Injector FORD FIESTA 2007 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 29 of 1226

100-00-1 3 General Information 100-00-1 3

DESCRIPTION AND OPERATION

Do not use damaged or defective tools or

equipment, particularly high-speed equipment such

i as grinding wheels. A damaged grinding wheel can

disintegrate without warning and cause serious

injury.

Wear suitable eye protection when using grinding,

chiseling or sand blasting equipment.

Wear a suitable breathing mask when using

abrasive blasting equipment, working with

asbestos-based materials or using spraying

equipment.

Make sure there is adequate ventilation to control

dusts, mists and fumes.

High Pressure Air, Lubrication and Oil

Test Equipment

See also Lubricants and Greases.

Always keep high-pressure equipment in good

condition, and regularly maintained, particularly at

joints and unions.

Never direct a high-pressure nozzle, for example

diesel injector, at the skin as the fluid may

, penetrate to the underlying tissue, and cause

serious injury.

Halon

See CFCs.

Legal Aspects

There are many laws and regulations relating to

health and safety in the use and disposal of

materials and equipment in a workshop.

For a safe working environment and to avoid

environmental pollution, workshops should be

familiar, in detail, with the many health and safety

laws and regulations within their country, published

by both national and local authorities.

Lubricants and Greases

Avoid all prolonged and repeated contact with

mineral oils. All lubricants and greases may be

irritating to the eyes and skin.

'

Transmission Fluids

Safety instructions

Certain Transmission and Power Steering fluids

supplied to Ford may contain additives which have

the potential to cause skin disease (dermatitis) to

exposed persons. The dermatitis may be irritant

or allergic in nature. Risks are higher where

prolonged or repeated skin contact with a fluid may

occur. These fluids are used for vehicle initial

fill

and service purposes. This sub-section is to:

Inform Service personnel who may come into

contact with these vehicle fluids (hazard

communication).

Summarise appropriate workplace control

measures and personal protective equipment

requirements.

Draw attention to the existence of Material

Safety Datasheets (MSDS's) for the fluids

(available from Ford Customer Service Division).

These MSDS's contain detailed information on

hazards and appropriate controls.

Control measures

Workplace risk assessments made under national

chemical control regulations should identify

operations involving the fluids as potentially

hazardous and specify workplace control and

worker awareness measures. In such

circumstances, the relevant Material Safety

Datasheet (see the details specified below) which

specifies hazards and control measures in detail

should be made available for guidance.

Avoid unprotected skin contact with the fluids, and

in particular, avoid prolonged or repeated skin

contact. Work practices should be organised so as

to minimise the potential for skin contact. This may

include the use of drip trays, absorbents, correct

fluid handling equipment (funnels etc), and

workplace housekeeping measures such as the

cleaning of contaminated surfaces.

Personnel engaged in operations where skin

contact could occur (such as fluid draining or filling)

