air condition FORD FIESTA 2007 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 31 of 1226

General Information

DESCRIPTION AND OPERATION

Two Pack

Can also contain harmful and toxic unreacted

resins and resin hardening agents. The

manufacturers instructions should be followed. See

also Resin-based Adhesives and

Isocyanate

Adhesives and Sealers under Adhesives and

Sealers.

Spraying should preferably be carried out in

exhausted ventilated booths removing vapor and

spray mists from the breathing zone. Individuals

working in booths should wear appropriate

respiratory protection. Those doing small-scale

repair work in the open workshop should wear

air-fed respirators.

Pressurized Equipment

See High Pressure Air, Lubrication and Oil Test

Equipment.

Solder

Solders are mixtures of metals such that the

melting point of the mixture is below that of the

constituent metals (normally lead and tin). Solder

application does not normally give rise to toxic lead

fumes, provided a

gaslair flame is used.

Oxy-acetylene flames should not be used, as they

are much hotter and will cause lead fumes to be

produced.

Some fumes may be produced by the application

of any flame to surfaces coated with grease, and

inhalation of these should be avoided.

Removal of excess solder should be undertaken

with care, to make sure that fine lead dust is not

produced, which can give toxic effects if inhaled.

Respiratory protection may be necessary.

Solder spillage and filings should be collected and

removed promptly to prevent general air

contamination by lead.

High standards of personal hygiene are necessary

in order to avoid ingestion of lead or inhalation of

solder dust from clothing.

Solvents

See also Chemical Materials, Fuels (Kerosene),

Fire.

For example acetone, white spirit, toluene, xylene,

trichloroethane.

2006.0 Fiesta 1212006

Used in cleaning and dewaxing materials, paints,

plastics, resins and thinners.

Some may be highly flammable or flammable.

Skin contact will degrease the skin and may result

in irritation and dermatitis following repeated or

prolonged contact. Some can be absorbed through

the skin in toxic or harmful quantities.

Splashes in the eye may cause severe irritation

and could lead to loss of vision.

Brief exposure of high concentrations of vapors or

mists will cause eye and throat irritation,

drowsiness, dizziness, headaches and, in the worst

circumstances, unconsciousness.

Repeated or prolonged exposure to excessive but

lower concentrations of vapors or mists, for which

there might not be adequate warning indications,

can cause more serious toxic or harmful effects.

Aspiration into the lungs, for example through

vomiting, is the most serious consequence of

swallowing.

Avoid splashes to the skin, eyes and clothing. Wear

protective gloves, goggles and clothing if

necessary.

Make sure there is good ventilation when in use,

avoid breathing fumes, vapors and spray mists and

keep containers tightly sealed. Do not use in

confined spaces.

When spraying materials containing solvents, for

example paints, adhesive, coatings, use extraction

ventilation or personal respiratory protection in the

absence of adequate general ventilation.

Do not apply heat or flame except under specific

and detailed manufacturers instructions.

Sound Insulation

See Fibre Insulation, Foams.

Suspended Loads

A CAUTI0N:Never improvise lifting tackle.

There is always a danger when loads are lifted or

suspended. Never work under an unsupported,

suspended or raised load, for example a

suspended engine.

Always make sure that lifting equipment such as

jacks, hoists, axle stands and slings are adequate

and suitable for the job, in good condition and

regularly maintained.

procarmanuals.com

Page 32 of 1226

100-00-1 6 General Information 100-00-1 6 '

DESCRIPTION AND OPERATION

Transmission Brake Bands

See Asbestos.

Underseal Welding

See

also Fire, Electric Shock, Gas Cylinders. (

Welding processes include Resistance Welding

(Spot Welding), Arc Welding and Gas Welding.

See Corrosion Protection.

Resistance Welding

Viton

In common with many other manufacturers

vehicles, some components have O-rings, seals

or gaskets, which contain a material known as

'Viton'.

Viton is a fluoroelastomer, that is a synthetic rubber

type material, which contains Fluorine. It is

commonly used for O-rings, gaskets and seals of

all types. Although Viton is the most well known

fluoroelastomer, there are others, including

Fluorel

and Tecmoflon.

When used under design conditions

fluoroelastomers are perfectly safe. If, however,

they are exposed to temperatures in excess of

400°C, the material will not burn, but will

decompose, and one of the products formed is

hydrofluoric acid.

This acid is extremely corrosive and may be

absorbed directly, through contact, into the general

body system.

O-rings, seals or gaskets which have been exposed

to very high temperatures will appear charred or

as a black sticky substance.

DO NOT; under any circumstances touch them or

the attached components.

Enquiries should be made to determine whether

Viton or any other fluoroelastomer has been used

in the affected O-ring, seal or gasket. If they are of

natural rubber or

nitrile there is no hazard. If in

doubt, be cautious, as the material may be Viton

or any fluoroelastomer.

If Viton or any other fluoroelastomers have been

used, the affected area should be decontaminated

before the commencement of work.

Disposable heavy duty plastic gloves should be

worn at all times, and the affected area washed

down using wire wool and a limewater (calcium

hydroxide) solution to neutralize the acid before

disposing of the decomposed Viton residue and

final cleaning of the area. After use, the plastic

gloves should be discarded carefully and safely. This process may cause particles of molten metal

to

be emitted at a high velocity, and the eyes and

skin must be protected.

