air condition FORD FIESTA 2007 Manual Online

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 862 of 1226

303-05-24 Accessory Drive 303-05-24

REMOVAL AND INSTALLATION

Power Steering Pump Belt - 1.4L Duratec-1 6V (Sigma)/l .6L

Duratec-1 6V (Sigma), Vehicles With: Air

Conditioning(21 567 0)

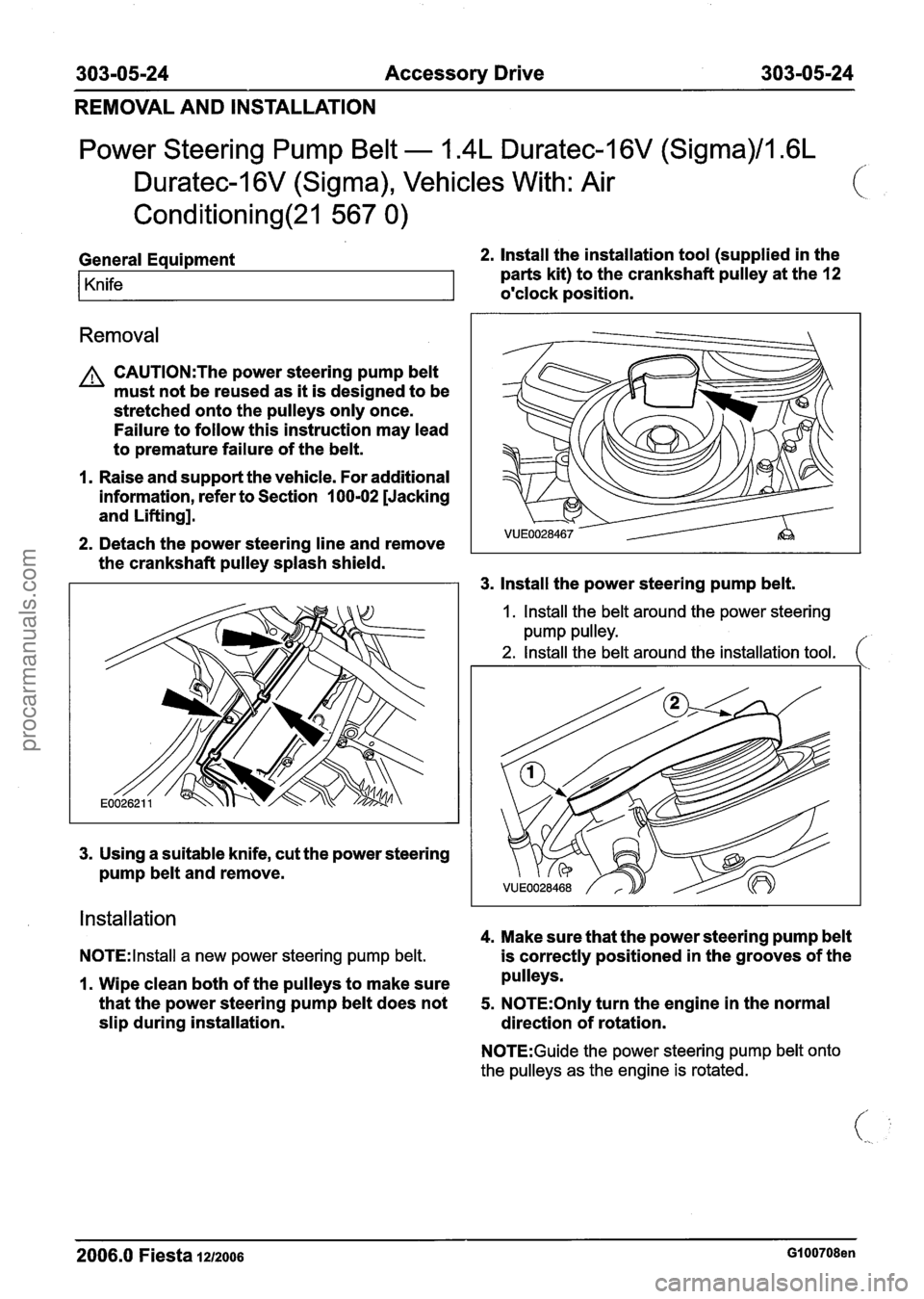

General Equipment 2. Install the installation tool (supplied in the

Knife parts kit) to the crankshaft pulley at the 12

o'clock position.

Removal

A CAUTI0N:The power steering pump belt

must not be reused as it is designed to be

stretched onto the pulleys only once.

Failure to follow this instruction may lead

to premature failure of the belt.

1. Raise and support the vehicle. For additional

information, refer to Section

100-02 [Jacking

and Lifting].

2. Detach the power steering line and remove

the crankshaft pulley splash shield.

3. Install the power steering pump belt.

I. Install the belt around the power steering

pump pulley.

2. Install the belt around the installation tool. (

Installation

4. Make sure that the power steering pump belt

N0TE:lnstall a new power steering pump belt. is correctly positioned in the grooves of the

1. Wipe clean both of the pulleys to make sure pulleys.

that the power steering pump belt does not

5. N0TE:Only turn the engine in the normal

slip during installation.

direction of rotation.

N0TE:Guide the power steering pump belt onto

the pulleys as the engine is rotated.