should wear impervious gloves made from

nitrile

rubber, certified to a chemical protection standard,

e.g. Europe Standard EN374. This glove type is

widely available from reputable suppliers of gloves

for chemical protection [including the manufacturers

Ansell-Admont

(Solvex Range), North Safety

products (North

Nitrile Latex Gloves range), and

2006.0 Fiesta 1212006 GI 7372en

procarmanuals.com

Page 437 of 1226

303-00-1 5 Engine System - General Information 303-00-1 5

DIAGNOSIS AND TESTING

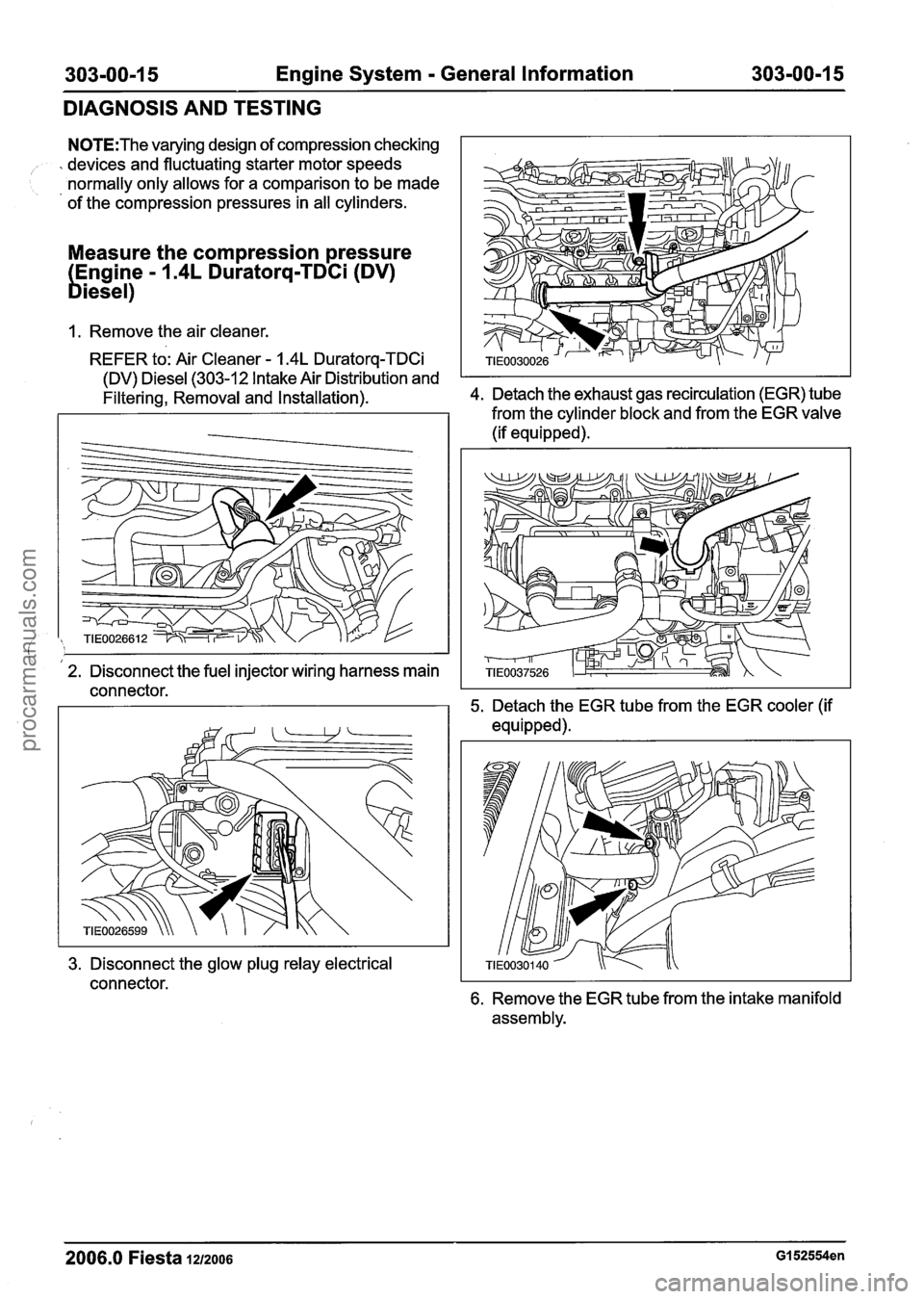

N0TE:The varying design of compression checking

% devices and fluctuating starter motor speeds

normally only allows for a comparison to be made

of the compression pressures in all cylinders.

Measure the compression pressure

Engine

- 1.4L Duratorq-TDCi (DV)

biesel)

1. Remove the air cleaner.

REFER to: Air Cleaner

- 1.4L Duratorq-TDCi

(DV) Diesel (303-12 Intake Air Distribution and

Filtering, Removal and

Installation). 4. Detach the exhaust gas recirculation (EGR) tube

from the cylinder block and from the EGR valve

(if equipped).

I I 2. Disconnect the fuel injector wiring harness main

connector. 5. Detach the EGR tube from the EGR cooler (if

equipped).

3. Disconnect the glow plug relay electrical

connector.

6. Remove the EGR tube from the intake manifold

assembly.

2006.0 Fiesta 1212006 GI 52554en

procarmanuals.com

Page 439 of 1226

303-00-1 7 Engine System - General Information 303-00-1 7

DIAGNOSIS AND TESTING

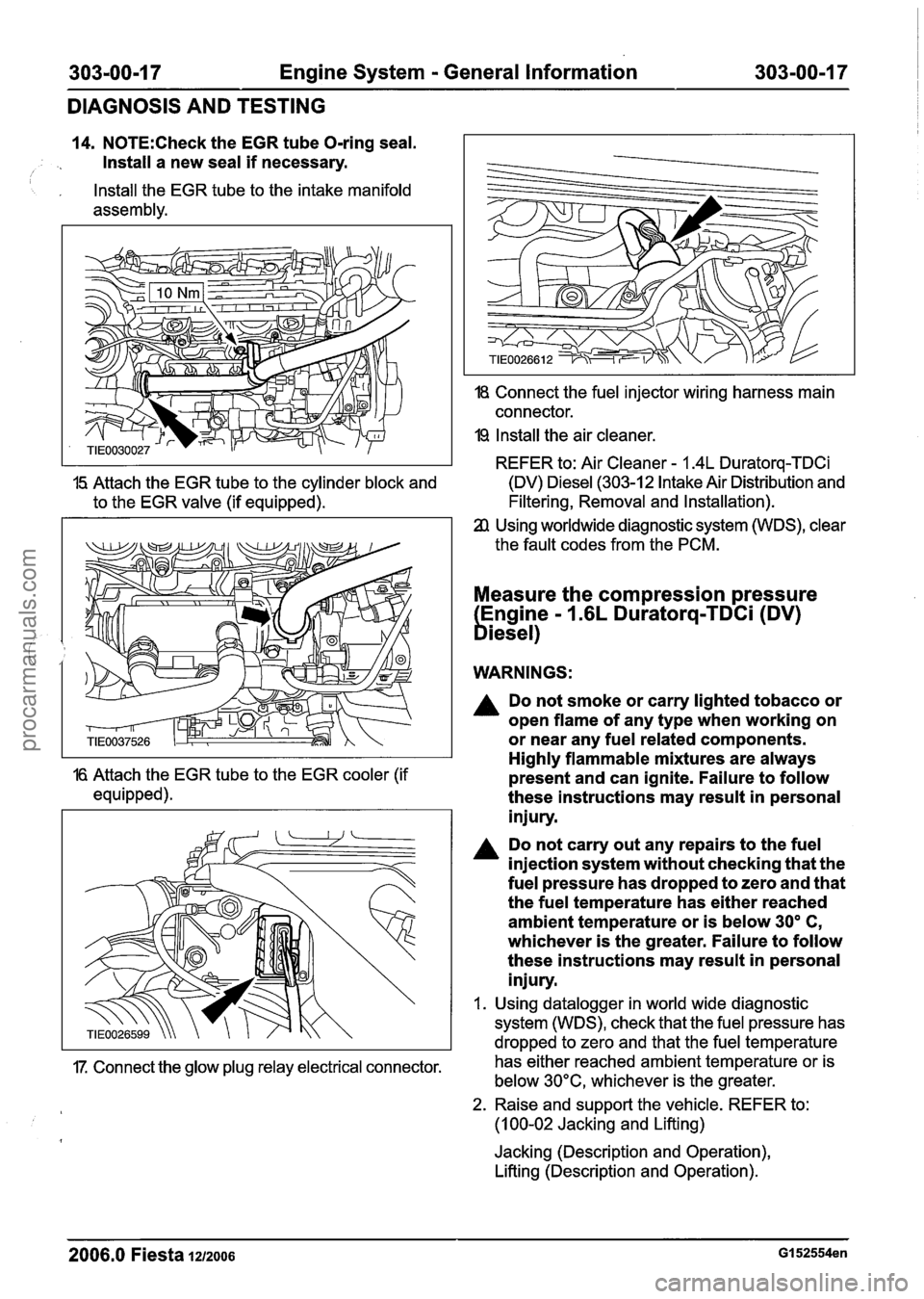

14. N0TE:Check the EGR tube O-ring seal.

Install a new seal

if necessary. I

, Install the EGR tube to the intake manifold

assembly.

