key FORD GRANADA 1985 Service User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 1985, Model line: GRANADA, Model: FORD GRANADA 1985Pages: 255, PDF Size: 14.98 MB

Page 69 of 255

Other items

34Disconnect the throttle cable from the

operating lever and bracket.

35Disconnect the right-hand exhaust

downpipe from the manifold then remove the

starter motor, the oil filter, and disconnect the

left-hand exhaust downpipe, in that order.

Refer to Part A, Section 8, paragraphs 1 to 8

of this Chapter.

Cylinder head bolts on the V6 engine may

be conventional (hexagon-headed) or Torx

type. The appropriate Torx key will be needed

to deal with the latter.

Before dismantling the engine into its main

components, the following ancillaries can be

removed. The actual items removed, and the

sequence of removal, will depend on the work

to be done.

Distributor and bracket

Spark plugs

Inlet manifold and associated items

Exhaust manifolds

Clutch

Alternator and bracket

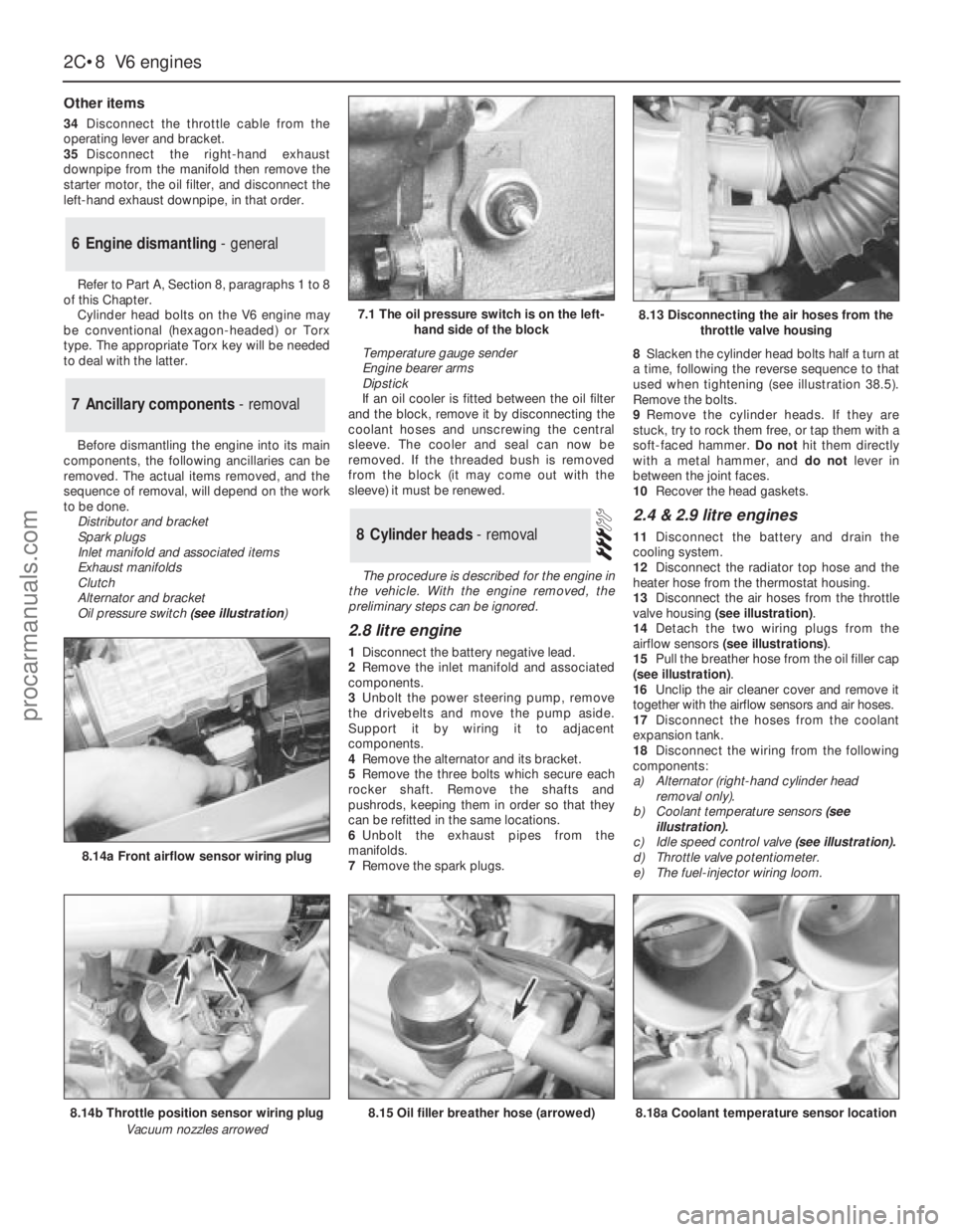

Oil pressure switch(see illustration) Temperature gauge sender

Engine bearer arms

Dipstick

If an oil cooler is fitted between the oil filter

and the block, remove it by disconnecting the

coolant hoses and unscrewing the central

sleeve. The cooler and seal can now be

removed. If the threaded bush is removed

from the block (it may come out with the

sleeve) it must be renewed.

The procedure is described for the engine in

the vehicle. With the engine removed, the

preliminary steps can be ignored.

2.8 litre engine

1Disconnect the battery negative lead.

2Remove the inlet manifold and associated

components.

3Unbolt the power steering pump, remove

the drivebelts and move the pump aside.

Support it by wiring it to adjacent

components.

4Remove the alternator and its bracket.

5Remove the three bolts which secure each

rocker shaft. Remove the shafts and

pushrods, keeping them in order so that they

can be refitted in the same locations.

6Unbolt the exhaust pipes from the

manifolds.

7Remove the spark plugs.8Slacken the cylinder head bolts half a turn at

a time, following the reverse sequence to that

used when tightening (see illustration 38.5).

Remove the bolts.

9Remove the cylinder heads. If they are

stuck, try to rock them free, or tap them with a

soft-faced hammer. Do nothit them directly

with a metal hammer, and do notlever in

between the joint faces.

10Recover the head gaskets.

2.4 & 2.9 litre engines

11Disconnect the battery and drain the

cooling system.

12Disconnect the radiator top hose and the

heater hose from the thermostat housing.

13Disconnect the air hoses from the throttle

valve housing (see illustration).

14Detach the two wiring plugs from the

airflow sensors (see illustrations).

15Pull the breather hose from the oil filler cap

(see illustration).

16Unclip the air cleaner cover and remove it

together with the airflow sensors and air hoses.

17Disconnect the hoses from the coolant

expansion tank.

18Disconnect the wiring from the following

components:

a)Alternator (right-hand cylinder head

removal only).

b)Coolant temperature sensors(see

illustration).

c)Idle speed control valve (see illustration).

d)Throttle valve potentiometer.

e)The fuel-injector wiring loom.8Cylinder heads - removal

7Ancillary components - removal

6Engine dismantling - general

2C•8V6 engines

7.1 The oil pressure switch is on the left-

hand side of the block

8.14b Throttle position sensor wiring plug

Vacuum nozzles arrowed

8.14a Front airflow sensor wiring plug

8.15 Oil filler breather hose (arrowed)8.18a Coolant temperature sensor location

8.13 Disconnecting the air hoses from the

throttle valve housing

procarmanuals.com

Page 71 of 255

4Remove the auxiliary drivebelts.

5Remove the fan and viscous clutch if fitted).

6Jam the crankshaft, either by engaging 5th

gear and applying the handbrake, or by

removing the starter motor and having an

assistant jam a screwdriver in the starter ring

gear teeth. Unbolt the crankshaft pulley. When

the pulley is secured to a vibration damper,

also remove the damper central bolt.