Arc Welding

This process emits a high level of ultra-violet radiation, which may cause arc-eye, and skin burns

to the operator and to other persons nearby.

Gas-shielded welding processes are particularly

hazardous in this respect. Personal protection must

be worn, and screens used to shield other

~eo~le. . .

CONTACT LENS WEARERS ARE ADVISED TO

REVERT TO ORDINARY SPECTACLES WHEN

ARC WELDING as the arc spectrum is believed to

emit microwaves which dry out the fluid between

the lens and the eye. This may result in blindness

when the lens is removed from the eve.

Metal spatter will also occur, and appropriate eye

and skin protection is necessary.

The heat of the welding arc will produce fumes and

gases from the metals being welded, the rods and

from any applied coatings or contamination on the

surfaces being worked on. These gases and fumes

may be toxic and inhalation of these should be

avoided. The use of extraction ventilation to remove

the fumes from the working area may be necessary

particularly in cases where the general ventilation

is poor, or where considerable welding work is

anticipated. In extreme cases or confined spaces

where adequate ventilation cannot be provided,

air-fed respirators may be necessary.

Gas Welding (and Cutting)

Oxy-acetylene torches may be used for welding

and cutting, and special care must be taken to

prevent leakage of these gases, with consequent

risk of fire and explosion.

("

The process will produce metal spatter and eye "

and skin protection is necessary.

2006.0 Fiesta 1212006 GI 7372en

procarmanuals.com

Page 58 of 1226

100-04-2 Noise, Vibration and Harshness 100-04-2

DESCRIPTION AND OPERATION

Noise, Vibration and Harshness (NVH)

Noise, vibration and harshness (NVH) is becoming

more important as vehicles become more '

Know the History of the Condition

sophisticated and passenger comfort levels

increase. This section is designed to aid in the

- Did it start suddenly or appear gradually?

diagnosis and testing and repair of NVH concerns.

- Was it related to some other occurrence such

- Noise is defined as sounds not associated with

as a collision or previous part replacement?

the operation of passenger compartment

- Know how the condition made itself known; it

equipment that interface with customer

may be an important clue to the cause.

satisfaction.

- Vibration is defined as impulses felt by the

customer that are not caused by road surface Know the Probability of Certain

changes. Conditions Develop~ng

- Harshness is a ride quality issue where the - Look for the simple rather than the complex.

customer feels that the vehicle response to the

road surface is sharply transmitted to the

- For example:

customer.

- Electrical conditions usually occur at

connections rather than components.

Diagnostic Theory - An engine no-start is more likely to be caused

by a loose wire or small adjustment rather

than a sheared-off

camshafi. Diagnosis is more than just following a series of

interrelated steps in order to find the solution to the - Know the difference between impossible and

specific condition. It is a way of looking at systems improbable. Certain failures

in a system can be

that are not functioning the way they should and improbable

but still happen.

finding out why. Also it is knowing how the system

- New parts are just that, new. It does not mean

should work and whether it is working correctly. they are always

good functioning parts.

There are basic rules for diagnosis. If these rules

are followed, the cause of the condition is usually

Do Not Cure the Symptom and Leave

found the first time through the system. the Cause

Know the System

- Know how the parts go together. Lowering

the pressure in a front tire may correct

the condition of a vehicle leaning to one side, but

it does not correct the original condition.

- Know how the system operates as well as its

limits and what happens when the system goes

Be Positive the Cause is Found

wrong.

- Sometimes this means checking the system - Double check findings.

against one that is known to be working

- What caused a worn component?

correctly.

- A loose transmission or engine mount could

indicate that other mounts are also loose.

Know the History of the System

Diagnostic Charts

A clue in any one of these areas may save time:

- How old or new is the system? Charts are a simple

way of expressing the

relationship between basic logic and a physical

- What kind of treatment has it had?

system of components. They help discover the ,.

- Has it been serviced in the past in such a

cause of a condition in the least time. Diagnostic (,-

manner that might relate to the present

charts combine many areas of diagnosis into one

condition? visual display:

- What is the service history?

2006.0 Fiesta 12/2006 G28448en

procarmanuals.com

Page 62 of 1226

100-04-6 Noise, Vibration and Harshness 100-04-6

DIAGNOSIS AND TESTING

2. AccelerationIDeceleration: With slow

acceleration and deceleration, a shake is

sometimes noticed in the steering

wheellcolumn,

seats, front floor panel, front door trim panel or

front end sheet metal. It is a low frequency

vibration (around

9-1 5 cycles per second). It

may or may not be increased by applying the

brakes lightly. REFER to

Idle

BoomIShakeNibration in the Driveline Noise

and Vibration Symptom Chart.

High Speed: A vibration is felt in the front floor

panel or seats with no visible shake, but with

an accompanying sound or rumble, buzz, hum,

drone or booming noise. Coast with the clutch

pedal depressed (manual transmission) or shift

control selector lever in "N" (NEUTRAL)

(automatic transmission) and engine idling. If

vibration is still evident, it may be related to

wheels, tires, front brake discs, wheel hubs or

front wheel bearings. REFER to Shake and

Vibration While Driving in the Driveline Noise

and Vibration Symptom Chart.

4. Engine rpm Sensitive: A vibration is felt

whenever the engine reaches a particular rpm.

