fuse diagram FORD FESTIVA 1991 Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 2 of 454

Back To Article

INST RUMENT PANEL

1991 ACCESSORIES & SAFET Y EQUIPMENT Ford Motor Co. Switches & Instrum ent Panels - Standard

DESCRIPTION & OPERATION

Instrument panel on Capri contains a speedometer, tachometer, fuel, water temperature, oil pressure and voltmeter gauges. A boost gauge is

incorporated into the tachometer on turbo models. Instrument panel is equipped with indicator/warning lights for charging system, air b ag,

manual shift, seat belt, turn signals, high beam and brakes. A CHECK ENGINE light, located on instrument panel, illuminates if a

computerized engine control fault occurs with engine running.

Instrument panel on Festiva contains a speedometer, fuel and water temperature gauges. Instrument panel is equipped with indicator/warning

lights for charging system, oil pressure, seat belt, rear defogger, turn signals, high beam and brakes. A CHECK ENGINE light, located on

instrument panel, illuminates if a computerized engine control fault occurs with engine running.

TROUBLE SHOOTING

FUEL GAUGE

Fuel Gauge Always Reads Empty

If fuel gauge always reads empty, check these items:

Check fuel gauge for open or damaged wires.

Check for open ground at fuel gauge sending unit.

Check for defective fuel sending unit.

Check for defective fuel gauge.

Check for defective instrument panel voltage regulator (Festiva).

Check for blown 10-amp METER fuse in fuse panel.

Check for open in Black/Yellow power feed wire from fuse panel instrument panel.

Check for fuel tank float full of fuel (sunk).

Fuel Gauge Always Reads Full

If fuel gauge always reads full, check these items:

Check for fuel gauge Yellow wire shorted to ground.

Check for defective fuel sending unit.

Check for defective fuel gauge.

Check for defective instrument panel voltage regulator (Festiva).

Fuel Gauge Inaccurate

If fuel gauge is inaccurate, check these items:

Check for faulty (loose or corroded) wire connections.

Check for defective fuel sending unit.

Check for defective instrument panel voltage regulator (Festiva).

TEMPERATURE GAUGE

Temperature Gauge Always Reads Cold

If temperature gauge always reads cold, check these items:

Check temperature gauge for open wire.

Check for defective temperature sender.

Check for defective temperature gauge.

Check for defective instrument panel voltage regulator (Festiva).

Check for blown 10-amp METER fuse in fuse panel.

Check for open in Black/Yellow power feed wire from fuse panel to instrument panel.

Temperature Gauge Always Reads Hot

CAUT ION: On m odels with Supplem ental Restraint System (SRS), observe safety precautions. T he air bag system

is powered directly from the battery and back-up power supply. Before any repairs are perform ed,

disconnect and shield battery ground cable. Disconnect the back-up power supply BEFORE servicing

ANY air bag com ponent. Use caution when working near steering colum n. Air bag could accidentally

deploy at any tim e.

NOTE:Ensure continuity exists between chassis ground and Black wire of instrum ent panel connector,

especially if fault exists in m ultiple gauge circuits. See appropriate chassis wiring diagram in the

WIRING DIAGRAMS Section.

Page 1 of 5 MITCHELL 1 ARTICLE - INSTRUMENT PANEL 1991 ACCESSORIES & SAFETY EQUIPMENT Ford Motor Co. Switches

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 7 of 454

Back To Article

DEFOGGER - REAR WINDOW

1991 ACCESSORIES & SAFET Y EQUIPMENT Rear Window Defoggers - Rear Window

DESCRIPTION & OPERATION

The rear window defogger consists of an electrical grid on rear window glass. The rear window defogger switch is located in the instrument

cluster bezel. On Capri, the switch is a push type and includes a small indicator light in the switch to indicate when rear defogger is on. On

Festiva, the switch is a rocker type and includes a small indicator light in instrument cluster to indicate when rear defogger is on.

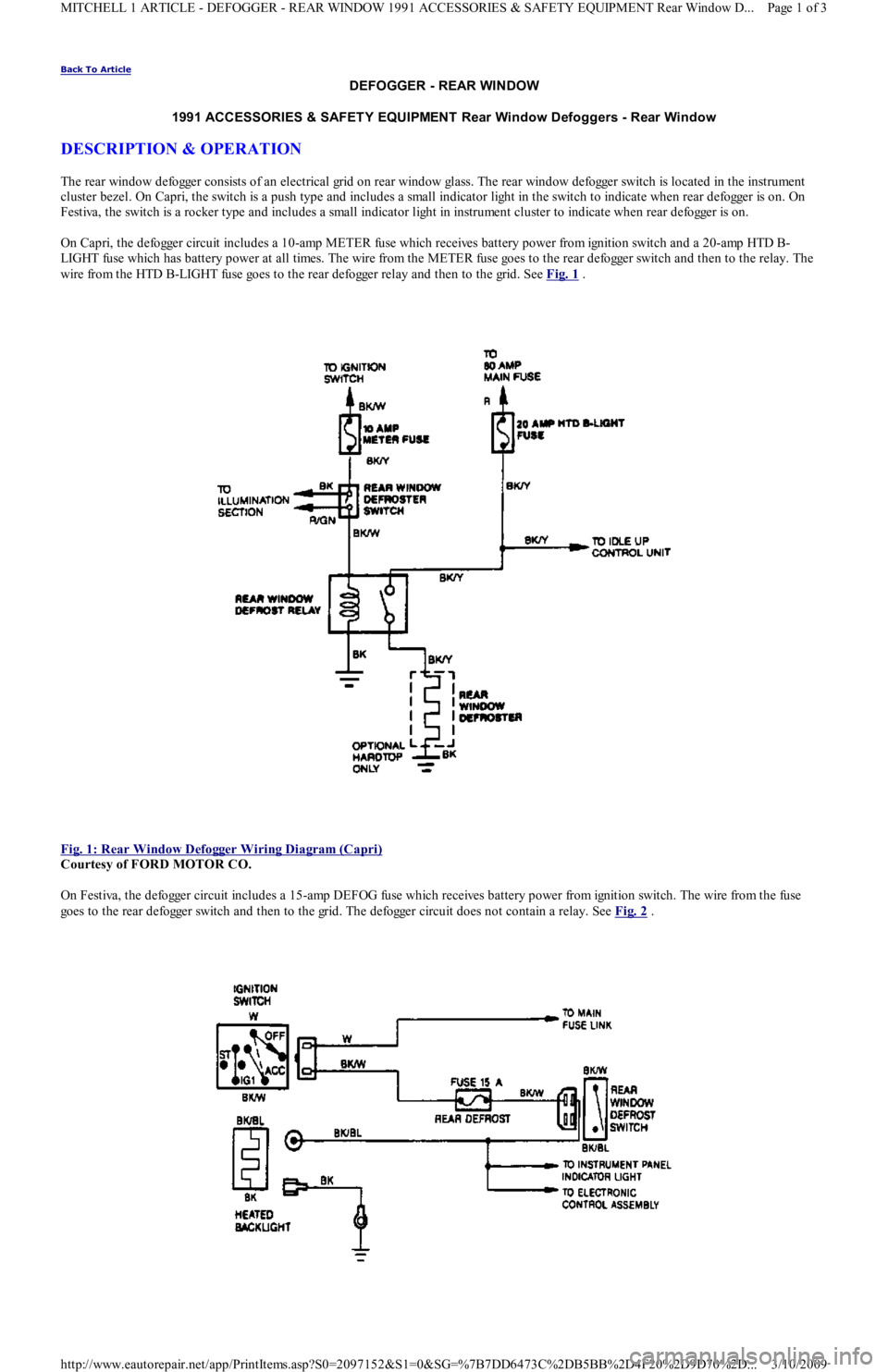

On Capri, the defogger circuit includes a 10-amp METER fuse which receives battery power from ignition switch and a 20-amp HTD B-

LIGHT fuse which has battery power at all times. The wire from the METER fuse goes to the rear defogger switch and then to the relay. The

wire from the HTD B-LIGHT fuse goes to the rear defogger relay and then to the grid. See Fig. 1

.

