check oil FORD FIESTA 2007 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 426 of 1226

303-004 Engine System - General Information 303-00-4

DIAGNOSIS AND TESTING

Engine

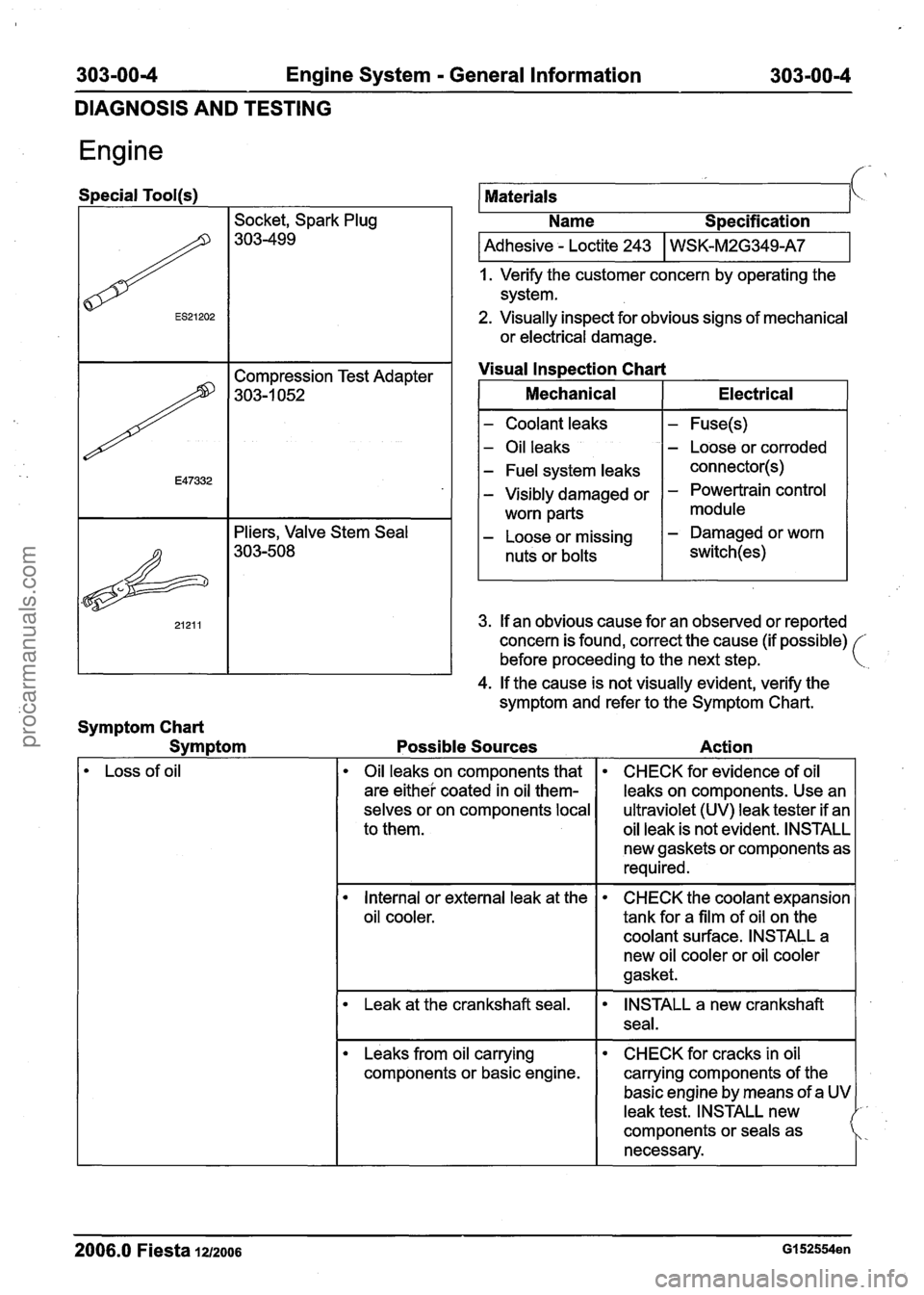

Special Tool(s)

Socket, Spark Plug

303-499

I Adhesive - Loctite 243 I WSK-M2G349A7 I

Materials

1. Verify the customer concern by operating the

system.

2. Visually inspect for obvious signs of mechanical

or electrical damage.

k.

Name S~ecification

Leaks from oil carrying

components or basic engine.

