height adjustment FORD FIESTA 1989 Service Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1989, Model line: FIESTA, Model: FORD FIESTA 1989Pages: 296, PDF Size: 10.65 MB

Page 194 of 296

10

1595Ford Fiesta Remake

Wheel alignment and steering angles

Front wheel toe setting:Pre-1990 models: Tolerance allowed before resetting required . . . . . . . . . . . . . . . . . 3.0 mm toe-out to 3.0 mm toe-in (0°30’ toe-out to 0°30’ toe-in)

Adjustment setting (if required) . . . . . . . . . . . . . . . . . . . . . . . . . . . . Parallel ± 1.0 mm (0° ± 0°10’)

1990 models onward: All models except Turbo:

Tolerance allowed before resetting required . . . . . . . . . . . . . . \

. . 4.5 mm toe-out to 0.5 mm toe-in (0°45’ toe-out to 0°05’ toe-in)

Adjustment setting (if required) . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 mm toe-out ± 1.0 mm (0°20’ toe-out ± 0°10’)

Turbo models:

Tolerance allowed before resetting required . . . . . . . . . . . . . . \

. . 4.0 mm toe-out to parallel (0°40’ toe-out to 0°0’)

Adjustment setting (if required) . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 mm toe-out ± 1.0 mm (0°20’ toe-out ± 0°10’)

Chapter 10

Suspension and steering

Auxiliary drivebelt check and renewal . . . . . . . . . . . . . . .See Chapter 1

Front hub bearings - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Front spindle carrier - removal and refitting . . . . . . . . . . . . . . . . . . . 2

Front suspension anti-roll bar - removal and refitting . . . . . . . . . . . . 6

Front suspension crossmember - removal and refitting . . . . . . . . . . 7

Front suspension lower arm - removal and refitting . . . . . . . . . . . . . 8

Front suspension strut - dismantling, examination and reassembly . . 5

Front suspension strut - removal and refitting . . . . . . . . . . . . . . . . . 4

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . 1

Power steering fluid cooler - removal and refitting . . . . . . . . . . . . . . 26

Power steering fluid level check . . . . . . . . . . . . .See

“Weekly Checks”

Power steering hydraulic system - bleeding . . . . . . . . . . . . . . . . . . . 27

Power steering pump - removal and refitting . . . . . . . . . . . . . . . . . . 25

Rear axle (all models except Courier) - removal and refitting . . . . . . 12

Rear axle pivot bushes (all models except Courier) - renewal . . . . . 13

Rear hub bearings - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Rear shock absorber (Courier models) - removal, examination and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . 16 Rear strut (all models except Courier) - dismantling, examination

and reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . 11

Rear strut (all models except Courier) - removal and refitting . . . . . 10

Rear suspension anti-roll bar (all models except Courier) - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Rear suspension assembly (Courier models) - removal and refitting . . 17

Rear suspension components (Courier models) - general . . . . . . . . 15

Rear suspension ride height (Courier models) - adjustment . . . . . . . 18

Steering column (manual steering) - removal and refitting . . . . . . . . 20

Steering column (power steering) - removal and refitting . . . . . . . . . 21

Steering gear (manual steering) - removal and refitting . . . . . . . . . . 23

Steering gear (power steering) - removal and refitting . . . . . . . . . . . 24

Steering gear rubber gaiters - renewal . . . . . . . . . . . . . . . . . . . . . . . 22

Steering wheel - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . 19

Suspension and steering check . . . . . . . . . . . . . . . . . . .See Chapter 1

Track rod end balljoint - removal and refitting . . . . . . . . . . . . . . . . . 28

Tyre condition and pressure checks . . . . . . . . . .See “Weekly Checks”

Wheel alignment and steering angles - general information . . . . . . . 29

10•1

Specifications Contents

Easy, suitable for

novice with little

experience Fairly easy,

suitable

for beginner with

some experience Fairly difficult,

suitable for competent

DIY mechanic

Difficult,

suitable for

experienced DIY

mechanic Very difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

procarmanuals.com

http://vnx.su

Page 205 of 296

mountings for signs of wear. Test the

operation of the unit, holding it in an upright

position, by moving the piston through a full

stroke, and then through short strokes of 50

to 100 mm. In both cases, the resistance felt

should be smooth and continuous. If the

resistance is jerky, or uneven, or if there is any

visible sign of wear or damage, the shock

absorber should be renewed. Note that if

either unit is to be renewed, it is good practice

to renew both together as a matched pair.

