ABS FORD GRANADA 1985 Service User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 1985, Model line: GRANADA, Model: FORD GRANADA 1985Pages: 255, PDF Size: 14.98 MB

Page 85 of 255

Cooling system

The cooling system is of pressurised type

and includes a front mounted crossflow

radiator, belt-driven water pump, temperature-

sensitive thermo-viscous fan (on DOHC

models, an electrically-operated cooling fan is

fitted, operated by a switch in the thermostat

housing), wax type thermostat, and an

expansion and degas tank.

The radiator matrix is of copper and brass

construction and the end tanks are of plastic.

On automatic transmission models the right-

hand side end tank incorporates the

transmission oil cooler.

The thermostat is located behind the water

outlet elbow at the front of the cylinder head

on OHCmodels, and on the front of the water

pump on V6 models. Its purpose is to ensure

rapid engine warm-up by restricting the flow of

coolant in the engine when cold, and also to

assist in regulating the normal operating

temperature of the engine.

The expansion tank incorporates a pressure

cap which effectively pressurises the cooling

system as the coolant temperature rises,

thereby increasing the boiling point of the

coolant. The tank also has a further degas

function. Any accumulation of air bubbles in

the coolant, in particular in the thermostat

housing and the radiator, is returned to the

tank and released in the air space thus

maintaining the efficiency of the coolant.

On models fitted with the auxiliary warning

system, the expansion tank contains a level

sensor which operates a warning light if the

coolant level falls significantly.

When the engine is started from cold, the

water pump circulates coolant around the

cylinder block, cylinder head(s) and inlet

manifold. The warm coolant passes through

the automatic choke housing (when

applicable) and through the heater matrix

before returning to the engine. As the coolant

expands, the level in the expansion tank rises.

Circulation of coolant through the radiator is

prevented while the thermostat is shut. When

the coolant reaches the predeterminedtemperature the thermostat opens and hot

water passes through the top hose to the top

of the radiator. As the water circulates down

through the radiator, it is cooled by the

passage of air past the radiator when the car is

in forward motion, supplemented by the action

of the thermo-viscous fan when necessary.

Having reached the bottom of the radiator, the

water is now cool and the cycle is repeated.

Circulation of water continues through the

expansion tank, inlet manifold and heater at all

times; the heater temperature control being by

an air flap.

The thermo-viscous fan is controlled by the

temperature of air behind the radiator. When

the air temperature reaches a predetermined

level, a bi-metallic coil commences to open a

valve within the unit and silicon fluid is fed

through a system of vanes. Half of the vanes

are driven directly by the water pump and the

remaining half are connected to the fan blades.

The vanes are arranged so that drive is

transmitted to the fan blades in relation to the

drag or viscosity of the fluid, and this in turn

depends on ambient temperature and engine

speed. The fan is therefore only operated when

required, and compared with direct drive type

fan represents a considerable improvement in

fuel economy, drivebelt wear and fan noise.

Air conditioning

Air conditioning is fitted as standard on

Scorpio models and is optionally available on

some other models. In conjunction with the

heater, the system enables any reasonable air

temperature to be achieved inside the car, it

also reduces the humidity of the incoming air,

aiding demisting even when cooling is not

required.

The refrigeration side of the air conditioning

system functions in a similar way to a

domestic refrigerator. A compressor, belt-

driven from the crankshaft pulley, draws

refrigerant in its gaseous phase from an

evaporator. The compressed refrigerant

passes through a condenser where it loses

heat and enters its liquid phase. After

dehydration the refrigerant returns to the

evaporator where it absorbs heat from air

passing over the evaporator fins. The

refrigerant becomes a gas again and the cycle

is repeated.Various subsidiary controls and sensors

protect the system against excessive

temperature and pressures. Additionally,

engine idle speed is increased when the

system is in use to compensate for the

additional load imposed by the compressor.

Precautions

Antifreeze mixture

Antifreeze mixture is poisonous. Keep it out

of reach of children and pets. Wash splashes

off skin and clothing with plenty of water.

Wash splashes off vehicle paintwork to avoid

discolouration.

Antifreeze/water mixture must be renewed

every two years to preserve its anti-corrosive

properties. In climates where antifreeze

protection is unnecessary, a corrosion

inhibitor may be used instead - consult a Ford

dealer. Never run the engine for long periods

with plain water as coolant. Only use the

specified antifreeze, as inferior brands may not

contain the necessary corrosion inhibitors, or

may break down at high temperatures.

Antifreeze containing methanol is particularly

to be avoided, as the methanol evaporates.

The specified mixture is 45 to 50%

antifreeze and 50 to 55% clean soft water (by

volume). Mix the required quantity in a clean

container.

Air conditioning refrigerant

Although the refrigerant is not itself toxic, in

the presence of a naked flame (or a lighted

cigarette) it forms a highly toxic gas. Liquid

refrigerant spilled on the skin will cause

frostbite. If refrigerant enters the eyes, rinse

them with a dilute solution of boric acid and

seek medical advice immediately.

In view of the above points, and of the need

for specialised equipment for evacuating and

recharging the system, any work which

requires the disconnection of a refrigerant line

must be left to a specialist.

Do not allow refrigerant lines to be exposed

to temperatures above 110°C (230°F) - eg

during welding or paint drying operations and

do not operate the air conditioning system if it

is known to be short of refrigerant, or further

damage may result.

1General information and

precautions

3•2Cooling, heating and ventilation systems

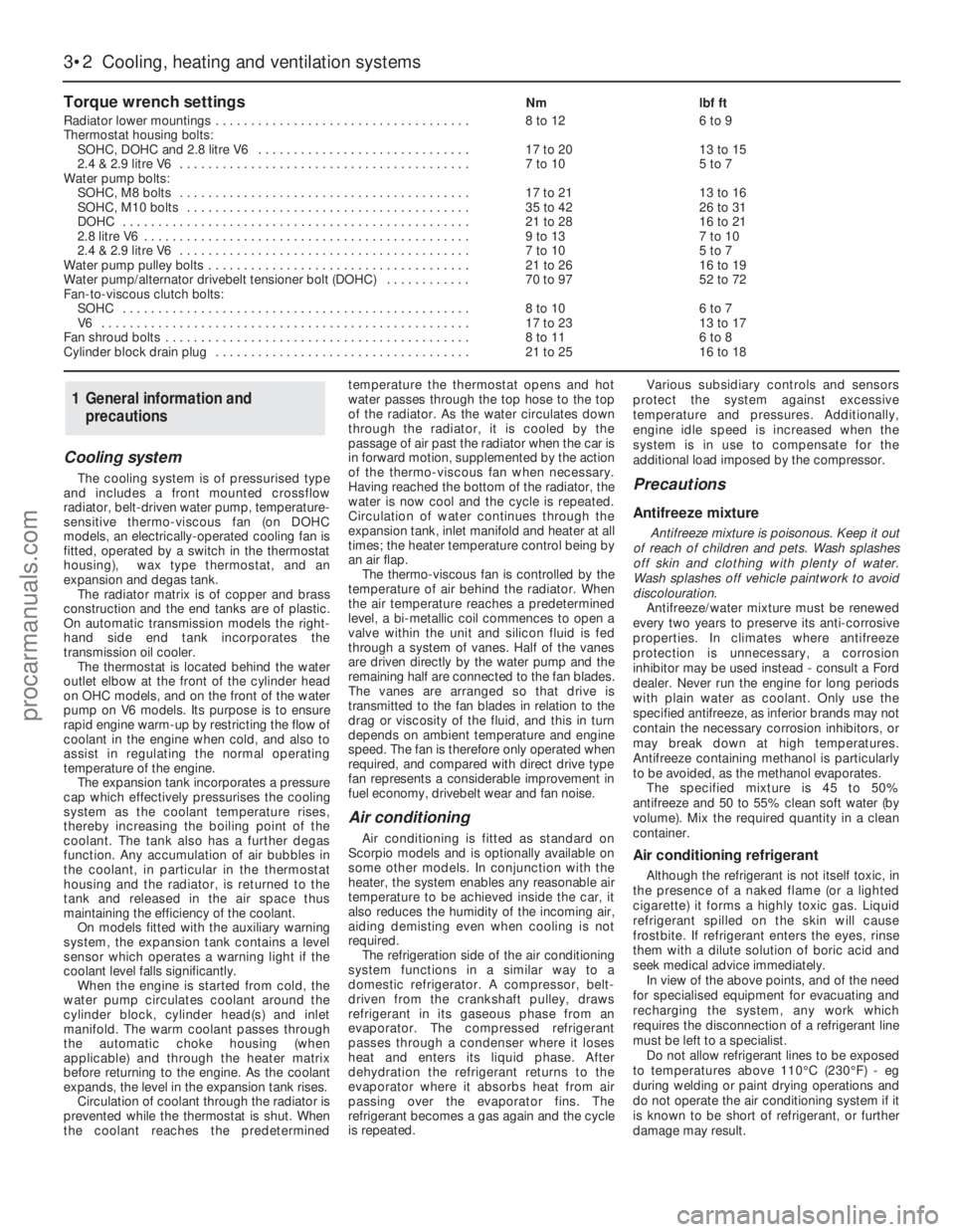

Torque wrench settingsNmlbf ft

Radiator lower mountings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 126 to 9

