 1 ARTICLE - INSTRUMENT PANEL 1991 ACCESSORIES & SAFETY EQUIPMENT Ford Motor Co. Switches

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 46 of 454

Back To Article

ELECT RICAL COMPONENT LOCAT OR

1991-92 ELECT RICAL COMPONENT LOCAT ION Ford Motor Co. Electrical Com ponents

BUZZERS, RELAYS & TIMERS

BUZZERS, RELAYS & TIMERS LOCATION

CIRCUIT PROTECTION DEVICES

CIRCUIT PROTECTION DEVICES LOCATION

CONTROL UNITS

CONTROL UNITS LOCATION

SENDING UNITS & SENSORS

SENDING UNITS & SENSORS LOCATION

MOTORS

MOTORS LOCATION

ComponentLocation

A/C Clutch Relay (1991)On right front of engine bay, near power

steering pump.

A/C RelayOn left front corner of engine bay, left of

cooling fan. See Fig. 1

& Fig. 2

A/C Wide Open Throttle (WAC) RelayOn left front corner of engine bay, left of

cooling fan. See Fig. 1

& Fig. 2 .

Cooling Fan RelayOn left front fender panel, near

headlight. See Fig. 1

& Fig. 2 .

Condenser Fan RelayOn left front of engine bay, left of

cooling fan. See Fig. 1

& Fig. 2 .

Daytime Running Light (DRL) Relay (Canada) (1992)On left front corner of engine bay, near

headlight. See Fig. 1

.

Fuel Pump RelayBehind left side of dash, near ECA.

Headlight RelayBehind left headlight. See Fig. 1 .

Horn RelayUnder left side of dash. See Fig. 3 .

Main RelayIn left front corner of engine bay, near

battery.

P a r kin g Ligh t R e l a yOn right front corner of engine bay. See

Fig. 1

.

Turn Signal/Flasher RelayUnder left side of dash, behind ECA.

See Fig. 3

.

ComponentLocation

A/C In-Line FuseOn left side of heater case.

Condenser Fan In-Line FuseOn right side of steering column.

Fuse PanelBehind access panel, to left of steering column.

Fusible LinksOn left front strut tower. See Fig. 1 .

ComponentLocation

Electronic Control Assembly (ECA)Behind left side of dash, left of steering column.

Passive Restraint ModuleUnder driver's seat.

ComponentLocation

Airflow MeterOn right front corner of engine bay. See Fig. 1 .

Coolant Temperature Sending UnitBelow thermostat housing.

Crankshaft Position SensorInside distributor. See Fig. 1 .

EGR Temperature Sensor (1991)In exhaust manifold, near EGR valve.

Engine Coolant Temperature (ECT) SensorOn top of engine, near injector No. 1.

Fuel Gauge Sending Unit (1992)In fu el t an k.

Throttle Position Sensor (TPS)On left side of throttle body. See Fig. 1 .

ComponentLocation

Blower MotorUnder center of dash, behind

radio.

Windshield Washer Motors:

Front (1991)On right front fender panel,

bottom of washer reservoir.

Front (1992)On left front corner of engine

bay, in front of battery.

RearOn body panel, behind right

rear quarter panel.

Windshield Wiper Motor

Page 1 of 3 MITCHELL 1 ARTICLE - ELECTRICAL COMPONENT LOCATOR 1991-92 ELECTRICAL COMPONENT LOCATION For...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 66 of 454

Autolamp Control RelayHeadlight Systems; Daytime Running Lights

Automatic Shutdown (ASD) RelayEngine Performance; Generators & Regulators

Autostick SwitchEngine Performance

Auxiliary Battery RelayGenerators & Regulators

Back-Up LightsBack-Up Lights; Exterior Lights

Barometric (BARO) Pressure SensorEngine Performance

BatteryPower Distribution

Battery Temperature SensorEngine Performance

Body Control ModuleBody Control Computer; Anti-Theft System; Daytime Running

Lights; Engine Performance; Headlight Systems; Warning Systems

Boost Control SolenoidEngine Performance

Boost SensorEngine Performance

Brake Fluid Level SwitchAnalog Instrument Panels

Brake On/Off (BOO) SwitchCruise Control Systems; Engine Performance; Shift Interlock

Systems

Buzzer ModuleWarning Systems

Camshaft Position (CMP) SensorEngine Performance

Central Control ModuleAnti-Theft System

ClockspringAir Bag Restraint System; Cruise Control Systems; Steering

Column Switches

Clutch Pedal Position SwitchStarters

Clutch Start SwitchStarters

Combination MeterAnalog Instrument Panels

Constant Control Relay Module (CCRM)Engine Performance; Electric Cooling Fans

Convenience CenterPower Distribution; Illumination/Interior Lights

Convertible Top MotorPower Convertible Top

Convertible Top SwitchPower Convertible Top

Crankshaft Position (CKP) SensorEngine Performance

Cruise Control ModuleCruise Control Systems

Cruise Control SwitchCruise Control Systems

Condenser Fan Relay(s)Electric Cooling Fans

Data Link Connector (DLC)Engine Performance

Da yt ime R u n n in g Ligh t s M o d u l eDaytime Running Lights; Exterior Lights

Defogger RelayRear Window Defogger

Diagnostic Energy Reserve Module (DERM)Air Bag Restraint System

Discriminating Sensor (Air Bag)Air Bag Restraint System

DistributorEngine Performance

Door Lock ActuatorsPower Door Locks; Remote Keyless Entry

Door Lock Relay(s)Power Door Locks

Electrochromic MirrorPower Mirrors

Electronic Level Control (ELC) Height SensorElectronic Suspension

Electronic Level Control (ELC) ModuleElectronic Suspension

Engine Coolant Temperature (ECT) Sending UnitAnalog Instrument Panels

Engine Coolant Temperature (ECT) SensorEngine Performance

Engine Control ModuleEngine Performance; Generators & Regulators; Starters

ETACS ECUWarning Systems; Power Windows; Remote Keyless Entry

Evaporative (EVAP) Emissions CanisterEngine Performance

EVAP Canister Purge SolenoidEngine Performance

EVAP Canister Vent SolenoidEngine Performance

Exhaust Gas Recirculation (EGR) ValveEngine Performance

Fuel Tank Vacuum SensorEngine Performance

F o g Ligh t sHeadlight Systems; Daytime Running Lights

F o g Ligh t R e l a yHeadlight Systems; Daytime Running Lights

Fuel Door Release SolenoidPower Fuel Door Release

Fuel Gauge Sending UnitAnalog Instrument Panels

Fuel InjectorsEngine Performance

Fuel PumpEngine Performance

Fuel Pump RelayEngine Performance; Power Distribution

Fuse/Relay BlockPower Distribution

Fusible LinksPower Distribution; Generators & Regulators; Starters

GeneratorGenerators & Regulators; Engine Performance; Power Distribution

Generic Electronic Module (GEM)Body Control Modules; Electronic Suspension

Glow Plug RelayEngine Performance

Glow PlugsEngine Performance

GroundsGround Distribution

Headlight Door ModuleHeadlight Doors

Headlight RelayHeadlight Systems; Daytime Running Lights

HeadlightsHeadlight Systems; Daytime Running Lights

Heated Oxygen Sensor(s) (HO2S)Engine Performance

Heated Windshield Control ModuleHeated Windshields

Page 4 of 6 MITCHELL 1 ARTICLE - GENERAL INFORMATION Using Mitchell1's Wiring Diagrams

