key FORD GRANADA 1985 Service Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1985, Model line: GRANADA, Model: FORD GRANADA 1985Pages: 255, PDF Size: 14.98 MB

Page 133 of 255

and bracket off the disc and tie them up out of

the way. Do not allow the caliper to hang on

the flexible hose.

3Remove the spring clip which secures the

disc (see illustration).

4Mark the relationship of the disc to the hub

if it is to be re-used, then remove the disc.

5Refit by reversing the removal operations.

Tighten the caliper bracket bolts to the

specified torque, and check that the brake

flexible hose is not kinked or fouling in any

position of the steering wheel.

6Pump the brake pedal to bring the pads up

to the disc.

1Chock the front wheels and release the

handbrake. Slacken the rear wheel nuts, raise

and support the vehicle and remove the

relevant rear wheel.

2Free the handbrake cable from its clip in the

suspension lower arm.

3Remove the two bolts which secure the

caliper bracket to the hub. Lift the caliper and

bracket off the disc and suspend it without

straining the flexible hose.

4Remove the spring clip from the wheel stud.

Mark the disc-to-hub relationship and remove

the disc.

5Refit by reversing the removal operations.

6Pump the brake pedal to bring the pads up

to the disc.1Disc pads can be inspected without

removing the front wheels, using a mirror and

a torch through the aperture in the rear face of

the caliper. If any one pad is worn down to the

minimum specified, all four pads (on both front

wheels) must be renewed.

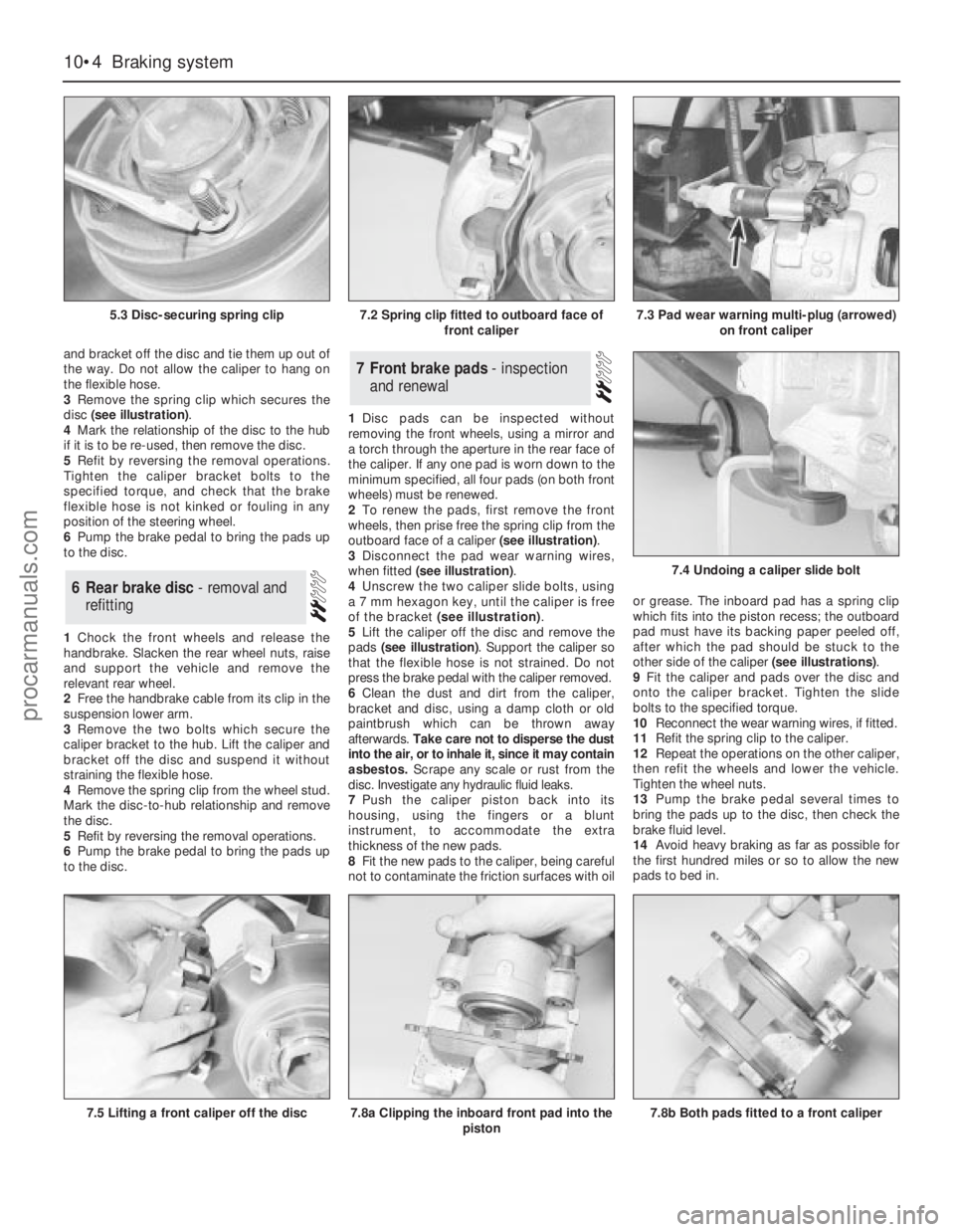

2To renew the pads, first remove the front

wheels, then prise free the spring clip from the

outboard face of a caliper (see illustration).

3Disconnect the pad wear warning wires,

when fitted (see illustration).

4Unscrew the two caliper slide bolts, using

a 7 mm hexagon key, until the caliper is free

of the bracket (see illustration).

5Lift the caliper off the disc and remove the

pads (see illustration). Support the caliper so

that the flexible hose is not strained. Do not

press the brake pedal with the caliper removed.

6Clean the dust and dirt from the caliper,

bracket and disc, using a damp cloth or old

paintbrush which can be thrown away

afterwards. Take care not to disperse the dust

into the air, or to inhale it, since it may contain

asbestos. Scrape any scale or rust from the

disc. Investigate any hydraulic fluid leaks.

7Push the caliper piston back into its

housing, using the fingers or a blunt

instrument, to accommodate the extra

thickness of the new pads.

8Fit the new pads to the caliper, being careful

not to contaminate the friction surfaces with oilor grease. The inboard pad has a spring clip

which fits into the piston recess; the outboard

pad must have its backing paper peeled off,

after which the pad should be stuck to the

other side of the caliper (see illustrations).

9Fit the caliper and pads over the disc and

onto the caliper bracket. Tighten the slide

bolts to the specified torque.

10Reconnect the wear warning wires, if fitted.

11Refit the spring clip to the caliper.

12Repeat the operations on the other caliper,

then refit the wheels and lower the vehicle.

Tighten the wheel nuts.

13Pump the brake pedal several times to

bring the pads up to the disc, then check the

brake fluid level.

14Avoid heavy braking as far as possible for

the first hundred miles or so to allow the new

pads to bed in.7Front brake pads - inspection

and renewal

6Rear brake disc - removal and

refitting

10•4Braking system

5.3 Disc-securing spring clip

7.5 Lifting a front caliper off the disc7.8a Clipping the inboard front pad into the

piston

7.4 Undoing a caliper slide bolt

7.8b Both pads fitted to a front caliper

7.2 Spring clip fitted to outboard face of

front caliper7.3 Pad wear warning multi-plug (arrowed)