Thermostat housing bolts:

SOHC, DOHC and 2.8 litre V6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 to 2013 to 15

2.4 & 2.9 litre V6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 to 105 to 7

Water pump bolts:

SOHC, M8 bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 to 2113 to 16

SOHC, M10 bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35 to 4226 to 31

DOHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 to 2816 to 21

2.8 litre V6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 to 137 to 10

2.4 & 2.9 litre V6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 to 105 to 7

Water pump pulley bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 to 2616 to 19

Water pump/alternator drivebelt tensioner bolt (DOHC) . . . . . . . . . . . .70 to 9752 to 72

Fan-to-viscous clutch bolts:

SOHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 106 to 7

V6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 to 2313 to 17

Fan shroud bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 116 to 8

Cylinder block drain plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 to 2516 to 18

procarmanuals.com

Page 91 of 255

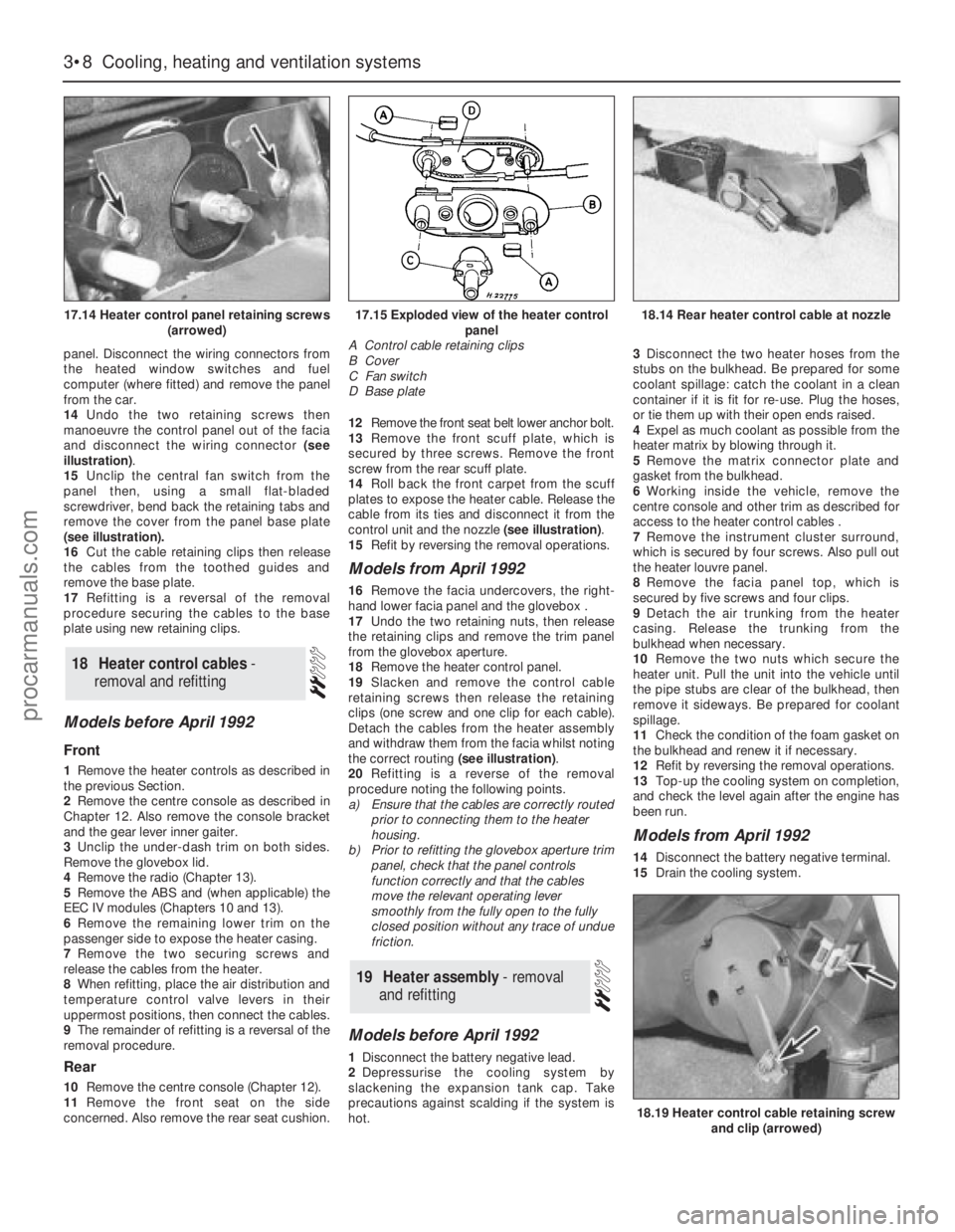

panel. Disconnect the wiring connectors from

the heated window switches and fuel

computer (where fitted) and remove the panel

from the car.

14Undo the two retaining screws then

manoeuvre the control panel out of the facia

and disconnect the wiring connector (see

illustration).

15Unclip the central fan switch from the

panel then, using a small flat-bladed

screwdriver, bend back the retaining tabs and

remove the cover from the panel base plate

(see illustration).

16Cut the cable retaining clips then release

the cables from the toothed guides and

remove the base plate.

17Refitting is a reversal of the removal

procedure securing the cables to the base

plate using new retaining clips.

Models before April 1992

Front

1Remove the heater controls as described in

the previous Section.

2Remove the centre console as described in

Chapter 12. Also remove the console bracket

and the gear lever inner gaiter.

3Unclip the under-dash trim on both sides.

Remove the glovebox lid.

4Remove the radio (Chapter 13).

5Remove the ABS and (when applicable) the

EEC IV modules (Chapters 10 and 13).

6Remove the remaining lower trim on the

passenger side to expose the heater casing.

7Remove the two securing screws and

release the cables from the heater.

8When refitting, place the air distribution and

temperature control valve levers in their

uppermost positions, then connect the cables.

9The remainder of refitting is a reversal of the

removal procedure.

Rear

10Remove the centre console (Chapter 12).

11Remove the front seat on the side

concerned. Also remove the rear seat cushion. 12Remove the front seat belt lower anchor bolt.

13Remove the front scuff plate, which is

secured by three screws. Remove the front

screw from the rear scuff plate.

14Roll back the front carpet from the scuff

plates to expose the heater cable. Release the

cable from its ties and disconnect it from the

control unit and the nozzle (see illustration).

15Refit by reversing the removal operations.

Models from April 1992

16Remove the facia undercovers, the right-

hand lower facia panel and the glovebox .

17Undo the two retaining nuts, then release

the retaining clips and remove the trim panel

from the glovebox aperture.

18Remove the heater control panel.

19Slacken and remove the control cable

retaining screws then release the retaining

clips (one screw and one clip for each cable).

Detach the cables from the heater assembly

and withdraw them from the facia whilst noting

the correct routing (see illustration).

20Refitting is a reverse of the removal

procedure noting the following points.

a)Ensure that the cables are correctly routed

prior to connecting them to the heater

housing.

b)Prior to refitting the glovebox aperture trim

panel, check that the panel controls

function correctly and that the cables

move the relevant operating lever

smoothly from the fully open to the fully

closed position without any trace of undue

friction.

Models before April 1992

1Disconnect the battery negative lead.

2Depressurise the cooling system by

slackening the expansion tank cap. Take

precautions against scalding if the system is

hot.3Disconnect the two heater hoses from the

stubs on the bulkhead. Be prepared for some

coolant spillage: catch the coolant in a clean

container if it is fit for re-use. Plug the hoses,

or tie them up with their open ends raised.

4Expel as much coolant as possible from the

heater matrix by blowing through it.

5Remove the matrix connector plate and

gasket from the bulkhead.

6Working inside the vehicle, remove the

centre console and other trim as described for

access to the heater control cables .

7Remove the instrument cluster surround,

which is secured by four screws. Also pull out

the heater louvre panel.

8Remove the facia panel top, which is

secured by five screws and four clips.

9Detach the air trunking from the heater

casing. Release the trunking from the

bulkhead when necessary.

