boot FORD FIESTA 1989 Service Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1989, Model line: FIESTA, Model: FORD FIESTA 1989Pages: 296, PDF Size: 10.65 MB

Page 19 of 296

3Check that the roadwheel nuts are tightened

to the specified torque wrench setting.

4 Refit the wheel covers.

16 Door, tailgate and bonnet

check and lubrication

1

1Check that the doors and tailgate/boot lid

close securely. Check that the bonnet safety

catch operates correctly. Check the operation

of the door check straps.

2 Lubricate the hinges, door check straps,

the striker plates and the bonnet catch

sparingly with a little oil or grease.

17 Seat belt check

1

1 Check the seat belts for satisfactory

operation and condition. Inspect the webbing

for fraying and cuts. Check that they retract

smoothly and without binding into their reels.

2 Check that the seat belt mounting bolts are

tight, and if necessary tighten them to the

specified torque wrench settings as given in

Chapter 11.

18 Bodywork, paint and exterior trim check

1

1The best time to carry out this check is after

the car has been washed so that any surface

blemish or scratch will be clearly evident and

not hidden by a film of dirt.

2 Starting at one front corner check the

paintwork all around the car, looking for minor

scratches or more serious dents. Check all

the trim and make sure that it is securely

attached over its entire length.

3 Check the security of all door locks, door

mirrors, badges, bumpers, front grille and

wheel trim. Anything found loose, or in need of

further attention should be done with reference

to the relevant Chapters of this manual.

4 Rectify any problems noticed with the

paintwork or body panels as described in

Chapter 11.

19 Road test

1

Check the operation and

performance of the braking

system

1 Make sure that the vehicle does not pull to

one side when braking, and that the wheels

do not lock prematurely when braking hard.

2 Check that there is no vibration through the

steering when braking. 3

Check that the handbrake operates

correctly, without excessive movement of the

lever, and that it holds the vehicle stationary

on a slope.

4 Test the operation of the brake servo unit

as follows. With the engine switched off,

depress the footbrake four or five times to

exhaust the vacuum, then hold the pedal

depressed. Start the engine, and there should

be a noticeable “give” in the brake pedal as

vacuum builds up. Allow the engine to run for

at least two minutes, and then switch it off. If

the brake pedal is depressed again, it should

be possible to detect a hiss from the servo as

the pedal is depressed. After about four or five

applications, no further hissing should be

heard, and the pedal should feel considerably

firmer.

Steering and suspension

5 Check for any abnormalities in the steering,

suspension, handling or road “feel”.

6 Drive the vehicle, and check that there are

no unusual vibrations or noises.

7 Check that the steering feels positive, with

no excessive sloppiness or roughness, and

check for any suspension noises when

cornering and driving over bumps.

Drivetrain

8 Check the performance of the engine,

transmission and driveshafts.

9 Check that the engine starts correctly, both

when cold and when hot.

10 Listen for any unusual noises from the

engine and transmission.

11 Make sure that the engine runs smoothly

when idling, and that there is no hesitation

when accelerating.

12 On manual transmission models, check

that all gears can be engaged smoothly

without noise, and that the gear lever action is

not abnormally vague or “notchy”.

13 On automatic transmission models, make

sure that the drive seems smooth without

jerks or engine speed “flare-ups”. Check that

all the gear positions can be selected with the

vehicle at rest. If any problems are found, they

should be referred to a Ford dealer.

14 Listen for a metallic clicking sound from

the front of the vehicle, as the vehicle is driven

slowly in a circle with the steering on full-lock.

Carry out this check in both directions. If a

clicking noise is heard, this indicates wear in a

driveshaft joint, in which case renew the joint

if necessary.

Clutch

15 Check that the clutch pedal moves

smoothly and easily through its full travel, and

that the clutch itself functions correctly, with

no trace of slip or drag. If the movement is

uneven or stiff in places, check that the cable

is routed correctly, with no sharp turns.

16 Inspect both ends of the clutch inner

cable, both at the transmission end and inside

the car, for signs of wear and fraying.

Instruments and electrical

equipment

17 Check the operation of all instruments

and electrical equipment.

18 Make sure that all instruments read

correctly, and switch on all electrical equipment

in turn, to check that it functions properly.

20 Automatic transmission fluid level check

1

1The level of the automatic transmission fluid

should be carefully maintained. Low fluid level

can lead to slipping or loss of drive, while

overfilling can cause foaming, loss of fluid and

transmission damage.

2 The transmission fluid level should only be

checked when the transmission is hot (at its

normal operating temperature). If the vehicle

has just been driven over 10 miles (15 miles in

a cold climate), and the fluid temperature is 60

to 70ºC, the transmission is hot.

Caution: If the vehicle has just been driven

for a long time at high speed or in city

traffic in hot weather, or if it has been

pulling a trailer, an accurate fluid level

reading cannot be obtained. In these

circumstances, allow the fluid to cool

down for about 30 minutes.

3 Park the vehicle on level ground, apply the

handbrake, and start the engine. While the

engine is idling, depress the brake pedal and

move the selector lever through all the gear

positions three times, beginning and ending in

“P”.

4 Allow the engine to idle for one minute, then

(with the engine still idling) remove the

dipstick from its tube. Note the condition and

colour of the fluid on the dipstick.

5 Wipe the fluid from the dipstick with a clean

rag, and re-insert it into the filler tube until the

cap seats.

6 Pull the dipstick out again, and note the

fluid level. The level should be between

the “MIN” and “MAX” marks. If the level is

on the “MIN” mark, stop the engine, and add

the specified automatic transmission fluid

through the dipstick tube, using a clean funnel

if necessary. It is important not to introduce

dirt into the transmission when topping-up.

7 Add the fluid a little at a time, and keep

checking the level as previously described

until it is correct. The difference between the

“MIN” and “MAX” marks on the dipstick is

approximately 0.4 litres.

8 The need for regular topping-up of the

transmission fluid indicates a leak, which

should be found and rectified without delay.

