clock FORD FIESTA 1989 Service Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1989, Model line: FIESTA, Model: FORD FIESTA 1989Pages: 296, PDF Size: 10.65 MB

Page 3 of 296

Lubricants and fluids

Refer to end of “Weekly Checks”

Capacities

Engine oil

At oil and filter change:HCS engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . 3.25 litres

CVH and PTE engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

3.50 litresZetec engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . 4.25 litres

Difference between dipstick minimum and maximum level notches . . . 0.5 to 1.0 litre

Cooling system

HCS engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . 7.1 litresCVH and PTE engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . 7.6 litresZetec engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . 7.0 litres

Fuel tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . 42.0 litres

Manual transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . 3.1 litres

Automatic transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

3.5 litres

Engine

Direction of crankshaft rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Clockwise (seen from right-hand side of vehicle)

Oil filter: HCS, CVH and PTE engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion C104

Zetec engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . Champion C148

Cooling system

Coolant protection at standard 40% antifreeze/water mixture ratio:Slush point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . -25ºC (-13ºF)Solidifying point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . -30ºC (-22ºF)

Coolant specific gravity at standard 40% antifreeze/water

mixture ratio and 15ºC/59ºF - with no other additives in coolant . . . . . 1.061

Fuel system

Idle speed*: 1.0, 1.1 and 1.3 litre HCS (carburettor) engines . . . . . . . . . . . . . . . . . 750 ± 50 rpm (cooling fan running)

1.4 and 1.6 litre CVH (carburettor) engines:

Manual transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

800 ± 50 rpm (cooling fan running)CTX automatic transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 850 ± 50 rpm (cooling fan running)

1.6 litre CVH (EFi fuel injection) engines: Idle speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . 900 ± 50 rpmBase idle speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . 750 ± 50 rpm

Idle mixture CO content*: 1.0, 1.1 and 1.3 litre HCS (carburettor) engines . . . . . . . . . . . . . . . . . 1.0 ± 0.5%

1.4 litre CVH (carburettor) engines . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 ± 0.25%

1.6 litre CVH (carburettor) engines . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 ± 0.5%

1.6 litre CVH (fuel injection) engines:Non turbo models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . 0.8 ± 0.25%

Turbo models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . 1.5 ± 0.25%

*Note: The idle speed and mixture CO content is only adjustable on the engines \

shown above. On all other engines, it is controlled by the engine

management system, and cannot be checked or adjusted without specialised\

test equipment.

Air filter element: 1.0, 1.1 and 1.3 litre HCS engines . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion W153

1.4 litre CVH and PTE engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion W226

1.6 litre CVH (carburettor) engines . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion W226

1.6 litre CVH (fuel injection) engines . . . . . . . . . . . . . . . . . . . . . . . . . . Champion U557

1.6 and 1.8 litre Zetec engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion U612

Fuel filter:

HCS, CVH (fuel injection) and PTE engines:Without quick-release fuel line fittings . . . . . . . . . . . . . . . . . . . . . . Champion L204

With quick-release fuel line fittings . . . . . . . . . . . . . . . . . . . . . . . . . Champion type not available

Zetec engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . Champion L218

1•2Servicing Specifications

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 13 of 296

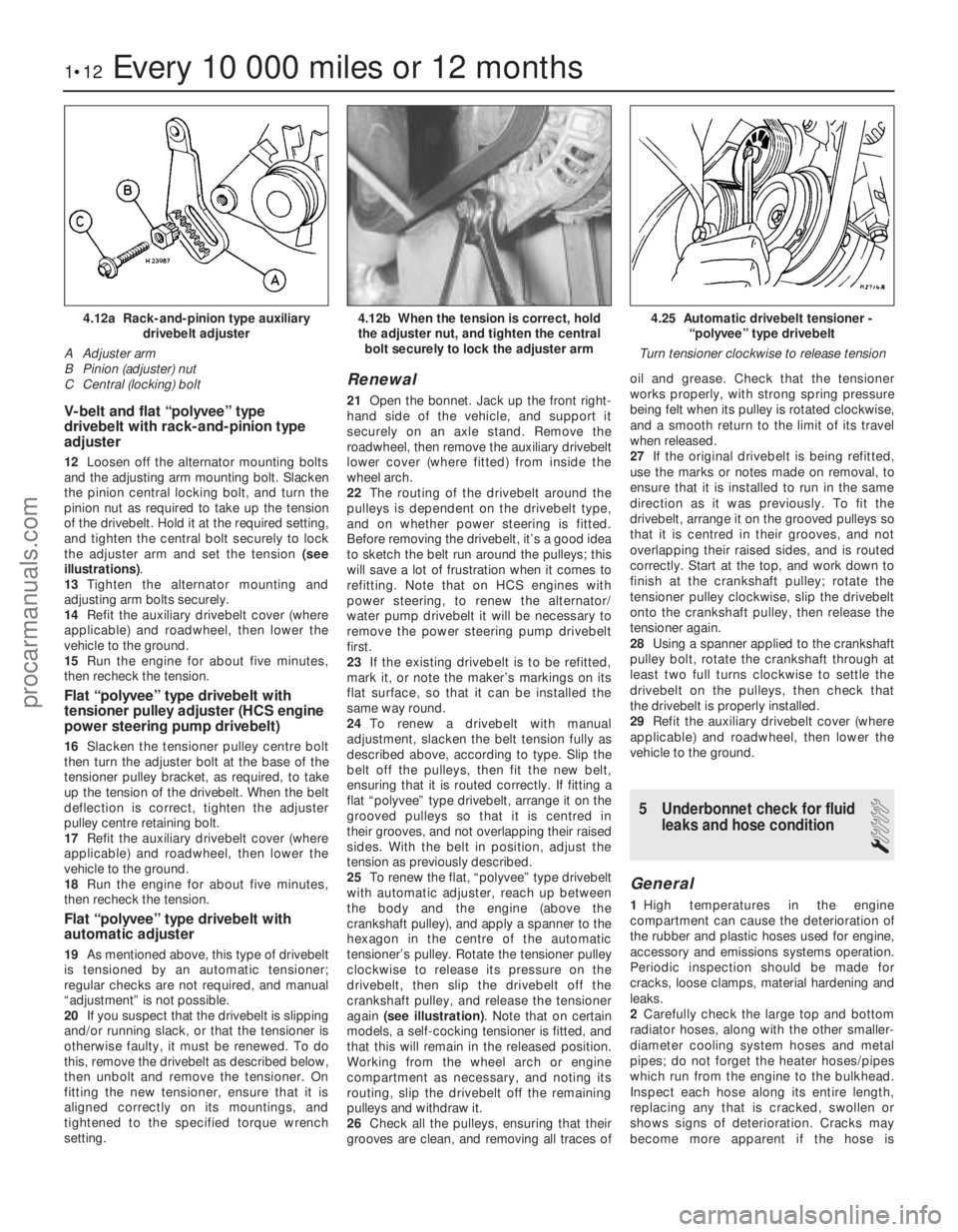

V-belt and flat “polyvee” type

drivebelt with rack-and-pinion type

adjuster

12Loosen off the alternator mounting bolts

and the adjusting arm mounting bolt. Slacken

the pinion central locking bolt, and turn the

pinion nut as required to take up the tension

of the drivebelt. Hold it at the required setting,

and tighten the central bolt securely to lock

the adjuster arm and set the tension (see

illustrations) .

13 Tighten the alternator mounting and

adjusting arm bolts securely.

