lock FORD FIESTA 2007 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 3 of 1226

2006.0 Fiesta

Workshop Manual

Table of Contents

GROUP 1 General lnformation

Service lnformation

General lnformation

Identification Codes

Jacking and Lifting

Noise, Vibration and

Harshness

Suspension

Suspension System - General

lnformation

Front Suspension

Rear Suspension

Wheels and Tires

Driveline

Front Drive Halfshafts

Brake System

Brake System - General

Information

Drum Brake

Front Disc Brake

Rear Disc Brake

Parking Brake and Actuation

Hydraulic Brake Actuation

Power Brake Actuation

Anti-Lock Control

Anti-Lock Control

- Traction

Control

Anti-Lock Control

- Stability

Assist

Steering System

Steering System - General

lnformation

Power Steering Steering Linkage

Steering Column

Steering Column Switches

Engine

Engine System - General

lnformation

Engine

- 1.25L Duratec-1 6V

(Sigma)/l.4L Duratec-1 6V

(Sigma)/l.GL Duratec-I 6V

(Sigma)

Engine

- 2.OL Duratec-HE

(MI41

Engine Cooling - 1.3L Duratec-8V

(Rocam)/l.25L Duratec-1 6V

(Sigma)/l.4L Duratec-1 6V

(Sigma)/l .6L Duratec-1 6V

(Sigma)

Engine Cooling

- 2.OL Duratec-HE

(MI41

Fuel Charging and Controls - 1.25L

Duratec-1 6V (Sigma)/l.4L

Duratec-16V (Sigma)/l.GL

Duratec-1 6V (Sigma)

Fuel Charging and Controls

- 2.OL

Duratec-HE (M14)

Accessory Drive

Starting System

Engine lgnition

Engine Ignition

- 2.OL Duratec-HE

(M14)

Engine Emission Control - 1.3L

Duratec-8V (Rocam)/l.25L

Duratec-1 6V (Sigma)/l.4L

Duratec-1 6V (Sigma)/l .6L

Duratec-1

6V (Sigma)

Engine Emission Control

- 2.OL

Duratec-HE (M14)

05/2005 2006.0 Fiesta

procarmanuals.com

Page 5 of 1226

Handles, Locks, Latches and Entry Systems 501-14

Wipers and Washers 501-16

Bumpers 501-19

Safety Belt System 50

I -20A

Supplemental Restraint

System 501 -20B

Body Repairs

- General

Information 501 -25

Body Repairs

- Vehicle Specific

lnformation and Tolerance

Checks 501 -26

To the best of our knowledge, the illustrations,

technical information, data and descriptions in

this issue were correct at the time of going to

print. The right to change prices, specifications,

equipment and maintenance instructions at

any time without notice is reserved as part of

FORD policy of continuous development and

improvement for the benefit of our customers.

No part of this publication may be reproduced,

stored in a data processing system or

transmitted in any form, electronic, mechanical,

photocopy, recording, translation or by any

other means without prior permission of

Ford-Werke Aktiengesellschaft. No liability can

be accepted for any inaccuracies in this

publication, although every possible care has

been taken to make it as complete and

accurate as possible.

Copyright

O

FORD-WERKE AKTIENGESELLSCHAFT

Service training programs D-FIGT-1

Printed in Germany

- rewi druckhaus, Wissen -

Printed on environmentally friendly

chlorine-free paper. (GB) Front End Sheet Metal Repairs

50 1 -27

Roof Sheet Metal Repairs 50 1 -28

Side Panel Sheet Metal Repairs 501 -29

Rear End Sheet Metal Repairs 501

-30

Paint

- General Information 501

-36

Frame and Mounting

Uni-Body, Subframe and Mounting

System 502-00

0512005 2006.0 Fiesta

procarmanuals.com

Page 9 of 1226

GROUP

Chassis

SECTION TITLE PAGE

Suspension

Suspension

System . General Information .................................................................... 204-00

........................................................................\

................................. Front Suspension .201 4.0

........................................................................\

................................. Rear Suspension .20 4.02

........................................................................\

.................................. Wheels and Tires 204-04

Driveline

Front Drive Halfshafts ........................................................................\

............................ 205-04

' Brake System

Brake System . General Information ........................................................................\

...... 206-00

........................................................................\

.......................................... Drum Brake .20 6.02

Front Disc Brake

........................................................................\

................................... 206-03

Rear Disc Brake

........................................................................\

.................................... 206-04

Parking Brake and Actuation

........................................................................\

................. 206-05

Hydraulic Brake Actuation ........................................................................\

...................... 206-06

Power Brake Actuation

........................................................................\

.......................... 206-07

........................................................................\

.................................. An ti-Lock Control .20 6.09A

Anti-Lock Control . Traction Control ........................................................................\

....... 206-09B

Anti-Lock Control . Stability Assist ........................................................................\