Fig. 1: Rear Window Defogger Wiring Diagram (Capri)

Courtesy of FORD MOTOR CO.

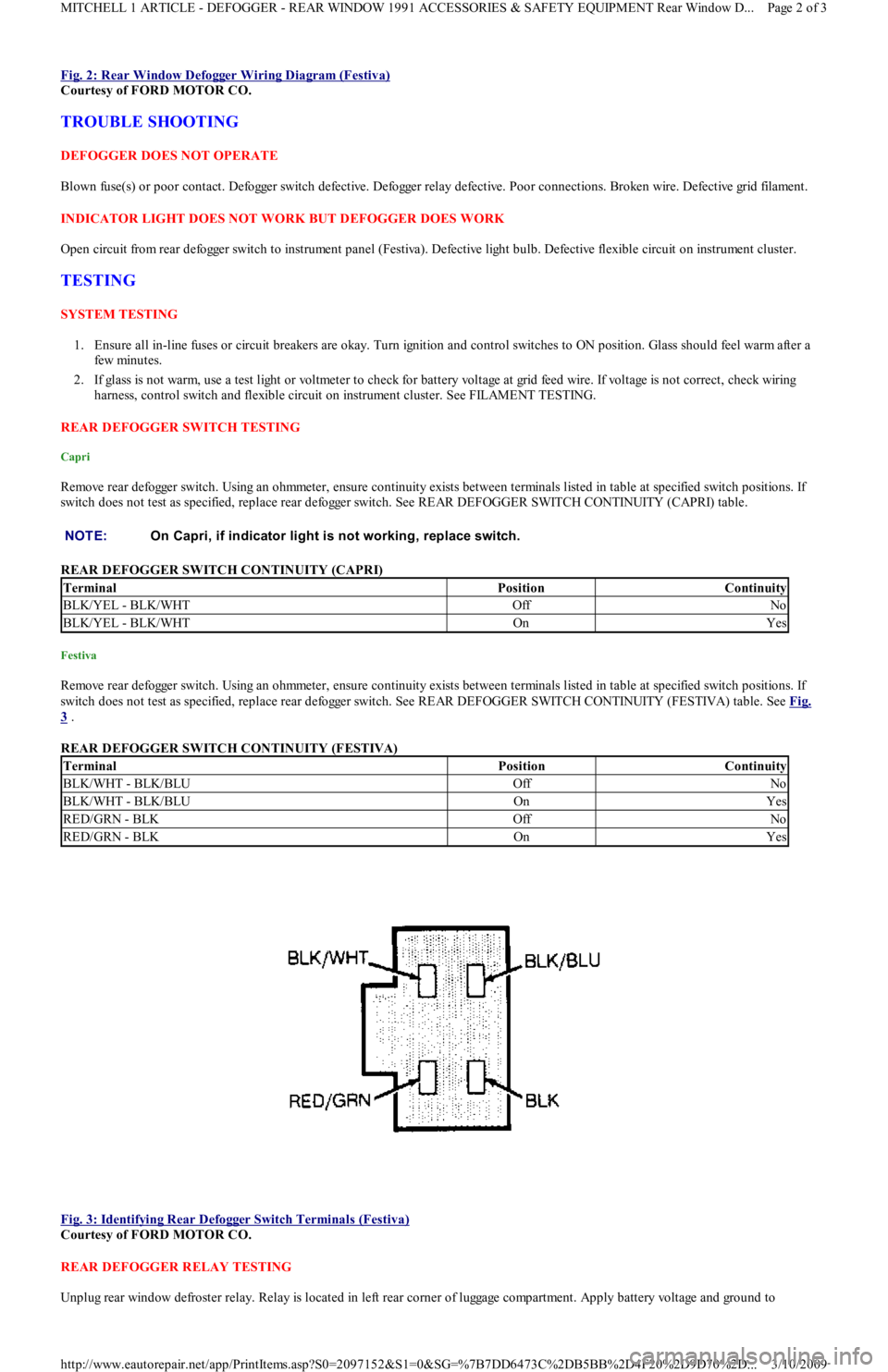

On Festiva, the defogger circuit includes a 15-amp DEFOG fuse which receives battery power from ignition switch. The wire from the fuse

goes to the rear defogger switch and then to the grid. The defogger circuit does not contain a relay. See Fig. 2

.

Page 1 of 3 MITCHELL 1 ARTICLE - DEFOGGER - REAR WINDOW 1991 ACCESSORIES & SAFETY EQUIPMENT Rear Window D

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 8 of 454

Fig. 2: Rear Window Defogger Wiring Diagram (Festiva)

Courtesy of FORD MOTOR CO.

TROUBLE SHOOTING

DEFOGGER DOES NOT OPERATE

Blown fuse(s) or poor contact. Defogger switch defective. Defogger relay defective. Poor connections. Broken wire. Defective grid filament.

INDICATOR LIGHT DOES NOT WORK BUT DEFOGGER DOES WORK

Open circuit from rear defogger switch to instrument panel (Festiva). Defective light bulb. Defective flexible circuit on instrument cluster.

TESTING

SYSTEM TESTING

1. Ensure all in-line fuses or circuit breakers are okay. Turn ignition and control switches to ON position. Glass should feel warm after a

few min u t es.

2. If glass is not warm, use a test light or voltmeter to check for battery voltage at grid feed wire. If voltage is not correct, check wiring

harness, control switch and flexible circuit on instrument cluster. See FILAMENT TESTING.

REAR DEFOGGER SWITCH TESTING

Capri

Remove rear defogger switch. Using an ohmmeter, ensure continuity exists between terminals listed in table at specified switch positions. If

switch does not test as specified, replace rear defogger switch. See REAR DEFOGGER SWITCH CONTINUITY (CAPRI) table.

REAR DEFOGGER SWITCH CONTINUITY (CAPRI)