2006.0 Fiesta 1212006 GI 00708en

procarmanuals.com

Page 871 of 1226

303-06-7 Starting System 303-06-7

DIAGNOSIS AND TESTING

TEST CONDITIONS DETAILSIRESU LTSIACTIONS

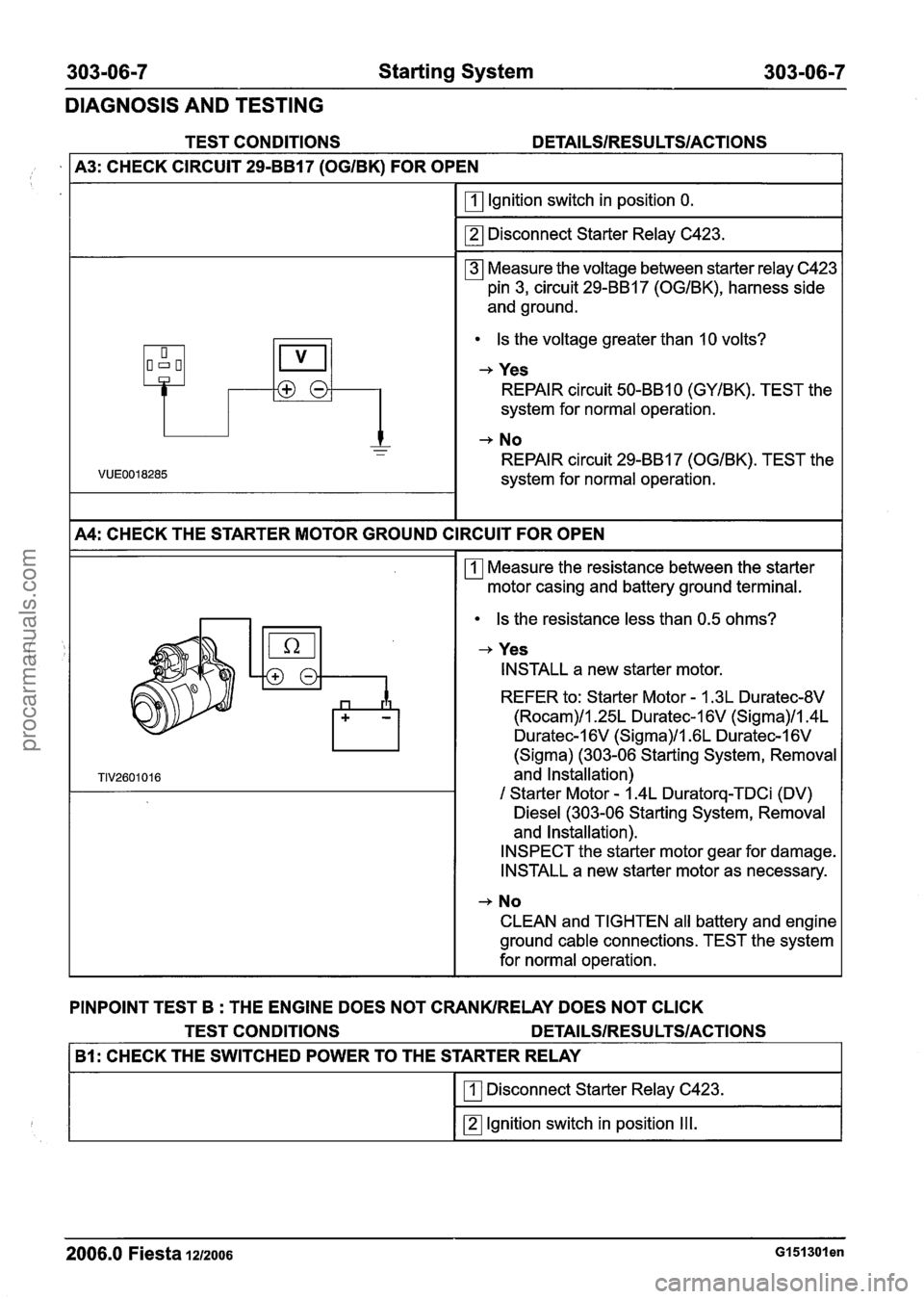

I A3: CHECK CIRCUIT 29-BB17 (OGIBK) FOR OPEN I

I Ignition switch in position 0. I

I rn Disconnect Starter Relay C423. I

Measure the voltage between starter relay C423

pin 3, circuit

29-8817 (OGIBK), harness side

Is the voltage greater than 10 volts?

+ Yes

REPAIR circuit 50-BB10 (GYIBK). TEST the

system for normal operation.

+ No

REPAIR circuit 29-BB17 (OGIBK). TEST the

system for normal operation.

I A4: CHECK THE STARTER MOTOR GROUND CIRCUIT FOR OPEN I - - --

Measure the resistance between the starter

motor casing and battery

1 ground terminal.

Is the resistance less than 0.5 ohms?

+ Yes

INSTALL a new starter motor.

REFER to: Starter Motor

- 1.3L Duratec-8V

(Rocam)/l.25L Duratec-1 6V (Sigma)/l.4L

Duratec-1 6V (Sigma)ll .6L Duratec-1 6V

(Sigma) (303-06 Starting System, Removal

and Installation)

I Starter Motor - 1.4L Duratorq-TDCi (DV)

Diesel (303-06 Starting System, Removal

and

Installation).

INSPECT the starter motor gear for damage.

INSTALL a new starter motor as necessary.

+ No

CLEAN and TIGHTEN all battery and engine

ground cable connections. TEST the system

for normal operation.

PINPOINT TEST B : THE ENGINE DOES NOT CRANKIRELAY DOES NOT CLICK

TEST CONDITIONS

DETAILSIRESU LTSIACTIONS

B1: CHECK THE SWITCHED POWER TO THE STARTER RELAY

Disconnect Starter Relay C423.

rn lgnition switch in position Ill.