9 The condition of the fluid should also be

checked along with the level. If the fluid on the

dipstick is black or a dark reddish-brown

colour, or if it has a burned smell, the fluid

should be changed. If you are in doubt about

the condition of the fluid, purchase some new

fluid, and compare the two for colour and smell.

1•18Every 10 000 miles or 12 months

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 20 of 296

21 Spark plug renewal and HTcomponent check

1

Note: Spark plug renewal at this service

interval is only necessary on the HCS, CVH

and PTE engines. On Zetec engines, the

recommended interval for spark plug renewal

is every 30 000 miles or three years.

Spark plug check and renewal

1 It is vital for the correct running, full

performance and proper economy of the engine

that the spark plugs perform with maximum

efficiency. The most important factor in ensuring

this is that the plugs fitted are appropriate for the

engine. The suitable type is given in the

Specifications Section at the beginning of this

Chapter, on the Vehicle Emissions Control

Information (VECI) label located on the

underside of the bonnet (only on models sold in

some areas) or in the vehicle’s Owner’s

Handbook. If the correct type is used and the

engine is in good condition, the spark plugs

should not need attention between scheduled

renewal intervals. Spark plug cleaning is rarely

necessary, and should not be attempted unless

specialised equipment is available, as damage

can easily be caused to the firing ends.

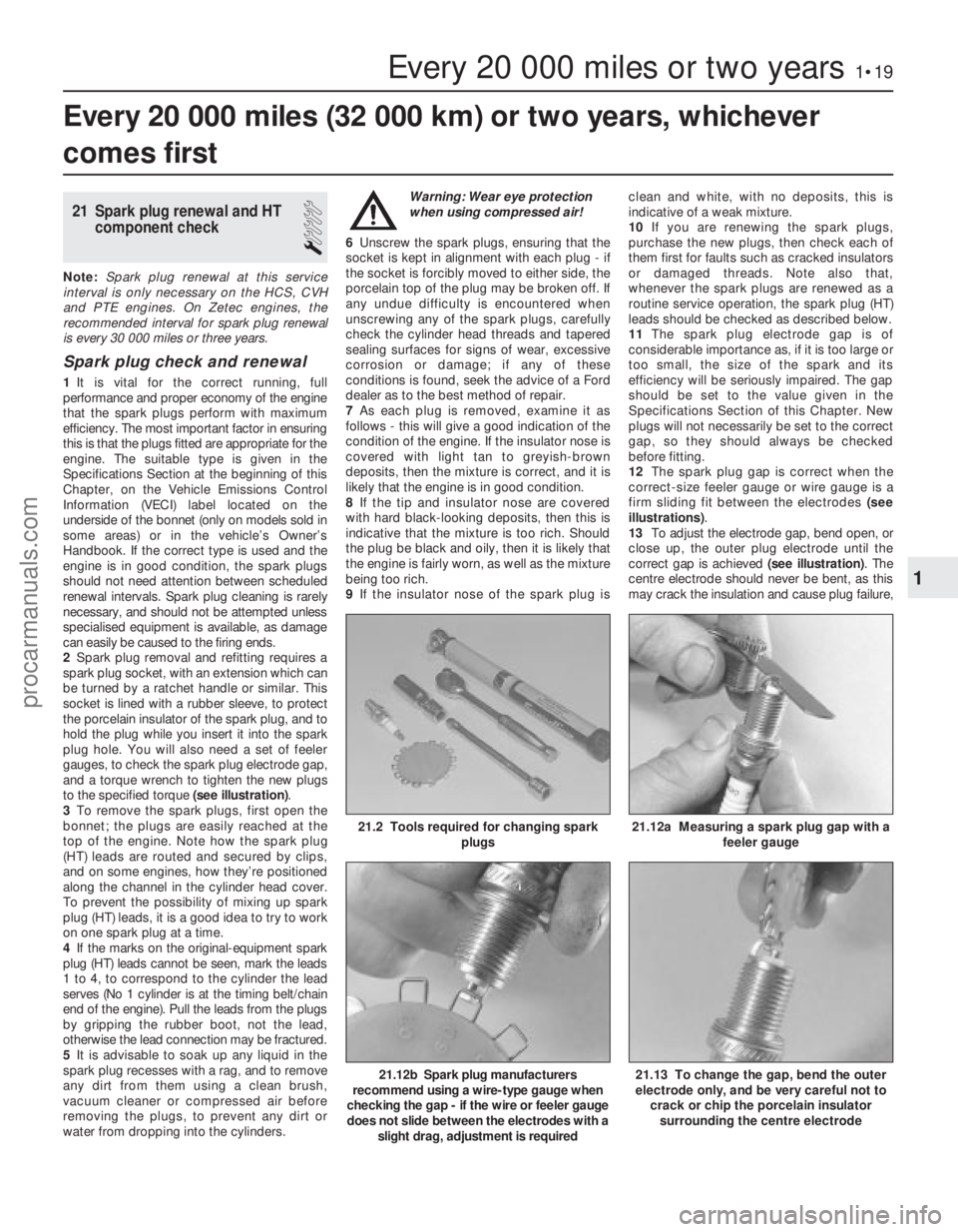

2 Spark plug removal and refitting requires a

spark plug socket, with an extension which can

be turned by a ratchet handle or similar. This

socket is lined with a rubber sleeve, to protect

the porcelain insulator of the spark plug, and to

hold the plug while you insert it into the spark

plug hole. You will also need a set of feeler

gauges, to check the spark plug electrode gap,

and a torque wrench to tighten the new plugs

to the specified torque (see illustration).

3 To remove the spark plugs, first open the

bonnet; the plugs are easily reached at the

top of the engine. Note how the spark plug

(HT) leads are routed and secured by clips,

and on some engines, how they’re positioned

along the channel in the cylinder head cover.

To prevent the possibility of mixing up spark

plug (HT) leads, it is a good idea to try to work

on one spark plug at a time.