Refitting

4Locate the unit in position and refit the

mounting bolts and nut. Do not fully tighten

the mountings at this stage.

5 Lower the vehicle to the ground and rock it

to settle the suspension. Raise the vehicle

again, as necessary, until the shock absorber

is at an angle of 50° ± 5° to the horizontal.

With the shock absorber in this position,

tighten the upper and lower mountings to the

specified torque.

17 Rear suspension assembly (Courier models) -

removal and refitting

3

Removal

1 Chock the front wheels then jack up the

rear of the car and support it on axle stands

(see “Jacking and Vehicle Support” ). Remove

the rear roadwheels.

2 Refer to Chapter 9 for details, and

disconnect the handbrake cable equaliser

from the primary cable. Remove the

handbrake rear cable from its adjuster and its

fixed body locations. Release the exhaust

system mountings as necessary to allow the

handbrake cable to be withdrawn over the

rear of the exhaust.

3 Disconnect the rear brake flexible hydraulic

brake hoses from their rigid line connections

(see illustration) . Clamp the hoses before

disconnecting them, to minimise the fluid loss

and air entry into the hydraulic system (see

Chapter 9 for details).

4 Detach the light-laden valve linkage from

the bracket on the suspension assembly. 5

Locate suitable jacks under the suspension

assembly to support its weight (not to lift it).

6 Unscrew the shock absorber lower

mounting bolts on each side.

7 Unscrew the two mounting bracket bolts

each side (see illustration) , check that all

associated fittings are clear, then lower the

suspension assembly and remove it from

under the vehicle.

Refitting

8 Refitting is a reversal of the removal

procedure, but note the following: a) Refit the front mounting brackets first,

and tighten the retaining bolts to the

specified torque.

b) Reconnect the shock absorber lower

mountings, but do not fully retighten the

securing bolts until after the vehicle is

lowered to the ground and is standing on

its wheels.

c) Ensure that all brake fluid line connections are clean before reconnecting them. Refer

to the appropriate Sections in Chapter 9

for specific details on reconnecting the

brake lines, bleeding the brake hydraulic

system, adjusting the light laden valve,

and reconnecting and adjusting the

handbrake cable.

d) Once the vehicle is standing on its

wheels, raise it again, as necessary, until

the shock absorbers are at an angle of

50° ± 5° to the horizontal. With the shock

absorbers in this position, tighten the

lower mountings to the specified torque.

18 Rear suspension ride height (Courier models) - adjustment

4

Checking of the ride height requires the use

of Ford special tools to accurately compress

the suspension to a pre-determined value.

Further special tools are then required to

reposition the torsion bars to the new setting.

This operation should be entrusted to a

Ford dealer, as it is not possible to carry out

the procedure accurately without the use

of the appropriate tools.

19 Steering wheel -

removal and refitting

2

Removal

Models without air bag

1 Drive the vehicle in a straight line onto a

level surface, so that the roadwheels are

pointing straight ahead.

2 Carefully prise the motif from the centre of

the steering wheel (see illustration).

3 Mark the relative positions of the steering

wheel and steering column shaft.

4 Unscrew the retaining bolt from the centre

of the steering wheel, then insert the ignition

key and turn it to position “I”. Grip the wheel

each side, then pull and withdraw it from the

column shaft.

Models with air bag

Warning: Handle the air bag with

extreme care as a precaution

against personal injury, and

always hold it with the cover

facing away from your body. If in doubt

concerning any proposed work involving

the air bag or its control circuitry, consult a

Ford dealer or other qualified specialist.

5 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

Warning: Before proceeding,

wait a minimum of 15 minutes,

as a precaution against

accidental firing of the air bag.

This period ensures that any stored energy

in the back-up capacitor is dissipated.

6 Undo the screws, and remove the steering

column lower shroud.

7 Undo the two external screws and the two

internal screws and remove the steering

column upper shroud.

10•12 Suspension and steering

19.2 Removing the motif from the steering wheel17.7 Courier rear suspension pivot

brackets locate on dowels in underbody17.3 Brake hose and rigid pipe connection on Courier rear suspension assembly

1595Ford Fiesta Remake

If the wheel is tight, tap it up

near the centre, using the

palm of your hand, or twist it

from side to side, whilst

pulling upwards to release it from the

shaft splines.

procarmanuals.com

http://vnx.su

Page 216 of 296

4Pull the latch end of the cable into the

engine compartment, noting cable routing and

clips fitted. Remove the cable from its clips.

