ABS FORD FIESTA 1989 Service Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1989, Model line: FIESTA, Model: FORD FIESTA 1989Pages: 296, PDF Size: 10.65 MB

Page 6 of 296

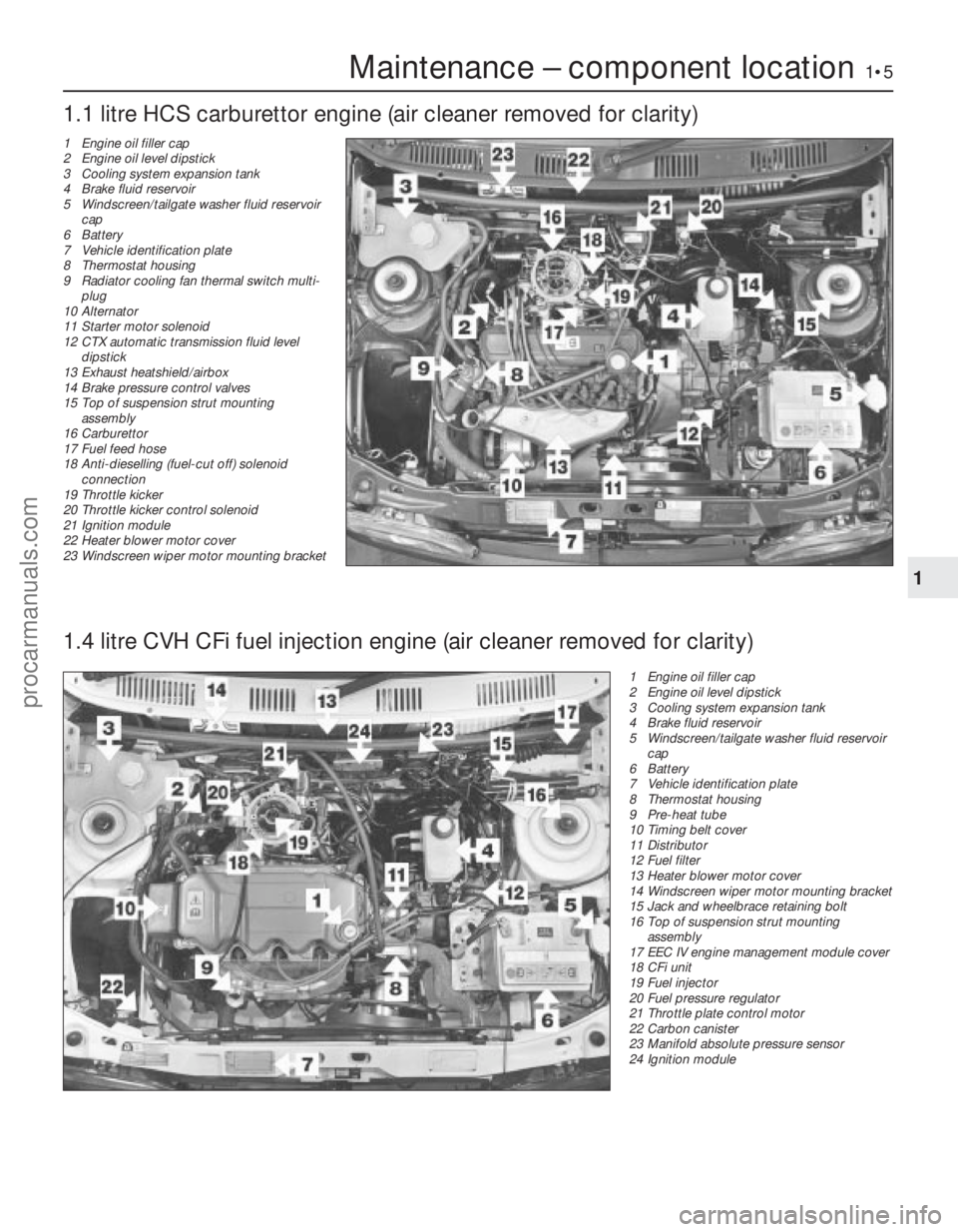

Maintenance – component location1•5

1 Engine oil filler cap

2 Engine oil level dipstick

3 Cooling system expansion tank

4 Brake fluid reservoir

5 Windscreen/tailgate washer fluid reservoircap

6 Battery

7 Vehicle identification plate

8 Thermostat housing

9 Pre-heat tube

10 Timing belt cover

11 Distributor

12 Fuel filter

13 Heater blower motor cover

14 Windscreen wiper motor mounting bracket

15 Jack and wheelbrace retaining bolt

16 Top of suspension strut mounting

assembly

17 EEC IV engine management module cover

18 CFi unit

19 Fuel injector

20 Fuel pressure regulator

21 Throttle plate control motor

22 Carbon canister

23 Manifold absolute pressure sensor

24 Ignition module

1.1 litre HCS carburettor engine (air cleaner removed for clarity)

1

1595Ford Fiesta Remake

1.4 litre CVH CFi fuel injection engine (air cleaner removed for clarity)

