engine FORD FIESTA 2007 Owner's Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 75 of 1226

I 00-04-1 9 Noise, Vibration and Harshness 100-04-19

DIAGNOSIS AND TESTING

PINPOINT TEST C : IDLE BOOMISHAKENIBRATIONISHUDDER

1 TEST CONDITIONS DETAILSIRESU LTSIACTIONS

C1: CHECK THE CABLEIHOSES

rn Check the engine compartment for any

component that may have a touch condition

between the engine and body or chassis. For

example: control cable, air conditioning

(AIC)

hoses, acceleration cable.

Are the components OK?

-+ Yes

GO to C2.

+ No

REPAIR or INSTALL new components as

necessary. ROAD TEST as necessary.

C2: CHECK THE ENGINE COOLING RADIATOR

rn Check the engine cooling radiator mountings

and bushings for security and condition. Check

the radiator installation for any component that

may have a touch condition.

Is the installation and bushings OK?

+ Yes

GO to C3.

-+ No

REPAIR or INSTALL new components as

necessary. ROAD TEST as necessary.

C3: CHECK THE EXHAUST SYSTEM

rn Carry out the exhaust system neutralizing

procedure.

REFER to: Exhaust System Neutralizing

(1 00-

04, General Procedures).

Is the exhaust system OK?

+ Yes

GO to C4.

+ No

REPAIR as necessary. ROAD TEST as

necessary.