Festiva

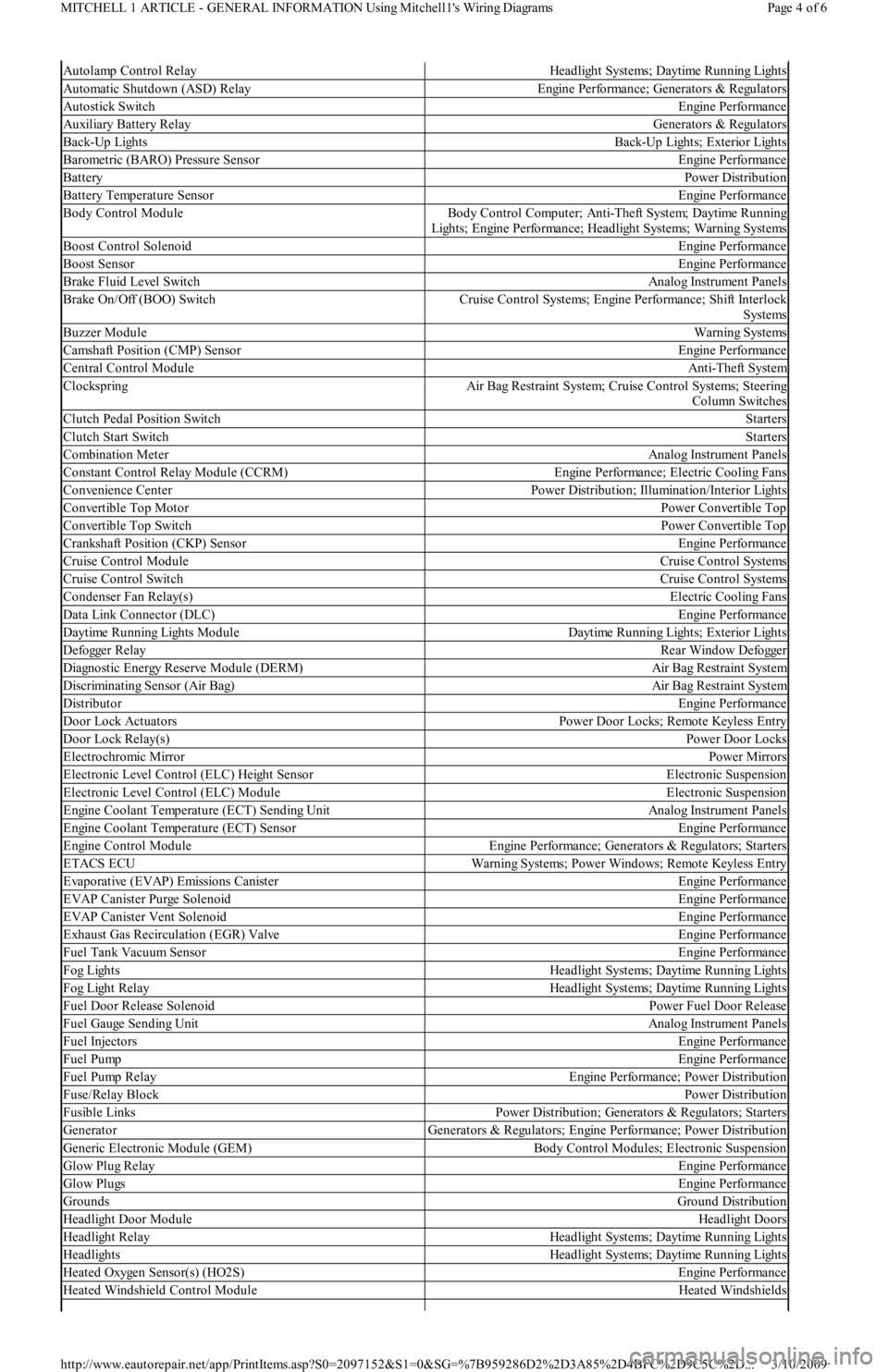

Remove rear defogger switch. Using an ohmmeter, ensure continuity exists between terminals listed in table at specified switch positions. If

switch does not test as specified, replace rear defogger switch. See REAR DEFOGGER SWITCH CONTINUITY (FESTIVA) table. See Fig.

3 .

REAR DEFOGGER SWITCH CONTINUITY (FESTIVA)

Fig. 3: Identifying Rear Defogger Switch Terminals (Festiva)

Courtesy of FORD MOTOR CO.

REAR DEFOGGER RELAY TESTING

Unplug rear window defroster relay. Relay is located in left rear corner of luggage compartment. Apply battery voltage and ground to NOTE:On Capri, if indicator light is not working, replace switch.