1 Engine oil filler cap

2 Engine oil level dipstick

3 Cooling system expansion tank

4 Brake fluid reservoir

5 Windscreen/tailgate washer fluid reservoir

cap

6 Battery

7 Vehicle identification plate

8 Thermostat housing

9 Radiator cooling fan thermal switch multi- plug

10 Alternator

11 Starter motor solenoid

12 CTX automatic transmission fluid level

dipstick

13 Exhaust heatshield/airbox

14 Brake pressure control valves

15 Top of suspension strut mounting

assembly

16 Carburettor

17 Fuel feed hose

18 Anti-dieselling (fuel-cut off) solenoid

connection

19 Throttle kicker

20 Throttle kicker control solenoid

21 Ignition module

22 Heater blower motor cover

23 Windscreen wiper motor mounting bracket

procarmanuals.com

http://vnx.su

Page 7 of 296

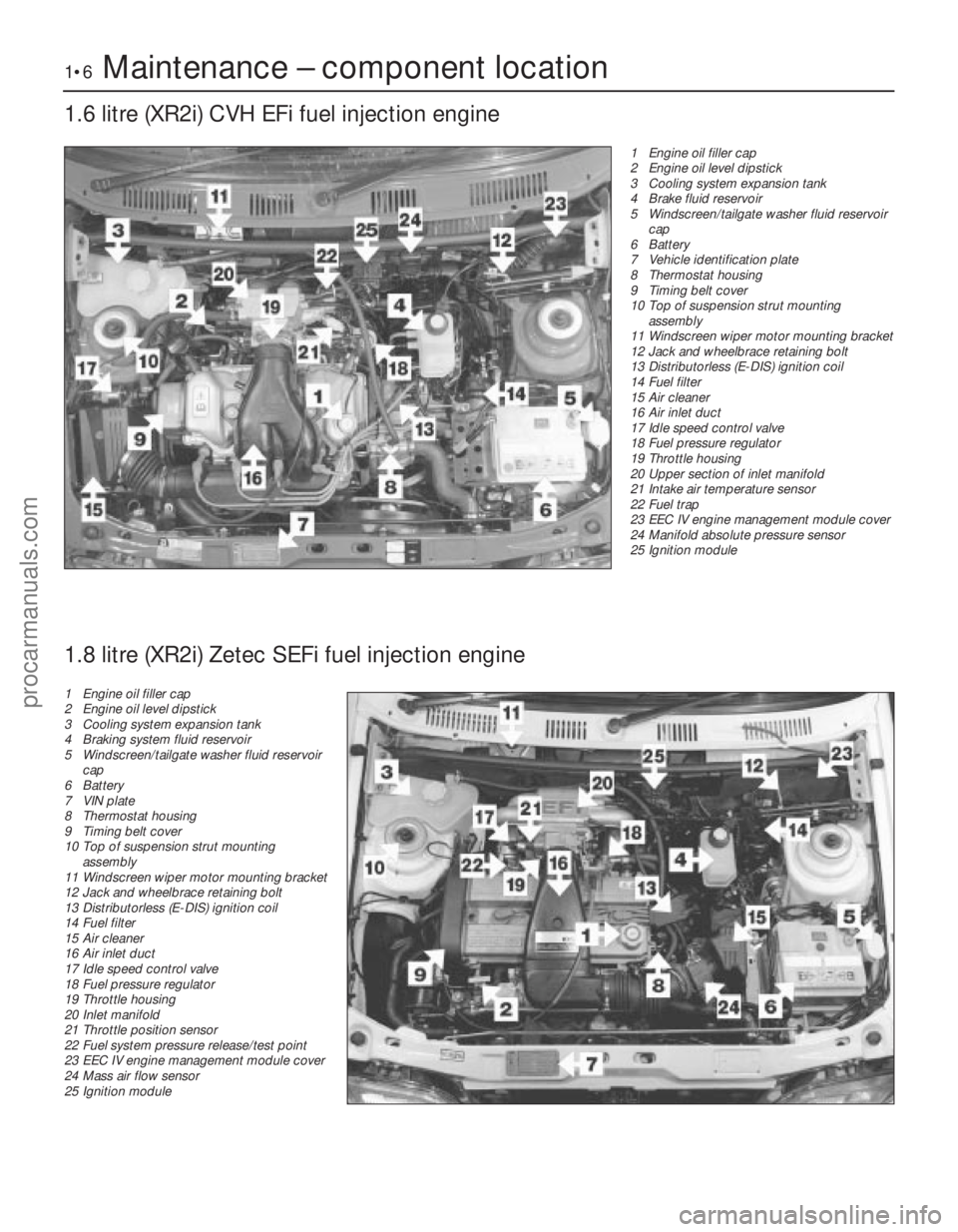

1•6Maintenance – component location

1.6 litre (XR2i) CVH EFi fuel injection engine

1595Ford Fiesta Remake1 Engine oil filler cap

2 Engine oil level dipstick

3 Cooling system expansion tank

4 Brake fluid reservoir

5 Windscreen/tailgate washer fluid reservoir

cap

6 Battery

7 Vehicle identification plate

8 Thermostat housing

9 Timing belt cover

10 Top of suspension strut mounting

assembly

11 Windscreen wiper motor mounting bracket

12 Jack and wheelbrace retaining bolt

13 Distributorless (E-DIS) ignition coil

14 Fuel filter

15 Air cleaner

16 Air inlet duct

17 Idle speed control valve

18 Fuel pressure regulator

19 Throttle housing

20 Upper section of inlet manifold

21 Intake air temperature sensor

22 Fuel trap

23 EEC IV engine management module cover

24 Manifold absolute pressure sensor

25 Ignition module

1.8 litre (XR2i) Zetec SEFi fuel injection engine

1 Engine oil filler cap

2 Engine oil level dipstick

3 Cooling system expansion tank

4 Braking system fluid reservoir

5 Windscreen/tailgate washer fluid reservoir

cap

6 Battery

7 VIN plate

8 Thermostat housing

9 Timing belt cover

10 Top of suspension strut mounting

assembly

11 Windscreen wiper motor mounting bracket

12 Jack and wheelbrace retaining bolt

13 Distributorless (E-DIS) ignition coil

14 Fuel filter

15 Air cleaner

16 Air inlet duct

17 Idle speed control valve

18 Fuel pressure regulator

19 Throttle housing

20 Inlet manifold

21 Throttle position sensor

22 Fuel system pressure release/test point

23 EEC IV engine management module cover

24 Mass air flow sensor

25 Ignition module

procarmanuals.com

http://vnx.su

Page 14 of 296

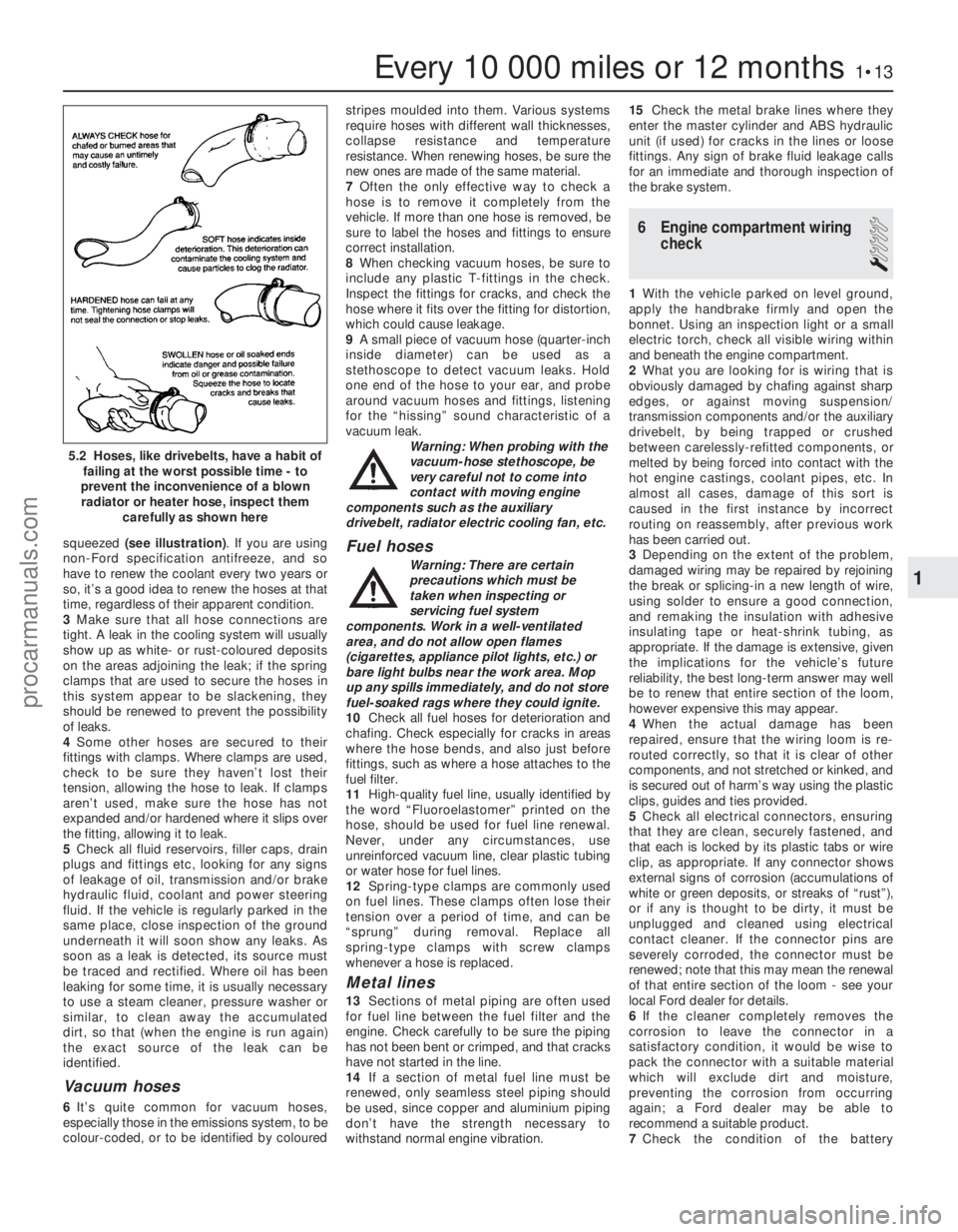

squeezed (see illustration) . If you are using

non-Ford specification antifreeze, and so

have to renew the coolant every two years or

so, it’s a good idea to renew the hoses at that

time, regardless of their apparent condition.

3 Make sure that all hose connections are

tight. A leak in the cooling system will usually

show up as white- or rust-coloured deposits

on the areas adjoining the leak; if the spring

clamps that are used to secure the hoses in

this system appear to be slackening, they

should be renewed to prevent the possibility

of leaks.

4 Some other hoses are secured to their

fittings with clamps. Where clamps are used,

check to be sure they haven’t lost their

tension, allowing the hose to leak. If clamps

aren’t used, make sure the hose has not

expanded and/or hardened where it slips over

the fitting, allowing it to leak.

5 Check all fluid reservoirs, filler caps, drain

plugs and fittings etc, looking for any signs

of leakage of oil, transmission and/or brake

hydraulic fluid, coolant and power steering

fluid. If the vehicle is regularly parked in the

same place, close inspection of the ground

underneath it will soon show any leaks. As

soon as a leak is detected, its source must

be traced and rectified. Where oil has been

leaking for some time, it is usually necessary

to use a steam cleaner, pressure washer or

similar, to clean away the accumulated

dirt, so that (when the engine is run again)

the exact source of the leak can be

identified.

Vacuum hoses

6 It’s quite common for vacuum hoses,

especially those in the emissions system, to be

colour-coded, or to be identified by coloured stripes moulded into them. Various systems

require hoses with different wall thicknesses,

collapse resistance and temperature

resistance. When renewing hoses, be sure the

new ones are made of the same material.

7

Often the only effective way to check a

hose is to remove it completely from the

vehicle. If more than one hose is removed, be

sure to label the hoses and fittings to ensure

correct installation.

8 When checking vacuum hoses, be sure to

include any plastic T-fittings in the check.

Inspect the fittings for cracks, and check the

hose where it fits over the fitting for distortion,

which could cause leakage.

9 A small piece of vacuum hose (quarter-inch

inside diameter) can be used as a

stethoscope to detect vacuum leaks. Hold

one end of the hose to your ear, and probe

around vacuum hoses and fittings, listening

for the “hissing” sound characteristic of a

vacuum leak. Warning: When probing with the

vacuum-hose stethoscope, be

very careful not to come into

contact with moving engine

components such as the auxiliary

drivebelt, radiator electric cooling fan, etc.