2006.0 Fiesta 1212006 G37349en

procarmanuals.com

Page 100 of 1226

204-01 -2 Front Suspension 204-01 -2

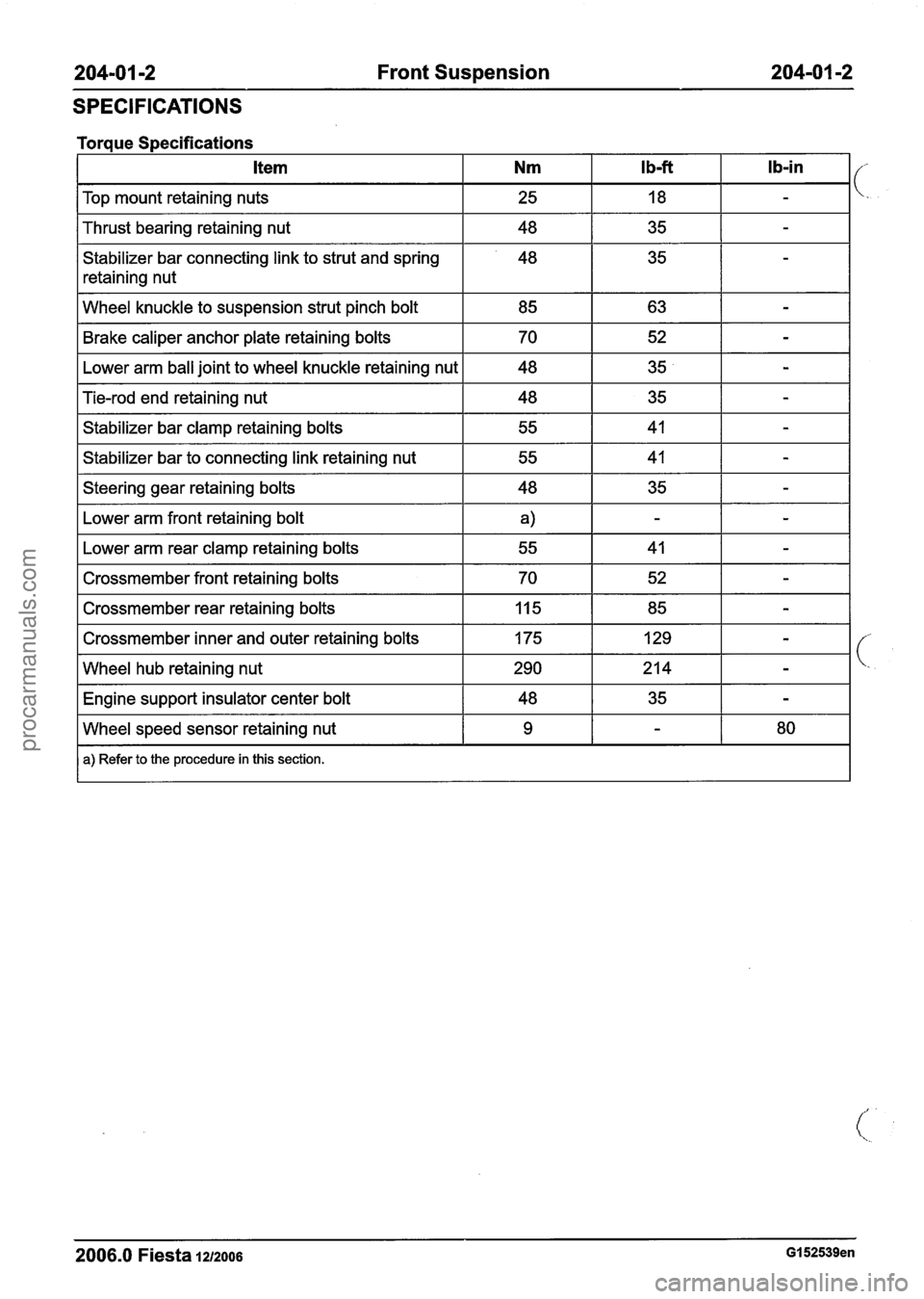

SPECIFICATIONS

I Top mount retaining nuts I 25 I 18 I - I

Torque Specifications

I Thrust bearing retaining nut I 48 I 35 I - I

Stabilizer bar connecting link to strut and spring

retaining nut Ib-in

I Wheel

knuckle to suspension strut pinch bolt I 85 I 63 I - I

Ib-ft Item Nm

Brake caliper anchor plate retaining bolts

Lower arm ball joint to wheel knuckle retaining nut

I Steering gear retaining bolts I 48 I 35 I - I

Tie-rod end retaining nut

Stabilizer bar clamp retaining bolts

Stabilizer bar to connecting link retaining nut

Fb.wer arm front retaining bolt I

70

48

I Lower arm rear clamp retaining bolts I 55 I 41 I - I

48

55

55

I Crossmember front retaining bolts I 70 I 52 I - I

52

35

I Crossmember rear retaining bolts 1 Iq5 1 85 I - I

-

-

35

41

41

I Crossmember inner and outer retaining bolts 1 175 1 129 1 - I

-

-

-

I Wheel hub retaining nut 1290 1214 1 - I

I Engine support insulator center bolt I 48 I 35 I - I

2006.0 Fiesta 1212006 GI 52539en

Wheel speed sensor retaining nut

a) Refer to the procedure in this section.

9 - 80

procarmanuals.com

Page 107 of 1226

204-01 -9 Front Suspension 204-0 I -9

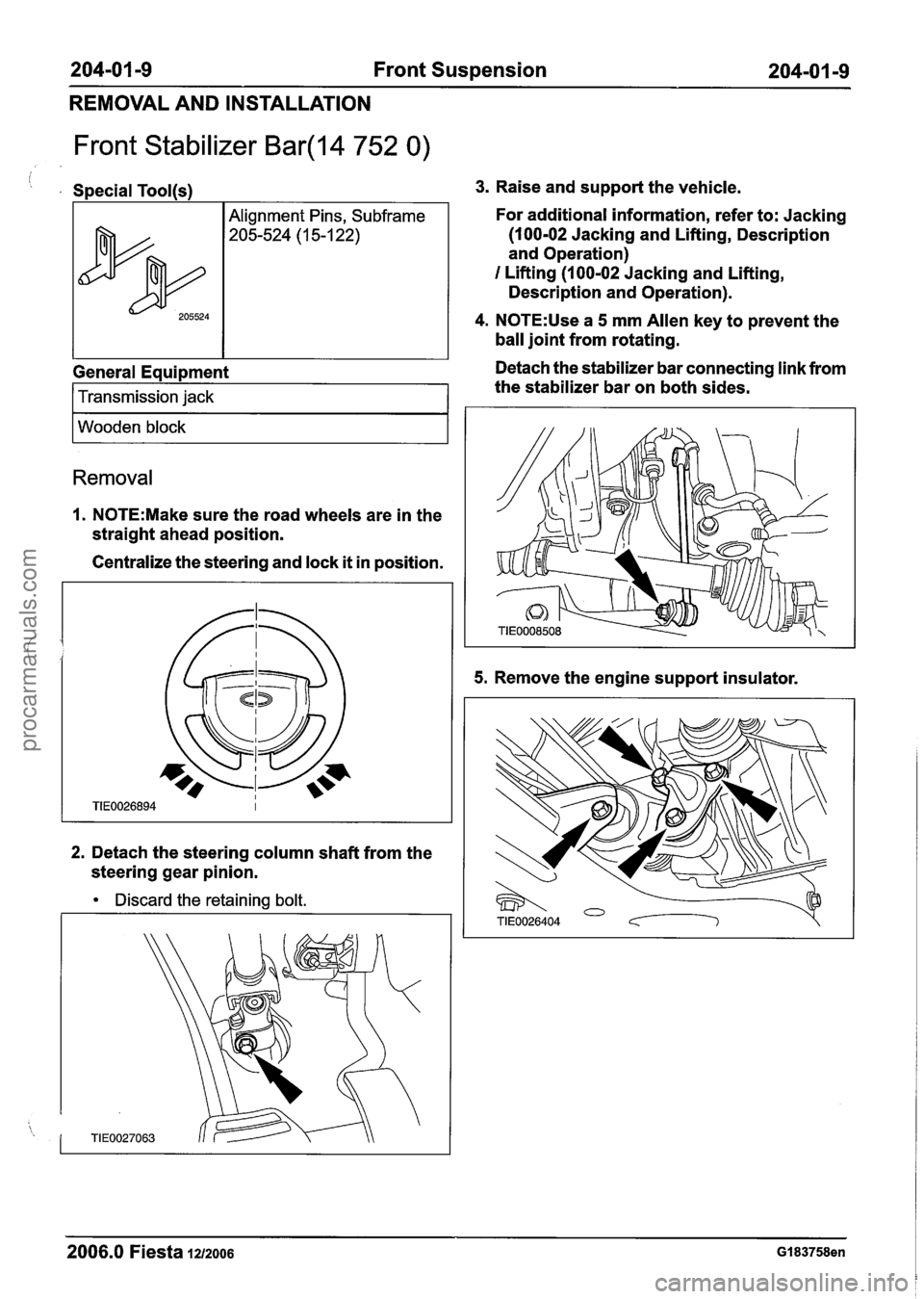

REMOVAL AND INSTALLATION

Front Stabilizer Bar(l4 752 0)

i , Special Tool(s1

General Equipment

205524

I Transmission jack 1

Alignment Pins, Subframe

205-524 (1 5-1 22)

I Wooden block I

Removal

1. N0TE:Make sure the road wheels are in the

straight ahead position.

Centralize the steering and lock

it in position.

2. Detach the steering column shaft from the

steering gear pinion.

Discard the retaining bolt.