TerminalPositionContinuity

BLK/YEL - BLK/WHTOffNo

BLK/YEL - BLK/WHTOnYes

TerminalPositionContinuity

BLK/WHT - BLK/BLUOffNo

BLK/WHT - BLK/BLUOnYes

RED/GRN - BLKOffNo

RED/GRN - BLKOnYes

Page 2 of 3 MITCHELL 1 ARTICLE - DEFOGGER - REAR WINDOW 1991 ACCESSORIES & SAFETY EQUIPMENT Rear Window D

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 66 of 454

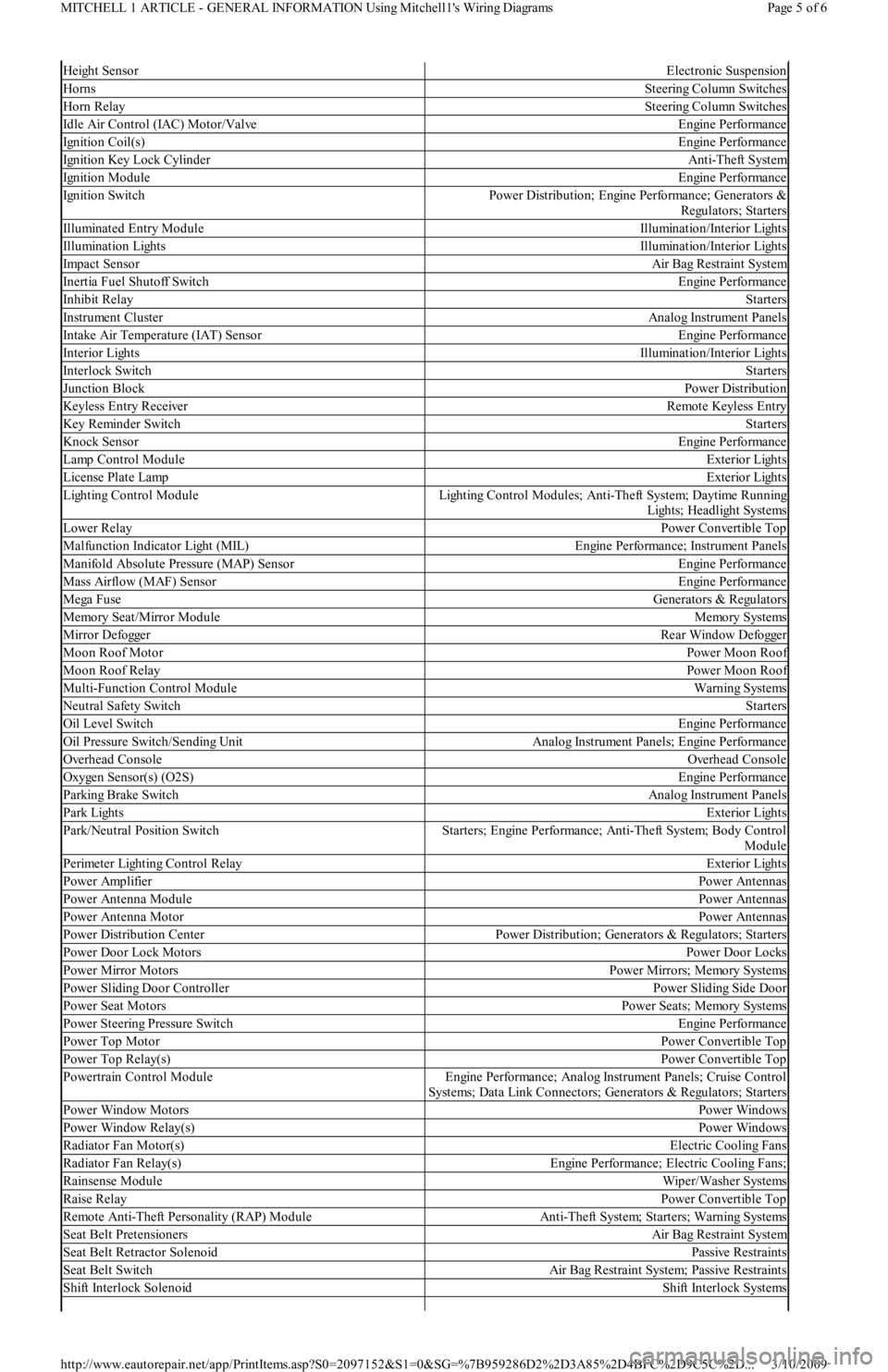

Autolamp Control RelayHeadlight Systems; Daytime Running Lights

Automatic Shutdown (ASD) RelayEngine Performance; Generators & Regulators

Autostick SwitchEngine Performance

Auxiliary Battery RelayGenerators & Regulators

Back-Up LightsBack-Up Lights; Exterior Lights

Barometric (BARO) Pressure SensorEngine Performance

BatteryPower Distribution

Battery Temperature SensorEngine Performance

Body Control ModuleBody Control Computer; Anti-Theft System; Daytime Running

Lights; Engine Performance; Headlight Systems; Warning Systems

Boost Control SolenoidEngine Performance

Boost SensorEngine Performance

Brake Fluid Level SwitchAnalog Instrument Panels

Brake On/Off (BOO) SwitchCruise Control Systems; Engine Performance; Shift Interlock

Systems

Buzzer ModuleWarning Systems

Camshaft Position (CMP) SensorEngine Performance

Central Control ModuleAnti-Theft System

ClockspringAir Bag Restraint System; Cruise Control Systems; Steering

Column Switches

Clutch Pedal Position SwitchStarters

Clutch Start SwitchStarters

Combination MeterAnalog Instrument Panels

Constant Control Relay Module (CCRM)Engine Performance; Electric Cooling Fans

Convenience CenterPower Distribution; Illumination/Interior Lights

Convertible Top MotorPower Convertible Top

Convertible Top SwitchPower Convertible Top

Crankshaft Position (CKP) SensorEngine Performance

Cruise Control ModuleCruise Control Systems

Cruise Control SwitchCruise Control Systems

Condenser Fan Relay(s)Electric Cooling Fans

Data Link Connector (DLC)Engine Performance

Da yt ime R u n n in g Ligh t s M o d u l eDaytime Running Lights; Exterior Lights

Defogger RelayRear Window Defogger

Diagnostic Energy Reserve Module (DERM)Air Bag Restraint System

Discriminating Sensor (Air Bag)Air Bag Restraint System

DistributorEngine Performance

Door Lock ActuatorsPower Door Locks; Remote Keyless Entry

Door Lock Relay(s)Power Door Locks

Electrochromic MirrorPower Mirrors

Electronic Level Control (ELC) Height SensorElectronic Suspension

Electronic Level Control (ELC) ModuleElectronic Suspension

Engine Coolant Temperature (ECT) Sending UnitAnalog Instrument Panels

Engine Coolant Temperature (ECT) SensorEngine Performance

Engine Control ModuleEngine Performance; Generators & Regulators; Starters

ETACS ECUWarning Systems; Power Windows; Remote Keyless Entry

Evaporative (EVAP) Emissions CanisterEngine Performance

EVAP Canister Purge SolenoidEngine Performance

EVAP Canister Vent SolenoidEngine Performance

Exhaust Gas Recirculation (EGR) ValveEngine Performance

Fuel Tank Vacuum SensorEngine Performance

F o g Ligh t sHeadlight Systems; Daytime Running Lights

F o g Ligh t R e l a yHeadlight Systems; Daytime Running Lights

Fuel Door Release SolenoidPower Fuel Door Release

Fuel Gauge Sending UnitAnalog Instrument Panels

Fuel InjectorsEngine Performance

Fuel PumpEngine Performance

Fuel Pump RelayEngine Performance; Power Distribution

Fuse/Relay BlockPower Distribution

Fusible LinksPower Distribution; Generators & Regulators; Starters

GeneratorGenerators & Regulators; Engine Performance; Power Distribution

Generic Electronic Module (GEM)Body Control Modules; Electronic Suspension

Glow Plug RelayEngine Performance

Glow PlugsEngine Performance

GroundsGround Distribution

Headlight Door ModuleHeadlight Doors

Headlight RelayHeadlight Systems; Daytime Running Lights

HeadlightsHeadlight Systems; Daytime Running Lights

Heated Oxygen Sensor(s) (HO2S)Engine Performance

Heated Windshield Control ModuleHeated Windshields

Page 4 of 6 MITCHELL 1 ARTICLE - GENERAL INFORMATION Using Mitchell1's Wiring Diagrams

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 67 of 454

Height SensorElectronic Suspension

HornsSteering Column Switches

Horn RelaySteering Column Switches

Idle Air Control (IAC) Motor/ValveEngine Performance

Ignition Coil(s)Engine Performance

Ignition Key Lock CylinderAnti-Theft System

Ignition ModuleEngine Performance

Ignition SwitchPower Distribution; Engine Performance; Generators &

Regulators; Starters

Illuminated Entry ModuleIllumination/Interior Lights

Illumination LightsIllumination/Interior Lights

Impact SensorAir Bag Restraint System

Inertia Fuel Shutoff SwitchEngine Performance

In h ib it Rel ayStarters

Instrument ClusterAnalog Instrument Panels

Intake Air Temperature (IAT) SensorEngine Performance

Interior LightsIllumination/Interior Lights

In t erl o ck Swit chStarters

Junction BlockPower Distribution

Keyless Entry ReceiverRemote Keyless Entry

Key Reminder SwitchStarters

Knock SensorEngine Performance

Lamp Control ModuleExterior Lights

License Plate LampExterior Lights

Lighting Control ModuleLighting Control Modules; Anti-Theft System; Daytime Running

Lights; Headlight Systems

Lower RelayPower Convertible Top

Malfunction Indicator Light (MIL)Engine Performance; Instrument Panels

Manifold Absolute Pressure (MAP) SensorEngine Performance

Mass Airflow (MAF) SensorEngine Performance

Mega FuseGenerators & Regulators

Memory Seat/Mirror ModuleMemory Systems

M ir r o r De fo gge rRear Window Defogger

Moon Roof MotorPower Moon Roof

Moon Roof RelayPower Moon Roof

Multi-Function Control ModuleWarning Systems

Neutral Safety SwitchStarters

Oil Level SwitchEngine Performance

Oil Pressure Switch/Sending UnitAnalog Instrument Panels; Engine Performance

Overhead ConsoleOverhead Console

Oxygen Sensor(s) (O2S)Engine Performance

Parking Brake SwitchAnalog Instrument Panels

Park LightsExterior Lights

Park/Neutral Position SwitchStarters; Engine Performance; Anti-Theft System; Body Control

Module

Perimeter Lighting Control RelayExterior Lights

Power AmplifierPower Antennas

Power Antenna ModulePower Antennas

Power Antenna MotorPower Antennas

Power Distribution CenterPower Distribution; Generators & Regulators; Starters

Power Door Lock MotorsPower Door Locks

Power Mirror MotorsPower Mirrors; Memory Systems

Power Sliding Door ControllerPower Sliding Side Door

Power Seat MotorsPower Seats; Memory Systems

Power Steering Pressure SwitchEngine Performance

Power Top MotorPower Convertible Top

Power Top Relay(s)Power Convertible Top

Powertrain Control ModuleEngine Performance; Analog Instrument Panels; Cruise Control

Systems; Data Link Connectors; Generators & Regulators; Starters

Power Window MotorsPower Windows

Power Window Relay(s)Power Windows

Radiator Fan Motor(s)Electric Cooling Fans

Radiator Fan Relay(s)Engine Performance; Electric Cooling Fans;

