engine coolant FORD FIESTA 2007 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 941 of 1226

303-1 4-1 7 Electronic Engine Controls 303-1 4-1 7

DIAGNOSIS AND TESTING

The DTC is always a 5 digit alphanumerical

code, for example

"POI 00".

The first digit of a code (letter) identifies the

system which has set the code. Provision has

been made for a total of four systems to be

identified although only the

'PI code is required

for EOBD.

- 'B' for the body

- 'C' for the chassis

- 'P' for the powertrain

- 'U' for the network communications systems

All of the

"xOxxxW codes are standardized codes.

However, any manufacturer can use additional

codes over and above the standardized codes.

These will be labelled

"xlxxx"

The third digit of a code (numeric) identifies the

sub-system which has set the code.

- 'Pxlxx' for metering of fuel and air supply

- 'Px2xx' for metering of fuel and air supply

- 'Px3xx' for ignition system - combustion

misfires

- 'Px4xx' for auxiliary emission control

equipment

- 'Px5xx' for vehicle speed, idle setting and

other related inputs

- 'Px6xx' for trip computer and other related

outputs

- 'Px7xx' for transmission.

- 'Px8xx' for transmission.

- 'Px9xx' category to be determined

- 'PxOxx' category to be determined

When a concern occurs, the actions taken

include storage of the relevant information and

actuation of the MIL occurs in line with the

relevant legislation.