2006.0 Fiesta 1212006 GI 51 301 en

procarmanuals.com

Page 872 of 1226

303-06-8 Starting System 303-06-8

DIAGNOSIS AND TESTING

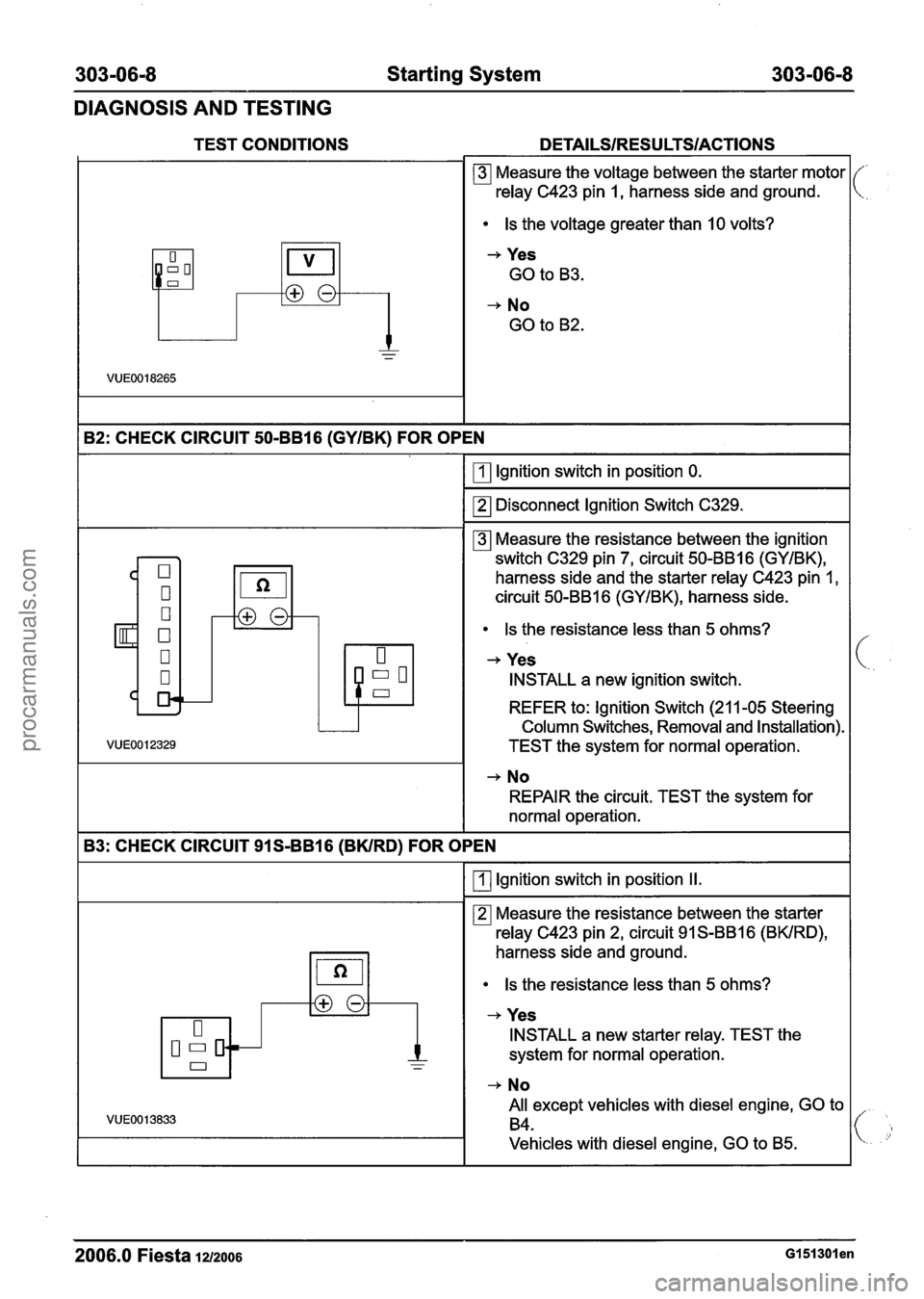

1 82: CHECK CIRCUIT 50-BB16 (GYIBK) FOR OPEN I

TEST CONDITIONS DETAILSIRESULTSIACTIONS

lgnition switch in position 0.

0 - -

VU E0018265

rn Disconnect lgnition Switch C329.

Measure the voltage between the starter motor

relay C423 pin

1, harness side and ground.

Is the voltage greater than

10 volts?

-+ Yes

GO to B3.

-+ No

GO to B2.

Measure the resistance between the ignition

switch C329 pin

7, circuit 50-BB16 (GYIBK),

harness side and the starter relay C423 pin

1,

circuit 50-BB16 (GYIBK), harness side.

Is the resistance less than 5 ohms?

-+ Yes

INSTALL a new ignition switch.

REFER to: lgnition Switch (21 1-05 Steering

Column Switches, Removal and Installation).

TEST the system for normal operation.

-+ No

REPAIR the circuit. TEST the system for

normal operation.

I B3: CHECK CIRCUIT 91s-BB16 (BKIRD) FOR OPEN I

I Ignition switch in position II. I

rn Measure the resistance between the starter

relay C423 pin 2, circuit 91 S-BB16 (BWRD),

harness side and ground.

Is the resistance less than 5 ohms?

-+ Yes

INSTALL a new starter relay. TEST the

system for normal operation.

-+ No

All except vehicles with diesel engine, GO to

B4.

Vehicles with diesel engine, GO to B5.

2006.0 Fiesta 1212006 GI 51 301 en

procarmanuals.com

Page 873 of 1226

303-06-9 Starting System 303-06-9 -- -

DIAGNOSIS AND TESTING

TEST CONDITIONS DETAILSIRESU LTSIACTIONS

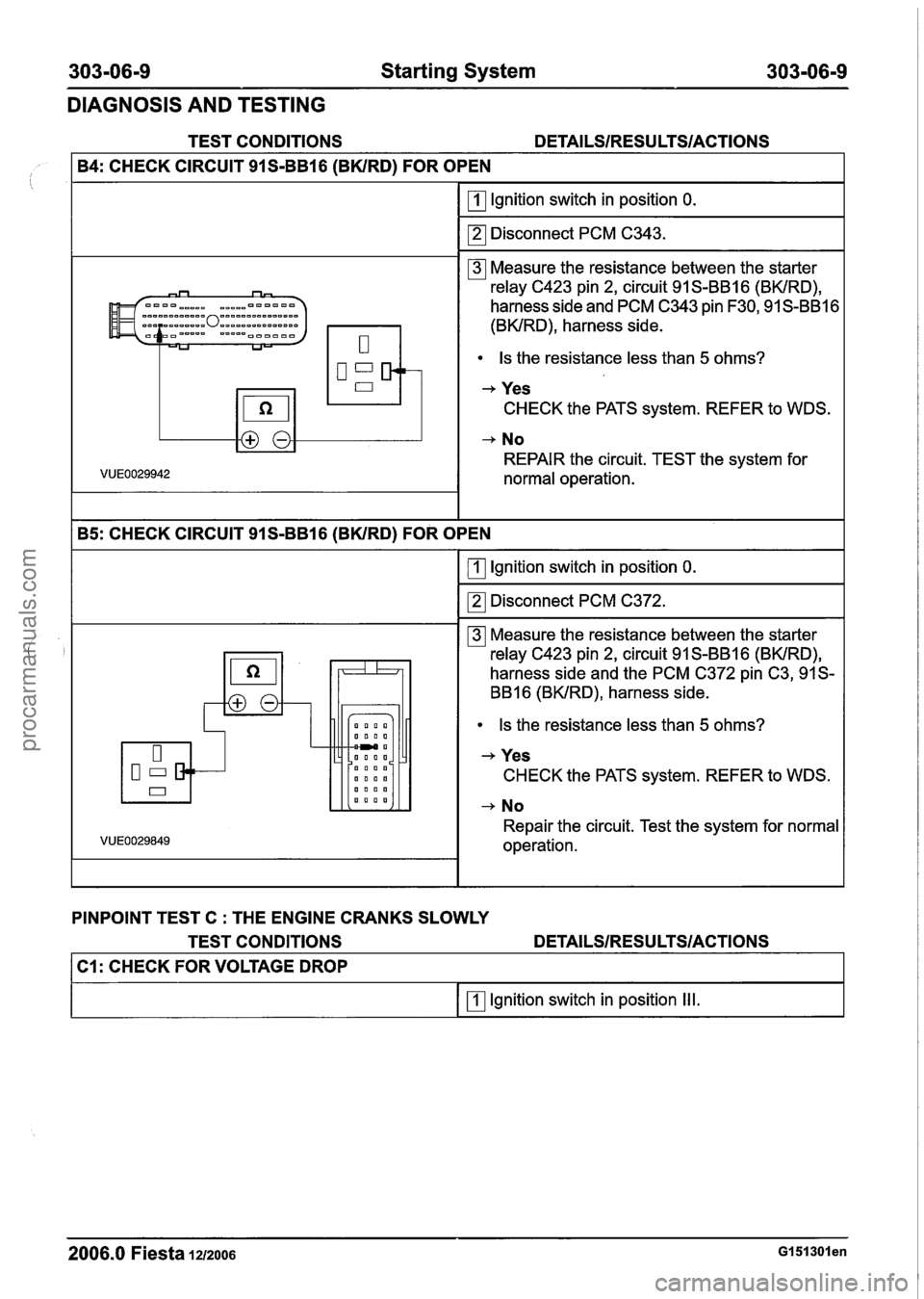

PINPOINT TEST C : THE ENGINE CRANKS SLOWLY

TEST CONDITIONS

DETAILSIRESULTSIACTIONS

B4: CHECK CIRCUIT 91s-BB16 (BWRD) FOR OPEN

C1: CHECK FOR VOLTAGE DROP

rn lgnition switch in position Ill.