on front caliper

procarmanuals.com

Page 136 of 255

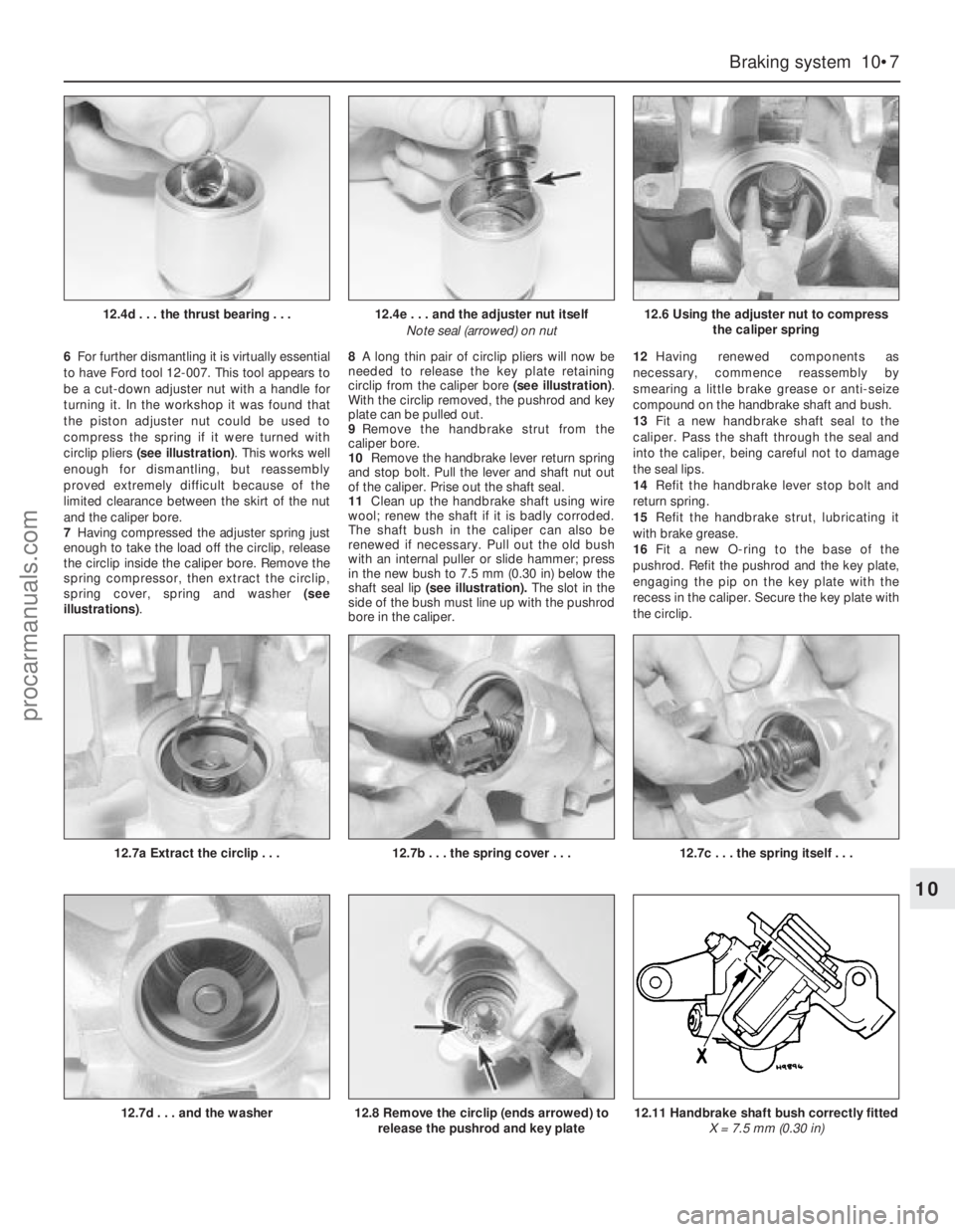

6For further dismantling it is virtually essential

to have Ford tool 12-007. This tool appears to

be a cut-down adjuster nut with a handle for

turning it. In the workshop it was found that

the piston adjuster nut could be used to

compress the spring if it were turned with

circlip pliers (see illustration). This works well

enough for dismantling, but reassembly

proved extremely difficult because of the

limited clearance between the skirt of the nut

and the caliper bore.

7Having compressed the adjuster spring just

enough to take the load off the circlip, release

the circlip inside the caliper bore. Remove the

spring compressor, then extract the circlip,

spring cover, spring and washer (see

illustrations). 8A long thin pair of circlip pliers will now be

needed to release the key plate retaining

circlip from the caliper bore (see illustration).

With the circlip removed, the pushrod and key

plate can be pulled out.

9Remove the handbrake strut from the

caliper bore.

10Remove the handbrake lever return spring

and stop bolt. Pull the lever and shaft nut out

of the caliper. Prise out the shaft seal.

11Clean up the handbrake shaft using wire

wool; renew the shaft if it is badly corroded.

The shaft bush in the caliper can also be

renewed if necessary. Pull out the old bush

with an internal puller or slide hammer; press

in the new bush to 7.5 mm (0.30 in) below the

shaft seal lip(seeillustration).The slot in the

side of the bush must line up with the pushrod

bore in the caliper.12Having renewed components as

necessary, commence reassembly by

smearing a little brake grease or anti-seize

compound on the handbrake shaft and bush.

13Fit a new handbrake shaft seal to the

caliper. Pass the shaft through the seal and

into the caliper, being careful not to damage

the seal lips.

14Refit the handbrake lever stop bolt and

return spring.

15Refit the handbrake strut, lubricating it

with brake grease.

16Fit a new O-ring to the base of the

pushrod. Refit the pushrod and the key plate,

engaging the pip on the key plate with the

recess in the caliper. Secure the key plate with

the circlip.

Braking system 10•7

10

12.4e . . . and the adjuster nut itself

Note seal (arrowed) on nut

12.7c . . . the spring itself . . .

12.6 Using the adjuster nut to compress

the caliper spring

12.7a Extract the circlip . . .12.7b . . . the spring cover . . .

12.7d . . . and the washer12.11 Handbrake shaft bush correctly fitted

X = 7.5 mm (0.30 in)12.8 Remove the circlip (ends arrowed) to

release the pushrod and key plate

12.4d . . . the thrust bearing . . .

procarmanuals.com

Page 138 of 255

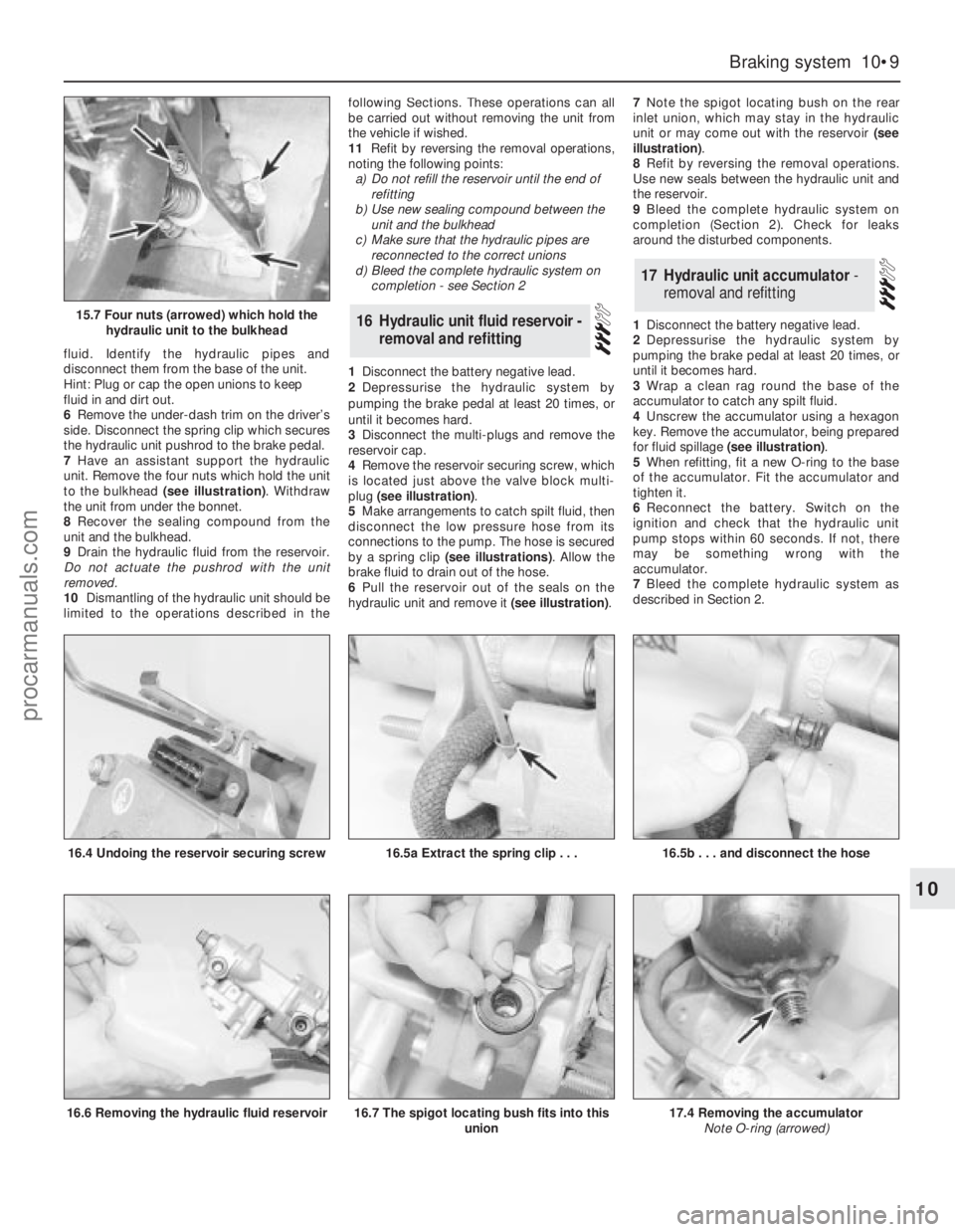

fluid. Identify the hydraulic pipes and

disconnect them from the base of the unit.