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 86 of 454

Back To Article

ENGINE COOLING FAN

1990-92 ENGINE COOLING Ford Motor Co. Engine Cooling Fans

DESCRIPTION

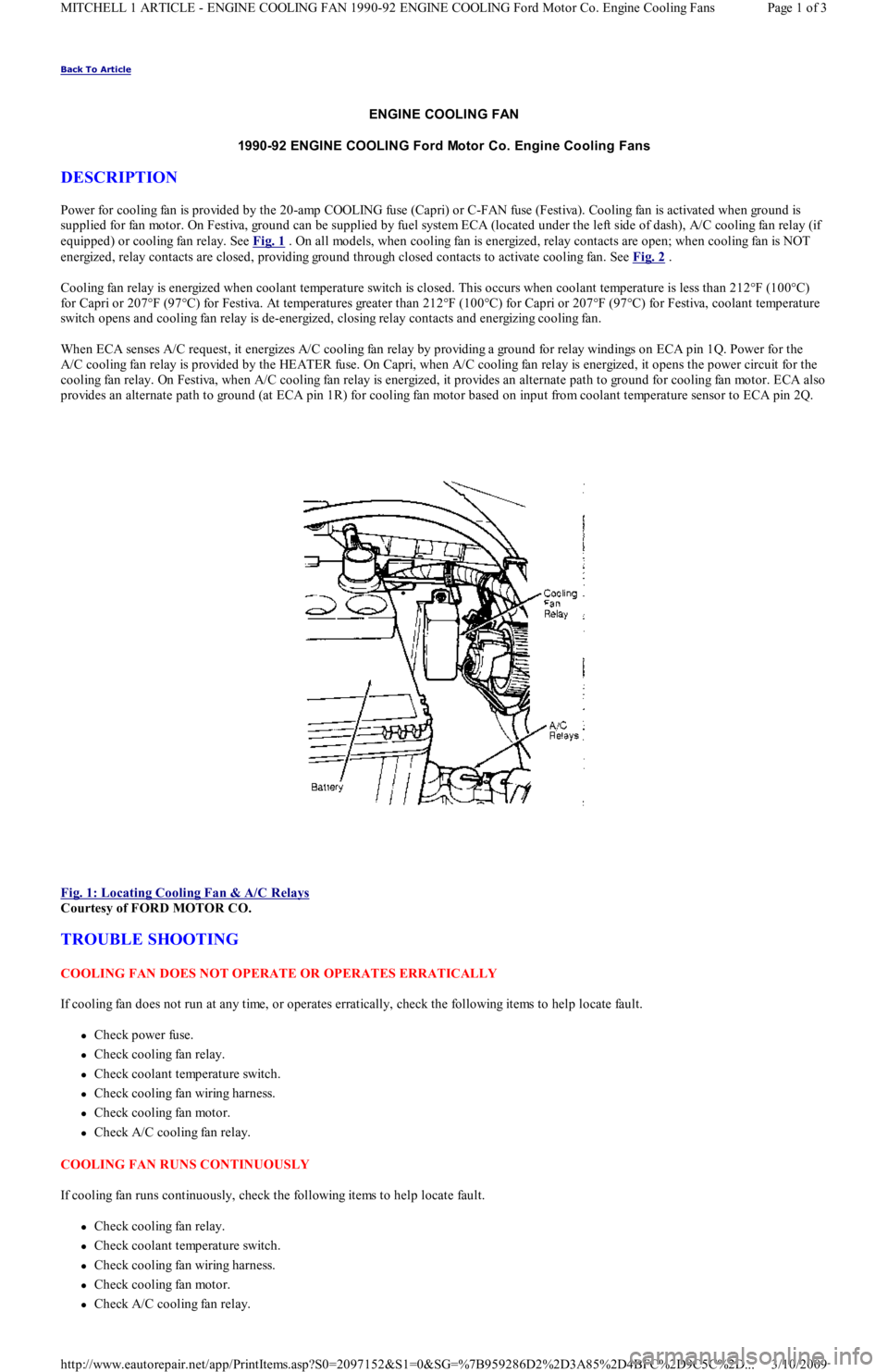

Power for cooling fan is provided by the 20-amp COOLING fuse (Capri) or C-FAN fuse (Festiva). Cooling fan is activated when ground is

supplied for fan motor. On Festiva, ground can be supplied by fuel system ECA (located under the left side of dash), A/C cooling fan relay (if

equipped) or cooling fan relay. See Fig. 1

. On all models, when cooling fan is energized, relay contacts are open; when cooling fan is NOT

energized, relay contacts are closed, providing ground through closed contacts to activate cooling fan. See Fig. 2

.

Cooling fan relay is energized when coolant temperature switch is closed. This occurs when coolant temperature is less than 212°F (1 00 °C)

for Capri or 207°F (97°C) for Festiva. At temperatures greater than 212°F (100°C) for Capri or 207°F (97°C) for Festiva, coolant temperature

switch opens and cooling fan relay is de-energized, closing relay contacts and energizing cooling fan.

When ECA senses A/C request, it energizes A/C cooling fan relay by providing a ground for relay windings on ECA pin 1Q. Power for the

A/C cooling fan relay is provided by the HEATER fuse. On Capri, when A/C cooling fan relay is energized, it opens the power circuit for the

cooling fan relay. On Festiva, when A/C cooling fan relay is energized, it provides an alternate path to ground for cooling fan mo t o r. E CA al so

provides an alternate path to ground (at ECA pin 1R) for cooling fan motor based on input from coolant temperature sensor to ECA pin 2Q.

Fig. 1: Locating Cooling Fan & A/C Relays

Courtesy of FORD MOTOR CO.

TROUBLE SHOOTING

COOLING FAN DOES NOT OPERATE OR OPERATES ERRATICALLY

If cooling fan does not run at any time, or operates erratically, check the following items to help locate fault.

Check power fuse.

Check cooling fan relay.

Check coolant temperature switch.

Check cooling fan wiring harness.

Check cooling fan motor.

Check A/C cooling fan relay.

COOLING FAN RUNS CONTINUOUSLY

If cooling fan runs continuously, check the following items to help locate fault.

Check cooling fan relay.

Check coolant temperature switch.

Check cooling fan wiring harness.

Check cooling fan motor.

Check A/C cooling fan relay.