10Remove the two nuts which secure the

heater unit. Pull the unit into the vehicle until

the pipe stubs are clear of the bulkhead, then

remove it sideways. Be prepared for coolant

spillage.

11Check the condition of the foam gasket on

the bulkhead and renew it if necessary.

12Refit by reversing the removal operations.

13Top-up the cooling system on completion,

and check the level again after the engine has

been run.

Models from April 1992

14Disconnect the battery negative terminal.

15Drain the cooling system.

19Heater assembly - removal

and refitting

18Heater control cables -

removal and refitting

3•8Cooling, heating and ventilation systems

17.14 Heater control panel retaining screws

(arrowed)

18.19 Heater control cable retaining screw

and clip (arrowed)

17.15 Exploded view of the heater control

panel

A Control cable retaining clips

B Cover

C Fan switch

D Base plate18.14 Rear heater control cable at nozzle

procarmanuals.com

Page 108 of 255

20Checking and adjustment should be

completed within 30 seconds of the meter

readings stabilising. If this has not been

possible, run the engine at 3000 rpm for 15

seconds, then allow the engine to idle. Re-

check the CO content and carry out further

adjustments if necessary.

21On completion of adjustment, stop the

engine and disconnect the tachometer and the

exhaust gas analyser. Refit the cover to the

adjustment screw.

2.4 & 2.9 litre V6 engines

22As with the 2.8 V6, idle speed is

electronically controlled. Basic idle speed

adjustment can only be carried out by a Ford

dealer using special equipment.

23On models not equipped with a catalytic

converter, mixture adjustment can be carried

out as described above.

24On models equipped with a catalytic

converter, the mixture is controlled by the EEC IV

module and no manual adjustment is possible.

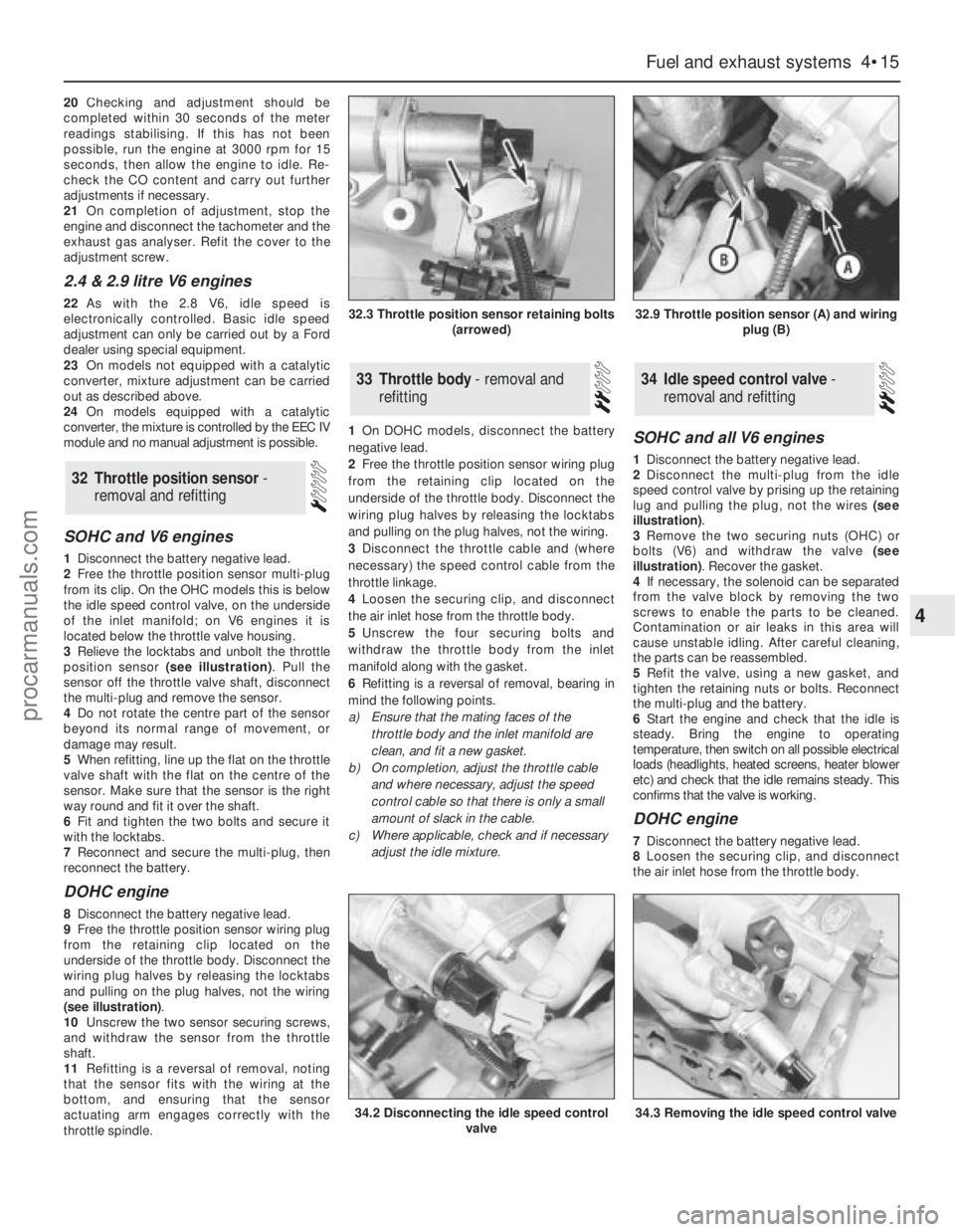

SOHC and V6 engines

1Disconnect the battery negative lead.

2Free the throttle position sensor multi-plug

from its clip. On the OHCmodels this is below

the idle speed control valve, on the underside

of the inlet manifold; on V6 engines it is

located below the throttle valve housing.

3Relieve the locktabs and unbolt the throttle

position sensor (see illustration). Pull the

sensor off the throttle valve shaft, disconnect

the multi-plug and remove the sensor.

4Do not rotate the centre part of the sensor

beyond its normal range of movement, or

damage may result.

5When refitting, line up the flat on the throttle

valve shaft with the flat on the centre of the

sensor. Make sure that the sensor is the right

way round and fit it over the shaft.

6Fit and tighten the two bolts and secure it

with the locktabs.

7Reconnect and secure the multi-plug, then

reconnect the battery.

DOHC engine

8Disconnect the battery negative lead.

9Free the throttle position sensor wiring plug

from the retaining clip located on the

underside of the throttle body. Disconnect the

wiring plug halves by releasing the locktabs

and pulling on the plug halves, not the wiring

(see illustration).

10Unscrew the two sensor securing screws,

and withdraw the sensor from the throttle

shaft.

11Refitting is a reversal of removal, noting

that the sensor fits with the wiring at the

bottom, and ensuring that the sensor

actuating arm engages correctly with the

throttle spindle.1On DOHC models, disconnect the battery

negative lead.

2Free the throttle position sensor wiring plug

from the retaining clip located on the

underside of the throttle body. Disconnect the

wiring plug halves by releasing the locktabs

and pulling on the plug halves, not the wiring.

3Disconnect the throttle cable and (where

necessary) the speed control cable from the

throttle linkage.

4Loosen the securing clip, and disconnect

the air inlet hose from the throttle body.

5Unscrew the four securing bolts and

withdraw the throttle body from the inlet

manifold along with the gasket.

6Refitting is a reversal of removal, bearing in

mind the following points.

a)Ensure that the mating faces of the

throttle body and the inlet manifold are

clean, and fit a new gasket.

b)On completion, adjust the throttle cable

and where necessary, adjust the speed

control cable so that there is only a small

amount of slack in the cable.

c)Where applicable, check and if necessary

adjust the idle mixture.

SOHC and all V6 engines

1Disconnect the battery negative lead.

2Disconnect the multi-plug from the idle

speed control valve by prising up the retaining

lug and pulling the plug, not the wires (see

illustration).

3Remove the two securing nuts (OHC) or

bolts (V6) and withdraw the valve (see

illustration). Recover the gasket.

4If necessary, the solenoid can be separated

from the valve block by removing the two

screws to enable the parts to be cleaned.

Contamination or air leaks in this area will

cause unstable idling. After careful cleaning,

the parts can be reassembled.

5Refit the valve, using a new gasket, and

tighten the retaining nuts or bolts. Reconnect

the multi-plug and the battery.

6Start the engine and check that the idle is

steady. Bring the engine to operating

temperature, then switch on all possible electrical

loads (headlights, heated screens, heater blower

etc) and check that the idle remains steady. This

confirms that the valve is working.

DOHC engine

7Disconnect the battery negative lead.