E47332

&

21211

CHECK for cracks in oil

carrying components of the

basic engine by means of a

leak test. INSTALL new

components or seals as

necessary.

2006.0 Fiesta 1212006 GI 52554en

Compression Test Adapter

303-1 052

Pliers, Valve Stem Seal

303-508

4. If the cause is not visually evident, verify the

symptom and refer to the Symptom Chart.

Symptom Chart Symptom Possible Sources Action

Visual

Inspection Chart

Loss of oil Mechanical

- Coolant

leaks

- Oil leaks

- Fuel system leaks

- Visibly damaged or

worn parts

- Loose or missing

nuts or bolts Electrical

- Fuse(s)

- Loose

or corroded

connector(s)

- Powertrain control

module

- Damaged or worn

switch(es)

Oil leaks on components that

are

eithei coated in oil them-

selves or on components local

to them.

Internal or external leak at the

oil cooler.

Leak at the crankshaft seal.

3. If an obvious cause for an observed or reported

concern is found, correct the cause (if possible)

before proceeding to the next step.

CHECK for evidence of oil

leaks on components. Use an

ultraviolet (UV) leak tester if an

oil leak is not evident, INSTALL

new gaskets or components as

required.

CHECK the coolant expansion

tank for a film of oil on the

coolant surface. INSTALL a

new oil cooler or oil cooler

gasket.

INSTALL a new crankshaft

seal.

procarmanuals.com

Page 427 of 1226

303-00-5 Engine System - General Information 303-00-5

DIAGNOSIS AND TESTING

Symptom

Oil consumption

Possible Sources Action

Use of the wrong type of

engine oil.

Faulty positive crankcase vent-

ilation (PCV) system.

- Hoses or ventilation or

breather valves are blocked.

This causes excessive

pressure in the crankcase

which causes more oil to

enter the combustion

chamber.

- PCV oil separator is faulty

and engine oil can enter the

combustion chamber

through the intake manifold.

Turbocharger seals (diesel

engine only).

DETERMINE the last type of

engine oil used and compare

with the specification. Change

the engine oil to the specifica-

tion.

CHECK if the PCV system is

operating correctly and repair

as necessary. REFER to:

Engine Emission Control (303-

08 Engine Emission Control

- 1.3L Duratec-8V

(Rocam)/l.25L Duratec-1 6V

(Sigma)/l.4L Duratec-1 6V

(Sigma)/l .6L Duratec-1 6V

(Sigma), Diagnosis and

Testing),

Engine Emission Control (303-

08 Engine Emission Control

- 2.OL Duratec-HE (M14),

Diagnosis and Testing),

Engine Emission Control

-

Vehicles With: Vacuum

Exhaust Gas Recirculation

(EGR) Valve (303-08 Engine

Emission Control

- 1.4L

Duratorq-TDCi (DV) Diesel,

Diagnosis and Testing),

Engine Emission Control (303-

08 Engine Emission Control

- 1.6L Duratorq-TDCi (DV)

Diesel, Description and

Operation).

INSTALL a new turbocharger.

REFER to:

Turbocharger (303-04 Fuel

Charging and Controls

-

Turbocharger - I .4L

Duratorq-TDCi (DV) Diesel,

Removal and lnstallation),

Turbocharger

- I .6L Duratorq-

TDCi (DV) Diesel (303-04

Fuel Charging and Controls

- Turbocharger - I .6L

Duratorq-TDCi (DV) Diesel,

Removal and lnstallation).

2006.0 Fiesta 1212006 GI 52554en

procarmanuals.com

Page 428 of 1226

303-00-6 Engine System - General Information 303-00-6

DIAGNOSIS AND TESTING

Symptom Possible Sources Action

Damaged gaskets or mating

surfaces.

- Cylinder head gasket is

damaged or mating face are

warped.

- Valve stem oil seals are

worn and engine oil can

enter the combustion

chamber between the valve

stem and the valve stem

guide.

Piston ring or cylinder liner

wear.

Damaged cylinder liners or

excessive clearance of engine

components.

- Pistons

- Piston rings (clearance in

groove and end gap)

- Cylinder liners

CHECK the gaskets and

mating surfaces for damage.

Remove the cylinder head.