Hint: Plug or cap the open unions to keep

fluid in and dirt out.

6Remove the under-dash trim on the driver’s

side. Disconnect the spring clip which secures

the hydraulic unit pushrod to the brake pedal.

7Have an assistant support the hydraulic

unit. Remove the four nuts which hold the unit

to the bulkhead (see illustration). Withdraw

the unit from under the bonnet.

8Recover the sealing compound from the

unit and the bulkhead.

9Drain the hydraulic fluid from the reservoir.

Do not actuate the pushrod with the unit

removed.

10Dismantling of the hydraulic unit should be

limited to the operations described in thefollowing Sections. These operations can all

be carried out without removing the unit from

the vehicle if wished.

11Refit by reversing the removal operations,

noting the following points:

a)Do not refill the reservoir until the end of

refitting

b)Use new sealing compound between the

unit and the bulkhead

c)Make sure that the hydraulic pipes are

reconnected to the correct unions

d)Bleed the complete hydraulic system on

completion - see Section 2

1Disconnect the battery negative lead.

2Depressurise the hydraulic system by

pumping the brake pedal at least 20 times, or

until it becomes hard.

3Disconnect the multi-plugs and remove the

reservoir cap.

4Remove the reservoir securing screw, which

is located just above the valve block multi-

plug (see illustration).

5Make arrangements to catch spilt fluid, then

disconnect the low pressure hose from its

connections to the pump. The hose is secured

by a spring clip (see illustrations). Allow the

brake fluid to drain out of the hose.

6Pull the reservoir out of the seals on the

hydraulic unit and remove it (see illustration).7Note the spigot locating bush on the rear

inlet union, which may stay in the hydraulic

unit or may come out with the reservoir (see

illustration).

8Refit by reversing the removal operations.

Use new seals between the hydraulic unit and

the reservoir.

9Bleed the complete hydraulic system on

completion (Section 2). Check for leaks

around the disturbed components.

1Disconnect the battery negative lead.

2Depressurise the hydraulic system by

pumping the brake pedal at least 20 times, or

until it becomes hard.

3Wrap a clean rag round the base of the

accumulator to catch any spilt fluid.

4Unscrew the accumulator using a hexagon

key. Remove the accumulator, being prepared

for fluid spillage (see illustration).

5When refitting, fit a new O-ring to the base

of the accumulator. Fit the accumulator and

tighten it.

6Reconnect the battery. Switch on the

ignition and check that the hydraulic unit

pump stops within 60 seconds. If not, there

may be something wrong with the

accumulator.

7Bleed the complete hydraulic system as

described in Section 2.

17Hydraulic unit accumulator -

removal and refitting

16Hydraulic unit fluid reservoir -

removal and refitting

Braking system 10•9

10

15.7 Four nuts (arrowed) which hold the

hydraulic unit to the bulkhead

16.4 Undoing the reservoir securing screw16.5a Extract the spring clip . . .

16.6 Removing the hydraulic fluid reservoir

16.5b . . . and disconnect the hose

16.7 The spigot locating bush fits into this

union17.4 Removing the accumulator

Note O-ring (arrowed)

procarmanuals.com

Page 146 of 255

The steering gear is of rack-and-pinion type.

Power assistance is standard on V6 models

and optional on others. The power-assisted

steering gear has a “variable ratio” effect

which increases the steering ratio about the

straight-ahead position: this provides quick

lock-to-lock action without the penalty of

over-responsiveness in open road driving.

The steering wheel is adjustable both up-

and-down and fore-and-aft. Both steering

column and shaft are designed to collapse

under impact. The steering shaft is connected

to the pinion by an intermediate shaft, which

has a universal joint at its upper end and a

flexible coupling at the lower end.

Front suspension is independent, of the

MacPherson strut type, with coil springs and

concentric telescopic shock absorbers. The

struts are attached to the tops of the stub axle

carriers, which are located at their lower ends

by balljoints incorporated in the lower

suspension arms. The lower suspension arms

pivot at their inner ends, where they are

attached to a central crossmember. The anti-

roll bar is attached to the rear of the arms and

serves to control fore-and-aft movement as

well as reducing roll.

Suspension geometry has been designed to

give good steering “feel”, resistance to pulling

caused by uneven braking effort or tyre

deflation, and (in the case of manual steering)

acceptably low steering wheel effort at parking

speeds. Only toe is adjustable in service.

The rear suspension is also independent. It

is of the semi-trailing arm type, with coil

springs and separate telescopic shock

absorbers. An optionally-available ride height

control system keeps the rear suspension

height constant, regardless of vehicle load.

Both front and rear wheel bearings are of a

special taper-roller type and require no

periodic adjustment in service.1Refer to Chapter 1, Section 35, to check the

power steering fluid level.

2If the fluid level falls so low that air enters

the pump, or after component renewal, the

system must be bled as follows.

3Remove the reservoir filler cap. Top-up with

clean fluid to the appropriate “cold” level. It is

important that the fluid is free of air bubbles,

so do not shake the container when topping-

up, and pour the fluid slowly.

4Disconnect the negative LT lead from the

ignition coil. Have an assistant crank the

engine on the starter in two second bursts, at

the same time turning the steering wheel from

lock to lock. Keep the reservoir topped up

whilst this is going on.

5When air bubbles no longer appear in the

fluid, stop the cranking. Reconnect the coil

negative lead and run the engine for a few

seconds, then stop it and check the level

again. Refit the filler cap.

6Run the vehicle for a few miles to warm up

the fluid and expel any remaining air, then stop

the engine and make a final fluid level check.

Manual steering

1Position the steering in the straight-ahead

position, then remove the ignition key so that

the steering is locked.

2Slacken the front wheel nuts. Raise and

support the front of the vehicle and remove

the front wheels.