Page 1 of 3 MITCHELL 1 ARTICLE - ENGINE COOLING FAN 1990-92 ENGINE COOLING Ford Motor Co. Engine Cooling Fans

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 87 of 454

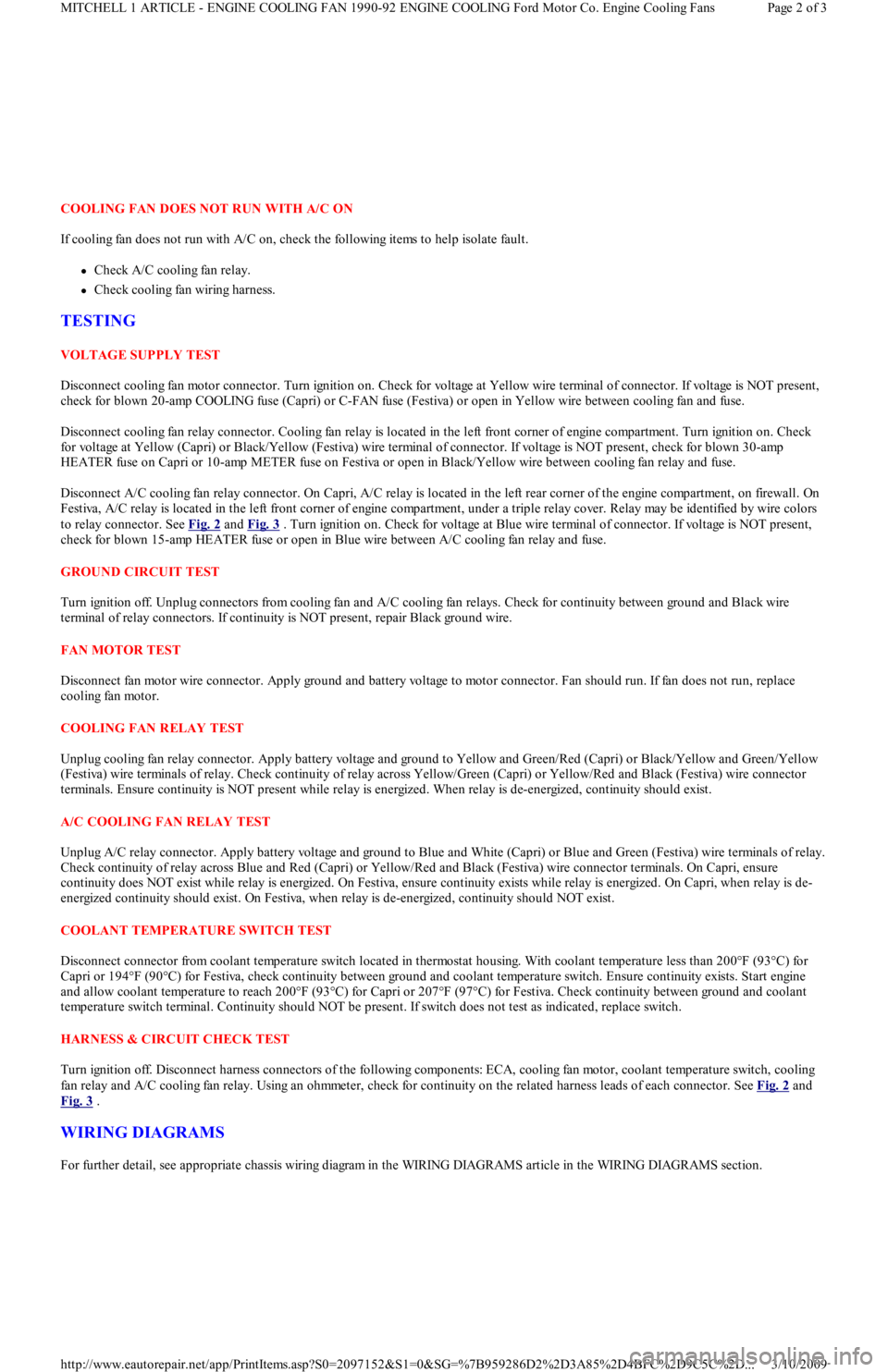

COOLING FAN DOES NOT RUN WITH A/C ON

If cooling fan does not run with A/C on, check the following items to help isolate fault.

Check A/C cooling fan relay.

Check cooling fan wiring harness.

TESTING

VOLTAGE SUPPLY TEST

Disconnect cooling fan motor connector. Turn ignition on. Check for voltage at Yellow wire terminal of connector. If voltage is NOT present,

check for blown 20-amp COOLING fuse (Capri) or C-FAN fuse (Festiva) or open in Yellow wire between cooling fan and fuse.

Disconnect cooling fan relay connector. Cooling fan relay is located in the left front corner of engine compartment. Turn ignition on. Check

for voltage at Yellow (Capri) or Black/Yellow (Festiva) wire terminal of connector. If voltage is NOT present, check for blown 30-amp

HEATER fuse on Capri or 10-amp METER fuse on Festiva or open in Black/Yellow wire between cooling fan relay and fuse.

Disconnect A/C cooling fan relay connector. On Capri, A/C relay is located in the left rear corner of the engine compartment, on firewall. On

Festiva, A/C relay is located in the left front corner of engine compartment, under a triple relay cover. Relay may be identified by wire colors

to relay connector. See Fig. 2

and Fig. 3 . Turn ignition on. Check for voltage at Blue wire terminal of connector. If voltage is NOT present,

check for blown 15-amp HEATER fuse or open in Blue wire between A/C cooling fan relay and fuse.

GROUND CIRCUIT TEST

Turn ignition off. Unplug connectors from cooling fan and A/C cooling fan relays. Check for continuity between ground and Black wire

terminal of relay connectors. If continuity is NOT present, repair Black ground wire.

FAN MOTOR TEST

Disconnect fan motor wire connector. Apply ground and battery voltage to motor connector. Fan should run. If fan does not run, replace

cooling fan motor.

COOLING FAN RELAY TEST

Unplug cooling fan relay connector. Apply battery voltage and ground to Yellow and Green/Red (Capri) or Black/Yellow and Green/Yellow

(Festiva) wire terminals of relay. Check continuity of relay across Yellow/Green (Capri) or Yellow/Red and Black (Festiva) wire connector

terminals. Ensure continuity is NOT present while relay is energized. When relay is de-energized, continuity should exist.

A/C COOLING FAN RELAY TEST

Unplug A/C relay connector. Apply battery voltage and ground to Blue and White (Capri) or Blue and Green (Festiva) wire terminals of relay.

Check continuity of relay across Blue and Red (Capri) or Yellow/Red and Black (Festiva) wire connector terminals. On Capri, ensure

continuity does NOT exist while relay is energized. On Festiva, ensure continuity exists while relay is energized. On Capri, when relay is de-

energized continuity should exist. On Festiva, when relay is de-energized, continuity should NOT exist.

COOLANT TEMPERATURE SWITCH TEST

Disconnect connector from coolant temperature switch located in thermostat housing. With coolant temperature less than 200°F (93°C) for

Capri or 194°F (90°C) for Festiva, check continuity between ground and coolant temperature switch. Ensure continuity exists. Start engine

and allow coolant temperature to reach 200°F (93°C) for Capri or 207°F (97°C) for Festiva. Check continuity between ground and coolant

temperature switch terminal. Continuity should NOT be present. If switch does not test as indicated, replace switch.