CHECK the mating faces, cylinder

head gasket and the evenness of

the cylinder head and engine

block mating faces. INSTALL new valve

seals.REFER

to:

Valve Seals (303-01 Engine

-

1.25L Duratec-1 6V

(Sigma)ll.4L Duratec-1 6V

(Sigma)/l .6L Duratec-I 6V

(Sigma), In-vehicle Repair),

Valve Seals (303-01 Engine

-

1.3L Duratec-8V (Rocam), In-

vehicle Repair),

Valve Seals (303-01 Engine

-

2.OL Duratec-HE (M14), In-

vehicle Repair),

Valve Seals (303-01 Engine

-

1.4L Duratorq-TDCi (DV)

Diesel, In-vehicle Repair),

Valve Seals (303-01 Engine

-

1.6L Duratorq-TDCi (DV)

CHECK the running surfaces

and clearances of the individual

engine components. INSTALL

new components as necessary.

INSTALL a new cylinder block

if necessary.

CHECK the pistons.

REFER to: Piston Inspection

(303-00 Engine System

-

General Information, General

Procedures).

CHECK the piston rings.

REFER to: (303-00 Engine

System

- General Information)

Piston Ring-to-Groove Clear- ance (General Procedures),

Piston Ring End Gap (General

Procedures).

2006.0 Fiesta 1212006 GI 52554en

procarmanuals.com

Page 429 of 1226

303-00-7 Engine System - General Information 303-00-7

DIAGNOSIS AND TESTING

Svm~tom Possible Sources Action

Coolant consumption Cooling system components.

Oil cooler.

CHECK the coooling system.

REFER to:

Engine

Cooling (303-03 Engine

Cooling - 1.3L Duratec-8V

(Rocam)/l.25L Duratec-1 6V

(Sigma)/l.4L Duratec-1 6V

(Sigma)ll .6L Duratec-1 6V

(Sigma), Diagnosis and

Testing),

Engine

Cooling (303-03 Engine

Cooling - 2.OL Duratec-HE

(M14), Diagnosis and

Testing),

Engine

Cooling (303-03 Engine

Cooling - 1.4L Duratorq-TDCi

(DV)

Diesel, Diagnosis and

Testing),

Engine

Cooling (303-03 Engine

Cooling - 1.6L Duratorq-TDCi

(DV)

Diesel, Diagnosis and

Testing).

INSTALL a new oil cooler.

Damaged gaskets or warped

mating faces. CHECK the cylinder head

gasket for damage. CHECK the

cylinder head for distortion. - -- - -

Cracks or fractures in engine

components surrounded by

coolant, such as cylinder liners

and cylinder head combustion

chamber.

- - - - - - - -

DETERMINE the damaged

engine

component(s) and

install new component(s) as

necessary.

Engine will not crank Battery or cables. CHECK the battery, bracket

and

cables.

REFER to: Battery (41 4-01

Battery, Mounting and

Cables, Diagnosis and

Testing).

Starter motor or cables. I CHECK the starting system.

REFER to: Starting System

(303-06 Starting System,

Diagnosis and Testing).

2006.0 Fiesta 1212006 GI 52554en

I Engine cranks but will not start Fuel tank is empty. CHECK the fuel level.

procarmanuals.com

Page 436 of 1226

303-00-1 4 Engine System - General Information 303-00-1 4

DIAGNOSIS AND TESTING

Symptom

Possible Sources

Action

Timing belt or timing chain

incorrectly tensioned.

CHECK the timing belt or

timing chain tension. INSTALL

a new timing belt or timing

chain as necessary. REFER to:

Timing Belt (303-01 Engine

-

I .25L Duratec-1 6V

(Sigma)/l.4L Duratec-1 6V

(Sigma)/l .6L Duratec-1 6V

(Sigma), In-vehicle Repair),

Timing Chain (303-01 Engine

- 1.3L Duratec-8V (Rocam),

In-vehicle Repair),

Timing Chain (303-01 Engine

- 2.OL Duratec-HE (M14), In-

vehicle Repair),

Timing Belt

(303-01 Engine -

1.4L Duratorq-TDCi (DV)

Diesel, In-vehicle Repair),

Timing Belt (303-01 Engine

-

I .6L Duratorq-TDCi (DV)

Diesel, In-vehicle Repair).

Noisy running or engine noise

Engine components

- Pistons

- Piston rings

- Connecting rod big end,

main bearing or thrust

bearing journals

- Connecting rods bent or

damaged.

CHECK the engine compon-

ents for wear or damage. Make

sure all components are within

specification. INSTALL new

components as necessary.

Engine - Oil Leaks

NOTE: Before installing new gaskets or seals, make

sure that the fault is clearly established.

