lock FORD FIESTA 2007 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 483 of 1226

Engine - 1.25L Duratec-1 6V (Sigma)ll.4L

Duratec-1 6V (Sigma)Il.GL Duratec-1 6V (Sigma)

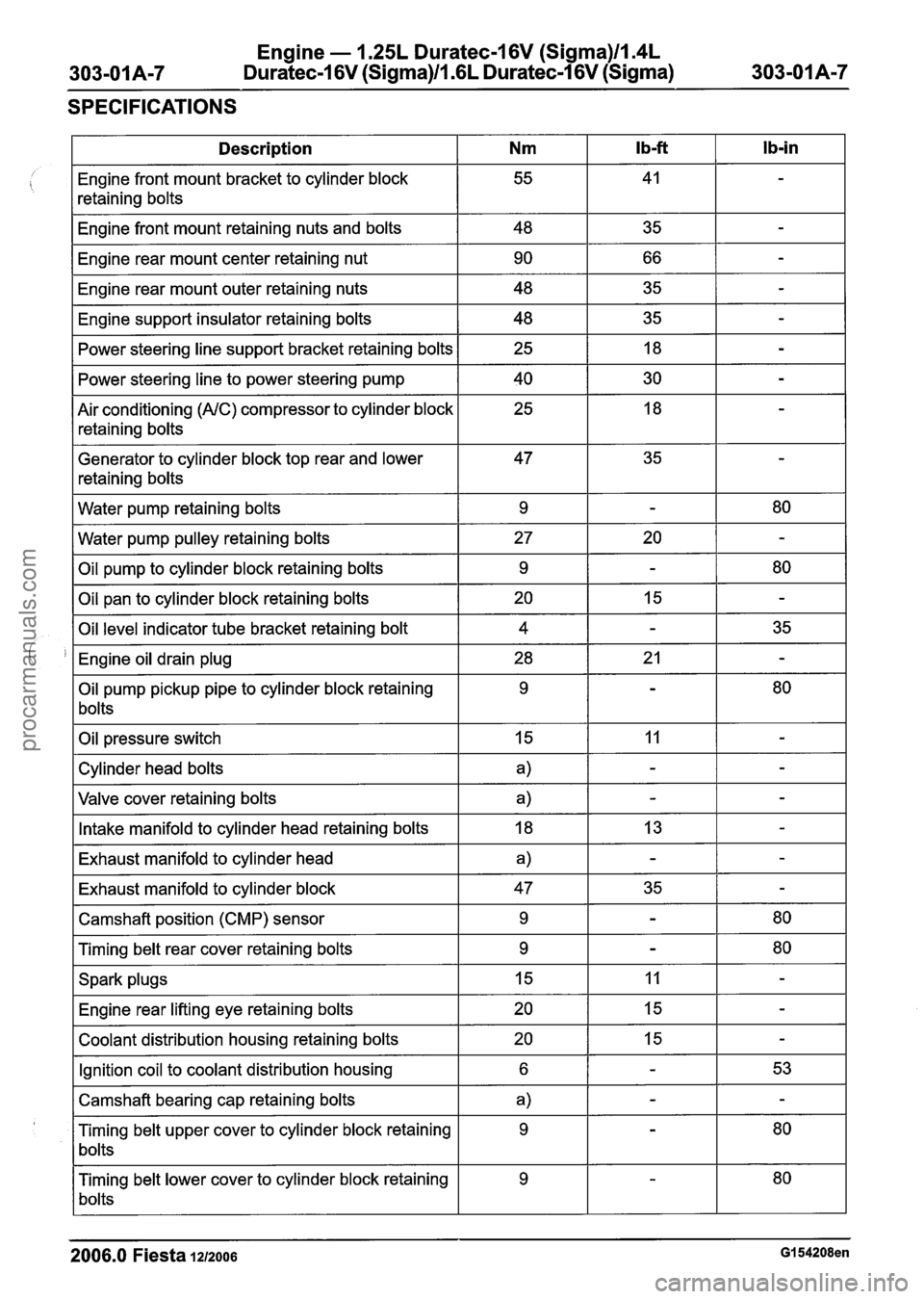

SPECIFICATIONS

2006.0 Fiesta 1212006 GI 54208en

Ib-in

-

-

-

-

-

-

-

-

-

80

-

80

-

35

-

80

-

-

-

-

-

-

80

80

-

-

-

53

-

80

80

Ib-ft

41

35

66

35 35 18

30

18

35

-

20

-

15

-

21

-

11

-

-

13

-

35

-

-

11

15

15

-

-

-

-

Description

Engine front mount bracket to cylinder block

retaining bolts

Engine front mount retaining nuts and bolts

Engine rear mount center retaining nut

Engine rear mount outer retaining nuts

Engine support insulator retaining bolts Power steering line support bracket retaining bolts

Power steering line to power steering pump

Air conditioning

(AIC) compressor to cylinder block

retaining bolts

Generator to cylinder block top rear and lower

retaining bolts

Water pump retaining bolts

Water pump pulley retaining bolts

Oil pump to cylinder block retaining bolts

Oil pan to cylinder block retaining bolts

Oil level indicator tube bracket retaining bolt

Engine oil drain plug

Oil pump pickup pipe to cylinder block retaining

bolts

Oil pressure switch

Cylinder head bolts

Valve cover retaining bolts

Intake manifold to cylinder head retaining bolts

Exhaust manifold to cylinder head

Exhaust manifold to cylinder block

Camshaft position (CMP) sensor

Timing belt rear cover retaining bolts

Spark plugs Engine rear lifting eye retaining bolts

Coolant distribution housing retaining bolts

Ignition coil to coolant distribution housing

Camshaft bearing cap retaining bolts

Timing belt upper cover to cylinder block retaining

bolts

Timing belt lower cover to cylinder block retaining

bolts

Nm

55

48 90

48

48 25

40 25

47

9

27 9

20 4

28 9

15

a)

a)

18

a)

47 9

9

15

20

20

6

a)

9

9

procarmanuals.com

Page 484 of 1226

Engine - I .25L Duratec-1 6V (Sigma)llI4L

Duratec-1 6V (Sigma)ll .6L Duratec-I 6V (Sigma)