It will disappear in neutral coasts. The vibration

can be duplicated by operating the engine at

the problem rpm while the vehicle is stationary.

It can be caused by any component, from the

accessory drive belt to the clutch or torque

converter which turns at engine speed when the

vehicle is stopped. REFER to Shake and

Vibration While Driving in the Driveline Noise

and Vibration Symptom Chart.

5. Noise and Vibration While Turning: Clicking,

popping or grinding noises may be due to the

following:

worn, damaged or incorrectly installed front

wheel bearing.

damaged

powertrainldrivetrain mounts.

Road Conditions

An experienced technician will always establish a

route that will be used for all NVH diagnosis road

tests. The road selected should be reasonably

smooth, level and free of undulations (unless a

particular condition needs to be identified). A

smooth asphalt road that allows driving over a

range of speeds is best. Gravel or bumpy roads

are unsuitable because of the additional road noise produced.

Once the route is established and

consistently used, the road noise variable is

eliminated from the test results.

N0TE:Some concerns may be apparent only on

smooth asphalt roads.

If a customer complains of a noise or vibration on

a particular road and only on a particular road, the

source of the concern may be the road surface. If

possible, try to test the vehicle on the same type

of road.

Vehicle Preparation

Carry out a thorough visual inspection of the

vehicle before carrying out the road test. Note

anything which is unusual. Do not repair or adjust

any condition until the road test is carried out,

unless the vehicle is inoperative or the condition

could pose a hazard to the technician. After

verifying that the condition has been corrected,

make sure all components removed have been

installed.

Power Steering Conditions

c !

Check for the noise in the following conditions to

verify the customer concern.

Check for the noise in several temperature

conditions.

Is the noise from when the vehicle was new?

Can the noise be repeated constantly or is it

random?

Check the condition of the vehicle age, mileage

and service record.

Interview the customer to find the operating

condition in which the noise will occur. Test the

vehicle based on the

detail(s) from the customer

interview.

Follow the power steering operation noise

condition tables below, to find which condition

the noise will occur.

Power Steering Operation Noise Check

Step 1 : Check for NVH concerns from non-steering

components, which may sound like noises coming

from the steering system.

I:. ':

2006.0 Fiesta 121zoo6 G37349en

procarmanuals.com

Page 65 of 1226

100-04-9 Noise, Vibration and Harshness 1 00-04-9

DIAGNOSIS AND TESTING

Step 3: According to each identified operating

condition (Column A, B,

C, D, E, F), check each

possible Steering System

NVH concern with the

detail symptom charts below.

Before conducting a vehicle test to identify a

NVH

concern carry out the following checks.

1. Check the tire pressures and adjust to

specification, as necessary.

2. Make sure the steering system fluid is correct,

the system is free of leaks and is operating

correctly.

3. Make sure the vehicle steering system

temperature is the same as described at the

customer interview.

4. All evaluations must take place in a relatively

quiet location.

5. The heating

- air conditioning (AIC) fan and

radio must be turned off during evaluations and

the windows closed.

Symptom Chart

Power Steering Moan Noise

Test Condition

Listen for steering moan noise with the vehicle

parked, transmission in neutral and all windows

closed in the following test conditions.

1. Engine speed at idle with no steering action.

2. Engine speed at idle with slow 90 degrees per

second turning of the steering wheel.

3. Engine speed at 1250 +I- 50 rpm with no

steering action.

4. Engine speed at 1250 +I- 50 rpm with slow 90

degrees per second turning of the steering

wheel.