Fuel hoses

Warning: There are certain

precautions which must be

taken when inspecting or

servicing fuel system

components. Work in a well-ventilated

area, and do not allow open flames

(cigarettes, appliance pilot lights, etc.) or

bare light bulbs near the work area. Mop

up any spills immediately, and do not store

fuel-soaked rags where they could ignite.

10 Check all fuel hoses for deterioration and

chafing. Check especially for cracks in areas

where the hose bends, and also just before

fittings, such as where a hose attaches to the

fuel filter.

11 High-quality fuel line, usually identified by

the word “Fluoroelastomer” printed on the

hose, should be used for fuel line renewal.

Never, under any circumstances, use

unreinforced vacuum line, clear plastic tubing

or water hose for fuel lines.

12 Spring- type clamps are commonly used

on fuel lines. These clamps often lose their

tension over a period of time, and can be

“sprung” during removal. Replace all

spring- type clamps with screw clamps

whenever a hose is replaced.

Metal lines

13 Sections of metal piping are often used

for fuel line between the fuel filter and the

engine. Check carefully to be sure the piping

has not been bent or crimped, and that cracks

have not started in the line.

14 If a section of metal fuel line must be

renewed, only seamless steel piping should

be used, since copper and aluminium piping

don’t have the strength necessary to

withstand normal engine vibration. 15

Check the metal brake lines where they

enter the master cylinder and ABS hydraulic

unit (if used) for cracks in the lines or loose

fittings. Any sign of brake fluid leakage calls

for an immediate and thorough inspection of

the brake system.

6 Engine compartment wiring check

1

1With the vehicle parked on level ground,

apply the handbrake firmly and open the

bonnet. Using an inspection light or a small

electric torch, check all visible wiring within

and beneath the engine compartment.

2 What you are looking for is wiring that is

obviously damaged by chafing against sharp

edges, or against moving suspension/

transmission components and/or the auxiliary

drivebelt, by being trapped or crushed

between carelessly-refitted components, or

melted by being forced into contact with the

hot engine castings, coolant pipes, etc. In

almost all cases, damage of this sort is

caused in the first instance by incorrect

routing on reassembly, after previous work

has been carried out.

3 Depending on the extent of the problem,

damaged wiring may be repaired by rejoining

the break or splicing-in a new length of wire,

using solder to ensure a good connection,

and remaking the insulation with adhesive

insulating tape or heat-shrink tubing, as

appropriate. If the damage is extensive, given

the implications for the vehicle’s future

reliability, the best long-term answer may well

be to renew that entire section of the loom,

however expensive this may appear.

4 When the actual damage has been

repaired, ensure that the wiring loom is re-

routed correctly, so that it is clear of other

components, and not stretched or kinked, and

is secured out of harm’s way using the plastic

clips, guides and ties provided.

5 Check all electrical connectors, ensuring

that they are clean, securely fastened, and

that each is locked by its plastic tabs or wire

clip, as appropriate. If any connector shows

external signs of corrosion (accumulations of

white or green deposits, or streaks of “rust”),

or if any is thought to be dirty, it must be

unplugged and cleaned using electrical

contact cleaner. If the connector pins are

severely corroded, the connector must be

renewed; note that this may mean the renewal

of that entire section of the loom - see your

local Ford dealer for details.

6 If the cleaner completely removes the

corrosion to leave the connector in a

satisfactory condition, it would be wise to

pack the connector with a suitable material

which will exclude dirt and moisture,

preventing the corrosion from occurring

again; a Ford dealer may be able to

recommend a suitable product.

7 Check the condition of the battery

Every 10 000 miles or 12 months1•13

5.2 Hoses, like drivebelts, have a habit of

failing at the worst possible time - to

prevent the inconvenience of a blown radiator or heater hose, inspect them

carefully as shown here

1

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 17 of 296

lubricant, together with dirt and water entry,

resulting in rapid deterioration of the balljoints

or steering gear.

3Check the power-assisted steering fluid

hoses (where fitted) for chafing or

deterioration, and the pipe and hose unions

for fluid leaks. Also check for signs of fluid

leakage under pressure from the steering gear

rubber gaiters, which would indicate failed

fluid seals within the steering gear.

4 Grasp the roadwheel at the 12 o’clock and

6 o’clock positions, and try to rock it. Very

slight free play may be felt, but if the

movement is appreciable, further investigation

is necessary to determine the source.

Continue rocking the wheel while an assistant

depresses the footbrake. If the movement is

now eliminated or significantly reduced, it is

likely that the hub bearings are at fault. If the

free play is still evident with the footbrake

depressed, then there is wear in the

suspension joints or mountings.

5 Now grasp the wheel at the 9 o’clock and 3

o’clock positions, and try to rock it as before.

Any movement felt now may again be caused

by wear in the hub bearings or the steering

track rod balljoints. If the outer track rod end

balljoint is worn, the visual movement will be

obvious. If the inner joint is suspect, it can be

felt by placing a hand over the rack-and-

pinion rubber gaiter, and gripping the track

rod. If the wheel is now rocked, movement will

be felt at the inner joint if wear has taken

place.

6 Using a large screwdriver or flat bar, check

for wear in the suspension mounting bushes

by levering between the relevant suspension

component and its attachment point. Some

movement is to be expected, as the

mountings are made of rubber, but excessive

wear should be obvious. Also check the

condition of any visible rubber bushes,

looking for splits, cracks or contamination of

the rubber.

7 With the vehicle standing on its wheels,

have an assistant turn the steering wheel

back-and-forth, about an eighth of a turn each

way. There should be very little, if any, lost

movement between the steering wheel and

roadwheels. If this is not the case, closely

observe the joints and mountings previously described, but in addition, check the steering

column universal joints for wear, and also

check the rack-and-pinion steering gear itself.

Rear suspension check

8

Chock the front wheels then jack up the

rear of the car and support it on axle stands

(see “Jacking and Vehicle Support” ). Remove

the rear roadwheels.

9 Check the rear hub bearings for wear, using

the method described for the front hub

bearings (paragraph 4).

10 Using a large screwdriver or flat bar,

check for wear in the suspension mounting

bushes by levering between the relevant

suspension component and its attachment

point. Some movement is to be expected, as

the mountings are made of rubber, but

excessive wear should be obvious. Check the

condition of the shock absorbers and their

bushes/mountings. On Van models, check the

leaves of the leaf springs for signs of cracking,

distortion, or other damage.

Roadwheel check and balancing

11 Periodically remove the roadwheels, and

clean any dirt or mud from the inside and

outside surfaces. Examine the wheel rims for

signs of rusting, corrosion or other damage.

Light alloy wheels are easily damaged by

“kerbing” whilst parking, and similarly, steel

wheels may become dented or buckled.

Renewal of the wheel is very often the only

course of remedial action possible.

12 The balance of each wheel and tyre

assembly should be maintained, not only to

avoid excessive tyre wear, but also to avoid

wear in the steering and suspension

components. Wheel imbalance is normally

signified by vibration through the vehicle’s

bodyshell, although in many cases it is

particularly noticeable through the steering

wheel. Conversely, it should be noted that

wear or damage in suspension or steering

components may cause excessive tyre wear.

Out-of-round or out-of-true tyres, damaged

wheels and wheel bearing wear/

maladjustment also fall into this category.

Balancing will not usually cure vibration

caused by such wear.

13 Wheel balancing may be carried out with

the wheel either on or off the vehicle. If balanced on the vehicle, ensure that the

wheel-to-hub relationship is marked in some

way prior to subsequent wheel removal, so

that it may be refitted in its original position.