......... 206-09C

Steering System

........................................................................\

. Steering System . General Information .21 1.00

........................................................................\

..................................... Power Steering -21 1-02

........................................................................\

.................................. Steering Linkage -21 1-03

Steering Column

........................................................................\

................................... 21 1-04

Steering Column Switches

........................................................................\

..................... 21 1-05

0512005 2006.0 Fiesta

procarmanuals.com

Page 15 of 1226

GROUP

Body and Paint

SECTION TITLE PAGE

Body and Paint

........................................................................\

.... Body System . General Information .50 1.00

........................................................................\

......................... Front End Body Panels .50 1.02

........................................................................\

........................................ Body Closures 501 -03

Interior Trim and Ornamentation ........................................................................\

............ 501-05

........................................................................\

.......... Exterior Trim and Ornamentation .50 1-08

........................................................................\

.................................. Rear View Mirrors 50 1 -09

........................................................................\

................................................... Seating 501 -10

........................................................................\

........... Glass, Frames and Mechanisms .SO1 1-1

........................................................................\

............... Instrument Panel and Console 502 1-1

............................................................... Handles, Locks, Latches and Entry Systems -501 -1 4

........................................................................\

............................. Wipers and Washers -501 -1 6

Bumpers ........................................................................\

................................................. 501 -1 9

........................................................................\

................................. Safety Belt System 50 I -2OA

........................................................................\

............. Supplemental Restraint System .50 I -2OB

Body Repairs - General Information ........................................................................\

...... 501-25

Body Repairs - Vehicle Specific Information and Tolerance Checks ............................. 501-26

........................................................................\

............. Front End Sheet Metal Repairs .50 1-27

........................................................................\

..................... Roof Sheet Metal Repairs -50 I -28

Side Panel Sheet Metal Repairs ........................................................................\

............ 501-29

........................................................................\

.............. Rear End Sheet Metal Repairs 50 1-30

........................................................................\

.................... Paint - General Information 501 -36

Frame and Mounting

Uni-Body, Subframe and Mounting System ................................................................... 502-00

0512005 2006.0

Fiesta

procarmanuals.com

Page 35 of 1226

100-00-1 9 General Information 100-00-1 9

DESCRIPTION AND OPERATION

Standard Workshop Practices

Vehicle in Workshop

When working on a vehicle in the workshop always

make sure that:

- the parking brake is applied or the wheels are

securely chocked to prevent the vehicle moving

forwards or backwards.

- the key is removed from key operated hood

locks before any work is carried out around the

front of the vehicle.

- if the engine is to be run, there is adequate

ventilation, or an extraction hose to remove

exhaust fumes.

- there is adequate room to raise the vehicle and

remove the wheels, if necessary.

- fender covers are always fitted if any work is to

be carried out in the engine compartment.

- the battery is disconnected if working on the

engine, underneath the vehicle, or if the vehicle

is raised.

Alternative Fuel - Dons

- Do work on the vehicle in a designated area,

that is well ventilated and with access restricted

to qualified personnel only.

- Install new warning labels to their original

locations.

- If possible always isolate the alternative fuel

tank, and run the vehicle on the alternative fuel

until it automatically switches to its normal fuel

prior to taking the vehicle into the workshop

service area.

- Only use tested and approved components and

pipes when repairing or servicing

LPG and CNG

systems.

Alternative Fuel - Do Nots

- Do not vent off LPG fuel.

- Do not use shop air pressure to force LPG fuel

from the fuel tank.

( A CAUTION:When electric arc welding on a - Do not use paint drying ovens above 40°C for vehicle, always disconnect the generator any alternative fuel vehicle. LPG and CNG fuel wiring to prevent the possibility of a surge tanks must be removed from the vehicle prior of current causing damage to the internal to being put into paint drying ovens above 40°C. components of the generator. - Do not modify the system or install new - if using welding equipment on the vehicle, a

components that are not designed for gas

suitable fire extinguisher is readily available.

vehicles.

Alternative Fuel

A WARNING:When servicing the fuel system

always follow the recommended

procedures. Failure to follow these

instructions may result in personal injury.

If the odor of liquefied petroleum gas (LPG) or

compressed natural gas

(CNG) is present in the

air in the workshop, warn all persons in the area

to:

- extinguish all flames and lighted tobacco.

- shut off electrical and air powered equipment.

- evacuate the area.

- ventilate the area.

- contact the fire control authorities.

- remove the vehicle to a dedicated, ventilated

area.

- Do not evacuate fuel tanks unless there is repair

that requires the removal of the fuel tank.

- Do not work on the fuel lines or system

components unless the alternative fuel has been

evacuated and the pressure in the system

reduced to atmospheric or less.

- Do not use anything other than the specified

leak detector fluid to trace fuel leaks.

Be aware of situations that may cause the

LPG or I

CNG fuel system to vent off fuel, such as: I

- extremely hot days.

- parking by a space heater.

- hoisting a vehicle up near a ceiling heater.