8Loosen the securing clip, and disconnect

the air inlet hose from the throttle body.

34Idle speed control valve -

removal and refitting33Throttle body - removal and

refitting

32Throttle position sensor -

removal and refitting

Fuel and exhaust systems 4•15

4

32.3 Throttle position sensor retaining bolts

(arrowed)32.9 Throttle position sensor (A) and wiring

plug (B)

34.2 Disconnecting the idle speed control

valve34.3 Removing the idle speed control valve

procarmanuals.com

Page 114 of 255

55Release the throttle position sensor wiring

connector from the clip under the throttle

body, and separate the two halves of the

connector.

56Remove the fuel-injectors.

57Check that all relevant wiring, hoses and

pipes have been disconnected to facilitate

removal of the manifold.

58Unscrew the ten bolts and two nuts

securing the inlet manifold to the cylinder

head, and carefully withdraw the manifold.

Recover the gasket.

59Recover the two plastic spark plug

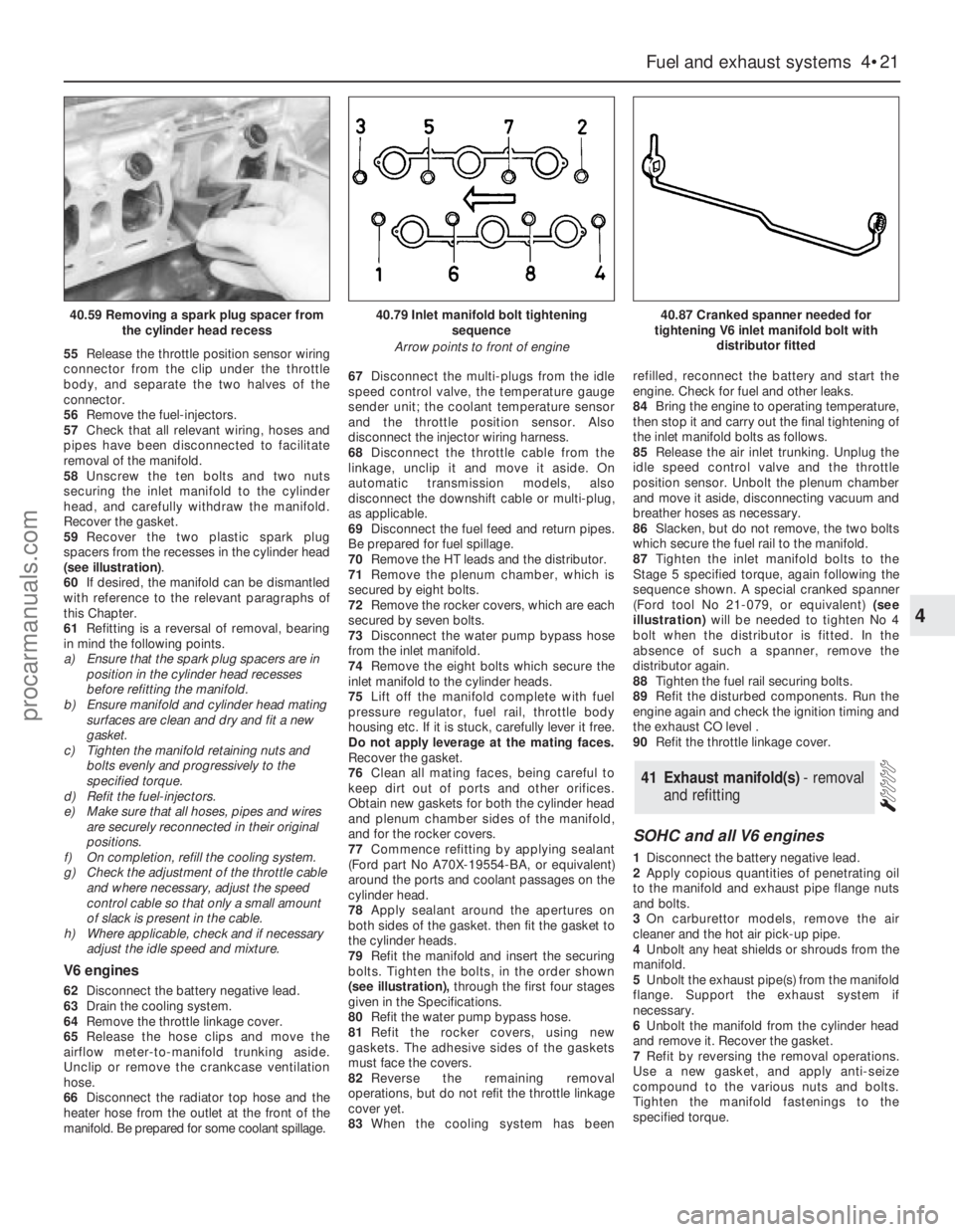

spacers from the recesses in the cylinder head

(see illustration).

60If desired, the manifold can be dismantled

with reference to the relevant paragraphs of

this Chapter.

61Refitting is a reversal of removal, bearing

in mind the following points.

a)Ensure that the spark plug spacers are in

position in the cylinder head recesses

before refitting the manifold.

b)Ensure manifold and cylinder head mating

surfaces are clean and dry and fit a new

gasket.

c)Tighten the manifold retaining nuts and

bolts evenly and progressively to the

specified torque.

d)Refit the fuel-injectors.

e)Make sure that all hoses, pipes and wires

are securely reconnected in their original

positions.

f)On completion, refill the cooling system.

g)Check the adjustment of the throttle cable

and where necessary, adjust the speed

control cable so that only a small amount

of slack is present in the cable.

h)Where applicable, check and if necessary

adjust the idle speed and mixture.

V6 engines

62Disconnect the battery negative lead.

63Drain the cooling system.

64Remove the throttle linkage cover.

65Release the hose clips and move the

airflow meter-to-manifold trunking aside.

Unclip or remove the crankcase ventilation

hose.

66Disconnect the radiator top hose and the

heater hose from the outlet at the front of the

manifold. Be prepared for some coolant spillage.67Disconnect the multi-plugs from the idle

speed control valve, the temperature gauge

sender unit; the coolant temperature sensor

and the throttle position sensor. Also

disconnect the injector wiring harness.

68Disconnect the throttle cable from the

linkage, unclip it and move it aside. On

automatic transmission models, also

disconnect the downshift cable or multi-plug,

as applicable.

69Disconnect the fuel feed and return pipes.

Be prepared for fuel spillage.

70Remove the HT leads and the distributor.

71Remove the plenum chamber, which is

secured by eight bolts.

72Remove the rocker covers, which are each

secured by seven bolts.

73Disconnect the water pump bypass hose

from the inlet manifold.

74Remove the eight bolts which secure the

inlet manifold to the cylinder heads.

75Lift off the manifold complete with fuel

pressure regulator, fuel rail, throttle body

housing etc. If it is stuck, carefully lever it free.

Do not apply leverage at the mating faces.

Recover the gasket.

76Clean all mating faces, being careful to

keep dirt out of ports and other orifices.

Obtain new gaskets for both the cylinder head

and plenum chamber sides of the manifold,

and for the rocker covers.

77Commence refitting by applying sealant

(Ford part No A70X-19554-BA, or equivalent)

around the ports and coolant passages on the

cylinder head.

78Apply sealant around the apertures on

both sides of the gasket. then fit the gasket to

the cylinder heads.

79Refit the manifold and insert the securing

bolts. Tighten the bolts, in the order shown

(see illustration),through the first four stages

given in the Specifications.

80Refit the water pump bypass hose.

81Refit the rocker covers, using new

gaskets. The adhesive sides of the gaskets

must face the covers.

82Reverse the remaining removal

operations, but do not refit the throttle linkage

cover yet.

83When the cooling system has beenrefilled, reconnect the battery and start the

engine. Check for fuel and other leaks.

84Bring the engine to operating temperature,

then stop it and carry out the final tightening of

the inlet manifold bolts as follows.

85Release the air inlet trunking. Unplug the

idle speed control valve and the throttle

position sensor. Unbolt the plenum chamber

and move it aside, disconnecting vacuum and

breather hoses as necessary.

86Slacken, but do not remove, the two bolts

which secure the fuel rail to the manifold.

87Tighten the inlet manifold bolts to the

Stage 5 specified torque, again following the

sequence shown. A special cranked spanner

(Ford tool No 21-079, or equivalent)(see

illustration)will be needed to tighten No 4

bolt when the distributor is fitted. In the

absence of such a spanner, remove the

distributor again.

88Tighten the fuel rail securing bolts.

89Refit the disturbed components. Run the

engine again and check the ignition timing and

the exhaust CO level .

90Refit the throttle linkage cover.