4 If the marks on the original-equipment spark

plug (HT) leads cannot be seen, mark the leads

1 to 4, to correspond to the cylinder the lead

serves (No 1 cylinder is at the timing belt/chain

end of the engine). Pull the leads from the plugs

by gripping the rubber boot, not the lead,

otherwise the lead connection may be fractured.

5 It is advisable to soak up any liquid in the

spark plug recesses with a rag, and to remove

any dirt from them using a clean brush,

vacuum cleaner or compressed air before

removing the plugs, to prevent any dirt or

water from dropping into the cylinders. Warning: Wear eye protection

when using compressed air!

6 Unscrew the spark plugs, ensuring that the

socket is kept in alignment with each plug - if

the socket is forcibly moved to either side, the

porcelain top of the plug may be broken off. If

any undue difficulty is encountered when

unscrewing any of the spark plugs, carefully

check the cylinder head threads and tapered

sealing surfaces for signs of wear, excessive

corrosion or damage; if any of these

conditions is found, seek the advice of a Ford

dealer as to the best method of repair.

7 As each plug is removed, examine it as

follows - this will give a good indication of the

condition of the engine. If the insulator nose is

covered with light tan to greyish-brown

deposits, then the mixture is correct, and it is

likely that the engine is in good condition.

8 If the tip and insulator nose are covered

with hard black-looking deposits, then this is

indicative that the mixture is too rich. Should

the plug be black and oily, then it is likely that

the engine is fairly worn, as well as the mixture

being too rich.

9 If the insulator nose of the spark plug is clean and white, with no deposits, this is

indicative of a weak mixture.

10

If you are renewing the spark plugs,

purchase the new plugs, then check each of

them first for faults such as cracked insulators

or damaged threads. Note also that,

whenever the spark plugs are renewed as a

routine service operation, the spark plug (HT)

leads should be checked as described below.

11 The spark plug electrode gap is of

considerable importance as, if it is too large or

too small, the size of the spark and its

efficiency will be seriously impaired. The gap

should be set to the value given in the

Specifications Section of this Chapter. New

plugs will not necessarily be set to the correct

gap, so they should always be checked

before fitting.

12 The spark plug gap is correct when the

correct-size feeler gauge or wire gauge is a

firm sliding fit between the electrodes (see

illustrations) .

13 To adjust the electrode gap, bend open, or

close up, the outer plug electrode until the

correct gap is achieved (see illustration). The

centre electrode should never be bent, as this

may crack the insulation and cause plug failure,

Every 20 000 miles (32 000 km) or two years, whichever

comes first

Every 20 000 miles or two years1•19

21.12b Spark plug manufacturers

recommend using a wire-type gauge when

checking the gap - if the wire or feeler gauge

does not slide between the electrodes with a slight drag, adjustment is required

21.12a Measuring a spark plug gap with a feeler gauge21.2 Tools required for changing spark plugs

21.13 To change the gap, bend the outer

electrode only, and be very careful not to crack or chip the porcelain insulator

surrounding the centre electrode

1

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 21 of 296

if nothing worse. If the outer electrode is not

exactly over the centre electrode, bend it gently

to align them. Special spark plug gap adjusting

tools are available from motor accessory shops,

or from certain spark plug manufacturers.

14Before fitting the spark plugs, check that

the threaded connector sleeves at the top of

the plugs are tight, and that the plug exterior

surfaces and threads are clean. Brown

staining on the porcelain, immediately above

the metal body, is quite normal, and does not

necessarily indicate a “leak” between the

body and insulator.

15 Apply a smear of copper-based grease or

anti-seize compound to the threads of each

plug, and screw them in by hand where

possible. Take extra care to enter the plug

threads correctly, as the cylinder head is of

aluminium alloy.

16 When each spark plug is started correctly

on its threads, screw it down until it just seats

lightly, then tighten it to the specified torque

wrench setting. If a torque wrench is not

available - and this is one case where the use of

a torque wrench is strongly recommended -

tighten each spark plug through no more than

1/4 of a turn (CVH and PTE engines) or 1/16 of a

turn (HCS and Zetec engines) after it seats. HCS

and Zetec engines are fitted with taper-seat

spark plugs, identifiable by not having a sealing

washer, and these in particular should NEVER

be overtightened - their tapered seats mean

they are almost impossible to remove if abused.

17 Reconnect the spark plug (HT) leads in

their correct order, using a twisting motion on

the boot until it is firmly seated on the end of

the spark plug and on the cylinder head cover.

Spark plug (HT) lead, distributor

cap and rotor arm check

18 The spark plug (HT) leads should be

checked whenever the plugs themselves are renewed. Start by making a visual check of

the leads while the engine is running. In a

darkened garage (make sure there is

ventilation) start the engine and observe each

lead. Be careful not to come into contact with

any moving engine parts. If there is a break in

the lead, you will see arcing or a small spark

at the damaged area.

19

The spark plug (HT) leads should be

inspected one at a time, to prevent mixing up

the firing order, which is essential for proper

engine operation. Each original lead should

be numbered to identify its cylinder. If the

number is illegible, a piece of tape can be

marked with the correct number, and

wrapped around the lead (the leads should be

numbered 1 to 4, with No 1 lead nearest the

timing belt end of the engine). The lead can

then be disconnected.

20 Check inside the boot for corrosion, which

will look like a white crusty powder. Clean this

off as much as possible; if it is excessive, or if

cleaning leaves the metal connector too badly

eroded to be fit for further use, the lead must

be renewed. Push the lead and boot back

onto the end of the spark plug. The boot

should fit tightly onto the end of the plug - if it

doesn’t, remove the lead and use pliers

carefully to crimp the metal connector inside

the boot until the fit is snug.

21 Using a clean rag, wipe the entire length

of the lead to remove built-up dirt and grease. Once the lead is clean, check for burns,

cracks and other damage. Do not bend the

lead sharply, because the conductor might

break.