Only fully trained personnel, who are conversant

with local standards, are to work on alternative fuel

vehicles.

2006.0 Fiesta 1212006 GI 7373en

procarmanuals.com

Page 36 of 1226

100-00-20 General Information 100-00-20

DESCRIPTION AND OPERATION

Towing the Vehicle

an instance, the discharged battery must

be recharged immediately after jump

A WARN1NG:When the vehicle is being starting

to avoid permanent damage. ( towed, the ignition switch must be in - Always make sure that the jumper cables are

position ll (steering lock released and adequate for the task. Heavy duty cables must

warning lamps illuminated). Only then will be used.

the turn signal lamps, horn and - Always make sure that the slave battery is of stop lamps be operational. Failure to follow the same voltage as the vehicle battery. The these instructions may result in personal batteries must be connected in parallel. injury. - Always make sure that switched electric circuits

N0TE:The removable towing eye (if equipped),

are switched off before connecting jumper

has a left-hand thread and must be fully tightened cables. This reduces the risk of arcing occurring

before towing can commence.

when the final connection is made.

When towing is necessary, the vehicle towing eyes

should be used. The rope must be securely

fastened to the towing eyes and must also be

attached to the other vehicle such that the rope will

not foul the bodywork.

When a vehicle with automatic transmission is

towed, the gear selector must be in position

N

(Neutral). Never tow a vehicle with automatic

transmission at a speed greater than 30 mph (50

kmlh) or for a distance greater than 30 miles (50

km). If it is necessary to tow the vehicle a greater

distance, the drive wheels must be lifted clear off

the ground.

I A WARN1NG:Make sure that the ends of the Alternatively the vehicle can be transported on a jumper cables do not touch each other or low loader or a trailer. ground against the vehicle body at any