SOHC and all V6 engines

1Disconnect the battery negative lead.

2Apply copious quantities of penetrating oil

to the manifold and exhaust pipe flange nuts

and bolts.

3On carburettor models, remove the air

cleaner and the hot air pick-up pipe.

4Unbolt any heat shields or shrouds from the

manifold.

5Unbolt the exhaust pipe(s) from the manifold

flange. Support the exhaust system if

necessary.

6Unbolt the manifold from the cylinder head

and remove it. Recover the gasket.

7Refit by reversing the removal operations.

Use a new gasket, and apply anti-seize

compound to the various nuts and bolts.

Tighten the manifold fastenings to the

specified torque.

41Exhaust manifold(s) - removal

and refitting

Fuel and exhaust systems 4•21

4

40.59 Removing a spark plug spacer from

the cylinder head recess40.79 Inlet manifold bolt tightening

sequence

Arrow points to front of engine40.87 Cranked spanner needed for

tightening V6 inlet manifold bolt with

distributor fitted

procarmanuals.com

Page 115 of 255

DOHC carburettor engine

8This procedure is essentially as described

above, noting the following points:

a)Note the plastic bush which is fitted to the

rear manifold stud. This must be removed

before the gasket can be withdrawn.

b)On refitting ensure that the mating

surfaces are clean and dry and fit new

gaskets.

c)Apply a thin coat of anti-seize compound

to the manifold studs to aid future

removal.

d)Tighten the manifold nuts to the specified

torque settings.

DOHC fuel-injection engine

9Disconnect the battery negative lead.

10Disconnect the wiring plug from the idle

speed control valve at the front of the plenum

chamber.

11Loosen the clamp, and detach the air inlet

hose from the air inlet tubing.

12Unscrew the securing nut, and release the

air inlet tube from the bracket on the engine

compartment front panel.

13Release the air cleaner lid securing clips,

then lift away the air inlet tube, plenum

chamber and air cleaner lid as an assembly,

disconnecting the breather hose from the air

inlet tube.

14On models fitted with a catalytic

converter, disconnect the exhaust gas oxygen

sensor wiring plug.

15Unscrew the securing nuts and disconnect

the exhaust downpipe from the manifold.

Recover the gasket. Support the exhaust

downpipe from underneath the vehicle (eg

with an axle stand) to avoid placing

unnecessary strain on the exhaust system.

16Unscrew the six securing nuts, and lift the

manifold from the cylinder head. Recover the

gasket.

17Refitting is a reversal of removal, bearing

in mind the following points.

a)Ensure that all mating faces are clean, and

use a new gasket.

b)Tighten the manifold securing nuts and

the downpipe securing nuts progressively

to the specified torque (where given).

SOHC and 2.8 litre V6 engines

1Periodically inspect the exhaust system for

freedom from corrosion and security of

mountings. Large holes will be obvious; small

holes may be found more easily by letting the

engine idle and partly obstructing the tailpipe

with a wad of cloth.

2Check the condition of the rubber

mountings by applying downward pressure on

the exhaust system and observing the

mountings for splits or cracks. Renew

deteriorated mountings.

3The exhaust systems fitted in production

have fewer sections than those available for

repair. Repair sections may be fitted to

production systems by cutting at the

appropriate point.

4The production exhaust systems are made

of aluminised and stainless steel. Repair

systems are available to the same standard, or

in standard quality (SQ) painted mild steel.

5It is recommended that the whole exhaust

system be removed even if only part requires

renewal, since separation of old joints, cutting

pipes etc is much easier away from the

vehicle. Proceed as follows.

6Disconnect the battery negative lead. Raise

and support the vehicle.

7Unbolt the manifold-to-downpipe flanged

joint(s).

8On V6 models, unbolt the left-hand front

silencer mounting.

9Release any earth straps.

10With the help of an assistant, unhook the

system from its mountings and remove it.

11Renew sections as necessary. Apply

exhaust jointing compound to sliding and

flanged joints, but do not tighten their clamps

yet. Use new sealing rings where necessary

(see illustration).

12Offer the system to the vehicle and hook it

onto the mountings.

13Refit any earth straps. On V6 models, also

refit the left-hand front silencer mounting.

14Loosely fit the manifold flange nuts.

Correct the alignment of the system, then

tighten all clamp nuts and bolts, starting at the

manifold flange(s) and working rearwards.

15Check that the system alignment is still

satisfactory then reconnect the battery. Run

the engine and check for leaks.

16When the system has warmed up, stop the

engine and carefully check the tightness of the

clamp nuts and bolts.

DOHC and 2.4 & 2.9 litre V6

engines

17Follow the above procedure, noting that

flanged joints incorporating gaskets may be

used to join exhaust sections on these

models. Where applicable, renew the gaskets

on refitting.

18On models fitted with a catalyticconverter, disconnect the battery negative

terminal and disconnect the exhaust gas

oxygen (HEGO) sensor wiring plug before

removing the downpipe.

DOHC engine

Note: The exhaust gas oxygen (HEGO) sensor

is delicate and will not work if it is dropped or

knocked, if the power supply is disrupted, or if

any cleaning materials are used on it. Never

touch the tip of the sensor as this can also

damage it.

1Ensure that the engine and the exhaust

system are cold.

2Disconnect the battery negative lead.

3Apply the handbrake, then jack up the front

of the vehicle, and support it securely on axle

stands (see “Jacking”).

4Disconnect the sensor wiring plug halves by

releasing the locktabs and pulling on the plug

halves, not the wiring.

5Slide the heat shield (where fitted) from the

sensor.

6Bearing in mind the note made at the start

of this operation, unscrew the sensor from the

exhaust downpipe, and recover the sealing

ring (see illustration).

7Commence refitting by ensuring that the

sensor threads and the corresponding threads

in the downpipe are clean.

8Refit the sensor using a new sealing ring,

and tighten it to the specified torque.

9Further refitting is a reversal of removal, but

on completion start the engine, and check for

leaks around the sensor sealing ring.

V6 engines

10The sensors fitted to these models can be

removed and refitted using the information

given above, noting that on early models there

was only one sensor, which was fitted at the

point where the two downpipes meet below

the engine, and on some later models there

are two sensors, one in each downpipe.

43Exhaust gas oxygen (HEGO)

sensor (models with catalytic

converter) - removal and

refitting

42Exhaust system - inspection,

repair and renewal

4•22Fuel and exhaust systems

43.6 Exhaust gas oxygen (HEGO) sensor

(viewed from underneath)

42.11 Exhaust pipe flanged joint

A Sealing ring

B Flange

procarmanuals.com

Page 116 of 255

Models up to July 1990

1The carbon canister is situated in the engine

compartment where it is mounted onto the

right-hand valance next to the suspension

strut mounting.

2To remove the canister first disconnect the

battery negative terminal. If necessary, undo

the two coolant expansion tank retaining

screws and position the tank clear of the

canister to improve access.

3Disconnect the vacuum hose from the top

of the canister.

4Slacken and remove the mounting bolt and

withdraw the canister from the engine

compartment.

5Refitting is a reverse of the removal

procedure.