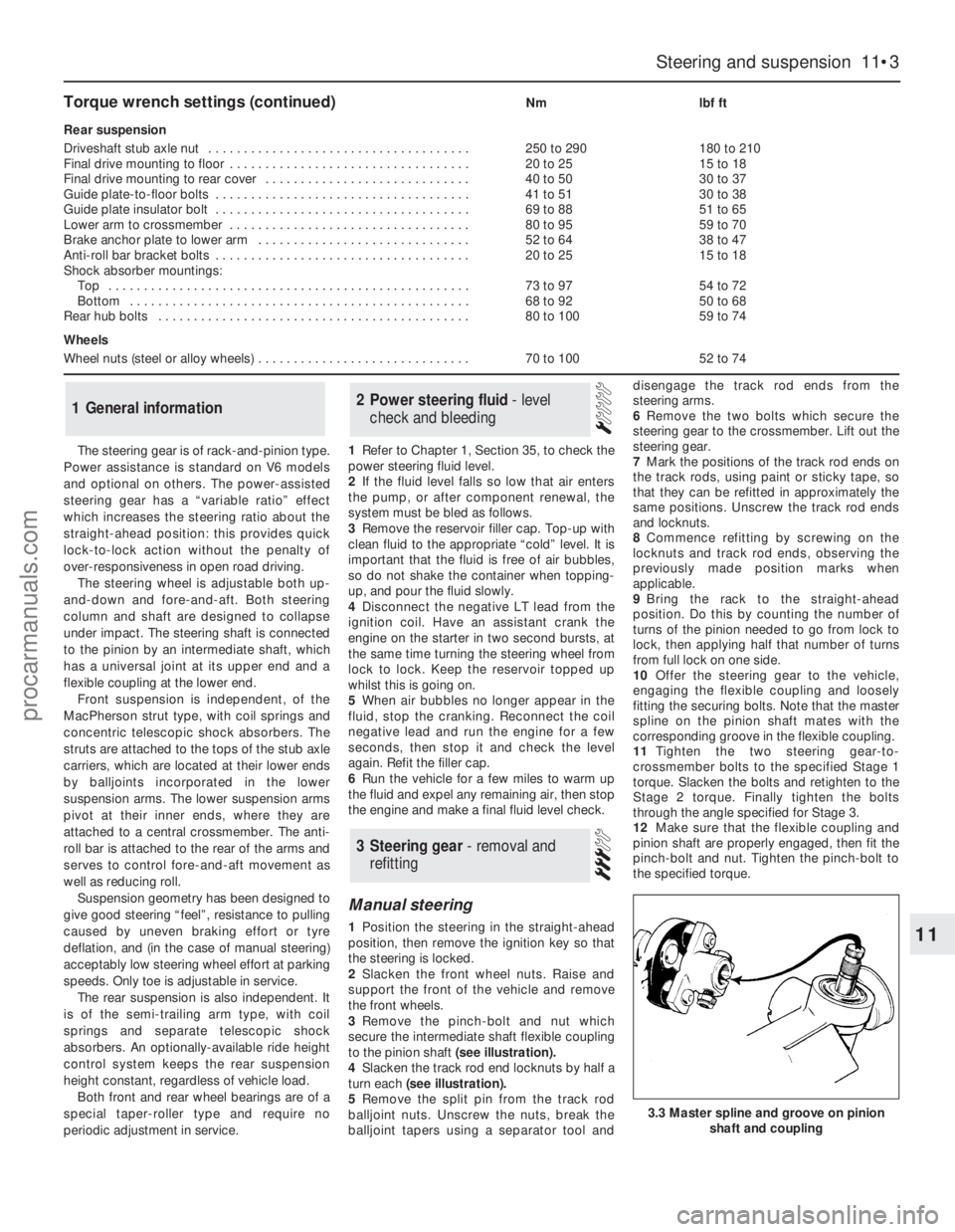

3Remove the pinch-bolt and nut which

secure the intermediate shaft flexible coupling

to the pinion shaft (see illustration).

4Slacken the track rod end locknuts by half a

turn each (see illustration).

5Remove the split pin from the track rod

balljoint nuts. Unscrew the nuts, break the

balljoint tapers using a separator tool anddisengage the track rod ends from the

steering arms.

6Remove the two bolts which secure the

steering gear to the crossmember. Lift out the

steering gear.

7Mark the positions of the track rod ends on

the track rods, using paint or sticky tape, so

that they can be refitted in approximately the

same positions. Unscrew the track rod ends

and locknuts.

8Commence refitting by screwing on the

locknuts and track rod ends, observing the

previously made position marks when

applicable.

9Bring the rack to the straight-ahead

position. Do this by counting the number of

turns of the pinion needed to go from lock to

lock, then applying half that number of turns

from full lock on one side.

10Offer the steering gear to the vehicle,

engaging the flexible coupling and loosely

fitting the securing bolts. Note that the master

spline on the pinion shaft mates with the

corresponding groove in the flexible coupling.

11Tighten the two steering gear-to-

crossmember bolts to the specified Stage 1

torque. Slacken the bolts and retighten to the

Stage 2 torque. Finally tighten the bolts

through the angle specified for Stage 3.

12Make sure that the flexible coupling and

pinion shaft are properly engaged, then fit the

pinch-bolt and nut. Tighten the pinch-bolt to

the specified torque.

3Steering gear - removal and

refitting

2Power steering fluid - level

check and bleeding1General information

Steering and suspension 11•3

11

3.3 Master spline and groove on pinion

shaft and coupling

Torque wrench settings (continued)Nmlbf ft

Rear suspension

Driveshaft stub axle nut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .250 to 290180 to 210

Final drive mounting to floor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 2515 to 18

Final drive mounting to rear cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40 to 5030 to 37

Guide plate-to-floor bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41 to 5130 to 38

Guide plate insulator bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69 to 8851 to 65

Lower arm to crossmember . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80 to 9559 to 70

Brake anchor plate to lower arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52 to 6438 to 47

Anti-roll bar bracket bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 2515 to 18

Shock absorber mountings:

Top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73 to 9754 to 72

Bottom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68 to 9250 to 68

Rear hub bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80 to 10059 to 74

Wheels

Wheel nuts (steel or alloy wheels) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70 to 10052 to 74

procarmanuals.com

Page 148 of 255

reference to horn switch plate retaining

screws. Note that the wheel is retained by a

bolt, not a nut as on earlier models. To gain

access to the bolt, prise out the horn button

and disconnect the wiring connectors.

1This operation is for correcting small errors

in steering wheel centralisation - up to 60°. For

larger errors, remove the steering wheel and

make a rough correction by repositioning the

wheel on refitting.

2Drive the vehicle in a straight line on a level

surface. Note the angle by which the steering

wheel deviates from the desired straight-

ahead position.

3Raise the front of the vehicle by driving it

onto ramps, or with a jack and axle stands

(see “Jacking”).

4Slacken both track rod end locknuts. Also

slacken the steering rack bellows outer clips.

5Make alignment marks between each track

rod end and its rod, so that the amount of

rotation applied can be accurately determined.

6Turn both track rodsin the same direction

to correct the steering wheel position. As a

rough guide, 19°of track rod rotation will

change the steering wheel position by 1°. To

correct error at the steering wheel, rotate both

track rods anti-clockwise (viewed from the

left-hand side of the vehicle), and the reverse

to correct as anti-clockwise errors. Both track

rods must be rotated by the same amount.

7Tighten the bellows clips and the track rod

end locknuts when adjustment is correct.

Lower the vehicle.

1Disconnect the battery negative lead.

2Position the steering in the straight-ahead

position.

3Remove the steering wheel. This is not

essential, but will improve access.

4Working under the bonnet, disconnect the

intermediate shaft universal joint from the

steering column shaft.5Remove the steering column shrouds and

disconnect the switch multi-plugs. Do not

forget the ignition/starter switch.

6Disconnect the bonnet release cable from the

operating lever on the underside of the column.

7Prise out the driver’s side air vent. Remove

the under-dash insulation and trim panel on

the driver’s side, unclipping the bulb failure

module, where applicable.