2006.0 Fiesta 12/2006 G37349en

procarmanuals.com

Page 68 of 1226

I 00-04-1 2 Noise, Vibration and Harshness I 00=04m12

DIAGNOSIS AND TESTING

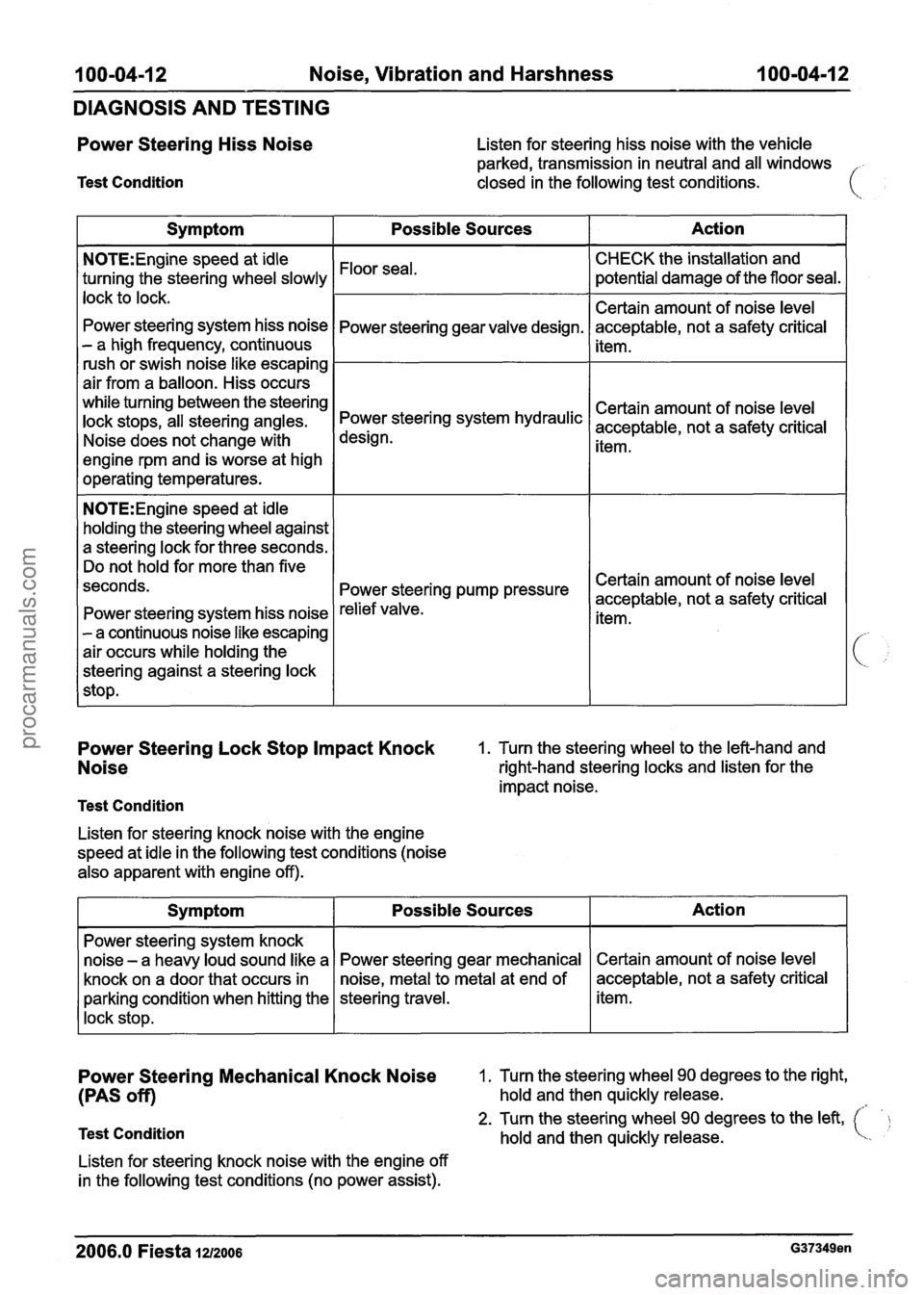

Power Steering Hiss Noise

Test Condition

Listen for steering hiss noise with the vehicle

parked, transmission in neutral and all windows

-

closed in the following test conditions.

Power Steering Lock Stop Impact Knock 1. Turn the steering wheel to the left-hand and

Noise right-hand steering locks and listen for the

impact noise.

Test Condition

Listen for steering knock noise with the engine

speed at idle in the following test conditions (noise

also apparent with engine off).

Action

CHECK the installation and

potential damage of the floor seal.

Certain amount of noise level

acceptable, not a safety critical

item.

Certain amount of noise level

acceptable, not a safety critical

item.

Certain amount of noise level

acceptable, not a safety critical

item.

Symptom

N0TE:Engine speed at idle

turning the steering wheel slowly

lock to lock.

Power steering system hiss noise

- a high frequency, continuous

rush or swish noise like escaping

air from a balloon. Hiss occurs

while turning between the steering

lock stops, all steering angles.

Noise does not change with

engine rpm and is worse at high

operating temperatures.

N0TE:Engine speed at idle

holding the steering wheel against

a steering lock for three seconds.

Do not hold for more than five

seconds.

Power steering system hiss noise

- a continuous noise like escaping

air occurs while holding the

steering against a steering lock

stop.

Possible Sources

Floor seal.

Power steering gear valve design.

Power steering system hydraulic

design.

Power pump pressure

relief valve.

Power Steering Mechanical Knock Noise 1. Turn the steering wheel 90 degrees to the right,

(PAS off) hold and then quickly release.

2. Turn the steering wheel 90 degrees to the left, Test Condition hold and then quickly release.

Listen for steering knock noise with the engine off

in the following test conditions (no power assist).

2006.0 Fiesta 1212006 G37349en

Action

Certain amount of noise level

acceptable, not a safety critical

item.

Symptom

Power steering system knock

noise

- a heavy loud sound like a

knock on a door that occurs in

parking condition when hitting the

lock stop.

Possible Sources

Power steering gear mechanical

noise, metal to metal at end of

steering travel.