18 Connect the fuel injector wiring harness main

connector.

19 Install the air cleaner.

REFER to: Air Cleaner

- 1.4L Duratorq-TDCi

15 Attach the EGR tube to the cylinder block and (DV) Diesel (303-12 Intake Air Distribution

and

to the EGR valve (if equipped). Filtering, Removal

and Installation).

Using worldwide diagnostic system (WDS), clear

the fault codes from the PCM.

Measure the compression pressure

Engine

- 1.6L Duratorq-TDCi (DV)

biesel)

WARNINGS:

A Do not smoke or carry lighted tobacco or

open flame of any type when working on

or near any fuel related components.

Highly flammable mixtures are always

16 Attach the EGR tube to the EGR cooler (if present and can ignite. Failure to follow

equipped). these instructions may result in personal

injury.

Do not carry out any repairs to the fuel

injection system without checking that the

fuel pressure has dropped to zero and that

the fuel temperature has either reached

ambient temperature or is below

30' C,

whichever is the greater. Failure to follow

these instructions may result in personal

injury.

I. Using datalogger in world wide diagnostic

system (WDS), check that the fuel pressure has

dropped to zero and that the fuel temperature

17. Connect the glow plug relay electrical connector. has

either reached ambient temperature or is

below 30°C, whichever is the greater.

2. Raise and support the vehicle. REFER to:

(1 00-02 Jacking and Lifting)

Jacking (Description and Operation),

Lifting (Description and Operation).

2006.0 Fiesta 1212006 GI 52554en

procarmanuals.com

Page 440 of 1226

303-00-1 8 Engine System - General Information 303=00-18

DIAGNOSIS AND TESTING

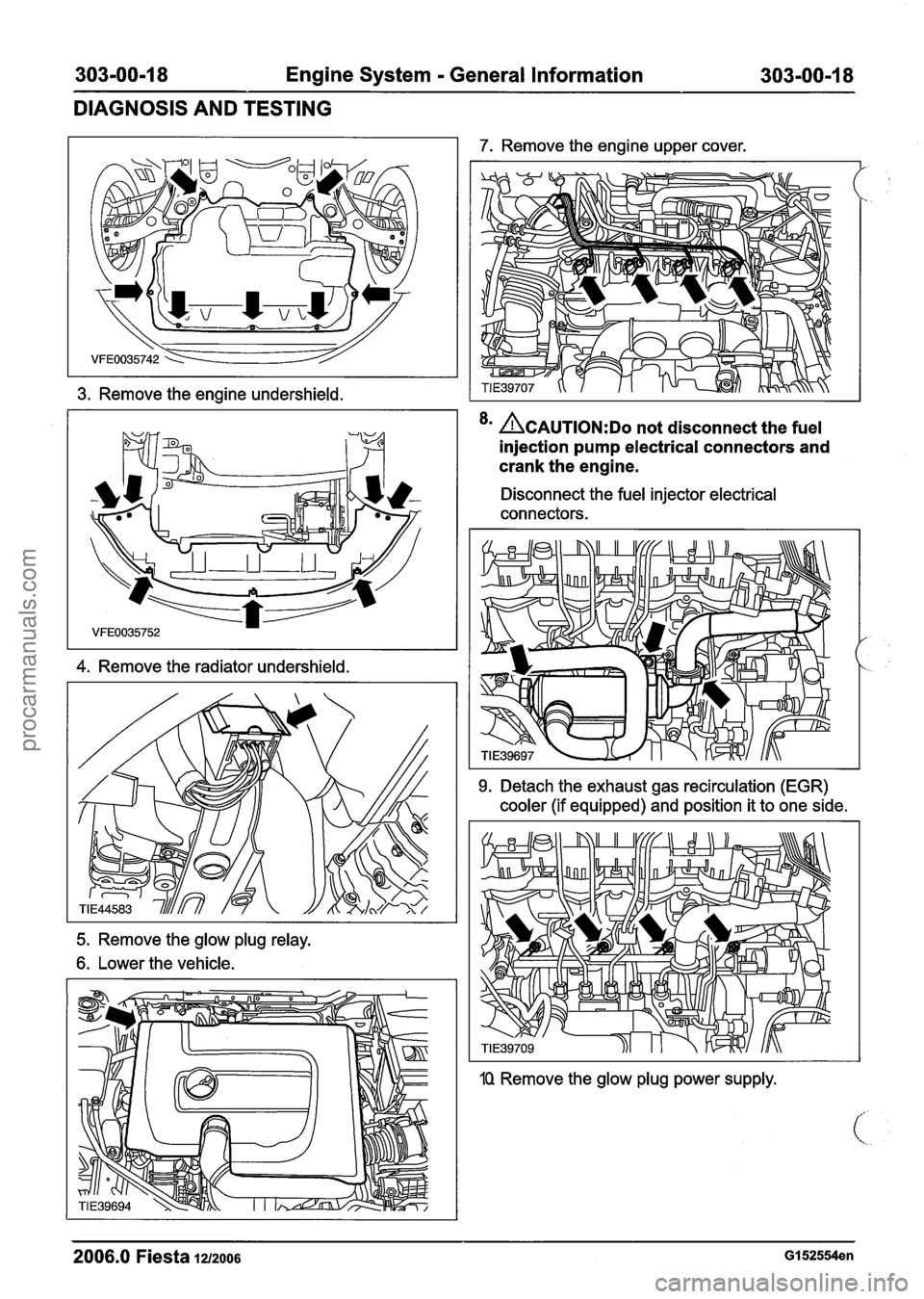

3. Remove the engine undershield.

4. Remove the radiator undershield.

7. Remove the engine upper cover.

<

8m ~CAUTION:DO not disconnect the fuel

injection pump electrical connectors and

crank the engine.