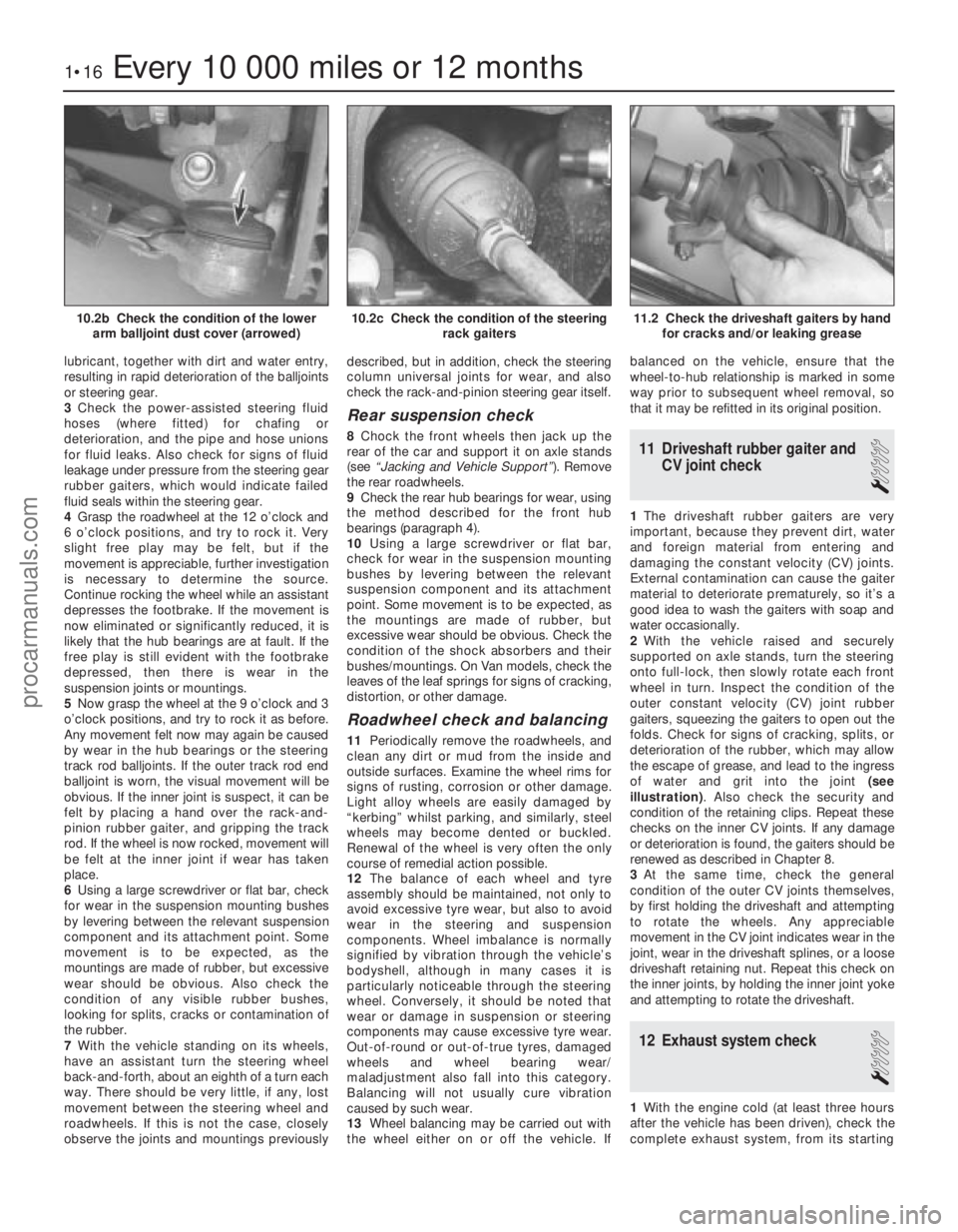

11 Driveshaft rubber gaiter and

CV joint check

1

1The driveshaft rubber gaiters are very

important, because they prevent dirt, water

and foreign material from entering and

damaging the constant velocity (CV) joints.

External contamination can cause the gaiter

material to deteriorate prematurely, so it’s a

good idea to wash the gaiters with soap and

water occasionally.

2 With the vehicle raised and securely

supported on axle stands, turn the steering

onto full-lock, then slowly rotate each front

wheel in turn. Inspect the condition of the

outer constant velocity (CV) joint rubber

gaiters, squeezing the gaiters to open out the

folds. Check for signs of cracking, splits, or

deterioration of the rubber, which may allow

the escape of grease, and lead to the ingress

of water and grit into the joint (see

illustration) . Also check the security and

condition of the retaining clips. Repeat these

checks on the inner CV joints. If any damage

or deterioration is found, the gaiters should be

renewed as described in Chapter 8.

3 At the same time, check the general

condition of the outer CV joints themselves,

by first holding the driveshaft and attempting

to rotate the wheels. Any appreciable

movement in the CV joint indicates wear in the

joint, wear in the driveshaft splines, or a loose

driveshaft retaining nut. Repeat this check on

the inner joints, by holding the inner joint yoke

and attempting to rotate the driveshaft.

12 Exhaust system check

1

1 With the engine cold (at least three hours

after the vehicle has been driven), check the

complete exhaust system, from its starting

1•16Every 10 000 miles or 12 months

11.2 Check the driveshaft gaiters by hand for cracks and/or leaking grease10.2c Check the condition of the steering rack gaiters10.2b Check the condition of the lowerarm balljoint dust cover (arrowed)

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 34 of 296

cover). Using a new gasket, fit the timing

chain cover, centring it with the aid of the

crankshaft pulley - lubricate the seal contact

surfaces beforehand. Refit and tighten the

retaining bolts but, where applicable, leave

out the timing cover bolt which also secures

the water pump at this stage.

8Where applicable, refit the water pump as

described in Chapter 3.

9 Refit the crankshaft pulley as described in

the previous Section.

10 Refit the sump as described in Section 11.

10Timing chain, sprockets and

tensioner - removal,

inspection and refitting

3

Removal

1 Remove the timing chain cover as

described in the previous Section.

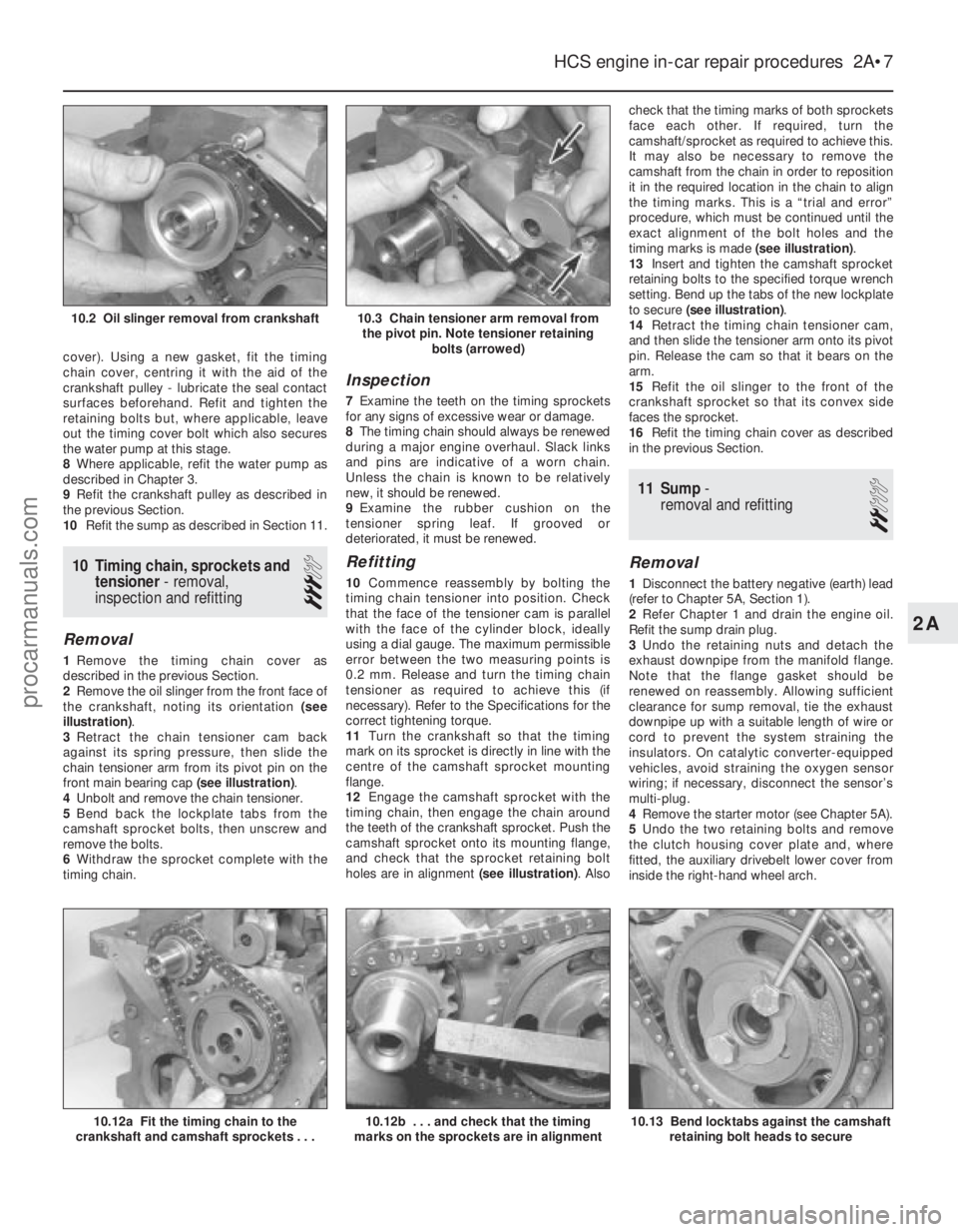

2 Remove the oil slinger from the front face of

the crankshaft, noting its orientation (see

illustration) .