7Remove the pulley or damper, using a puller

if necessary.

8Disconnect the coolant hoses from the front

of the engine, including the water pump

bypass hose.

9Disconnect the heater connecting pipe from

the timing cover and unbolt the two clips

which secure the pipe to the cover of the

cylinder block (see illustration).

10If not already done, remove the starter motor.11Remove the sump.

12Remove the nine securing bolts and

remove the timing cover complete with water

pump and thermostat.

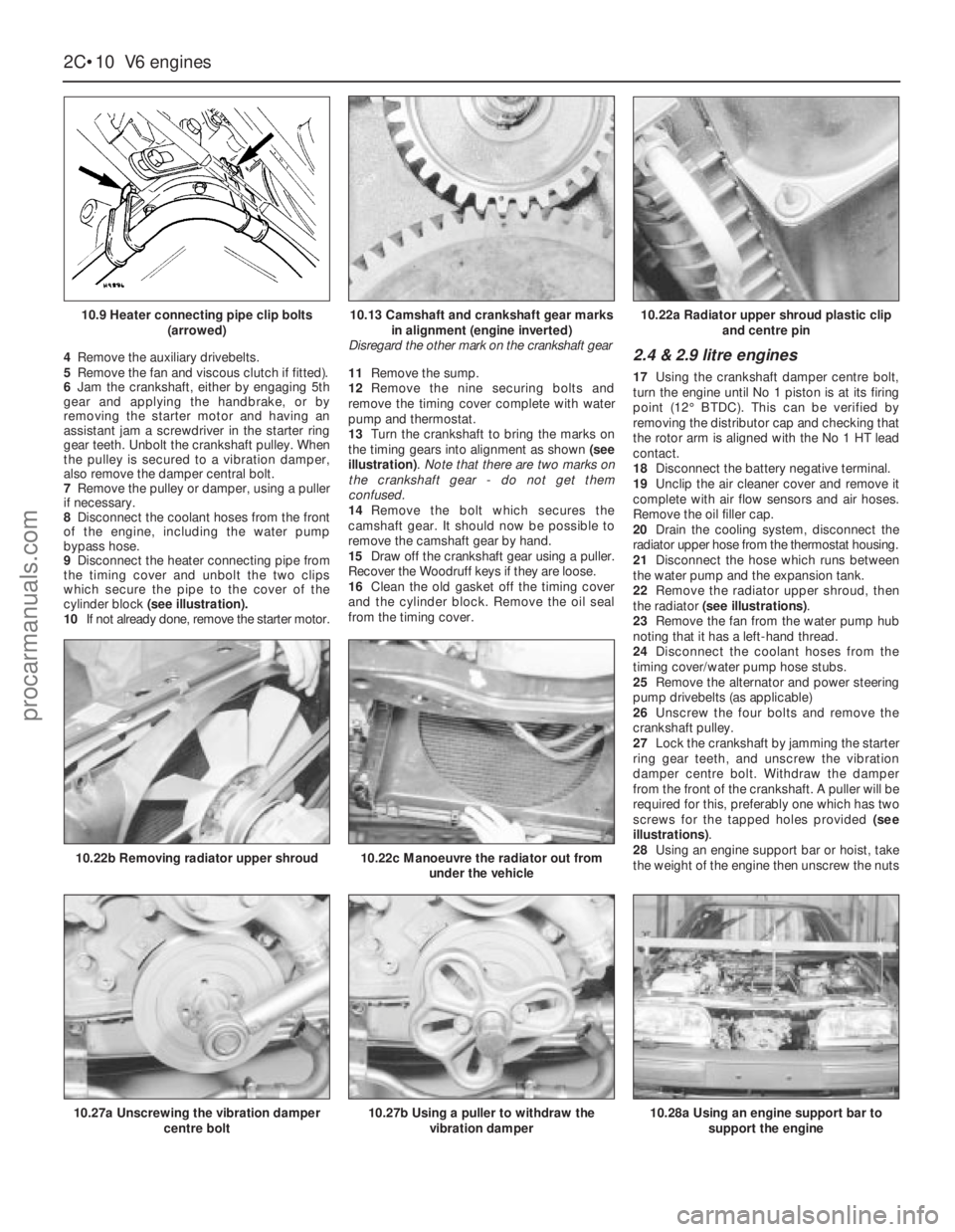

13Turn the crankshaft to bring the marks on

the timing gears into alignment as shown (see

illustration). Note that there are two marks on

the crankshaft gear - do not get them

confused.

14Remove the bolt which secures the

camshaft gear. It should now be possible to

remove the camshaft gear by hand.

15Draw off the crankshaft gear using a puller.

Recover the Woodruff keys if they are loose.

16Clean the old gasket off the timing cover

and the cylinder block. Remove the oil seal

from the timing cover.2.4 & 2.9 litre engines

17Using the crankshaft damper centre bolt,

turn the engine until No 1 piston is at its firing

point (12°BTDC). This can be verified by

removing the distributor cap and checking that

the rotor arm is aligned with the No 1 HT lead

contact.

18Disconnect the battery negative terminal.

19Unclip the air cleaner cover and remove it

complete with air flow sensors and air hoses.

Remove the oil filler cap.

20Drain the cooling system, disconnect the

radiator upper hose from the thermostat housing.

21Disconnect the hose which runs between

the water pump and the expansion tank.

22Remove the radiator upper shroud, then

the radiator (see illustrations).

23Remove the fan from the water pump hub

noting that it has a left-hand thread.

24Disconnect the coolant hoses from the

timing cover/water pump hose stubs.

25Remove the alternator and power steering

pump drivebelts (as applicable)

26Unscrew the four bolts and remove the

crankshaft pulley.

27Lock the crankshaft by jamming the starter

ring gear teeth, and unscrew the vibration

damper centre bolt. Withdraw the damper

from the front of the crankshaft. A puller will be

required for this, preferably one which has two

screws for the tapped holes provided (see

illustrations).

28Using an engine support bar or hoist, take

the weight of the engine then unscrew the nuts

2C•10V6 engines

10.9 Heater connecting pipe clip bolts

(arrowed)

10.27a Unscrewing the vibration damper

centre bolt

10.22b Removing radiator upper shroud10.22c Manoeuvre the radiator out from

under the vehicle

10.27b Using a puller to withdraw the

vibration damper10.28a Using an engine support bar to

support the engine

10.13 Camshaft and crankshaft gear marks

in alignment (engine inverted)

Disregard the other mark on the crankshaft gear10.22a Radiator upper shroud plastic clip

and centre pin

procarmanuals.com

Page 72 of 255

from the top of the engine mounting brackets

(see illustrations).

29Drain the engine oil, retaining it for further

use only if it is not contaminated or due for

renewal.

30Unbolt the coolant distribution pipe bracket

from the timing cover (see illustration).

31Disconnect the leads and remove the

starter motor.

32Ensure that the front roadwheels and the

steering wheels are in the straight-ahead

position, then remove the pinch-bolt from the

steering shaft coupling and slide the coupling

down the shaft (see illustration).

33Unscrew the sump retaining nuts and

bolts. The rear bolts can only be unscrewed

using a box spanner or thin-walled socket.

34Release the brake hydraulic lines from

their support brackets by pulling out their

retaining clips.

35Unscrew the two bolts from each of the

crossmember side brackets. Lower the

crossmember just enough to be able to

remove the sump. In practice, as the car is

standing on its roadwheels, the car body

should be raised by placing two axle stands

under the front jacking points (see

illustration).