5 Detach the cable from its release lever on

the steering column, by aligning the cable

core with the slot on the release lever and

withdrawing the end fixing. Detach the cable

from its outer core abutment on the steering

column lock housing.

6 Unclip the cable from its pedal box

location, then detach the bulkhead grommet

and pass the cable through into the engine

compartment. Withdraw the cable from the

vehicle.

7 The release lever on the steering column

may be removed, if required, by unhooking

the spring from its retaining arms, then

disengaging its retaining arms from the

steering column lock housing.

Refitting

8 Refit the release lever, if removed, by

reversing the method of removal.

9 To install the release cable, first pass the

latch end of the cable down the right-hand

side of the steering column, through its

bulkhead location, and out into the engine

compartment.

10 Fit the cable to its clip on the pedal box

assembly, then reconnect the cable to the

release lever and the steering column lock

housing abutment by reversing the method of

removal.

11 Where applicable, refit the choke warning

light switch/pull control assembly, to the lower steering column shroud, by reversing the

method of removal. Refit the shroud.

12

Seat the release cable grommet into the

bulkhead.

13 Route and secure the release cable in the

engine compartment.

14 Reconnect the release cable to the latch,

then refit the latch to the body, setting the

latch at its maximum height position, and

tightening only the bottom retaining screw.

15 Adjust the latch for flush bonnet closure in

accordance with Section 8.

8 Bonnet latch - adjustment

1

1To adjust the bonnet latch, remove the two

upper latch retaining screws, then with the

latch raised to its maximum height position

and secured with the lower retaining screw,

close the bonnet.

2 Slacken the lower latch retaining screw,

through the gap between the leading edge of

the bonnet and the radiator grille slot, then

set the bonnet so it sits flush with its

surrounding panels - it may be necessary to

adjust the height of the bump stops (see

Section 6) if they have been moved in any

way, or if fitting a new bonnet.

3 With the desired bonnet closure obtained,

fully tighten the lower latch retaining screw,

then open the bonnet and refit the two upper

latch retaining screws, tightening to the

specified torque.

9 Body adhesive emblems -

renewal

1

1 Using a length of strong thin diameter cord

(fishing line is ideal), break the adhesive bond

between the emblem and the panel.

2 Thoroughly clean all traces of the old

adhesive from the emblem location, using

methylated spirit, taking all normal safety

precautions. Allow the emblem location to

dry.

3 Gently heat the new emblem until it is warm

to the touch. 4

Peel the protective backing paper from the

emblem then, taking care not to touch the

adhesive, position the emblem on the panel.

Maintain hand pressure evenly for at least

thirty seconds to ensure a good bond.

10 Body trim mouldings -

removal and refitting

1

Roof drip rail moulding (all

models except Courier)

Removal

1 Remove the drip rail moulding by gently

raising the forward end from its retaining

flange, taking care not to bend or kink it, then

carefully pull it off the retaining flange (see

illustration) .

Refitting

2To refit the drip rail moulding, first align the

rear of the moulding to the roof panel edge by

the tailgate, then, using the flat palm of the

hand, gently tap the moulding down.

3 If fitting the Ford roof rack, the drip rail

mouldings on both sides must be removed

and replaced by a ten-piece moulding kit,

available from Ford dealerships.

Roof drip rail moulding (Courier

models)

Removal

4 These are released by lifting and gripping

the moulding’s inboard edge, then by

rotating the whole length of the moulding

towards the outside of the vehicle to release it

from its outboard lip.

Refitting

5 Refitting is the reverse of the removal

procedure; ensure that the moulding’s

outboard edge is seated securely in its lip

before pressing the inboard edge firmly into

place.