If the oil leak cannot be identified clearly by a visual

inspection, carry out an ultraviolet

(UV) test:

Ultraviolet (UV) Testing

1. Clean the engine and transmission with a

suitable cleaning fluid.

2. Pour the UV-test fluid in accordance with the

quantity specified by the manufacturer through

the oil filler neck into the engine and install the

oil filler cap.

A WARN1NG:Vehicles with manual transaxle,

shift the transaxle into Neutral. Failure to

follow this instruction may result in

personal injury.

3. Start the engine and let it run for about five

minutes. 4.

Switch off the engine.

N0TE:lf no leak can be found, road test the vehicle

under various loads and check the engine for leaks

again.

5. Check the engine for oil leaks using a suitable

UV lamp.

'

6. Rectify any leaks found and check the engine

for oil leaks.

Measure the compression pressure

N0TE:The powertrain control module (PCM)

receives an error message when the fuel pump

relay is removed or electrical components are

disconnected. This error message must be deleted

from the fault memory using WDS after completing

the compression test.

(' ,

'I N0TE:Valve clearance must be set correctly before

performing a compression test. Make sure the

engine is at the normal operating temperature.

2006.0 Fiesta 1212006 GI 52554en

procarmanuals.com

Page 448 of 1226

303-00-26 Engine System - General Information 303-00-26