36Extract the nine bolts and remove the

timing cover complete with water pump (see

illustration). Removal of the radiator grille will

provide better access to the cover bolts.

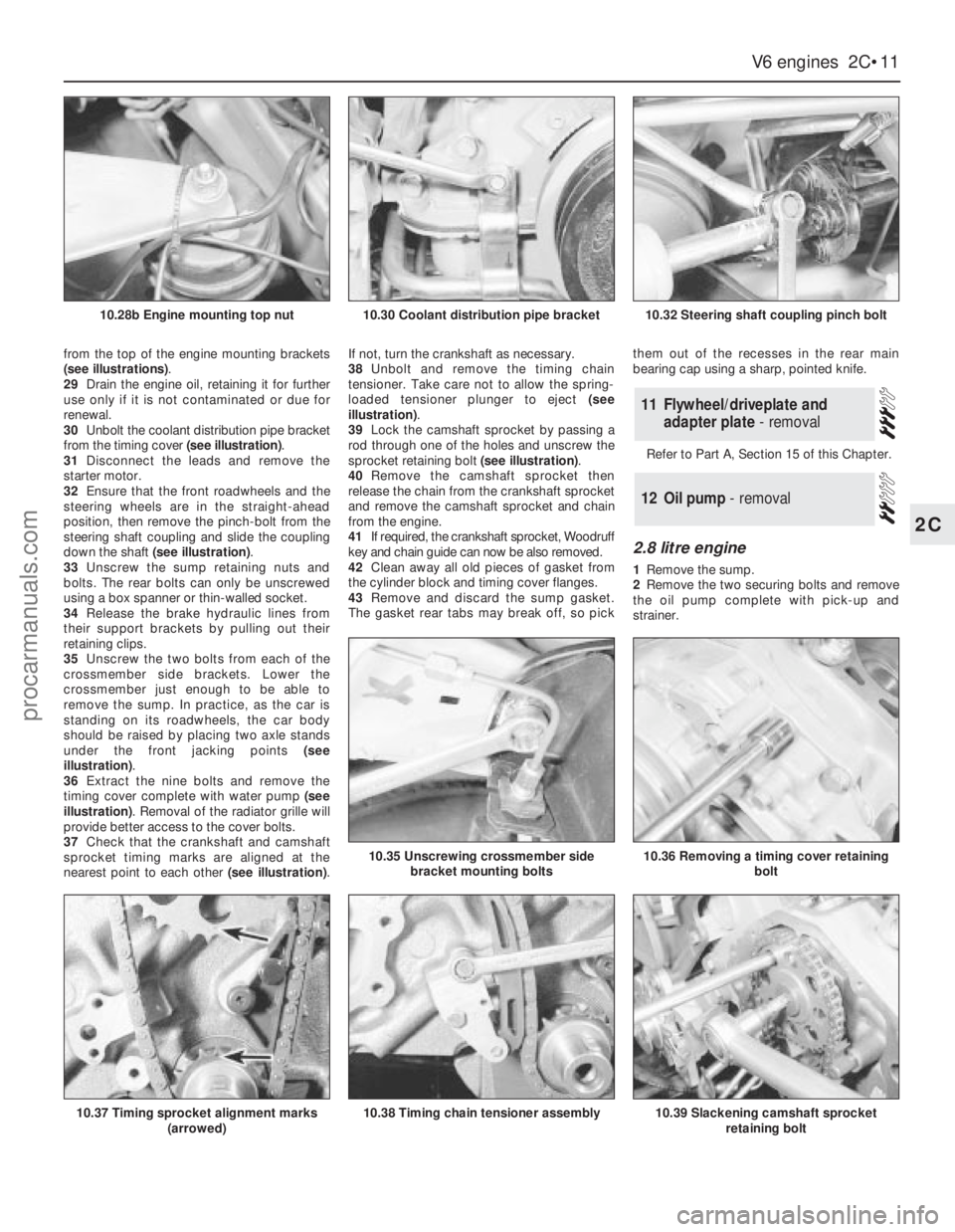

37Check that the crankshaft and camshaft

sprocket timing marks are aligned at the

nearest point to each other (see illustration).If not, turn the crankshaft as necessary.

38Unbolt and remove the timing chain

tensioner. Take care not to allow the spring-

loaded tensioner plunger to eject (see

illustration).

39Lock the camshaft sprocket by passing a

rod through one of the holes and unscrew the

sprocket retaining bolt (see illustration).

40Remove the camshaft sprocket then

release the chain from the crankshaft sprocket

and remove the camshaft sprocket and chain

from the engine.

41If required, the crankshaft sprocket, Woodruff

key and chain guide can now be also removed.

42Clean away all old pieces of gasket from

the cylinder block and timing cover flanges.

43Remove and discard the sump gasket.

The gasket rear tabs may break off, so pickthem out of the recesses in the rear main

bearing cap using a sharp, pointed knife.

Refer to Part A, Section 15 of this Chapter.

2.8 litre engine

1Remove the sump.

2Remove the two securing bolts and remove

the oil pump complete with pick-up and

strainer.

12Oil pump - removal

11Flywheel/driveplate and

adapter plate - removal

V6 engines 2C•11

2C

10.28b Engine mounting top nut10.30 Coolant distribution pipe bracket10.32 Steering shaft coupling pinch bolt

10.37 Timing sprocket alignment marks

(arrowed)

10.36 Removing a timing cover retaining

bolt10.35 Unscrewing crossmember side

bracket mounting bolts

10.38 Timing chain tensioner assembly10.39 Slackening camshaft sprocket

retaining bolt

procarmanuals.com

Page 76 of 255

Refer to Part A, Section 33 of this Chapter.

The crankcase ventilation system is very

simple. One hose joins the rear air inlet

trunking to the oil filler cap, and another hose

joins the left-hand rocker cover to the plenum

chamber. Filtered (and metered) air passes

through the oil filler cap into the engine, and is

extracted, along with any other fumes, via the

second hose. Refer to Chapter 1 for

maintenance of the system.

Refer to Part A, Section 35 of this Chapter

but disregard the reference to new cylinder

head bolts when these are of the conventional

(hexagon-headed) type. Only Torx type bolts

need to be renewed.

1Wipe the bearing shell locations in the

crankcase with a clean rag and fit the mainbearing upper half shells in position (see

illustration).

2Clean the main bearing shell locations and

fit the half shells in the caps.

3Fit the flanged shells to No 3 bearing.

4Lubricate the shells and the main bearing

journals with engine oil.

5Lubricate a new rear oil seal and fit it to the

end of the crankshaft, lips facing inwards.

6Carefully place the crankshaft in position

(see illustration).

7Make sure that the surfaces are clean, then

apply a film of sealant (Ford No A-70SX-

19554-BA, or equivalent) to the mating faces

of the crankcase and the rear main bearing

cap.

8Fit the bearing caps, with the arrows on the

caps pointing to the front of the engine (see

illustration).

9Insert the main bearing cap bolts. The bolts

for bearing caps No 2 and 3 have rounded

heads, and are 14 mm (0.55 in) longer than

those for caps 1 and 4.

10Tighten the main bearing cap bolts

progressively to the specified torque.

11Make sure that the crankshaft is free to

rotate. Some stiffness is to be expected withnew components, but there should be no tight

spots or binding.

12Press the crankshaft rear oil seal firmly

against the rear main bearing.

13Check the crankshaft endfloat, levering

the crankshaft back and forth and inserting

feeler blades between the crankshaft and No 3

main bearing (see illustration). Excessive

endfloat can only be due to wear of the

crankshaft or bearing shell flanges.