procarmanuals.com

Page 72 of 1226

100-04-16 Noise, Vibration and Harshness 100-04-1 6

DIAGNOSIS AND TESTING

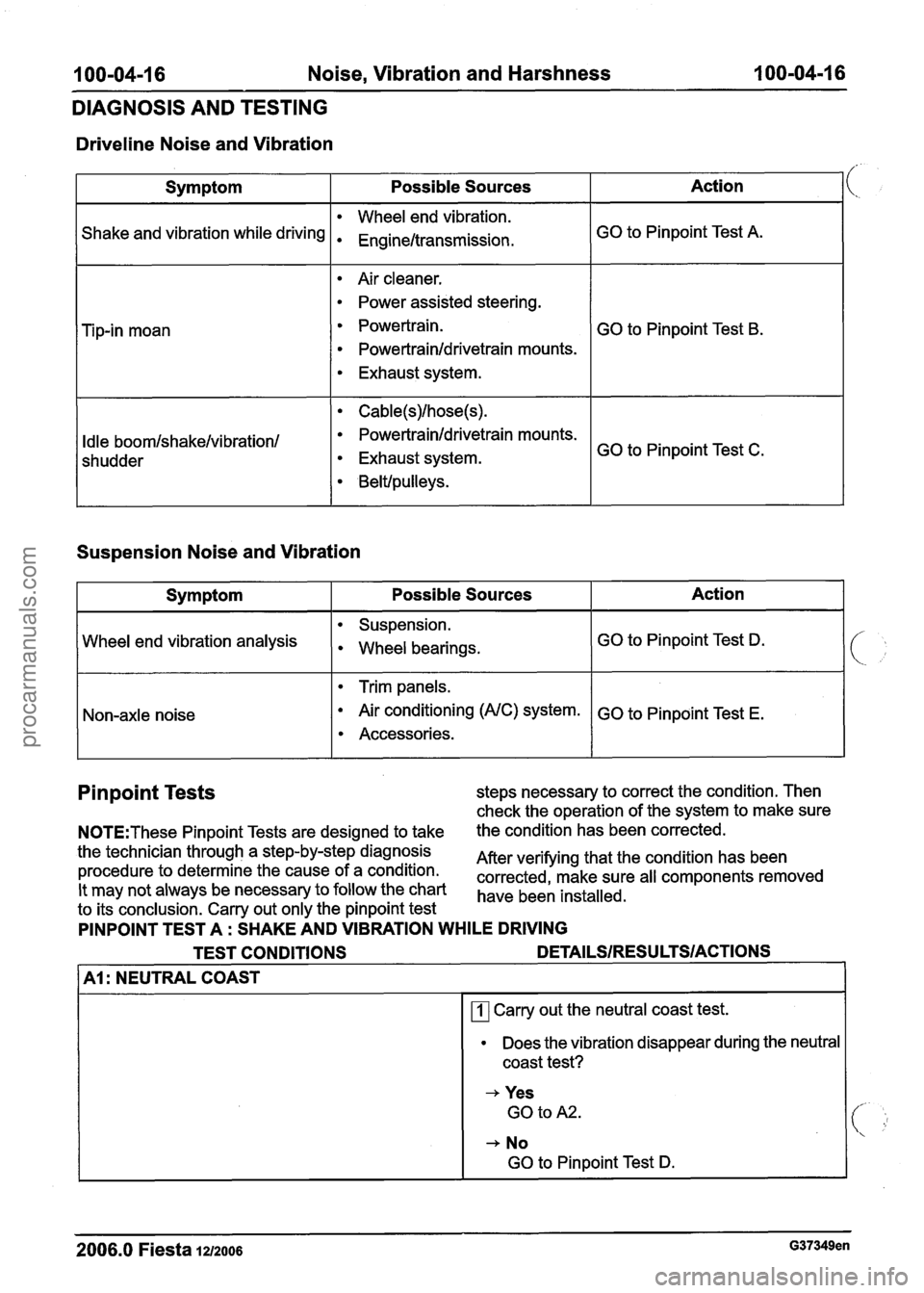

Driveline Noise and Vibration

Suspension Noise and Vibration

Action

GO to Pinpoint Test A.

GO to Pinpoint Test

B.

GO to Pinpoint Test C.

Symptom

Shake and vibration while driving

Tip-in moan

Idle boomlshake/vibration/

shudder

Pinpoint Tests steps necessary to correct the condition. Then

check the operation of the system to make sure

N0TE:These Pinpoint Tests are designed to take the

condition has been corrected.

the technician through

a step-by-step diagnosis ~fi~~ verifying that the condition has been procedure to determine the cause of a condition. corrected, make sure all components removed It may not always be necessary to follow the chart have been installed. to its conclusion. Carry out only the pinpoint test

PINPOINT TEST A : SHAKE AND VIBRATION WHILE DRIVING

TEST CONDITIONS

DETAILSIRESU LTSIACTIONS 1

Possible Sources

Wheel end vibration.

. Engine/transmissiOnm

Air cleaner.

Power assisted steering.

Powertrain.

Powertrainldrivetrain mounts.

Exhaust system.

Cable(s)lhose(s).

Powertrainldrivetrain mounts.

Exhaust system.

Belt/ pulleys.

I A1 : NEUTRAL COAST I

Action

GO to Pinpoint Test D.

GO to Pinpoint Test E,

Symptom

Wheel end vibration analysis

Nan-axle noise

Carry out the neutral coast test.

Does the vibration disappear during the neutral

coast test?

+ Yes

GO to A2.

+ No

GO to Pinpoint Test D.

Possible Sources

Suspension.

. Wheel bearings,

Trim panels.

Air conditioning (A/C) system.

Accessories.