DIAGNOSIS AND TESTING

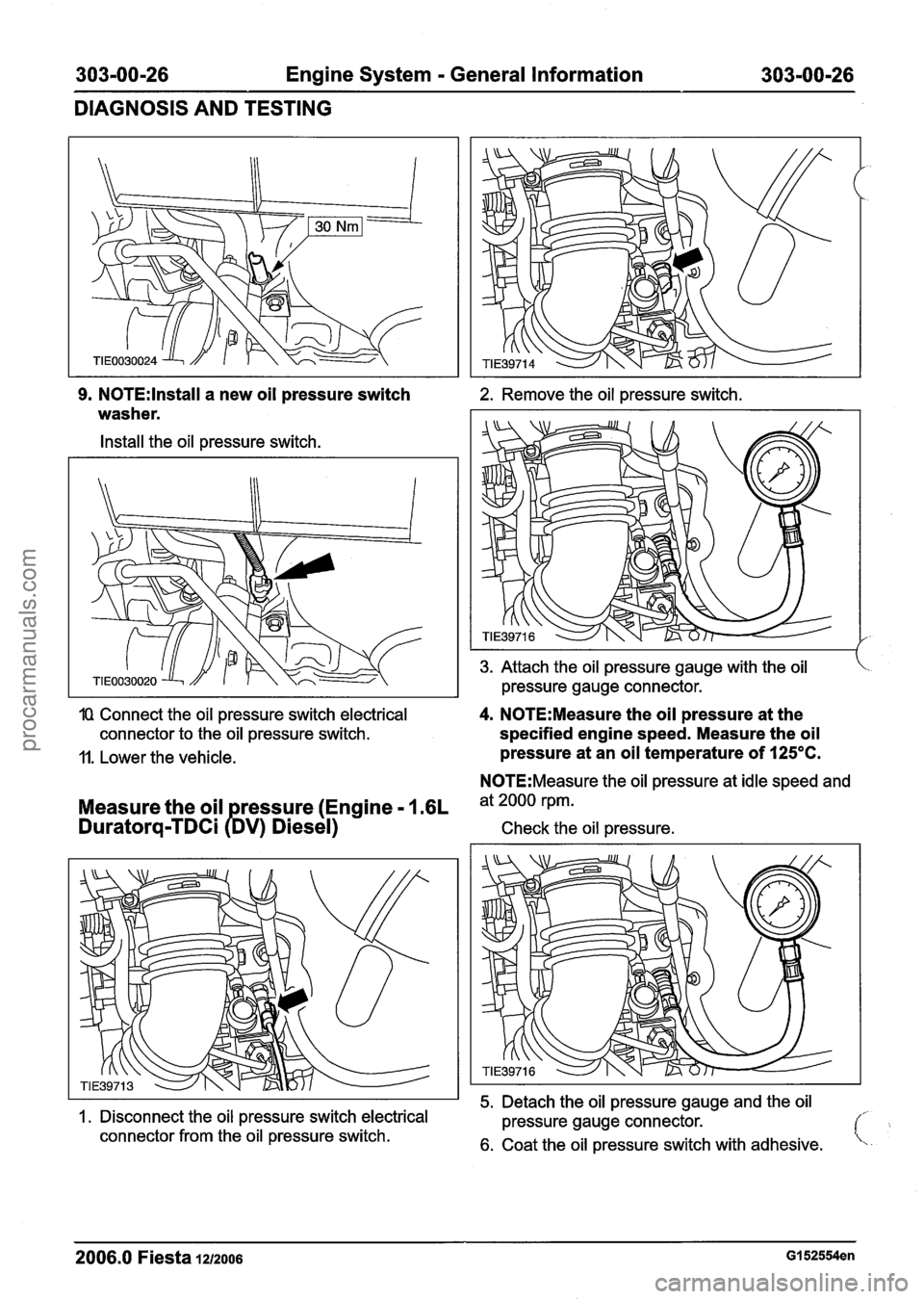

9. N0TE:lnstall a new oil pressure switch

washer.

Install the oil pressure switch.

10 Connect the oil pressure switch electrical

connector to the oil pressure switch.

11. Lower the vehicle.

Measure the oil ressure (Engine - 1.6L

Duratorq-TDCi &v) Diesel)

2. Remove the oil pressure switch.

3. Attach the oil pressure gauge with the oil

pressure gauge connector.

4. N0TE:Measure the oil pressure at the

specified engine speed. Measure the oil

pressure at an oil temperature of

125°C.

N0TE:Measure the oil pressure at idle speed and

at

2000 rpm.

Check the oil pressure.

5. Detach the oil pressure gauge and the oil I. Disconnect the oil pressure switch electrical

pressure gauge connector.

connector from the oil pressure switch. (',

6. Coat the oil pressure switch with adhesive.

2006.0 Fiesta 1u2oos GI 52554en

procarmanuals.com

Page 453 of 1226

303-00-31 Engine System - General Information 303-00-31

DIAGNOSIS AND TESTING

11. Connect the oil pressure switch electrical

connector to the oil pressure switch.

12 Lower the vehicle.

Valve train analysis - static (engine off)

Remove the valve cover.

Check all components of the valve train for damage

and wear. Make sure that only original components

are installed and that all nuts and bolts are

tightened to the specified torque.