Disconnect the fuel injector electrical

connectors.

9. Detach the exhaust gas recirculation (EGR)

cooler (if equipped) and position it to one side.

5. Remove the glow plug relay.

6. Lower the vehicle.

1Q Remove the glow plug power supply.

2006.0 Fiesta 1212006 GI 52554en

procarmanuals.com

Page 441 of 1226

303-00-1 9 Engine System - General Information 303-00-1 9

DIAGNOSIS AND TESTING

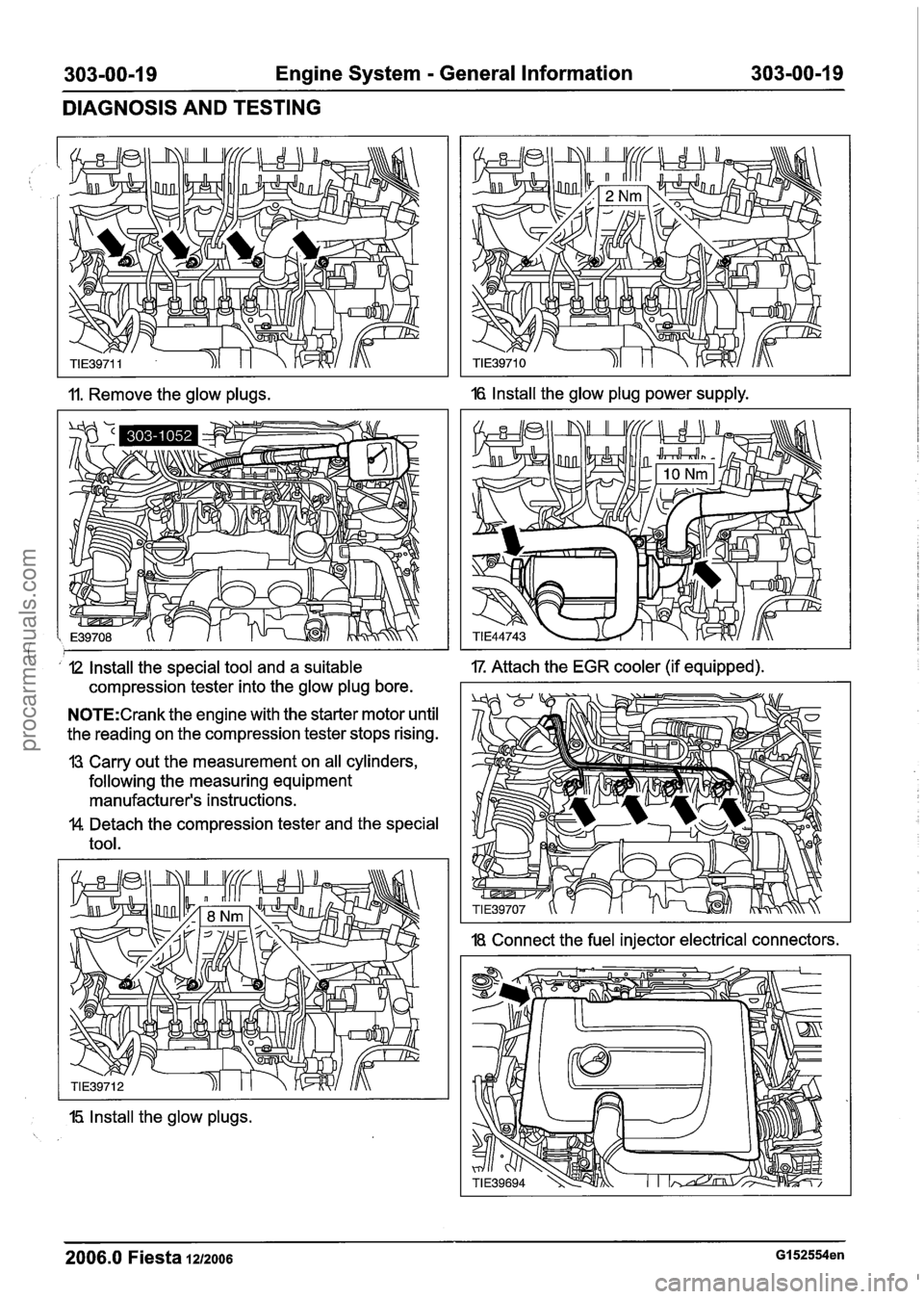

11. Remove the glow plugs. 16 Install the glow plug power supply.

I ' I2 Install the special tool and a suitable IT Attach the EGR cooler (if equipped).

compression tester into the glow plug bore.

N0TE:Crank the engine with the starter motor until

the reading on the compression tester stops rising.

13 Carry out the measurement on all cylinders,

following the measuring equipment

manufacturer's instructions.

$4 Detach the compression tester and the special

tool.