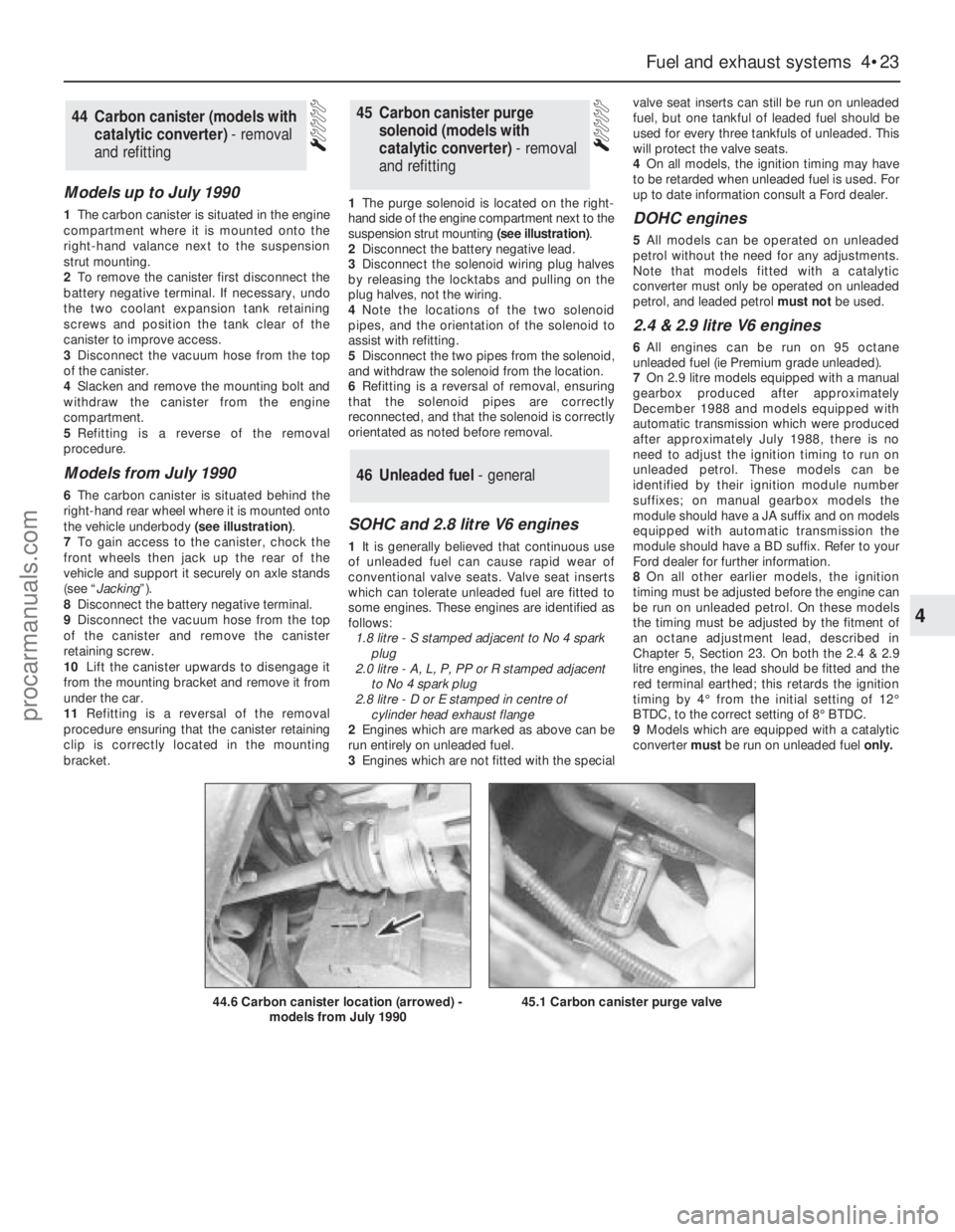

Models from July 1990

6The carbon canister is situated behind the

right-hand rear wheel where it is mounted onto

the vehicle underbody (see illustration).

7To gain access to the canister, chock the

front wheels then jack up the rear of the

vehicle and support it securely on axle stands

(see “Jacking”).

8Disconnect the battery negative terminal.

9Disconnect the vacuum hose from the top

of the canister and remove the canister

retaining screw.

10Lift the canister upwards to disengage it

from the mounting bracket and remove it from

under the car.

11Refitting is a reversal of the removal

procedure ensuring that the canister retaining

clip is correctly located in the mounting

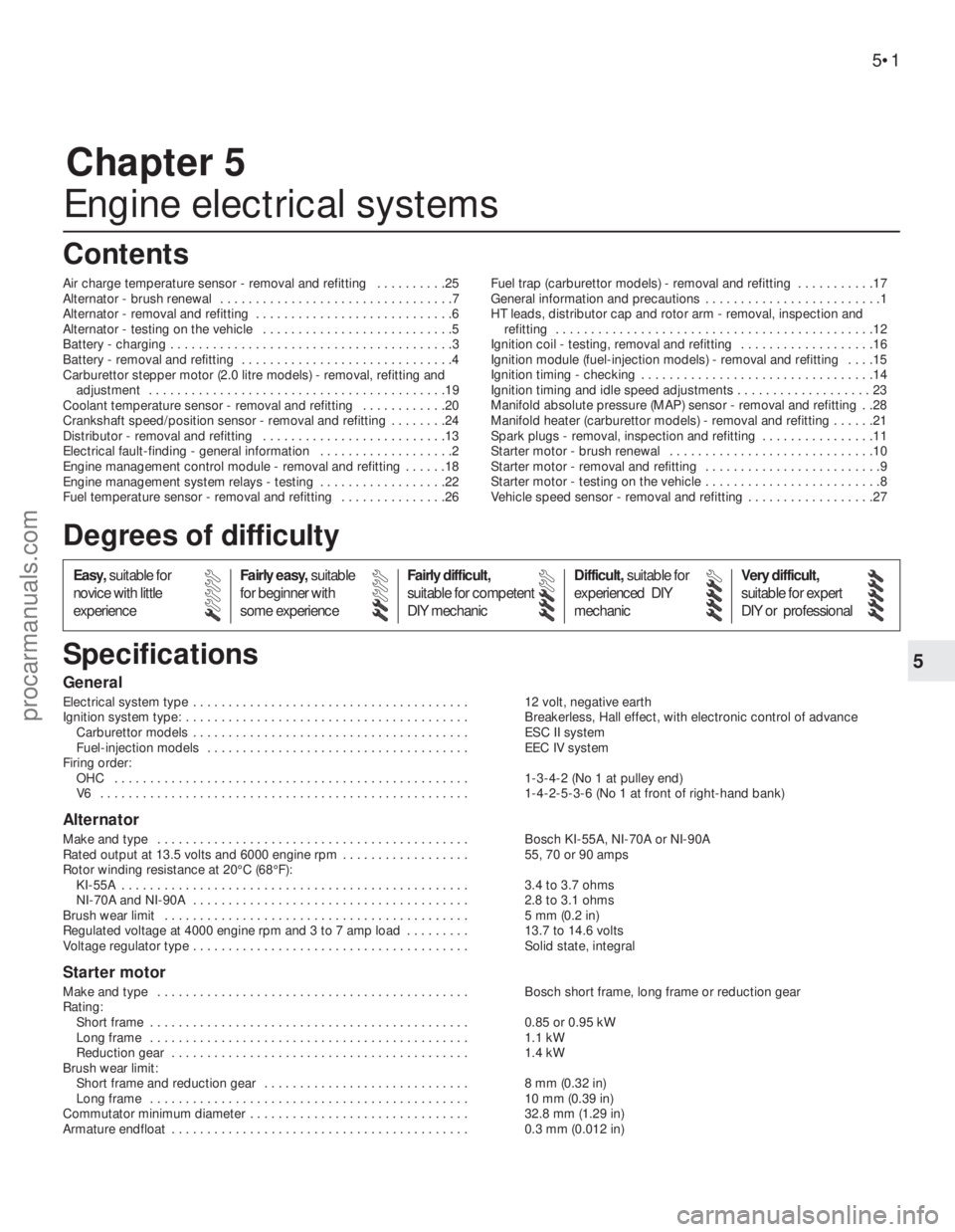

bracket.1The purge solenoid is located on the right-

hand side of the engine compartment next to the

suspension strut mounting (see illustration).

2Disconnect the battery negative lead.

3Disconnect the solenoid wiring plug halves

by releasing the locktabs and pulling on the

plug halves, not the wiring.

4Note the locations of the two solenoid

pipes, and the orientation of the solenoid to

assist with refitting.

5Disconnect the two pipes from the solenoid,

and withdraw the solenoid from the location.

6Refitting is a reversal of removal, ensuring

that the solenoid pipes are correctly

reconnected, and that the solenoid is correctly

orientated as noted before removal.

SOHC and 2.8 litre V6 engines

1It is generally believed that continuous use

of unleaded fuel can cause rapid wear of

conventional valve seats. Valve seat inserts

which can tolerate unleaded fuel are fitted to

some engines. These engines are identified as

follows:

1.8 litre - S stamped adjacent to No 4 spark

plug

2.0 litre - A, L, P, PP or R stamped adjacent

to No 4 spark plug

2.8 litre - D or E stamped in centre of

cylinder head exhaust flange

2Engines which are marked as above can be

run entirely on unleaded fuel.

3Engines which are not fitted with the specialvalve seat inserts can still be run on unleaded

fuel, but one tankful of leaded fuel should be

used for every three tankfuls of unleaded. This

will protect the valve seats.

4On all models, the ignition timing may have

to be retarded when unleaded fuel is used. For

up to date information consult a Ford dealer.

DOHC engines

5All models can be operated on unleaded

petrol without the need for any adjustments.

Note that models fitted with a catalytic

converter must only be operated on unleaded

petrol, and leaded petrol must notbe used.

2.4 & 2.9 litre V6 engines

6All engines can be run on 95 octane

unleaded fuel (ie Premium grade unleaded).

7On 2.9 litre models equipped with a manual

gearbox produced after approximately

December 1988 and models equipped with

automatic transmission which were produced

after approximately July 1988, there is no

need to adjust the ignition timing to run on

unleaded petrol. These models can be

identified by their ignition module number

suffixes; on manual gearbox models the

module should have a JA suffix and on models

equipped with automatic transmission the

module should have a BD suffix. Refer to your

Ford dealer for further information.