14 Refit the auxiliary drivebelt cover (where

applicable) and roadwheel, then lower the

vehicle to the ground.

15 Run the engine for about five minutes,

then recheck the tension.

Flat “polyvee” type drivebelt with

tensioner pulley adjuster (HCS engine

power steering pump drivebelt)

16 Slacken the tensioner pulley centre bolt

then turn the adjuster bolt at the base of the

tensioner pulley bracket, as required, to take

up the tension of the drivebelt. When the belt

deflection is correct, tighten the adjuster

pulley centre retaining bolt.

17 Refit the auxiliary drivebelt cover (where

applicable) and roadwheel, then lower the

vehicle to the ground.

18 Run the engine for about five minutes,

then recheck the tension.

Flat “polyvee” type drivebelt with

automatic adjuster

19 As mentioned above, this type of drivebelt

is tensioned by an automatic tensioner;

regular checks are not required, and manual

“adjustment” is not possible.

20 If you suspect that the drivebelt is slipping

and/or running slack, or that the tensioner is

otherwise faulty, it must be renewed. To do

this, remove the drivebelt as described below,

then unbolt and remove the tensioner. On

fitting the new tensioner, ensure that it is

aligned correctly on its mountings, and

tightened to the specified torque wrench

setting.

Renewal

21 Open the bonnet. Jack up the front right-

hand side of the vehicle, and support it

securely on an axle stand. Remove the

roadwheel, then remove the auxiliary drivebelt

lower cover (where fitted) from inside the

wheel arch.

22 The routing of the drivebelt around the

pulleys is dependent on the drivebelt type,

and on whether power steering is fitted.

Before removing the drivebelt, it’s a good idea

to sketch the belt run around the pulleys; this

will save a lot of frustration when it comes to

refitting. Note that on HCS engines with

power steering, to renew the alternator/

water pump drivebelt it will be necessary to

remove the power steering pump drivebelt

first.

23 If the existing drivebelt is to be refitted,

mark it, or note the maker’s markings on its

flat surface, so that it can be installed the

same way round.

24 To renew a drivebelt with manual

adjustment, slacken the belt tension fully as

described above, according to type. Slip the

belt off the pulleys, then fit the new belt,

ensuring that it is routed correctly. If fitting a

flat “polyvee” type drivebelt, arrange it on the

grooved pulleys so that it is centred in

their grooves, and not overlapping their raised

sides. With the belt in position, adjust the

tension as previously described.

25 To renew the flat, “polyvee” type drivebelt

with automatic adjuster, reach up between

the body and the engine (above the

crankshaft pulley), and apply a spanner to the

hexagon in the centre of the automatic

tensioner’s pulley. Rotate the tensioner pulley

clockwise to release its pressure on the

drivebelt, then slip the drivebelt off the

crankshaft pulley, and release the tensioner

again (see illustration) . Note that on certain

models, a self-cocking tensioner is fitted, and

that this will remain in the released position.

Working from the wheel arch or engine

compartment as necessary, and noting its

routing, slip the drivebelt off the remaining

pulleys and withdraw it.

26 Check all the pulleys, ensuring that their

grooves are clean, and removing all traces of oil and grease. Check that the tensioner

works properly, with strong spring pressure

being felt when its pulley is rotated clockwise,

and a smooth return to the limit of its travel

when released.

27

If the original drivebelt is being refitted,

use the marks or notes made on removal, to

ensure that it is installed to run in the same

direction as it was previously. To fit the

drivebelt, arrange it on the grooved pulleys so

that it is centred in their grooves, and not

overlapping their raised sides, and is routed

correctly. Start at the top, and work down to

finish at the crankshaft pulley; rotate the

tensioner pulley clockwise, slip the drivebelt

onto the crankshaft pulley, then release the

tensioner again.

28 Using a spanner applied to the crankshaft

pulley bolt, rotate the crankshaft through at

least two full turns clockwise to settle the

drivebelt on the pulleys, then check that

the drivebelt is properly installed.

29 Refit the auxiliary drivebelt cover (where

applicable) and roadwheel, then lower the

vehicle to the ground.

5 Underbonnet check for fluid leaks and hose condition

1

General

1High temperatures in the engine

compartment can cause the deterioration of

the rubber and plastic hoses used for engine,

accessory and emissions systems operation.

Periodic inspection should be made for

cracks, loose clamps, material hardening and

leaks.

2 Carefully check the large top and bottom

radiator hoses, along with the other smaller-

diameter cooling system hoses and metal

pipes; do not forget the heater hoses/pipes

which run from the engine to the bulkhead.

Inspect each hose along its entire length,

replacing any that is cracked, swollen or

shows signs of deterioration. Cracks may

become more apparent if the hose is

1•12Every 10 000 miles or 12 months

4.25 Automatic drivebelt tensioner - “polyvee” type drivebelt

Turn tensioner clockwise to release tension4.12b When the tension is correct, hold

the adjuster nut, and tighten the central bolt securely to lock the adjuster arm4.12a Rack-and-pinion type auxiliary drivebelt adjuster

A Adjuster arm

B Pinion (adjuster) nut

C Central (locking) bolt

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 16 of 296

10If adjustment to the mixture is required,

the tamperproof cap will need to be removed

from the carburettor to gain access to the

mixture screw. To do this, first unclip the fuel

trap from the side of the air cleaner unit, then

remove the air cleaner unit, ensuring that the

crankcase ventilation trap remains connected.

Prise free the tamperproof cap (with the aid of

a thin-bladed screwdriver), then with the

vacuum and emissions control pipes

connected to it, relocate the air cleaner unit

temporarily into position.

11 Turn the mixture adjustment screw

clockwise to weaken the mixture, or

anti-clockwise to richen it, until the CO

reading is as given in the Specifications. If a

CO meter is not being used, weaken the

mixture as described, then enrich the mixture until the maximum engine speed is obtained,

consistent with even running.

12

If necessary, re-adjust the idle speed then

check the CO reading again. Repeat as

necessary until both the idle speed and CO

reading are correct.

13 Where required by law (as in some

European countries), fit a new tamperproof

cap to the mixture adjustment screw.

14 Disconnect the tachometer and the CO

meter, refit the air cleaner unit, and reconnect

the fan switch lead to complete.

Base idle speed and mixture

check and adjustment - 1.6 litre

EFi engines

15 Proceed as described above in

paragraphs 3 to 6 inclusive, then continue as

follows.

16 Run the engine at a fast idle speed until it

reaches its normal operating temperature and

the cooling fan cuts in. Check the CO content

of the exhaust, and compare it against the

specified reading. If the CO content reading is

incorrect, it can be adjusted by prising free

the tamperproof cap for access to the mixture

CO adjustment screw (see illustration), and

turning the screw in the required direction to

suit.

17 The operational idle speed is controlled by

the EEC IV engine management module and is

not adjustable. However, if the base idle

speed is incorrect, the module will not have an

accurate datum point from which to establish the normal operational idle speed. If idle

problems have been experienced, the base

idle speed should be checked as follows.

18

Disconnect the multi-plug from the idle

speed control valve and increase the engine

speed to 2000 rpm, hold it at that speed for

30 seconds, then fully release the throttle and

check if the base idle speed registered is as

specified.

19 If adjustment is necessary, prise free the

tamperproof plug using a suitable small

screwdriver to gain access to the base idle

speed adjustment screw in the throttle body.

Turn the screw in the required direction to

adjust the base idle speed to the specified

amount. Turning the screw anti-clockwise

increases the idle speed (see illustration).