22 Disconnect the lead from the ignition coil

by pressing together the plastic retaining

catches (where fitted) and pulling the end

fitting off the coil terminal. Check for corrosion

and for a tight fit. If a meter with the correct

measuring range is available, measure the

resistance of the disconnected lead from its

coil connector to its spark plug connector. If

the resistance recorded for any of the leads

exceeds the value specified, all the leads

should be renewed as a set. Refit the lead to

the coil, noting that each coil terminal is

marked with its respective cylinder number,

so that there is no risk of mixing up the leads

and upsetting the firing order.

23 Inspect the remaining spark plug (HT)

leads, ensuring that each is securely fastened

at the distributor cap or ignition coil and spark

plug when the check is complete. If any sign

of arcing, severe connector corrosion, burns,

cracks or other damage is noticed, obtain new

spark plug (HT) leads, renewing them as a set.

If new spark plug leads are to be fitted,

remove and refit them one at a time, to avoid

mix-ups in the firing order. 24

On models with distributor ignition

systems, refer to Chapter 5B and remove the

distributor cap then thoroughly clean it inside

and out with a dry lint-free rag.

25 Examine the HT lead segments inside the

cap. If they appear badly burned or pitted

renew the cap. Also check the carbon brush

in the centre of the cap, ensuring that it is free

to move and stands proud of its holder. Make

sure that there are no sign of cracks or black

“tracking” lines running down the inside of the

cap, which will also mean renewal if evident.

26 Inspect the rotor arm checking it for

security and also for signs of deterioration as

described above.

27 Refit the cap as described in Chapter 5B

on completion.

22 Idle speed control valve cleaning and maintenance

1

Note: The idle speed control valve may be

mounted on the air cleaner, on the engine

compartment bulkhead, or on the side of the inlet

manifold according to valve make and year of

manufacture. Valves manufactured by Weber are

mounted on the air cleaner and only these valves

require the periodic maintenance described

below. Bulkhead and inlet manifold mounted

valves are manufactured by Hitachi and are

maintenance free. Refer to the warning note in

Section 1 of Chapter 4C before proceeding.

1 Remove the valve as described in Chap-

ter 4C, Section 14.

2 Immerse the valve head in a suitable

container filled with clean petrol, and allow it

to soak for approximately three minutes.

3 Clean the valve bore, slots and piston with

petrol, using a suitable lint-free cloth, then

gently move the piston up and down in its

bore using a small screwdriver (see

illustration) . Ensure that no cloth particles

enter the bore, and do not use the slots to

move the piston.

4 Rinse the valve again with clean petrol, then

dry it using an air line (or other source of

compressed air).

Warning: Wear eye protection

when using compressed air!

5 Clean the mating faces of the valve and the

air filter housing then refit as described in

Chapter 4C, Section 14.

1•20Every 20 000 miles or two years

22.3 Gently move the idle speed control

valve piston up and down in its bore using

a small screwdriver (1.6 litre EFi engine)

1595Ford Fiesta Remake

It’s often difficult to insert spark plugs

into their holes without cross-threading

them. To avoid this possibility, fit a

short piece of rubber hose over the end

of the spark plug. The flexible hose

acts as a universal joint, to help align

the plug with the plug hole. Should the

plug begin to cross-thread, the hose

will slip on the spark plug, preventing

thread damage.

If new spark plug leads are tobe fitted, remove the leads

one at a time and fit each

new lead in exactly the same

position as the old one.

procarmanuals.com

http://vnx.su

Page 271 of 296

1595 Ford Fiesta Remake

The jack supplied with the vehicle tool kit

should only be used for changing the

roadwheels - see “Wheel changing” at the

front of this manual. When jacking up the

vehicle to carry out repair or maintenance

tasks, a pillar or trolley type jack of suitable

lifting capacity must be used, supplemented

with axle stands positioned only beneath the

appropriate points under the vehicle (see

illustration) . Note that the vehicle must never

be jacked up at the rear under the axle beam. The maximum kerb weight of the vehicle must

not be exceeded when jacking and supporting

the vehicle. Do not under any circumstances

jack up the rear of the vehicle under the rear axle.

Never work under, around or near a raised

vehicle unless it is adequately supported in at

least two places with axle stands.

The radio/cassette unit fitted as standard or

optional equipment may be equipped with a

built-in security code, to deter thieves. If the

power source to the unit is cut, the anti-theft

system will activate. Even if the power source

is immediately reconnected, the radio/

cassette unit will not function until the correct security code has been entered. Therefore,

if you do not know the correct security

code for the radio/cassette unit do not

disconnect either of the battery terminals, or

remove the radio/cassette unit from the

vehicle. To enter the correct security code, follow the instructions provided with the

radio/cassette player or vehicle handbook.

If an incorrect code is entered, the unit will

become locked, and cannot be operated.

If this happens, or if the security code is lost

or forgotten, seek the advice of your Ford

dealer.

Jacking and vehicle supportREF•5

REF

Radio/cassette unit anti-theft system - precaution

Underside view of the vehicle showing the jacking point locations

A Jacking points for trolley jack (always use a suitable block

of wood to protect the

vehicle body)

B Axle stand positions

C Jacking points for owner jack and wheel-free hoist

Buying spare parts

Spare parts are available from many

sources, including maker’s appointed

garages, accessory shops, and motor factors.

To be sure of obtaining the correct parts, it

will sometimes be necessary to quote the

vehicle identification number. If possible, it

can also be useful to take the old parts along

for positive identification. Items such as

starter motors and alternators may be

available under a service exchange scheme -

any parts returned should always be clean.

Our advice regarding spare part sources is

as follows.

Officially-appointed garages

This is the best source of parts which are

peculiar to your car, and which are not

otherwise generally available (eg badges,

interior trim, certain body panels, etc). It is

also the only place at which you should buy

parts if the vehicle is still under warranty.

Accessory shops

These are very good places to buy materials and components needed for the

maintenance of your car (oil, air and fuel

filters, spark plugs, light bulbs, drivebelts, oils

and greases, brake pads, touch-up paint, etc).