2006.0 Fiesta 1212006 GI 52554en

procarmanuals.com

Page 541 of 1226

Engine - 1.25L Duratec-1 6V (Sigma)ll.4L

303-01 A-65 Duratec-1 6V (Sigma)ll .6L Duratec-1 6V (Sigma) 303-01 A-65

IN-VEHICLE REPAIR

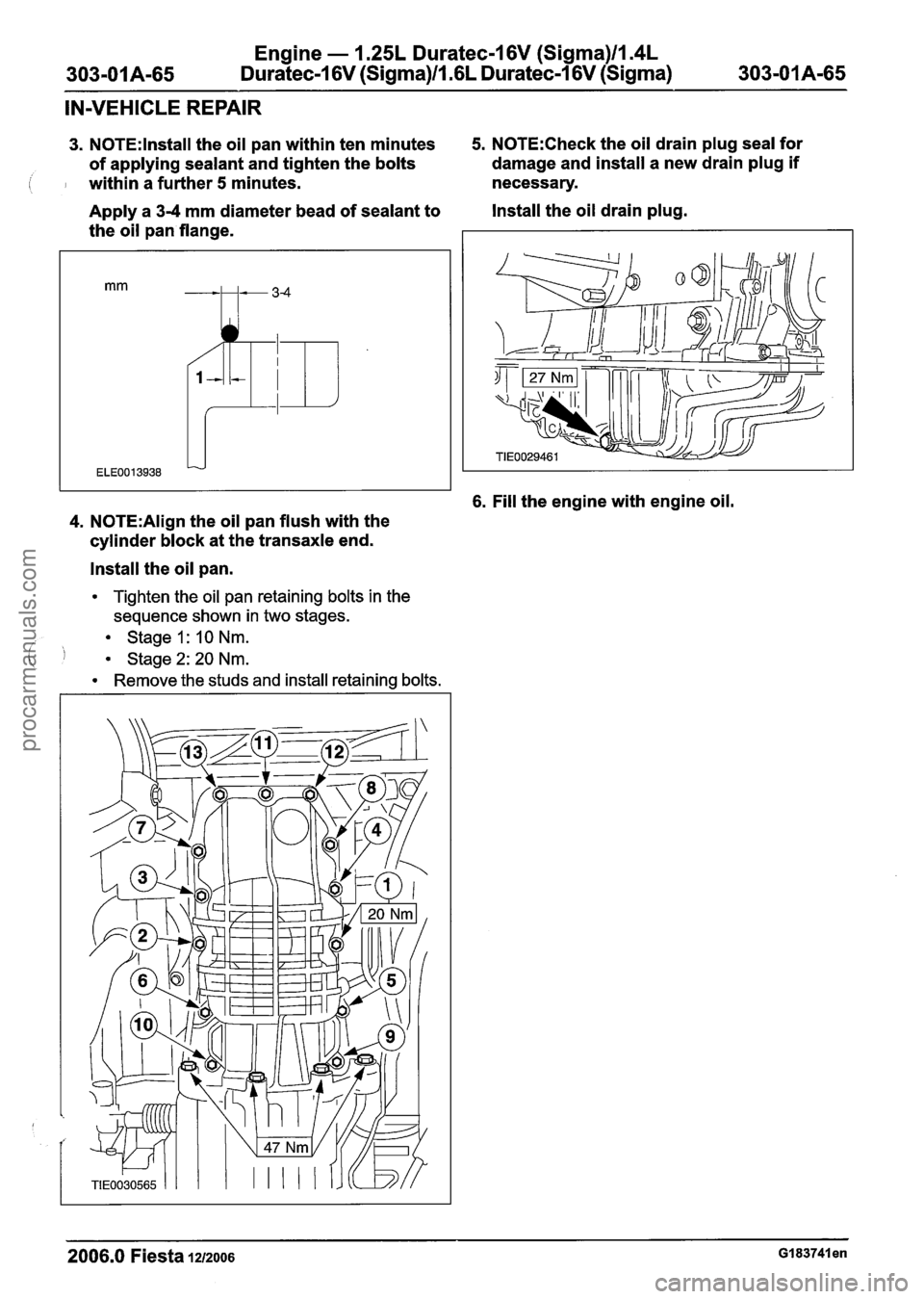

3. N0TE:lnstall the oil pan within ten minutes 5. N0TE:Check the oil drain plug seal for

of applying sealant and tighten the bolts damage

and install a new drain plug if

( I within a further 5 minutes. necessary.

Apply a 3-4 mm diameter bead of sealant to Install the oil drain plug.

the oil pan flange.

6. Fill the engine with engine oil.

4. N0TE:Align the oil pan flush with the

cylinder block at the transaxle end.

Install the oil pan.

Tighten the oil pan retaining bolts in the

sequence shown in two stages.

Stage

I : 10 Nm.

( I Stage2:20Nm.

Remove the studs and install retaining bolts.

2006.0 Fiesta 1212006 GI 83741 en

procarmanuals.com

Page 610 of 1226

Engine - 1.25L Duratec-1 6V (Sigma)ll.4L

303-01 A-I 34 Duratec-1 6V (Sigma)ll .6L Duratec-I 6V (Sigma) 303-01 A-1 34

INSTALLATION

Engine - Vehicles With: Autom

Special Tool(s)

