battery FORD GRANADA 1985 Service Manual Online

[x] Cancel search | Manufacturer: FORD, Model Year: 1985, Model line: GRANADA, Model: FORD GRANADA 1985Pages: 255, PDF Size: 14.98 MB

Page 149 of 255

3Depress the locking button with a small

screwdriver. Draw the lock barrel out of its

housing using the key (see illustration).

4Refit by reversing the removal operations.

1The intermediate shaft and flexible coupling

are not available separately, and so must be

renewed as a unit.

2Disconnect the battery negative lead.

3Position the steering straight-ahead.

4Remove the pinch-bolts which secure the

upper and lower ends of the intermediate

shaft. Free the universal joint from the column

shaft, then pull the flexible coupling off the

pinion shaft.

5When refitting, engage the master spline on

the pinion shaft with the groove in the flexible

coupling.

6Tighten the pinch-bolts to the specified

torque.

7Reconnect the battery.

Refer to Chapter 1, Section 21.

All engines except DOHC

1Disconnect the battery negative lead.

2Wipe clean around the unions, then

disconnect the high pressure and return pipes

from the pump and the reservoir. Be prepared

for fluid spillage; take steps to keep fluid out of

the alternator.

3Remove the pump drivebelt(s).

4Remove the pump mounting, pivot and

adjustment bolts (as applicable) and lift the

pump from the engine (see illustration).

5If a new pump is to be fitted, recover the

pulley and mounting plate from the old pump.6Refit by reversing the removal operations.

Adjust the drivebelt tension on completion and

bleed the steering hydraulic system.

DOHC engines

7The pump is mounted on a bracket on the

front right-hand side of the cylinder block. To

improve access to the pump, firmly apply the

handbrake then jack up the front of the car

and support it securely on axle stands (see

“Jacking”).

8Place a suitable container under the pump,

unscrew the fluid pipe unions, and drain the

fluid.

9Remove the drivebelt with reference to

Chapter 1.

10Prevent the pulley from rotating using a

strap wrench (which can be improvised using

an old drivebelt and a large socket and

wrench), and unscrew the three pulley

securing bolts (see illustration). Withdraw the

pulley.

11Unscrew the three pump securing bolts

from the front of the pump bracket, and the

single bolt from the rear of the bracket, and

withdraw the pump (see illustration).

12Refitting is a reversal of removal, bearing

in mind the following points:

a)Reconnect the fluid unions using new O-

rings.

b)On completion, top-up and bleed the

power steering fluid circuit.1Disconnect the battery negative lead.

2Clean around the hose unions on the

steering gear. Remove the single securing

bolt, withdraw the hoses and catch the fluid

which will drain from the reservoir.

3Clean around the hose unions on the pump.

Disconnect the unions and remove the hoses.

4Refit in the reverse order to removal, using

new O-rings.

5Top-up the steering fluid and bleed the

system.

1Slacken the front wheel nuts, raise and

support the vehicle and remove the front

wheel on the side concerned.

2Slacken the track rod end locknut by half a

turn.

3Remove the split pin from the track rod end

balljoint nut. Unscrew the nut a few turns (see

illustration).

4Break the balljoint taper with a proprietary

balljoint separator (see illustration). Remove

the separator and the nut and disengage the

track rod end from the steering arm.

5Unscrew the track rod end from the track

rod, being careful not to disturb the locknut.

13Track rod end - removal and

refitting

12Power steering hoses -

removal and refitting

11Power steering pump -

removal and refitting

10Power steering pump

drivebelt - removal, refitting

and tensioning

9Steering intermediate shaft

and flexible coupling - removal

and refitting

11•6Steering and suspension

8.3 Depress the column lock locking button

11.11 . . . for access to the front pump

securing bolts (arrowed)13.3 Track rod end balljoint nut unscrewed

11.4 Steering pump pivot bolt (arrowed) -

V6 model shown11.10 Unbolt the power steering pump

pulley . . .

procarmanuals.com

Page 150 of 255

6When refitting, screw the track rod end onto

the track rod as far as the locknut, then back it

off half a turn.

7Insert the ball-pin into the steering arm.

Tighten the balljoint nut to the specified torque

and secure with a new split pin. Nip up the

track rod end locknut, but do not tighten it fully

yet.