- --

2006.0 Fiesta 1212006 G37349en

procarmanuals.com

Page 73 of 1226

100-04-1 7 Noise, Vibration and Harshness 100-04-17

DIAGNOSIS AND TESTING

TEST CONDITIONS DETAILSIRESULTSIACTIONS

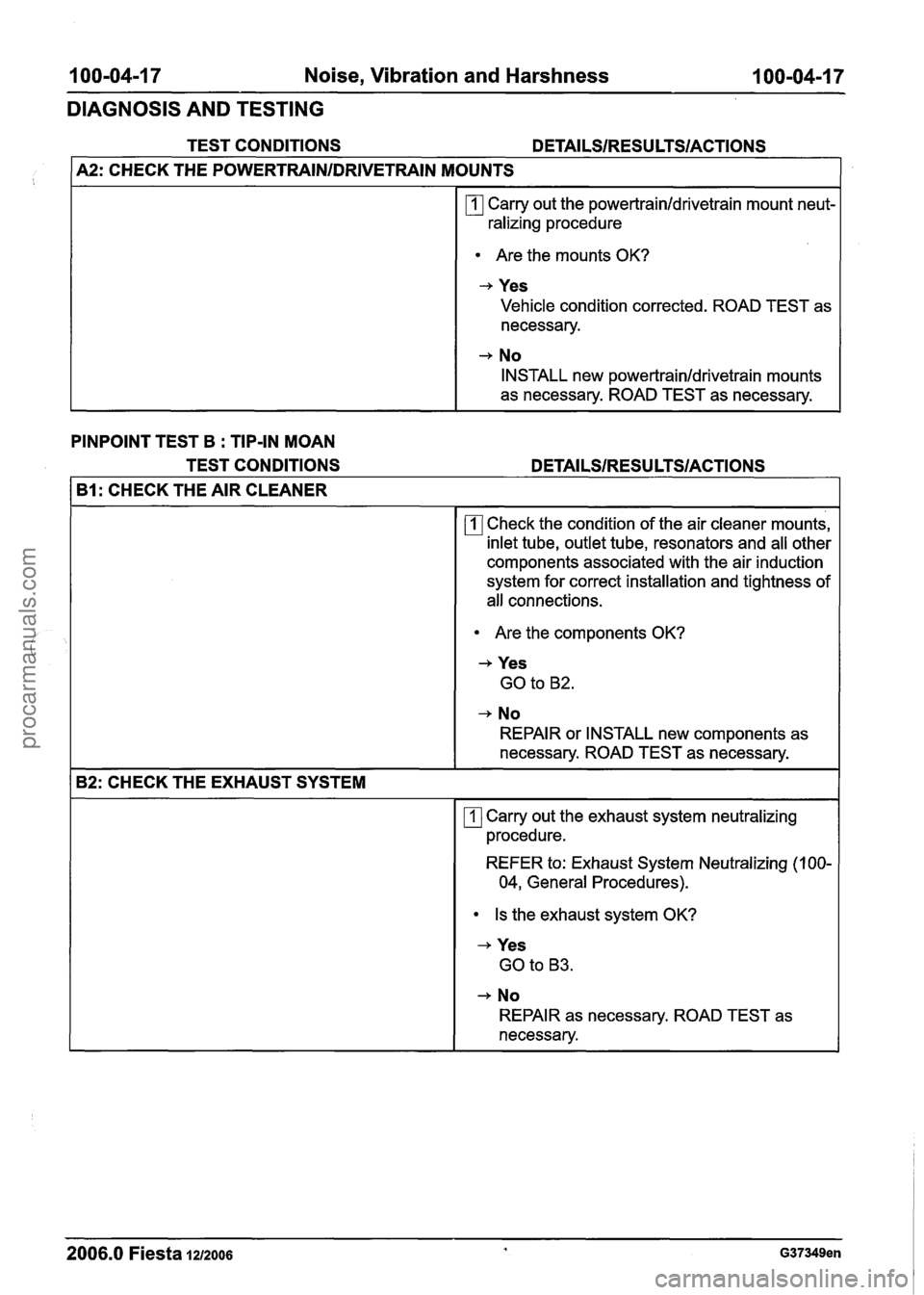

A2: CHECK THE POWERTRAINIDRIVETRAIN MOUNTS

Carry out the

powertrainldrivetrain mount neut-

ralizing procedure

Are the mounts OK?

-+ Yes

Vehicle condition corrected. ROAD TEST as

necessary.

+ No

INSTALL new

powertrainldrivetrain mounts

as necessary. ROAD TEST as necessary.

PINPOINT TEST B

: TIP-IN MOAN

TEST CONDITIONS

DETAILSIRESU LTSIACTIONS

B1: CHECK THE AIR CLEANER

Check the condition of the air cleaner mounts,

inlet tube, outlet tube, resonators and all other

components associated with the air induction

system for correct installation and tightness of

all connections.

Are the components OK?

+ Yes

GO to

B2.

-+ No

REPAIR or INSTALL new components as

necessary. ROAD TEST as necessary.

82: CHECK THE EXHAUST SYSTEM

Carry out the exhaust system neutralizing

procedure.

REFER to: Exhaust System Neutralizing

(1 00-

04, General Procedures).

Is the exhaust system

OK?

-+ Yes GO to

B3.

+ No

REPAIR as necessary. ROAD TEST as

necessary.