I I Remover/lnstaller, Hose (

General Eaui~ment

1 Straight edge I

I Securing straps I

atic Transaxle

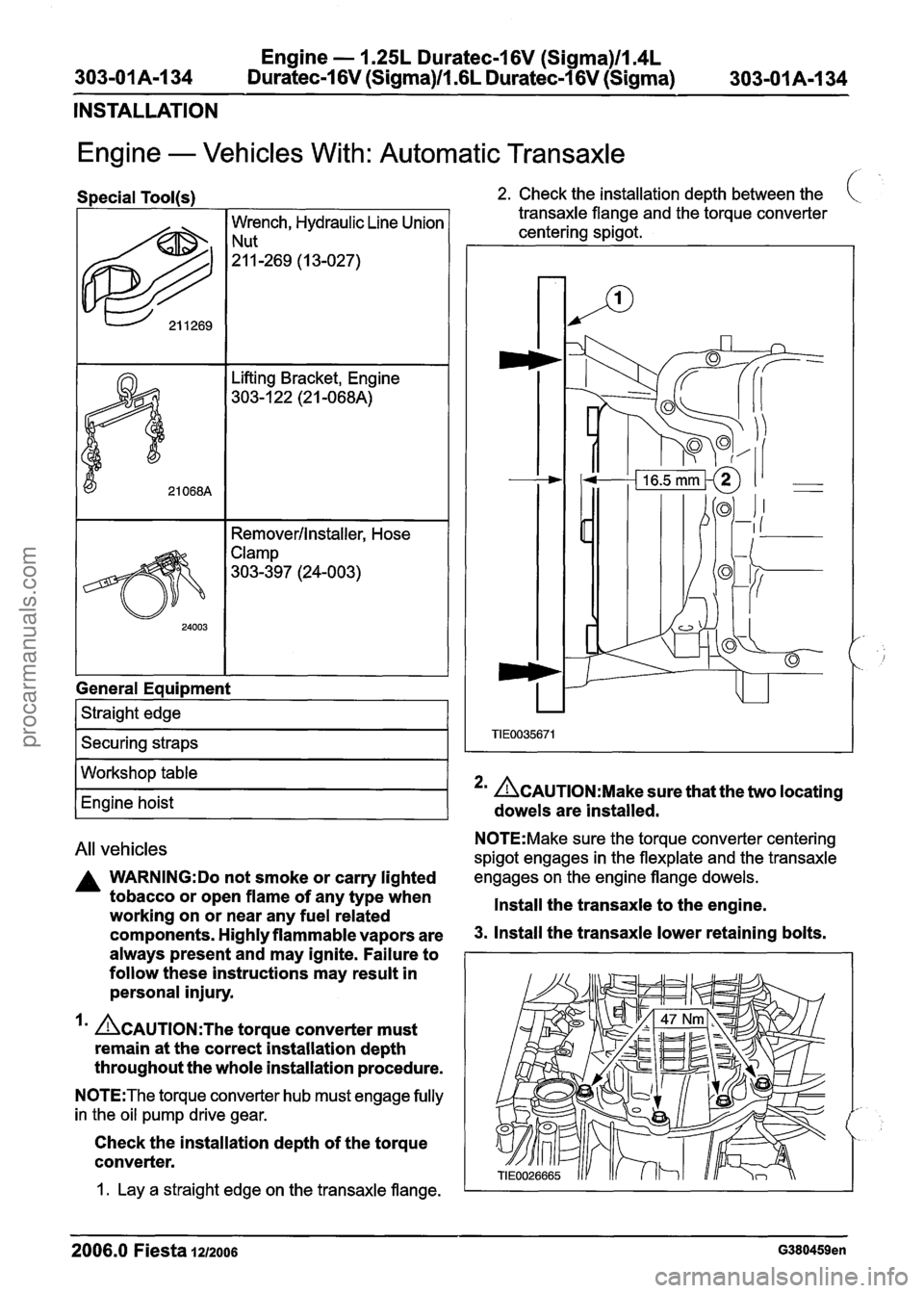

2. Check the installation depth between the

transaxle flange and the torque converter c

centering spigot.

All vehicles N0TE:Make sure the torque converter centering

spigot engages in the flexplate and the transaxle

A WARNING:Do not smoke or carry lighted engages on the engine flange dowels.

tobacco or open flame of any type when

Install the transaxle to the engine.

working on or near any fuel related

components. Highly flammable vapors are 3. Install the transaxle lower retaining bolts.

always present and may ignite. Failure to I I

Workshop table

Engine hoist

follow these instructions may result in

personal injury.

'' &AUTION:T~~ torque converter must

remain at the correct installation depth

throughout the whole installation procedure.

N0TE:The torque converter hub must engage fully

in the oil pump drive gear.

Check the installation depth of the torque

converter.

*' &AUTION:M~~~ sure that the two locating

dowels are installed.