20 Increase the engine speed to 2000 rpm

again, hold it at that speed for 30 seconds,

then fully release the throttle once more.

Check and further adjust the base idle speed

if required, then fit a new tamperproof plug

into position.

21 Reconnect the idle speed control valve

multi-plug and check that the engine speed

briefly rises to about 900 rpm, then drops

down to the specified normal idle speed.

22 On completion, disconnect the

tachometer and the CO meter, but continue

running the engine at idle speed for a period

of about five minutes, to enable the engine

management module to relearn its values

before switching it off.

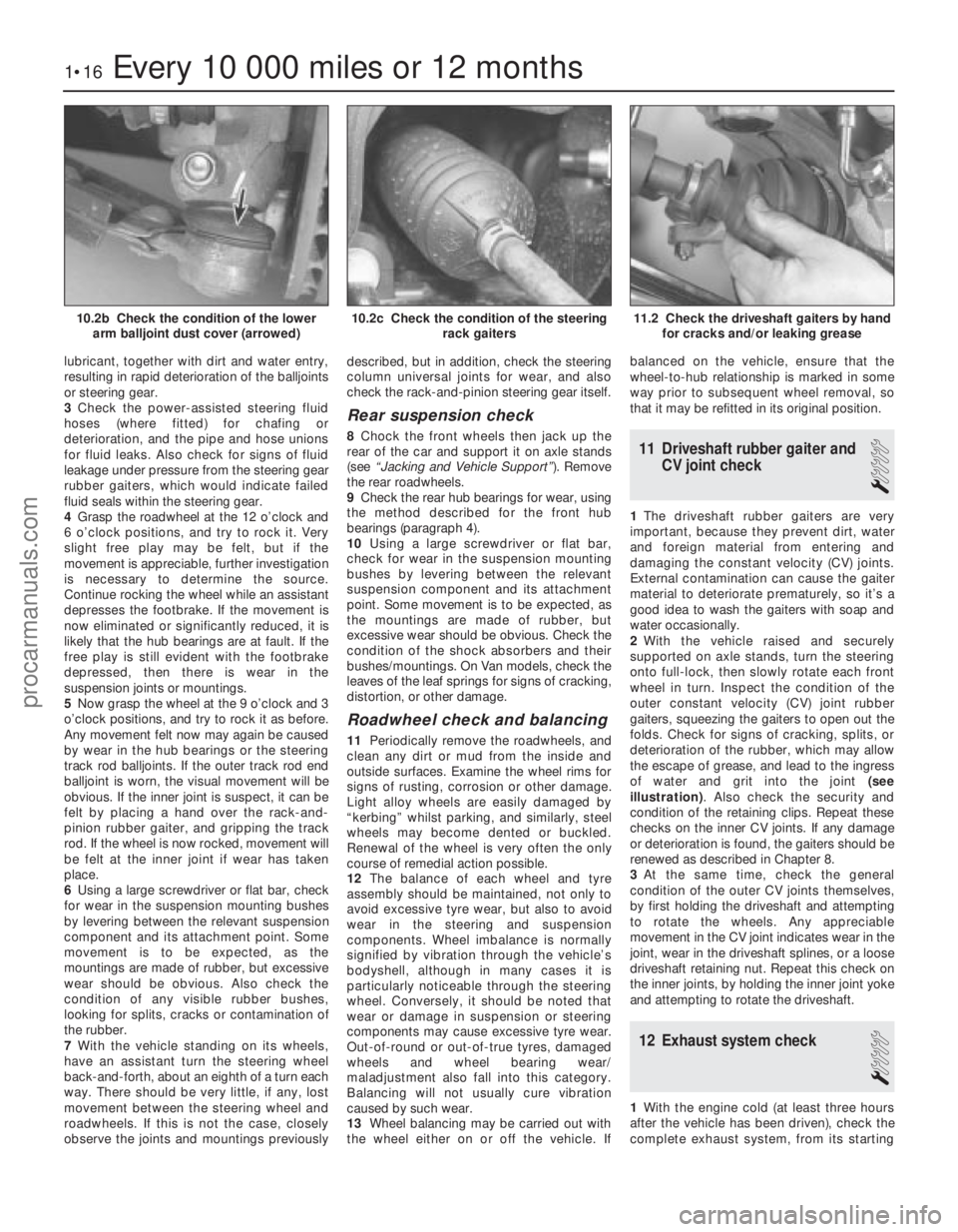

10 Steering, suspension and roadwheel check

2

Front suspension and steering

check

1Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and Vehicle Support” ).

2 Visually inspect the balljoint dust covers

and the steering gear gaiters for splits, chafing

or deterioration (see illustrations) . Any wear

of these components will cause loss of

Every 10 000 miles or 12 months1•15

9.9d Idle speed mixture adjusting

screw (A) and idle speed adjusting screw (B) (Weber TLD carburettor)9.9c Idle speed mixture adjusting

screw (A) and idle speed adjusting screw (B) (Weber DFTM carburettor)9.9b Idle speed adjusting screw (A) and

mixture adjusting screw (B) (Weber TLDM carburettor)

10.2a Check the condition of the track rodend balljoint dust cover (arrowed)9.19 Base idle speed adjustment screw(arrowed) on the 1.6 litre EFi engine

9.16 Adjusting the idle mixture CO content on the 1.6 litre EFi engine

1

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 17 of 296

lubricant, together with dirt and water entry,

resulting in rapid deterioration of the balljoints

or steering gear.

3Check the power-assisted steering fluid

hoses (where fitted) for chafing or

deterioration, and the pipe and hose unions

for fluid leaks. Also check for signs of fluid

leakage under pressure from the steering gear

rubber gaiters, which would indicate failed

fluid seals within the steering gear.

4 Grasp the roadwheel at the 12 o’clock and

6 o’clock positions, and try to rock it. Very

slight free play may be felt, but if the

movement is appreciable, further investigation

is necessary to determine the source.

Continue rocking the wheel while an assistant

depresses the footbrake. If the movement is

now eliminated or significantly reduced, it is

likely that the hub bearings are at fault. If the

free play is still evident with the footbrake

depressed, then there is wear in the

suspension joints or mountings.

5 Now grasp the wheel at the 9 o’clock and 3

o’clock positions, and try to rock it as before.

Any movement felt now may again be caused

by wear in the hub bearings or the steering

track rod balljoints. If the outer track rod end

balljoint is worn, the visual movement will be

obvious. If the inner joint is suspect, it can be

felt by placing a hand over the rack-and-

pinion rubber gaiter, and gripping the track

rod. If the wheel is now rocked, movement will

be felt at the inner joint if wear has taken

place.

6 Using a large screwdriver or flat bar, check

for wear in the suspension mounting bushes

by levering between the relevant suspension

component and its attachment point. Some

movement is to be expected, as the

mountings are made of rubber, but excessive

wear should be obvious. Also check the

condition of any visible rubber bushes,

looking for splits, cracks or contamination of

the rubber.

7 With the vehicle standing on its wheels,

have an assistant turn the steering wheel

back-and-forth, about an eighth of a turn each

way. There should be very little, if any, lost

movement between the steering wheel and

roadwheels. If this is not the case, closely

observe the joints and mountings previously described, but in addition, check the steering

column universal joints for wear, and also

check the rack-and-pinion steering gear itself.

Rear suspension check

8

Chock the front wheels then jack up the

rear of the car and support it on axle stands

(see “Jacking and Vehicle Support” ). Remove

the rear roadwheels.

9 Check the rear hub bearings for wear, using

the method described for the front hub

bearings (paragraph 4).