14Coat the rear main bearing cap sealing

wedges with sealant and press into position

with a blunt screwdriver(see illustration).The

rounded end of each wedge carries a red paint

mark, which must face the bearing cap.

1Slide the spacer ring onto the camshaft,

chamfered side first. Refit the Woodruff key if

it was removed.

2Lubricate the camshaft bearings, the

camshaft and thrust plate.

3Carefully insert the camshaft from the front

and fit the thrust plate and self-locking

securing bolts. Tighten the bolts to the

specified torque (see illustrations).

4Fit the timing cover dowels and O-ring seals

onto the crankcase. The chamfered end of the

dowels must face outwards towards the timing

cover (see illustration).

5Ensure that the mating faces of the

crankcase and front intermediate plate are

32Camshaft and intermediate

plate - refitting

31Crankshaft and main

bearings - refitting

30Engine reassembly - general

information

29Crankcase ventilation system -

general information

28Flywheel ring gear -

examination and renovation

V6 engines 2C•15

2C

31.1 Rear main bearing shell in the

crankcase31.6 Placing the crankshaft in position

31.8 Main bearing cap markings - arrow

points to front of engine31.13 Checking crankshaft endfloat31.14 Fitting the rear main bearing cap

sealing wedges

27.16b Removing the oil pump cover

If the old bearings are being

refitted (although this is false

economy unless they are

practically new) make sure

they are fitted in their original positions.

procarmanuals.com

Page 78 of 255

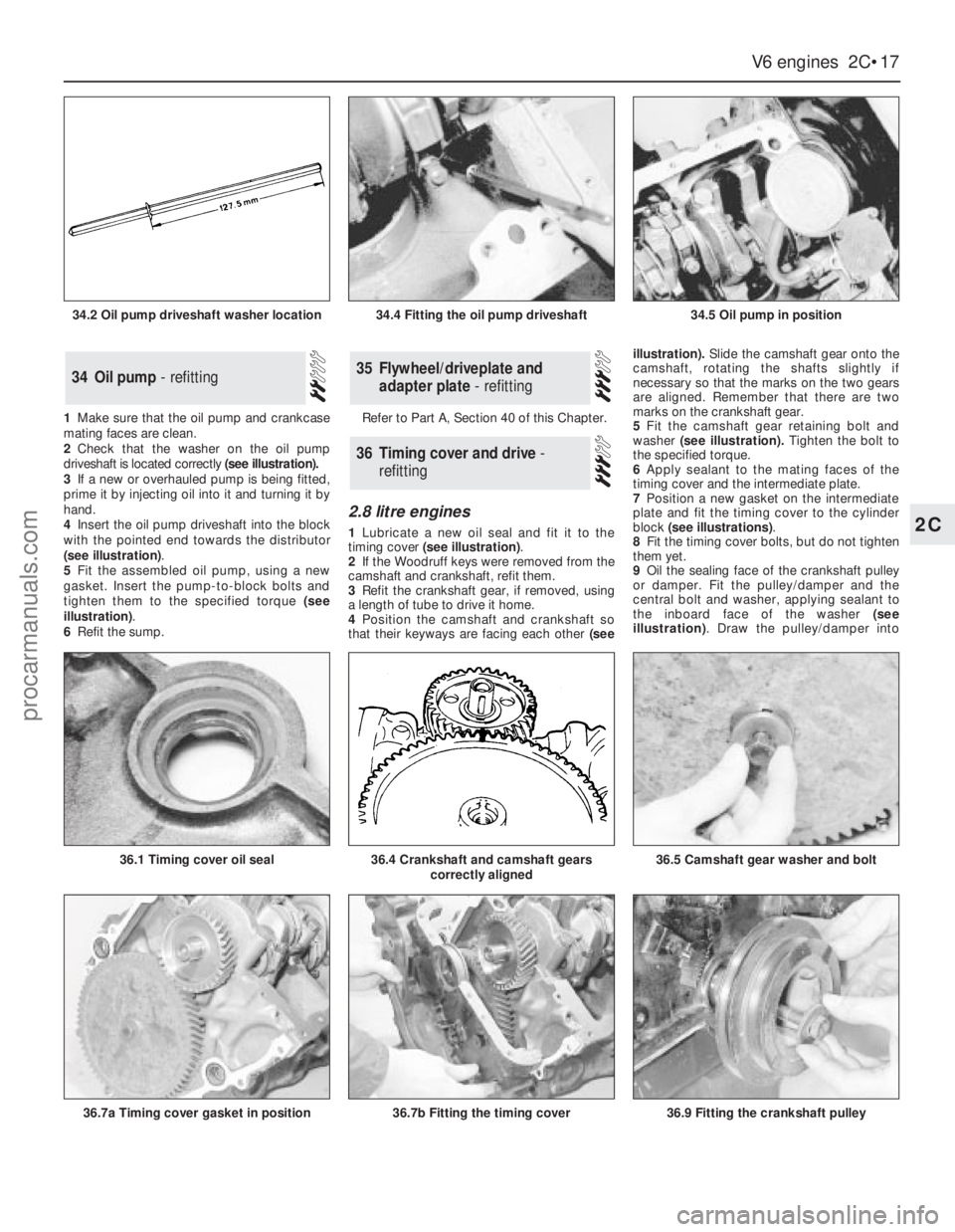

1Make sure that the oil pump and crankcase

mating faces are clean.

2Check that the washer on the oil pump

driveshaft is located correctly (see illustration).

3If a new or overhauled pump is being fitted,

prime it by injecting oil into it and turning it by

hand.

4Insert the oil pump driveshaft into the block

with the pointed end towards the distributor

(see illustration).

5Fit the assembled oil pump, using a new

gasket. Insert the pump-to-block bolts and

tighten them to the specified torque (see

illustration).

6Refit the sump.Refer to Part A, Section 40 of this Chapter.

2.8 litre engines

1Lubricate a new oil seal and fit it to the

timing cover (see illustration).

2If the Woodruff keys were removed from the

camshaft and crankshaft, refit them.

3Refit the crankshaft gear, if removed, using

a length of tube to drive it home.

4Position the camshaft and crankshaft so

that their keyways are facing each other(seeillustration).Slide the camshaft gear onto the

camshaft, rotating the shafts slightly if

necessary so that the marks on the two gears

are aligned. Remember that there are two

marks on the crankshaft gear.

5Fit the camshaft gear retaining bolt and

washer(see illustration).Tighten the bolt to

the specified torque.

6Apply sealant to the mating faces of the

timing cover and the intermediate plate.

7Position a new gasket on the intermediate

plate and fit the timing cover to the cylinder

block (see illustrations).

8Fit the timing cover bolts, but do not tighten

them yet.

9Oil the sealing face of the crankshaft pulley

or damper. Fit the pulley/damper and the

central bolt and washer, applying sealant to

the inboard face of the washer (see

illustration). Draw the pulley/damper into

36Timing cover and drive -

refitting

35Flywheel/driveplate and

adapter plate - refitting34Oil pump - refitting

V6 engines 2C•17

2C

34.2 Oil pump driveshaft washer location34.4 Fitting the oil pump driveshaft34.5 Oil pump in position

36.7a Timing cover gasket in position

36.1 Timing cover oil seal36.5 Camshaft gear washer and bolt36.4 Crankshaft and camshaft gears

correctly aligned

36.7b Fitting the timing cover36.9 Fitting the crankshaft pulley

procarmanuals.com

Page 79 of 255

place by tightening the bolt; this will centralise

the timing cover.

10Tighten the timing cover bolts evenly to

the specified torque.

11Jam the crankshaft and tighten the pulley/

damper central bolt to the specified torque.

12Refit the sump.