15 Install the glow plugs.

18. Connect the fuel injector electrical connectors.

I

2006.0 Fiesta 1212006 GI 52554en

procarmanuals.com

Page 497 of 1226

Engine - 1.25L Duratec-I 6V (Sigma)ll14L

Duratec-1 6V (Sigma)ll16L Duratec-1 6V (Sigma)

IN-VEHICLE REPAIR

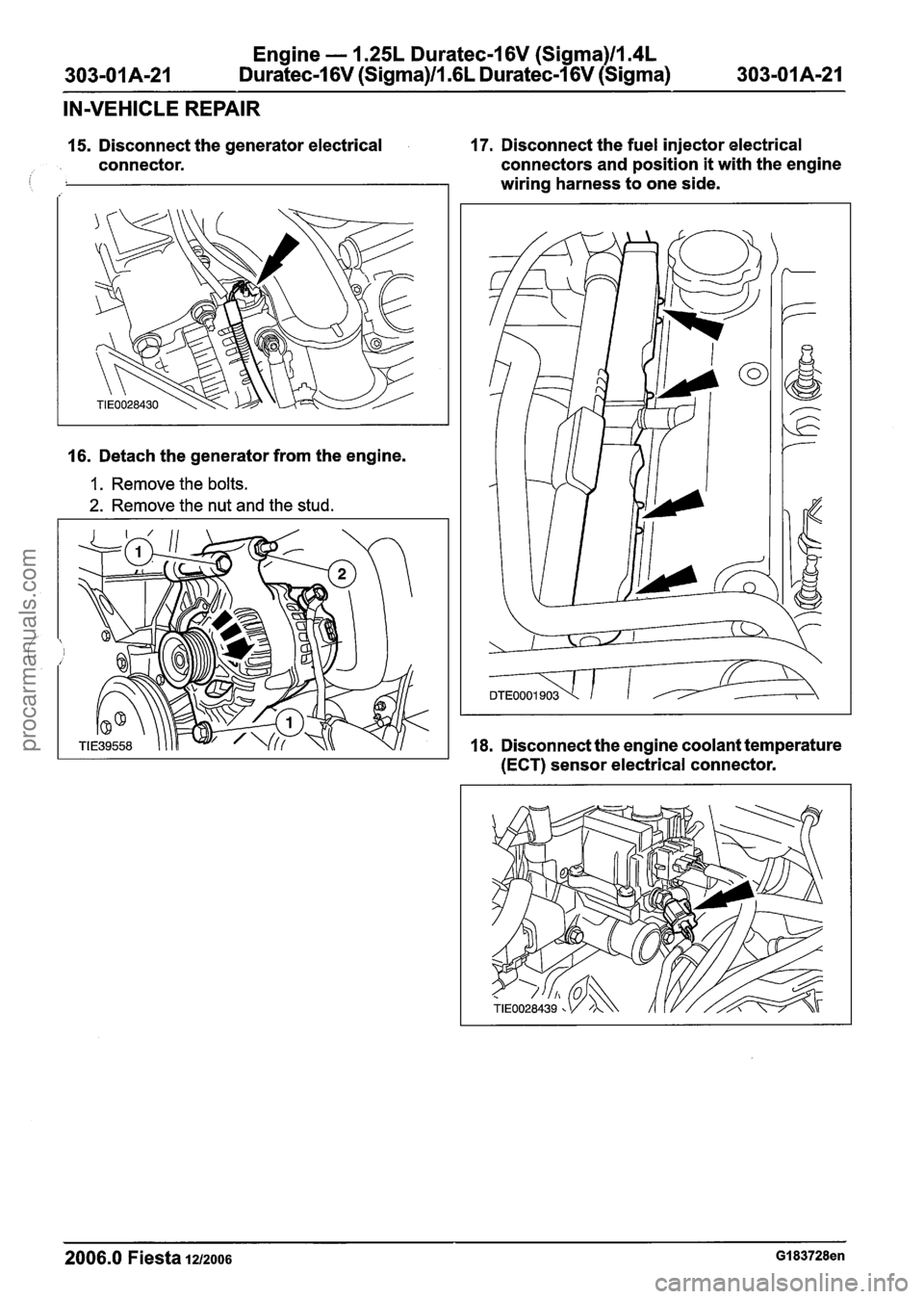

15. Disconnect the generator electrical 17. Disconnect the fuel injector electrical

connector. connectors and

position it with the engine

i wiring harness to one side.

16. Detach the generator from the engine.

1. Remove the bolts.

2. Remove the nut and the stud.

18. Disconnect the engine coolant temperature

(ECT) sensor electrical connector.

2006.0 Fiesta 1~12006 GI 83728en

procarmanuals.com

Page 499 of 1226

Engine - 1.25L Dura

303-01 A-23 Duratec-1

6V (Sigma)ll .(

:ec-I 6V (Sigma)llm4L

L

Duratec-1 6V (Sigma)