VU E0029942

2006.0 Fiesta 1212006 GI 51 301 en

lgnition switch in position 0.

Disconnect PCM C343.

rn Measure the resistance between the starter

relay C423 pin 2, circuit 91 S-BB16 (BWRD),

harness side and PCM C343 pin

F30,91 S-BBI 6

(BWRD), harness side.

Is the resistance less than 5 ohms?

+ Yes

CHECK the PATS system. REFER to WDS.

-, No

REPAIR the circuit. TEST the system for

normal operation.

B5: CHECK CIRCUIT 91s-BB16 (BWRD) FOR OPEN

Inl

I I It I

-0 @

-

0

lY2't

VUE0029849

lgnition switch in position 0.

Disconnect PCM C372.

rn Measure the resistance between the starter

relay C423 pin 2, circuit 91 S-BB16 (B WRD),

harness side and the PCM C372 pin

C3,91S-

BB16 (BWRD), harness side.

Is the resistance less than 5 ohms?

+ Yes

CHECK the PATS system. REFER to WDS.

-, No

Repair the circuit. Test the system for normal

operation.

procarmanuals.com

Page 898 of 1226

Engine Emission Control - 2.OL Duratec-HE

303-08B-4

(MI41 303-08B-4

DESCRIPTION AND OPERATION

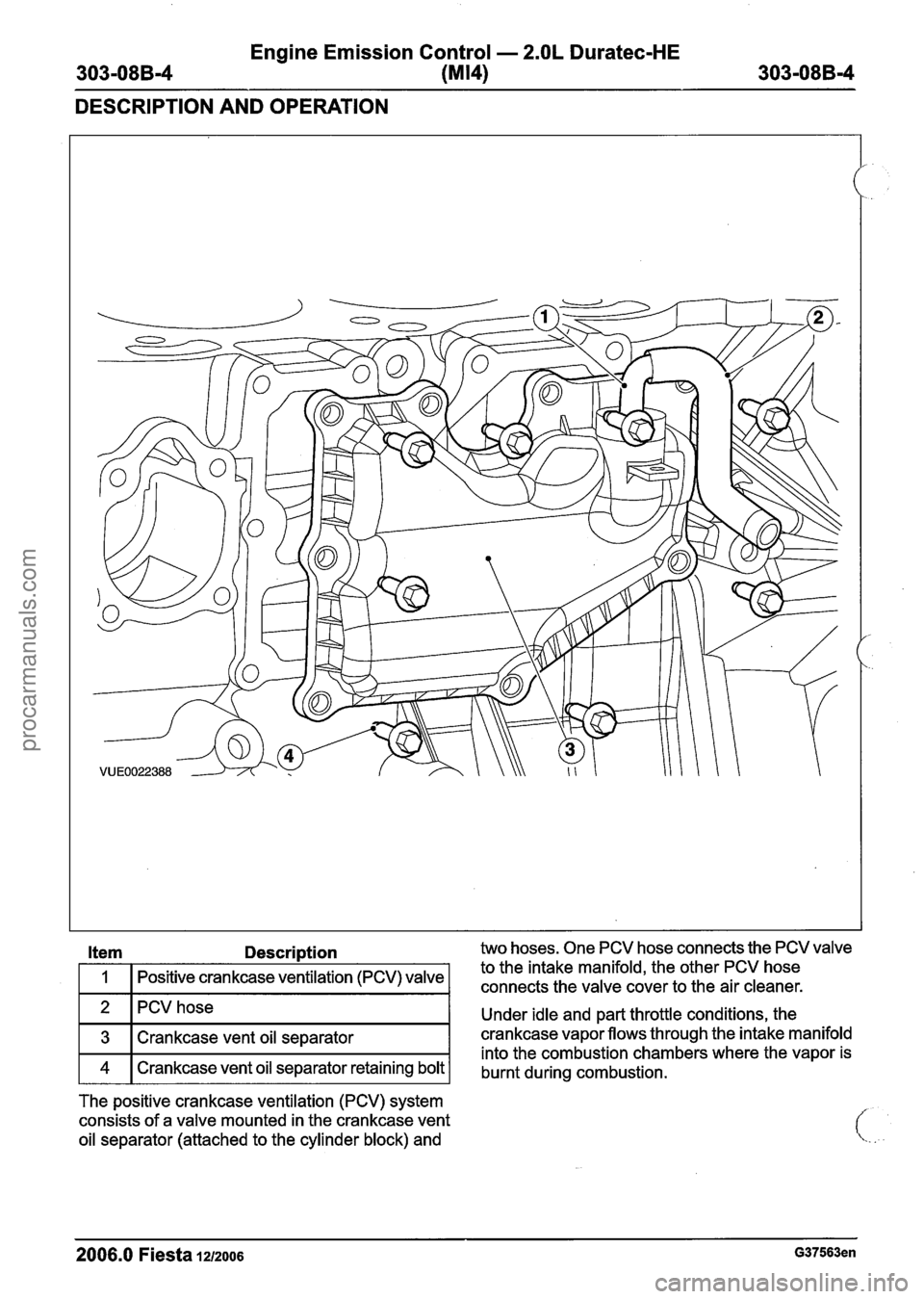

Item Description two hoses. One PCV hose connects the PCV valve

to the intake manifold, the other PCV hose

2

3

The positive crankcase ventilation (PCV) system

consists of a valve mounted in the crankcase vent

oil separator (attached to the cylinder block) and

connects the valve cover to the air cleaner. 1

4

2006.0 Fiesta 1212006 G37563en

Positive crankcase ventilation (PCV) valve

PCV hose

Crankcase vent oil

se~arator

Under idle and part throttle conditions, the

crankcase vapor flows through the intake manifold

Crankcase vent oil separator retaining

bolt into the combustion chambers where the vapor is

burnt during combustion.