3. Raise and support the vehicle.

For additional information, refer to: Jacking

(100-02 Jacking and Lifting, Description

and Operation)

I Lifting (1 00-02 Jacking and Lifting,

Description and Operation).

4. N0TE:Use a 5 mm Allen key to prevent the

ball joint from rotating.

Detach the stabilizer bar connecting link from

the stabilizer bar on both sides.

5. Remove the engine support insulator.

2006.0 Fiesta 1212006 GI 83758en

procarmanuals.com

Page 110 of 1226

204-01 -1 2 Front Suspension 204-01 -1 2 ---- - -

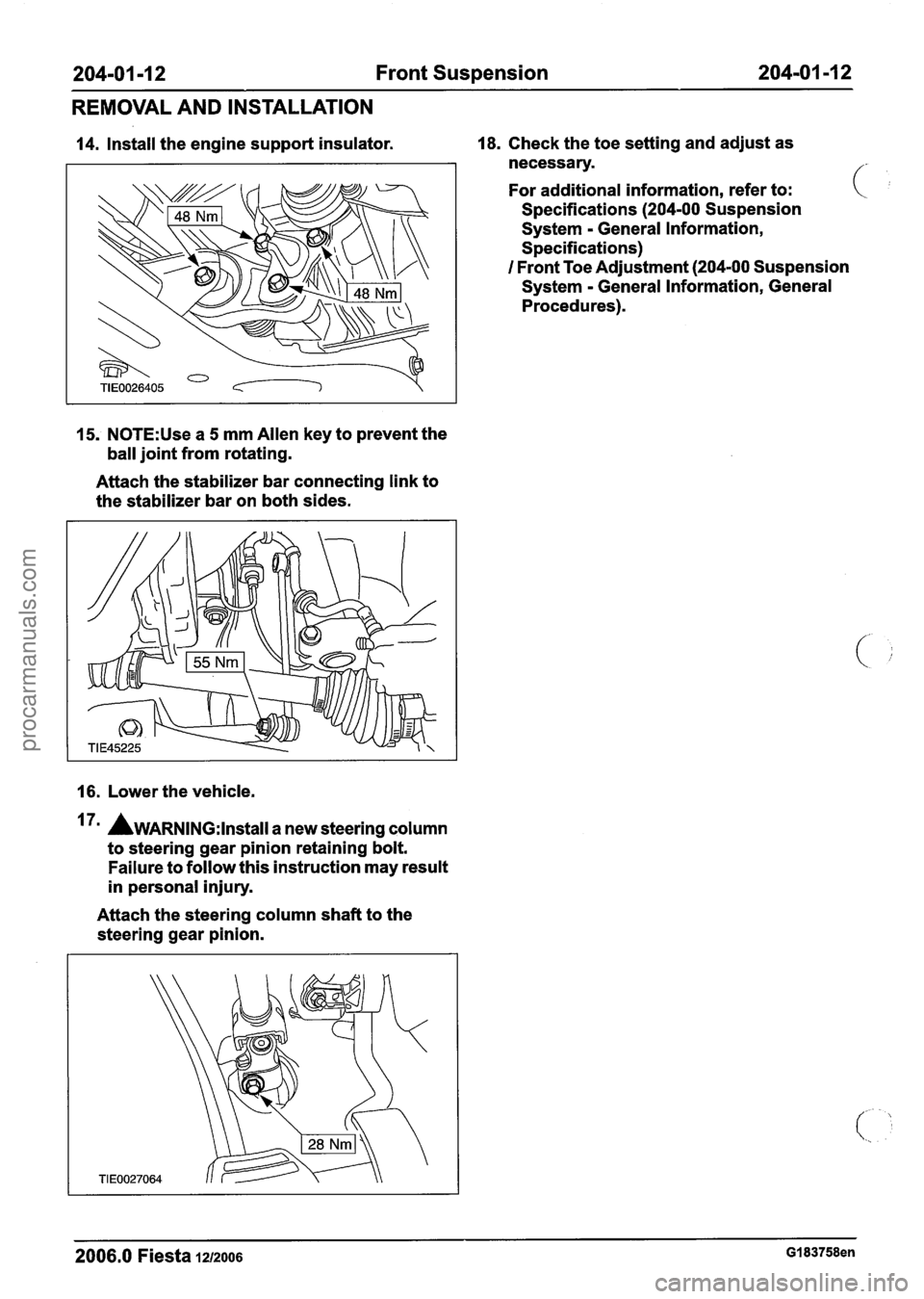

REMOVAL AND INSTALLATION

14. Install the engine support insulator. 18. Check the toe setting and adjust as

necessary.

For additional information, refer to:

Specifications

(204-00 Suspension

System

- General Information,

Specifications)

I Front Toe Adjustment (204-00 Suspension

System

- General Information, General

Procedures).

15. N0TE:Use a 5 mm Allen key to prevent the

ball joint from rotating.

Attach the stabilizer bar connecting link to

the stabilizer bar on both sides.

16. Lower the vehicle.

7m AWARNING:I~~~~II a new steering column

to steering gear pinion retaining bolt.

Failure to follow this instruction may result

in personal injury.

Attach the steering column shaft to the

steering gear pinion.