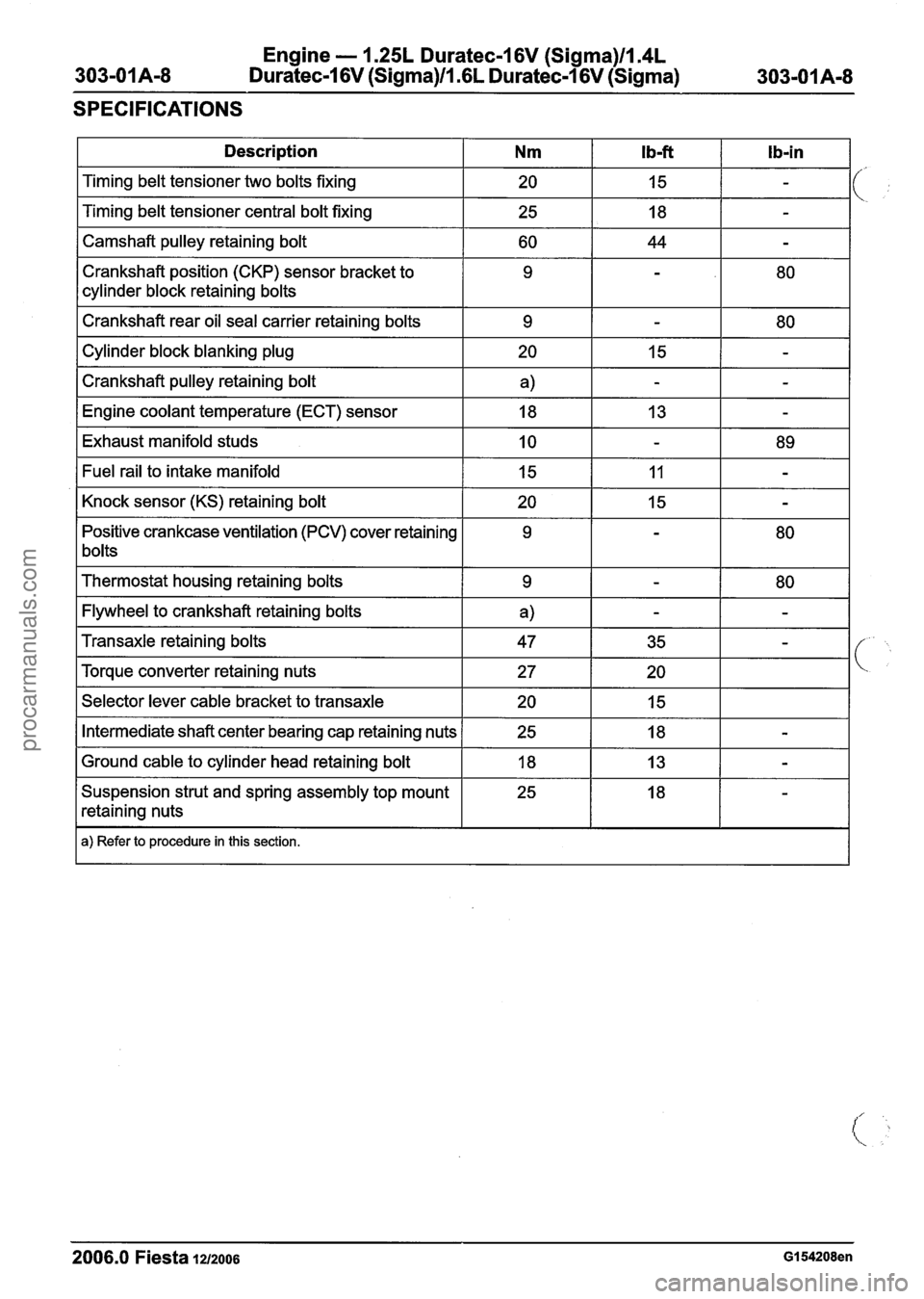

SPECIFICATIONS

1 Description I Nm I Ib-ft I Ib-in I

I Camshaft pulley retaining bolt I 60 I 44 I - I

Timing belt tensioner two bolts fixing

Timing belt tensioner central bolt fixing

Crankshaft position (CKP) sensor bracket to

cylinder block retaining bolts

I Crankshaft rear oil seal carrier retaining bolts I 9 1 - I 80 I

20

25

I Cylinder block blanking plug I 20 I 15 1 - I

I Crankshaft pulley retaining bolt I a) I - I - I

15

18

I Engine coolant temperature (ECT) sensor I 18 I 13 I - I

-

-

I Exhaust manifold studs I 10 I - I 89 I

Positive crankcase ventilation (PCV) cover retaining

1 bolts Fuel

rail to intake manifold

Knock sensor (KS) retaining bolt

I Thermostat housing retaining bolts I 9 I - 1 80 I

I Flywheel to crankshaft retaining bolts I a) I - I - I

15

20

I Selector lever cable bracket to transaxle I 20 I 15 I I

11

15

Transaxle retaining bolts

Torque converter retaining nuts

I Intermediate shaft center bearing cap retaining nuts 1 25 I 18 I - I

-

-

I Ground cable to cylinder head retaining bolt I 18 I 13 I - I

47

27

Suspension strut and spring assembly top mount

retaining nuts

I a) Refer to procedure in this section.