time while the cables are attached to the

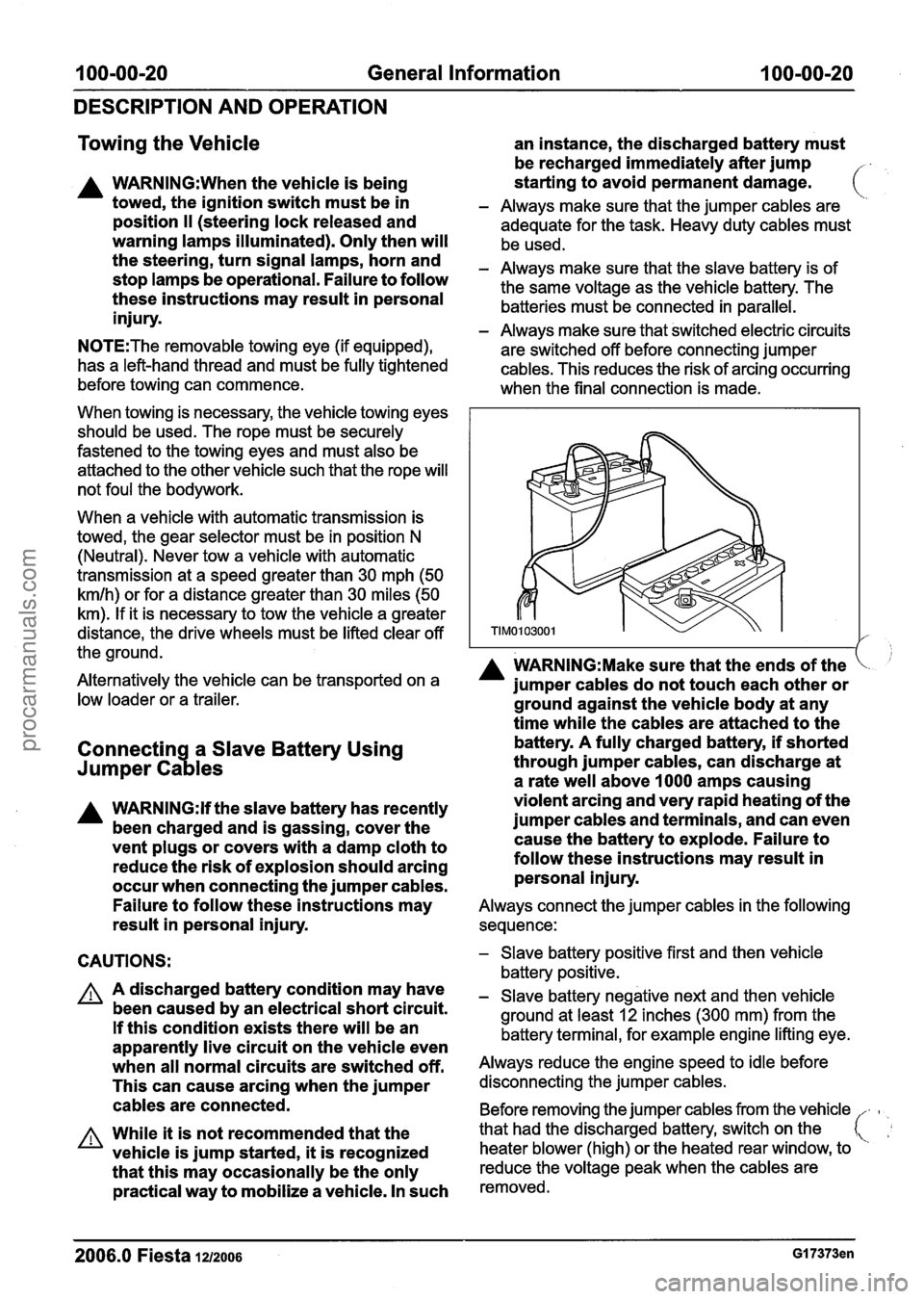

Connectin a Slave Battery Using

73

battery. A fully charged battery, if shorted

Jumper Ca les through jumper cables, can discharge at

a rate well above

I000 amps causing

A WARNING:H the slave battery has recently violent arcing

and very rapid heating of the

been charged and is gassing, cover the jumper cables and

terminals, and can even

vent plugs or covers with a damp cloth to cause

the battery to explode. Failure to

reduce the risk of explosion should arcing follow

these instructions may result in

occur when connecting the jumper cables. personal injury.

Failure to follow these instructions may

Always connect the jumper cables in the following

result in personal injury. sequence:

CAUTIONS:

A A discharged battery condition may have

been caused by an electrical short circuit.

If this condition exists there will be an

apparently live circuit on the vehicle even

when all normal circuits are switched off.

This can cause arcing when the jumper

cables are connected.

A While it is not recommended that the

vehicle is jump started,

it is recognized

that this may occasionally be the only

practical way to mobilize a vehicle. In such

- Slave battery positive first and then vehicle

battery positive.

- Slave battery negative next and then vehicle

ground at least

12 inches (300 mm) from the

battery terminal, for example engine lifting eye.

Always reduce the engine speed to idle before

disconnecting the jumper cables.

Before removing the jumper cables from the vehicle

-

heater blower (high) or the heated rear window, to

that

had the discharged battery, switch on the

reduce the voltage peak when the cables are

removed.