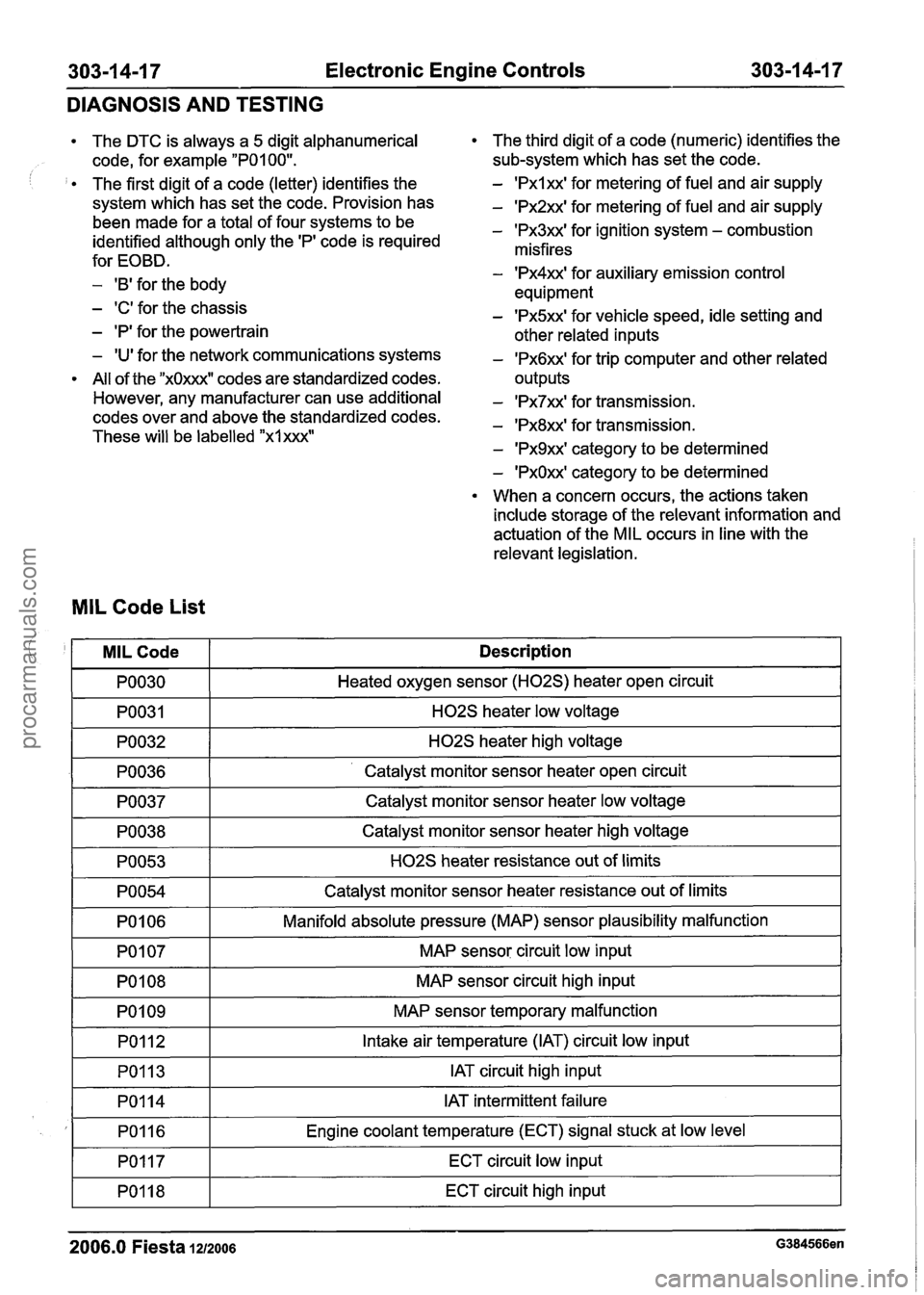

MIL Code List

I PO030 I Heated oxygen sensor (H02S) heater open circuit I

! '