3 Retract the chain tensioner cam back

against its spring pressure, then slide the

chain tensioner arm from its pivot pin on the

front main bearing cap (see illustration).

4 Unbolt and remove the chain tensioner.

5 Bend back the lockplate tabs from the

camshaft sprocket bolts, then unscrew and

remove the bolts.

6 Withdraw the sprocket complete with the

timing chain.

Inspection

7 Examine the teeth on the timing sprockets

for any signs of excessive wear or damage.

8 The timing chain should always be renewed

during a major engine overhaul. Slack links

and pins are indicative of a worn chain.

Unless the chain is known to be relatively

new, it should be renewed.

9 Examine the rubber cushion on the

tensioner spring leaf. If grooved or

deteriorated, it must be renewed.

Refitting

10 Commence reassembly by bolting the

timing chain tensioner into position. Check

that the face of the tensioner cam is parallel

with the face of the cylinder block, ideally

using a dial gauge. The maximum permissible

error between the two measuring points is

0.2 mm. Release and turn the timing chain

tensioner as required to achieve this (if

necessary). Refer to the Specifications for the

correct tightening torque.

11 Turn the crankshaft so that the timing

mark on its sprocket is directly in line with the

centre of the camshaft sprocket mounting

flange.

12 Engage the camshaft sprocket with the

timing chain, then engage the chain around

the teeth of the crankshaft sprocket. Push the

camshaft sprocket onto its mounting flange,

and check that the sprocket retaining bolt

holes are in alignment (see illustration). Alsocheck that the timing marks of both sprockets

face each other. If required, turn the

camshaft/sprocket as required to achieve this.

It may also be necessary to remove the

camshaft from the chain in order to reposition

it in the required location in the chain to align

the timing marks. This is a “trial and error”

procedure, which must be continued until the

exact alignment of the bolt holes and the

timing marks is made

(see illustration).

13 Insert and tighten the camshaft sprocket

retaining bolts to the specified torque wrench

setting. Bend up the tabs of the new lockplate

to secure (see illustration) .

14 Retract the timing chain tensioner cam,

and then slide the tensioner arm onto its pivot

pin. Release the cam so that it bears on the

arm.

15 Refit the oil slinger to the front of the

crankshaft sprocket so that its convex side

faces the sprocket.

16 Refit the timing chain cover as described

in the previous Section.

11 Sump -

removal and refitting

2

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Refer Chapter 1 and drain the engine oil.

Refit the sump drain plug.

3 Undo the retaining nuts and detach the

exhaust downpipe from the manifold flange.

Note that the flange gasket should be

renewed on reassembly. Allowing sufficient

clearance for sump removal, tie the exhaust

downpipe up with a suitable length of wire or

cord to prevent the system straining the

insulators. On catalytic converter-equipped

vehicles, avoid straining the oxygen sensor

wiring; if necessary, disconnect the sensor’s

multi-plug.

4 Remove the starter motor (see Chapter 5A).

5 Undo the two retaining bolts and remove

the clutch housing cover plate and, where

fitted, the auxiliary drivebelt lower cover from

inside the right-hand wheel arch.

HCS engine in-car repair procedures 2A•7

10.12a Fit the timing chain to the

crankshaft and camshaft sprockets . . .

10.3 Chain tensioner arm removal from the pivot pin. Note tensioner retaining bolts (arrowed)10.2 Oil slinger removal from crankshaft

10.13 Bend locktabs against the camshaftretaining bolt heads to secure10.12b . . . and check that the timing

marks on the sprockets are in alignment

2A

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 57 of 296

clamp brackets and disconnect the pipe joint

union over the top of the cylinder head cover.

Place absorbent rags beneath the union as it

is disconnected to soak up escaping fluid and

plug the open unions to prevent dirt entry and

further fluid loss. Move the pipe(s) clear just

sufficiently to allow removal of the cylinder

head cover.

5Remove the timing belt upper cover (see

Section 7).

6 Disconnect the crankcase breather hose

from the cylinder head cover union (see

illustration) .

7 Unplug the HT leads from the spark plugs

and withdraw them, unclipping the leads from

the cover.

8 Working progressively, unscrew the

cylinder head cover retaining bolts, noting the

spacer sleeve and rubber seal at each, then

withdraw the cover (see illustration).

9 Discard the cover gasket; this mustbe

renewed whenever it is disturbed. Check that

the sealing faces are undamaged, and that the

rubber seal at each retaining bolt is

serviceable; renew any worn or damaged

seals.

Refitting

10 On refitting, clean the cover and cylinder

head gasket faces carefully, then fit a new

gasket to the cover, ensuring that it locates

correctly in the cover grooves (see illustration).

11 Refit the cover to the cylinder head, then

insert the rubber seal and spacer sleeve at

each bolt location (see illustration). Start allbolts finger-tight, ensuring that the gasket

remains seated in its groove.

12

Working in a diagonal sequence from the

centre outwards, and in two stages (see

Specifications), tighten the cover bolts to the

specified torque wrench setting.

13 Refit the HT leads, clipping them into

place so that they are correctly routed; each is

numbered, and can also be identified by the

numbering on its respective coil terminal.

14 Reconnect the crankcase breather hose,

and refit the timing belt upper cover.

Reconnect and adjust the accelerator cable,

then refit the air inlet components (see

Chapter 4B).

15 On models with power steering,

reconnect the high pressure fluid pipe then

bleed the system as described in Chapter 10.

5 Valve clearances -

general information

Refer to Section 5 in Part B of this Chapter.

6 Crankshaft pulley -

removal and refitting

1

Removal

1 Remove the auxiliary drivebelt - either

remove the drivebelt completely, or just secure it clear of the crankshaft pulley,

depending on the work to be carried out (see

Chapter 1).

2

If necessary, rotate the crankshaft until the

timing marks align (see Section 3).

3 The crankshaft must now be locked to

prevent its rotation while the pulley bolt is

unscrewed. To do this, remove the starter

motor (Chapter 5A) and lock the starter ring

gear teeth using a suitable screwdriver.

4 It should now just be possible to reach

between the crankshaft pulley and the body

side member to undo and remove the pulley

bolt and withdraw the pulley. However, if

additional working clearance is needed,

proceed as follows.

5 If not already done, chock the rear wheels

then jack up the front of the car and support it

on axle stands (see “Jacking and Vehicle

Support” ). Remove the front right-hand

roadwheel.

6 Support the weight of the

engine/transmission using a trolley jack, with

a wooden spacer to prevent damage to the

sump.

7 From above, unscrew the three bolts

securing the engine’s front right-hand (Y-

shaped) mounting bracket to the alternator

mounting bracket. Unfasten the engine’s rear

right-hand mounting from the body by

unscrewing first the single nut (and washer)

immediately to the rear of the timing belt

cover, then the bolt in the wheel arch

8 With the engine’s right-hand mountings

unfastened from the body, lower the

engine/transmission on the jack until a socket

spanner can be fitted to the crankshaft pulley

bolt.

9 With the starter ring gear teeth locked,

unscrew the crankshaft pulley bolt and

withdraw the pulley (see illustration).

Refitting

10Refitting is the reverse of the removal

procedure; ensure that the pulley’s keyway is

aligned with the crankshaft’s locating key, and

tighten the pulley bolt to the specified torque

wrench setting. If the engine mountings were

disturbed, use the jack to adjust the height of

the engine/transmission until the bolts (and

nut, with washer) can be refitted and screwed

2C•4 Zetec engine in-car repair procedures

6.9 Unscrew pulley bolt to release

crankshaft pulley4.11 Ensure rubber seal is fitted to eachcover bolt spacer, as shown

4.10 Ensure gasket is located correctly in cover groove4.8 Removing cylinder head cover

1595Ford Fiesta Remake

4.6 Disconnecting crankcase breather

hose from cylinder head cover unionprocarmanuals.com

http://vnx.su

Page 61 of 296

and the timing belt have been removed. Note

the “FRONT” marking identifying the

sprocket’s outboard face, and the

thrustwasher behind it; note which way round

the thrustwasher is fitted (see illustration).

Note the sprocket-locating Woodruff key; if

this is loose, it should be removed for safe

storage with the sprocket.

9 Check the sprockets as described in

paragraph 14 of Section 8.

10 Refitting is the reverse of the removal

procedure.

Timing belt guide pulleys

11 Remove the timing belt covers (see

Section 7).

12 Unbolt and withdraw the pulley(s); check

their condition as described in paragraph 14

of Section 8.

13 Refitting is the reverse of the removal

procedure; tighten the pulley bolts to the

specified torque wrench setting.