10 Using a large screwdriver or flat bar,

check for wear in the suspension mounting

bushes by levering between the relevant

suspension component and its attachment

point. Some movement is to be expected, as

the mountings are made of rubber, but

excessive wear should be obvious. Check the

condition of the shock absorbers and their

bushes/mountings. On Van models, check the

leaves of the leaf springs for signs of cracking,

distortion, or other damage.

Roadwheel check and balancing

11 Periodically remove the roadwheels, and

clean any dirt or mud from the inside and

outside surfaces. Examine the wheel rims for

signs of rusting, corrosion or other damage.

Light alloy wheels are easily damaged by

“kerbing” whilst parking, and similarly, steel

wheels may become dented or buckled.

Renewal of the wheel is very often the only

course of remedial action possible.

12 The balance of each wheel and tyre

assembly should be maintained, not only to

avoid excessive tyre wear, but also to avoid

wear in the steering and suspension

components. Wheel imbalance is normally

signified by vibration through the vehicle’s

bodyshell, although in many cases it is

particularly noticeable through the steering

wheel. Conversely, it should be noted that

wear or damage in suspension or steering

components may cause excessive tyre wear.

Out-of-round or out-of-true tyres, damaged

wheels and wheel bearing wear/

maladjustment also fall into this category.

Balancing will not usually cure vibration

caused by such wear.

13 Wheel balancing may be carried out with

the wheel either on or off the vehicle. If balanced on the vehicle, ensure that the

wheel-to-hub relationship is marked in some

way prior to subsequent wheel removal, so

that it may be refitted in its original position.

11 Driveshaft rubber gaiter and

CV joint check

1

1The driveshaft rubber gaiters are very

important, because they prevent dirt, water

and foreign material from entering and

damaging the constant velocity (CV) joints.

External contamination can cause the gaiter

material to deteriorate prematurely, so it’s a

good idea to wash the gaiters with soap and

water occasionally.

2 With the vehicle raised and securely

supported on axle stands, turn the steering

onto full-lock, then slowly rotate each front

wheel in turn. Inspect the condition of the

outer constant velocity (CV) joint rubber

gaiters, squeezing the gaiters to open out the

folds. Check for signs of cracking, splits, or

deterioration of the rubber, which may allow

the escape of grease, and lead to the ingress

of water and grit into the joint (see

illustration) . Also check the security and

condition of the retaining clips. Repeat these

checks on the inner CV joints. If any damage

or deterioration is found, the gaiters should be

renewed as described in Chapter 8.

3 At the same time, check the general

condition of the outer CV joints themselves,

by first holding the driveshaft and attempting

to rotate the wheels. Any appreciable

movement in the CV joint indicates wear in the

joint, wear in the driveshaft splines, or a loose

driveshaft retaining nut. Repeat this check on

the inner joints, by holding the inner joint yoke

and attempting to rotate the driveshaft.

12 Exhaust system check

1

1 With the engine cold (at least three hours

after the vehicle has been driven), check the

complete exhaust system, from its starting

1•16Every 10 000 miles or 12 months

11.2 Check the driveshaft gaiters by hand for cracks and/or leaking grease10.2c Check the condition of the steering rack gaiters10.2b Check the condition of the lowerarm balljoint dust cover (arrowed)

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 28 of 296

2A

1595Ford Fiesta Remake

General

Engine type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . Four-cylinder, in-line overhead valve

Engine code:1.0 litre carburettor models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TLB

1.1 litre carburettor models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . GUE or GUD

1.1 litre CFi fuel injection models . . . . . . . . . . . . . . . . . . . . . . . . . . . . G6A

1.3 litre carburettor models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . JBC

1.3 litre CFi fuel injection models . . . . . . . . . . . . . . . . . . . . . . . . . . . . J6B

Capacity: 1.0 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . 999 cc

1.1 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . 1118 cc

1.3 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . 1297 cc

Bore:

1.0 and 1.1 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68.68 mm

1.3 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . 73.96 mm

Stroke:

1.0 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . 67.40 mm

1.1 and 1.3 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75.48 mm

Compression ratio:

Carburettor models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . 9.5:1

CFi fuel injection models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.8:1

Firing order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . 1-2-4-3 (No 1 cylinder at timing chain end)

Direction of crankshaft rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Clockwise (seen from right-hand side of vehicle)

Valves

Valve clearance (cold): Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . 0.20 mm

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . 0.30 mm

Chapter 2 Part A:

HCS engine in-car repair procedures

Auxiliary drivebelt check and renewal . . . . . . . . . . . . . . .See Chapter 1

Compression test - description and interpretation . . . . . . . . . . . . . . 2

Crankshaft oil seals - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Crankshaft pulley - removal and refitting . . . . . . . . . . . . . . . . . . . . . 8

Cylinder head - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 7

Cylinder head rocker cover - removal and refitting . . . . . . . . . . . . . . 4

Cylinder head rocker gear - removal, inspection and refitting . . . . . 6

Engine oil and filter renewal . . . . . . . . . . . . . . . . . . . . . . .See Chapter 1

Engine oil level check . . . . . . . . . . . . . . . . . . . . . .See

“Weekly Checks”

Engine/transmission mountings - inspection and renewal . . . . . . . . 15 Flywheel - removal, inspection and refitting . . . . . . . . . . . . . . . . . . . 16

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . 1

Oil pump - dismantling, inspection and reassembly . . . . . . . . . . . . . 13

Oil pump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Sump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Timing chain cover - removal and refitting . . . . . . . . . . . . . . . . . . . . 9

Timing chain, sprockets and tensioner - removal, inspection

and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . 10

Top Dead Centre (TDC) for No 1 piston - locating . . . . . . . . . . . . . . 3

Valve clearances - checking and adjustment . . . . . . . . . . . . . . . . . . 5

2A•1

Specifications Contents

Easy, suitable for

novice with little

experience Fairly easy,

suitable

for beginner with

some experience Fairly difficult,

suitable for competent

DIY mechanic

Difficult,

suitable for

experienced DIY

mechanic Very difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

procarmanuals.com

http://vnx.su

Page 30 of 296

connecting rods (after removing the cylinder

head and sump) without removing the engine.

However, this is not recommended. Work of

this nature is more easily and thoroughly

completed with the engine on the bench, as

described in Chapter 2D.

2 Compression test-

description and interpretation

2

1 When engine performance is down, or if

misfiring occurs which cannot be attributed to

the ignition or fuel systems, a compression

test can provide diagnostic clues as to the

engine’s condition. If the test is performed

regularly, it can give warning of trouble before

any other symptoms become apparent.

2 The engine must be fully warmed-up to

normal operating temperature, the oil level

must be correct and the battery must be fully

charged. The aid of an assistant will also be

required.

3 On fuel injection engines, refer to Chap-

ter 12 and remove the fuel pump fuse from the

fusebox. Now start the engine and allow it to

run until it stalls.

4 Disable the ignition system by

disconnecting the multi-plug from the DIS or

E-DIS ignition coil. Remove all the spark plugs

with reference to Chapter 1 if necessary.

5 Fit a compression tester to the No 1

cylinder spark plug hole - the type of tester

which screws into the plug thread is to be

preferred.

6 Arrange for an assistant to hold the

accelerator pedal fully depressed to the floor,

while at the same time cranking the engine

over for several seconds on the starter motor.