Door side moulding

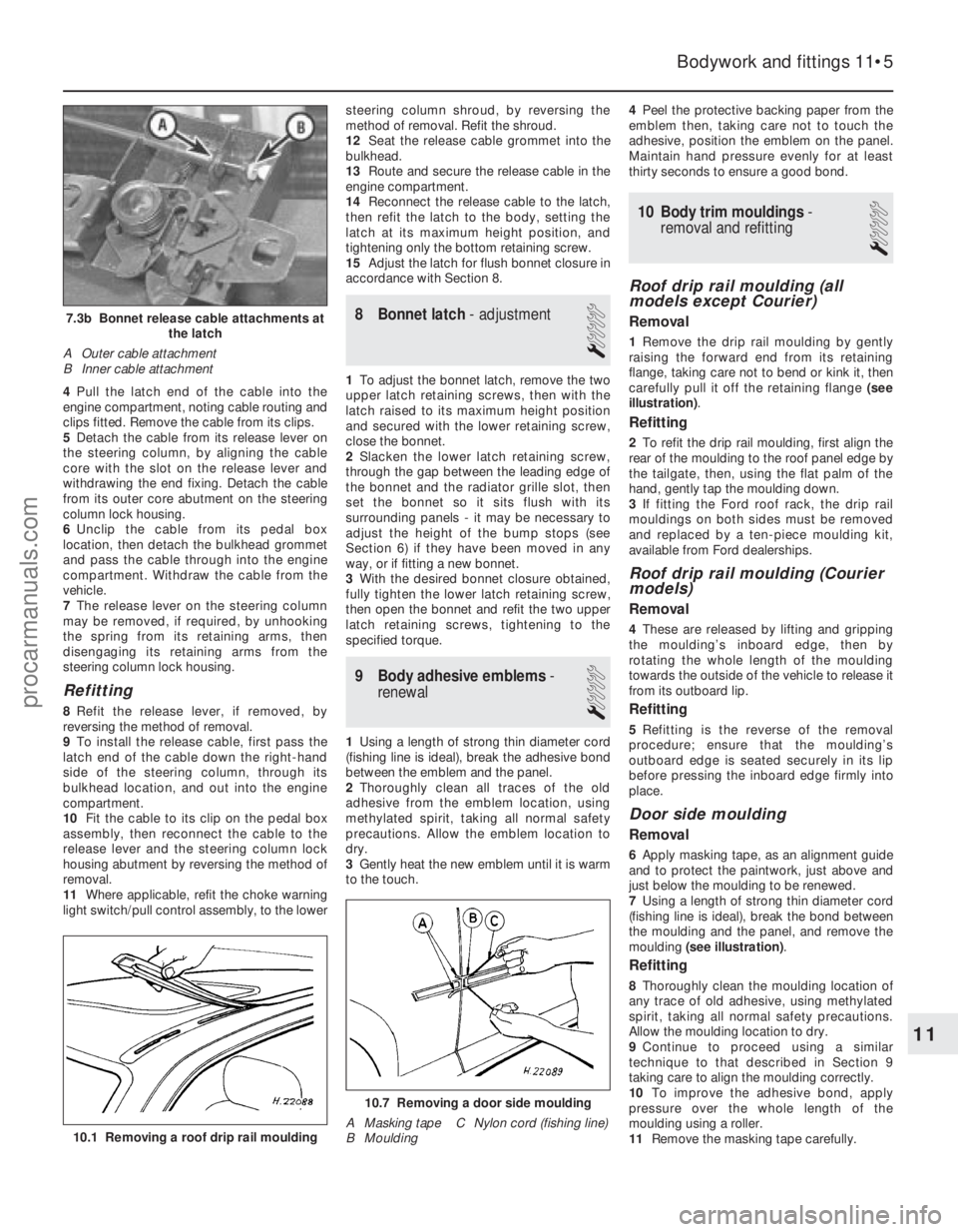

Removal

6 Apply masking tape, as an alignment guide

and to protect the paintwork, just above and

just below the moulding to be renewed.

7 Using a length of strong thin diameter cord

(fishing line is ideal), break the bond between

the moulding and the panel, and remove the

moulding (see illustration) .

Refitting

8Thoroughly clean the moulding location of

any trace of old adhesive, using methylated

spirit, taking all normal safety precautions.

Allow the moulding location to dry.

9 Continue to proceed using a similar

technique to that described in Section 9

taking care to align the moulding correctly.

10 To improve the adhesive bond, apply

pressure over the whole length of the

moulding using a roller.

11 Remove the masking tape carefully.

Bodywork and fittings 11•5

7.3b Bonnet release cable attachments at

the latch

A Outer cable attachment

B Inner cable attachment

10.7 Removing a door side moulding

A Masking tape C Nylon cord (fishing line)

B Moulding

10.1 Removing a roof drip rail moulding

11

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su