303-01 Am23

IN-VEHICLE REPAIR

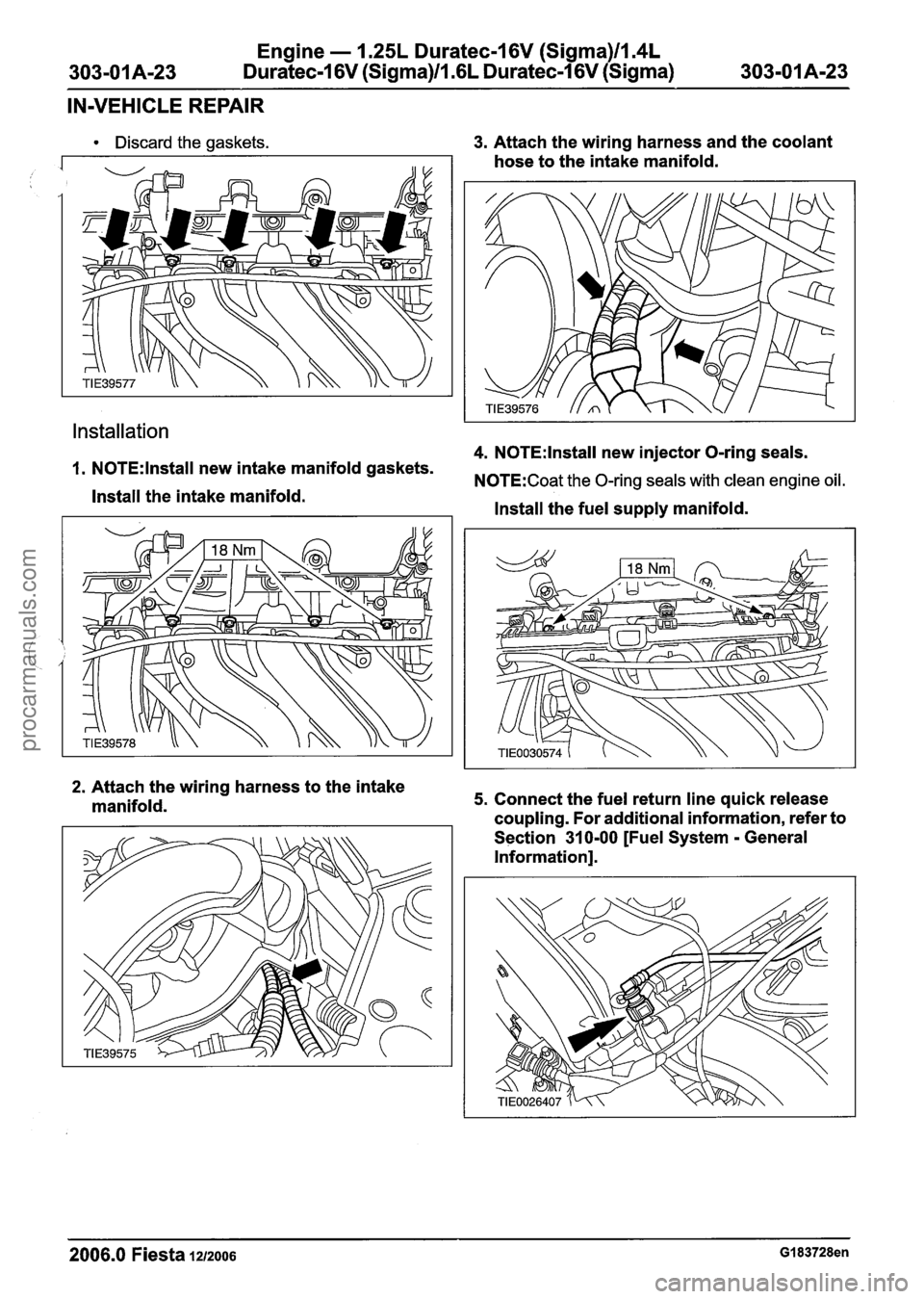

Discard the gaskets.

Installation

3. Attach the wiring harness and the coolant

hose to the intake manifold.

4. N0TE:lnstall new injector O-ring seals.

1. N0TE:lnstall new intake manifold gaskets. N0TE:Coat the 0-rina seals with clean enaine oil.

Install the intake manifold. V "

Install the fuel supply manifold.

2. Attach the wiring harness to the intake

manifold. 5. Connect the fuel return line quick release

coupling. For additional information, refer to

Section

31 0-00 [Fuel System - General

Information].

2006.0 Fiesta 1212006 GI 83728en

procarmanuals.com

Page 500 of 1226

Engine - 1.25L Duratec-1 6V (Sigma)llI4L

Duratec-1 6V (Sigma)/l .6L Duratec-1 6V (Sigma)