Observe the compression gauge reading. The

compression will build up fairly quickly in a

healthy engine. Low compression on the first

stroke, followed by gradually-increasing

pressure on successive strokes, indicates

worn piston rings. A low compression on the

first stroke which does not rise on successive

strokes, indicates leaking valves or a blown

head gasket (a cracked cylinder head could

also be the cause). Deposits on the underside

of the valve heads can also cause low

compression. Record the highest gauge

reading obtained, then repeat the procedure

for the remaining cylinders.

7 Due to the variety of testers available, and

the fluctuation in starter motor speed when

cranking the engine, different readings

are often obtained when carrying out

the compression test. For this reason, actual

compression pressure figures are not quoted

by Ford. However, the most important factor

is that the compression pressures are uniform

in all cylinders, and that is what this test is

mainly concerned with.

8 Add some engine oil (about three squirts

from a plunger type oil can) to each cylinder

through the spark plug holes, and then repeat

the test. 9

If the compression increases after the oil is

added, it is indicative that the piston rings are

definitely worn. If the compression does not

increase significantly, the leakage is occurring

at the valves or the head gasket. Leakage

past the valves may be caused by burned

valve seats and/or faces, or warped, cracked

or bent valves.

10 If two adjacent cylinders have equally low

compressions, it is most likely that the head

gasket has blown between them. The

appearance of coolant in the combustion

chambers or on the engine oil dipstick would

verify this condition.

11 If one cylinder is about 20 percent lower

than the other, and the engine has a slightly

rough idle, a worn lobe on the camshaft could

be the cause.

12 On completion of the checks, refit the

spark plugs and reconnect the HT leads and

the ignition coil plug. Refit the fuel pump fuse

to the fusebox.

3 Top Dead Centre (TDC) for No 1 piston - locating

2

1Top dead centre (TDC) is the highest point

of the cylinder that each piston reaches as the

crankshaft turns. Each piston reaches its TDC

position at the end of its compression stroke,

and then again at the end of its exhaust

stroke. For the purpose of engine timing, TDC

at the end of the compression stroke for No 1

piston is used. On the HCS engine, No 1

cylinder is at the crankshaft pulley/timing

chain end of the engine. Proceed as follows.

2 Ensure that the ignition is switched off.

Disconnect the HT leads from the spark plugs,

then unscrew and remove the plugs as

described in Chapter 1.

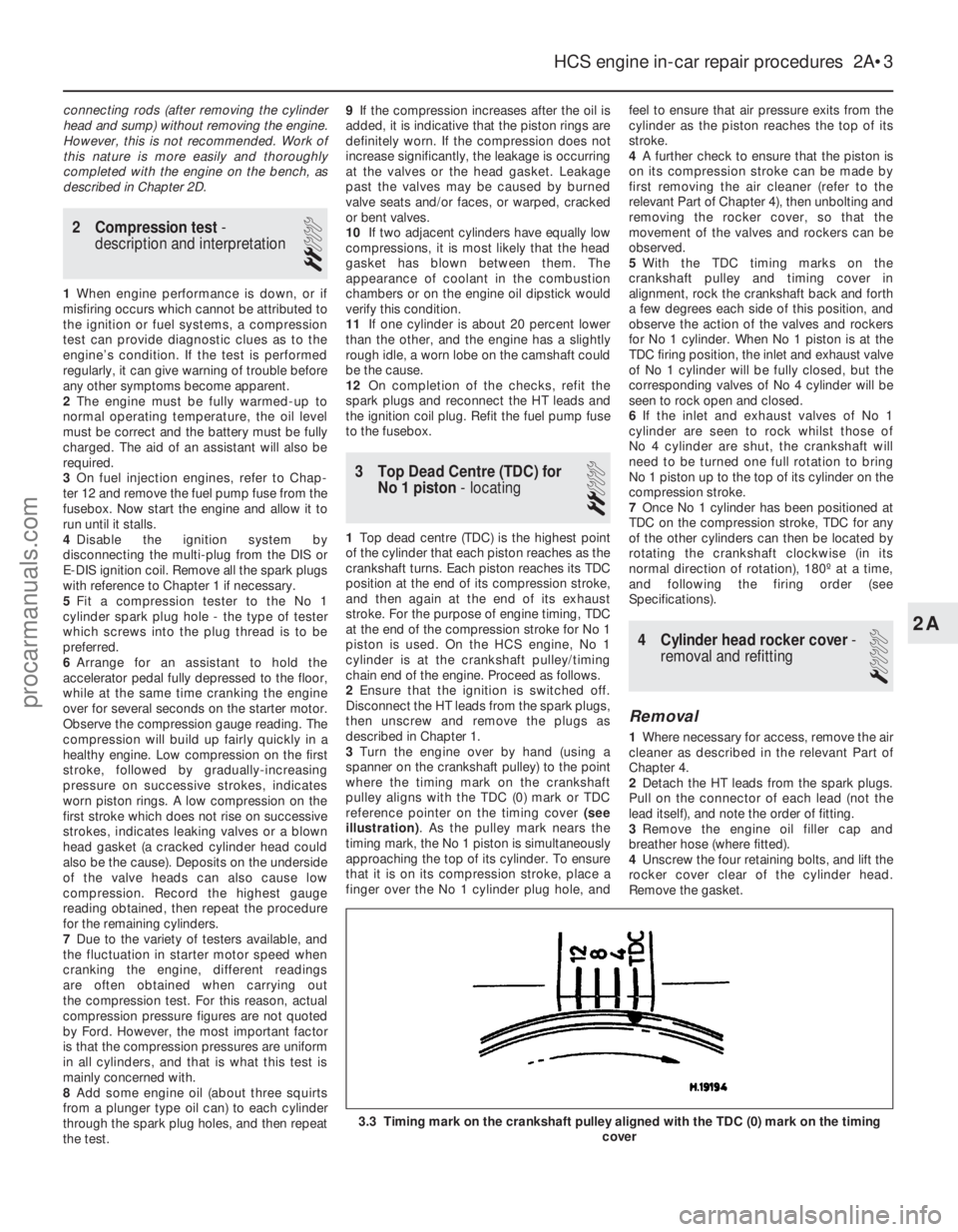

3 Turn the engine over by hand (using a

spanner on the crankshaft pulley) to the point

where the timing mark on the crankshaft

pulley aligns with the TDC (0) mark or TDC

reference pointer on the timing cover (see

illustration) . As the pulley mark nears the

timing mark, the No 1 piston is simultaneously

approaching the top of its cylinder. To ensure

that it is on its compression stroke, place a

finger over the No 1 cylinder plug hole, and feel to ensure that air pressure exits from the

cylinder as the piston reaches the top of its

stroke.

4

A further check to ensure that the piston is

on its compression stroke can be made by

first removing the air cleaner (refer to the

relevant Part of Chapter 4), then unbolting and

removing the rocker cover, so that the

movement of the valves and rockers can be

observed.

5 With the TDC timing marks on the

crankshaft pulley and timing cover in

alignment, rock the crankshaft back and forth

a few degrees each side of this position, and

observe the action of the valves and rockers

for No 1 cylinder. When No 1 piston is at the

TDC firing position, the inlet and exhaust valve

of No 1 cylinder will be fully closed, but the

corresponding valves of No 4 cylinder will be

seen to rock open and closed.

6 If the inlet and exhaust valves of No 1

cylinder are seen to rock whilst those of

No 4 cylinder are shut, the crankshaft will

need to be turned one full rotation to bring

No 1 piston up to the top of its cylinder on the

compression stroke.

7 Once No 1 cylinder has been positioned at

TDC on the compression stroke, TDC for any

of the other cylinders can then be located by

rotating the crankshaft clockwise (in its

normal direction of rotation), 180º at a time,

and following the firing order (see

Specifications).