-1 H02S heater low voltage I

I PO032 I H02S heater high voltage I

MILCode

PO036 1- ' Catalyst monitor sensor heater open circuit I

Description

PO037

I PO054 I Catalyst monitor sensor heater resistance out of limits I

Catalyst monitor sensor heater low voltage

PO038

PO053

I PO106 I Manifold absolute pressure (MAP) sensor plausibility malfunction I

-

Catalyst monitor sensor heater high voltage

H02S heater resistance out of limits

I PO107 I MAP sensor circuit low input I

PO108

PO1 09 MAP sensor

circuit high input

MAP sensor temporary malfunction

PO1 12

PO113

I PO117 I ECT circuit low input I

Intake air temperature (IAT) circuit low input

IAT circuit high input

I

2006.0 Fiesta 1212006 G384566en

PO114

PO1 16

PO118

IAT intermittent failure

Engine coolant temperature (ECT) signal stuck at low level

ECT circuit high input

procarmanuals.com

Page 959 of 1226

303-1 4-35 Electronic Engine Controls 303-1 4-35

REMOVAL AND INSTALLATION

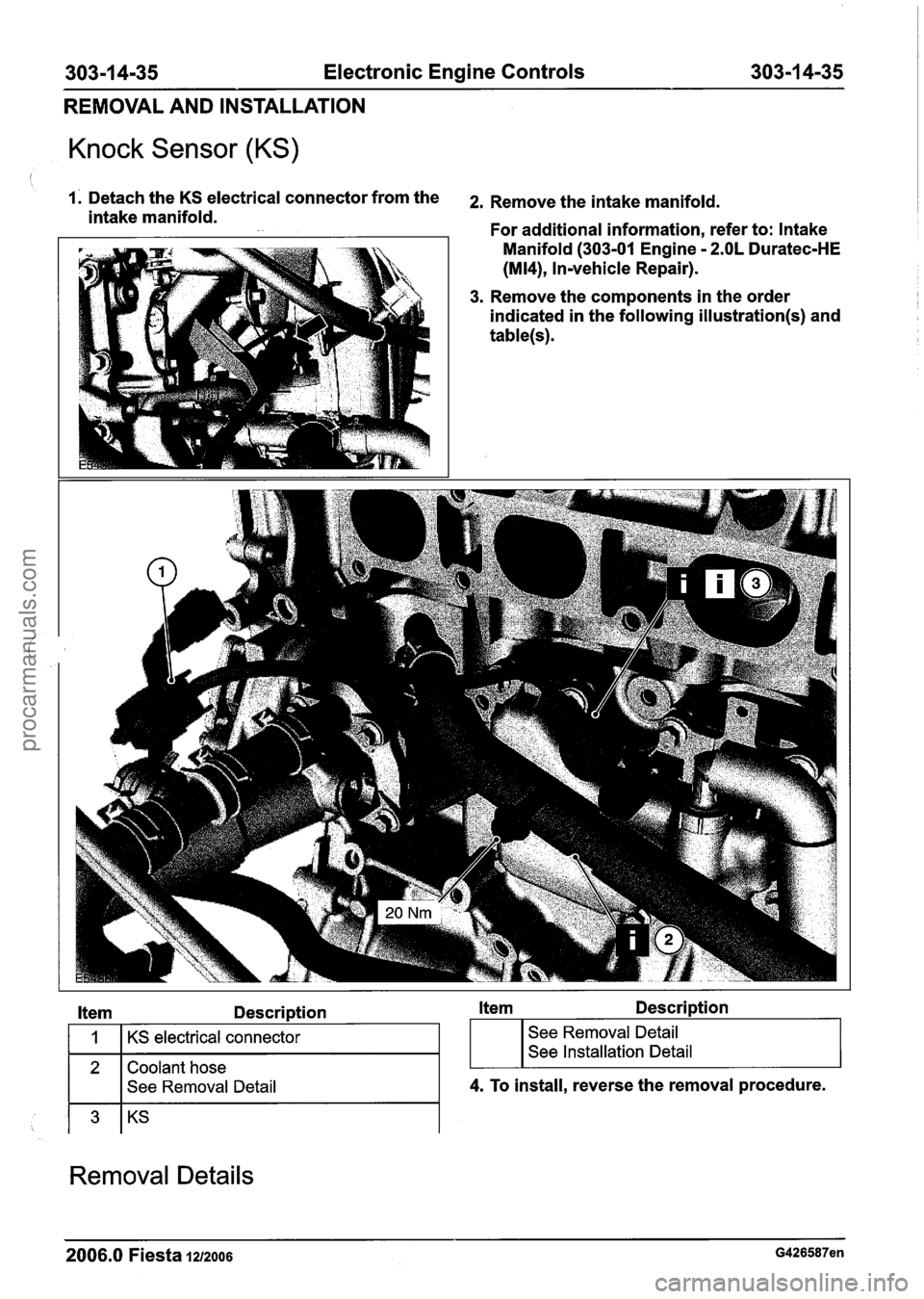

Knock Sensor (KS)

1. Detach the KS electrical connector from the 2, Remove the intake manifold. intake manifold.

For additional information, refer to: Intake

1 Manifold (303-01 Engine - 2.OL Duratec-HE

(M14), Invehicle Repair).

3. Remove the components in the order

indicated in the following

illustration(s) and

table(s).

Item Description Item Description

2 Coolant hose

I I See Removal Detail

1

I I

4. To install, reverse the removal procedure.

KS electrical connector

Removal Details

; I I

See Removal Detail

See Installation Detail

2006.0 Fiesta 1212006 G426587en

procarmanuals.com

Page 960 of 1226

303-1 4-36 Electronic Engine Controls 303-1 4-36

REMOVAL AND INSTALLATION

Ifem 2 Coolant hose kern 3 KS

I. Detach the coolant hose from the coolant N0TE:Make a note of the position of the KS and

hose retaining clip and position it to one

when installed.

make sure

it is positioned in the same position

.

side.

Installation Details

ltem 3 KS

NOTE: Prior to installing the KS, clean the engine

block and KS mating surfaces.

N0TE:Make sure the KS is installed in the same

position as removed.

(I.

2006.0 Fiesta 1212006 G426587en

procarmanuals.com

Page 991 of 1226

Automatic TransmissionlTransaxle -

Vehicles With: 4-Speed Automatic

307-01 -31 Transmission (AW81-40) 307-01 -31

DESCRIPTION AND OPERATION

The transmission control unit determines hill climb

mode or trailer operation from the change in throttle

; valve position supplied by the PCM in relation to

the acceleration of the vehicle.