35

20

2006.0 Fiesta 1212006 GI 54208en

-

procarmanuals.com

Page 486 of 1226

303-01 A-I 0

Engine - I .25L Duratec-1 6V (Sigma)ll.4L

Duratec-1 6V (Sigma)/l .6L Duratec-1 6V (Sigma)

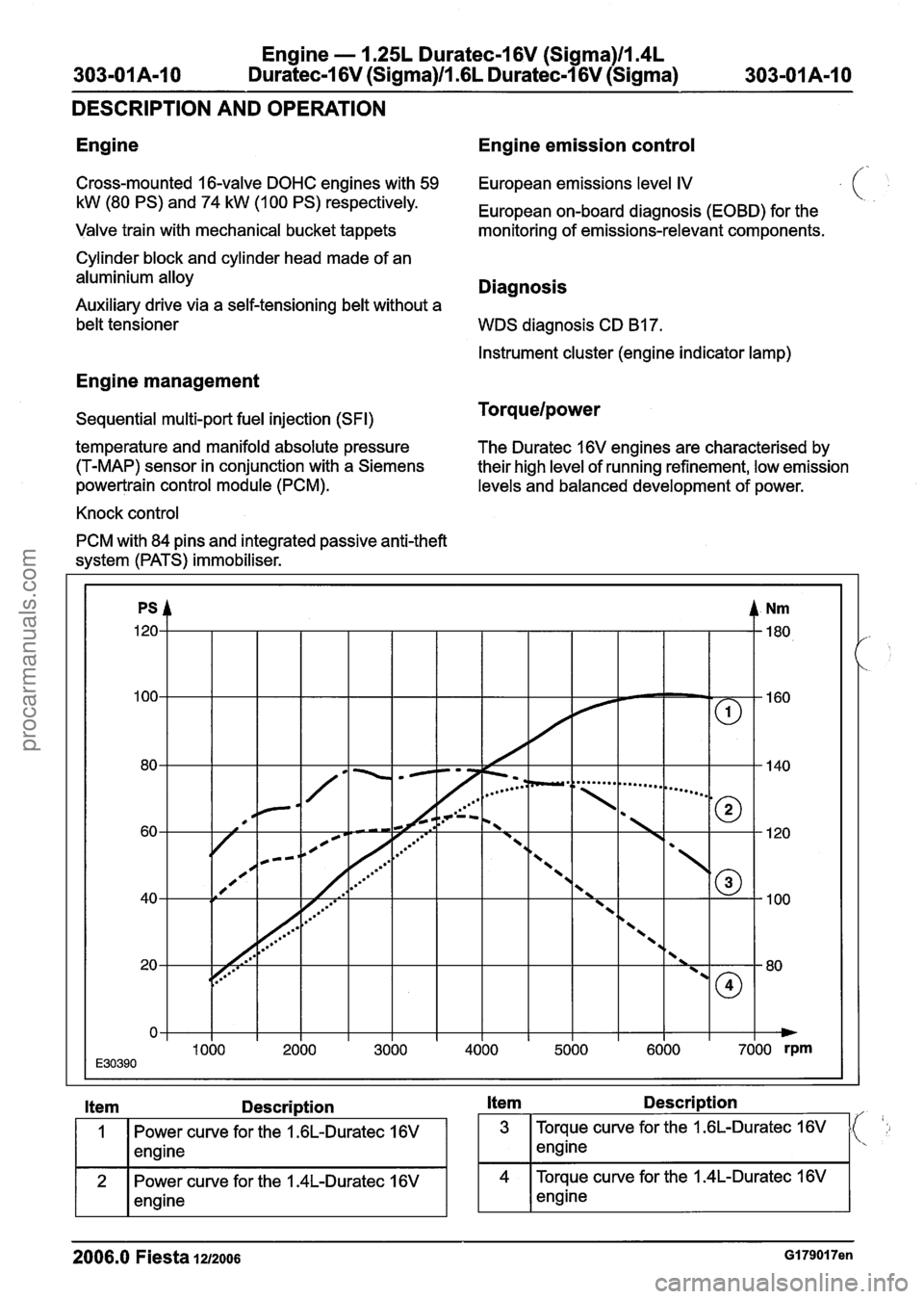

DESCRIPTION AND OPERATION

Engine Engine emission control

Cross-mounted 16-valve DOHC engines with 59 European emissions level IV

kW (80 PS) and 74 kW (1 00 PS) respectively.

European on-board diagnosis (EOBD) for the

Valve train with mechanical bucket tappets monitoring of emissions-relevant components.

Cylinder block and cylinder head made of an

aluminium alloy

Diagnosis

Auxiliary drive via a self-tensioning belt without a

belt tensioner WDS diagnosis CD

817.

Instrument cluster (engine indicator lamp)

Engine management

Sequential multi-port fuel injection (SFI)

temperature and manifold absolute pressure (T-MAP) sensor in conjunction with a Siemens

powertrain control module (PCM).

Knock control

PCM with 84 pins and integrated passive anti-theft

system (PATS) immobiliser. Torquelpower

The Duratec 16V engines are characterised by

their high level of running refinement, low emission

levels and balanced development of power.

Description Description

Power curve for the 1.6L-Duratec 16V 3 Torque curve for the 1.6L-Duratec 16V ( ',I