8Refit the roadwheel, lower the vehicle and

tighten the wheel nuts to the specified torque.

9Check the toe setting as described in the

following Section. (This may not be strictly

necessary if the same track rod end has been

refitted, but is certainly advisable if any

components have been renewed.)

10Tighten the track rod end locknut when

toe is correct.

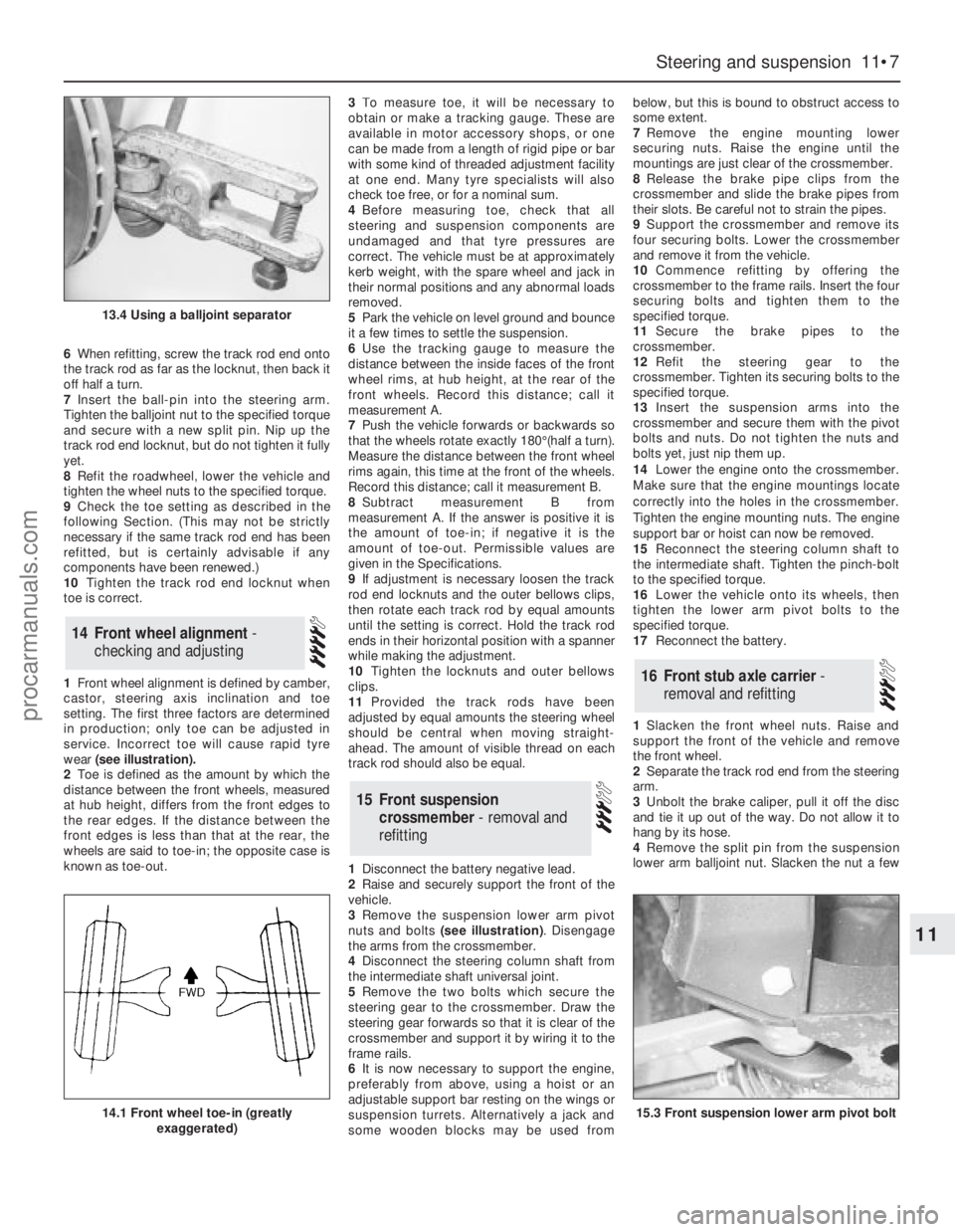

1Front wheel alignment is defined by camber,

castor, steering axis inclination and toe

setting. The first three factors are determined

in production; only toe can be adjusted in

service. Incorrect toe will cause rapid tyre

wear (see illustration).