- -

2006.0 Fiesta 1212006 + G37349en

procarmanuals.com

Page 74 of 1226

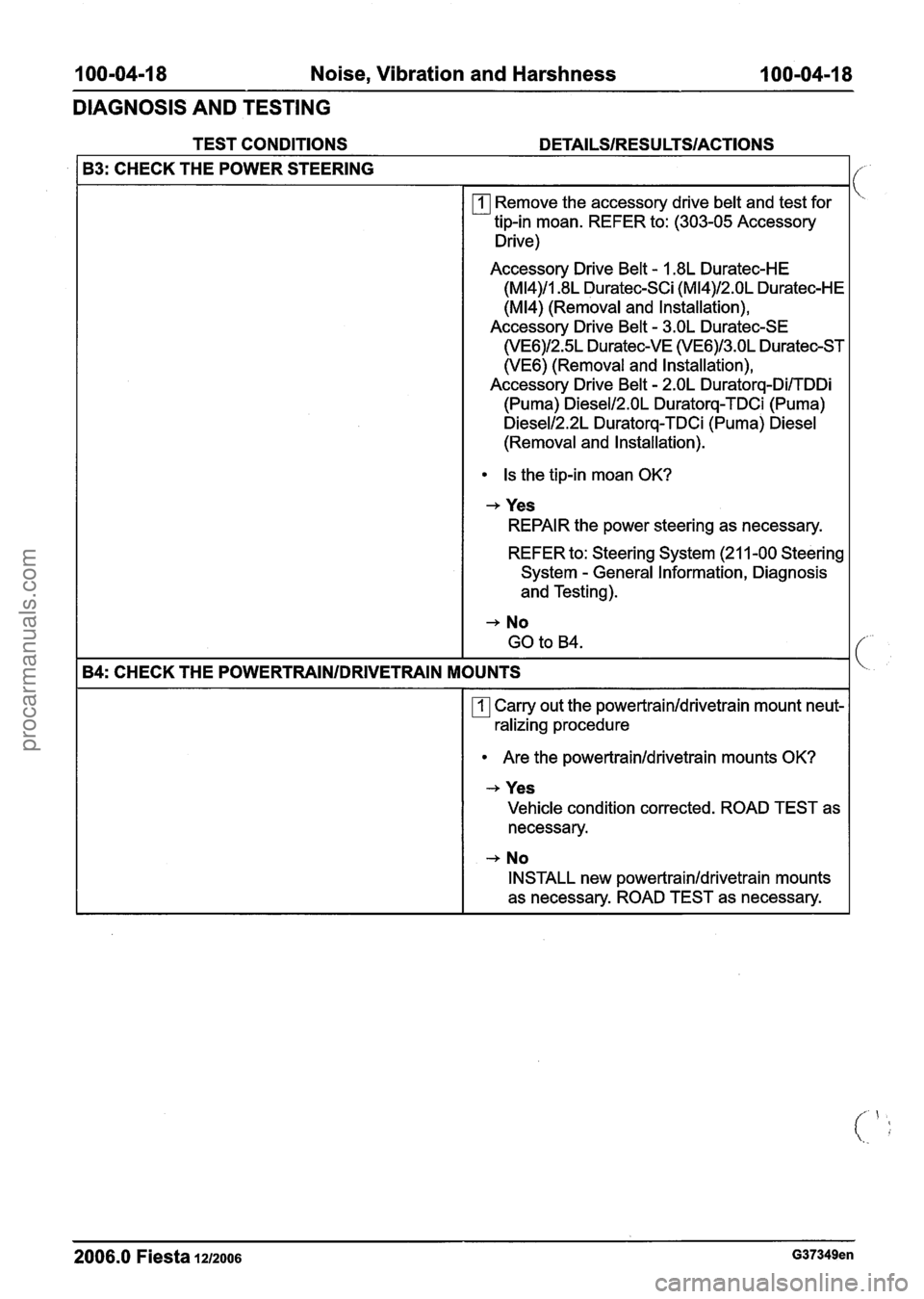

100=04=18 Noise, Vibration and Harshness 100-04-18

DIAGNOSIS AND TESTING

TEST CONDITIONS DETAILSIRESU LTSIACTIONS

--

2006.0 Fiesta 1212006 G37349en

B3: CHECK THE POWER STEERING

B4: CHECK THE POWERTRAINIDRIVETRAIN

rn Remove the accessory drive belt and test for

tip-in moan. REFER to: (303-05 Accessory

Drive)

Accessory Drive Belt

- 1.8L Duratec-HE

(M14)/1.8L Duratec-SCi (M14)/2.OL Duratec-HE

(M14) (Removal and Installation),

Accessory Drive Belt

- 3.OL Duratec-SE

(VE6)/2.5L Duratec-VE (VE6)/3.OL Duratec-ST

(VE6) (Removal and Installation),

Accessory Drive Belt

- 2.OL Duratorq-DilTDDi

(Puma) Diesell2.0L Duratorq-TDCi (Puma)

Diesel12.2L Duratorq-TDCi (Puma) Diesel

(Removal and lnstallation).

Is the tip-in moan OK?

-+ Yes

REPAIR the power steering as necessary.

REFER to: Steering System (21 1-00 Steering

System

- General Information, Diagnosis

and Testing).

-+ No

GO to B4.

MOUNTS

rn Carry out the powertrainldrivetrain mount neut-

ralizing procedure

Are the

powertrainldrivetrain mounts OK?

-+ Yes

Vehicle condition corrected. ROAD TEST as

necessary.