2006.0 Fiesta 1~12006 GI 7373en

procarmanuals.com

Page 55 of 1226

100-02-5 Jacking and Lifting 100-02-5

DESCRIPTION AND OPERATION

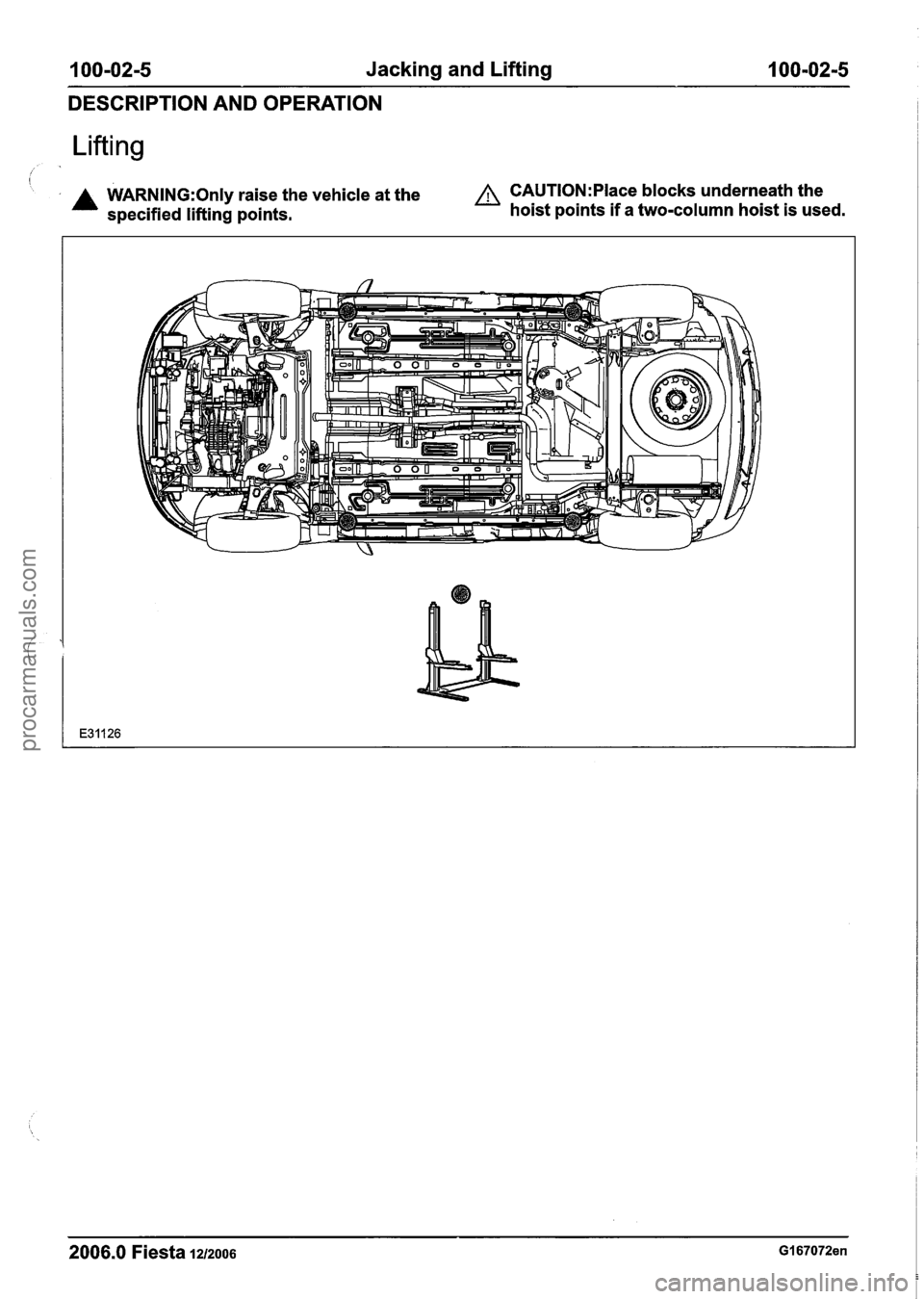

Lifting

/' A WARNING:Only raise the vehicle at the A CAUTI0N:Place blocks underneath the

specified lifting points. hoist points

if a two-column hoist is used.