1. Lay a straight edge on the transaxle flange. I

2006.0 Fiesta 1212006 G380459en

procarmanuals.com

Page 632 of 1226

303-01 B-I 0 Engine - 2.OL Duratec-HE (M14) 303-01 B-I 0 - -- --

DESCRIPTION AND OPERATION

Valve tappets Camshaft drive

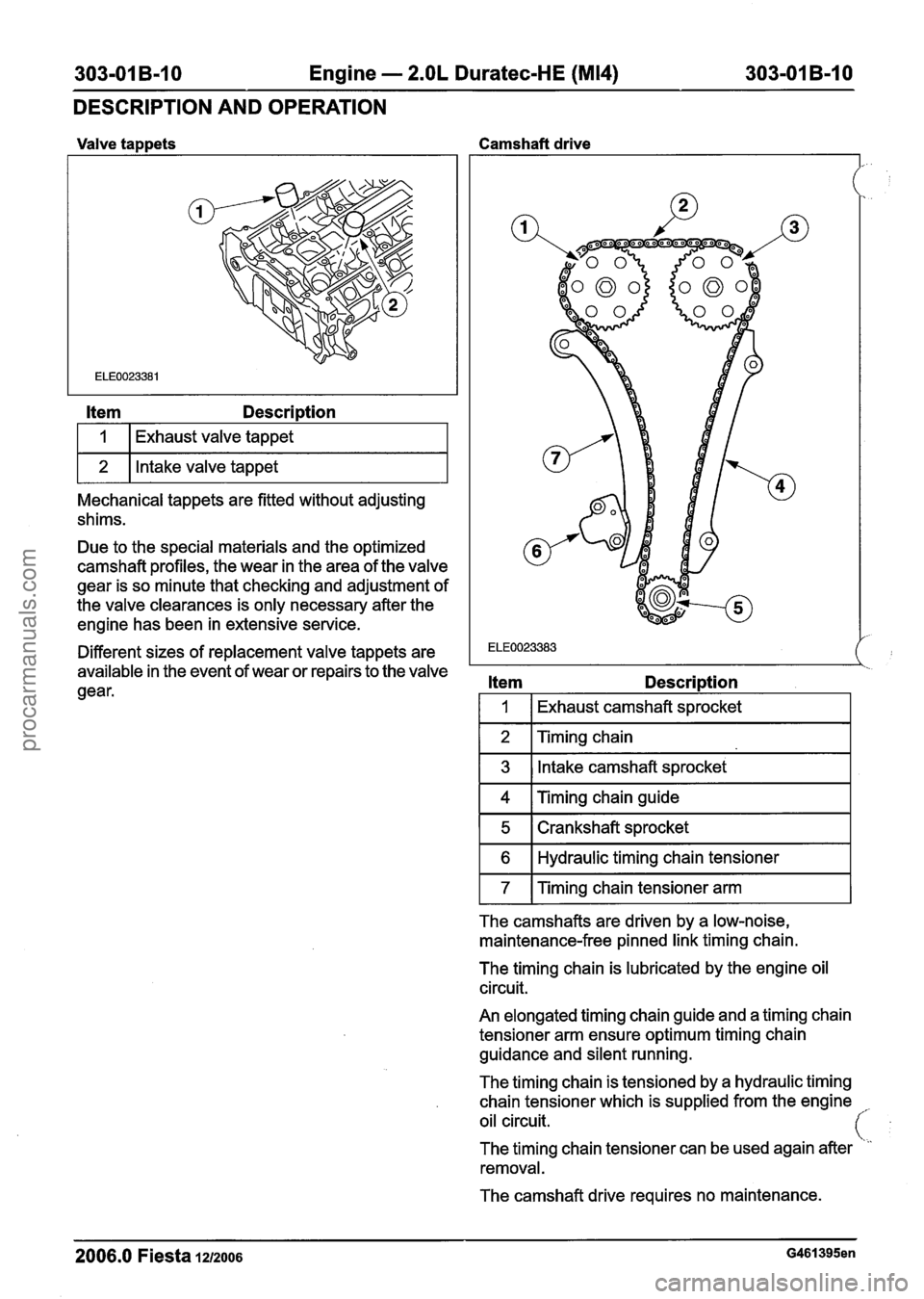

Item Description

I 1 I Exhaust valve tappet I

1 2 1 Intake valve tappet I

Mechanical tappets are fitted without adjusting

shims.

Due to the special materials and the optimized

camshaft profiles, the wear in the area of the valve

gear is so minute that checking and adjustment of

the valve clearances is only necessary after the

engine has been in extensive service.

Different sizes of replacement valve tappets are

I ELE0023383

available in the event of wear or repairs to the valve ' '2

gear. Item Description

I 1 I Exhaust camshaft sprocket

1 2 I Timing chain I

1 3 1 Intake camshaft sprocket I

1 4 I ~imin~ chain guide I

1 5 1 Crankshaft sprocket I

1 6 1 Hydraulic timing chain tensioner I

1 7 1 ~imin~ chain tensioner arm 1 - -

The camshafts are driven by a low-noise,

maintenance-free pinned link timing chain.

The timing chain is lubricated by the engine oil

circuit.

An elongated timing chain guide and a timing chain

tensioner arm ensure optimum timing chain

guidance and silent running.

The timing chain is tensioned by a hydraulic timing

chain tensioner which is supplied from the engine

,.

oil circuit.

The timing chain tensioner can be used again after

removal.

The camshaft drive requires no maintenance.

2006.0 Fiesta 1212006 G461395en

procarmanuals.com