2006.0 Fiesta 1212006 GI 83758en

procarmanuals.com

Page 119 of 1226

204-01 -21 Front Suspension 204-01 -21

REMOVAL AND INSTALLATION

Front Wheel Bearing(l4 41 1 0)

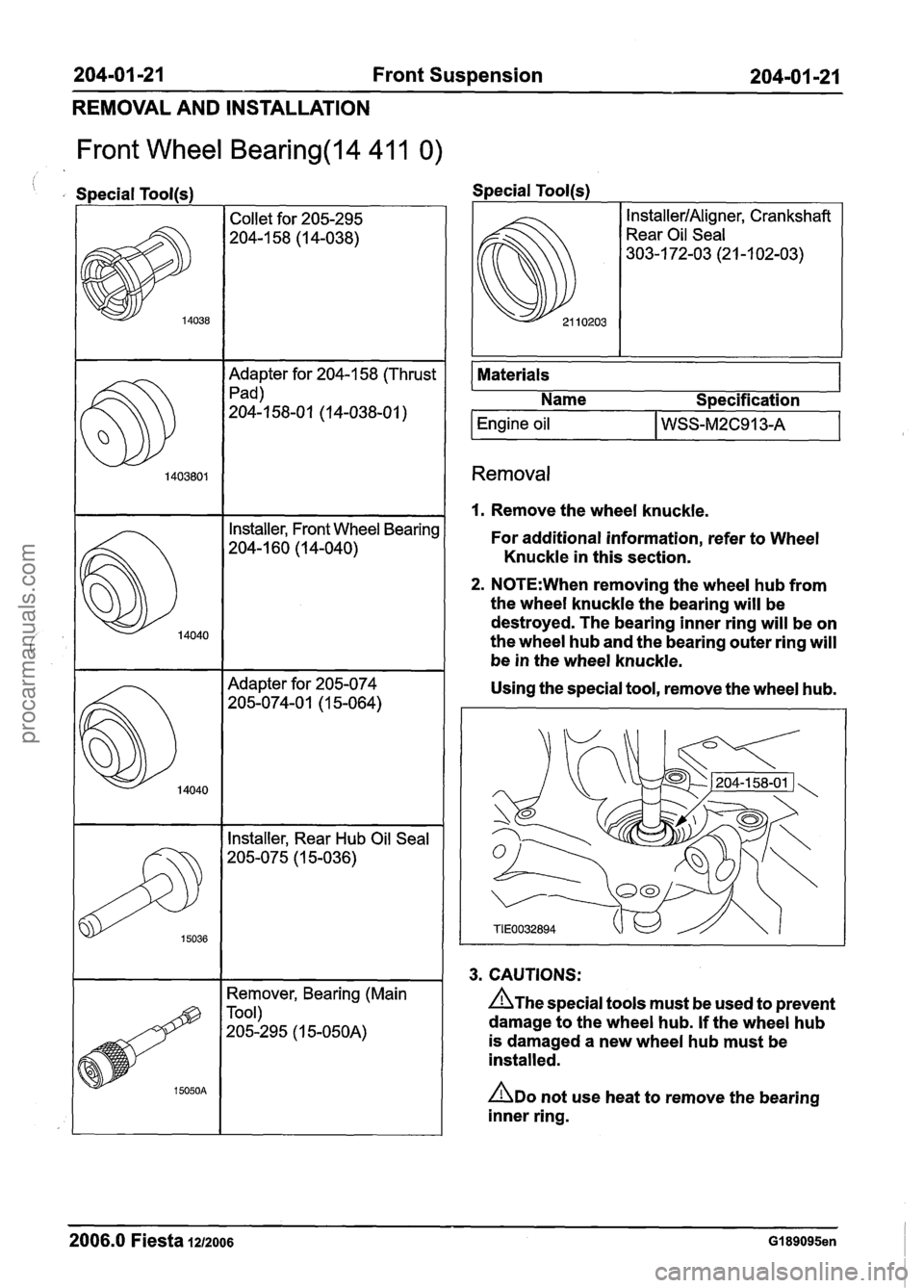

, Special Toolls) Special Tool(s)

Adapter for 204-1 58 (Thrust

Pad)

204-1 58-01 (1 4-038-01

)

Installer, Rear Hub Oil Seal

205-075 (1 5-036)

14040

14040

Remover, Bearing (Main

Tool)

205-295 (1

5-050A)

Installer, Front Wheel Bearing

204-1 60 (1 4-040)

Adapter for 205-074

205-074-0 1 (1 5-064)

I I

Materials 1

@l 0203

I Name I Specification

Engine oil I WSS-M2C913-A

InstallerIAligner, Crankshaft

Rear Oil Seal

303-1 72-03 (2 1 -1 02-03)

Removal

I. Remove the wheel knuckle.

For additional information, refer to Wheel

Knuckle in this section.

2. N0TE:When removing the wheel hub from

the wheel knuckle the bearing will be

destroyed. The bearing inner ring will be on

the wheel hub and the bearing outer ring will

be in the wheel knuckle.

Using the special tool, remove the wheel hub.

3. CAUTIONS:

n~he special tools must be used to prevent

damage to the wheel hub. If the wheel hub

is damaged a new wheel hub must be

installed.

ADO not use heat to remove the bearing

inner ring.