HARNESS & CIRCUIT CHECK TEST

Turn ignition off. Disconnect harness connectors of the following components: ECA, cooling fan motor, coolant temperature switch, cooling

fan relay and A/C cooling fan relay. Using an ohmmeter, check for continuity on the related harness leads of each connector. See Fig. 2

and

Fig. 3

.

WIRING DIAGRAMS

For further detail, see appropriate chassis wiring diagram in the WIRING DIAGRAMS article in the WIRING DIAGRAMS section.

Page 2 of 3 MITCHELL 1 ARTICLE - ENGINE COOLING FAN 1990-92 ENGINE COOLING Ford Motor Co. Engine Cooling Fans

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 150 of 454

Back To Article

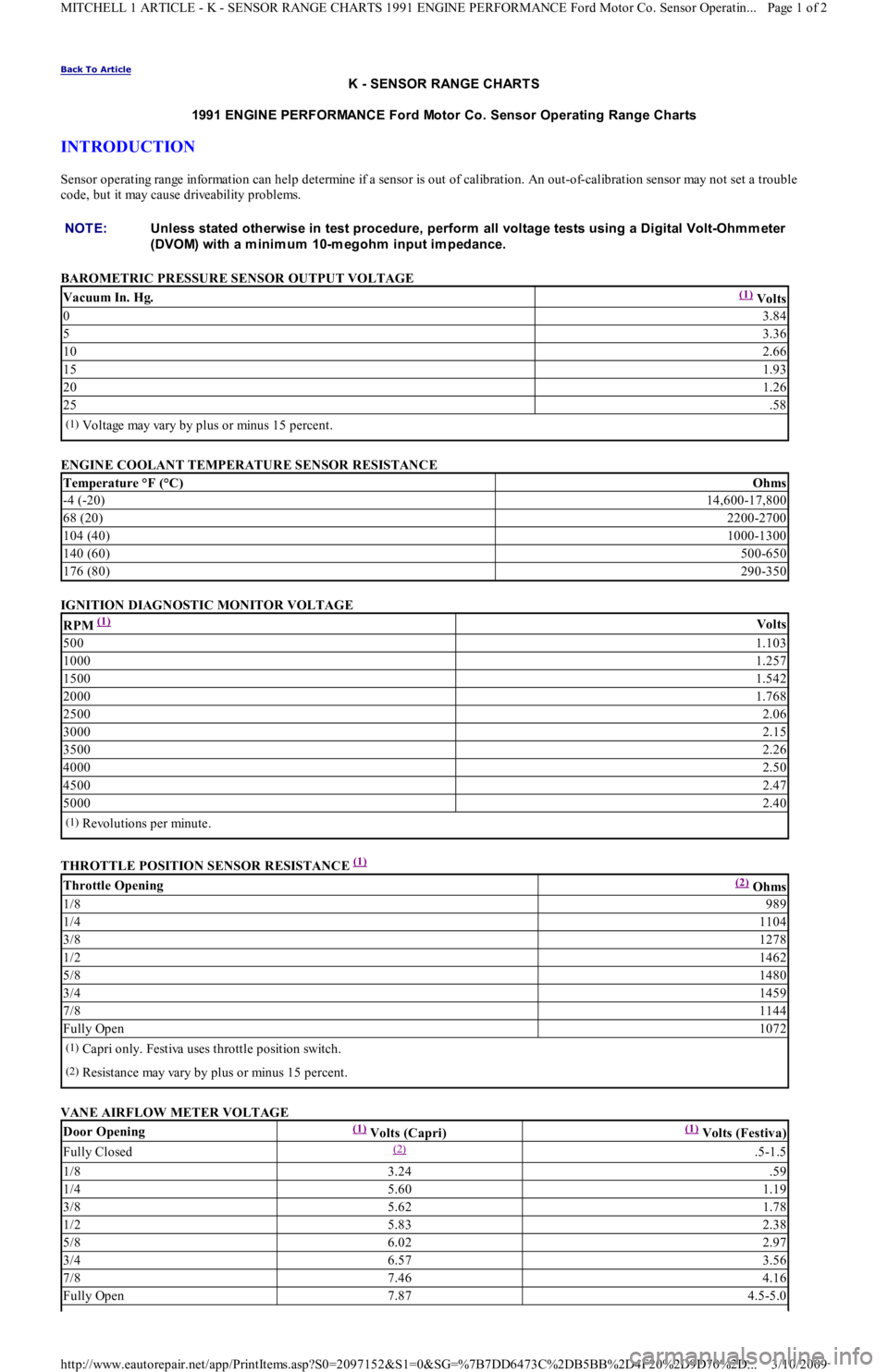

K - SENSOR RANGE CHART S

1991 ENGINE PERFORMANCE Ford Motor Co. Sensor Operating Range Charts

INTRODUCTION

Sensor operating range information can help determine if a sensor is out of calibration. An out-of-calibration sensor may not set a trouble

code, but it may cause driveability problems.

BAROMETRIC PRESSURE SENSOR OUTPUT VOLTAGE

ENGINE COOLANT TEMPERATURE SENSOR RESISTANCE

IGNITION DIAGNOSTIC MONITOR VOLTAGE

THROTTLE POSITION SENSOR RESISTANCE

(1)

VANE AIRFLOW METER VOLTAGE NOTE:Unless stated otherwise in test procedure, perform all voltage tests using a Digital Volt-Ohm m eter

(DVOM) with a m inim um 10-m egohm input im pedance.

Vacuum In. Hg.(1) Volts

03.84

53.36

102.66

151.93

201.26

25.58

(1)Voltage may vary by plus or minus 15 percent.

Temperature °F (°C)Ohms

-4 (-20)14,600-17,800

68 (20)2200-2700

104 (40)1000-1300

140 (60)500-650

176 (80)290-350

RPM (1) Volts

5001.103

10001.257

15001.542

20001.768

25002.06

30002.15

35002.26

40002.50

45002.47

50002.40

(1)Revolutions per minute.

Throttle Opening(2) Ohms

1/8989

1/41104

3/81278

1/21462

5/81480

3/41459

7/81144

Fully Open1072

(1)Capri only. Festiva uses throttle position switch.

(2)Resistance may vary by plus or minus 15 percent.