13If the water pump was removed from the

timing cover, refit it using a new gasket.

14If the engine is still in the vehicle, reverse

the steps taken to gain access.

2.4 & 2.9 litre engines

15If the crankshaft sprocket was removed,

check that the key slots in the end of the

crankshaft and camshaft are in alignment at

the closest point to each other (see

illustration).16Fit the crankshaft sprocket and chain

guide.

17Engage the chain around the teeth of the

crankshaft sprocket.

18Engage the camshaft sprocket in the

upper loop of the chain in such a way so that

the camshaft sprocket will slip onto the key

slot when the timing mark is aligned with that

on the crankshaft sprocket (see illustration).

Some trial and error may be involved in

achieving this.

19Lock the camshaft sprocket and tighten

the retaining bolt to the specified torque.

20Retract the chain tensioner. To do this,

insert the plunger (bevelled side entering), then

release the pawl with a small screwdriver

pushed into the hole in the tensioner body

(see illustration).21Compress the plunger/slipper and retain it

in the retracted position using a cable-tie or

similar. New chain tensioners are supplied

complete with a retainer (see illustration).

22Bolt the tensioner in position, at the same

time removing the plunger retainer. Tighten the

bolts to the specified torque.

23Locate a new gasket on the front face of

the engine.

24Renew the timing cover oil seal and apply

grease to the lips.

25Fit the timing cover, centre it and align it

with the sump mounting flange.

26Although a special tool (21-137) is

available for centring the cover, a piece of

plastic pipe, or a socket of suitable thickness,

will serve as an adequate substitute.

Alternatively measure the space between the

crankshaft nose and the timing cover damper

recess at several different points and adjust

the position of the cover until all the

measurements are equal. A strip of metal 14.0

mm wide will serve as a gauge if calipers are

not available (see illustrations).

27Tighten the timing cover bolts (see

illustration)and fit the Woodruff key (where

removed) for the vibration damper.

28Apply jointing compound to the front and

rear sump flange areas on the timing

cover/cylinder block and rear main bearing

cap. Make sure that the bearing surfaces are

perfectly clean. Checking that the rear tabs of

the gasket enter the recesses in the main

bearing cap, locate a new sump gasket on the

crankcase (see illustration).

2C•18V6 engines

36.15 Crankshaft and camshaft key and

slot alignment

36.26b Using a socket to check the

crankshaft to timing cover gap

36.21 Timing chain tensioner retracted

using a cable-tie36.26a Measuring the crankshaft to timing

cover gap

36.27 Timing cover retaining bolts

(arrowed)36.28 Sump gasket at rear main bearing

cap

36.18 Fitting timing chain and sprockets36.20 Releasing timing chain tensioner

pawl

procarmanuals.com

Page 80 of 255

29Fit the sump and the retaining nuts and

bolts. Tighten them progressively in two stages.

30Oil the lip of the timing cover oil seal and

the contact surface of the crankshaft damper.

31Fit the damper to the crankshaft, being

careful not to dislodge the Woodruff key. Draw

the damper into position using the retaining

bolt and washer.

32Remove the bolt and apply sealant to the

faces of the washer. Refit the bolt and washer

then jam the starter gear ring teeth and tighten

the bolt to the specified torque.

33Refit the crankshaft pulley and tighten the

retaining bolts to the specified torque.

34Refit the crossmember side brackets and

brake pipes.

35Reconnect the engine mountings and

remove the engine hoist or axle stands (see

“Jacking”).36Connect the steering shaft coupling with

the steering wheel and front roadwheels in the

straight-ahead position. Fit the pinch-bolt and

tighten it to the specified torque.

37Fit the starter motor and connect the leads.

38Bolt the coolant distributor pipe to the

timing cover.

39Refit the alternator and power steering

pump drivebelts and tension them (see

illustrations).

40Fit the fan and radiator, connect all coolant

hoses, and fit the radiator upper shroud.

41Fit the air cleaner cover with attachments.

42Fill the engine with oil and coolant and

connect the battery.

2.8 litre engine

1Clean the mating faces of the crankcase

and sump. Ensure that the grooves in the seal

carriers are clean.

2Fit the rubber seals in the grooves.

3Apply sealing compound on the crankcase

and slide the tabs of the gasket under the cut-

outs in the rubber seals (see illustration).

4Ensure that the gasket hole lines up with the

holes in the gasket crankcase and fit the

sump. Take care not to dislodge the gasket.

5Fit the 24 securing bolts. Tighten them in

the sequence shown to the Stage 1 specified

torque starting at point A (see illustration),then to the Stage 2 torque starting at point B.

6Fit the sump drain plug, using a new

washer, and tighten it to the specified torque.

7If the engine is in the vehicle, reverse the

steps taken to gain access.

2.4 & 2.9 litre engines

8Refer to paragraphs 28 to 29, Section 36.

2.8 litre engine

1Lubricate the valve tappets with clean

engine oil and insert them in the cylinder

block. Ensure that they are fitted in their

original locations (see illustration).

2Ensure that the mating faces of the cylinder

block and the cylinder heads are clean.

3Position the new cylinder head gaskets over

the guide bushes on the cylinder block. Check

that they are correctly located. The right and

left-hand gaskets are different. The gaskets

are marked FRONT TOP (see illustration).

4Carefully lower the cylinder heads onto the

cylinder block. Oil the threads and contact

faces of the cylinder head bolts and insert

them into their holes.