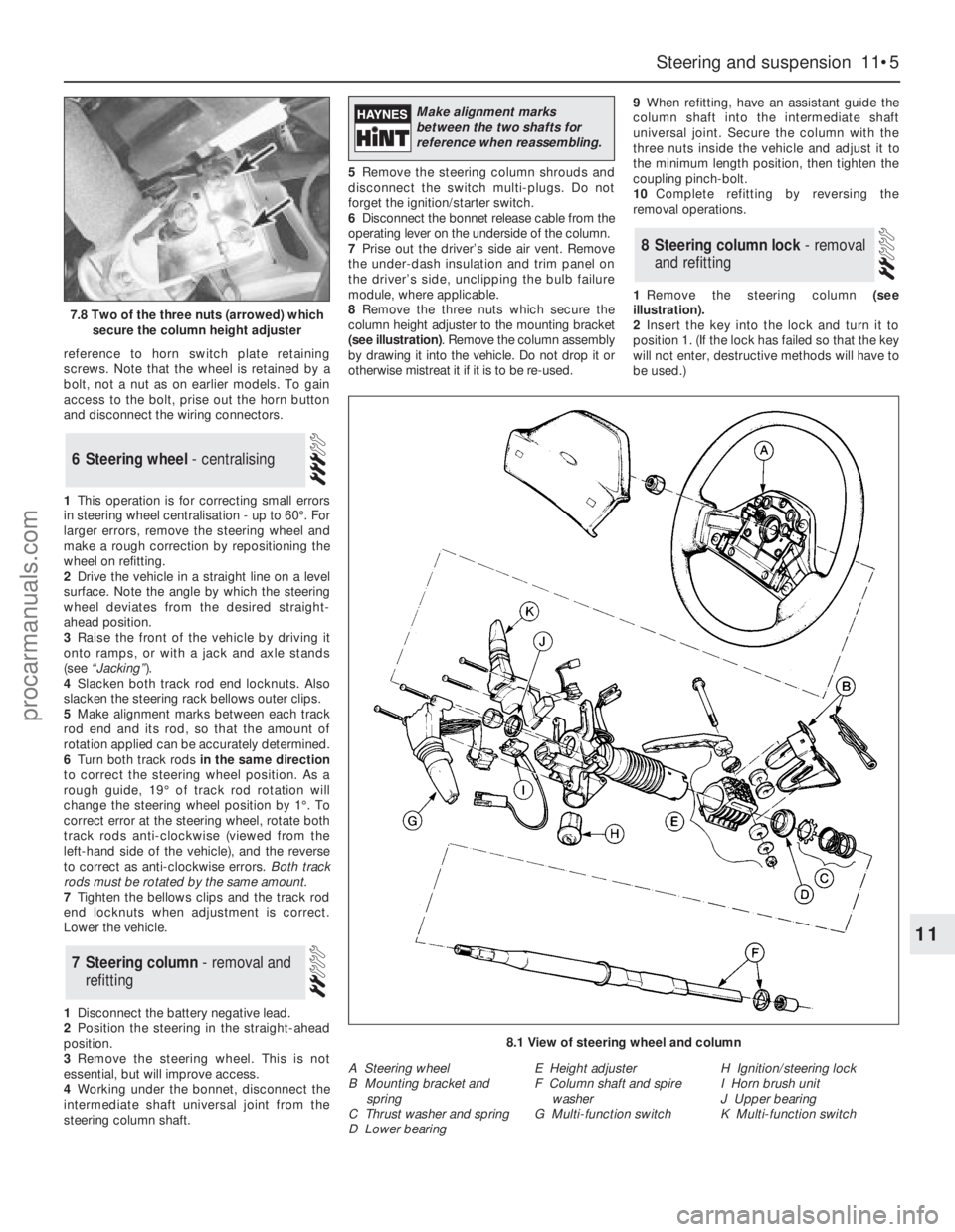

8Remove the three nuts which secure the

column height adjuster to the mounting bracket

(see illustration). Remove the column assembly

by drawing it into the vehicle. Do not drop it or

otherwise mistreat it if it is to be re-used.9When refitting, have an assistant guide the

column shaft into the intermediate shaft

universal joint. Secure the column with the

three nuts inside the vehicle and adjust it to

the minimum length position, then tighten the

coupling pinch-bolt.

10Complete refitting by reversing the

removal operations.

1Remove the steering column (see

illustration).

2Insert the key into the lock and turn it to

position 1. (If the lock has failed so that the key

will not enter, destructive methods will have to

be used.)

8Steering column lock - removal

and refitting

7Steering column - removal and

refitting

6Steering wheel - centralising

Steering and suspension 11•5

11

7.8 Two of the three nuts (arrowed) which

secure the column height adjuster

8.1 View of steering wheel and column

A Steering wheel

B Mounting bracket and

spring

C Thrust washer and spring

D Lower bearingE Height adjuster

F Column shaft and spire

washer

G Multi-function switchH Ignition/steering lock

I Horn brush unit

J Upper bearing

K Multi-function switch

Make alignment marks

between the two shafts for

reference when reassembling.

procarmanuals.com

Page 149 of 255

3Depress the locking button with a small

screwdriver. Draw the lock barrel out of its

housing using the key (see illustration).

4Refit by reversing the removal operations.

1The intermediate shaft and flexible coupling

are not available separately, and so must be

renewed as a unit.

2Disconnect the battery negative lead.

3Position the steering straight-ahead.

4Remove the pinch-bolts which secure the

upper and lower ends of the intermediate

shaft. Free the universal joint from the column

shaft, then pull the flexible coupling off the

pinion shaft.

5When refitting, engage the master spline on

the pinion shaft with the groove in the flexible

coupling.

6Tighten the pinch-bolts to the specified

torque.

7Reconnect the battery.

Refer to Chapter 1, Section 21.

All engines except DOHC

1Disconnect the battery negative lead.

2Wipe clean around the unions, then

disconnect the high pressure and return pipes

from the pump and the reservoir. Be prepared

for fluid spillage; take steps to keep fluid out of

the alternator.

3Remove the pump drivebelt(s).

4Remove the pump mounting, pivot and

adjustment bolts (as applicable) and lift the

pump from the engine (see illustration).

5If a new pump is to be fitted, recover the

pulley and mounting plate from the old pump.6Refit by reversing the removal operations.

Adjust the drivebelt tension on completion and

bleed the steering hydraulic system.

DOHC engines

7The pump is mounted on a bracket on the

front right-hand side of the cylinder block. To

improve access to the pump, firmly apply the

handbrake then jack up the front of the car

and support it securely on axle stands (see

“Jacking”).

8Place a suitable container under the pump,

unscrew the fluid pipe unions, and drain the

fluid.

9Remove the drivebelt with reference to

Chapter 1.

10Prevent the pulley from rotating using a

strap wrench (which can be improvised using

an old drivebelt and a large socket and

wrench), and unscrew the three pulley

securing bolts (see illustration). Withdraw the

pulley.

11Unscrew the three pump securing bolts

from the front of the pump bracket, and the

single bolt from the rear of the bracket, and

withdraw the pump (see illustration).

12Refitting is a reversal of removal, bearing

in mind the following points:

a)Reconnect the fluid unions using new O-

rings.

b)On completion, top-up and bleed the

power steering fluid circuit.1Disconnect the battery negative lead.

2Clean around the hose unions on the

steering gear. Remove the single securing

bolt, withdraw the hoses and catch the fluid

which will drain from the reservoir.

3Clean around the hose unions on the pump.

Disconnect the unions and remove the hoses.

4Refit in the reverse order to removal, using

new O-rings.

5Top-up the steering fluid and bleed the

system.

1Slacken the front wheel nuts, raise and

support the vehicle and remove the front

wheel on the side concerned.

2Slacken the track rod end locknut by half a

turn.

3Remove the split pin from the track rod end

balljoint nut. Unscrew the nut a few turns (see

illustration).

4Break the balljoint taper with a proprietary

balljoint separator (see illustration). Remove

the separator and the nut and disengage the

track rod end from the steering arm.

5Unscrew the track rod end from the track

rod, being careful not to disturb the locknut.

13Track rod end - removal and

refitting

12Power steering hoses -

removal and refitting

11Power steering pump -

removal and refitting

10Power steering pump

drivebelt - removal, refitting

and tensioning

9Steering intermediate shaft

and flexible coupling - removal

and refitting

11•6Steering and suspension

8.3 Depress the column lock locking button

11.11 . . . for access to the front pump

securing bolts (arrowed)13.3 Track rod end balljoint nut unscrewed

11.4 Steering pump pivot bolt (arrowed) -

V6 model shown11.10 Unbolt the power steering pump

pulley . . .