Components of this nature sold by a

reputable shop are of the same standard as

those used by the car manufacturer.

Besides components, these shops also sell

tools and general accessories, usually have

convenient opening hours, charge lower

prices, and can often be found not far from

home. Some accessory shops have parts

counters where the components needed for

almost any repair job can be purchased or

ordered.

Motor factors

Good factors will stock all the more

important components which wear out

comparatively quickly, and can sometimes

supply individual components needed for the

overhaul of a larger assembly (eg brake seals

and hydraulic parts, bearing shells, pistons,

valves, alternator brushes). They may also

handle work such as cylinder block reboring,

crankshaft regrinding and balancing, etc.

Tyre and exhaust specialists

These outlets may be independent, or

members of a local or national chain. They

frequently offer competitive prices when

compared with a main dealer or local garage,

but it will pay to obtain several quotes before

making a decision. When researching prices,

also ask what “extras” may be added - for

instance, fitting a new valve and balancing the

wheel are both commonly charged on top of

the price of a new tyre.

Other sources

Beware of parts or materials obtained from

market stalls, car boot sales or similar outlets.

Such items are not invariably sub-standard,

but there is little chance of compensation if

they do prove unsatisfactory. In the case of

safety-critical components such as brake

pads, there is the risk not only of financial loss

but also of an accident causing injury or

death. Second-hand components or assemblies

obtained from a car breaker can be a good

buy in some circumstances, but this sort of

purchase is best made by the experienced

DIY mechanic.

Buying spare parts

procarmanuals.com

http://vnx.su

Page 281 of 296

1595 Ford Fiesta Remake

failure of components such as fuses or spark

plugs may only be pointers to some

underlying fault.

The pages which follow provide an easy

reference guide to the more common

problems which may occur during the

operation of the vehicle. These problems and

their possible causes are grouped under

headings denoting various components or

systems, such as Engine, Cooling system,

etc. The Chapter and/or Section which deals

with the problem is also shown in brackets.

Whatever the fault, certain basic principles

apply. These are as follows:

Verify the fault . This is simply a matter of

being sure that you know what the symptoms are before starting work. This is particularly

important if you are investigating a fault for

someone else, who may not have described it

very accurately.

Don’t overlook the obvious . For example, if

the vehicle won’t start, is there petrol in the

tank? (Don’t take anyone else’s word on this

particular point, and don’t trust the fuel gauge

either!) If an electrical fault is indicated, look

for loose or broken wires before digging out

the test gear. Cure the disease, not the symptom .

Substituting a flat battery with a fully-charged

one will get you off the hard shoulder, but if

the underlying cause is not attended to, the

new battery will go the same way. Similarly, changing oil-fouled spark plugs for a new set

will get you moving again, but remember that

the reason for the fouling (if it wasn’t simply an

incorrect grade of plug) will have to be

established and corrected.

Don’t take anything for granted . Particularly,

don’t forget that a “new” component may

itself be defective (especially if it’s been

rattling around in the boot for months), and

don’t leave components out of a fault

diagnosis sequence just because they are

new or recently fitted. When you do finally

diagnose a difficult fault, you’ll probably

realise that all the evidence was there from

the start.

Fault findingREF•15

REF

Engine

Engine fails to rotate when attempting to start

m

m Battery terminal connections loose or corroded (Chapter 5A).

m

m Battery discharged or faulty (Chapter 5A).

m

m Broken, loose or disconnected wiring in the starting circuit

(Chapter 5A).

m m Defective starter solenoid or switch (Chapter 5A).

m

m Defective starter motor (Chapter 5A).

m

m Flywheel ring gear or starter pinion teeth loose or broken

(Chapters 2A, 2B, 2C or 5A).

m m Engine earth strap broken or disconnected (Chapter 5A).

m

m Automatic transmission not in Park/Neutral position, or starter

inhibitor switch faulty (Chapter 7B).

Engine rotates, but will not start

m mFuel tank empty.

m

m Battery discharged (engine rotates slowly) (Chapter 5A).

m

m Battery terminal connections loose or corroded (Chapter 5A).

m

m Ignition components damp or damaged (Chapters 1 and 5B).

m

m Broken, loose or disconnected wiring in the ignition circuit

(Chapters 1 and 5B).

m m Worn, faulty or incorrectly-gapped spark plugs (Chapter 1).

m

m Major mechanical failure (eg camshaft drive) (Chapters 2A, 2B

or 2C).

Engine difficult to start when cold

m mBattery discharged (Chapter 5A).

m

m Battery terminal connections loose or corroded (Chapter 5A).

m

m Worn, faulty or incorrectly-gapped spark plugs (Chapter 1).

m

m Other ignition system fault (Chapters 1 and 5B).

m

m Engine management system fault (Chapters 1, 4A, 4B, 4C, 4D, 4E

or 5B).

m m Low cylinder compressions (Chapters 2A, 2B or 2C).

Engine difficult to start when hot

m

mAir filter element dirty or clogged (Chapter 1).

m

m Engine management system fault (Chapters 1, 4A, 4B, 4C, 4D, 4E

or 5B).

m m Low cylinder compressions (Chapters 2A, 2B or 2C).

m

m Faulty hydraulic tappet(s) (Chapters 2B or 2C).

Starter motor noisy or excessively-rough in

engagement

m mFlywheel ring gear or starter pinion teeth loose or broken

(Chapters 2A, 2B, 2C or 5A).

m m Starter motor mounting bolts loose or missing (Chapter 5A).

m

m Starter motor internal components worn or damaged (Chapter 5A).

Engine starts but stops immediately

m

mLoose or faulty electrical connections in the ignition circuit

(Chapters 1 and 5B).

m m Engine management system fault (Chapters 1, 4A, 4B, 4C, 4D, 4E

or 5B).

m m Vacuum leak at the inlet manifold (Chapters 1, 4A, 4B, 4C, 4D or 4E).