Rainsense ModuleWiper/Washer Systems

Raise RelayPower Convertible Top

Remote Anti-Theft Personality (RAP) ModuleAnti-Theft System; Starters; Warning Systems

Seat Belt PretensionersAir Bag Restraint System

Seat Belt Retractor SolenoidPassive Restraints

Seat Belt SwitchAir Bag Restraint System; Passive Restraints

Shift Interlock SolenoidShift Interlock Systems

Page 5 of 6 MITCHELL 1 ARTICLE - GENERAL INFORMATION Using Mitchell1's Wiring Diagrams

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 69 of 454

Back To Article

WIRING DIAGRAMS

1991 WIRING DIAGRAMS Ford Motor Co.

IDENTIFICATION

COMPONENT LOCATION MENU

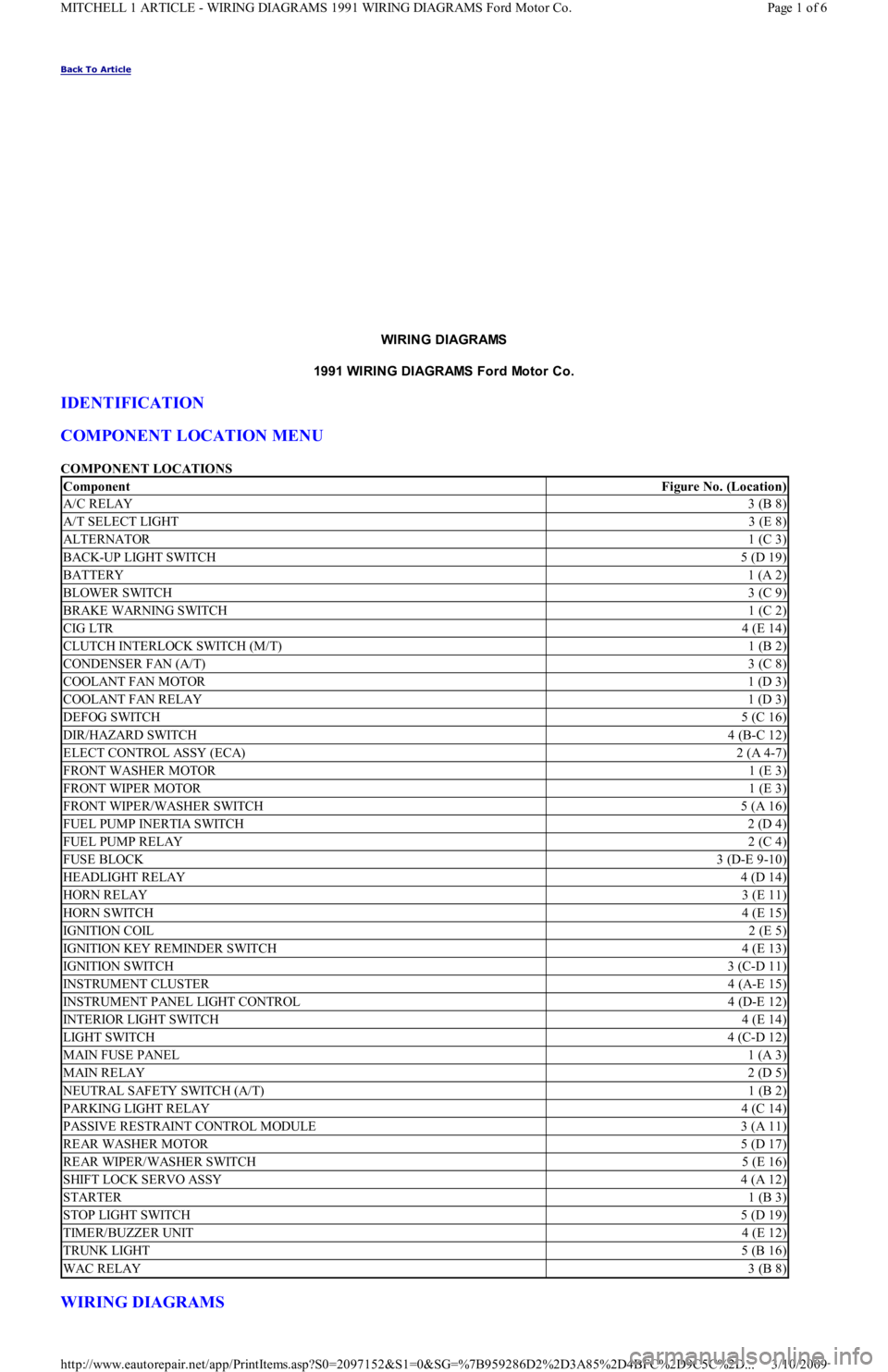

COMPONENT LOCATIONS

WIRING DIAGRAMS

ComponentFigure No. (Location)

A/C RELAY3 (B 8)

A/T SELECT LIGHT3 (E 8)

ALTERNATOR1 (C 3)

BACK-UP LIGHT SWITCH5 (D 19)

BATTERY1 (A 2)

BLOWER SWITCH3 (C 9)

BRAKE WARNING SWITCH1 (C 2)

CIG LTR4 (E 14)

CLUTCH INTERLOCK SWITCH (M/T)1 (B 2)

CONDENSER FAN (A/T)3 (C 8)

COOLANT FAN MOTOR1 (D 3)

COOLANT FAN RELAY1 (D 3)

DEFOG SWITCH5 (C 16)

DIR/HAZARD SWITCH4 (B-C 12)

ELECT CONTROL ASSY (ECA)2 (A 4-7)

FRONT WASHER MOTOR1 (E 3)

FRONT WIPER MOTOR1 (E 3)

FRONT WIPER/WASHER SWITCH5 (A 16)

FUEL PUMP INERTIA SWITCH2 (D 4)

FUEL PUMP RELAY2 (C 4)

FUSE BLOCK3 (D-E 9-10)

HEADLIGHT RELAY4 (D 14)

HORN RELAY3 (E 11)

HORN SWITCH4 (E 15)

IGNITION COIL2 (E 5)

IGNITION KEY REMINDER SWITCH4 (E 13)

IGNITION SWITCH3 (C-D 11)

INSTRUMENT CLUSTER4 (A-E 15)

INSTRUMENT PANEL LIGHT CONTROL4 (D-E 12)

INTERIOR LIGHT SWITCH4 (E 14)

LIGHT SWITCH4 (C-D 12)

MAIN FUSE PANEL1 (A 3)

MAIN RELAY2 (D 5)

NEUTRAL SAFETY SWITCH (A/T)1 (B 2)

PARKING LIGHT RELAY4 (C 14)

PASSIVE RESTRAINT CONTROL MODULE3 (A 11)

REAR WASHER MOTOR5 (D 17)

REAR WIPER/WASHER SWITCH5 (E 16)

SHIFT LOCK SERVO ASSY4 (A 12)

STARTER1 (B 3)

STOP LIGHT SWITCH5 (D 19)

TIMER/BUZZER UNIT4 (E 12)

TRUNK LIGHT5 (B 16)

WAC RELAY3 (B 8)

Page 1 of 6 MITCHELL 1 ARTICLE - WIRING DIAGRAMS 1991 WIRING DIAGRAMS Ford Motor Co.