procarmanuals.com

Page 899 of 1226

Engine Emission Control - 2.OL Duratec-HE

303-08B-5

(MI41 303-08B-5

DESCRIPTION AND OPERATION

[ E57308

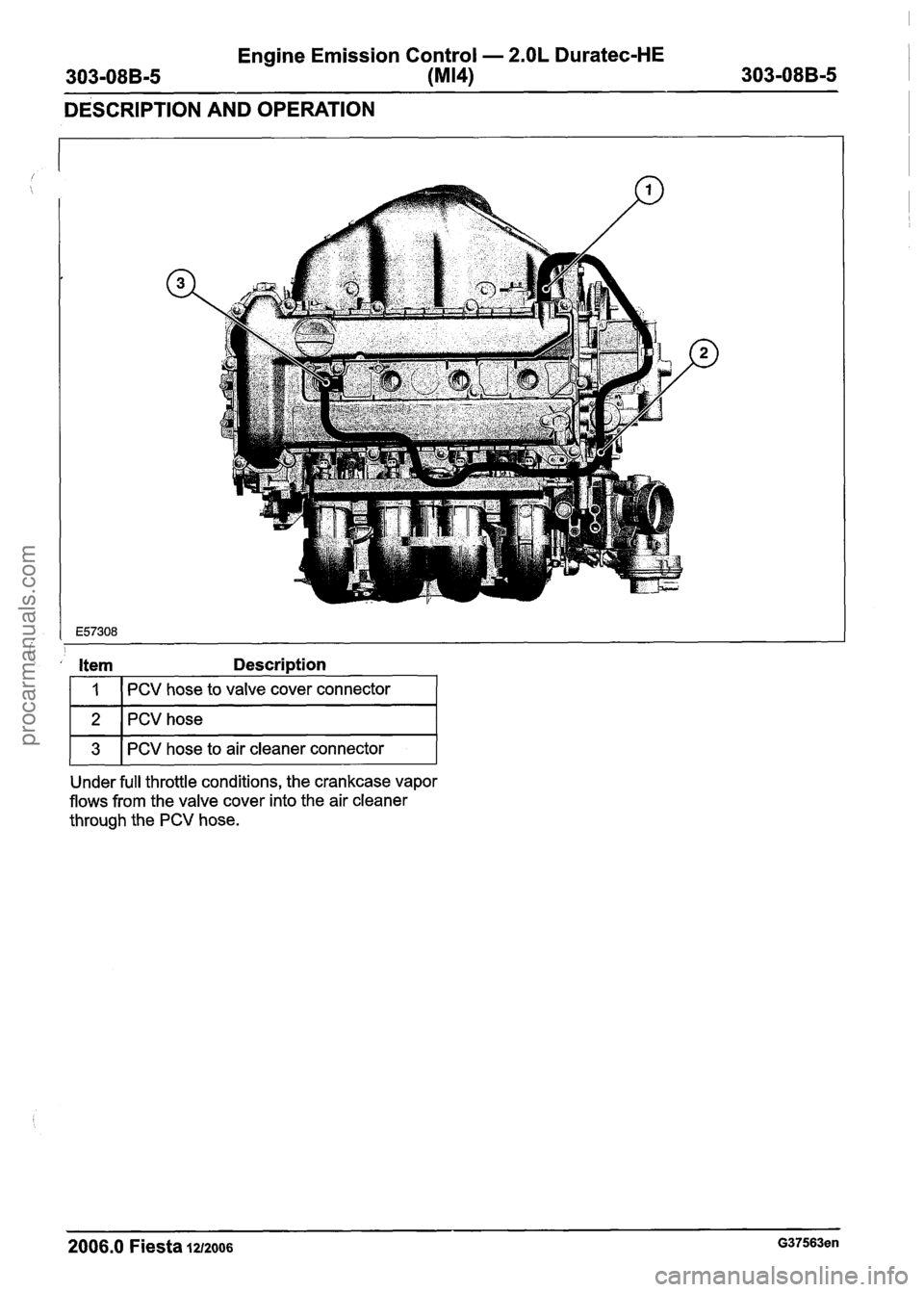

i, ' Item Description I

I 1 ( PCV hose to valve cover connector I

Under full throttle conditions, the crankcase vapor

flows from the valve cover into the air cleaner

through the PCV hose.