Depending on the driving resistance, the

transmission control unit chooses between two

gearshift maps which have been specially

programmed for this purpose and in which the shift

timings are again chosen as a function of the

accelerator pedal position and the vehicle speed..

Hill descent mode

The hill descent mode is used to take better

advantage of engine braking during hill descents.

A 'hill descent' situation is recognised by the

transmission control unit if the vehicle is

accelerating without operation of the accelerator

pedal.

If in addition the brake is also depressed then the

transmission control unit automatically shifts back

from 4th into 3rd gear.

( ' Cold start mode

In order to reach operating temperature as quickly

as possible under low ambient temperatures,

gearshifts into 4th gear and engagement of the

torque converter clutch (TCC) are suppressed if

one of the following conditions is met:

Transmission fluid temperature below +20 "C

Coolant temperature below - 40°C

The following are actuated: SSA shift solenoid valve,

SSB shift solenoid valve,

Shift solenoid valve, TCC.

Overheating protection mode

The overheating protection mode serves to protect

the transmission against overheating and the

serious damage that this can cause.

If the transmission fluid temperature reaches a

temperature of around 135

"C, the transmission

control employs a shift pattern designed to prevent

a further increase in the transmission fluid

temperature. When

the transmission fluid temperature drops

back below approx. 125

"C, the transmission

control exits the overheating protection mode.

The MIL warning lamp is actuated by the

transmission control unit if the transmission fluid

temperature reaches approximately 140

"C.

The MIL warning lamp goes out again when the

transmission fluid temperature drops back to below

around 130

"C.

Main line pressure control

In order to ensure the highest possible efficiency

of the automatic transmission and to limit the power

losses from the fluid pump, the main line pressure

is adapted accordingly by the main regulating valve

as a function of the accelerator pedal position

(driver torque demand) and the selector lever

position.

This is influenced by the following variables:

Accelerator pedal position and actuation

Selector lever position

The following are actuated:

Main 'regulating valve

Engagement of the TCC

The TCC is engaged in 3rd and 4th gear depending

on the current driving situation.

Engagement is controlled in accordance with the

shift map stored in the control unit.

This is influenced by the following variables:

Accelerator pedal position and actuation,

Vehicle speed,

Selector lever position,

Transmission fluid temperature,

Coolant temperature.

The following are actuated:

Shift solenoid valve, TCC.

Torque reduction during gearshifts

In order to improve the quality of gearshifts and to

avoid gearshift judder, the engine torque is reduced

by the PCM in response to a request from the

transmission control unit during gearshifts.

The engine torque is also reduced during

engagement and disengagement of the TCC.

2006.0 Fiesta 1212006 G380530en

procarmanuals.com

Page 995 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4Speed Automatic

307-01 -35 Transmission (AW81-40) 307-01 -35

DESCRIPTION AND OPERATION

Engine speed

1 The engine speed is detected by the crankshaft

position (CKP) sensor and passed on to the PCM.

The engine speed is transmitted from the PCM via

the CAN

databus to the transmission control unit.

The transmission control unit uses this signal for:

Torque reduction during gearshifts,

Pressure control during gearshifts.

Engine load

The PCM determines a load signal which is

transmitted via the CAN

databus to the

transmission control unit.

The transmission control unit uses this signal for:

Torque reduction during gearshifts,

Pressure control during gearshifts,

Shift timing adaptation during upshifts,

Shift timing adaptation during shifts from 3rd to

4th gear,

Hill climb mode,

( ' Hill descent mode. ' ,

Torque reduction request signal

Before performing a gearshift, the transmission

control unit sends a signal via the CAN

databus to

the PCM requesting a torque reduction.

The PCM then reduces the engine torque, ensuring

that the gearshift is as smooth and judder-free as

possible.

Brake signal

The PCM receives a signal from the stoplamp

switch when the brake pedal is depressed.

This signal is transmitted via the CAN

databus to

the transmission control unit.

The transmission control unit uses this signal for:

Gearshift control,

Engagement of the TCC

Accelerator pedal position

The PCM receives the current accelerator pedal

position signal from the Accelerator Pedal Position

(APP) sensor.