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 72 of 454

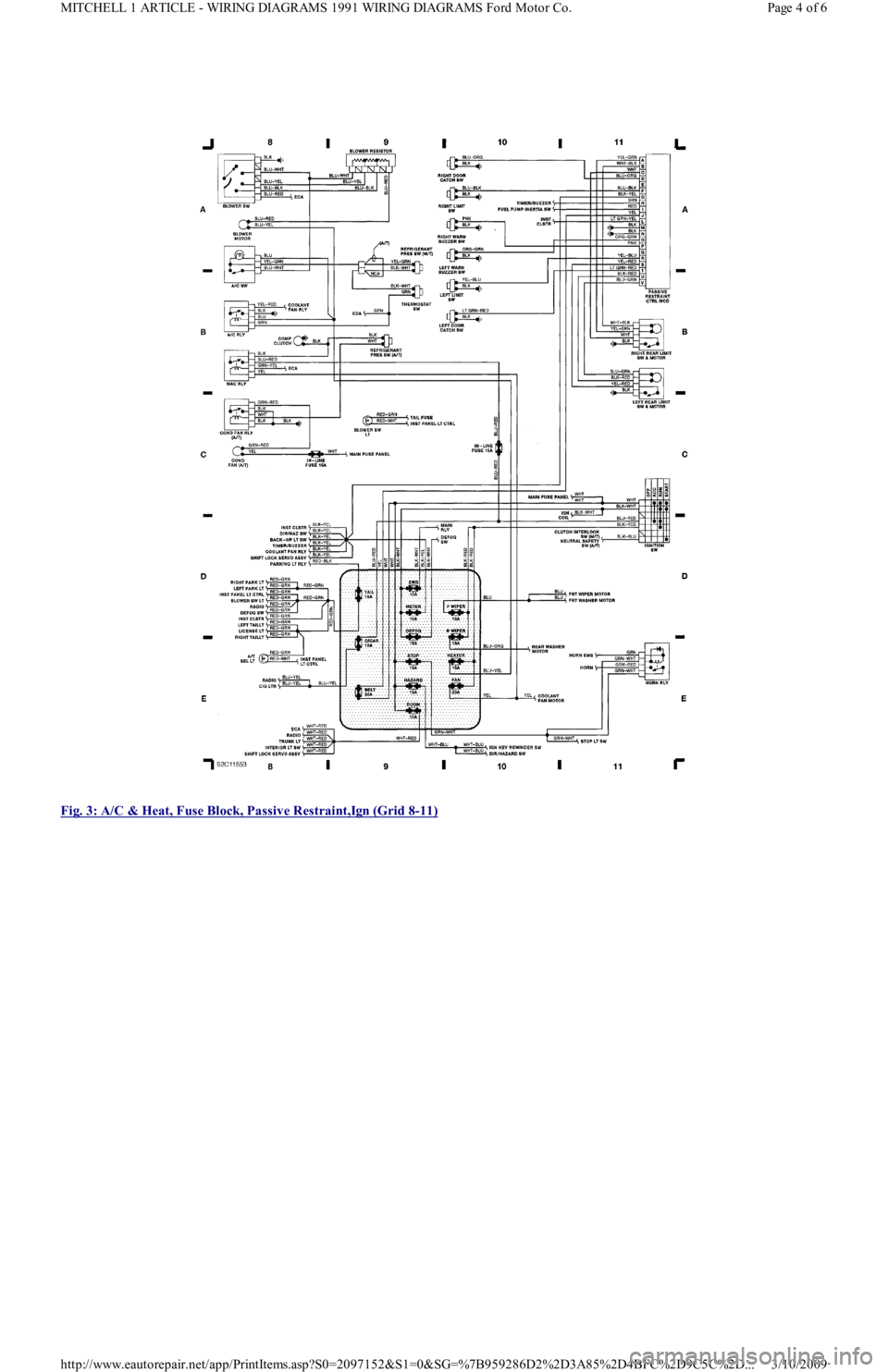

Fig. 3: A/C & Heat, Fuse Block, Passive Restraint,Ign (Grid 8

-11)

Page 4 of 6 MITCHELL 1 ARTICLE - WIRING DIAGRAMS 1991 WIRING DIAGRAMS Ford Motor Co.

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 87 of 454

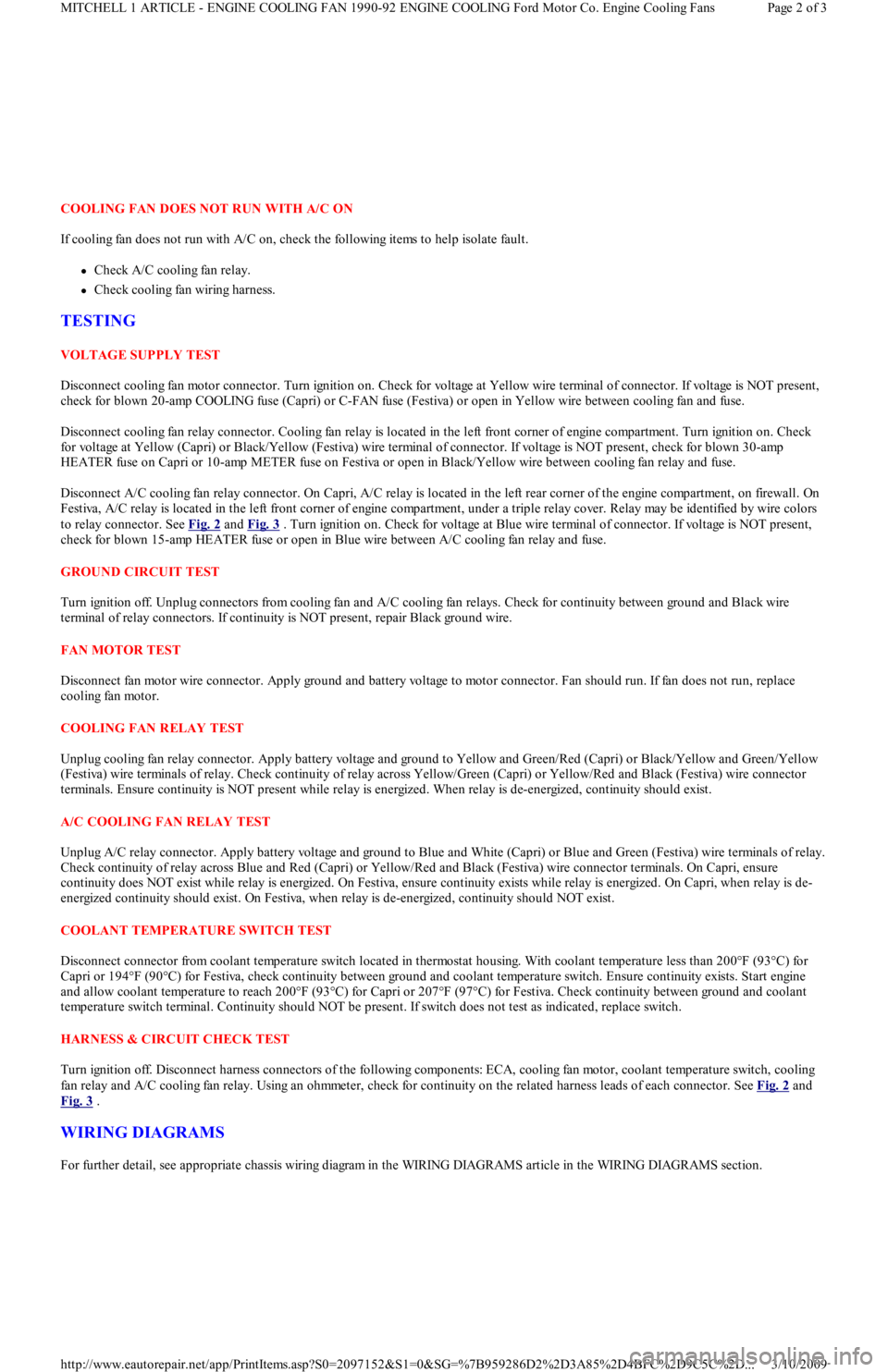

COOLING FAN DOES NOT RUN WITH A/C ON

If cooling fan does not run with A/C on, check the following items to help isolate fault.