8On all other earlier models, the ignition

timing must be adjusted before the engine can

be run on unleaded petrol. On these models

the timing must be adjusted by the fitment of

an octane adjustment lead, described in

Chapter 5, Section 23. On both the 2.4 & 2.9

litre engines, the lead should be fitted and the

red terminal earthed; this retards the ignition

timing by 4°from the initial setting of 12°

BTDC, to the correct setting of 8°BTDC.

9Models which are equipped with a catalytic

converter must be run on unleaded fuel only.

46Unleaded fuel - general

45Carbon canister purge

solenoid (models with

catalytic converter) - removal

and refitting44Carbon canister (models with

catalytic converter) - removal

and refitting

Fuel and exhaust systems 4•23

4

44.6 Carbon canister location (arrowed) -

models from July 199045.1 Carbon canister purge valve

procarmanuals.com

Page 118 of 255

Chapter 5

Engine electrical systems

Air charge temperature sensor - removal and refitting . . . . . . . . . .25

Alternator - brush renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Alternator - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Alternator - testing on the vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Battery - charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Battery - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Carburettor stepper motor (2.0 litre models) - removal, refitting and

adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Coolant temperature sensor - removal and refitting . . . . . . . . . . . .20

Crankshaft speed/position sensor - removal and refitting . . . . . . . .24

Distributor - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . .13

Electrical fault-finding - general information . . . . . . . . . . . . . . . . . . .2

Engine management control module - removal and refitting . . . . . .18

Engine management system relays - testing . . . . . . . . . . . . . . . . . .22

Fuel temperature sensor - removal and refitting . . . . . . . . . . . . . . .26Fuel trap (carburettor models) - removal and refitting . . . . . . . . . . .17

General information and precautions . . . . . . . . . . . . . . . . . . . . . . . . .1

HT leads, distributor cap and rotor arm - removal, inspection and

refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Ignition coil - testing, removal and refitting . . . . . . . . . . . . . . . . . . .16

Ignition module (fuel-injection models) - removal and refitting . . . .15

Ignition timing - checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Ignition timing and idle speed adjustments . . . . . . . . . . . . . . . . . . . 23

Manifold absolute pressure (MAP) sensor - removal and refitting . .28

Manifold heater (carburettor models) - removal and refitting . . . . . .21

Spark plugs - removal, inspection and refitting . . . . . . . . . . . . . . . .11

Starter motor - brush renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Starter motor - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . .9

Starter motor - testing on the vehicle . . . . . . . . . . . . . . . . . . . . . . . . .8

Vehicle speed sensor - removal and refitting . . . . . . . . . . . . . . . . . .27

General

Electrical system type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 volt, negative earth

Ignition system type: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Breakerless, Hall effect, with electronic control of advance

Carburettor models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ESC II system

Fuel-injection models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . EEC IV system

Firing order:

OHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3-4-2 (No 1 at pulley end)

V6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4-2-5-3-6 (No 1 at front of right-hand bank)

Alternator

Make and type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Bosch KI-55A, NI-70A or NI-90A

Rated output at 13.5 volts and 6000 engine rpm . . . . . . . . . . . . . . . . . . 55, 70 or 90 amps

Rotor winding resistance at 20°C (68°F):

KI-55A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.4 to 3.7 ohms

NI-70A and NI-90A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.8 to 3.1 ohms

Brush wear limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 mm (0.2 in)

Regulated voltage at 4000 engine rpm and 3 to 7 amp load . . . . . . . . . 13.7 to 14.6 volts

Voltage regulator type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Solid state, integral

Starter motor

Make and type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Bosch short frame, long frame or reduction gear

Rating:

Short frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.85 or 0.95 kW

Long frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.1 kW

Reduction gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4 kW

Brush wear limit:

Short frame and reduction gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 mm (0.32 in)

Long frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 mm (0.39 in)

Commutator minimum diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32.8 mm (1.29 in)

Armature endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.3 mm (0.012 in)

5•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanicDifficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Specifications Contents

5

procarmanuals.com

Page 120 of 255

engine coolant temperature sensor. The

crankshaft speed/position sensor is activated

by a toothed disc on the rear of the crankshaft,

inside the cylinder block. The disc has 35

equally spaced teeth (one every 10°), with a

gap in the 36th position. The gap is used by

the sensor to determine the crankshaft

position relative to Top Dead Centre (TDC) of

No 1 piston.

The ignition advance is a function of the

ESC II module, and is controlled by vacuum.

The module is connected to the carburettor by

a vacuum pipe, and a transducer in the

module translates the vacuum signal into an

electrical voltage. From the vacuum signal, the

module determines engine load; engine speed

and temperature are determined from the

crankshaft speed/position sensor and the

engine coolant temperature sensor. The

module has a range of spark advance settings

stored in the memory, and a suitable setting is

selected for the relevant engine speed, load

and temperature. The degree of advance can

thus be constantly varied to suit the prevailing

engine speed and load conditions.

On DOHC fuel-injected engines, a

development of the EEC IV (Electronic Engine

Control IV) engine management system is

used to control both the ignition and fuel-

injection systems. The EEC IV module receives

information from a crankshaft speed/position

sensor (the same as that fitted to the

carburettor models), a throttle position sensor,

an engine coolant temperature sensor, a fuel

temperature sensor, an air charge temperature

sensor, a Manifold Absolute Pressure (MAP)

sensor, and a vehicle speed sensor (mounted

on the gearbox). Additionally, on models with

a catalytic converter, an additional input is

supplied to the EEC IV module from an

exhaust gas oxygen (HEGO) sensor. On

models with automatic transmission,

additional sensors are fitted to the

transmission to inform the EEC IV module

when the transmission is in neutral, and when

the downshift is being operated.

The module provides outputs to control the

fuel pump, fuel-injectors, idle speed, ignition

system and automatic transmission .

Additionally, on models with air conditioning,

the EEC IV module disengages the air

conditioning compressor clutch when starting

the engine or when the engine is suddenly

accelerated. On models fitted with a catalytic

converter, the EEC IV module also controls the

carbon canister purge solenoid valve.

Using the inputs from the various sensors,

the EEC IV module computes the optimum

ignition advance, and fuel-injector pulse

duration to suit the prevailing engine

conditions.

On 2.4 & 2.9 litre V6 engines, the system

operates in much the same way as that fitted

to the DOHC fuel-injected engine, noting the

following points.

a)There is no crankshaft speed/position

sensor.

b)The vehicle speed sensor is only fitted to

models equipped with a catalytic

converter.Precautions

ESC II module

Although it will tolerate all normal under-

bonnet conditions, the ESC II module may be

adversely affected by water entry during

steam cleaning or pressure washing of the

engine bay.

If cleaning the engine bay, therefore, take

care not to direct jets of water or steam at the

ESC II module. If this cannot be avoided,

remove the module completely, and protect its

multi-plug with a plastic bag.

Ignition system HT voltage

Take care to avoid receiving electric shocks

from the HT side of the ignition system. Do not

handle HT leads, or touch the distributor or

coil, when the engine is running. When tracing

faults in the HT system, use well insulated

tools to manipulate live leads. Electronic

ignition HT voltage could prove fatal.

Electronic ignition systems

General

Further details of the various systems are

given in the relevant Sections of this Chapter.

While some repair procedures are given, the

usual course of action is to renew the

component concerned. The owner whose

interest extends beyond mere component

renewal should obtain a copy of the

Automobile Electrical & Electronic Systems

Manual, available from the publishers of this

manual.

It is necessary to take extra care when

working on the electrical system, to avoid

damage to semi-conductor devices (diodes

and transistors), and to avoid the risk of

personal injury. In addition to the precautions

given in Safety first!at the beginning of this

manual, observe the following when working

on the system:

Always remove rings, watches, etc before

working on the electrical system.Even with the

battery disconnected, capacitive discharge

could occur if a component’s live terminal is

earthed through a metal object. This could

cause a shock or nasty burn.

Do not reverse the battery connections.

Components such as the alternator, electronic

control units, or any other components having

semi-conductor circuitry, could be irreparably

damaged.

If the engine is being started using jump

leads and a slave battery, connect thebatteries positive-to-positiveand negative-to-

negative(see “Jump starting”). This also

applies when connecting a battery charger.

Never disconnect the battery terminals, the

alternator, any electrical wiring, or any test

instruments, when the engine is running.

Do not allow the engine to turn the alternator

when the alternator is not connected.