Power curve for the 1.4L-Duratec 16V 4

Torque

curve for the 1.4L-Duratec 16V

2006.0 Fiesta 1212006 GI 7901 7en

procarmanuals.com

Page 513 of 1226

Engine - 1.25L Duratec-1 6V (Sigma)lIl4L

303-01 A-37 Duratec-1 6V (Sigma)ll.GL Duratec-1 6V (Sigma) 303-01A-37

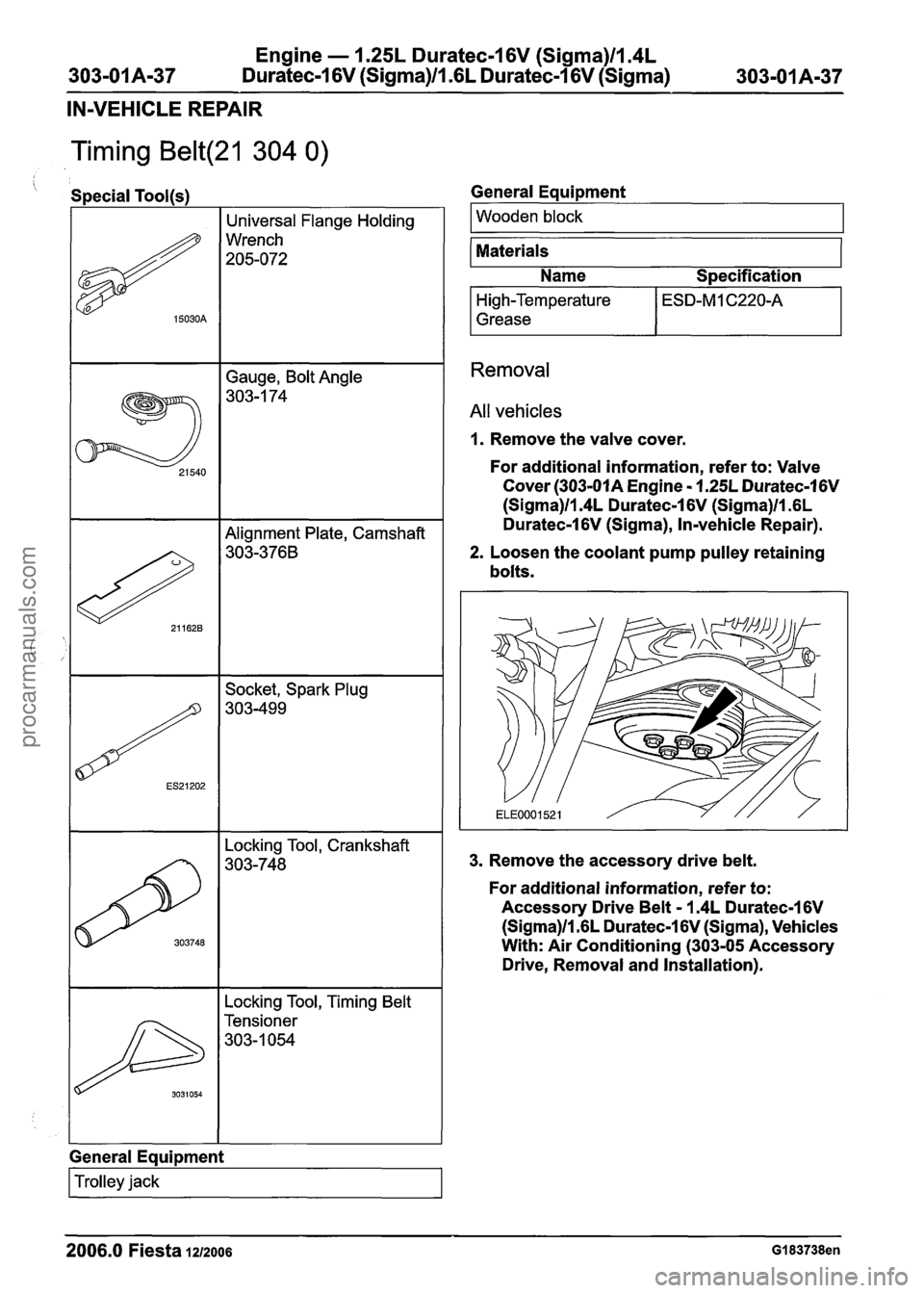

IN-VEHICLE REPAIR

Timing Belt(21 304 0)

Gauge, Bolt Angle

303-1 74

' Special Tool(s)

# 15030A

Locking Tool, Timing Belt

I Tensioner

303-1054

Universal Flange Holding

Wrench

205-072

303748

General Equipment

Locking Tool, Crankshaft

303-748

I Trolley jack I

General Eaui~ment

I Wooden block I - --

Materials

Name

S~ecification

High-Temperature

Grease

Removal

All vehicles

1. Remove the valve cover.

For additional information, refer to: Valve

Cover

(303-01A Engine - 1.25L Duratec-1 6V

(Sigma)ll.4L Duratec-1 6V (Sigma)ll .6L

Duratec-1

6V (Sigma), In-vehicle Repair).

2. Loosen the coolant pump pulley retaining

bolts.

3. Remove the accessory drive belt.

For additional information, refer to:

Accessory Drive Belt

- 1.4L Duratec-I 6V

(Sigma)/l.GL Duratec-1 6V (Sigma), Vehicles

With: Air Conditioning (303-05 Accessory

Drive, Removal and Installation).

2006.0 Fiesta 1212006 GI 83738en

procarmanuals.com

Page 515 of 1226

Engine - 1.25L Duratec-1 6V (Sigma)ll.4L

303-01 A-39 Duratec-1 6V (Sigma)/l .6L

Duratec-1 6V (Sigma)