-+ No

l NSTALL new powertrainldrivetrain mounts

as necessary. ROAD TEST as necessary.

procarmanuals.com

Page 75 of 1226

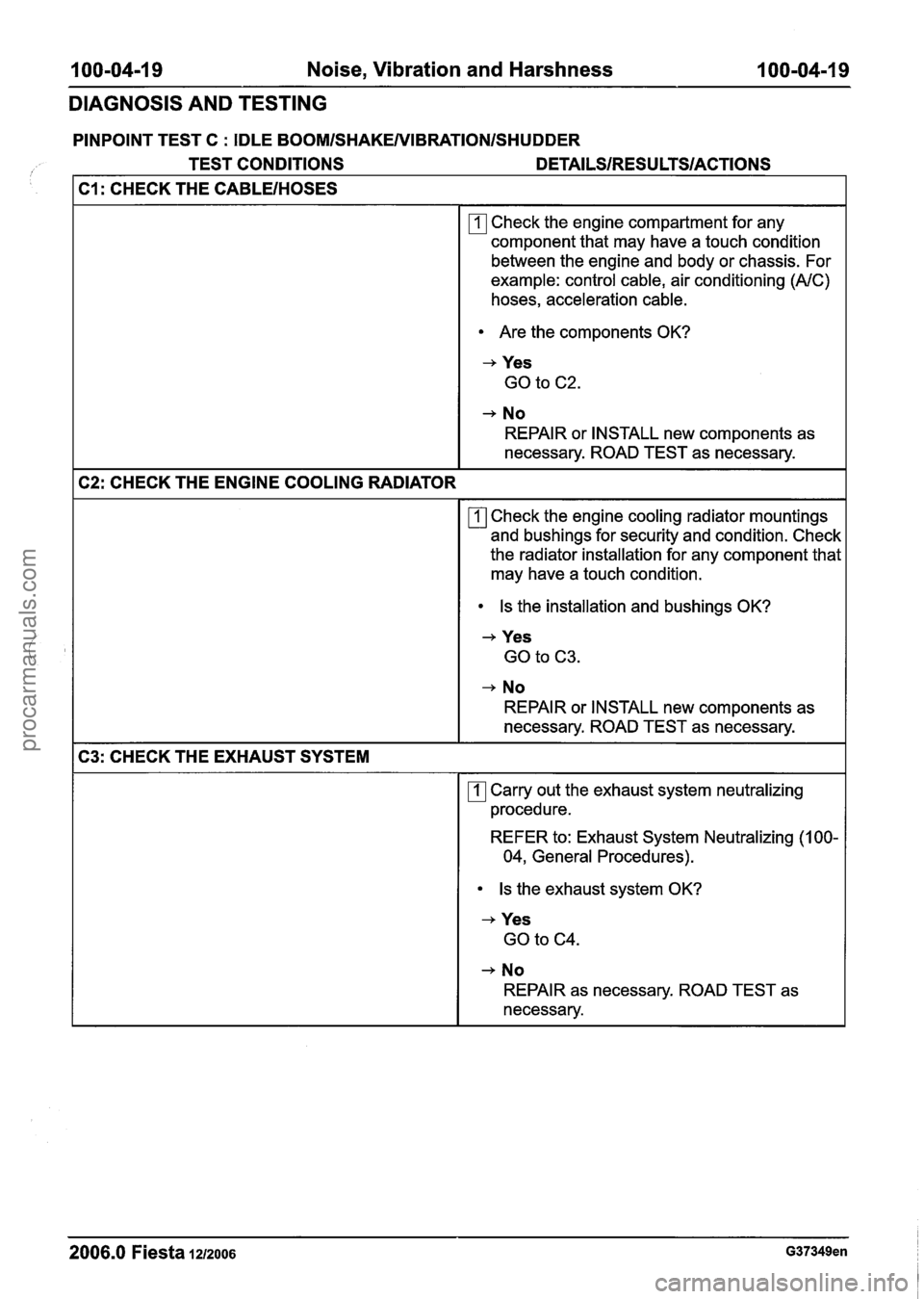

I 00-04-1 9 Noise, Vibration and Harshness 100-04-19

DIAGNOSIS AND TESTING

PINPOINT TEST C : IDLE BOOMISHAKENIBRATIONISHUDDER

1 TEST CONDITIONS DETAILSIRESU LTSIACTIONS

C1: CHECK THE CABLEIHOSES

rn Check the engine compartment for any

component that may have a touch condition

between the engine and body or chassis. For

example: control cable, air conditioning

(AIC)

hoses, acceleration cable.

Are the components OK?

-+ Yes

GO to C2.

+ No

REPAIR or INSTALL new components as

necessary. ROAD TEST as necessary.

C2: CHECK THE ENGINE COOLING RADIATOR

rn Check the engine cooling radiator mountings

and bushings for security and condition. Check

the radiator installation for any component that

may have a touch condition.

Is the installation and bushings OK?

+ Yes

GO to C3.

-+ No

REPAIR or INSTALL new components as

necessary. ROAD TEST as necessary.

C3: CHECK THE EXHAUST SYSTEM

rn Carry out the exhaust system neutralizing

procedure.

REFER to: Exhaust System Neutralizing

(1 00-

04, General Procedures).

Is the exhaust system OK?

+ Yes

GO to C4.

+ No

REPAIR as necessary. ROAD TEST as

necessary.

2006.0 Fiesta 1212006 G37349en

procarmanuals.com