- -- --

2006.0 Fiesta 1212006 GI 67072en

procarmanuals.com

Page 64 of 1226

I 00-04-8 Noise, Vibration and Harshness 100-04-8

DIAGNOSIS AND TESTING

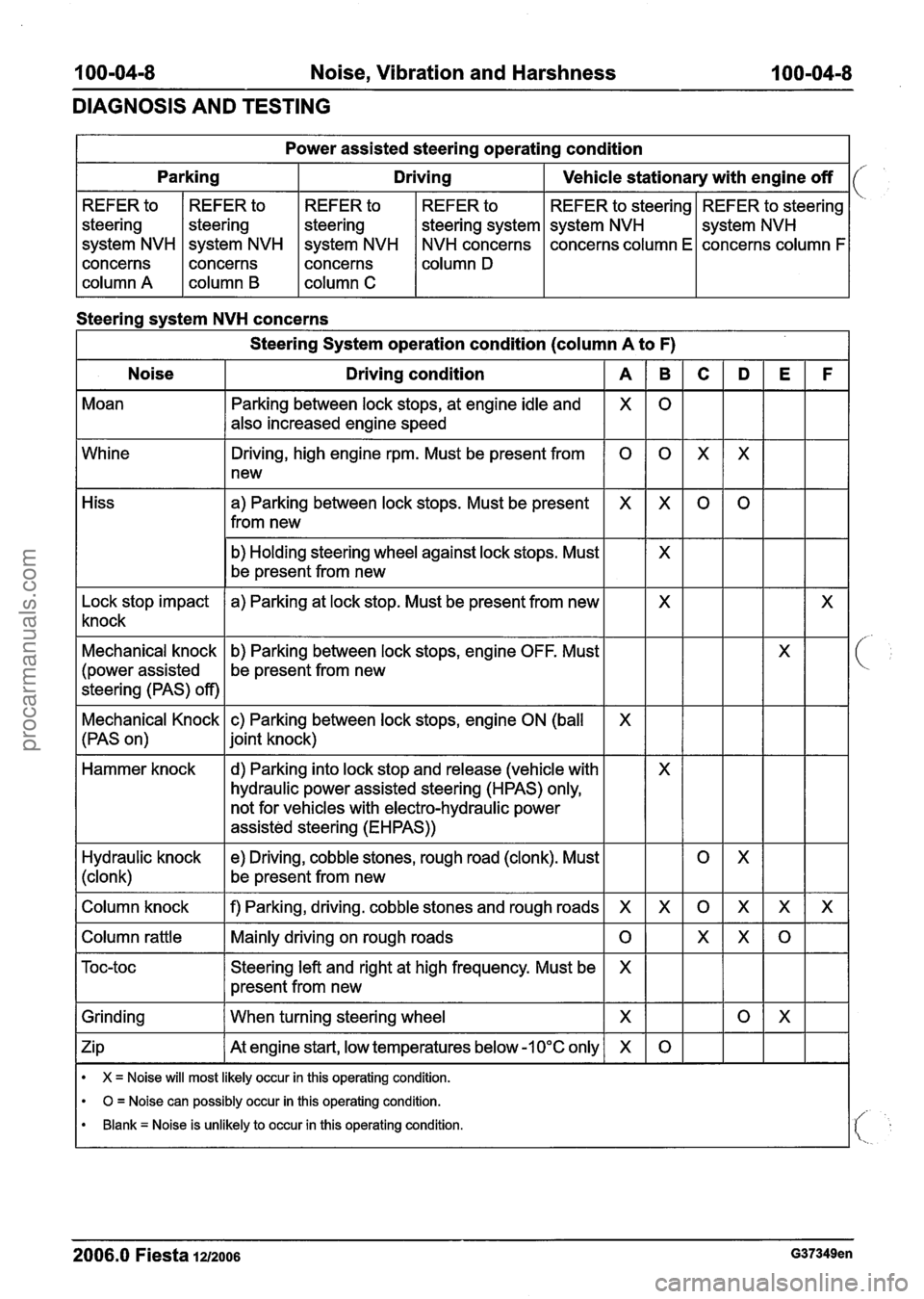

Steering system NVH concerns Power

assisted steering operating condition

I Steering System operation condition (column A to F) 1

Noise I Driving condition I A

Parking

Moan REFER

to

steering

system NVH

concerns

column A REFER

to

steering

system NVH

concerns

column

B

Driving

Whine REFER

to

steering

system NVH

concerns

column C

Vehicle stationary with engine off

Parking between lock stops, at engine idle and

also increased engine speed REFER

to

steering system

NVH concerns

column

D

REFER to steering

system NVH

concerns column E

X

Hiss REFER

to steering

system NVH

concerns column F

Driving, high engine rpm. Must be present from

1 new

0

b) Holding steering wheel against lock stops. Must

be present from new

a) Parking between lock

stops. Must be present

from new

X

Lock stop impact

knock a) Parking

at lock stop. Must be present from new

Mechanical knock

(power assisted

steering (PAS) off) b)

Parking between lock stops, engine OFF. Must

be present from new

Mechanical Knock c) Parking between lock stops, engine

ON (ball

(PAS on)

1 joint knock)

X

Hammer knock

Column knock

I f) Parking, driving. cobble stones and rough roads I X

- -

d) Parking into lock stop and release (vehicle

hydraulic power assisted steering (HPAS) only,

not for vehicles with electro-hydraulic power

assisted steering (EHPAS))

Hydraulic knock

(clonk)

Column rattle I Mainly driving on rough roads 1 0

e) Driving, cobble stones, rough road (clonk). Must

be present from new

Grinding

I When turning steering wheel I

Steering left and right at high frequency. Must be

present from new

Zip

I At engine start, -1 0°C only I X

X

X = Noise will most likely occur in this operating condition.

0 = Noise can possibly occur in this operating condition.

Blank = Noise is unlikely to occur in this operating condition.