-

2

3

2006.0 Fiesta 1212006 G37563en

PCV hose

PCV hose to air cleaner connector

procarmanuals.com

Page 930 of 1226

303-1 4-6 Electronic Engine Controls 303-1 4-6

DESCRIPTION

AND OPERATION

Item Descri~tion

1 5 1 Crankshaft Position (CKP) sensor 1

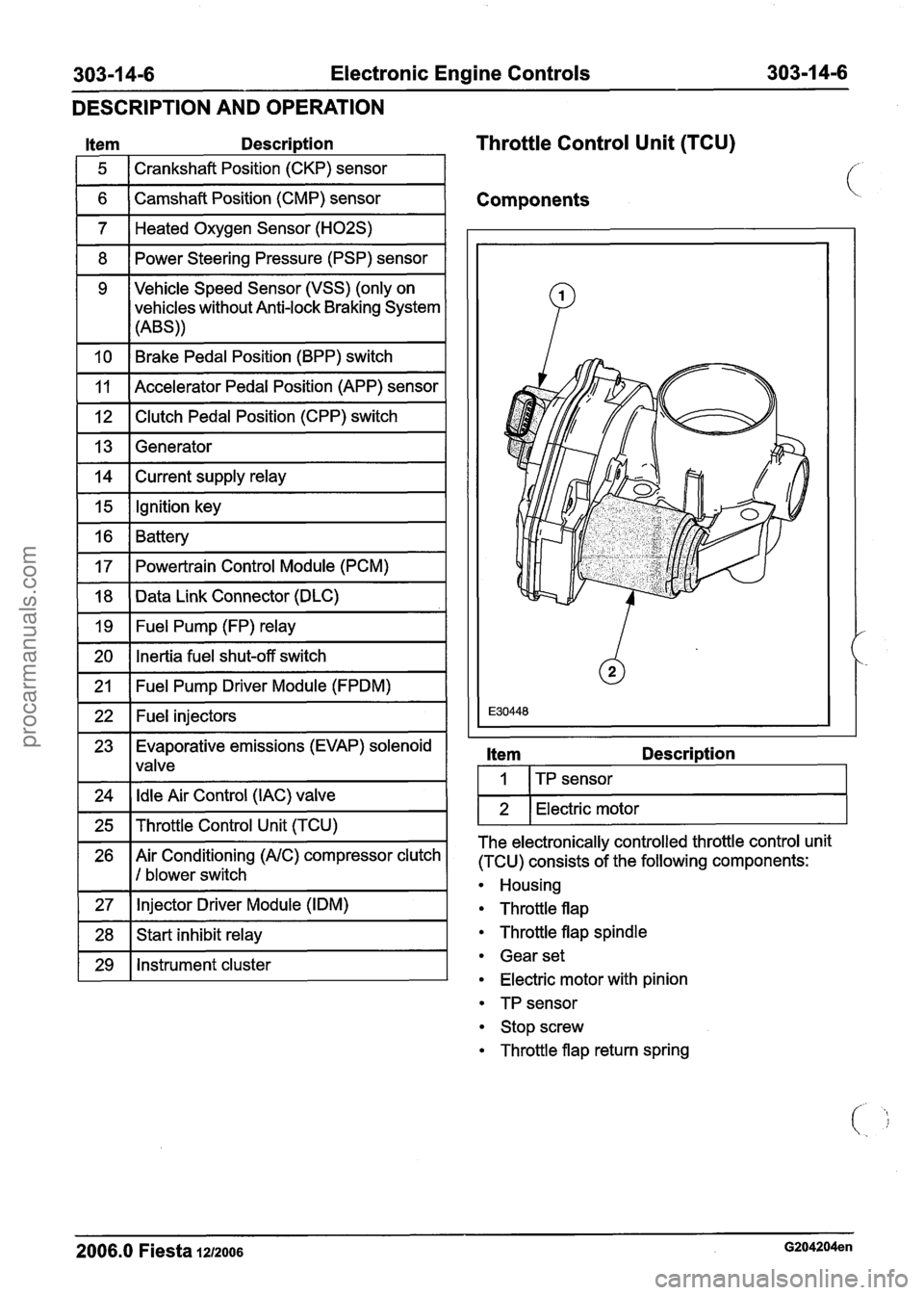

Throttle Control Unit (TCU)

1 6 ( Camshaft Position (CMP) sensor I Components

1 7 1 Heated Oxygen Sensor (H02S) I

1 8 1 Power Steering Pressure (PSP) sensor I

1 10 1 Brake Pedal Position (BPP) switch I

9 Vehicle Speed Sensor (VSS)

(only on

vehicles without Anti-lock Braking System

(ABS))

1 12 1 Clutch Pedal Position (CPP) switch I

11

1 13 1 Generator I

Accelerator Pedal Position (APP) sensor

1 14 1 Current supply relay I

1 15 1 Ignition key I -

16

17

1 20 1 Inertia fuel shut-off switch I

Battery

Powertrain Control Module (PCM)

-

18

19

1 21 1 Fuel Pump Driver Module (FPDM) I

Data Link Connector (DLC)

Fuel Pump (FP) relay

1 22 1 Fuel injectors I

23 Evaporative emissions (EVAP) solenoid

1 lvalve

1 24 1 Idle Air Control (IAC) valve 1

1 25 1 Throttle Control Unit (TCU) I

26 Air Conditioning (AIC) compressor clutch

1 I 1 blower switch

1 27 1 Injector Driver

Module (IDM) I

1 28 1 Start inhibit relay I

1 29 1 Instrument cluster I

Item Descri~tion

I I ITP sensor I

1 2 1 Electric motor I

The electronically controlled throttle control unit

(TCU) consists of the following components:

Housing

Throttle flap

Throttle flap spindle

Gear set

Electric motor with pinion

TP sensor

Stop screw

Throttle flap return spring

2006.0 Fiesta 1212006 G204204en

procarmanuals.com

Page 939 of 1226

303-1 4-1 5 Electronic Engine Controls 303-1 4-1 5

DIAGNOSIS AND TESTING

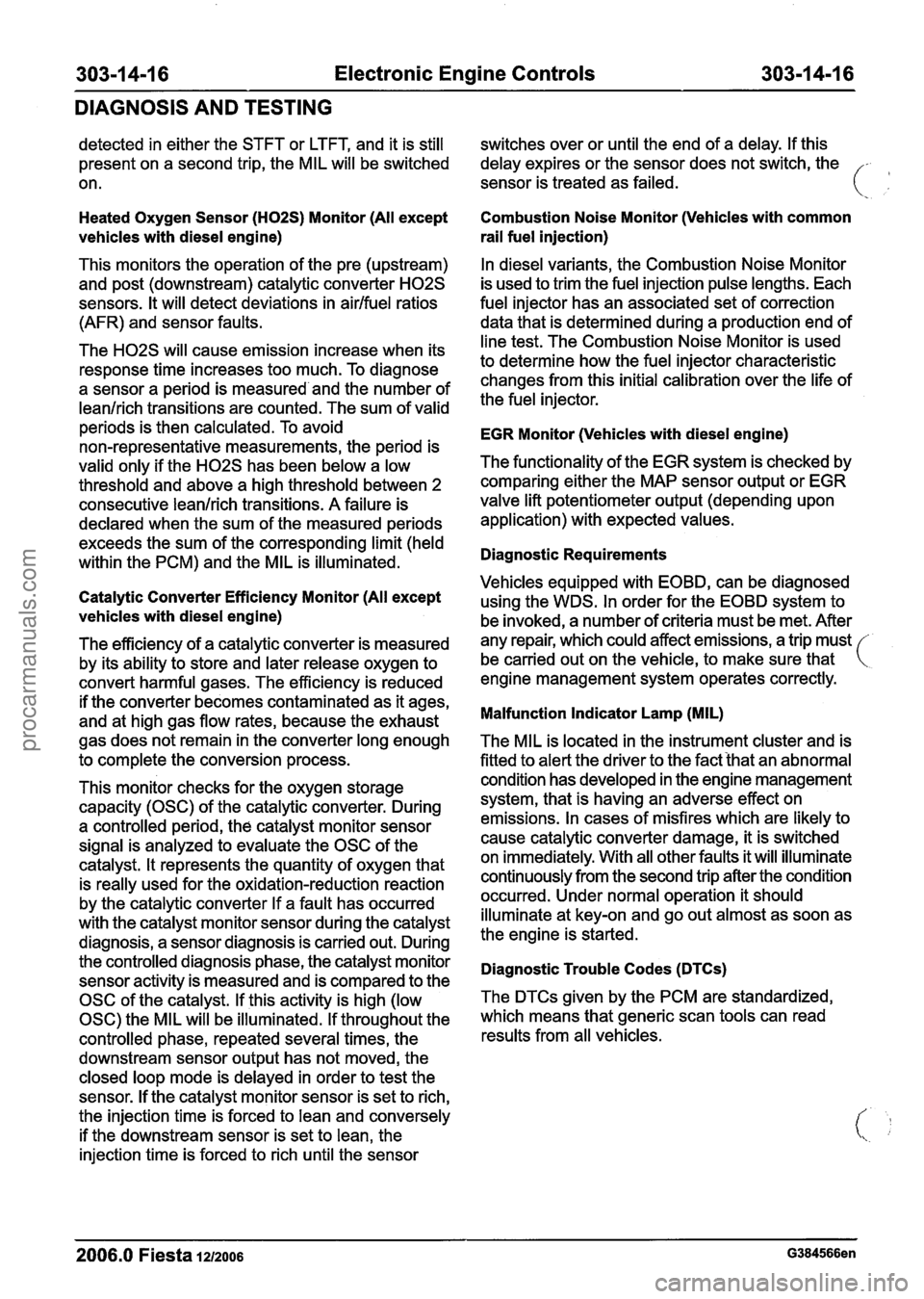

Monitors

The purpose of the monitors is to continuously

check the operation of the emission related sensors

and actuators. It then establishes if they are

operating within specified tolerances. All monitors

carry out their functions in such a way as to be

unnoticeable by the driver of the vehicle. Each one

is carried out under specific conditions of load,

speed and engine temperature. The Comprehensive Component Monitor, Combustion

Misfire Monitor and

AirIFuel Ratio Monitor operate

continuously. The remaining monitors are only

invoked under certain operating conditions. On

diesel variants, all of the monitors operate under

normal driving conditions: There are no monitors

which intervene and cause special operating

modes to enable the monitors to work. Some diesel

monitors are non-continuous. This means that in

a drive cycle, monitoring is done as and when

suitable driving conditions exist and potential faults

are accumulated and compared with acceptance

criteria. Examples of this type are the turbocharger

boost pressure and exhaust gas recirculation

(EGR) monitors on vehicles with common rail fuel

injection.