Door Opening(1) Volts (Capri)(1) Volts (Festiva)

Fully Closed(2) .5-1.5

1/83.24.59

1/45.601.19

3/85.621.78

1/25.832.38

5/86.022.97

3/46.573.56

7/87.464.16

Fully Open7.874.5-5.0

Page 1 of 2 MITCHELL 1 ARTICLE - K - SENSOR RANGE CHARTS 1991 ENGINE PERFORMANCE Ford Motor Co. Sensor Operatin

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 153 of 454

Back To Article

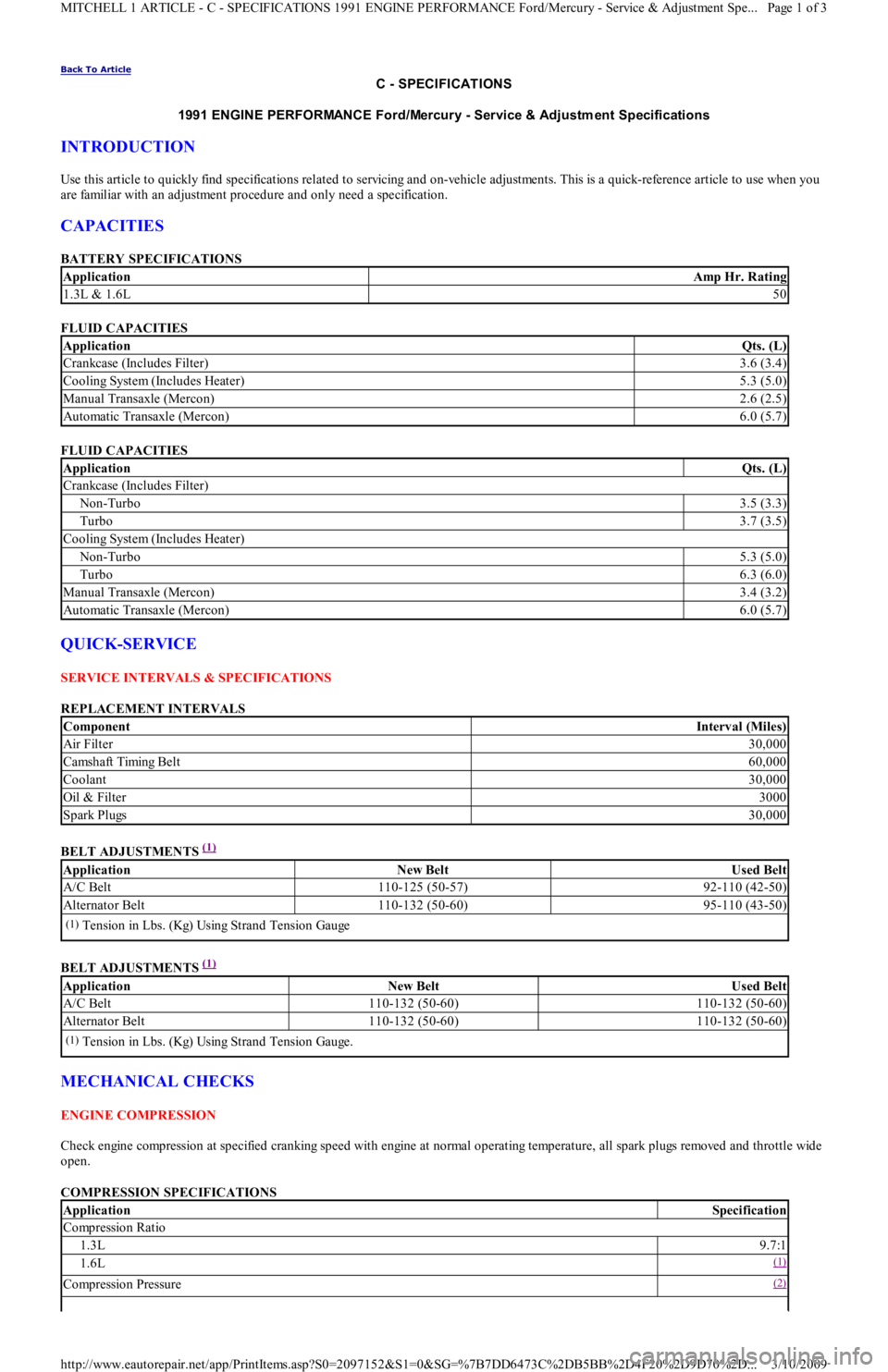

C - SPECIFICATIONS

1991 ENGINE PERFORMANCE Ford/Mercury - Service & Adjustm ent Specifications

INTRODUCTION

Use this article to quickly find specifications related to servicing and on-vehicle adjustments. This is a quick-reference article to use when you

are familiar with an adjustment procedure and only need a specification.

CAPACITIES

BATTERY SPECIFICATIONS

FLUID CAPACITIES

FLUID CAPACITIES

QUICK-SERVICE

SERVICE INTERVALS & SPECIFICATIONS

REPLACEMENT INTERVALS

BELT ADJUSTMENTS

(1)

BELT ADJUSTMENTS

(1)

MECHANICAL CHECKS

ENGINE COMPRESSION

Check engine compression at specified cranking speed with engine at normal operating temperature, all spark plugs removed and throttle wide

open.

COMPRESSION SPECIFICATIONS

ApplicationAmp Hr. Rating

1.3L & 1.6L50

ApplicationQts. (L)

Crankcase (Includes Filter)3.6 (3.4)

Cooling System (Includes Heater)5.3 (5.0)

Manual Transaxle (Mercon)2.6 (2.5)

Automatic Transaxle (Mercon)6.0 (5.7)

ApplicationQts. (L)

Crankcase (Includes Filter)

Non-Turbo3.5 (3.3)

Turbo3.7 (3.5)

Cooling System (Includes Heater)

Non-Turbo5.3 (5.0)

Turbo6.3 (6.0)

Manual Transaxle (Mercon)3.4 (3.2)

Automatic Transaxle (Mercon)6.0 (5.7)

ComponentInterval (Miles)

Air Filter30,000

Camsh aft Timin g Bel t60,000

Coolant30,000

Oil & Filter3000

Spark Plugs30,000

ApplicationNew BeltUsed Belt

A/C Belt110-125 (50-57)92-110 (42-50)

Alternator Belt110-132 (50-60)95-110 (43-50)

(1)Tension in Lbs. (Kg) Using Strand Tension Gauge

ApplicationNew BeltUsed Belt

A/C Belt110-132 (50-60)110-132 (50-60)

Alternator Belt110-132 (50-60)110-132 (50-60)

(1)Tension in Lbs. (Kg) Using Strand Tension Gauge.