2006.0 Fiesta 1212006 G37349en

procarmanuals.com

Page 68 of 1226

I 00-04-1 2 Noise, Vibration and Harshness I 00=04m12

DIAGNOSIS AND TESTING

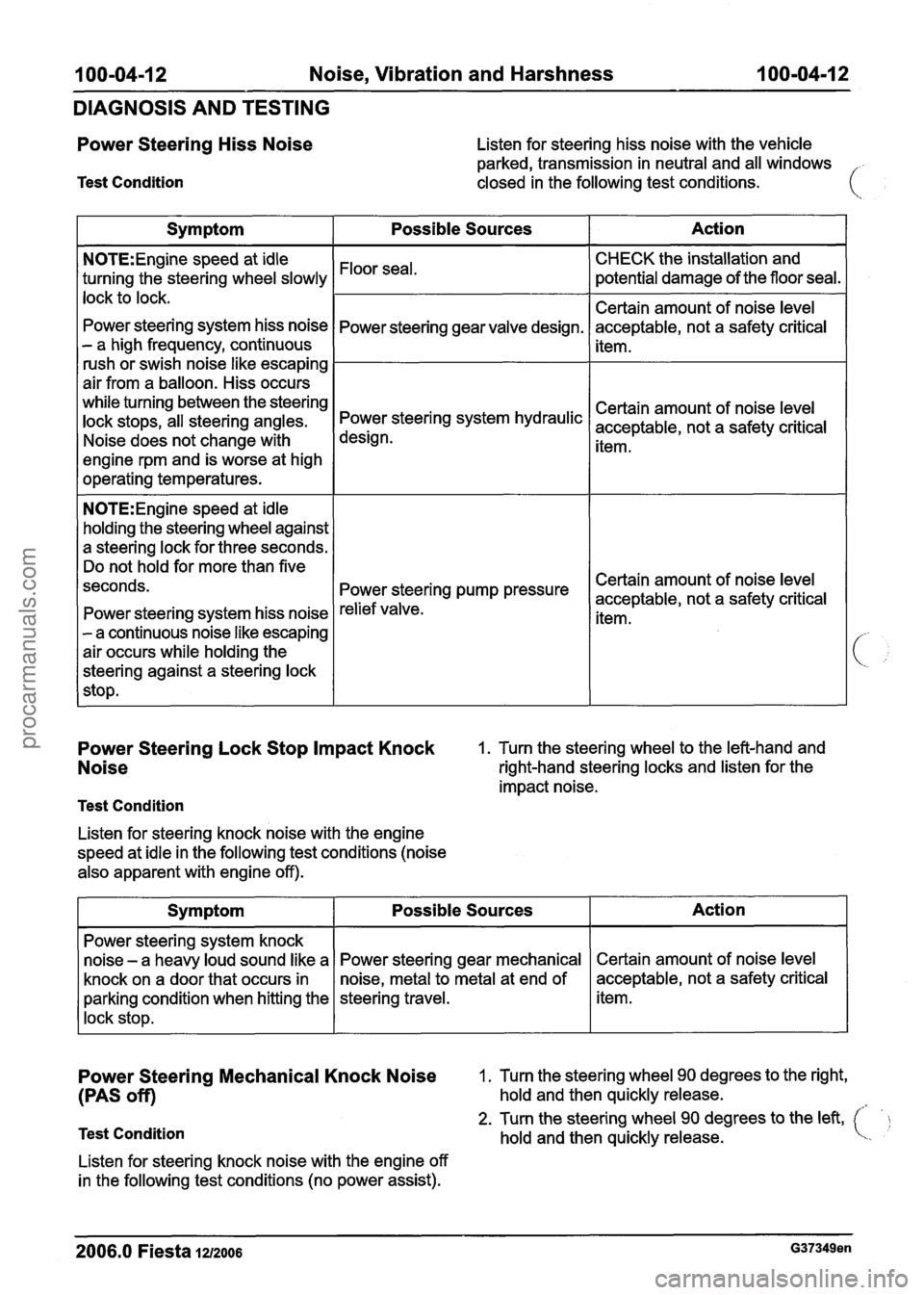

Power Steering Hiss Noise

Test Condition

Listen for steering hiss noise with the vehicle

parked, transmission in neutral and all windows

-

closed in the following test conditions.

Power Steering Lock Stop Impact Knock 1. Turn the steering wheel to the left-hand and

Noise right-hand steering locks and listen for the

impact noise.

Test Condition

Listen for steering knock noise with the engine

speed at idle in the following test conditions (noise

also apparent with engine off).

Action

CHECK the installation and

potential damage of the floor seal.

Certain amount of noise level

acceptable, not a safety critical

item.

Certain amount of noise level

acceptable, not a safety critical

item.

Certain amount of noise level

acceptable, not a safety critical

item.

Symptom

N0TE:Engine speed at idle

turning the steering wheel slowly

lock to lock.

Power steering system hiss noise

- a high frequency, continuous

rush or swish noise like escaping

air from a balloon. Hiss occurs

while turning between the steering

lock stops, all steering angles.

Noise does not change with

engine rpm and is worse at high

operating temperatures.

N0TE:Engine speed at idle

holding the steering wheel against

a steering lock for three seconds.

Do not hold for more than five

seconds.

Power steering system hiss noise

- a continuous noise like escaping

air occurs while holding the

steering against a steering lock

stop.

Possible Sources

Floor seal.

Power steering gear valve design.

Power steering system hydraulic

design.

Power pump pressure

relief valve.

Power Steering Mechanical Knock Noise 1. Turn the steering wheel 90 degrees to the right,

(PAS off) hold and then quickly release.

2. Turn the steering wheel 90 degrees to the left, Test Condition hold and then quickly release.

Listen for steering knock noise with the engine off

in the following test conditions (no power assist).

2006.0 Fiesta 1212006 G37349en

Action

Certain amount of noise level

acceptable, not a safety critical

item.

Symptom

Power steering system knock

noise

- a heavy loud sound like a

knock on a door that occurs in

parking condition when hitting the

lock stop.

Possible Sources

Power steering gear mechanical

noise, metal to metal at end of

steering travel.