procarmanuals.com

Page 153 of 255

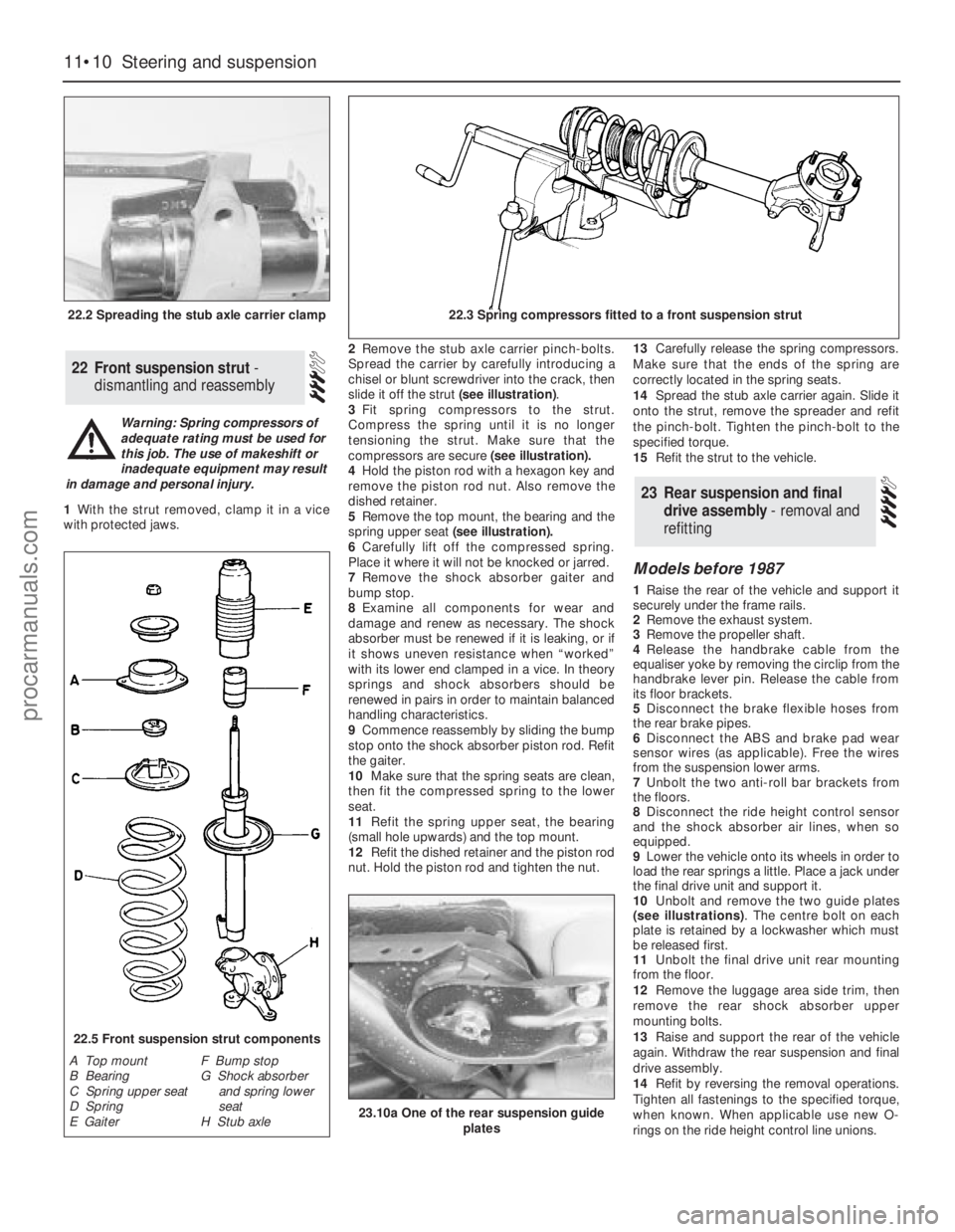

1With the strut removed, clamp it in a vice

with protected jaws.2Remove the stub axle carrier pinch-bolts.

Spread the carrier by carefully introducing a

chisel or blunt screwdriver into the crack, then

slide it off the strut (see illustration).

3Fit spring compressors to the strut.

Compress the spring until it is no longer

tensioning the strut. Make sure that the

compressors are secure (see illustration).

4Hold the piston rod with a hexagon key and

remove the piston rod nut. Also remove the

dished retainer.

5Remove the top mount, the bearing and the

spring upper seat(see illustration).

6Carefully lift off the compressed spring.

Place it where it will not be knocked or jarred.

7Remove the shock absorber gaiter and

bump stop.

8Examine all components for wear and

damage and renew as necessary. The shock

absorber must be renewed if it is leaking, or if

it shows uneven resistance when “worked”

with its lower end clamped in a vice. In theory

springs and shock absorbers should be

renewed in pairs in order to maintain balanced

handling characteristics.

9Commence reassembly by sliding the bump

stop onto the shock absorber piston rod. Refit

the gaiter.

10Make sure that the spring seats are clean,

then fit the compressed spring to the lower

seat.

11Refit the spring upper seat, the bearing

(small hole upwards) and the top mount.

12Refit the dished retainer and the piston rod

nut. Hold the piston rod and tighten the nut.13Carefully release the spring compressors.

Make sure that the ends of the spring are

correctly located in the spring seats.

14Spread the stub axle carrier again. Slide it

onto the strut, remove the spreader and refit

the pinch-bolt. Tighten the pinch-bolt to the

specified torque.

15Refit the strut to the vehicle.

Models before 1987

1Raise the rear of the vehicle and support it

securely under the frame rails.

2Remove the exhaust system.

3Remove the propeller shaft.

4Release the handbrake cable from the

equaliser yoke by removing the circlip from the

handbrake lever pin. Release the cable from

its floor brackets.

5Disconnect the brake flexible hoses from

the rear brake pipes.

6Disconnect the ABS and brake pad wear

sensor wires (as applicable). Free the wires

from the suspension lower arms.

7Unbolt the two anti-roll bar brackets from

the floors.

8Disconnect the ride height control sensor

and the shock absorber air lines, when so

equipped.

9Lower the vehicle onto its wheels in order to

load the rear springs a little. Place a jack under

the final drive unit and support it.

10Unbolt and remove the two guide plates

(see illustrations). The centre bolt on each

plate is retained by a lockwasher which must

be released first.

11Unbolt the final drive unit rear mounting

from the floor.

12Remove the luggage area side trim, then

remove the rear shock absorber upper

mounting bolts.

13Raise and support the rear of the vehicle

again. Withdraw the rear suspension and final

drive assembly.

14Refit by reversing the removal operations.

Tighten all fastenings to the specified torque,

when known. When applicable use new O-

rings on the ride height control line unions.

23Rear suspension and final

drive assembly - removal and

refitting

22Front suspension strut -

dismantling and reassembly

11•10Steering and suspension

22.2 Spreading the stub axle carrier clamp22.3 Spring compressors fitted to a front suspension strut

22.5 Front suspension strut components

A Top mount

B Bearing

C Spring upper seat

D Spring

E GaiterF Bump stop

G Shock absorber

and spring lower

seat

H Stub axle

Warning: Spring compressors of

adequate rating must be used for

this job. The use of makeshift or

inadequate equipment may result

in damage and personal injury.

23.10a One of the rear suspension guide

plates

procarmanuals.com

Page 159 of 255

important also to keep watch on those parts of

the vehicle not immediately visible, for

instance the underside, inside all the wheel

arches, and the lower part of the engine

compartment.

The basic maintenance routine for the

bodywork is washing - preferably with a lot of

water, from a hose. This will remove all the

loose solids which may have stuck to the

vehicle. It is important to flush these off in

such a way as to prevent grit from scratching

the finish. The wheel arches and underframe

need washing in the same way, to remove any

accumulated mud, which will retain moisture

and tend to encourage rust. Paradoxically

enough, the best time to clean the underframe

and wheel arches is in wet weather, when the

mud is thoroughly wet and soft. In very wet

weather, the underframe is usually cleaned of

large accumulations automatically, and this is

a good time for inspection.

Periodically, except on vehicles with a wax-

based underbody protective coating, it is a

good idea to have the whole of the underframe

of the vehicle steam-cleaned, engine

compartment included, so that a thorough

inspection can be carried out to see what

minor repairs and renovations are necessary.

Steam-cleaning is available at many garages,

and is necessary for the removal of the

accumulation of oily grime, which sometimes

is allowed to become thick in certain areas. If

steam-cleaning facilities are not available,

there are some excellent grease solvents

available which can be brush-applied; the dirt

can then be simply hosed off. Note that these

methods should not be used on vehicles with

wax-based underbody protective coating, or

the coating will be removed. Such vehicles

should be inspected annually, preferably just

prior to Winter, when the underbody should be

washed down, and any damage to the wax

coating repaired. Ideally, a completely fresh

coat should be applied. It would also be worth

considering the use of such wax-based

protection for injection into door panels, sills,

box sections, etc, as an additional safeguard

against rust damage, where such protection is

not provided by the vehicle manufacturer.

After washing paintwork, wipe off with a

chamois leather to give an unspotted clear

finish. A coat of clear protective wax polish will

give added protection against chemical

pollutants in the air. If the paintwork sheen has

dulled or oxidised, use a cleaner/polisher

combination to restore the brilliance of the

shine. This requires a little effort, but such

dulling is usually caused because regular

washing has been neglected. Care needs to

be taken with metallic paintwork, as special

non-abrasive cleaner/polisher is required to

avoid damage to the finish. Always check that

the door and ventilator opening drain holes

and pipes are completely clear, so that water

can be drained out. Brightwork should be

treated in the same way as paintwork.

Windscreens and windows can be kept clear

of the smeary film which often appears, by theuse of proprietary glass cleaner. Never use

any form of wax or other body or chromium

polish on glass.

Mats and carpets should be brushed or

vacuum-cleaned regularly, to keep them free

of grit. If they are badly stained, remove them

from the vehicle for scrubbing or sponging,

and make quite sure they are dry before

refitting. Seats and interior trim panels can be

kept clean by wiping with a damp cloth. If they

do become stained (which can be more

apparent on light-coloured upholstery), use a

little liquid detergent and a soft nail brush to

scour the grime out of the grain of the material.