10 Camshaft oil seals - renewal

4

Note:While it is possible to reach either oil

seal, once the respective sprocket has been

removed (see Section 9) to allow the seal to be

prised out, this procedure is not

recommended. Not only are the seals very

soft, making this difficult to do without risk of damage to the seal housing, but it would be

very difficult to ensure that the valve timing

and the timing belt’s tension, once disturbed,

are correctly reset. Owners are advised to

follow the whole procedure outlined below.

1

Release the tension from the timing belt as

described in Section 8, paragraphs 1 to 12.

Note: If the timing belt is found to be

contaminated by oil, remove it completely as

described, then renew the oil seal (see below).

Wash down the engine timing belt area and all

related components, to remove all traces of

oil. Fit a new belt on reassembly.

2 If the timing belt is still clean, slip it off the

sprocket, taking care not to twist it too

sharply; use the fingers only to handle the

belt. Do not rotate the crankshaft until the

timing belt is refitted. Cover the belt, and

secure it so that it is clear of the working area

and cannot slip off the remaining sprocket.

3 Unfasten the sprocket bolt and withdraw

the sprocket (see Section 9).

4 Unbolt the camshaft right-hand bearing

cap, and withdraw the defective oil seal.

Clean the seal housing, and polish off any

burrs or raised edges, which may have

caused the seal to fail in the first place.

5 To fit a new seal, Ford recommend the use

of their service tool 21-009B, with a bolt

(10 mm thread size, 70 mm long) and a

washer, to draw the seal into place when the

camshaft bearing cap is bolted down; a

substitute can be made using a suitable

socket (see illustration) . Grease the seal lips

and periphery to ease installation, and draw the seal into place until it is flush with the

housing/bearing cap outer edge. Refit the

bearing cap, using sealant and tightening the

cap bolts as described in Section 11.

6

For most owners, the simplest answer will

be to grease the seal lips, and to slide it onto

the camshaft (until it is flush with the

housing’s outer edge). Refit the bearing cap,

using sealant and tightening the cap bolts as

described in Section 11 (see illustration).

Take care to ensure that the seal remains

absolutely square in its housing, and is not

distorted as the cap is tightened down.

7 Refit the sprocket to the camshaft,

tightening the retaining bolt loosely, then slip

the timing belt back onto the sprocket (refer to

paragraphs 16 and 19 of Section 8) and

tighten the bolt securely.

8 The remainder of the reassembly

procedure, including checking the camshaft

alignment (valve timing) and setting the timing

belt tension, is as described in paragraphs 20

to 25 of Section 8.

11 Camshafts and hydraulic tappets - removal, inspection

and refitting

4

Removal

1 Release the tension from the timing belt as

described in Section 8, paragraphs 1 to 12.

2 Either remove the timing belt completely

(Section 8, paragraphs 13 and 14) or slip it off

the camshaft sprockets, taking care not to

twist it too sharply; use the fingers only to

handle the belt. Cover the belt, and secure it

so that it is clear of the working area. Do not

rotate the crankshaft until the timing belt is

refitted.

3 Unfasten the sprocket bolts as described in

Section 8, paragraph 16, and withdraw the

sprockets; while both are the same and could

be interchanged, it is good working practice

to mark them so that each is refitted only to its

original location (see illustration) .

4 Working in the sequence shown, slacken

progressively, by half a turn at a time, the

camshaft bearing cap bolts (see illustration).

Work only as described, to release gradually

2C•8 Zetec engine in-car repair procedures

11.4 Camshaft bearing cap slackening

sequence

Note: Viewed from front of vehicle, showing

bearing cap numbers

11.3 Using forked holding tool while

camshaft toothed pulley bolt is slackened10.6 Alternatively, seal can be inserted

when camshaft bearing cap is unbolted

10.5 Using socket and toothed pulley bolt to install camshaft oil seal9.8 “FRONT” marking on outside face of

crankshaft toothed pulley - note which way round thrustwasher behind is fitted

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 66 of 296

the transmission are absolutely clean and

flat. Any shims found on removal of the

sump must be refitted in their original

locations.

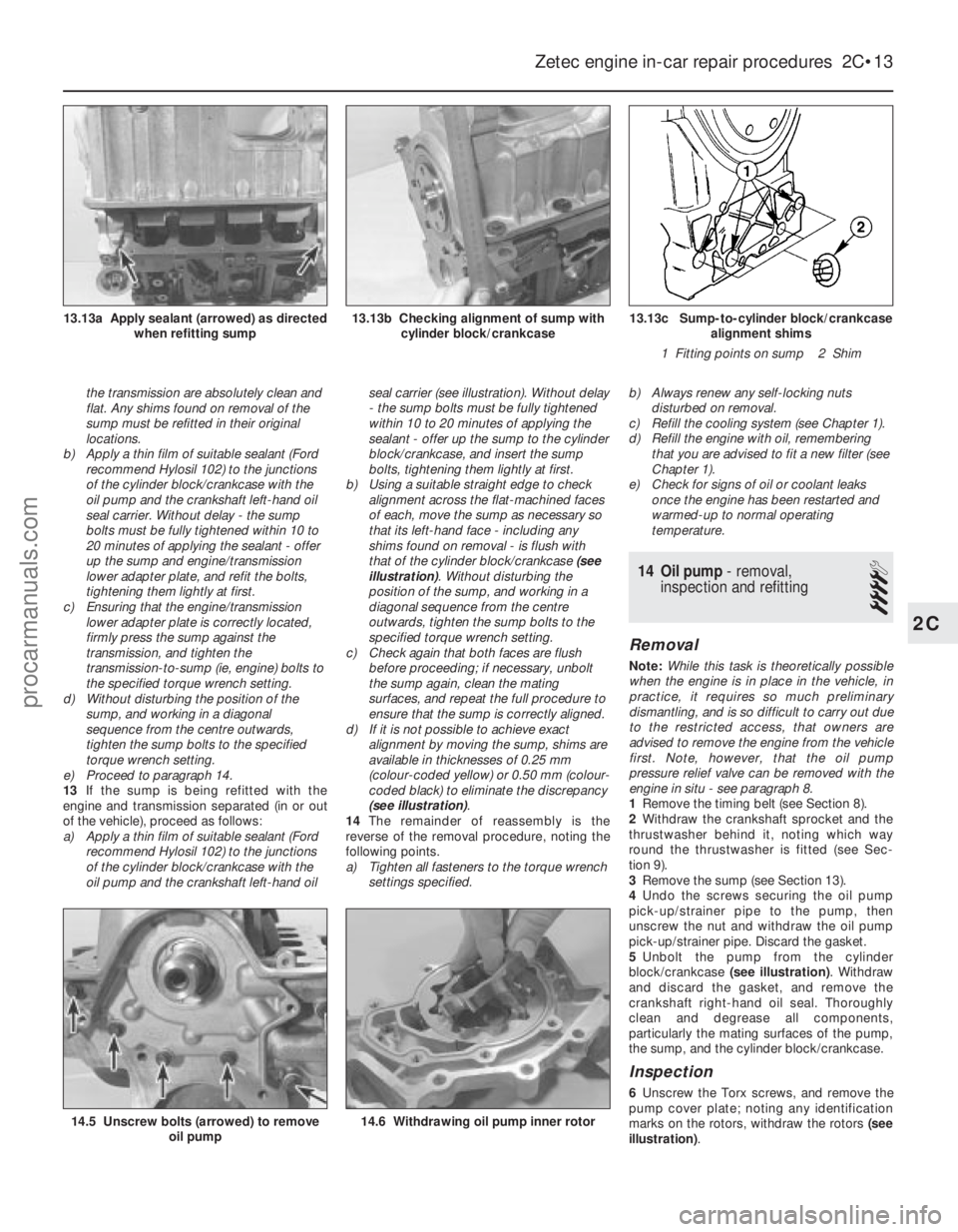

b) Apply a thin film of suitable sealant (Ford

recommend Hylosil 102) to the junctions

of the cylinder block/crankcase with the

oil pump and the crankshaft left-hand oil

seal carrier. Without delay - the sump

bolts must be fully tightened within 10 to

20 minutes of applying the sealant - offer

up the sump and engine/transmission

lower adapter plate, and refit the bolts,

tightening them lightly at first.

c) Ensuring that the engine/transmission

lower adapter plate is correctly located,

firmly press the sump against the

transmission, and tighten the

transmission-to-sump (ie, engine) bolts to

the specified torque wrench setting.

d) Without disturbing the position of the

sump, and working in a diagonal

sequence from the centre outwards,

tighten the sump bolts to the specified

torque wrench setting.

e) Proceed to paragraph 14.