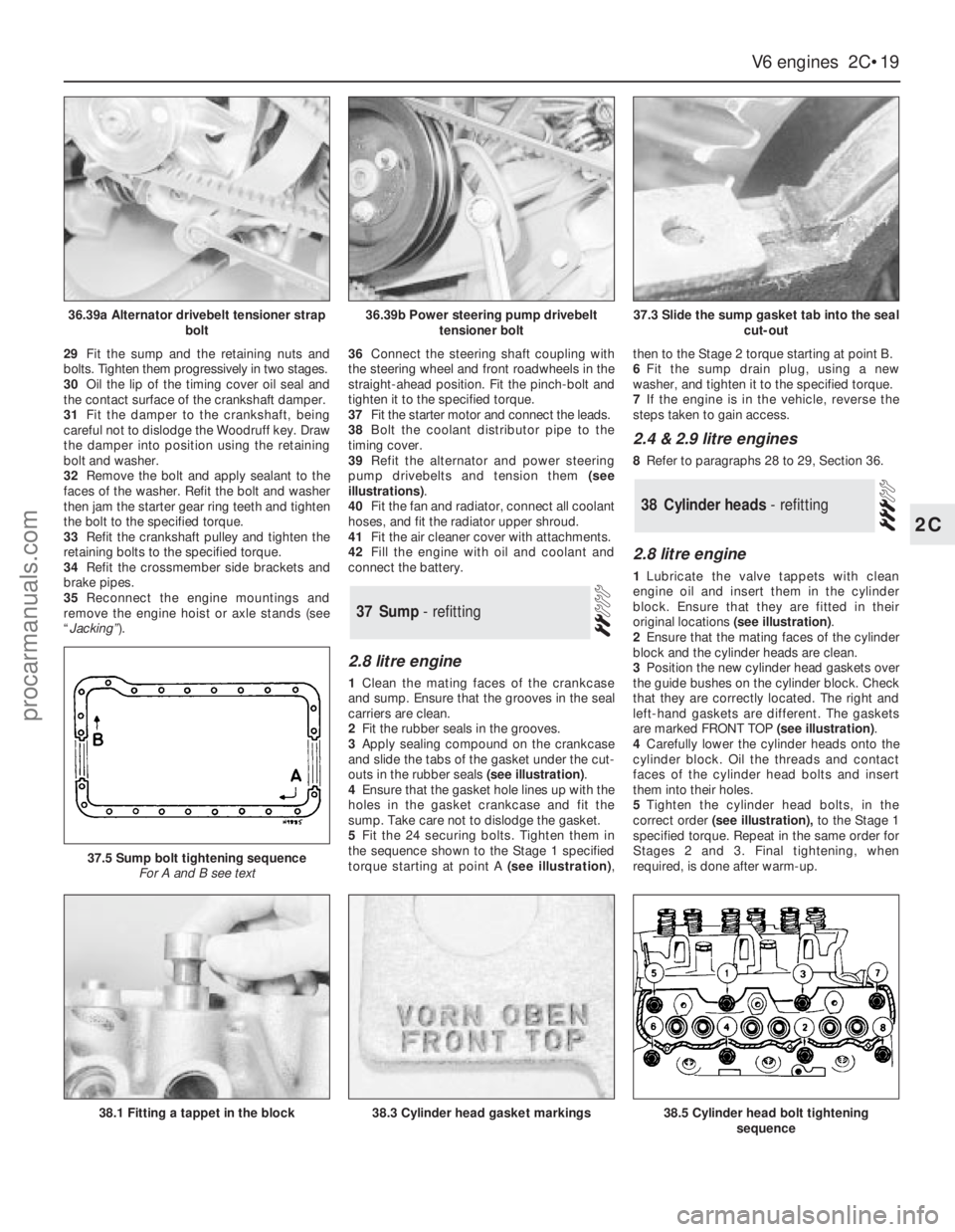

5Tighten the cylinder head bolts, in the

correct order(see illustration),to the Stage 1

specified torque. Repeat in the same order for

Stages 2 and 3. Final tightening, when

required, is done after warm-up.

38Cylinder heads - refitting

37Sump - refitting

V6 engines 2C•19

2C

36.39a Alternator drivebelt tensioner strap

bolt36.39b Power steering pump drivebelt

tensioner bolt37.3 Slide the sump gasket tab into the seal

cut-out

38.1 Fitting a tappet in the block

37.5 Sump bolt tightening sequence

For A and B see text

38.3 Cylinder head gasket markings38.5 Cylinder head bolt tightening

sequence

procarmanuals.com

Page 99 of 255

25To remove the pump, first remove the fuel

tank.

26Unscrew the fuel pump/fuel level sender

unit by engaging two crossed screwdrivers in

the slots on either side of the unit mounting

flange. Recover the seal.

27Refitting is a reversal of removal. It is

necessary to fit a new seal.

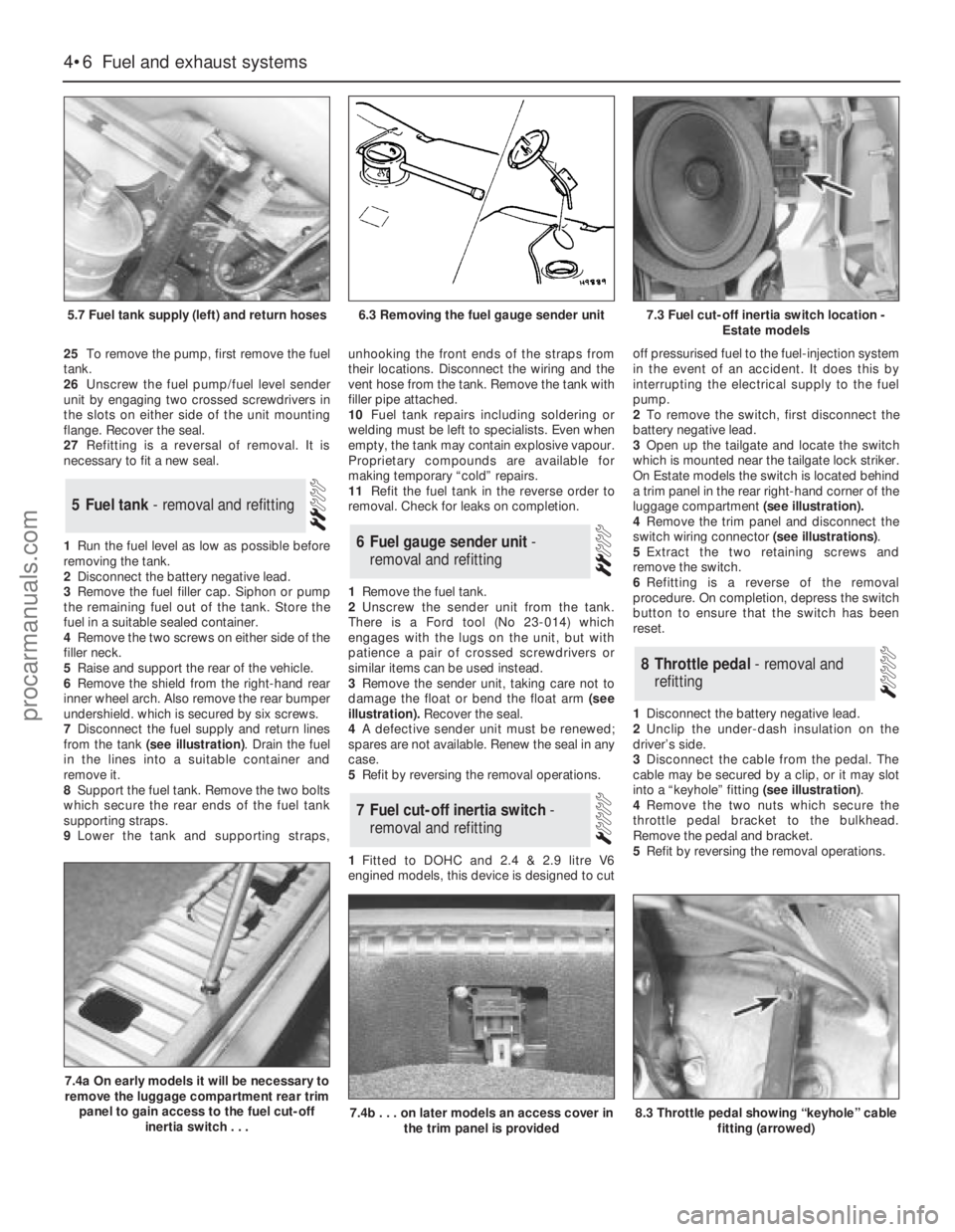

1Run the fuel level as low as possible before

removing the tank.

2Disconnect the battery negative lead.

3Remove the fuel filler cap. Siphon or pump

the remaining fuel out of the tank. Store the

fuel in a suitable sealed container.

4Remove the two screws on either side of the

filler neck.

5Raise and support the rear of the vehicle.

6Remove the shield from the right-hand rear

inner wheel arch. Also remove the rear bumper

undershield. which is secured by six screws.

7Disconnect the fuel supply and return lines

from the tank (see illustration). Drain the fuel

in the lines into a suitable container and

remove it.

8Support the fuel tank. Remove the two bolts

which secure the rear ends of the fuel tank

supporting straps.

9Lower the tank and supporting straps,unhooking the front ends of the straps from

their locations. Disconnect the wiring and the

vent hose from the tank. Remove the tank with

filler pipe attached.

10Fuel tank repairs including soldering or

welding must be left to specialists. Even when

empty, the tank may contain explosive vapour.

Proprietary compounds are available for

making temporary “cold” repairs.

11Refit the fuel tank in the reverse order to

removal. Check for leaks on completion.

1Remove the fuel tank.

2Unscrew the sender unit from the tank.