This signal is transmitted via the CAN

databus to

the transmission control unit.

The transmission control unit uses this signal for:

Controlling the main line pressure,

Gearshift control,

Engagement of the TCC,

Shift timing adaptation during upshifts,

Shift timing adaptation during shifts from 3rd to

4th gear,

Shift timing adaptation during shifts from 4th to

3rd gear,

Avoidance of gearshift judder during

engagement of a transmission range,

Torque reduction when pulling away.

Coolant temperature

The coolant temperature is detected by the Engine

Coolant Temperature (ECT) sensor and passed

on to the PCM.

This signal is transmitted via the CAN

databus to

the transmission control unit.

The transmission control unit uses this signal for:

Cold start mode,

Engagement of the TCC

Selector lever position

The transmission control unit transmits the selector

lever position to the instrument cluster.

The instrument cluster uses the signal to send a

request for a warning tone to the GEM when the

selector lever is not in position "P" and the driver's

door is opened.

-

2006.0 Fiesta 1212006 G380530en

procarmanuals.com

Page 1006 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4Speed Automatic

307-01 -46 Transmission

(AW81-40) 307101 -46

DIAGNOSIS AND TESTING

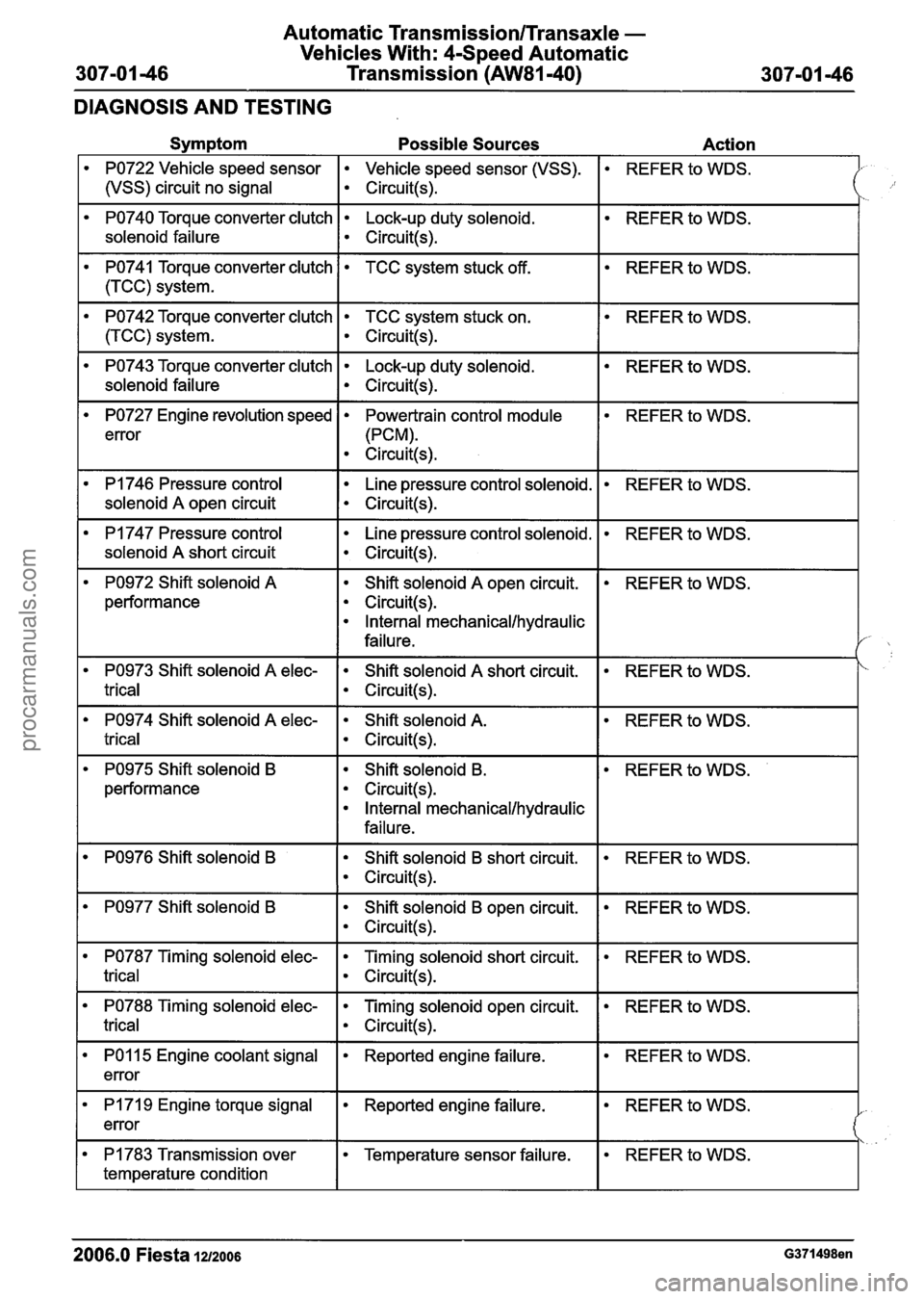

Symptom Possible Sources Action

PO722 Vehicle speed sensor Vehicle speed sensor (VSS).

1 (vSS) circuit no signal I circuit(+

REFER to WDS.

PO740 Torque converter clutch Lock-up duty solenoid.

solenoid failure

I ~ircuit(s).

REFER to WDS.

REFER to WDS.

PO741 Torque converter clutch