ApplicationSpecification

Compression Ratio

1.3L9.7:1

1.6L(1)

Compression Pressure(2)

Page 1 of 3 MITCHELL 1 ARTICLE - C - SPECIFICATIONS 1991 ENGINE PERFORMANCE Ford/Mercury - Service & Adjustment Spe

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

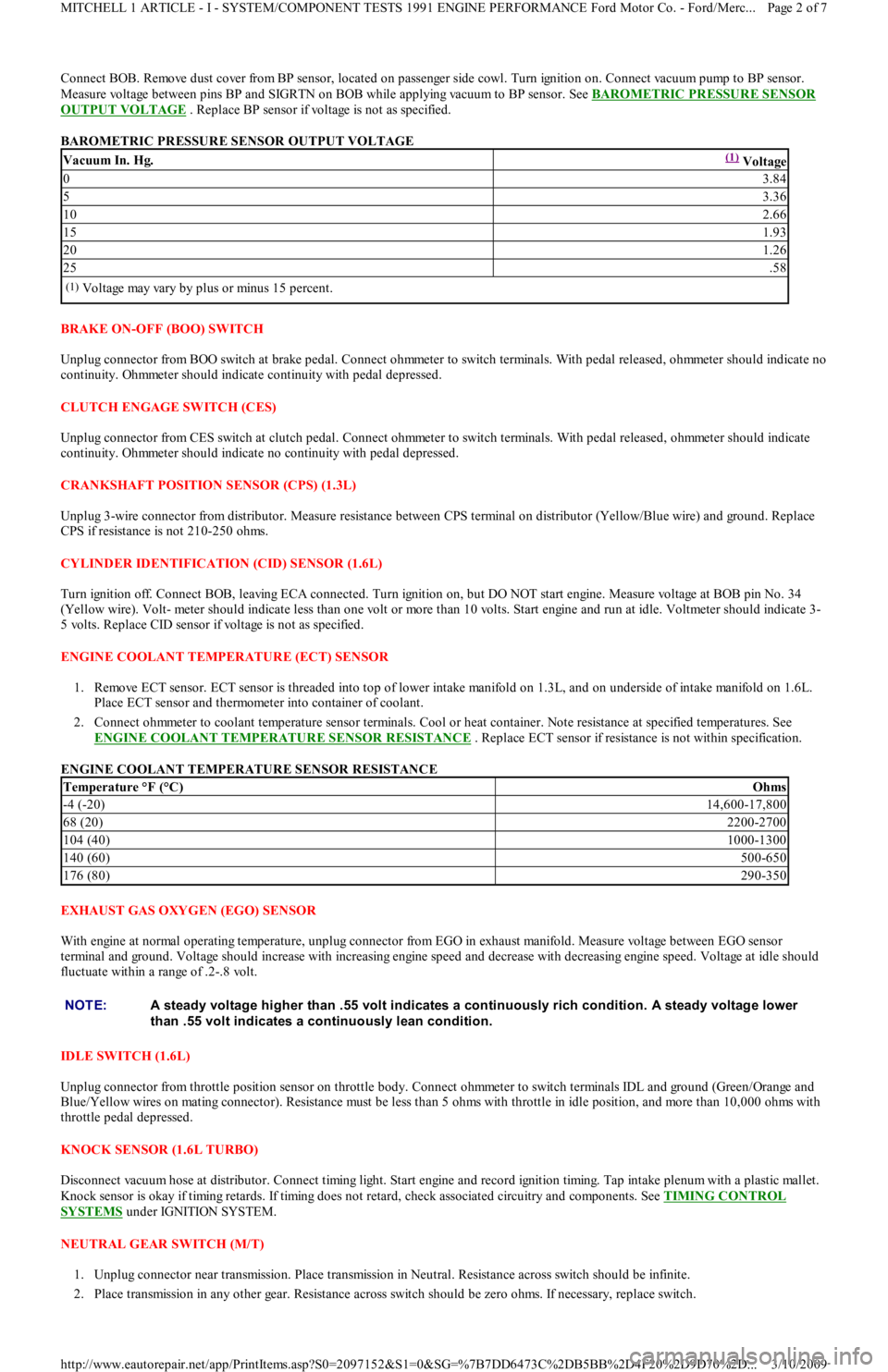

Page 162 of 454

Connect BOB. Remove dust cover from BP sensor, located on passenger side cowl. Turn ignition on. Connect vacuum pump to BP sensor.

Measure voltage between pins BP and SIGRTN on BOB while applying vacuum to BP sensor. See BAROMETRIC PRESSURE SENSOR

OUTPUT VOLTAGE . Replace BP sensor if voltage is not as specified.

BAROMETRIC PRESSURE SENSOR OUTPUT VOLTAGE

BRAKE ON-OFF (BOO) SWITCH

Unplug connector from BOO switch at brake pedal. Connect ohmmeter to switch terminals. With pedal released, ohmmeter should indicate no

continuity. Ohmmeter should indicate continuity with pedal depressed.

CLUTCH ENGAGE SWITCH (CES)

Unplug connector from CES switch at clutch pedal. Connect ohmmeter to switch terminals. With pedal released, ohmmeter should indicate

continuity. Ohmmeter should indicate no continuity with pedal depressed.

CRANKSHAFT POSITION SENSOR (CPS) (1.3L)

Unplug 3-wire connector from distributor. Measure resistance between CPS terminal on distributor (Yellow/Blue wire) and ground. Replace

CPS if resistance is not 210-250 ohms.

CYLINDER IDENTIFICATION (CID) SENSOR (1.6L)

Turn ignition off. Connect BOB, leaving ECA connected. Turn ignition on, but DO NOT start engine. Measure voltage at BOB pin No. 34

(Yellow wire). Volt- meter should indicate less than one volt or more than 10 volts. Start engine and run at idle. Voltmeter should indicate 3-

5 volts. Replace CID sensor if voltage is not as specified.

ENGINE COOLANT TEMPERATURE (ECT) SENSOR

1. Remove ECT sensor. ECT sensor is threaded into top of lower intake manifold on 1.3L, and on underside of intake manifold on 1.6L.

Place ECT sensor and thermometer into container of coolant.

2. Connect ohmmeter to coolant temperature sensor terminals. Cool or heat container. Note resistance at specified temperatures. See

ENGINE COOLANT TEMPERATURE SENSOR RESISTANCE

. Replace ECT sensor if resistance is not within specification.

ENGINE COOLANT TEMPERATURE SENSOR RESISTANCE

EXHAUST GAS OXYGEN (EGO) SENSOR

With engine at normal operating temperature, unplug connector from EGO in exhaust manifold. Measure voltage between EGO sensor

terminal and ground. Voltage should increase with increasing engine speed and decrease with decreasing engine speed. Voltage at idle should

fluctuate within a range of .2-.8 volt.

IDLE SW ITCH (1.6L)

Unplug connector from throttle position sensor on throttle body. Connect ohmmeter to switch terminals IDL and ground (Green/Orange and

Blue/Yellow wires on mating connector). Resistance must be less than 5 ohms with throttle in idle position, and more than 10,000 ohms with

throttle pedal depressed.

KNOCK SENSOR (1.6L TURBO)

Disconnect vacuum hose at distributor. Connect timing light. Start engine and record ignition timing. Tap intake plenum with a plastic mallet.

Knock sensor is okay if timing retards. If timing does not retard, check associated circuitry and components. See TIMING CONTROL

SYSTEMS under IGNITION SYSTEM.

NEUTRAL GEAR SWITCH (M/T)

1. Unplug connector near transmission. Place transmission in Neutral. Resistance across switch should be infinite.

2. Place transmission in any other gear. Resistance across switch should be zero ohms. If necessary, replace switch.

Vacuum In. Hg.(1) Voltage

03.84

53.36

102.66

151.93

201.26

25.58

(1)Voltage may vary by plus or minus 15 percent.