procarmanuals.com

Page 69 of 1226

100-04-13 Noise, Vibration and Harshness 100-04-13

DIAGNOSIS AND TESTING

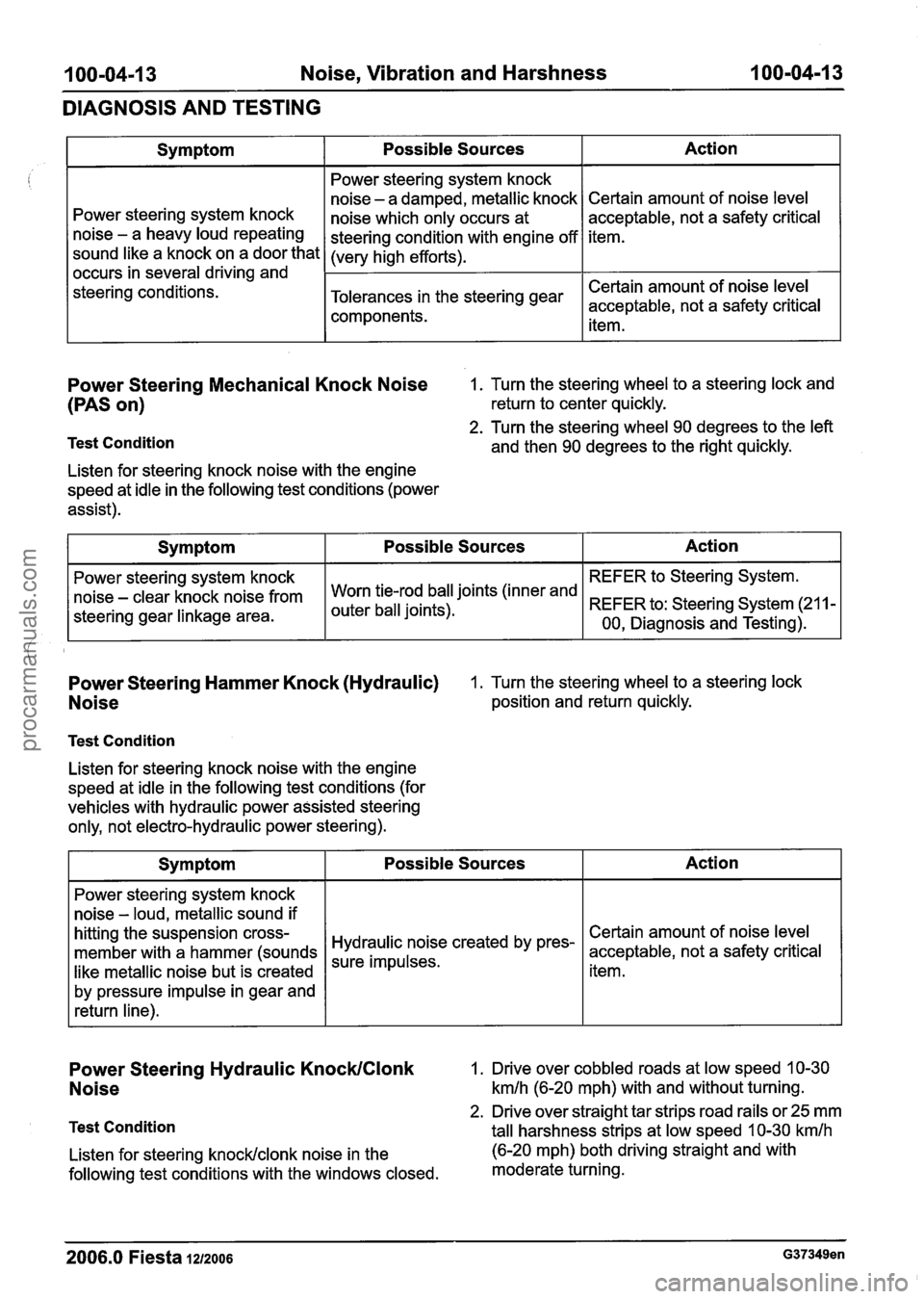

Power Steering Mechanical Knock Noise 1. Turn the steering wheel to a steering lock and

(PAS on) return to center quickly.

2. Turn the steering wheel 90 degrees to the left

Test Condition and then 90 degrees to the right quickly.

Listen for steering knock noise with the engine

speed at idle in the following test conditions (power

assist).

Action

Certain amount of noise level

acceptable, not a safety critical

item.

Certain amount of noise level

acceptable, not a safety critical

item.

Symptom

Power steering system knock

noise - a heavy loud repeating

sound like a knock on a door that

occurs in several driving and

steering conditions.

Power Steering Hammer Knock (Hydraulic) 1. Turn the steering wheel to a steering lock

Noise position and return quickly.

Possible Sources

Power steering system knock

noise

- a damped, metallic knock

noise which only occurs at

steering condition with engine off

(very high efforts),

Tolerances in the steering gear

components.

Test Condition

Action

REFER to Steering System.

REFER to: Steering System (21

1 -

00, Diagnosis and Testing).

Symptom

Power steering system knock

noise - clear knock noise from

steering gear linkage area.

Listen for steering knock noise with the engine

speed at idle in the following test conditions (for

vehicles with hydraulic power assisted steering only, not electro-hydraulic power steering).

Possible Sources

Worn tie-rod ball joints (inner and

outer ball joints).

Symptom Possible Sources Action

hitting the suspension cross- Certain

amount of noise level

by pressure impulse in gear and

return line).

Power Steering Hydraulic KnocWClonk 1. Drive over cobbled roads at low speed 10-30

Noise kmlh (6-20 mph) with and without turning.

2. Drive over straight tar strips road rails or 25 mm

Test Condition tall harshness strips at low speed 10-30 kmlh

Listen for steering knocklclonk noise in the (6-20

mph) both driving straight and with

following test conditions with the windows closed. moderate turning.

2006.0 Fiesta 1212006 G37349en

procarmanuals.com