( Comprehensive Component Monitor (CCM)

When the CCM detects a component operating out

of tolerance, it sets a Diagnostic Trouble Code

(DTC), which is stored in the EEPROM. If the same

concern is confirmed during the next trip the MIL

will be switched on. The CCM monitors many

components, sub-systems and signals. The

following is a list of those that can effect emissions

depending on application:

Electronic Ignition (El) System.

Crankshaft Position (CKP) Sensor.

Ignition Coil.

Electronic Throttle Control Unit.

Camshaft Position (CMP) Sensor.

Air Conditioning

(AIC) Clutch.

Idle Air Control (IAC) Valve.

Mass Air Flow (MAF) Sensor.

Manifold Absolute Pressure (MAP) Sensor.

Intake Air Temperature (IAT) Sensor.

Engine Coolant Temperature (ECT) Sensor.

Cylinder Head Temperature (CHT) Sensor.

Heated Oxygen Sensor

(H02S).

Catalyst Monitor Sensor.

Charge Air Temperature Sensor.

Knock Sensor (KS).

Throttle Position (TP) Sensor.

Vehicle Speed Sensor (VSS).

Boost Pressure Sensor.

Cam-Crank Phasing Sensor.

EEPROM.

High Pressure Fuel Injection Pump.

Exhaust Gas Recirculation (EGR) Valve Monitor.

Fuel Injectors.

Turbocharger.

Combustion Noise Monitor.

Barometric Pressure (BARO) Sensor.

Combustion Misfire Monitor (All except vehicles

with diesel engine)

The combustion misfire monitor operates independently of the others, and can detect misfires

caused by the ignition system, fuel system or

mechanical engine components. As each cylinder

fires, a characteristic crankshaft acceleration is

produced. The monitor detects irregularities in the

acceleration pattern using the crankshaft position (CKP) sensor, thus detecting the misfire. It can

also detect which cylinder has misfired.

Combustion misfires can be categorized as follows:

Type

A: These can cause catalytic converter

damage due to excessive internal temperatures.

If a certain number of misfires occur over a

pre-determined number of engine revolutions, the

MIL will be switched on to alert the driver of the

concern.

Type B: These can lead to an increase in emissions

to a point above the EOBD threshold. If the misfire

is detected during a second trip, over a,

pre-determined number of engine revolutions, the

MIL will be switched on. If the misfire does not

occur over the next three trips, the MIL will be

extinguished

AirIFuel Ratio (AFR) Monitor (All except vehicles

with diesel engine)

The H02S fitted before the catalytic converter

(upstream) measures the oxygen content of the

exhaust gas and the variations in it. This then

enables the PCM to adjust the opening times of

the fuel injectors to maintain the correct AFR. This

is known as Short Term Fuel Trim (STFT). If the

same variation is registered a pre-determined

number of times, a permanent correction factor is

applied. This is known as Long Term Fuel Trim

(LTFT), which is stored in the EEPROM. When the

correction factors exceed pre-determined limits a

DTC will be set in the EEPROM. If a concern is

2006.0 Fiesta 1212006 G384566en

procarmanuals.com

Page 940 of 1226

Electronic Engine Controls

DIAGNOSIS AND TESTING

detected in either the STFT or LTFT, and it is still

present on a second trip, the MIL will be switched

on.

Heated Oxygen Sensor (H02S) Monitor (All except

vehicles with diesel engine)

This monitors the operation of the pre (upstream)

and post (downstream) catalytic converter

H02S

sensors. It will detect deviations in airlfuel ratios

(AFR) and sensor faults.

The

H02S will cause emission increase when its

response time increases too much. To diagnose

a sensor a period is measured and the number of

leanlrich transitions are counted. The sum of valid

periods is then calculated. To avoid

non-representative measurements, the period is

valid only if the

H02S has been below a low

threshold and above a high threshold between 2

consecutive leanlrich transitions.

A failure is

declared when the sum of the measured periods

exceeds the sum of the corresponding limit (held

within the PCM) and the MIL is illuminated.

Catalytic Converter Efficiency Monitor (All except

vehicles with diesel engine)

The efficiency of a catalytic converter is measured

by its ability to store and later release oxygen to

convert harmful gases. The efficiency is reduced

if the converter becomes contaminated as it ages,

and at high gas flow rates, because the exhaust

gas does not remain in the converter long enough

to complete the conversion process. switches

over or until the end of a delay. If this

delay expires or the sensor does not switch, the

sensor is treated as failed.

Combustion Noise Monitor (Vehicles with common

rail fuel injection)

In diesel variants, the Combustion Noise Monitor

is used to trim the fuel injection pulse lengths. Each

fuel injector has an associated set of correction

data that is determined during a production end of

line test. The Combustion Noise Monitor is used

to determine how the fuel injector characteristic

changes from this initial calibration over the life of

the fuel injector.

EGR Monitor (Vehicles with diesel engine)

The functionality of the EGR system is checked by

comparing either the MAP sensor output or EGR

valve lift potentiometer output (depending upon

application) with expected values.

Diagnostic Requirements

Vehicles equipped with EOBD, can be diagnosed

using the WDS. In order for the EOBD system to

be invoked, a number of criteria must be met. After

any repair, which could affect emissions, a trip must

be carried out on the vehicle, to make sure that

engine management system operates correctly.

Malfunction Indicator Lamp (MIL)

The MIL is located in the instrument cluster and is

fitted to alert the driver to the fact that an abnormal

This monitor checks for the oxygen storage condition

has developed in the engine management

capacity (OSC) of the catalytic converter. During system,

that is having an adverse effect on

a controlled period, the catalyst monitor sensor emissions.

In cases of misfires which are likely to

signal is analyzed to evaluate the OSC of the cause

catalytic converter damage, it is switched

catalyst. It represents the quantity of oxygen that on immediately.

With all other faults it will illuminate

is really used for the oxidation-reduction reaction continuously

from the second trip after the condition

by the catalytic converter If a fault has occurred occurred.