1 (TCC) system.

PO742 Torque converter clutch TCC system stuck on.

I circuit(s).

TCC system stuck off.

REFER to WDS.

PO743 Torque converter clutch Lock-up duty solenoid.

solenoid failure

I circuit(s).

REFER to WDS.

REFER to WDS.

PO727 Engine revolution speed

error

PI 746 Pressure control

I solenoid A open circuit

Powertrain control module

(PCM).

Circuit(s).

I

Line pressure control solenoid.

Circuit(s).

REFER to WDS.

PI 747 Pressure control

solenoid

A short circuit

Line pressure control solenoid.

Circuit(s).

REFER to WDS.

PO972 Shift solenoid A

performance Shift solenoid

A open

circuit.

Circuit(s).

Internal mechanical/hydraulic

failure.

REFER to WDS.

REFER to WDS.

PO974 Shift solenoid A elec- Shift solenoid A.

trical I circuit(!+

PO973 Shift solenoid A elec-

trical

REFER to WDS. Shift solenoid A short circuit.

Circuit(s).

PO975 Shift solenoid B

performance Shift solenoid

B.

Circuit(s).

Internal mechanical/hydraulic

failure.

REFER

to WDS.

PO976 Shift solenoid B Shift solenoid B short circuit.

Circuit(s).

REFER to WDS.

PO977 Shift solenoid B Shift solenoid B open circuit.

Circuit(s).

REFER to WDS.

PO787 Timing solenoid elec- Timing solenoid short circuit.

trical I circuit(s).

REFER to WDS.

REFER to WDS. PO788 Timing solenoid elec-

trical

-- - -

Timing solenoid open circuit.

Circuit(s).

REFER to WDS. PO1 15 Engine coolant signal

error Reported engine failure.

REFER to WDS. I PI 71 9 Engine torque signal

error Reported engine failure.

REFER to WDS. PI 783 Transmission over

temperature condition

2006.0 Fiesta 12/2006 G371498en

Temperature sensor failure.