Engine idles erratically

m

mEngine management system fault (Chapters 1, 4A, 4B, 4C, 4D, 4E

or 5B).

m m Air filter element clogged (Chapter 1).

m

m Vacuum leak at the inlet manifold or associated hoses (Chap-

ters 1, 4A, 4B, 4C, 4D or 4E).

m m Worn, faulty or incorrectly-gapped spark plugs (Chapter 1).

m

m Incorrect valve clearances (Chapter 2A).

m

m Faulty hydraulic tappet(s) (Chapters 2B or 2C).

m

m Uneven or low cylinder compressions (Chapters 2A, 2B or 2C).

m

m Camshaft lobes worn (Chapters 2A, 2B or 2C).

m

m Timing chain and sprockets worn (Chapter 2A).

m

m Timing belt incorrectly-tensioned (Chapters 2B or 2C).

Engine misfires at idle speed

m

mWorn, faulty or incorrectly-gapped spark plugs (Chapter 1).

m

m Faulty spark plug HT leads (Chapter 1).

m

m Engine management system fault (Chapters 1, 4A, 4B, 4C, 4D, 4E

or 5B).

m m Vacuum leak at the inlet manifold or associated hoses (Chap-

ters 1, 4A, 4B, 4C, 4D or 4E).

m m Incorrect valve clearances (Chapter 2A).

m

m Faulty hydraulic tappet(s) (Chapters 2B or 2C).

m

m Uneven or low cylinder compressions (Chapters 2A, 2B and 2C).

m

m Disconnected, leaking or perished crankcase ventilation hoses

(Chapters 1 and 4E).

Engine misfires throughout the driving speed range

m mFuel filter choked (Chapter 1).

m

m Fuel pump faulty or delivery pressure low (Chapters 4A, 4B, 4C or 4D).\

m

m Fuel tank vent blocked or fuel pipes restricted (Chapters 4A, 4B,

4C, 4D or 4E).

m m Vacuum leak at the inlet manifold or associated hoses (Chap-

ters 1, 4A, 4B, 4C, 4D or 4E).

m m Worn, faulty or incorrectly-gapped spark plugs (Chapter 1).

m

m Faulty spark plug HT leads (Chapter 1).

m

m Faulty ignition coil (Chapter 5B).

m

m Engine management system fault (Chapters 1, 4A, 4B, 4C, 4D, 4E

or 5B).

m m Uneven or low cylinder compressions (Chapters 2A, 2B or 2C).