Never test for alternator output by “flashing”

the output lead to earth.

Never use an ohmmeter of the type

incorporating a hand-cranked generator for

circuit or continuity testing.

Always ensure that the battery negative lead

is disconnected when working on the

electrical system.

Before using electric-arc welding equipment

on the car, disconnect the battery, alternator,

and components such as the fuel-

injection/ignition electronic control unit, to

protect them from the risk of damage.

Refer to Chapter 13

1In normal use the battery should not require

charging from an external source, unless the

vehicle is laid up for long periods, when it

should be recharged every six weeks or so. If

vehicle use consists entirely of short runs in

darkness it is also possible for the battery to

become discharged. Otherwise, a regular

need for recharging points to a fault in the

battery or elsewhere in the charging system.

2There is no need to disconnect the battery

from the vehicle wiring when using a battery

charger, but switch off the ignition and leave

the bonnet open.

3Domestic battery chargers (up to about 6

amps output) may safely be used overnight

without special precautions. Make sure that

the charger is set to deliver 12 volts before

connecting it. Connect the leads (red or

positive to the positive terminal, black or

negative to the negative terminal) before

switching the charger on at the mains.

4When charging is complete, switch off at

the mains beforedisconnecting the charger

from the battery. Remember that the battery

will be giving off hydrogen gas, which is

potentially explosive.

5Charging at a higher rate should only be

carried out under carefully controlled

conditions. Very rapid or “boost” charging

should be avoided if possible, as it is liable to

cause permanent damage to the battery

through overheating.

6During any sort of charging, battery

electrolyte temperature should never exceed

38°C (100°F). If the battery becomes hot, or

the electrolyte is effervescing vigorously,

charging should be stopped.

3Battery - charging

2Electrical fault-finding - general

information

Engine electrical systems 5•3

5

Warning. The voltages produced

by the electronic ignition system

are considerably higher than those

produced by conventional

systems. Extreme care must be taken when

working on the system with the ignition

switched on. Persons with surgically-

implanted cardiac pacemaker devices

should keep well clear of the ignition

circuits, components and test equipment.

procarmanuals.com

Page 126 of 255

into position or the wiring pins will be

damaged.

25Refit the module retaining bolts and

tighten them securely.

26Rotate the distributor until the marks made

on removal are aligned then securely tighten

the clamp bolt.

27Reconnect the distributor wiring

connector and the battery negative terminal.

28Run the engine to normal operating

temperature and check the ignition timing.

All engines except DOHC fuel-

injection

1The ignition coil is mounted on the left-hand

side of the engine compartment (see

illustration). If it fails, there will be no spark

and the engine will stop.

2To test the coil an ohmmeter will be

required. Disconnect the LT and HT leads from

the coil and measure the resistance between

the two LT terminals (primary resistance), then

between the HT terminal and either LT

terminal (secondary resistance). Desired

values are given in the Specifications. In fact

most test gear will not be able to distinguish

between a normal primary resistance (which is

very low) and a short-circuit.

3In the absence of an ohmmeter, test the coil

by substitution of a known good unit.4To remove the coil, disconnect the LT and

HT leads, then remove the two screws which

secure the coil clamp. Lift out the coil.

5Refit by reversing the removal operations.

2.0 litre DOHC fuel-injection

engines

6Refer to the above paragraphs but note that

on some models the coil heat shield must be

removed for access to the coil securing bolts.

The heat shield is secured by two screws. An

earthing lead and/or a suppressor may also be

secured by one of the coil retaining screws

(see illustration).

1On carburettor models, a fuel trap is fitted in

the vacuum pipe between the inlet manifold

and the ESC II module.

2Disconnect the battery negative lead.

3Disconnect the vacuum pipes from the trap

and remove it. Dispose of it carefully, it may

contain fuel.

4When refitting, note that the end of the trap

marked CARB goes towards the manifold, and

the end marked DIST towards the module.

5Reconnect the battery.

ESC II module (carburettor

models)

SOHC engines

1Disconnect the battery negative lead.

2Disconnect the vacuum pipe from the

module (see illustration).

3Release the locking catch and disconnect

the multi-plug from the module (see

illustration).

4Remove the three securing screws and

detach the module and bracket from the left-

hand inner wing.

5Refit by reversing the removal operations.

Make sure that the multi-plug is securely fitted

and the locking catch engaged.Note: From January 1987, a new type of

module was fitted to the 1.8 litre engine. The

new module is smaller than the old unit and is

in the engine compartment mounted onto the

left-hand wing valance. The new module is

known as the ESC Hybrid Module.(see

illustration)

DOHC engine

6Removal and refitting is as above.

7The module is located on the left-hand side

of the engine compartment and is secured by

two screws.

EEC IV module (fuel-injection

models)

SOHC and 2.8 litre V6 engines

8Disconnect the battery negative lead.

9Remove the under-dash trim on the

passenger side.

10Unclip the module and lower it onto the

vehicle floor.

11Remove the control bolt from the multi-

plug and disconnect the plug from the module.

12Refit by reversing the removal operations.

DOHC and 2.4 & 2.9 litre V6 engines

13The module is situated behind the

passenger side of the facia and is accessible

from underneath the glovebox.

14To remove the module first disconnect the

battery negative terminal.

15Reach up behind the glovebox and unclip

the module from the mounting bracket (see

illustration).

18Engine management control

module - removal and refitting

17Fuel trap (carburettor

models) - removal and refitting

16Ignition coil - testing, removal

and refitting

Engine electrical systems 5•9

5

16.1 Ignition coil location16.6 Suppresser secured by one of the coil

retaining screws

18.2 Disconnecting the ESC II module

vacuum pipe18.5 Engine management module - 1.8 litre

engine from January 198718.3 ESC II module multi-plug

procarmanuals.com

Page 129 of 255

1The sensor is located in the upper section of

the inlet manifold (DOHC fuel-injection

engines) or the side of the plenum chamber

(V6 engines).

2To remove the sensor, first disconnect the

battery negative lead.

3Disconnect the sensor wiring plug by pulling

on the plug, not the wiring (see illustration).

4Unscrew the sensor from the inlet manifold

and remove it.

5Refitting is a reversal of removal, applying a

smear of sealant to the threads of the sensor

and tightening it to the specified torque.

1Fitted to 2.0 litre DOHC fuel-injected

engines,this sensor is located in the top of the

fuel rail.

2To remove the sensor, first disconnect the

battery negative lead, and to improve access,

disconnect the wiring plug from the air charge

temperature sensor (in the inlet manifold).

Disconnect the sensor wiring plug by pulling

on the plug, not the wiring.

3Disconnect the fuel temperature sensor

wiring plug, again pulling on the plug (see

illustration).

4Unscrew the sensor from the fuel rail and

remove it.

5Refitting is a reversal of removal, tightening

the sensor to the specified torque.1Fitted to DOHC fuel-injected engines and to

V6 engines with catalytic converters, this

sensor is located in the left-hand side of the

gearbox/transmission.

2To remove the sensor first disconnect the

battery negative lead.

3Firmly apply the handbrake then jack up the

vehicle and support it securely on axle stands

(see “Jacking”).

4Detach the sensor wiring connector from

the bracket, and separate the two halves of

the connector (see illustration).

5Unscrew the securing bolt, and withdraw

the wiring connector bracket, noting the

orientation.

6Withdraw the sensor from the

gearbox/transmission casing.

7Before refitting the sensor, examine the O-

ring, and renew if damaged or worn.

8Refitting is a reversal of removal, ensuring

that the wiring connector bracket is correctly

located.

1On DOHC fuel-injected engines, this sensor

is located on the right-hand side of the engine

compartment where it is mounted either on

the suspension turret or on the bulkhead (see

illustration). V6 engines have the sensormounted on the centre of the engine

compartment bulkhead.

2To remove the sensor first disconnect the

battery negative terminal.

3Remove the two sensor retaining screws

and carefully withdraw the sensor, taking care

not to strain the wiring.

4Disconnect the wiring plug from the sensor,

pulling on the plug not the wiring, then

disconnect the vacuum hose and remove the

sensor.

5Refitting is a reversal of removal.

28Manifold absolute pressure

(MAP) sensor - removal and

refitting

27Vehicle speed sensor -

removal and refitting

26Fuel temperature sensor -

removal and refitting

25Air charge temperature

sensor - removal and refitting

5•12Engine electrical systems

25.3 Disconnecting the air charge

temperature sensor wiring plug

28.1 Manifold Absolute Pressure (MAP)

sensor location - models equipped with a

catalytic converter

26.3 Disconnecting the fuel temperature

sensor wiring plug27.4 Vehicle speed sensor wiring plug

(arrowed)

procarmanuals.com