Do not forget to keep the headlining clean in

the same way as the upholstery. When using

liquid cleaners inside the vehicle, do not over-

wet the surfaces being cleaned. Excessive

damp could get into the seams and padded

interior, causing stains, offensive odours or

even rot. If the inside of the vehicle gets wet

accidentally, it is worthwhile taking some

trouble to dry it out properly, particularly

where carpets are involved. Do not leave oil or

electric heaters inside the vehicle for this

purpose.

Repairs of minor scratches in

bodywork

If the scratch is very superficial, and does

not penetrate to the metal of the bodywork,

repair is very simple. Lightly rub the area of the

scratch with a paintwork renovator, or a very

fine cutting paste, to remove loose paint from

the scratch, and to clear the surrounding

bodywork of wax polish. Rinse the area with

clean water.

Apply touch-up paint to the scratch using a

fine paint brush; continue to apply fine layers

of paint until the surface of the paint in the

scratch is level with the surrounding

paintwork. Allow the new paint at least two

weeks to harden, then blend it into the

surrounding paintwork by rubbing the scratch

area with a paintwork renovator or a very fine

cutting paste. Finally, apply wax polish.

Where the scratch has penetrated right

through to the metal of the bodywork, causing

the metal to rust, a different repair technique is

required. Remove any loose rust from the

bottom of the scratch with a penknife, then

apply rust-inhibiting paint to prevent the

formation of rust in the future. Using a rubber

or nylon applicator, fill the scratch with

bodystopper paste. If required, this paste can

be mixed with cellulose thinners to provide a

very thin paste which is ideal for filling narrow

scratches. Before the stopper-paste in the

scratch hardens, wrap a piece of smoothcotton rag around the top of a finger. Dip the

finger in cellulose thinners, and quickly sweep

it across the surface of the stopper-paste in

the scratch; this will ensure that the surface of

the stopper-paste is slightly hollowed. The

scratch can now be painted over as described

earlier in this Section.

Repairs of dents in bodywork

When deep denting of the vehicle’s

bodywork has taken place, the first task is to

pull the dent out, until the affected bodywork

almost attains its original shape. There is little

point in trying to restore the original shape

completely, as the metal in the damaged area

will have stretched on impact, and cannot be

reshaped fully to its original contour. It is

better to bring the level of the dent up to a

point which is about 3 mm below the level of

the surrounding bodywork. In cases where the

dent is very shallow anyway, it is not worth

trying to pull it out at all. If the underside of the

dent is accessible, it can be hammered out

gently from behind, using a mallet with a

wooden or plastic head. Whilst doing this,

hold a suitable block of wood firmly against

the outside of the panel, to absorb the impact

from the hammer blows and thus prevent a

large area of the bodywork from being “belled-

out”.

Should the dent be in a section of the

bodywork which has a double skin, or some

other factor making it inaccessible from

behind, a different technique is called for. Drill

several small holes through the metal inside

the area - particularly in the deeper section.

Then screw long self-tapping screws into the

holes, just sufficiently for them to gain a good

purchase in the metal. Now the dent can be

pulled out by pulling on the protruding heads

of the screws with a pair of pliers.

The next stage of the repair is the removal

of the paint from the damaged area, and from

an inch or so of the surrounding “sound”

bodywork. This is accomplished most easily

by using a wire brush or abrasive pad on a

power drill, although it can be done just as

effectively by hand, using sheets of abrasive

paper. To complete the preparation for filling,

score the surface of the bare metal with a

screwdriver or the tang of a file, or

alternatively, drill small holes in the affected

area. This will provide a really good “key” for

the filler paste.

To complete the repair, see the Section on

filling and respraying.

Repairs of rust holes or gashes in

bodywork

Remove all paint from the affected area, and

from an inch or so of the surrounding “sound”

bodywork, using an abrasive pad or a wire

brush on a power drill. If these are not

available, a few sheets of abrasive paper will

do the job most effectively. With the paint

removed, you will be able to judge the severity

of the corrosion, and therefore decide whether

to renew the whole panel (if this is possible) or

4Minor body damage - repair

3Maintenance - upholstery and

carpets

12•2Bodywork and fittings

procarmanuals.com

Page 164 of 255

the door through the large cut-out. Further

displacement or removal of the foamrubber

sheet may be necessary.

7Refit in the reverse order to removal, noting

the following points:

a)Apply a little grease to the interior handle

rods where they pass through the plastic

bushes

b)When securing the interior handle, have

the locking lever in the “unlocked”

position, hold the assembly forwards as

far as itwill go and tighten the securing

screw

c)Check all functions before refitting the trim

panel.

Door weatherstrip

1Open the door and remove the weatherstrip

securing screw from the latch end. In the case

of the rear door, also remove the screw from

the hinge end.

2Carefully lift the latch end of the

weatherstrip and pull it off the door.

3Refit by reversing the removal operations,

using your palm to seat the weatherstrip.

Aperture weatherstrip

4Open the door. Remove the scuff plate

securing screws from the bottom of the door

aperture.

5Pull the old weatherstrip out of the door

aperture.

6Fit the new weatherstrip, starting at the

right-angled corner at the top. Fit the

weatherstrip to the other corners and bends,

leaving the straight sections until last.

7Refit the scuff, plate securing screws.

All models except Estate

1Disconnect the battery negative lead.

2Remove the tailgate interior trim panel,

which is secured by eleven screws.

3Remove the six nuts which secure the

tailgate handle. Remove the handle and

recover the gasket.

4Disconnect the tailgate lock switch multi-

plug. Release the switch locking tab and

remove the switch.

5Disconnect the operating rod from the lock

lever (see illustration). Extract the U-clip and

remove the lock barrel.

6Refit by reversing the removal operations.

Estate models

7The tailgate lock barrel can be removed and

refitted as described above, bearing in mind

the notes made in Section 8 when removing

the interior trim panels and noting that the lock

assembly is retained by two Torx bolts.1Open up the boot lid and remove the trim

panel from the inside of the lid.

2Unscrew the four boot lid exterior trim

retaining panel bolts (two situated on each

side of the lock) then carefully prise out the

nine panel retaining clips and remove the

panel from the boot lid.

3Undo the two lock barrel retaining nuts then

partially withdraw the barrel and disconnect the

wiring connector and lock operating rod from

the barrel. Remove the lock barrel from the lid.

4Undo the four lid lock retaining bolts then

withdraw the lock assembly from the boot lid,

disconnecting the central locking and warning

switch wiring plugs (see illustration).

5Refitting is a reversal of the removal

procedure tightening all retaining bolts

securely. On completion check the operation

of the boot lid lock and lock barrel before

refitting the trim panel.

1Disconnect the battery negative lead.

2Remove the tailgate interior trim panel,

which is secured by eleven screws.

3Unhook the operating rod from the tailgate

latch. Also disconnect the lock switch and

solenoid multi-plugs.4Remove the three bolts which secure the

tailgate latch. Remove the latch.

5Refit by reversing the removal operations.

1Open the tailgate and support it with a piece

of wood.

2Release the strut from its mountings by

raising the spring clips with a small

screwdriver, then pulling the strut off the ball-

stands. Do not raise the clips more than 4 mm

(0.16 in) if the strut is to be re-used.

3Do not attempt to dismantle a strut, and

dispose of it safely. It contains gas under

pressure.

4To refit a strut, position it over the ball-

studs. Push on each end in turn until it snaps

home.

1Open the fuel filler flap. Remove the key.

2Apply pressure to the lock barrel at the key

slot, using the thumb of one hand. With the

other hand insert a screwdriver into the cut-

out in the filler flap to release the lock barrel

retaining spring. As the spring is released,

thumb pressure will eject the lock barrel into

the petrol tank (see illustration).

3To refit, push the lock barrel into the flap

until the retaining spring clicks home.

Front door

1Open the door and remove the screws

which secure the front and rear edges of the

trim panel (see illustration).

2Remove the two screws from under the

covers on the door pocket. Unclip and remove

the pocket.

3On models with electrically-operated

windows and mirrors, prise out and disconnect

the window and mirror switches. The window

switch multi-plugs on the driver’s side are

22Door interior trim panel -

removal and refitting

21Fuel filler lock barrel -

removal and refitting

20Tailgate strut - removal and

refitting

19Tailgate latch assembly -

removal and refitting

18Boot lid lock barrel - removal

and refitting

17Tailgate lock barrel - removal

and refitting

16Door weatherstrip - removal

and refitting

Bodywork and fittings 12•7

12

17.5 Operating rod (arrowed) connected to

tailgate lock lever18.4 Boot lid lock retaining bolts (arrowed)

- Saloon models

21.2 Removing the fuel filler flap lock barrel

procarmanuals.com

Page 167 of 255

Later models

7The radiator grille of these models can be

removed and refitted as described above,

noting that it will also be necessary to remove

the headlamp wiper arms (where fitted) before

the grille can be removed. To remove a wiper

arm, lift the cover to gain access to the

retaining nut then undo the nut and pull the

arm off the spindle (see illustration). On

refitting, position the arm so that it is correctly

aligned with the base of the headlamp and

locate it on the spindle splines. Refit the

spindle nut and tighten it securely.