4 Cylinder head rocker cover -

removal and refitting

1

Removal

1 Where necessary for access, remove the air

cleaner as described in the relevant Part of

Chapter 4.

2 Detach the HT leads from the spark plugs.

Pull on the connector of each lead (not the

lead itself), and note the order of fitting.

3 Remove the engine oil filler cap and

breather hose (where fitted).

4 Unscrew the four retaining bolts, and lift the

rocker cover clear of the cylinder head.

Remove the gasket.

HCS engine in-car repair procedures 2A•3

3.3 Timing mark on the crankshaft pulley aligned with the TDC (0) mar\

k on the timing cover

2A

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 40 of 296

2B

1595Ford Fiesta Remake

General

Engine type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . Four-cylinder, in-line overhead camshaft

Engine code:1.4 litre CVH engine: Carburettor models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. FUF or FUG

CFi fuel injection models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F6E

1.4 litre PTE engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . F4A

1.6 litre CVH engine: Carburettor models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. LUH

EFi fuel injection models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . LJC or LJD

Turbo models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . LHA

Capacity:

1.4 litre CVH and PTE engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1392 cc

1.6 litre CVH engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . 1596 cc

Bore:

1.4 litre CVH and PTE engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77.24 mm

1.6 litre CVH engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . 79.96 mm

Stroke:

1.4 litre CVH and PTE engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74.30 mm

1.6 litre CVH engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . 79.52 mm

Compression ratio:

1.4 litre CVH carburettor engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.5:1

1.4 litre CVH CFi fuel injection engine . . . . . . . . . . . . . . . . . . . . . . . . 8.5:1

1.4 litre PTE engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . 9.5:1

1.6 litre CVH engine: Carburettor models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. 9.5:1

EFi fuel injection models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.75:1

Turbo models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . 8.0:1

Firing order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . 1-3-4-2 (No 1 cylinder at timing belt end)

Direction of crankshaft rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Clockwise (seen from right-hand side of vehicle)

Chapter 2 Part B:

CVH and PTE engine in-car repair procedures

Auxiliary drivebelt check and renewal . . . . . . . . . . . . . . .See Chapter 1

Camshaft oil seal - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Camshaft, rocker arms and tappets - removal, inspection and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . 11

Compression test - description and interpretation . . . . . . . . . . . . . . 2

Crankshaft oil seals - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Crankshaft pulley - removal and refitting . . . . . . . . . . . . . . . . . . . . . 6

Cylinder head - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 12

Cylinder head rocker cover - removal and refitting . . . . . . . . . . . . . . 4

Engine oil and filter renewal . . . . . . . . . . . . . . . . . . . . . . .See Chapter 1

Engine oil level check . . . . . . . . . . . . . . . . . . . . . .See

“Weekly Checks”

Engine/transmission mountings - renewal . . . . . . . . . . . . . . . . . . . . 17 Flywheel/driveplate - removal, inspection and refitting . . . . . . . . . . 18

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . 1

Oil pump - dismantling, inspection and reassembly . . . . . . . . . . . . . 15

Oil pump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Sump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Timing belt - removal, refitting and adjustment . . . . . . . . . . . . . . . . 8

Timing belt covers - removal and refitting . . . . . . . . . . . . . . . . . . . . . 7

Timing belt tensioner and sprockets - removal, inspection

and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . 9

Top Dead Centre (TDC) for No 1 piston - locating . . . . . . . . . . . . . . 3

Valve clearances - general information . . . . . . . . . . . . . . . . . . . . . . . 5

2B•1

Specifications Contents

Easy, suitable for

novice with little

experience Fairly easy,

suitable

for beginner with

some experience Fairly difficult,

suitable for competent

DIY mechanic

Difficult,

suitable for

experienced DIY

mechanic Very difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

procarmanuals.com

http://vnx.su

Page 42 of 296

1 General information

How to use this Chapter

This Part of Chapter 2 is devoted to repair

procedures possible while the engine is still

installed in the vehicle, and includes only the

Specifications relevant to those procedures.

Similar information concerning the 1.3 litre

HCS engine, and the 1.6 and 1.8 litre Zetec

engines, will be found in Parts A and C of this

Chapter respectively. Since these procedures

are based on the assumption that the engine

is installed in the vehicle, if the engine has

been removed from the vehicle and mounted

on a stand, some of the preliminary

dismantling steps outlined will not apply.

Information concerning engine/transmission

removal and refitting, and engine overhaul, can

be found in Part D of this Chapter, which also

includes the Specifications relevant to those

procedures.

Engine description

The engine is a four-cylinder, in-line

overhead camshaft type, designated CVH

(Compound Valve angle, Hemispherical

combustion chamber) or PTE (Pent roof, high

Torque, low Emission). The PTE engine was

introduced for 1994 and, apart from

modifications to the cylinder head, camshaft

and intake system, is virtually identical to the

CVH engine it replaces. The engine is

mounted transversely at the front of the

vehicle together with the transmission to form

a combined power unit. The crankshaft is supported in five split-

shell type main bearings within the cast-iron

crankcase. The connecting rod big-end

bearings are split-shell type, and the pistons

are attached by interference-fit gudgeon pins.

Each piston has two compression rings and

one oil control ring.

The cylinder head is of light alloy

construction, and supports the camshaft in five

bearings. Camshaft drive is by a toothed

composite rubber timing belt, which is driven by

a sprocket on the front end of the crankshaft.

The timing belt also drives the water pump,

which is mounted below the cylinder head. Hydraulic cam followers (tappets) operate the

rocker arms and valves. The tappets are

operated by pressurised engine oil. When a

valve closes, the oil passes through a port in the

body of the cam follower, through four grooves

in the plunger and into the cylinder feed

chamber. From the chamber, the oil flows to a

ball-type non-return valve and into the pressure

chamber. The tension of the coil spring causes

the plunger to press against the valve, and so

eliminates any free play. As the cam lifts the

follower, the oil pressure in the pressure

chamber is increased, and the non-return valve

closes off the port feed chamber. This in turn

provides a rigid link between the cam follower,

the cylinder and the plunger. These then rise as a unit to open the valve. The cam follower-to-

cylinder clearance allows the specified quantity

of oil to pass from the pressure chamber, oil only

being allowed past the cylinder bore when the

pressure is high during the moment of the valve

opening. When the valve closes, the escape of

oil will produce a small clearance, and no

pressure will exist in the pressure chamber. The

feed chamber oil then flows through the non-

return valve and into the pressure chamber, so

that the cam follower cylinder can be raised by

the pressure of the coil spring, eliminating free

play until the valve is operated again.

As wear occurs between the rocker arm

and the valve stem, the quantity of oil that

flows into the pressure chamber will be

slightly more than the quantity lost during the

expansion cycle of the cam follower.

Conversely, when the cam follower is

compressed by the expansion of the valve, a

slightly smaller quantity of oil will flow into the

pressure chamber than was lost. A rotor-type oil pump is mounted on the

timing cover end of the engine, and is driven

by a gear on the front end of the crankshaft. A

full-flow type oil filter is fitted, and is mounted

on the side of the crankcase.