2006.0 Fiesta 1212006 GI 89095en

procarmanuals.com

Page 120 of 1226

204-01 -22 Front Suspension 204101 122

REMOVAL AND INSTALLATION

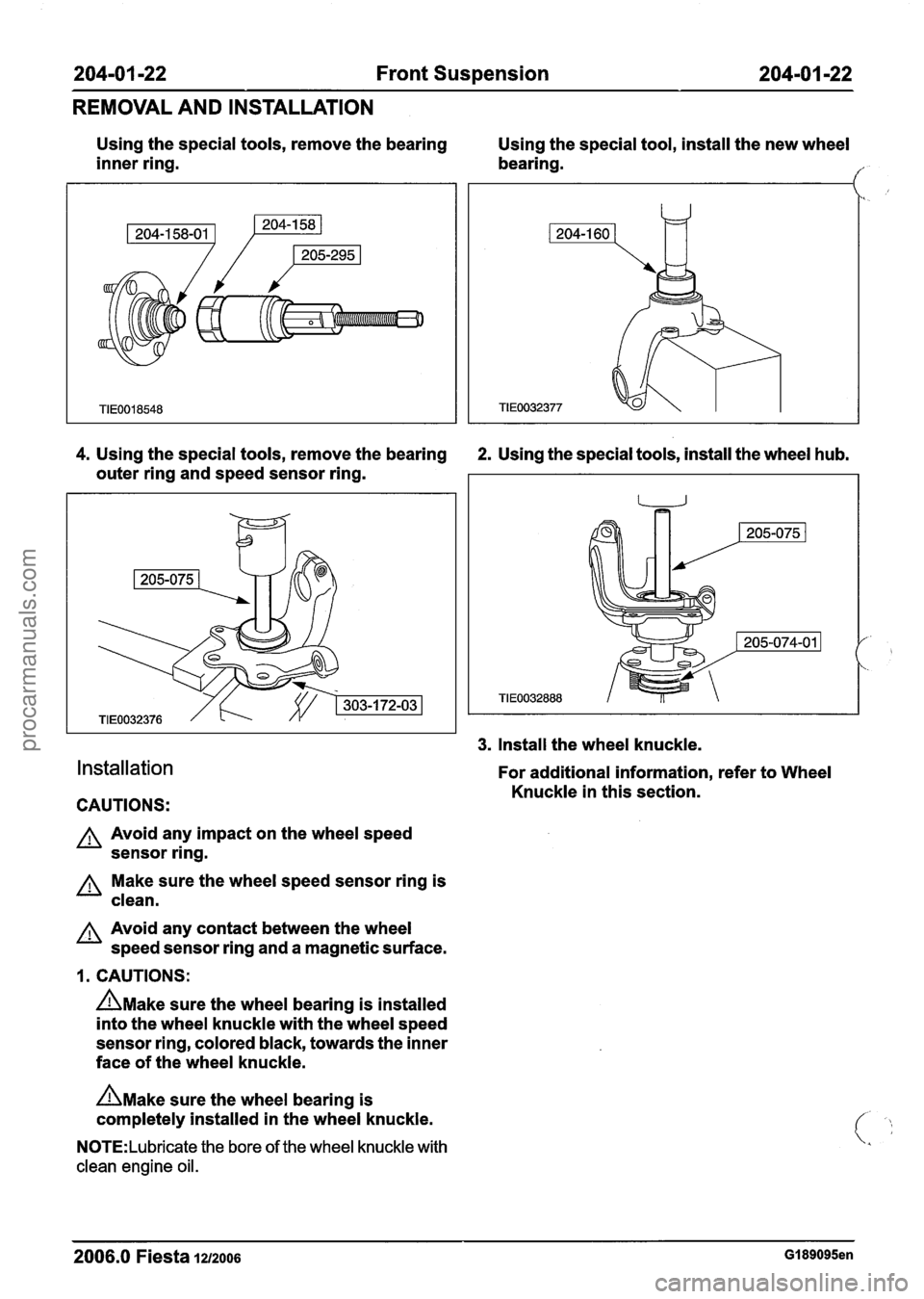

Using the special tools, remove the bearing

Using the special tool, install the new wheel

inner ring. bearing.

I"

4. Using the special tools, remove the bearing 2. Using the special tools, install the wheel hub.

outer ring and speed sensor ring.

Installation

CAUTIONS:

A Avoid any impact on the wheel speed

sensor ring.

Make sure the wheel speed sensor ring is

clean.

A Avoid any contact between the wheel

speed sensor ring and a magnetic surface.

1. CAUTIONS:

n~ake sure the wheel bearing is installed

into the wheel knuckle with the wheel speed

sensor ring, colored black, towards the inner

face of the wheel knuckle.

n~ake sure the wheel bearing is

completely installed in the wheel knuckle.

N0TE:Lubricate the bore of the wheel knuckle with

clean engine oil.

3. Install the wheel knuckle.

For additional information, refer to Wheel

Knuckle in this section.