procarmanuals.com

Page 1117 of 1226

308-03-27 Manual TransmissionlTransaxle 308-03-27

REMOVAL

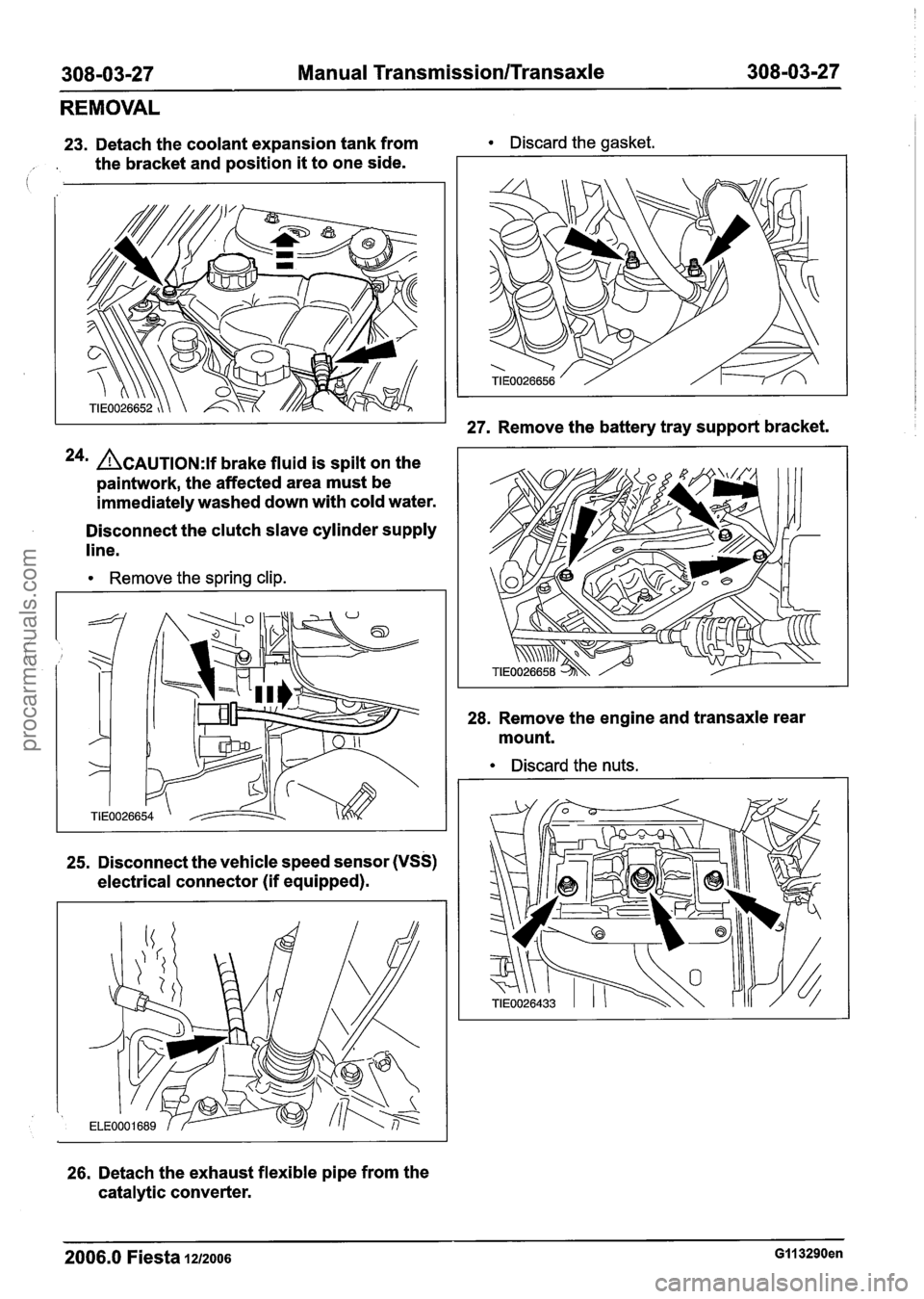

23. Detach the coolant expansion tank from Discard the gasket.

, . the bracket and position it to one side.

24m ACAUTION:~~ brake fluid is spilt on the

paintwork, the affected area must be

immediately washed down with cold water.

Disconnect the clutch slave cylinder supply

line.

Remove the spring clip.

25. Disconnect the vehicle speed sensor (VSS)

electrical connector (if equipped).

26. Detach the exhaust flexible pipe from the

catalytic converter.

27. Remove the battery tray support bracket.

28. Remove the engine and transaxle rear

mount.

Discard the nuts.

2006.0 Fiesta 1212006 GI1 3290en

procarmanuals.com