13 If the sump is being refitted with the

engine and transmission separated (in or out

of the vehicle), proceed as follows:

a) Apply a thin film of suitable sealant (Ford recommend Hylosil 102) to the junctions

of the cylinder block/crankcase with the

oil pump and the crankshaft left-hand oil seal carrier (see illustration). Without delay

- the sump bolts must be fully tightened

within 10 to 20 minutes of applying the

sealant - offer up the sump to the cylinder

block/crankcase, and insert the sump

bolts, tightening them lightly at first.

b) Using a suitable straight edge to check

alignment across the flat-machined faces

of each, move the sump as necessary so

that its left-hand face - including any

shims found on removal - is flush with

that of the cylinder block/crankcase (see

illustration) . Without disturbing the

position of the sump, and working in a

diagonal sequence from the centre

outwards, tighten the sump bolts to the

specified torque wrench setting.

c) Check again that both faces are flush

before proceeding; if necessary, unbolt

the sump again, clean the mating

surfaces, and repeat the full procedure to

ensure that the sump is correctly aligned.

d) If it is not possible to achieve exact

alignment by moving the sump, shims are

available in thicknesses of 0.25 mm

(colour-coded yellow) or 0.50 mm (colour-

coded black) to eliminate the discrepancy

(see illustration) .

14 The remainder of reassembly is the

reverse of the removal procedure, noting the

following points.

a) Tighten all fasteners to the torque wrench settings specified. b)

Always renew any self-locking nuts

disturbed on removal.

c) Refill the cooling system (see Chapter 1).

d) Refill the engine with oil, remembering

that you are advised to fit a new filter (see

Chapter 1).

e) Check for signs of oil or coolant leaks once the engine has been restarted and

warmed-up to normal operating

temperature.

14 Oil pump - removal,

inspection and refitting

4

Removal

Note: While this task is theoretically possible

when the engine is in place in the vehicle, in

practice, it requires so much preliminary

dismantling, and is so difficult to carry out due

to the restricted access, that owners are

advised to remove the engine from the vehicle

first. Note, however, that the oil pump

pressure relief valve can be removed with the

engine in situ - see paragraph 8.

1 Remove the timing belt (see Section 8).

2 Withdraw the crankshaft sprocket and the

thrustwasher behind it, noting which way

round the thrustwasher is fitted (see Sec-

tion 9).

3 Remove the sump (see Section 13).

4 Undo the screws securing the oil pump

pick-up/strainer pipe to the pump, then

unscrew the nut and withdraw the oil pump

pick-up/strainer pipe. Discard the gasket.

5 Unbolt the pump from the cylinder

block/crankcase (see illustration). Withdraw

and discard the gasket, and remove the

crankshaft right-hand oil seal. Thoroughly

clean and degrease all components,

particularly the mating surfaces of the pump,

the sump, and the cylinder block/crankcase.

Inspection

6 Unscrew the Torx screws, and remove the

pump cover plate; noting any identification

marks on the rotors, withdraw the rotors (see

illustration) .

Zetec engine in-car repair procedures 2C•13

13.13c Sump-to-cylinder block/crankcase

alignment shims

1 Fitting points on sump 2 Shim13.13b Checking alignment of sump with cylinder block/crankcase13.13a Apply sealant (arrowed) as directed when refitting sump

14.6 Withdrawing oil pump inner rotor14.5 Unscrew bolts (arrowed) to remove oil pump

2C

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 84 of 296

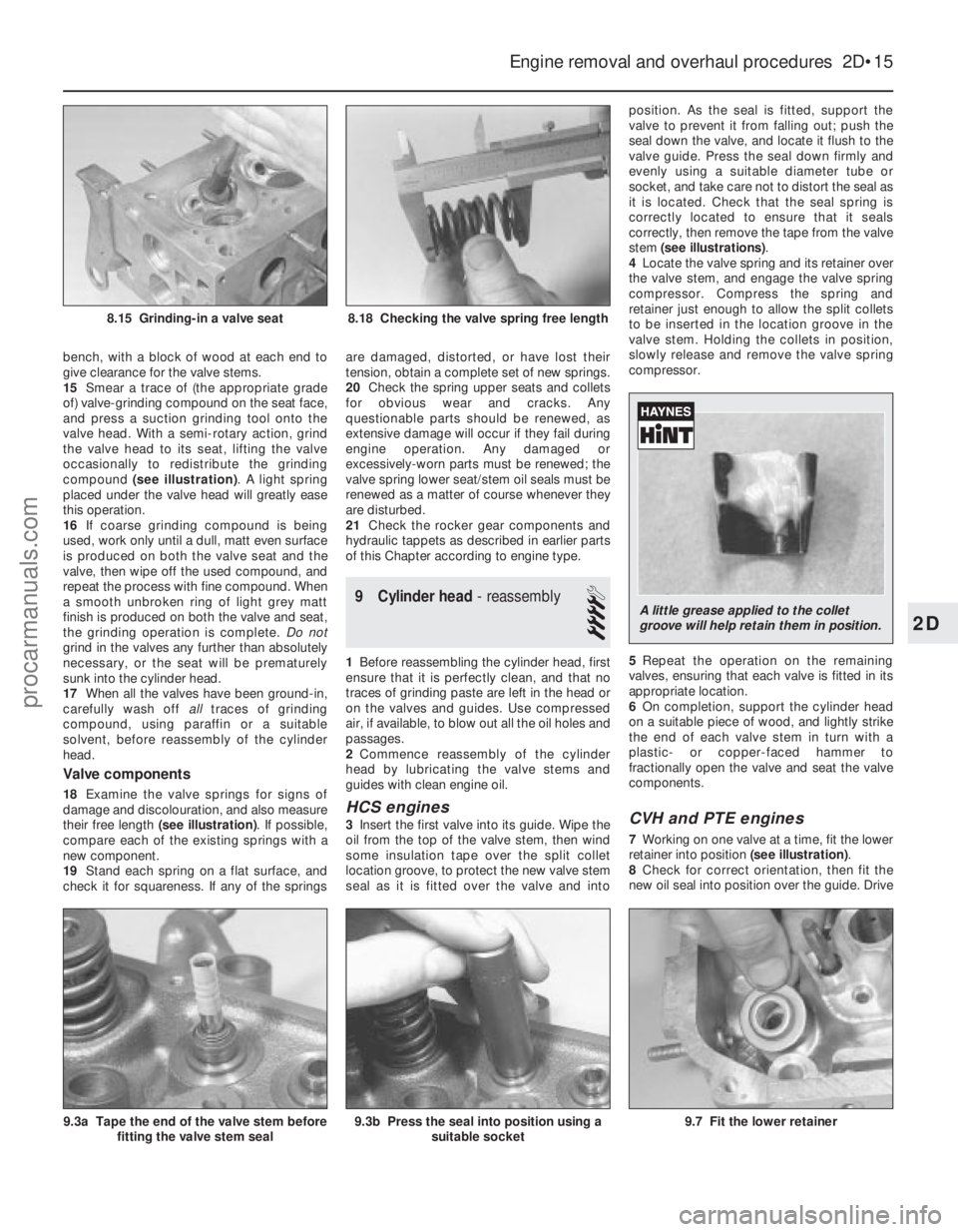

bench, with a block of wood at each end to

give clearance for the valve stems.

15Smear a trace of (the appropriate grade

of) valve-grinding compound on the seat face,

and press a suction grinding tool onto the

valve head. With a semi-rotary action, grind

the valve head to its seat, lifting the valve

occasionally to redistribute the grinding

compound (see illustration) . A light spring

placed under the valve head will greatly ease

this operation.

16 If coarse grinding compound is being

used, work only until a dull, matt even surface

is produced on both the valve seat and the

valve, then wipe off the used compound, and

repeat the process with fine compound. When

a smooth unbroken ring of light grey matt

finish is produced on both the valve and seat,

the grinding operation is complete. Do not

grind in the valves any further than absolutely

necessary, or the seat will be prematurely

sunk into the cylinder head.

17 When all the valves have been ground-in,

carefully wash off alltraces of grinding

compound, using paraffin or a suitable

solvent, before reassembly of the cylinder

head.

Valve components

18 Examine the valve springs for signs of

damage and discolouration, and also measure

their free length (see illustration) . If possible,

compare each of the existing springs with a

new component.

19 Stand each spring on a flat surface, and

check it for squareness. If any of the springs are damaged, distorted, or have lost their

tension, obtain a complete set of new springs.

20

Check the spring upper seats and collets

for obvious wear and cracks. Any

questionable parts should be renewed, as

extensive damage will occur if they fail during

engine operation. Any damaged or

excessively-worn parts must be renewed; the

valve spring lower seat/stem oil seals must be

renewed as a matter of course whenever they

are disturbed.

21 Check the rocker gear components and

hydraulic tappets as described in earlier parts

of this Chapter according to engine type.

9 Cylinder head - reassembly

4

1Before reassembling the cylinder head, first

ensure that it is perfectly clean, and that no

traces of grinding paste are left in the head or

on the valves and guides. Use compressed

air, if available, to blow out all the oil holes and

passages.