Repair operations possible with

the engine in the car

The following work can be carried out with

the engine in the car:

a) Compression pressure - testing.

b) Rocker cover - removal and refitting.

c) Timing belt - removal, refitting and

adjustment.

d) Camshaft oil seal - renewal.

e) Camshaft - removal and refitting.

f) Cylinder head - removal and refitting.

g) Cylinder head and pistons - decarbonising.

h) Crankshaft pulley - removal and refitting.

i) Crankshaft oil seals - renewal.

j) Oil filter renewal.

k) Sump - removal and refitting.

l) Flywheel - removal, inspection and refitting.

m) Mountings - removal and refitting.

Note: It is possible to remove the pistons and

connecting rods (after removing the cylinder

head and sump) without removing the engine.

However, this is not recommended. Work of

this nature is more easily and thoroughly

completed with the engine on the bench, as

described in Chapter 2D.

2 Compression test -

description and interpretation

2

Refer to Section 2 in Part A of this Chap-

ter.

3 Top Dead Centre (TDC) for

No 1 piston - locating

2

1Top dead centre (TDC) is the highest point

of the cylinder that each piston reaches as the

crankshaft turns. Each piston reaches its TDC

position at the end of its compression stroke,

and then again at the end of its exhaust

stroke. For the purpose of engine timing, TDC

on the compression stroke for No 1 piston is

used. No 1 cylinder is at the timing belt end of

the engine. Proceed as follows.

2 Remove the upper timing belt cover as

described in Section 7.

3 Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and Vehicle Support” ).

4 Undo the retaining bolts, and remove the

cover from the underside of the crankshaft

pulley.

5 Fit a spanner onto the crankshaft pulley bolt,

and turn the crankshaft in its normal direction

of rotation (clockwise, viewed from the pulley

end) to the point where the crankshaft pulley

timing notch is aligned with the TDC (0) timing

mark on the timing belt cover.

6 Although the crankshaft is now in top dead

centre alignment, with piston Nos 1 and 4 at

the top of their stroke, the No 1 piston may

not be on its compression stroke. To confirm

that it is, check that the timing pointer on the

camshaft sprocket is exactly aligned with the

TDC mark on the front face of the cylinder

head (see illustrations) . If the pointer is not

aligned, turn the crankshaft pulley one further

CVH and PTE engine in-car repair procedures 2B•3

3.6b Camshaft sprocket timing mark

aligned with the TDC mark on the front

face of the cylinder head3.6a Crankshaft pulley notch (arrowed)aligned with the TDC (0) mark on the

timing belt cover

2B

1595Ford Fiesta Remake

Turning the engine will be

easier if the spark plugs are

removed first - see Chapter 1.

procarmanuals.com

http://vnx.su

Page 54 of 296

2C

1595Ford Fiesta Remake

General

Engine type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . Four-cylinder, in-line, double overhead camshafts

Engine code:1.6 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . L1G

1.8 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . RDB or RQC

Capacity:

1.6 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . 1597 cc

1.8 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . 1796 cc

Bore:

1.6 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . 76.0 mm

1.8 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . 80.6 mm

Stroke - all models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . 88.0 mm

Compression ratio: 1.6 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . 10.3:1

1.8 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . 10.0:1

Firing order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . 1-3-4-2 (No 1 cylinder at timing belt end)

Direction of crankshaft rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Clockwise (seen from right-hand side of vehicle)

Cylinder head

Hydraulic tappet bore inside diameter . . . . . . . . . . . . . . . . . . . . . . . . . . 28.395 to 28.425 mm

Camshafts and hydraulic tappets

Camshaft bearing journal diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25.960 to 25.980 mm

Camshaft bearing journal-to-cylinder head running clearance . . . . . . . 0.020 to 0.070 mm

Camshaft endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . 0.080 to 0.220 mm

Lubrication

Engine oil type/specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See “Lubricants, fluids and tyre pressures”

Engine oil capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . See “Lubricants, fluids and tyre pressures”

Oil pressure: Idling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . 1.3 to 2.5 bar

At 4000 rpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . 3.7 to 5.5 bars

Oil pump clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . Not specified

Chapter 2 Part C:

Zetec engine in-car repair procedures

Auxiliary drivebelt check and renewal . . . . . . . . . . . . . . .See Chapter 1

Camshaft oil seals - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Camshafts and hydraulic tappets - removal, inspection and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . 11

Compression test - description and interpretation . . . . . . . . . . . . . . 2

Crankshaft oil seals - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Crankshaft pulley - removal and refitting . . . . . . . . . . . . . . . . . . . . . 6

Cylinder head - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 12

Cylinder head cover - removal and refitting . . . . . . . . . . . . . . . . . . . 4

Engine oil and filter renewal . . . . . . . . . . . . . . . . . . . . . . .See Chapter 1

Engine oil level check . . . . . . . . . . . . . . . . . . . . . . . . . “Weekly Checks”Engine/transmission mountings - inspection and renewal . . . . . . . . 16

Flywheel/driveplate - removal, inspection and refitting . . . . . . . . . . 17

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . 1

Oil pump - removal, inspection and refitting . . . . . . . . . . . . . . . . . . . 14

Sump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Timing belt - removal, refitting and adjustment . . . . . . . . . . . . . . . . 8

Timing belt covers - removal and refitting . . . . . . . . . . . . . . . . . . . . . 7

Timing belt tensioner and sprockets - removal, inspection

and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . 9

Top Dead Centre (TDC) for No 1 piston - locating . . . . . . . . . . . . . . 3

Valve clearances - general information . . . . . . . . . . . . . . . . . . . . . . . 5

2C•1

Specifications Contents

Easy, suitable for

novice with little

experience Fairly easy,

suitable

for beginner with

some experience Fairly difficult,

suitable for competent

DIY mechanic

Difficult,

suitable for

experienced DIY

mechanic Very difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

procarmanuals.com

http://vnx.su

Page 56 of 296

fitted with three piston rings: two

compression rings and an oil control ring.

After manufacture, the cylinder bores and

piston skirts are measured and classified into

three grades, which must be carefully

matched together, to ensure the correct

piston/cylinder clearance; no oversizes are

available to permit reboring.The inlet and exhaust valves are each

closed by coil springs; they operate in guides

which are shrink-fitted into the cylinder head,

as are the valve seat inserts. Both camshafts are driven by the same

toothed timing belt, each operating eight

valves via self-adjusting hydraulic tappets,

thus eliminating the need for routine checking

and adjustment of the valve clearances. Each

camshaft rotates in five bearings that are line-

bored directly in the cylinder head and the

(bolted-on) bearing caps; this means that the

bearing caps are not available separately from

the cylinder head, and must not be

interchanged with caps from another engine. The water pump is bolted to the right-hand

end of the cylinder block, inboard of the

timing belt, and is driven with the power

steering pump and alternator by a flat

“polyvee”-type auxiliary drivebelt from the

crankshaft pulley.

When working on this engine, note that

Torx-type (both male and female heads) and

hexagon socket (Allen head) fasteners are

widely used; a good selection of bits, with the

necessary adapters, will be required, so that

these can be unscrewed without damage and,

on reassembly, tightened to the torque

wrench settings specified. Lubrication is by means of an eccentric-

rotor trochoidal pump, which is mounted on

the crankshaft right-hand end, and draws oil

through a strainer located in the sump. The

pump forces oil through an externally-

mounted full-flow cartridge-type filter - on

some versions of the engine, an oil cooler is

fitted to the oil filter mounting, so that clean oil

entering the engine’s galleries is cooled by the

main engine cooling system.