procarmanuals.com

http://vnx.su

Page 293 of 296

1595 Ford Fiesta Remake

IndexREF•27

REF

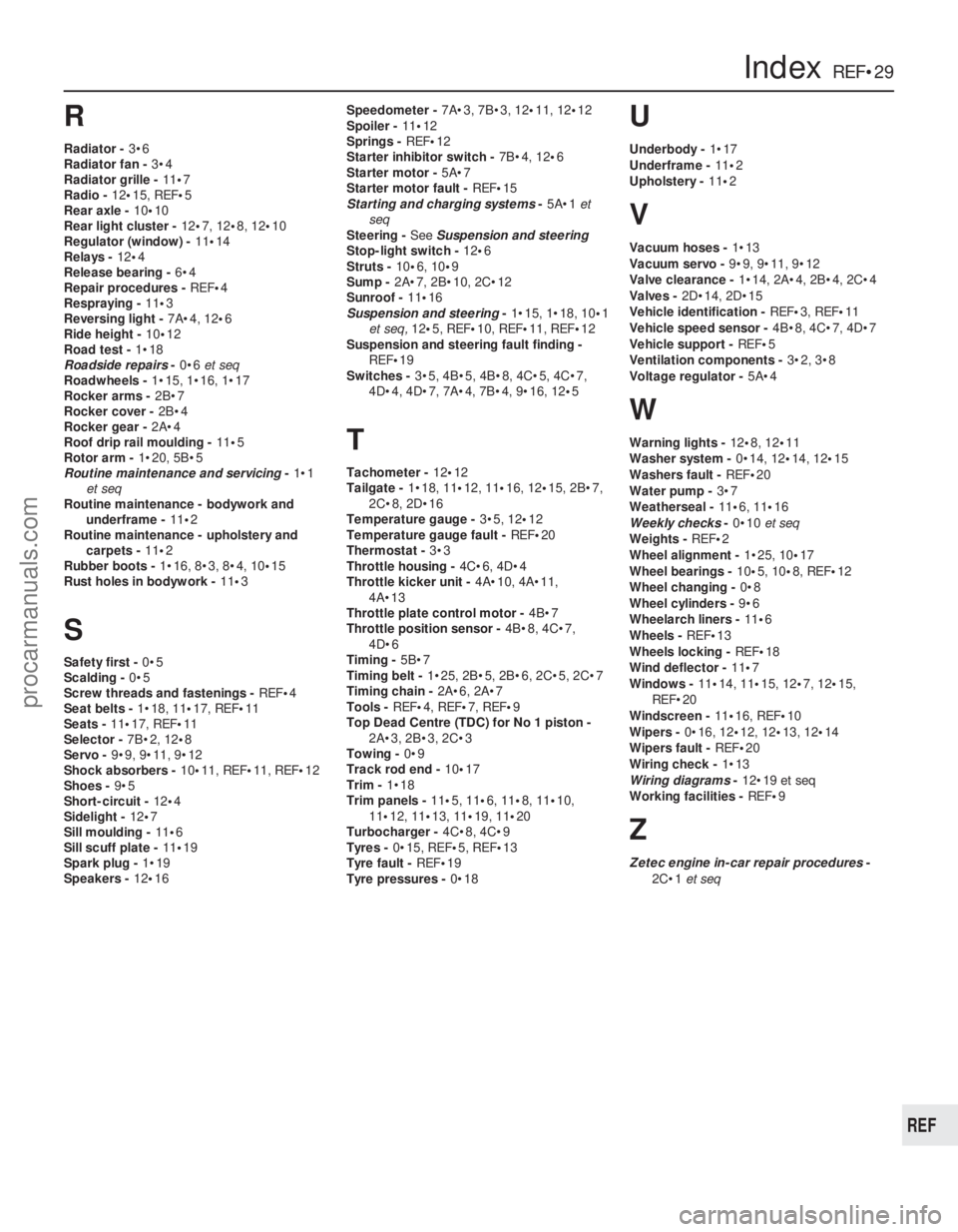

Note: References throughout this index relate to Chapter•page number

A

Accelerator cable -4A•4, 4B•4, 4C•4, 4D•3

Accelerator pedal - 4A•4, 4B•4, 4C•4, 4D•3

Accelerator pump - 4A•8

Acknowledgements - 0•4

Aerial - 12•16

Air bags - 0•5, 12•17

Air cleaner - 1•22, 1•23, 4A•3, 4B•4, 4C•3,

4D•3, 4E•5

Air temperature control system - 1•23,

4B•8, 4C•7, 4D•6

Alarm system - 12•17, REF• 5

Alternator - 5A•4

Anti-lock braking system (ABS) - 9•11,

9•14, 9•16

Anti-roll bar - 10•7, 10•11

Anti-theft alarm system - 12•17, REF•5

Antifreeze - 0•12, 0•17, 1•21, 1•22, 3•2

Asbestos - 0•5

ATF - 0•17, 1•18, 1•24

Automatic choke - 4A•16, 4A•17

Automatic transmission -2A•10, 2B•13,

2C•15, 2D•6, 2D•8, 2D•10, 7B•1 et seq,

12 •6, 12 •8

Automatic transmission fault finding - REF• 18

Automatic transmission fluid - 0•17, 1•18,

1•24

Auxiliary lights - 12•7, 12•10

Axle - 10•10

B

Backfire - REF•16

Backrest - 11•17

Ballast resistor - 4B•9

Balljoint - 10•17

Battery - 0•5, 0•14, 5A•2, 5A•3

Battery fault - REF•20

Big-end bearings - 2D•21, 2D•24

Bleeding braking system - 9•10, 9•11

Bleeding power steering - 10•17

Body electrical systems -1•18, 12 •1et seq,

REF• 11

Body electrical system fault finding - 5A•2,

12 •3, REF •20

Bodywork and fittings -1•18, 11 •1et seq,

REF• 13

Bonnet - 1•18, 11•4,11•5

Boot - 1•16

Boots - 8•3, 8•4, 10 •15

Brake fluid - 0•13, 0•17, 1•26, 12 •6

Braking system -1•17, 9•1 et seq, 12•6,

REF• 10, REF•11, REF• 12

Braking system fault finding - REF•18 Bulbs -

0•16, 12 •7,12•8

Bumpers - 11•7, 11•8

Burning - 0•5

Buying spare parts - REF•5

C

Cables -4A•4, 4B•4, 4C•4, 4D•3, 6•1, 7B•2,

9•12, 9•13, 12 •12

Calipers - 9•3

Camshaft - 2B•6, 2B•7, 2C•7, 2C•8, 2D•16

Camshaft position sensor - 4D•6

Carburettor - 4A•7, 4A•8, 4A•9, 4A•11,

4A•13, 4A•14, 4A•15, 4A•17, 4A•18

Carpets - 11•2

Cassette player - 12•15, REF •5

Catalytic converter - 4E•2, 4E•5

Centre console - 11•20, 12 •5

Charcoal canister - 4E•6

Charging system - 5A•3

Choke - 4A•4, 4A•16, 4A•17

Cigarette lighter - 12•9, 12 •12

Clock - 12•8, 12•12

Clutch -1•18, 6•1 et seq

Clutch fault finding - REF•17

Coil - 5B•4

Compression test - 2A•3, 2B•3, 2C•3

Connecting rods - 2D•17, 2D•24, 2D•25

Console - 11•20, 12•5

Contents - 0•2

Conversion factors - REF•6

Coolant - 0•12, 0•17, 1•21, 1•22, 3•2

Coolant pump - 3•7

Coolant temperature sensor - 4B•8, 4C•7,

4D•6

Cooling ,heating and ventilation systems -

3•1 et seq

Cooling system fault finding - REF•16

Courtesy light - 12•6, 12•9

Crankcase - 2D•19

Crankcase ventilation system - 1•24

Crankshaft - 2A•6, 2A•9, 2B•4, 2B•6,

2B•12, 2C•4, 2C•7, 2C•14, 2D•18,

2D•22, 2D•24

Crankshaft position sensor - 4B•8, 4C•7,

4D•6, 5B•5

Crossmember - 10•7

Crushing - 0•5

Cushion - 11•17

CV joint - 1•16, 8•3, 8•4

CVH and PTE engine in-car repair

procedures -2B•1 et seq

Cylinder block - 2D•19

Cylinder head - 2A•4, 2A•5, 2B•4, 2B•9,

2C•3, 2C•10, 2D•12, 2D•14, 2D•15

D

Dents in bodywork - 11•2

Depressurising fuel system - 4B•3, 4C•3,

4D•2

Differential - 7A•3, 7B•3

Dimensions - REF•1

Direction indicators - 12•7, 12•9, 12•10

Discs - 9•4

Distributor - 1•20, 5B•5, 5B•6, 5B•7

Doors - 1•18, 11• 6,11•9, 11 •10,,11 •11,

11 •13, 11•14, 11•15, REF •11

Drip rail moulding - 11•5

Drivebelt - 1•11

Driveplate - 2B•14, 2C•16

Driveshafts -1•16, 8•1 et seq,REF•12

Driveshafts fault finding - REF•19

Drivetrain - 1•18

Drums - 9•4

E

Earth fault - 12•4

EEC IV engine management module - 4C•6

Electric shock - 0•5

Electric windows - 11•14, 12 •7, 12•15,

REF•20

Emblems - 11•5

Emission control system - 1•24, 4E•1

Engine fault finding - REF•15, REF•16,

REF •18

Engine oil - 0•12, 0•17, 1•9

Engine removal and overhaul procedures -

2D•1 et seq

Environmental considerations - REF•4

Evaporative emission control systems - 1•24, 4E•2, 4E•5