303-01 A-39

IN-VEHICLE REPAIR

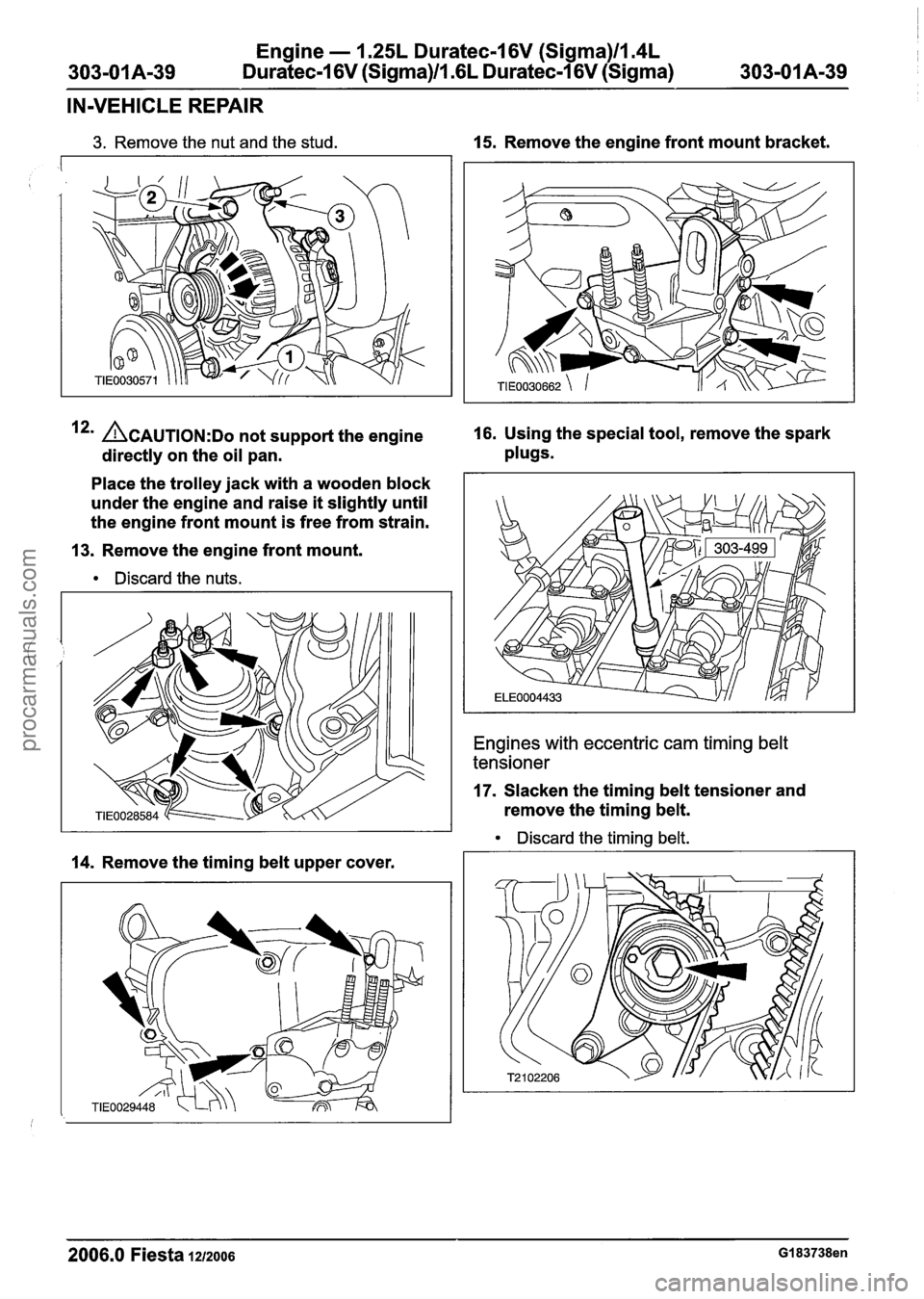

3. Remove the nut and the stud. 15. Remove the engine front mount bracket.

&AUTION:D~ not support the engine 16. Using the special tool, remove the spark

directly on the oil pan. plugs.

Place the trolley jack with a wooden block

under the engine and raise

it slightly until

the engine front mount is free from strain.

13. Remove the engine front mount.

Discard the nuts.

14. Remove the timing belt upper cover.

Engines with eccentric cam timing belt

tensioner

17. Slacken the timing belt tensioner and

remove the timing belt.

Discard the timing belt.

2006.0 Fiesta 1212006 GI 83738en

procarmanuals.com

Page 516 of 1226

Engine - 1.25L Duratec-1 6V (Sigma)llm4L

Duratec-1 6V (Sigma)/l .6L Duratec-1 6V (Sigma)