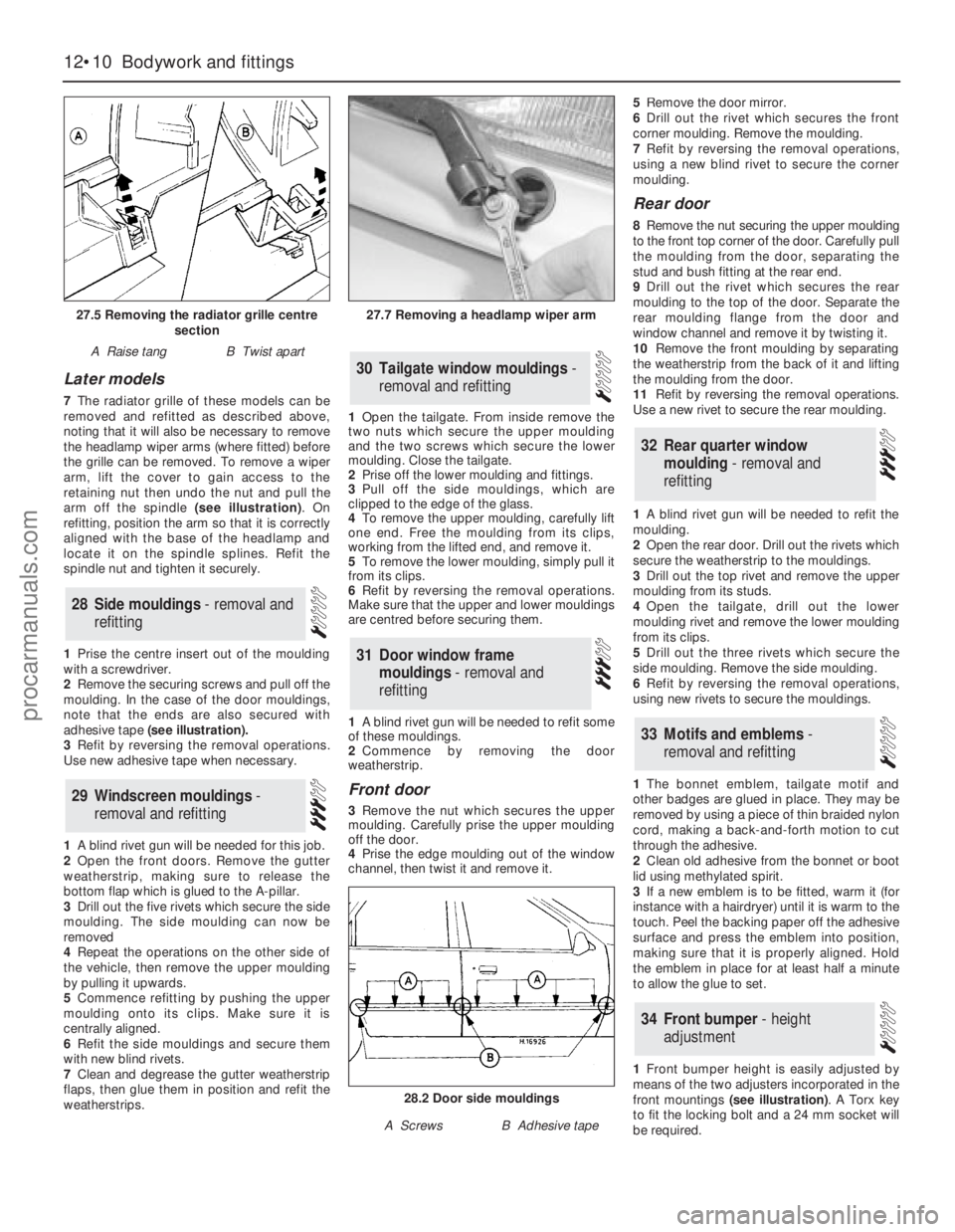

1Prise the centre insert out of the moulding

with a screwdriver.

2Remove the securing screws and pull off the

moulding. In the case of the door mouldings,

note that the ends are also secured with

adhesive tape (see illustration).

3Refit by reversing the removal operations.

Use new adhesive tape when necessary.

1A blind rivet gun will be needed for this job.

2Open the front doors. Remove the gutter

weatherstrip, making sure to release the

bottom flap which is glued to the A-pillar.

3Drill out the five rivets which secure the side

moulding. The side moulding can now be

removed

4Repeat the operations on the other side of

the vehicle, then remove the upper moulding

by pulling it upwards.

5Commence refitting by pushing the upper

moulding onto its clips. Make sure it is

centrally aligned.

6Refit the side mouldings and secure them

with new blind rivets.

7Clean and degrease the gutter weatherstrip

flaps, then glue them in position and refit the

weatherstrips.1Open the tailgate. From inside remove the

two nuts which secure the upper moulding

and the two screws which secure the lower

moulding. Close the tailgate.

2Prise off the lower moulding and fittings.

3Pull off the side mouldings, which are

clipped to the edge of the glass.

4To remove the upper moulding, carefully lift

one end. Free the moulding from its clips,

working from the lifted end, and remove it.

5To remove the lower moulding, simply pull it

from its clips.

6Refit by reversing the removal operations.

Make sure that the upper and lower mouldings

are centred before securing them.

1A blind rivet gun will be needed to refit some

of these mouldings.

2Commence by removing the door

weatherstrip.

Front door

3Remove the nut which secures the upper

moulding. Carefully prise the upper moulding

off the door.

4Prise the edge moulding out of the window

channel, then twist it and remove it. 5Remove the door mirror.

6Drill out the rivet which secures the front

corner moulding. Remove the moulding.

7Refit by reversing the removal operations,

using a new blind rivet to secure the corner

moulding.

Rear door

8Remove the nut securing the upper moulding

to the front top corner of the door. Carefully pull

the moulding from the door, separating the

stud and bush fitting at the rear end.

9Drill out the rivet which secures the rear

moulding to the top of the door. Separate the

rear moulding flange from the door and

window channel and remove it by twisting it.

10Remove the front moulding by separating

the weatherstrip from the back of it and lifting

the moulding from the door.

11Refit by reversing the removal operations.

Use a new rivet to secure the rear moulding.

1A blind rivet gun will be needed to refit the

moulding.

2Open the rear door. Drill out the rivets which

secure the weatherstrip to the mouldings.

3Drill out the top rivet and remove the upper

moulding from its studs.

4Open the tailgate, drill out the lower

moulding rivet and remove the lower moulding

from its clips.

5Drill out the three rivets which secure the

side moulding. Remove the side moulding.

6Refit by reversing the removal operations,

using new rivets to secure the mouldings.

1The bonnet emblem, tailgate motif and

other badges are glued in place. They may be

removed by using a piece of thin braided nylon

cord, making a back-and-forth motion to cut

through the adhesive.

2Clean old adhesive from the bonnet or boot

lid using methylated spirit.

3If a new emblem is to be fitted, warm it (for

instance with a hairdryer) until it is warm to the

touch. Peel the backing paper off the adhesive

surface and press the emblem into position,

making sure that it is properly aligned. Hold

the emblem in place for at least half a minute

to allow the glue to set.

1Front bumper height is easily adjusted by

means of the two adjusters incorporated in the

front mountings (see illustration). A Torx key

to fit the locking bolt and a 24 mm socket will

be required.

34Front bumper - height

adjustment

33Motifs and emblems -

removal and refitting

32Rear quarter window

moulding - removal and

refitting

31Door window frame

mouldings - removal and

refitting

30Tailgate window mouldings -

removal and refitting

29Windscreen mouldings -

removal and refitting

28Side mouldings - removal and

refitting

12•10Bodywork and fittings

27.5 Removing the radiator grille centre

section

A Raise tangB Twist apart

27.7 Removing a headlamp wiper arm

28.2 Door side mouldings

A ScrewsB Adhesive tape

procarmanuals.com