--

2006.0 Fiesta 1212006 GI 89095en

procarmanuals.com

Page 147 of 1226

204-04-3 Wheels and Tires 204-04-3

DIAGNOSIS AND TESTING

Wheels and Tires

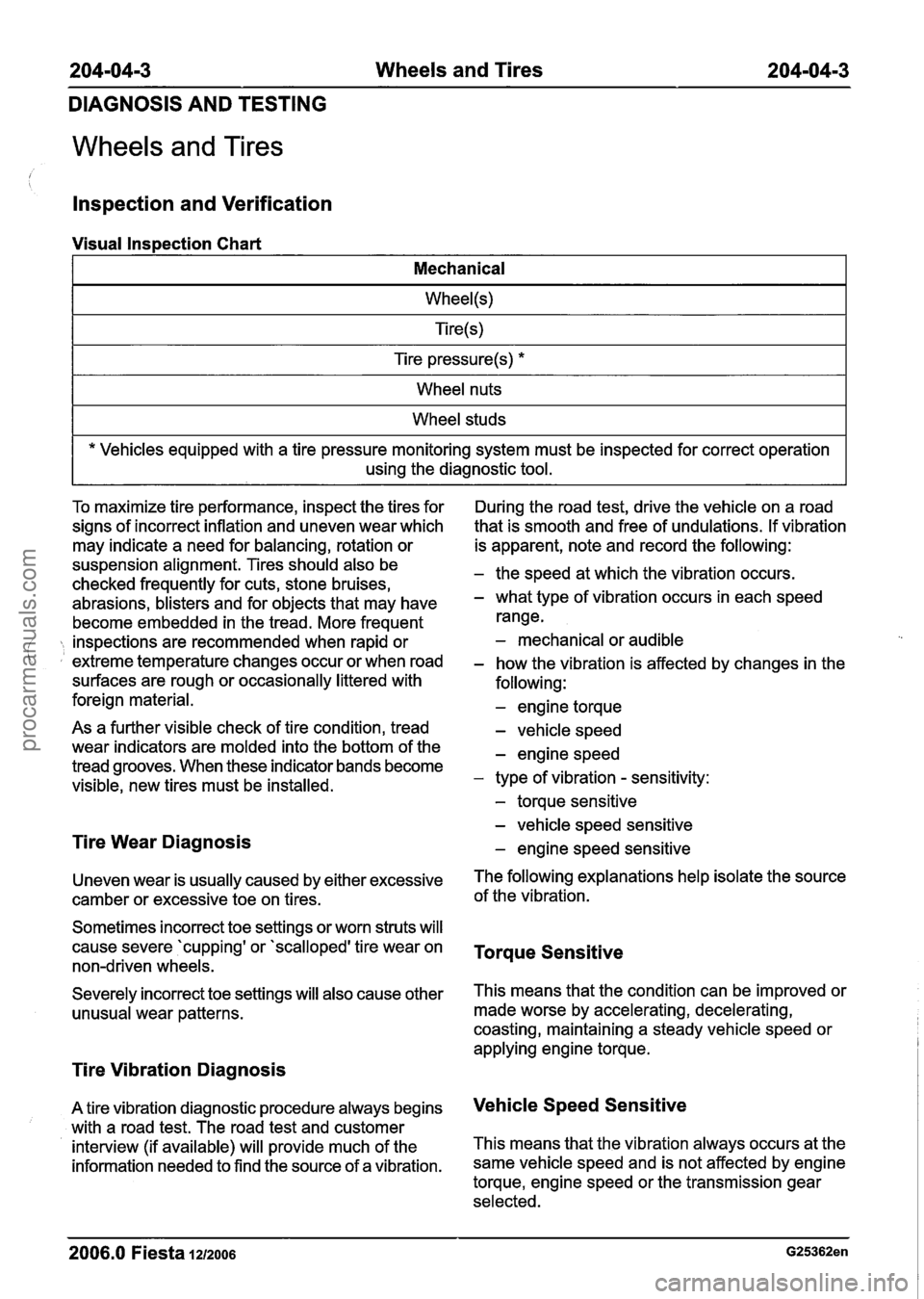

lnspection and Verification

Visual Inspection Chart

I Mechanical I

I Tire pressure(s) * I

I Wheel nuts I

I Wheel studs I

* Vehicles equipped with a tire pressure monitoring system must be inspected for correct operation

using the diagnostic tool.

To maximize tire performance, inspect the tires for

signs of incorrect inflation and uneven wear which

may indicate a need for balancing, rotation or

suspension alignment. Tires should also be

checked frequently for cuts, stone bruises,

abrasions, blisters and for objects that may have

become embedded in the tread. More frequent

inspections are recommended when rapid or ( extreme temperature changes occur or when road

surfaces are rough or occasionally littered with

foreign material.

As a further visible check of tire condition, tread

wear indicators are molded into the bottom of the

tread grooves. When these indicator bands become

visible, new tires must be installed.

Tire Wear Diagnosis

Uneven wear is usually caused by either excessive

camber or excessive toe on tires.

Sometimes incorrect toe settings or worn struts will

cause severe 'cupping' or 'scalloped' tire wear on

non-driven wheels.

Severely incorrect toe settings will also cause other unusual wear patterns.

Tire Vibration Diagnosis

A tire vibration diagnostic procedure always begins

with a road test. The road test and customer

interview (if available) will provide much of the

information needed to find the source of a vibration. During

the road test, drive the vehicle on a road

that is smooth and free of undulations. If vibration

is apparent, note and record the following:

- the speed at which the vibration occurs.

- what type of vibration occurs in each speed

range.

- mechanical or audible

- how the vibration is affected by changes in the

following:

- engine torque

- vehicle speed

- engine speed

- type of vibration - sensitivity:

- torque sensitive

- vehicle speed sensitive

- engine speed sensitive

The following explanations help isolate the source

of the vibration.

Torque Sensitive

This means that the condition can be improved or

made worse by accelerating, decelerating,

coasting, maintaining a steady vehicle speed or

applying engine torque.

Vehicle Speed Sensitive

This means that the vibration always occurs at the

same vehicle speed and is not affected by engine

torque, engine speed or the transmission gear

selected.