Repair operations possible with

the engine in the car

The following work can be carried out with

the engine in the car:

a) Compression pressure - testing.

b) Cylinder head cover - removal and

refitting.

c) Timing belt covers - removal and refitting.

d) Timing belt - renewal.

e) Timing belt tensioner and sprockets - removal and refitting.

f) Camshaft oil seals - renewal.

g) Camshafts and hydraulic tappets - removal and refitting.

h) Cylinder head - removal and refitting.

i) Cylinder head and pistons - decarbonising.

j) Sump - removal and refitting.

k) Crankshaft oil seals - renewal.

l) Oil pump - removal and refitting. m)

Flywheel/driveplate - removal and

refitting.

n) Engine/transmission mountings - removal and refitting.

Note: It is possible to remove the pistons and

connecting rods (after removing the cylinder

head and sump) without removing the engine.

However, this is not recommended. Work of

this nature is more easily and thoroughly

completed with the engine on the bench, as

described in Chapter 2D.

2 Compression test -

description and interpretation

2

Refer to Section 2 in Part A of this Chapter.

3 Top Dead Centre (TDC) for No 1 piston - locating

2

1Top dead centre (TDC) is the highest point

of the cylinder that each piston reaches as the

crankshaft turns. Each piston reaches its TDC

position at the end of its compression stroke,

and then again at the end of its exhaust

stroke. For the purpose of engine timing, TDC

on the compression stroke for No 1 piston is

used. No 1 cylinder is at the timing belt end of

the engine. Proceed as follows.

2 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

3 Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and Vehicle Support” ). Remove

the right-hand roadwheel.

4 Remove the auxiliary drivebelt cover (see

Chapter 1) to expose the crankshaft pulley

and timing marks.

5 Fit a spanner onto the crankshaft pulley

bolt, and turn the crankshaft in its normal

direction of rotation (clockwise, viewed from

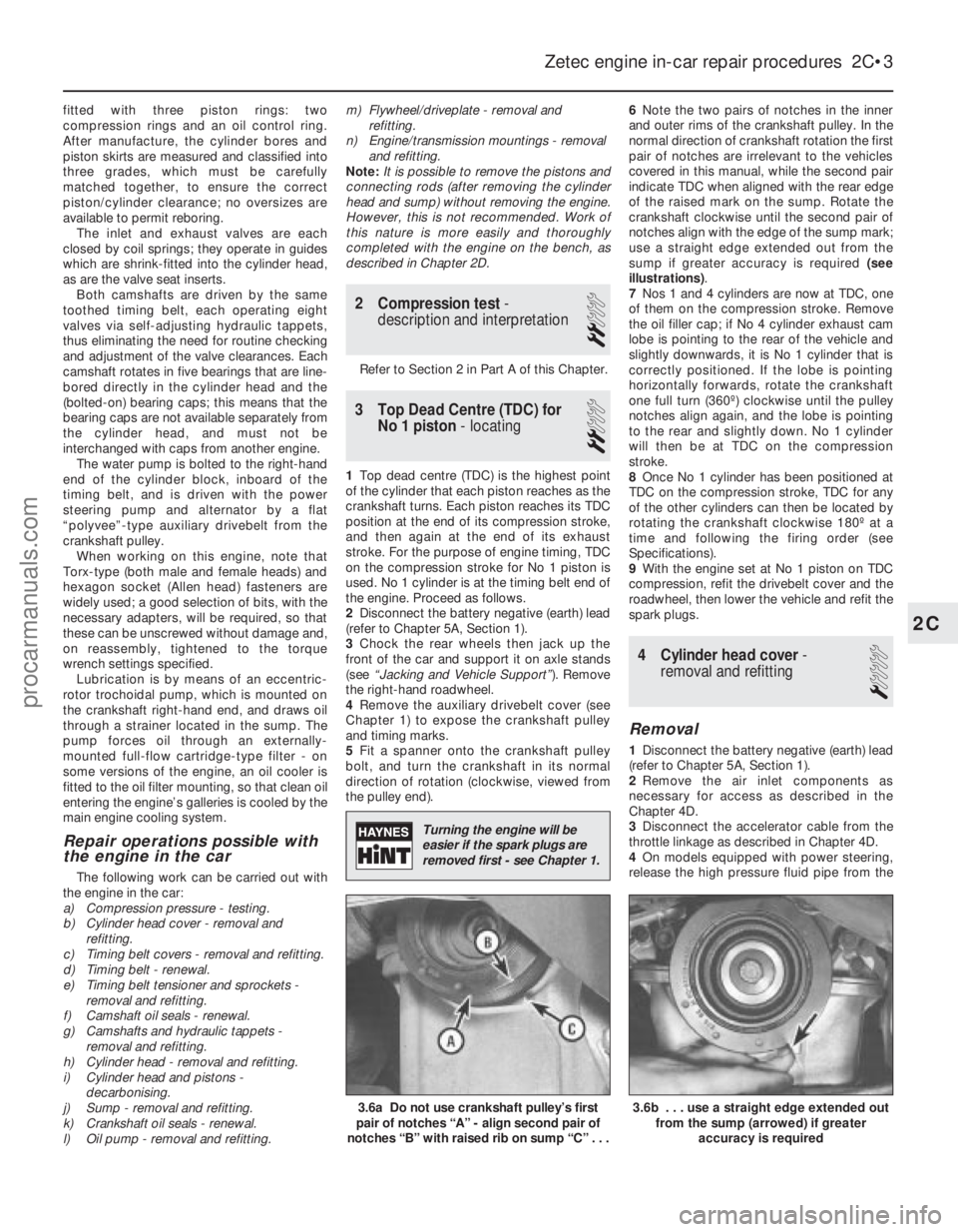

the pulley end). 6

Note the two pairs of notches in the inner

and outer rims of the crankshaft pulley. In the

normal direction of crankshaft rotation the first

pair of notches are irrelevant to the vehicles

covered in this manual, while the second pair

indicate TDC when aligned with the rear edge

of the raised mark on the sump. Rotate the

crankshaft clockwise until the second pair of

notches align with the edge of the sump mark;

use a straight edge extended out from the

sump if greater accuracy is required (see

illustrations) .

7 Nos 1 and 4 cylinders are now at TDC, one

of them on the compression stroke. Remove

the oil filler cap; if No 4 cylinder exhaust cam

lobe is pointing to the rear of the vehicle and

slightly downwards, it is No 1 cylinder that is

correctly positioned. If the lobe is pointing

horizontally forwards, rotate the crankshaft

one full turn (360º) clockwise until the pulley

notches align again, and the lobe is pointing

to the rear and slightly down. No 1 cylinder

will then be at TDC on the compression

stroke.

8 Once No 1 cylinder has been positioned at

TDC on the compression stroke, TDC for any

of the other cylinders can then be located by

rotating the crankshaft clockwise 180º at a

time and following the firing order (see

Specifications).

9 With the engine set at No 1 piston on TDC

compression, refit the drivebelt cover and the

roadwheel, then lower the vehicle and refit the

spark plugs.

4 Cylinder head cover -

removal and refitting

1

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Remove the air inlet components as

necessary for access as described in the

Chapter 4D.

3 Disconnect the accelerator cable from the

throttle linkage as described in Chapter 4D.

4 On models equipped with power steering,

release the high pressure fluid pipe from the

Zetec engine in-car repair procedures 2C•3

3.6b . . . use a straight edge extended out from the sump (arrowed) if greater

accuracy is required3.6a Do not use crankshaft pulley’s first

pair of notches “A” - align second pair of

notches “B” with raised rib on sump “C” . . .

2C

1595Ford Fiesta Remake

Turning the engine will be

easier if the spark plugs are

removed first - see Chapter 1.

procarmanuals.com

http://vnx.su