Check A/C cooling fan relay.

Check cooling fan wiring harness.

TESTING

VOLTAGE SUPPLY TEST

Disconnect cooling fan motor connector. Turn ignition on. Check for voltage at Yellow wire terminal of connector. If voltage is NOT present,

check for blown 20-amp COOLING fuse (Capri) or C-FAN fuse (Festiva) or open in Yellow wire between cooling fan and fuse.

Disconnect cooling fan relay connector. Cooling fan relay is located in the left front corner of engine compartment. Turn ignition on. Check

for voltage at Yellow (Capri) or Black/Yellow (Festiva) wire terminal of connector. If voltage is NOT present, check for blown 30-amp

HEATER fuse on Capri or 10-amp METER fuse on Festiva or open in Black/Yellow wire between cooling fan relay and fuse.

Disconnect A/C cooling fan relay connector. On Capri, A/C relay is located in the left rear corner of the engine compartment, on firewall. On

Festiva, A/C relay is located in the left front corner of engine compartment, under a triple relay cover. Relay may be identified by wire colors

to relay connector. See Fig. 2

and Fig. 3 . Turn ignition on. Check for voltage at Blue wire terminal of connector. If voltage is NOT present,

check for blown 15-amp HEATER fuse or open in Blue wire between A/C cooling fan relay and fuse.

GROUND CIRCUIT TEST

Turn ignition off. Unplug connectors from cooling fan and A/C cooling fan relays. Check for continuity between ground and Black wire

terminal of relay connectors. If continuity is NOT present, repair Black ground wire.

FAN MOTOR TEST

Disconnect fan motor wire connector. Apply ground and battery voltage to motor connector. Fan should run. If fan does not run, replace

cooling fan motor.

COOLING FAN RELAY TEST

Unplug cooling fan relay connector. Apply battery voltage and ground to Yellow and Green/Red (Capri) or Black/Yellow and Green/Yellow

(Festiva) wire terminals of relay. Check continuity of relay across Yellow/Green (Capri) or Yellow/Red and Black (Festiva) wire connector

terminals. Ensure continuity is NOT present while relay is energized. When relay is de-energized, continuity should exist.

A/C COOLING FAN RELAY TEST

Unplug A/C relay connector. Apply battery voltage and ground to Blue and White (Capri) or Blue and Green (Festiva) wire terminals of relay.

Check continuity of relay across Blue and Red (Capri) or Yellow/Red and Black (Festiva) wire connector terminals. On Capri, ensure

continuity does NOT exist while relay is energized. On Festiva, ensure continuity exists while relay is energized. On Capri, when relay is de-

energized continuity should exist. On Festiva, when relay is de-energized, continuity should NOT exist.

COOLANT TEMPERATURE SWITCH TEST

Disconnect connector from coolant temperature switch located in thermostat housing. With coolant temperature less than 200°F (93°C) for

Capri or 194°F (90°C) for Festiva, check continuity between ground and coolant temperature switch. Ensure continuity exists. Start engine

and allow coolant temperature to reach 200°F (93°C) for Capri or 207°F (97°C) for Festiva. Check continuity between ground and coolant

temperature switch terminal. Continuity should NOT be present. If switch does not test as indicated, replace switch.

HARNESS & CIRCUIT CHECK TEST

Turn ignition off. Disconnect harness connectors of the following components: ECA, cooling fan motor, coolant temperature switch, cooling

fan relay and A/C cooling fan relay. Using an ohmmeter, check for continuity on the related harness leads of each connector. See Fig. 2

and

Fig. 3

.

WIRING DIAGRAMS

For further detail, see appropriate chassis wiring diagram in the WIRING DIAGRAMS article in the WIRING DIAGRAMS section.

Page 2 of 3 MITCHELL 1 ARTICLE - ENGINE COOLING FAN 1990-92 ENGINE COOLING Ford Motor Co. Engine Cooling Fans