2006.0 Fiesta 1212006

procarmanuals.com

Page 148 of 1226

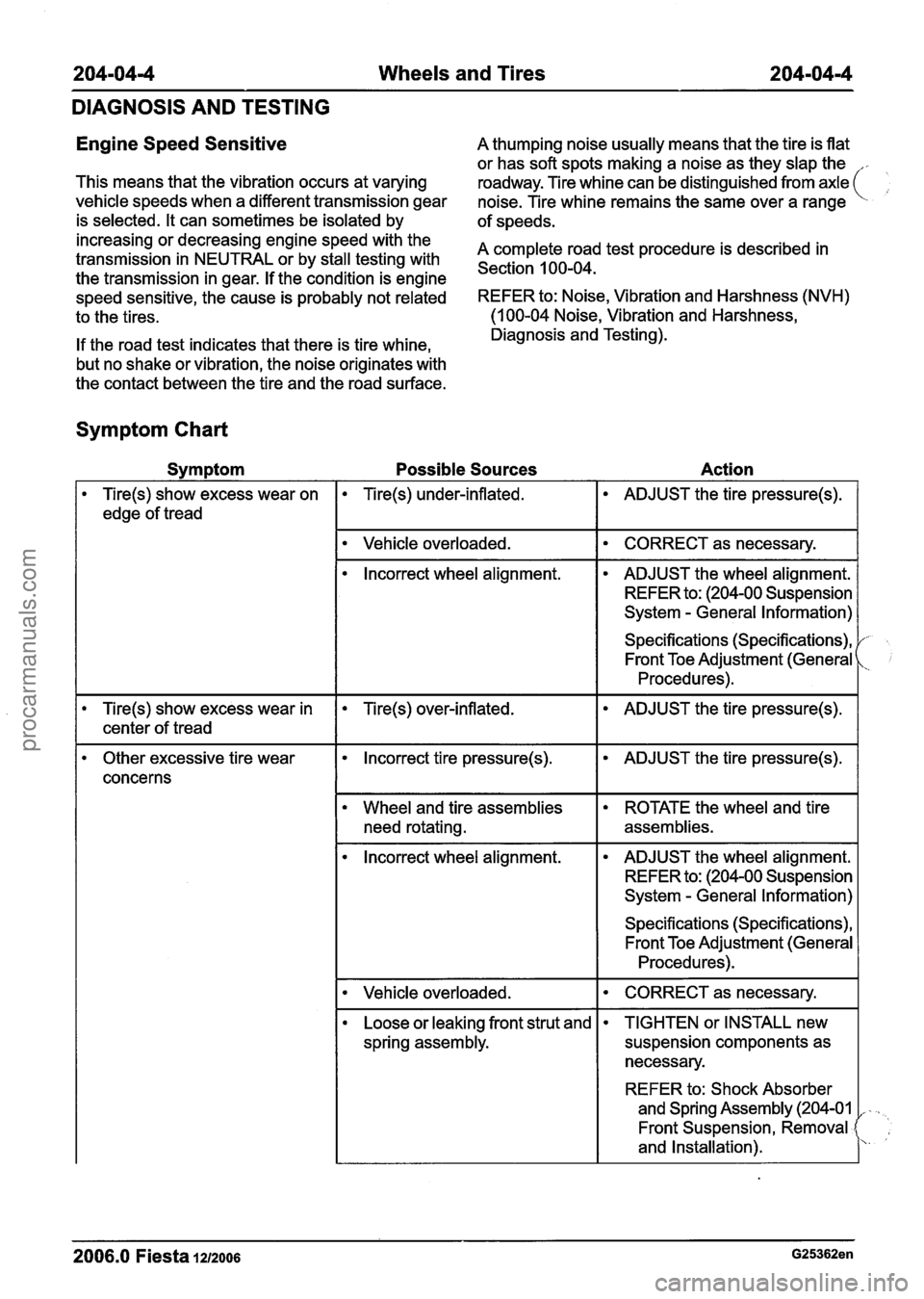

204-0414 Wheels and Tires 204-04-4

DIAGNOSIS AND TESTING

Engine Speed Sensitive A thumping noise usually means that the tire is flat

or has soft spots making a noise as they slap the

This means that the vibration occurs at varying

roadway. Tire whine can be distinguished from axle

vehicle speeds when a different transmission gear

noise. Tire whine remains the same over a range

is selected. It can sometimes be isolated by

of speeds.

increasing Or decreasing engine with the A complete road test procedure is described in transmission in NEUTRAL or by stall testing with Section the transmission in gear. If the condition is engine

speed sensitive, the-cause is probably not related

REFER to: Noise, Vibration and Harshness (NVH)

to the tires. (1

00-04 Noise, Vibration and Harshness,

If the road test indicates that there is tire whine, Diagnosis and

Testing).

but no shake or vibration, the noise originates with

the contact between the tire and the road surface.

Symptom Chart

Symptom Possible Sources Action

Tire(s) show excess wear on

edge of tread

I Vehicle overloaded. I CORRECT as necessary. I

Tire(s) under-inflated.

lncorrect wheel alignment. ADJUST the tire pressure(s).

ADJUST the wheel alignment.

REFER to: (204-00 Suspension

System

- General Information)

Specifications (Specifications), Front Toe Adjustment (General

Procedures).

Tire(s) show excess wear in Tire(s) over-inflated.

I I

ADJUST the tire pressure(s).

I center of tread

Other excessive tire wear Incorrect tire pressure(s).

concerns

need rotating.

ADJUST the tire pressure(s).

ROTATE the wheel and tire

assemblies.

lncorrect wheel alignment. ADJUST the wheel alignment.

REFER to: (204-00 Suspension

System

- General Information)

Specifications (Specifications), Front Toe Adjustment (General

Procedures).

I Vehicle overloaded.

Loose or leaking front strut and

spring assembly. CORRECT as necessary.

I

2006.0 Fiesta 1212006 G25362en

TIGHTEN

or INSTALL new

suspension components as

necessary.

REFER to: Shock Absorber

and Spring Assembly (204-01

,

Front Suspension, Removal

and Installation).

procarmanuals.com

Page 155 of 1226

205-04-3 Front Drive Halfshafts 205-04-3

DESCRIPTION AND OPERATION

Front Drive Halfshafts

Drives hafts

Conventional driveshafts are used on the front axle.

For servicing purposes it is important to note that

the inner tripod joints are pressed onto the shaft.

This has made it possible to reduce noise levels

when the vehicle is pulling away from standing.

The outer joint has not been approved for service

repairs, so in the event of a fault it is necessary to

replace the complete shaft and outer joint

assembly. The inner joints are dismantled with the

aid of a puller. The driveshaft needs to be removed

first.