Temperature °F (°C)Ohms

-4 (-20)14,600-17,800

68 (20)2200-2700

104 (40)1000-1300

140 (60)500-650

176 (80)290-350

NOTE:A steady voltage higher than .55 volt indicates a continuously rich condition. A steady voltage lower

than .55 volt indicates a continuously lean condition.

Page 2 of 7 MITCHELL 1 ARTICLE - I - SYSTEM/COMPONENT TESTS 1991 ENGINE PERFORMANCE Ford Motor Co. - Ford/Merc

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 168 of 454

Back To Article

G - T EST S W/CODES

1991-92 ENGINE PERFORMANCE Ford Motor Co. Self-Diagnostics

INTRODUCTION

If no faults were found while performing BASIC TESTING , proceed with self-diagnostics. If no fault codes or only pass codes are present

after entering self-diagnostics, proceed to TESTS W/O CODES article in the ENGINE PERFORMANCE Section for diagnosis by symptom

(i.e., ROUGH IDLE, NO START, etc.).

This article uses many abbreviations for devices, signal names, and wire colors. See SELF

-DIAGNOSTICS ABBREVIATIONS table.

Abbreviations for wire colors used in individual PINPOINT TEST diagrams are as follows:

BLK - Black

BLU - Blue

BRN - Brown

GRN - Green

LT GRN - Light Green

ORG - Orange

PNK - Pink

RED - Red

WHT - White

YEL - Yellow

SELF-DIAGNOSTICS ABBREVIATIONS

SELF-DIAGNOSTIC SYSTEM

Hard Failures

Hard failures cause CHECK ENGINE light (MIL) to come on and remain on until problem is repaired. If MIL comes on and remains on (light

may flash) during vehicle operation, cause of malfunction must be determined using diagnostic (code) charts. If a sensor fails, ECA will use a

substitute value in its calculations to permit continued engine operation. In this condition (limp-in mode), vehicle will run but driveability will

not be optimum.

Intermittent Failures

Intermittent failures may cause MIL to flicker or come on and go off after intermittent defect goes away. Corresponding trouble code, however,

will be retained in ECA memory. If related defect does not reoccur within a certain time frame, related trouble code will be erased from ECA

ApplicationAbbreviation

Analog Volt/OhmmeterVOM

Barometric Pressure SensorBP

Breakout BoxBOB

Canister Purge Control SolenoidCANP

CHECK ENGINE LightMIL

Crankshaft Position SensorCPS

Cylinder Identification SensorCID

Electronic Control AssemblyECA

Electronic Engine ControlEEC

Engine Coolant Temperature SensorECT

Exhaust Gas Oxygen SensorEGO

Idle Speed ControlISC

Ignition Diagnostic MonitorIDM

Keep Alive PowerKAPWR

Key On Engine OffKOEO

Key On Engine RunningKOER

Knock ControlKC

Power & Ground ConnectionsPGC

Fuel Pressure Regulator Control SolenoidPRC

Reference Voltage & Signal ReturnVREF

Self-Test InputSTI

Self-Test OutputSTO

Signal ReturnSIGRTN

Solenoid Controlled By GroundSCG

Switch Monitor LampSML

Switch To GroundSTG

Switch To PowerSTP

Throttle Position SensorTP

Vane Airflow MeterVAF

Vane Air Temperature SensorVAT

Vehicle PowerVPWR

Vehicle Speed SensorVSS

Page 1 of 20 MITCHELL 1 ARTICLE - G - TESTS W/CODES 1991-92 ENGINE PERFORMANCE Ford Motor Co. Self-Diagnostics

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 170 of 454

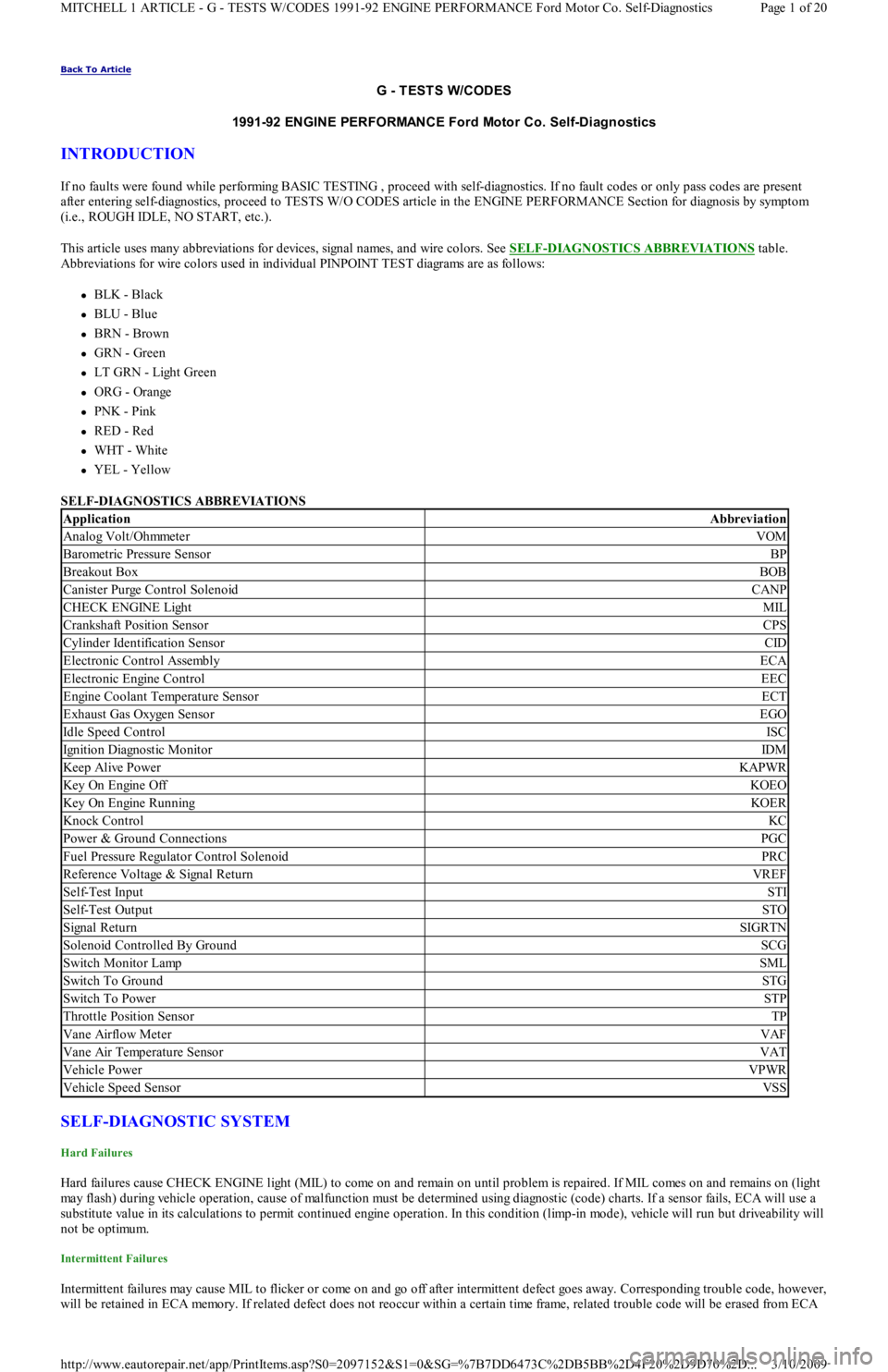

Engine control system communicates malfunctions to technician through service codes. These service codes are 2-digit numbers representing a

particular defect. Service codes are transmitted through STO connector.