Exhaust and emission control systems -

4E•1 et seq

Exhaust emission checks - REF•13

Exhaust manifold - 4E•3

Exhaust system - 1•16, 4E•1, 4E•2, REF •5,

REF •12

Exhaust system fault - REF•17

Expansion tank - 3•6

F

Facia - 11•20, 12 •5

Fan - 3•4

Fast-idle speed adjustment - 4A•13, 4A•15,

4A•9, 4A•7

Fault finding - REF•14et seq

Fault finding - automatic transmission -

REF •18

Fault finding - braking system - REF•18

procarmanuals.com

http://vnx.su

Page 295 of 296

R

Radiator -3•6

Radiator fan - 3•4

Radiator grille - 11•7

Radio - 12•15, REF •5

Rear axle - 10•10

Rear light cluster - 12•7, 12•8, 12 •10

Regulator (window) - 11•14

Relays - 12•4

Release bearing - 6•4

Repair procedures - REF•4

Respraying - 11•3

Reversing light - 7A•4, 12•6

Ride height - 10•12

Road test - 1•18

Roadside repairs -0•6 et seq

Roadwheels - 1•15, 1•16, 1•17

Rocker arms - 2B•7

Rocker cover - 2B•4

Rocker gear - 2A•4

Roof drip rail moulding - 11•5

Rotor arm - 1•20, 5B•5

Routine maintenance and servicing -1•1

et seq

Routine maintenance - bodywork and

underframe - 11•2

Routine maintenance - upholstery and carpets - 11•2

Rubber boots - 1•16, 8•3, 8•4, 10 •15

Rust holes in bodywork - 11•3

S

Safety first - 0•5

Scalding - 0•5

Screw threads and fastenings - REF•4

Seat belts - 1•18, 11•17, REF•11

Seats - 11•17, REF •11

Selector - 7B•2, 12•8

Servo - 9•9, 9•11, 9•12

Shock absorbers - 10•11, REF •11, REF•12

Shoes - 9•5

Short-circuit - 12•4

Sidelight - 12•7

Sill moulding - 11•6

Sill scuff plate - 11•19

Spark plug - 1•19

Speakers - 12•16 Speedometer -

7A•3, 7B•3, 12•11, 12•12

Spoiler - 11•12

Springs - REF•12

Starter inhibitor switch - 7B•4, 12•6

Starter motor - 5A•7

Starter motor fault - REF•15

Starting and charging systems -5A•1 et

seq

Steering - See Suspension and steering

Stop-light switch - 12•6

Struts - 10•6, 10• 9

Sump - 2A•7, 2B•10, 2C•12

Sunroof - 11•16

Suspension and steering -1•15, 1•18, 10 •1

et seq, 12•5, REF •10, REF •11, REF• 12

Suspension and steering fault finding -

REF •19

Switches - 3•5, 4B•5, 4B•8, 4C•5, 4C•7,

4D•4, 4D•7, 7A•4, 7B•4, 9•16, 12 •5

T

Tachometer - 12•12

Tailgate - 1•18, 11•12, 11•16, 12•15, 2B•7,

2C•8, 2D•16

Temperature gauge - 3•5, 12•12

Temperature gauge fault - REF•20

Thermostat - 3•3

Throttle housing - 4C•6, 4D•4

Throttle kicker unit - 4A•10, 4A•11,

4A•13

Throttle plate control motor - 4B•7

Throttle position sensor - 4B•8, 4C•7,

4D•6

Timing - 5B•7

Timing belt - 1•25, 2B•5, 2B•6, 2C•5, 2C•7

Timing chain - 2A•6, 2A•7

Tools - REF•4, REF•7, REF•9

Top Dead Centre (TDC) for No 1 piston - 2A•3, 2B•3, 2C•3

Towing - 0•9

Track rod end - 10•17

Trim - 1•18

Trim panels - 11•5, 11 •6, 11•8, 11 •10,

11 •12, 11•13, 11•19, 11•20

Turbocharger - 4C•8, 4C•9

Tyres - 0•15, REF•5, REF •13

Tyre fault - REF•19

Tyre pressures - 0•18

U

Underbody -1•17

Underframe - 11•2

Upholstery - 11•2

V

Vacuum hoses - 1•13

Vacuum servo - 9•9, 9•11, 9•12

Valve clearance - 1•14, 2A•4, 2B•4, 2C•4

Valves - 2D•14, 2D•15

Vehicle identification - REF•3, REF •11

Vehicle speed sensor - 4B•8, 4C•7, 4D•7

Vehicle support - REF•5

Ventilation components - 3•2, 3•8

Voltage regulator - 5A•4

W

Warning lights - 12•8, 12•11

Washer system - 0•14, 12•14, 12•15

Washers fault - REF•20

Water pump - 3•7

Weatherseal - 11•6, 11•16

Weekly checks -0•10 et seq

Weights - REF•2

Wheel alignment - 1•25, 10•17

Wheel bearings - 10•5, 10 •8, REF •12

Wheel changing - 0•8

Wheel cylinders - 9•6

Wheelarch liners - 11•6

Wheels - REF•13

Wheels locking - REF•18

Wind deflector - 11•7

Windows - 11•14, 11•15, 12 •7, 12•15,

REF•20

Windscreen - 11•16, REF •10

Wipers - 0•16, 12• 12, 12•13, 12•14

Wipers fault - REF•20

Wiring check - 1•13

Wiring diagrams - 12•19 et seq

Working facilities - REF•9

Z

Zetec engine in-car repair procedures -

2C•1 et seq

IndexREF•29

REF

1595 Ford Fiesta Remakeprocarmanuals.com

http://vnx.su