In order to install a new boot on the outer joint, it

is first necessary to remove the driveshaft and then

disassemble the inner joint. A special service kit is

available in service for this purpose, consisting of

the inner and outer boot and the necessary small

parts.

The same amount of grease is used to pack the

inner and outer joints.

- The PAC nut used for securing the driveshaft to ' the wheel hub must not be reused.

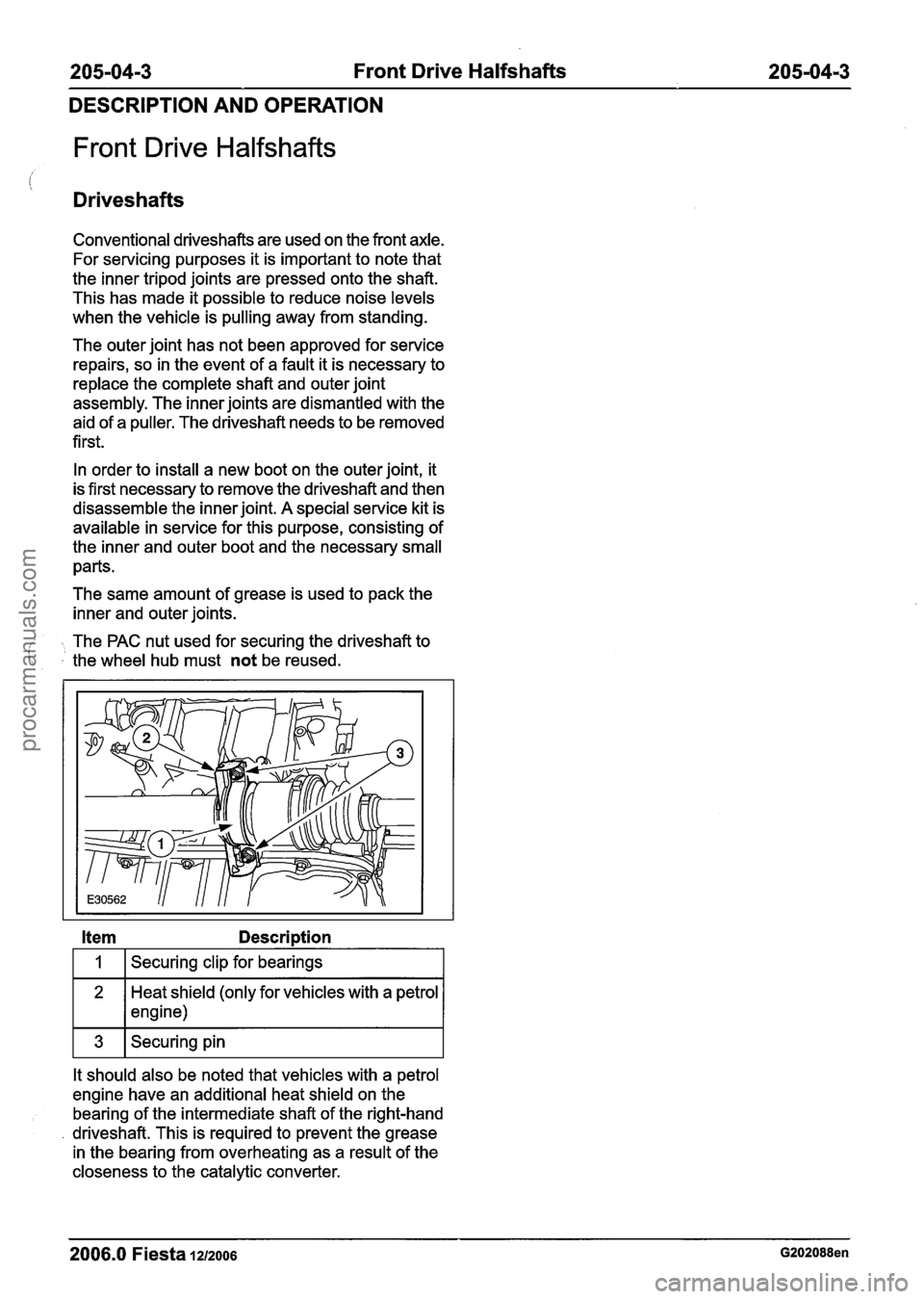

Item Description

I 1 I Securing clip for bearings I

Heat shield (only for vehicles with a petrol

1 * 1 engine)

It should also be noted that vehicles with a petrol

engine have an additional heat shield on the bearing of the intermediate shaft of the right-hand

driveshaft. This is required to prevent the grease

in the bearing from overheating as a result of the

closeness to the catalytic converter.

2006.0 Fiesta 1212006 G202088en

procarmanuals.com

Page 157 of 1226

205-04-5 Front Drive Halfshafts 205-04-5

DIAGNOSIS AND TESTING

Possible Sources Action

Halfshaft Joint Pullout Outer front drive halfshaft INSPECT

and REPAIR or

retainer circlip missing or not

I I INSTALL new as necessary.

Front suspension components

worn or damaged.

correctly seated differential

side. CHECK

for worn bushings or

bent components (front stabil-

izer bar, front suspension lower

arm). REPAIR or INSTALL new

as necessary. REFER to

Section

204-01 [Front

Suspension]. REFER to Halfshaft

LH

-

1 Halfshaft RH - in this section.

Engineltransaxle assembly

misalignment. CHECK engine mounts for

damage or wear. REPAIR or

INSTALL new as necessary.

Frame rail or strut tower out of

position or damaged. CHECK underbody dimen-

sions. REFER to Section

501 -

00 [Body System - General

Information].

-- - --

2006.0 Fiesta 1212006 G25403en

procarmanuals.com