Service codes are displayed as timed pulses, and may be read with a VOM or Super Star II tester. VOM displays codes by needle sweeps. See

Fig. 2

.

Turn ignition off. Ensure all procedures of EQUIPMENT HOOK

-UP have been followed. Engine should be at normal operating

temperature.

Fig. 2: Reading Service Codes With VOM

Courtesy of FORD MOTOR CO.

VOM

Disconnect and reconnect jumper wire from STI terminal to ground. Turn ignition on. Record displayed codes. Erase codes, and repeat test

procedure to verify all codes are currently valid. See ERASING CODES & RETESTING . Service only those codes which appear during

retest. Refer to TROUBLE CODE DEFINITION

table to find appropriate pinpoint test.

MIL

Turn ignition on. Connect a jumper wire between STI connector and ground. Observe MIL, and record pulses to determine codes stored.

SUPER STAR II Tester

Set center button to TEST position. Turn ignition on. Turn tester on. When activated, tester should display 888 for 2 seconds. Release and

reset center TEST button. After all codes are displayed, release center button. All codes in tester memory may now be reviewed.

ERASING CODES & RETESTING

Erasing codes and retesting will give an indication of whether codes are hard or intermittent defects. Hard codes reset immediately and will be

displayed during retest.

Disconnect negative battery cable. Press brake pedal for 5-10 seconds. Turn off VOM or Super Star II tester. Reconnect battery. Perform tests

under RETRIEVING CODES

to again display and record codes.

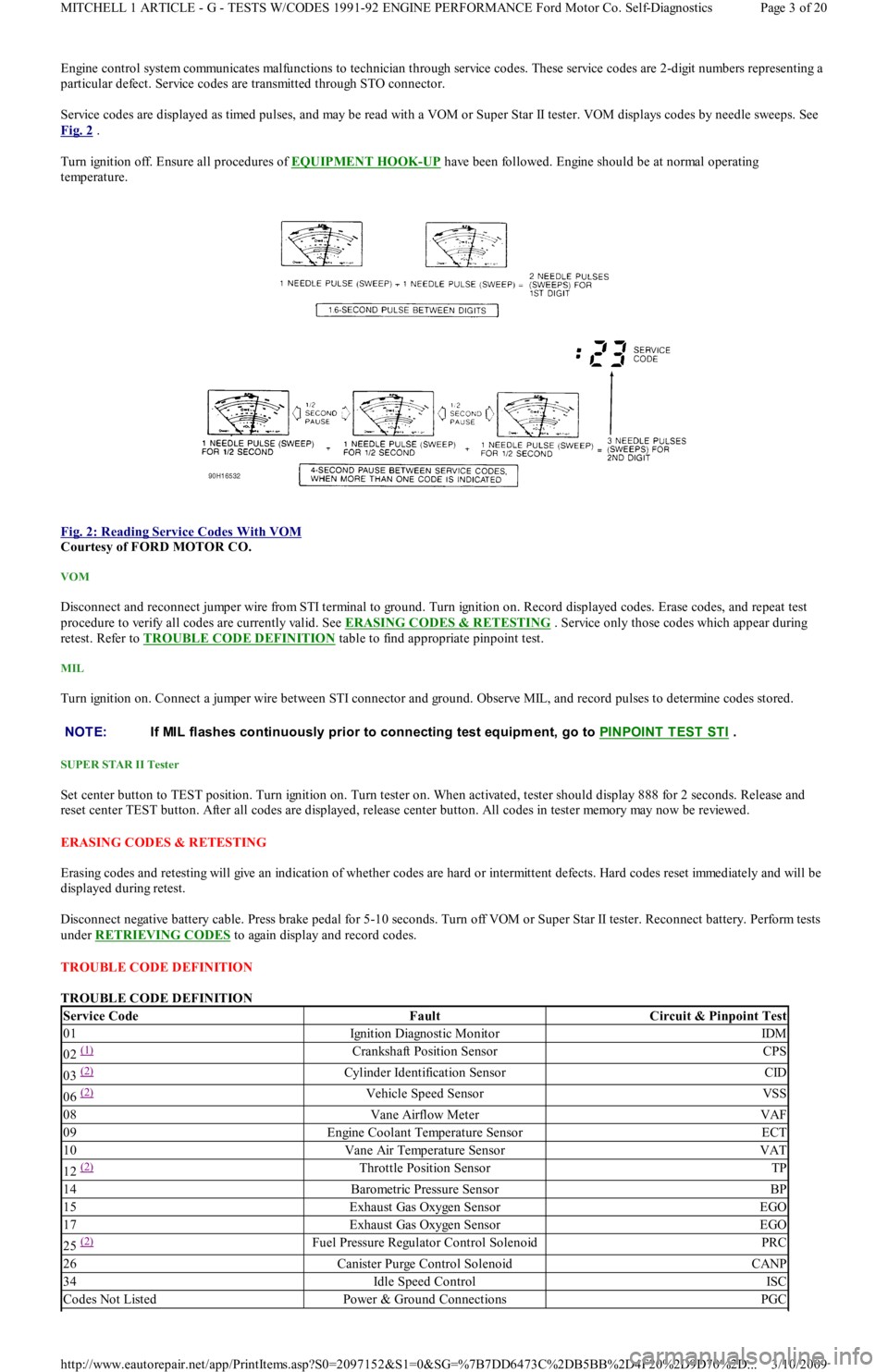

TROUBLE CODE DEFINITION

TROUBLE CODE DEFINITION

NOTE:If MIL flashes continuously prior to connecting test equipm ent, go to PINPOINT T EST ST I .

Service CodeFaultCircuit & Pinpoint Test

01Ignition Diagnostic MonitorIDM

02 (1) Crankshaft Position SensorCPS

03 (2) Cylinder Identification SensorCID

06 (2) Vehicle Speed SensorVSS

08Vane Airflow MeterVAF

09Engine Coolant Temperature SensorECT

10Vane Air Temperature SensorVAT

12 (2) Throttle Position SensorTP

14Barometric Pressure SensorBP

15Exhaust Gas Oxygen SensorEGO

17Exhaust Gas Oxygen SensorEGO

25 (2) Fuel Pressure Regulator Control SolenoidPRC

26Canister Purge Control SolenoidCANP

34Idle Speed ControlISC

Codes Not ListedPower & Ground ConnectionsPGC

Page 3 of 20 MITCHELL 1 ARTICLE - G - TESTS W/CODES 1991-92 ENGINE PERFORMANCE Ford Motor Co. Self-Diagnostics

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...