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 214 of 454

Back To Article

GENERAL INFORMATION

T rouble Shooting - Basic Procedures

* PLEASE READ THIS FIRST *

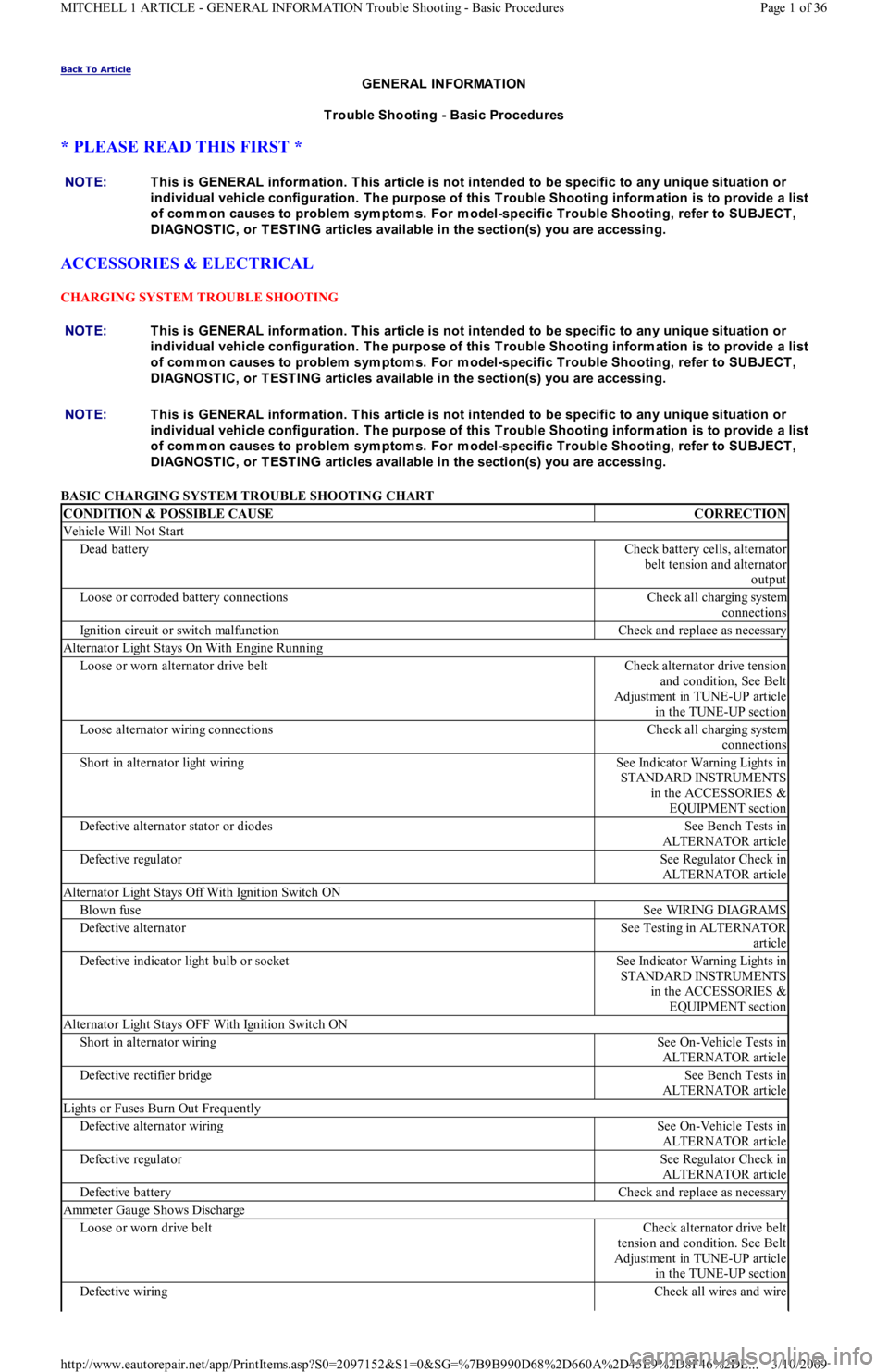

ACCESSORIES & ELECTRICAL

CHARGING SYSTEM TROUBLE SHOOTING

BASIC CHARGING SYSTEM TROUBLE SHOOTING CHART NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to SUBJECT ,

DIAGNOST IC, or T EST ING articles available in the section(s) you are accessing.

NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to SUBJECT ,

DIAGNOST IC, or T EST ING articles available in the section(s) you are accessing.

NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to SUBJECT ,

DIAGNOST IC, or T EST ING articles available in the section(s) you are accessing.

CONDITION & POSSIBLE CAUSECORRECTION

Vehicle Will Not Start

Dead batteryCheck battery cells, alternator

belt tension and alternator

output

Loose or corroded battery connectionsCheck all charging system

connections

Ignition circuit or switch malfunctionCheck and replace as necessary

Alternator Light Stays On With Engine Running

Loose or worn alternator drive beltCheck alternator drive tension

and condition, See Belt

Adjustment in TUNE-UP article

in the TUNE-UP section

Loose alternator wiring connectionsCheck all charging system

connections

Short in alternator light wiringSee Indicator Warning Lights in

STANDARD INSTRUMENTS

in the ACCESSORIES &

EQUIPMENT section

Defective alternator stator or diodesSee Bench Tests in

ALTERNATOR article

Defective regulatorSee Regulator Check in

ALTERNATOR article

Alternator Light Stays Off With Ignition Switch ON

Blown fuseSee WIRING DIAGRAMS

Defective alternatorSee Testing in ALTERNATOR

article

Defective indicator light bulb or socketSee Indicator Warning Lights in

STANDARD INSTRUMENTS

in the ACCESSORIES &

EQUIPMENT section

Alternator Light Stays OFF With Ignition Switch ON

Short in alternator wiringSee On-Vehicle Tests in

ALTERNATOR article

Defective rectifier bridgeSee Bench Tests in

ALTERNATOR article

Lights or Fuses Burn Out Frequently

Defective alternator wiringSee On-Vehicle Tests in

ALTERNATOR article

Defective regulatorSee Regulator Check in

ALTERNATOR article

Defective batteryCheck and replace as necessary

Ammeter Gauge Shows Discharge

Loose or worn drive beltCheck alternator drive belt

tension and condition. See Belt

Adjustment in TUNE-UP article

in the TUNE-UP section

Defective wiringCheck all wires and wire

Page 1 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 345 of 454

Back To Article

HEAT ER SYST EM

1990-92 HEAT ER SYST EMS Ford Motor Co.

DESCRIPTION

The heater system consists of control panel, blower case, heater case, air control doors and ducts. The control panel incorporates 3 control

levers and a 3-speed fan switch. The control panel is located in the center of the instrument panel. All air control doors are cable operated

from the control panel.

The blower case is mounted on the bulkhead, behind the instrument panel on passenger's side of vehicle. The blower case houses a blower

motor, blower motor resistor and the fresh/recirculation air door. The heater case contains mode select door, temperature air mix door and

heater core.

OPERATION

Three control levers, temperature mix, fresh/recirculation and mode select, mechanically operate their associated cables and doors. The

temperature control lever adjusts the mix of fresh or recirculated air with heated air. In full heat position, all airflow goes through the heater

core.

In full cool position, the mix air door closes, allowing airflow to by-pass the heater core. The mode select lever, directs airflow to selected

vents. The fresh/recirculation control lever allows selection of fresh (outside) air or recirculated compartment air.

AJUSTMENT

FRESH/RECIRCULATION CONTROL CABLE

Remove the glove box. Remove fresh/recirculation cable retaining clip. Move control lever to RECIRCULATION position, while holding the

lever door in RECIRCULATION position. Ensure control lever does not move. Install fresh/recirculation cable retaining clip.

MODE SELECT CABLE

Remove mode select cable retaining clip. Move mode select lever to VENT position. Hold mode select lever downward against its stop.

Ensure that mode select lever does not move. Install mode select cable retaining clip.

TEMPERATURE CONTROL CABLE

Set temperature control lever to maximum cold position. Remove temperature cable retaining clip. Hold temperature control lever upward and

against its stop. Ensure that temperature lever does not move. Install temperature cable retaining clip.

TROUBLE SHOOTING

BLOWER MOTOR INOPERATIVE

Check blown motor fuse. Check for defective blower motor and/or blower motor resistor. Check blower motor switch. Check for open in

ground wire. Check for loose electrical connectors or poor connections. See WIRING DIAGRAMS

in this article.

BLOWER DOES NOT CHANGE SPEED

Check for defective blower motor. Check blower motor wiring harness. Check blower motor resistor. Check for blower motor fan switch. See

WIRING DIAGRAMS

in this article.

BLOWER RUNS CONSTANTLY

Check for defective blower motor resistor. Check for short in blower switch or wiring. See WIRING DIAGRAMS

in this article.

HEATER TEMPERATURE INSUFFICIENT

Check for proper coolant level. Check water pump for noise, leaks or wear. Check heater hoses for leaks or restrictions. Check heater core for

leaks, plugs or restrictions. Check inlet and outlet heater hoses for hot water flow. Check thermostat condition and operation. Check air mix

door position and adjust cable if necessary.

IMPROPER WARM AIR DISTRIBUTION

Check air mix door position. Adjust cable as necessary. Check function control door position. Adjust cable as necessary. Check for restriction

in ventilation air duct assembly. Repair as necessary.

TESTING BLOWER MOTOR & RESISTOR

1. Ensure 15-amp blower motor fuse is okay. Using voltmeter, check for battery voltage at blower motor Blue/Yellow terminal. If battery

voltage is present, go to next step. If battery voltage is not present, repair open in Blue/Yellow wire between blower motor and fuse box.

2. Disconnect blower motor connector. Using a jumper wire, apply battery voltage to Blue/Yellow terminal and ground the Blue/Red

terminal. If blower motor does not run, replace blower motor. If blower motor runs, go to next step.

3. Reconnect blower motor connector. Turn ignition on. Turn blower motor off. Disconnect the blower motor resistor connector. Using a

voltmeter, measure voltage at Blue/Red terminal of resistor connector. If battery voltage is not present, repair open in Blue/Red wire

between resistor and blower motor. If voltage is present, go to next step.

4. Using a jumper wire, ground Blue/Black, Blue/Yellow and Blue/White terminals of the blower fan switch one at a time. If the motor

runs at 3 different speeds, go to next step. If not, repair open in wire that failed to operate blower motor.

Page 1 of 4 MITCHELL 1 ARTICLE - HEATER SYSTEM 1990-92 HEATER SYSTEMS Ford Motor Co.

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...