There is a Ford tool (No 23-014) which

engages with the lugs on the unit, but with

patience a pair of crossed screwdrivers or

similar items can be used instead.

3Remove the sender unit, taking care not to

damage the float or bend the float arm(see

illustration).Recover the seal.

4A defective sender unit must be renewed;

spares are not available. Renew the seal in any

case.

5Refit by reversing the removal operations.

1Fitted to DOHC and 2.4 & 2.9 litre V6

engined models, this device is designed to cutoff pressurised fuel to the fuel-injection system

in the event of an accident. It does this by

interrupting the electrical supply to the fuel

pump.

2To remove the switch, first disconnect the

battery negative lead.

3Open up the tailgate and locate the switch

which is mounted near the tailgate lock striker.

On Estate models the switch is located behind

a trim panel in the rear right-hand corner of the

luggage compartment (see illustration).

4Remove the trim panel and disconnect the

switch wiring connector (see illustrations).

5Extract the two retaining screws and

remove the switch.

6Refitting is a reverse of the removal

procedure. On completion, depress the switch

button to ensure that the switch has been

reset.

1Disconnect the battery negative lead.

2Unclip the under-dash insulation on the

driver’s side.

3Disconnect the cable from the pedal. The

cable may be secured by a clip, or it may slot

into a “keyhole” fitting (see illustration).

4Remove the two nuts which secure the

throttle pedal bracket to the bulkhead.

Remove the pedal and bracket.

5Refit by reversing the removal operations.

8Throttle pedal - removal and

refitting

7Fuel cut-off inertia switch -

removal and refitting

6Fuel gauge sender unit -

removal and refitting

5Fuel tank - removal and refitting

4•6Fuel and exhaust systems

5.7 Fuel tank supply (left) and return hoses

7.4a On early models it will be necessary to

remove the luggage compartment rear trim

panel to gain access to the fuel cut-off

inertia switch . . .

7.4b . . . on later models an access cover in

the trim panel is provided8.3 Throttle pedal showing “keyhole” cable

fitting (arrowed)

6.3 Removing the fuel gauge sender unit7.3 Fuel cut-off inertia switch location -

Estate models

procarmanuals.com

Page 102 of 255

1Check the cost and availability of spare parts

before deciding to dismantle the carburettor. If

the unit has seen much service, fitting a new or

reconditioned carburettor may prove more

satisfactory than any attempt at overhaul.

2Obtain a carburettor repair kit, which will

contain the necessary gaskets, diaphragms

and other renewable items.

3With the carburettor removed from the

vehicle, clean it thoroughly externally and

place it on a clean worksurface.

4 Referringto the exploded view of the

carburettor(see illustration),remove each

component part whilst making a note of its

fitted position. Make alignment marks on

linkages etc.

5Reassemble in the reverse order to

dismantling, using new gaskets, O-rings etc.

6To check the choke pull-down after

reassembly, position the fast idle screw on the

highest step of the cam. Press the pull-down

adjusting screw towards the pull-down

diaphragm and measure the choke valve

opening with a twist drill or gauge rod of the

specified diameter. Adjust if necessary using

a 2 mm Allen key (see illustration).

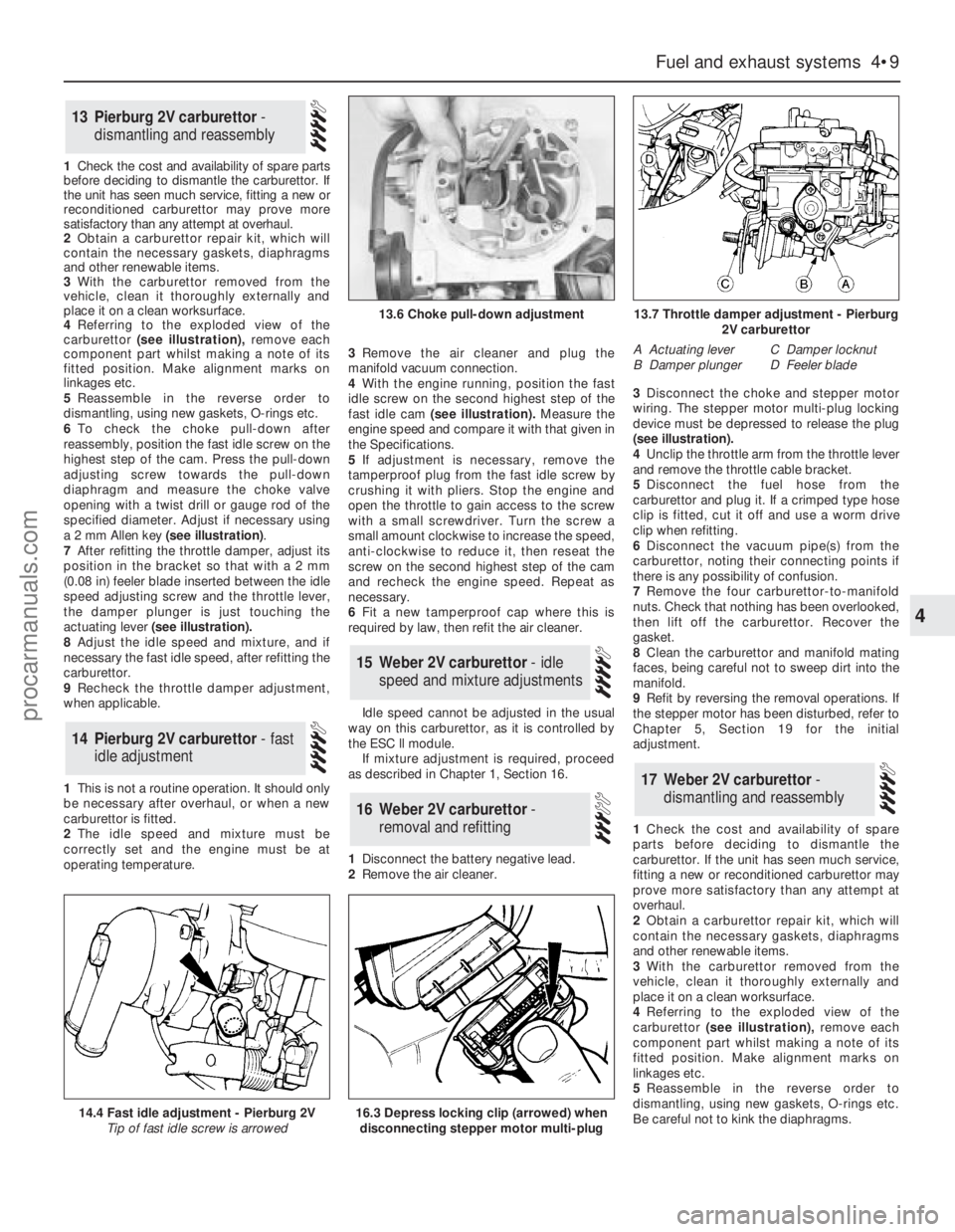

7After refitting the throttle damper, adjust its

position in the bracket so that with a 2 mm

(0.08 in) feeler blade inserted between the idle

speed adjusting screw and the throttle lever,

the damper plunger is just touching the

actuating lever(see illustration).

8Adjust the idle speed and mixture, and if

necessary the fast idle speed, after refitting the

carburettor.

9Recheck the throttle damper adjustment,

when applicable.

1This is not a routine operation. It should only

be necessary after overhaul, or when a new

carburettor is fitted.

2The idle speed and mixture must be

correctly set and the engine must be at

operating temperature.3Remove the air cleaner and plug the

manifold vacuum connection.

4With the engine running, position the fast

idle screw on the second highest step of the

fast idle cam(see illustration).Measure the

engine speed and compare it with that given in

the Specifications.