IN-VEHICLE REPAIR

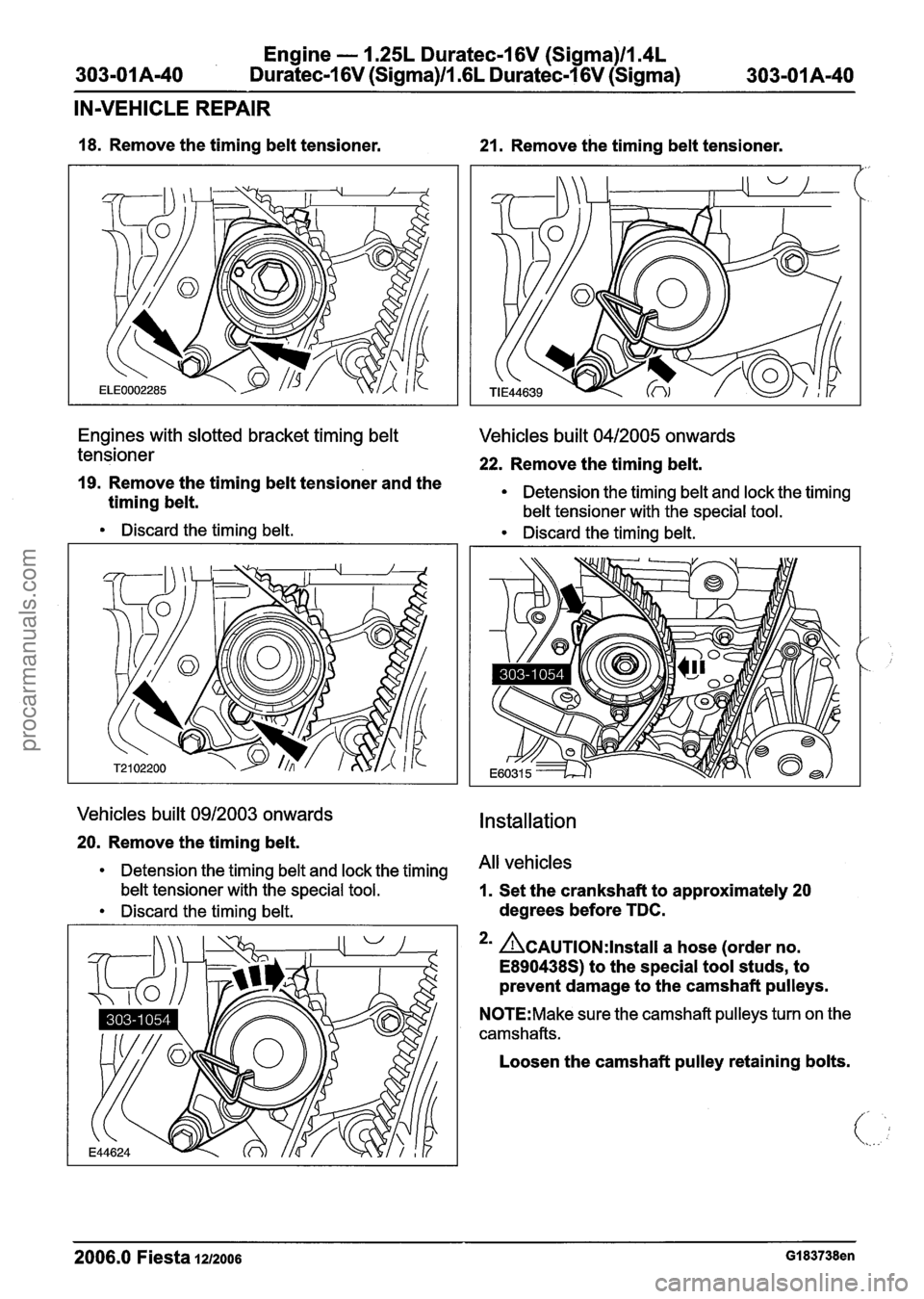

18. Remove the timing belt tensioner. 21. Remove the timing belt tensioner.

Engines with slotted bracket timing belt Vehicles built 0412005 onwards

tensioner

22. Remove the timing belt.

19. Remove the timing belt tensioner and the

timing belt. Detension the timing belt and lock the timing

belt tensioner with the special tool.

Vehicles built 0912003 onwards

20. Remove the timing belt.

Detension the timing belt and lock the timing

belt tensioner with the special tool.

Discard the timing belt.

Discard the timing belt. Discard the timing belt.

Installation

All vehicles

1. Set the crankshaft to approximately 20

degrees before TDC.

2m &~~~l~~:lnstall a hose (order no.

E890438S) to the special tool studs, to

prevent damage to the camshaft pulleys.

N0TE:Make sure the camshaft pulleys turn on the

camshafts.

Loosen the camshaft pulley retaining bolts.

2006.0 Fiesta 1212006 GI 83738en

procarmanuals.com

Page 517 of 1226

Engine - 1.25L Dura

303-01 A-41 Duratec-I 6V (Sigma)ll.~

:eel 6V (Sigma)llI4L

iL Duratec-1 6V (Sigma) 303-01 A-41

IN-VEHICLE REPAIR

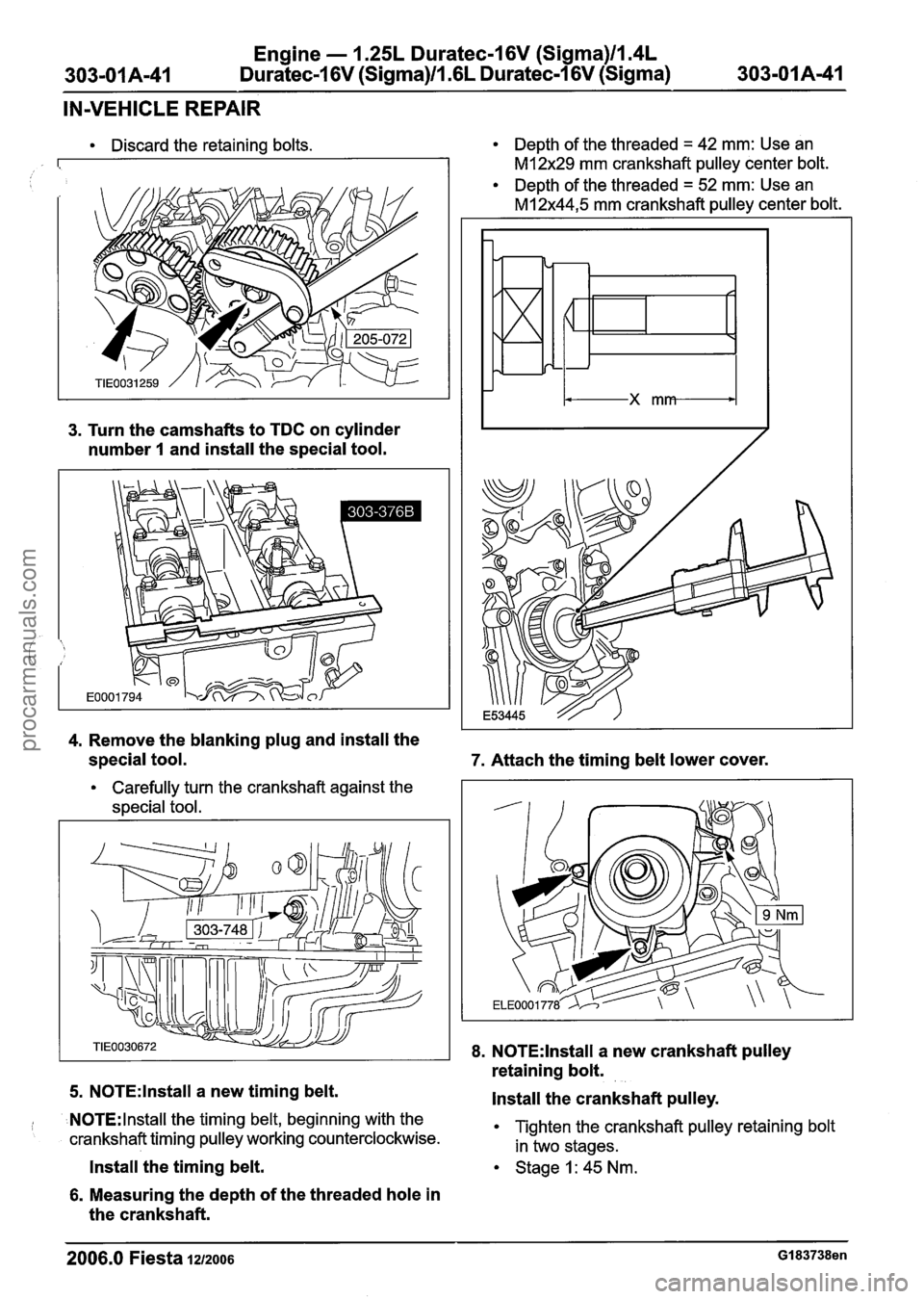

Discard the retaining bolts.

3. Turn the camshafts to TDC on cylinder

number

1 and install the special tool.

4. Remove the blanking plug and install the

special tool.

Carefully turn the crankshaft against the

special tool.

5.

N0TE:lnstall a new timing belt.

N0TE:lnstall the timing belt, beginning with the

crankshaft timing pulley working counterclockwise.

Install the timing belt.