Under normal operation it should

with the catalyst monitor sensor during the catalyst illuminate

at key-on and go out almost as soon as

diagnosis, a sensor diagnosis is carried out. During the

engine is started.

the controlled diagnosis phase, the catalyst monitor

Diagnostic Trouble Codes (DTCs) sensor activity is measured and is compared to the

OSC of the catalyst. If this activity is high (low The

DTCs given

by the PCM are standardized,

0SC)theMILwillbeilluminated.Ifthroughoutthe whichmeansthatgenericscantoolscanread

controlled phase, repeated several times, the results from

all vehicles.

downstream sensor output has not moved, the

closed loop mode is delayed in order to test the

sensor. If the catalyst monitor sensor is set to rich,

the injection time is forced to lean and conversely

if the downstream sensor is set to lean, the

injection time is forced to rich until the sensor

2006.0 Fiesta 1212006 G384566en

procarmanuals.com

Page 944 of 1226

303-1 4-20 Electronic Engine Controls 303-1 4-20

DIAGNOSIS AND TESTING

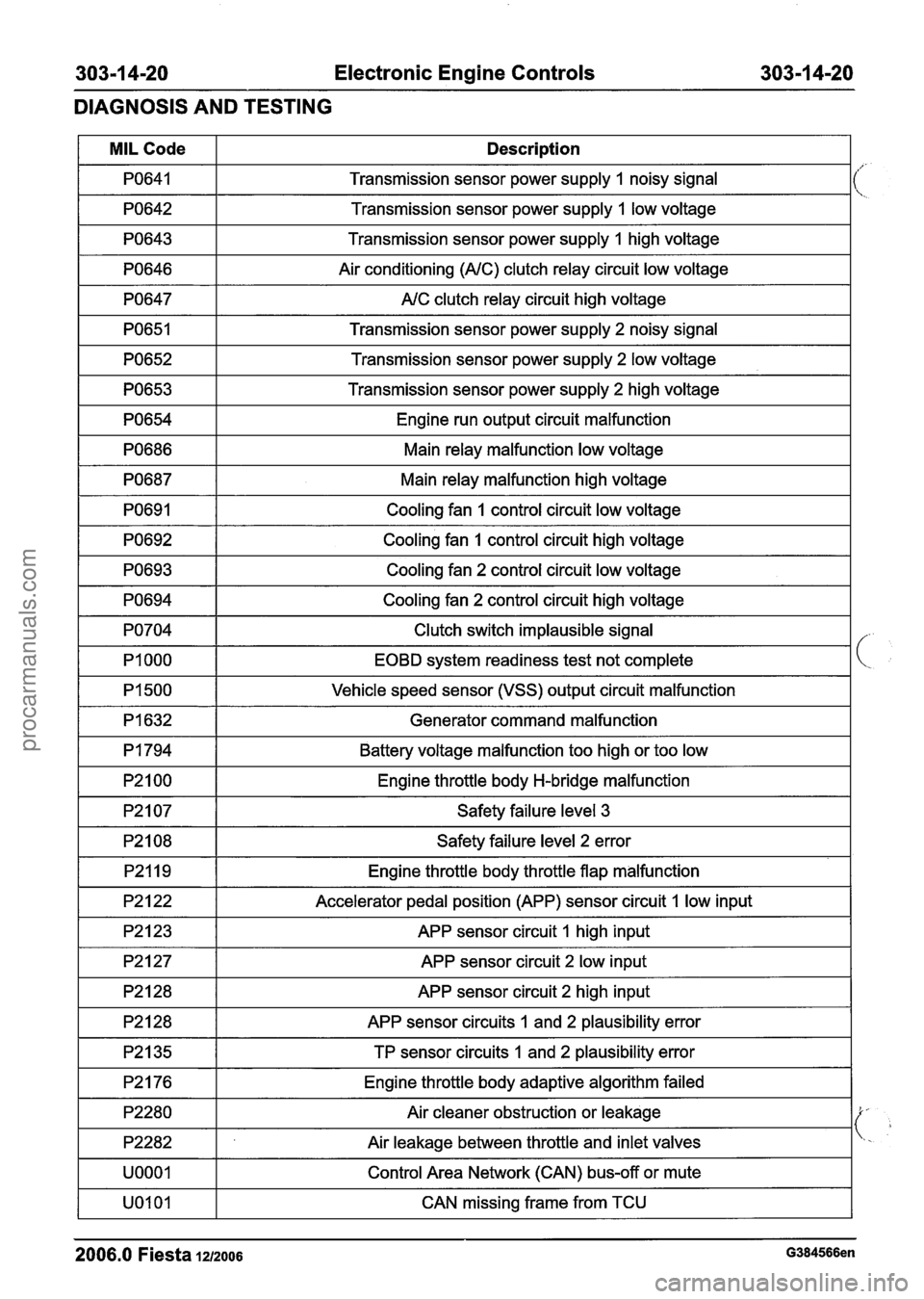

1 PO643 1 Transmission sensor power supply 1 high voltage I

MIL Code

PO641

PO642

1 PO646 1 Air conditioning (NC) clutch relay circuit low voltage I

1 PO647 1 NC clutch relay circuit high voltage I

Description

Transmission sensor power supply 1 noisy signal

Transmission sensor power supply

I low voltage

I PO651 I Transmission sensor power supply 2 noisy signal I

i

PO652

PO653

Transmission sensor power supply 2 low voltage

Transmission sensor power supply

2 high voltage

PO654

PO686

1 PO692 1 Cooling fan 1 control circuit high voltage I

Engine run output circuit malfunction

Main relay malfunction low voltage

PO687

PO691

1 PO693 1 Cooling fan 2 control circuit low voltage I

Main relay malfunction high voltage

Cooling fan

1 control circuit low voltage

1 PO694 1 Cooling fan 2 control circuit high voltage I

I PI500 I Vehicle speed sensor (VSS) output circuit malfunction I

PO704

PI 000

Generator command malfunction I

Clutch switch implausible signal

EOBD system readiness test not complete

I P2107 I Safety failure level 3 I

PI 794

P2100

I P2108 I Safety failure level 2 error I

Battery voltage malfunction too high or too low

Engine throttle body H-bridge malfunction

APP sensor circuit 1 high input I

P2119

P2122

1 P2127 1 APP sensor circuit 2 low input I

Engine throttle body throttle flap malfunction

Accelerator pedal position (APP) sensor circuit

1 low input

1 P2128 1 APP sensor circuit 2 high input I

1 P2176 1 Engine throttle body adaptive algorithm failed 1

P2128

P2135

APP sensor circuits I and 2 plausibility error

TP sensor circuits 1 and 2 plausibility error

I UOOOl I Control Area Network (CAN) bus-off or mute I

P2280

P2282

I UOlOl I CAN missing frame from TCU I

Air cleaner obstruction or leakage

Air leakage between throttle and inlet valves

2006.0 Fiesta 1212006 G384566en

procarmanuals.com