2 Commence reassembly of the cylinder

head by lubricating the valve stems and

guides with clean engine oil.

HCS engines

3 Insert the first valve into its guide. Wipe the

oil from the top of the valve stem, then wind

some insulation tape over the split collet

location groove, to protect the new valve stem

seal as it is fitted over the valve and into position. As the seal is fitted, support the

valve to prevent it from falling out; push the

seal down the valve, and locate it flush to the

valve guide. Press the seal down firmly and

evenly using a suitable diameter tube or

socket, and take care not to distort the seal as

it is located. Check that the seal spring is

correctly located to ensure that it seals

correctly, then remove the tape from the valve

stem (see illustrations)

.

4 Locate the valve spring and its retainer over

the valve stem, and engage the valve spring

compressor. Compress the spring and

retainer just enough to allow the split collets

to be inserted in the location groove in the

valve stem. Holding the collets in position,

slowly release and remove the valve spring

compressor.

5 Repeat the operation on the remaining

valves, ensuring that each valve is fitted in its

appropriate location.

6 On completion, support the cylinder head

on a suitable piece of wood, and lightly strike

the end of each valve stem in turn with a

plastic- or copper-faced hammer to

fractionally open the valve and seat the valve

components.CVH and PTE engines

7 Working on one valve at a time, fit the lower

retainer into position (see illustration).

8 Check for correct orientation, then fit the

new oil seal into position over the guide. Drive

Engine removal and overhaul procedures 2D•15

9.3a Tape the end of the valve stem before fitting the valve stem seal

8.18 Checking the valve spring free length8.15 Grinding-in a valve seat

9.7 Fit the lower retainer9.3b Press the seal into position using a suitable socket

2D

1595Ford Fiesta Remake

A little grease applied to the collet

groove will help retain them in position.

procarmanuals.com

http://vnx.su

Page 103 of 296

removal procedure. Refit the timing belt and

tensioner as described in Chapter 2C, noting

that a new tensioner spring and retaining pin

must be fitted if the timing belt has been

removed for the first time. Tighten all

fasteners to the specified torque, and refill the

system with coolant as described in Chap-

ter 1.

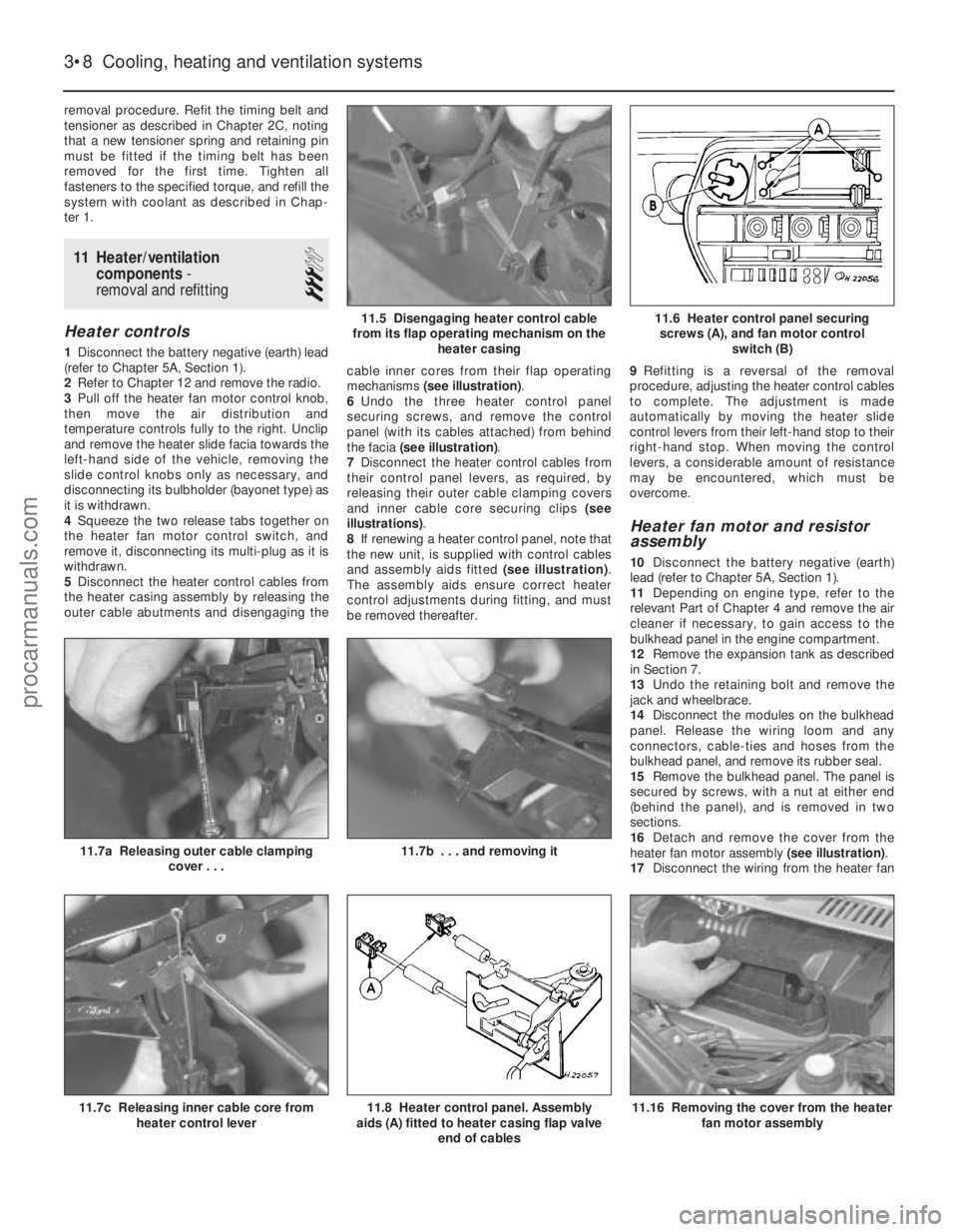

11 Heater/ventilationcomponents -

removal and refitting

3

Heater controls

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Refer to Chapter 12 and remove the radio.

3 Pull off the heater fan motor control knob,

then move the air distribution and

temperature controls fully to the right. Unclip

and remove the heater slide facia towards the

left-hand side of the vehicle, removing the

slide control knobs only as necessary, and

disconnecting its bulbholder (bayonet type) as

it is withdrawn.

4 Squeeze the two release tabs together on

the heater fan motor control switch, and

remove it, disconnecting its multi-plug as it is

withdrawn.

5 Disconnect the heater control cables from

the heater casing assembly by releasing the

outer cable abutments and disengaging the cable inner cores from their flap operating

mechanisms

(see illustration) .

6 Undo the three heater control panel

securing screws, and remove the control

panel (with its cables attached) from behind

the facia (see illustration) .

7 Disconnect the heater control cables from

their control panel levers, as required, by

releasing their outer cable clamping covers

and inner cable core securing clips (see

illustrations) .

8 If renewing a heater control panel, note that

the new unit, is supplied with control cables

and assembly aids fitted (see illustration).

The assembly aids ensure correct heater

control adjustments during fitting, and must

be removed thereafter. 9

Refitting is a reversal of the removal

procedure, adjusting the heater control cables

to complete. The adjustment is made

automatically by moving the heater slide

control levers from their left-hand stop to their

right-hand stop. When moving the control

levers, a considerable amount of resistance

may be encountered, which must be

overcome.

Heater fan motor and resistor

assembly

10 Disconnect the battery negative (earth)

lead (refer to Chapter 5A, Section 1).

11 Depending on engine type, refer to the

relevant Part of Chapter 4 and remove the air

cleaner if necessary, to gain access to the

bulkhead panel in the engine compartment.

12 Remove the expansion tank as described

in Section 7.

13 Undo the retaining bolt and remove the

jack and wheelbrace.

14 Disconnect the modules on the bulkhead

panel. Release the wiring loom and any

connectors, cable-ties and hoses from the

bulkhead panel, and remove its rubber seal.

15 Remove the bulkhead panel. The panel is

secured by screws, with a nut at either end

(behind the panel), and is removed in two

sections.

16 Detach and remove the cover from the

heater fan motor assembly (see illustration).

17 Disconnect the wiring from the heater fan

3•8 Cooling, heating and ventilation systems

11.16 Removing the cover from the heater

fan motor assembly11.8 Heater control panel. Assembly

aids (A) fitted to heater casing flap valve

end of cables11.7c Releasing inner cable core fromheater control lever

11.7b . . . and removing it11.7a Releasing outer cable clamping

cover . . .

11.6 Heater control panel securing screws (A), and fan motor control switch (B)11.5 Disengaging heater control cable

from its flap operating mechanism on the heater casing

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su