6. Measuring the depth of the threaded hole in

the crankshaft.

Depth of the threaded = 42 mm: Use an

M12x29 mm crankshaft pulley center bolt.

Depth of the threaded

= 52 mm: Use an

MI 2x44,5 mm crankshaft pulley center bolt.

7. Attach the timing belt lower cover.

8. N0TE:lnstall a new crankshaft pulley

retaining bolt.

Install the crankshaft pulley.

Tighten the crankshaft pulley retaining bolt

in two stages.

Stage1:45Nm.

2006.0 Fiesta 1212006 GI 83738en

procarmanuals.com

Page 518 of 1226

Engine - 1.25L Duratec-1 6V (Sigma)ll.4L

303-01 A-42 Duratec-1 6V (Sigma)/lm6L Duratec-1 6V (Sigma) 303-01 A-42

IN-VEHICLE REPAIR

Stage 2: 90 degrees.

Engines with eccentric cam timing belt

tensioner

Tension the timing belt by turning the

tensioner clockwise until the arrow points in

line with the center of the rectangular hole

and tighten the bolt.

9. Install the timing belt tensioner. Vehicles built 0912003 onwards

10. Tension the timing belt.

Tension the timing belt by turning the

tensioner counterclockwise until the arrow

points at the mark and tighten the bolt.

I*' AWARNING:D~ not remove the special

tool, until the timing belt is correctly

positioned. Failure to follow this instruction

may result in personal injury, or may

damage the timing belt tensioner.

Install the timing belt tensioner.

/--

13. Tension the timing belt.

Remove the special tool.

Engines with slotted bracket timing belt

tensioner

I I. Install the timing belt tensioner and tension

the timing belt.

Screw in the bolts finger tight.

2006.0 Fiesta 1212006 GI 83738en

procarmanuals.com

Page 540 of 1226

Engine - 1.25L Duratec-1 6V (Sigma)lla4L

303-01 A-64 Duratec-1 6V (Sigma)ll .6L Duratec-1 6V (Sigma) 303-01 A-64

IN-VEHICLE REPAIR

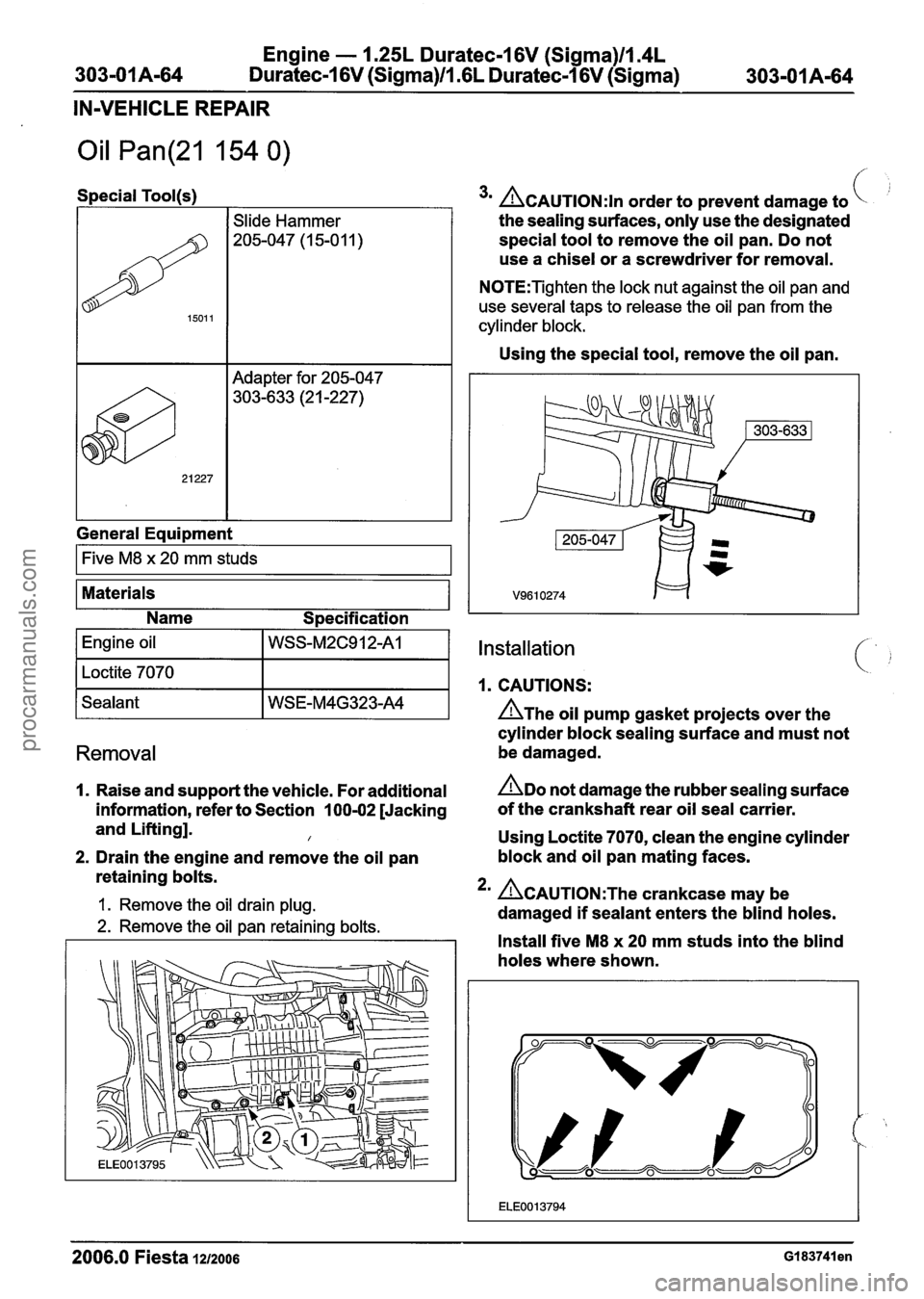

Oil Pan(21 154 0)

Special Tool(s)

Adapter for 205-047

303-633 (2

1 -227)

1501 1

General Equipment

Slide Hammer

205-047 (1 5-0 1 1 )

I Five M8 x 20 mm studs I

Materials

Name

S~ecification

3m CAUTION:^^ order to prevent damage to

the sealing surfaces, only use the designated

special tool to remove the oil pan. Do not

use a chisel or a screwdriver for removal.