IN-VEHICLE REPAIR

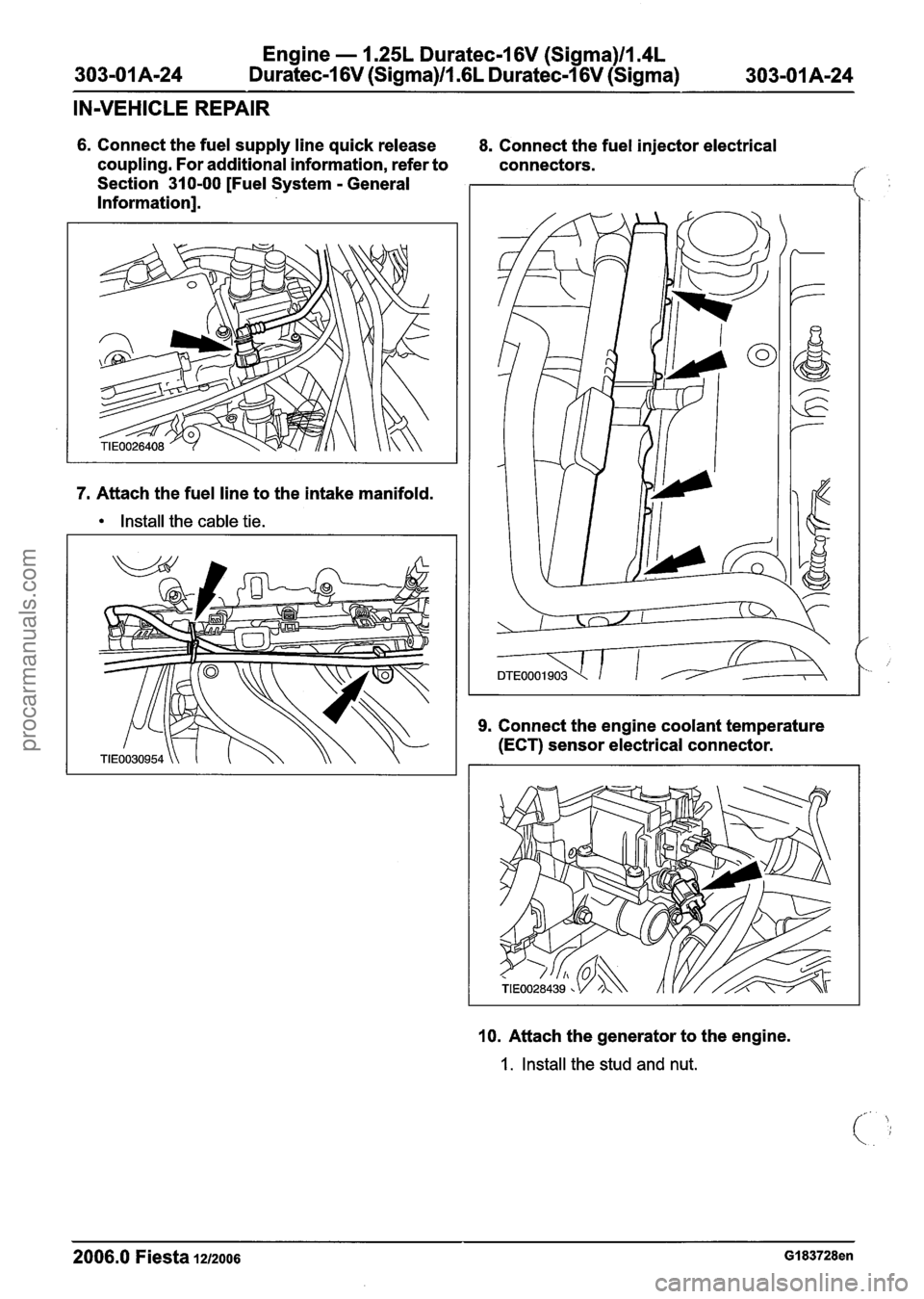

6. Connect the fuel supply line quick release

coupling. For additional information, refer to

Section 310-00 [Fuel System

- General

Information].

7. Attach the fuel line to the intake manifold.

Install the cable tie. 8.

Connect the fuel injector electrical

connectors.

9. Connect the engine coolant temperature

(ECT) sensor electrical connector.

10. Attach the generator to the engine.

1. Install the stud and nut.

2006.0 Fiesta 1212006 GI 83728en

procarmanuals.com

Page 581 of 1226

Engine - 1.25L Duratec-1 6V (Sigma)ll.4L

303-01 A-1 05 Duratec-1 6V (Sigma)/l .6L

Duratec-1 6V (Sigma) 303-01 A-1 05

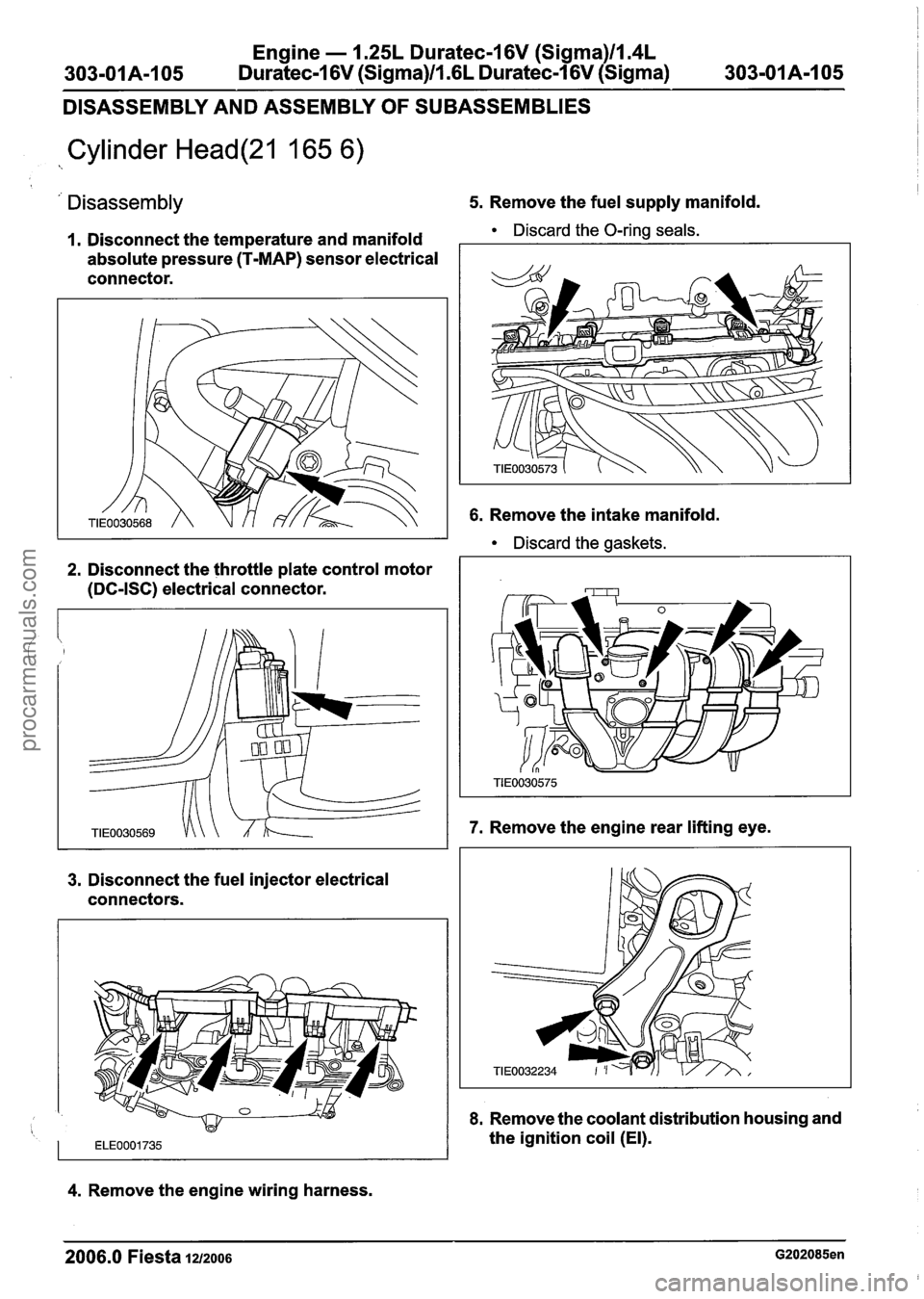

DISASSEMBLY AND ASSEMBLY

OF SUBASSEMBLIES

Cylinder Head(21 165 6)

' Disassembly 5. Remove the fuel supply manifold.