5If adjustment is necessary, remove the

tamperproof plug from the fast idle screw by

crushing it with pliers. Stop the engine and

open the throttle to gain access to the screw

with a small screwdriver. Turn the screw a

small amount clockwise to increase the speed,

anti-clockwise to reduce it, then reseat the

screw on the second highest step of the cam

and recheck the engine speed. Repeat as

necessary.

6Fit a new tamperproof cap where this is

required by law, then refit the air cleaner.

Idle speed cannot be adjusted in the usual

way on this carburettor, as it is controlled by

the ESC ll module.

If mixture adjustment is required, proceed

as described in Chapter 1, Section 16.

1Disconnect the battery negative lead.

2Remove the air cleaner.3Disconnect the choke and stepper motor

wiring. The stepper motor multi-plug locking

device must be depressed to release the plug

(seeillustration).

4Unclip the throttle arm from the throttle lever

and remove the throttle cable bracket.

5Disconnect the fuel hose from the

carburettor and plug it. If a crimped type hose

clip is fitted, cut it off and use a worm drive

clip when refitting.

6Disconnect the vacuum pipe(s) from the

carburettor, noting their connecting points if

there is any possibility of confusion.

7Remove the four carburettor-to-manifold

nuts. Check that nothing has been overlooked,

then lift off the carburettor. Recover the

gasket.

8Clean the carburettor and manifold mating

faces, being careful not to sweep dirt into the

manifold.

9Refit by reversing the removal operations. If

the stepper motor has been disturbed, refer to

Chapter 5, Section 19 for the initial

adjustment.

1Check the cost and availability of spare

parts before deciding to dismantle the

carburettor. If the unit has seen much service,

fitting a new or reconditioned carburettor may

prove more satisfactory than any attempt at

overhaul.

2Obtain a carburettor repair kit, which will

contain the necessary gaskets, diaphragms

and other renewable items.

3With the carburettor removed from the

vehicle, clean it thoroughly externally and

place it on a clean worksurface.

4 Referringto the exploded view of the

carburettor(see illustration),remove each

component part whilst making a note of its

fitted position. Make alignment marks on

linkages etc.

5Reassemble in the reverse order to

dismantling, using new gaskets, O-rings etc.

Be careful not to kink the diaphragms.

17Weber 2V carburettor -

dismantling and reassembly

16Weber 2V carburettor -

removal and refitting

15Weber 2V carburettor - idle

speed and mixture adjustments

14Pierburg 2V carburettor - fast

idle adjustment

13Pierburg 2V carburettor -

dismantling and reassembly

Fuel and exhaust systems 4•9

4

14.4 Fast idle adjustment - Pierburg 2V

Tip of fast idle screw is arrowed

13.6 Choke pull-down adjustment13.7 Throttle damper adjustment - Pierburg

2V carburettor

A Actuating lever

B Damper plungerC Damper locknut

D Feeler blade

16.3 Depress locking clip (arrowed) when

disconnecting stepper motor multi-plug

procarmanuals.com

Page 107 of 255

16Start the engine and note the engine

speed (rpm). The engine speed should

increase above the normal idle speed, and

should be as given in the Specifications.

17If the engine speed is not as specified,

remove the tamperproof plug from the top of

the throttle kicker housing, and turn the

adjustment screw to give the specified speed.

18On completion of adjustment, fit a new

tamperproof cap.

19Disconnect the tubing from the inlet

manifold, and reconnect the throttle kicker

vacuum hose.

20Refit the plastic shield and the air cleaner.

On 2.4 & 2.9 litre V6 models especially,

residual pressure will remain in the fuel lines

long after the vehicle was last used therefore

the fuel system must be depressurised before

any hose is disconnected; the system is

depressurised via the vent valve on the fuel

rail, noting that it may be necessary to depress

the valve several times before the pressure is

fully released. As an added precaution place a

rag over the valve as it is depressed to catch

any fuel which is forcibly expelled. Before

carrying out any operation on the fuel system

refer to the precautions given in Safety first! at

the beginning of this Manual and follow them

implicitly. Petrol is a highly dangerous and

volatile liquid and the precautions necessary

when handling it cannot be overstressed.

Access to the relays is obtained by

removing the facia top cover (crash pad).

The relays are located on the passenger

side(see illustration). Also see Chapter 13,

Section 16.

See Chapter 1, Section 41.

SOHC and 2.8 litre V6 engines

1Idle speed is controlled by the EEC IV

module and no direct adjustment is possible.

2Idle mixture adjustment should not be

necessary on a routine basis. After component

renewal or a similar circumstance it may be

checked and adjusted as follows.

3The engine must be at operating temperature.

The valve clearances must be correct, the air

cleaner element must be clean and the ignition

system must be in good condition.

4Connect an exhaust gas analyser (CO

meter) and a tachometer (rev. counter) to the

engine as instructed by their makers.

5Run the engine at 3000 rpm for 15 seconds,

then allow it to idle. Repeat the procedure

every 60 seconds until adjustment is

complete.

6With the engine idling after the 3000 rpm

burst, record the CO level when the reading

has stabilised. The desired value is given in the

Specifications.

7If adjustment is necessary, remove the

tamperproof plug from the mixture adjusting

screw on the underside of the vane airflow

meter (see illustration).

8On V6 models, note that adjustment should

first be carried out on the front airflow meter.The rear meter should only be adjusted if the

range of adjustment on the front meter is

insufficient.

9Turn the mixture adjusting screw with a

hexagon key until the CO level is correct (see

illustration).

10Stop the engine and disconnect the test

gear.

11Fit a new tamperproof plug if required.

DOHC engine

Note: Before carrying out any adjustments

ensure that the ignition timing and spark plug

gaps are as specified. To carry out the

adjustments, an accurate tachometer and an

exhaust gas analyser (CO meter) will be

required.

12Idle speed is controlled by the EEC IV

module, and manual adjustment is not possible,

although the “base” idle speed can be adjusted

by a Ford dealer using special equipment.

13On models with a catalytic converter, the

mixture is controlled by the EEC IV module,

and no manual adjustment is possible.

14On models without a catalytic converter,

the idle mixture can be adjusted as follows.

15Run the engine until it is at normal

operating temperature.

16Stop the engine and connect a tachometer

and an exhaust gas analyser in accordance

with the manufacturer’s instructions.

17Start the engine and run it at 3000 rpm

for 15 seconds, ensuring that all electrical

loads (headlamps, heater blower, etc) are

switched off, then allow the engine to idle, and

check the CO content. Note that the reading

will initially rise, then fall and finally stabilise.

18If adjustment is necessary, remove the

cover from the mixture adjustment

potentiometer (located on the right-hand side

of the engine compartment, behind the MAP

sensor), and turn the screw to give the

specified CO content (see illustration).

19If adjustment does not produce a change

in reading, the potentiometer may be at the

extreme of the adjustment range. To centralise

the potentiometer, turn the adjustment screw

20 turns clockwise followed by 10 turns anti-

clockwise, then repeat the adjustment

procedure.

31Fuel-injection system - idle

speed and mixture adjustment

30Fuel filter - renewal

29Fuel-injection system relays -

location

28Fuel-injection system -

depressurisation

4•14Fuel and exhaust systems

31.18 Remove the cover from the mixture

adjustment potentiometer31.9 Idle mixture adjustment - fuel-injection

models

29.2 Fuel injection system relays - 2.4 and

2.9 litre V6 engines

A Power relayB Fuel pump relay

31.7 Tamperproof plug (arrowed) covering

mixture adjusting screw

Airflow meter is inverted for photo

procarmanuals.com