N0TE:Tighten the lock nut against the oil pan and

use several taps to release the oil pan from the

cylinder block.

Using the special tool, remove the oil pan.

Installation

1. CAUTIONS:

n~he oil pump gasket projects over the

cylinder block sealing surface and must not

Removal be damaged.

I. Raise and support the vehicle. For additional ADO not damage the rubber sealing surface

information, refer to Section 100-02 [Jacking of

the crankshaft rear oil seal carrier.

and Lifting].

I Using Loctite 7070, clean the engine cylinder

2. Drain the engine and remove the oil pan block and

oil pan mating faces.

retaining bolts.

1. Remove the oil drain plug. 2m ~CAUTION:T~~ crankcase may be

damaged

if sealant enters the blind holes. 2. Remove the oil pan retaining bolts.

I I Install five M8 x 20 mm studs into the blind

holes where shown.

2006.0 Fiesta 1212006 GI 83741 en

procarmanuals.com

Page 541 of 1226

Engine - 1.25L Duratec-1 6V (Sigma)ll.4L

303-01 A-65 Duratec-1 6V (Sigma)ll .6L Duratec-1 6V (Sigma) 303-01 A-65

IN-VEHICLE REPAIR

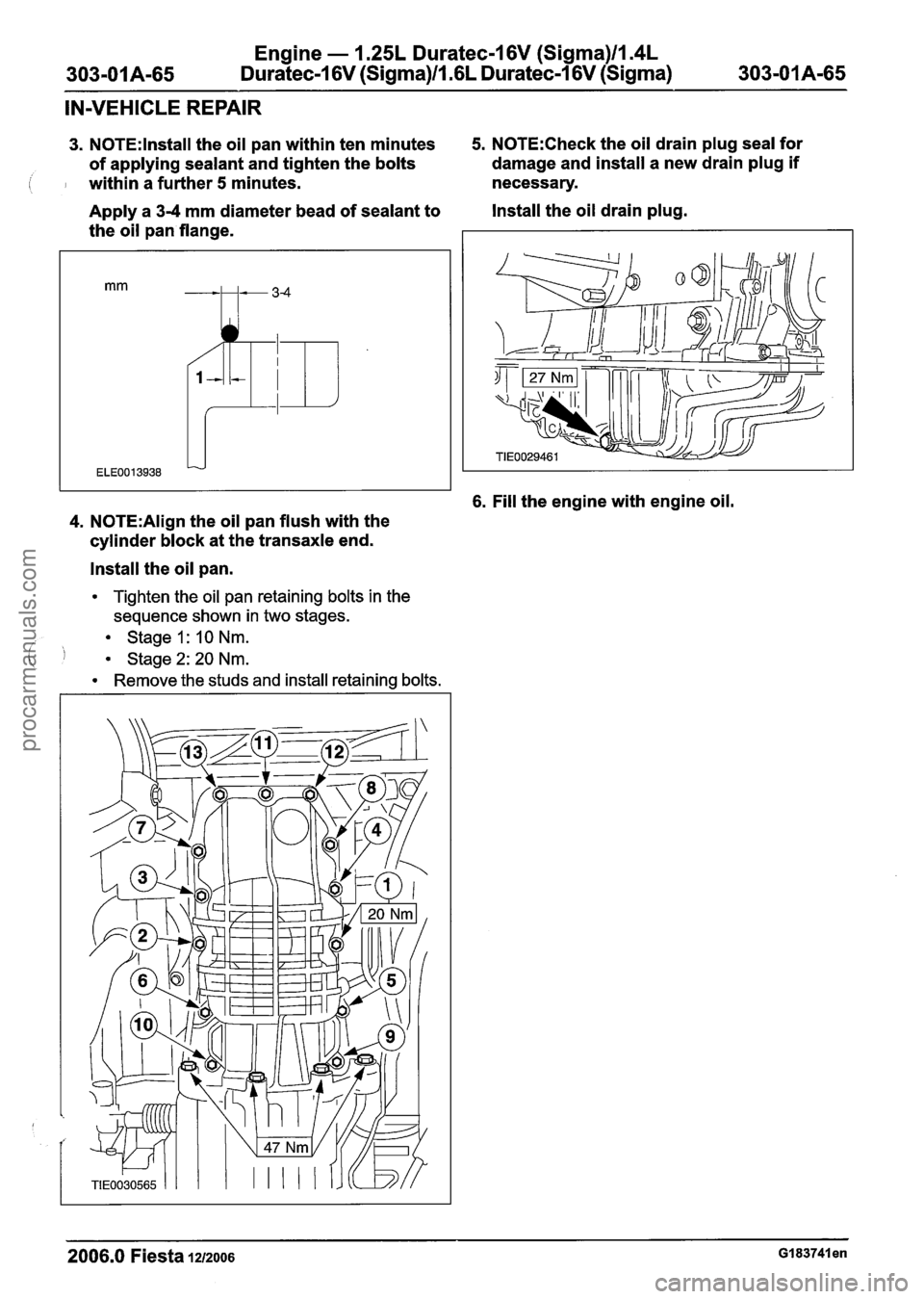

3. N0TE:lnstall the oil pan within ten minutes 5. N0TE:Check the oil drain plug seal for

of applying sealant and tighten the bolts damage

and install a new drain plug if

( I within a further 5 minutes. necessary.

Apply a 3-4 mm diameter bead of sealant to Install the oil drain plug.

the oil pan flange.

6. Fill the engine with engine oil.

4. N0TE:Align the oil pan flush with the

cylinder block at the transaxle end.

Install the oil pan.

Tighten the oil pan retaining bolts in the

sequence shown in two stages.

Stage

I : 10 Nm.

( I Stage2:20Nm.

Remove the studs and install retaining bolts.

2006.0 Fiesta 1212006 GI 83741 en

procarmanuals.com