I. Disconnect the temperature and manifold Discard the O-ring seals.

absolute pressure (T-MAP) sensor electrical

connector.

2. Disconnect the throttle plate control motor

(DC-ISC) electrical connector.

3. Disconnect the fuel injector electrical

connectors.

6. Remove the intake manifold.

Discard the gaskets.

7. Remove the engine rear lifting eye.

8. Remove the coolant distribution housing and

1 ~~~0001735 the ignition coil (El).

4. Remove the engine wiring harness.

2006.0 Fiesta 1212006 G202085en

procarmanuals.com

Page 583 of 1226

Engine - 1.25L Duratec-1 6V (Sigma)ll.4L

303-01 A-I 07 Duratec-I 6V (Sigma)/l.GL Duratec-1 6V (Sigma)

303-01 A-I 07

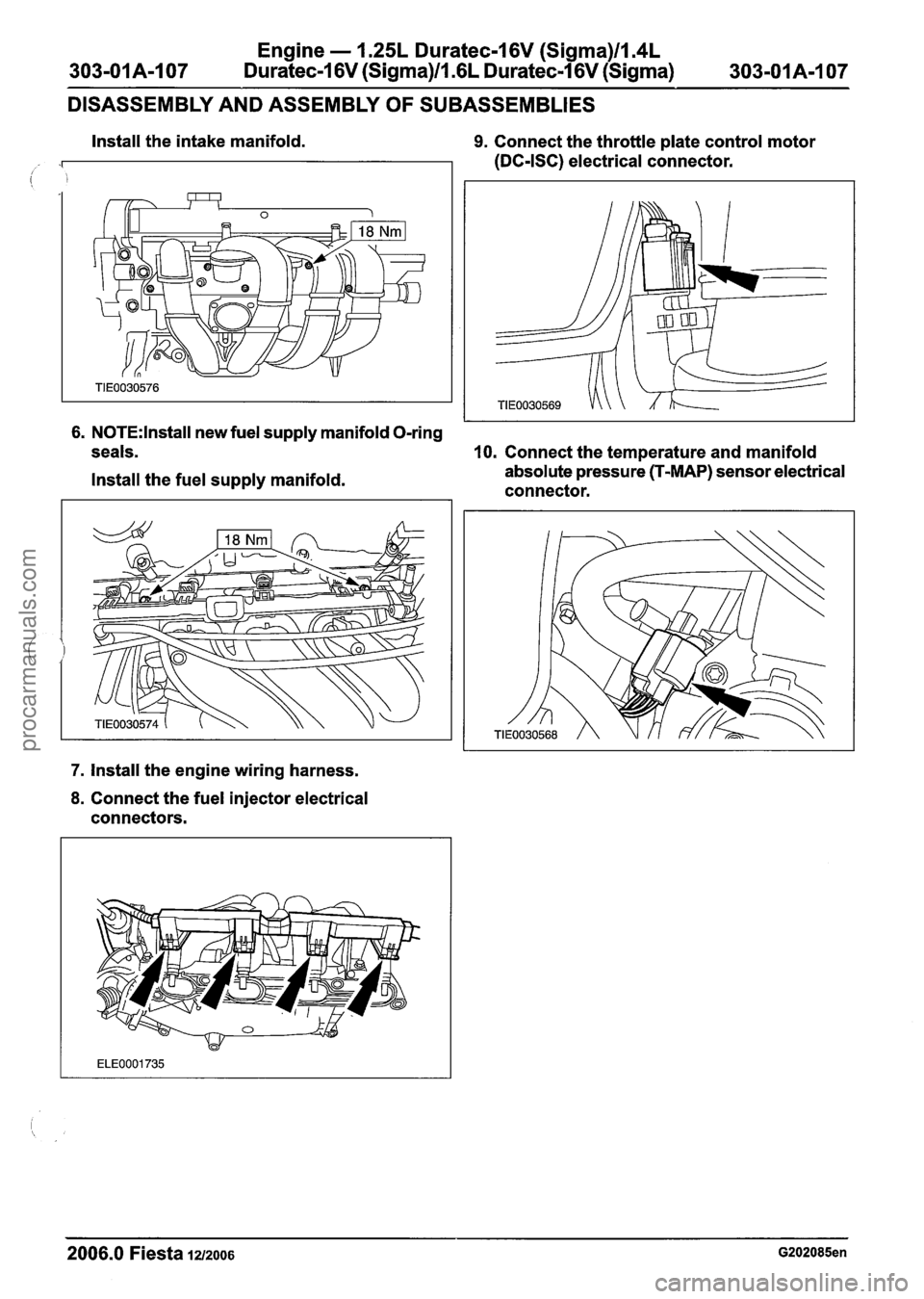

DISASSEMBLY AND ASSEMBLY

OF SUBASSEMBLIES

Install the intake manifold. 9. Connect the throttle plate control motor

(DC-ISC) electrical connector.

6. N0TE:lnstall new fuel supply manifold O-ring

seals.

10. Connect the temperature and manifold

Install the fuel supply manifold. absolute pressure (T-MAP)

sensor electrical

connector.

7. Install the engine wiring harness.

8. Connect the fuel injector electrical

connectors.

2006.0 Fiesta 1212006 G202085en

procarmanuals.com