2Toe is defined as the amount by which the

distance between the front wheels, measured

at hub height, differs from the front edges to

the rear edges. If the distance between the

front edges is less than that at the rear, the

wheels are said to toe-in; the opposite case is

known as toe-out.3To measure toe, it will be necessary to

obtain or make a tracking gauge. These are

available in motor accessory shops, or one

can be made from a length of rigid pipe or bar

with some kind of threaded adjustment facility

at one end. Many tyre specialists will also

check toe free, or for a nominal sum.

4Before measuring toe, check that all

steering and suspension components are

undamaged and that tyre pressures are

correct. The vehicle must be at approximately

kerb weight, with the spare wheel and jack in

their normal positions and any abnormal loads

removed.

5Park the vehicle on level ground and bounce

it a few times to settle the suspension.

6Use the tracking gauge to measure the

distance between the inside faces of the front

wheel rims, at hub height, at the rear of the

front wheels. Record this distance; call it

measurement A.

7Push the vehicle forwards or backwards so

that the wheels rotate exactly 180°(half a turn).

Measure the distance between the front wheel

rims again, this time at the front of the wheels.

Record this distance; call it measurement B.

8Subtract measurement B from

measurement A. If the answer is positive it is

the amount of toe-in; if negative it is the

amount of toe-out. Permissible values are

given in the Specifications.

9If adjustment is necessary loosen the track

rod end locknuts and the outer bellows clips,

then rotate each track rod by equal amounts

until the setting is correct. Hold the track rod

ends in their horizontal position with a spanner

while making the adjustment.

10Tighten the locknuts and outer bellows

clips.

11Provided the track rods have been

adjusted by equal amounts the steering wheel

should be central when moving straight-

ahead. The amount of visible thread on each

track rod should also be equal.

1Disconnect the battery negative lead.

2Raise and securely support the front of the

vehicle.

3Remove the suspension lower arm pivot

nuts and bolts (see illustration). Disengage

the arms from the crossmember.

4Disconnect the steering column shaft from

the intermediate shaft universal joint.

5Remove the two bolts which secure the

steering gear to the crossmember. Draw the

steering gear forwards so that it is clear of the

crossmember and support it by wiring it to the

frame rails.

6It is now necessary to support the engine,

preferably from above, using a hoist or an

adjustable support bar resting on the wings or

suspension turrets. Alternatively a jack and

some wooden blocks may be used frombelow, but this is bound to obstruct access to

some extent.

7Remove the engine mounting lower

securing nuts. Raise the engine until the

mountings are just clear of the crossmember.

8Release the brake pipe clips from the

crossmember and slide the brake pipes from

their slots. Be careful not to strain the pipes.

9Support the crossmember and remove its

four securing bolts. Lower the crossmember

and remove it from the vehicle.

10Commence refitting by offering the

crossmember to the frame rails. Insert the four

securing bolts and tighten them to the

specified torque.

11Secure the brake pipes to the

crossmember.

12Refit the steering gear to the

crossmember. Tighten its securing bolts to the

specified torque.

13Insert the suspension arms into the

crossmember and secure them with the pivot

bolts and nuts. Do not tighten the nuts and

bolts yet, just nip them up.

14Lower the engine onto the crossmember.

Make sure that the engine mountings locate

correctly into the holes in the crossmember.

Tighten the engine mounting nuts. The engine

support bar or hoist can now be removed.

15Reconnect the steering column shaft to

the intermediate shaft. Tighten the pinch-bolt

to the specified torque.

16Lower the vehicle onto its wheels, then

tighten the lower arm pivot bolts to the

specified torque.

17Reconnect the battery.

1Slacken the front wheel nuts. Raise and

support the front of the vehicle and remove

the front wheel.

2Separate the track rod end from the steering

arm.

3Unbolt the brake caliper, pull it off the disc

and tie it up out of the way. Do not allow it to

hang by its hose.

4Remove the split pin from the suspension

lower arm balljoint nut. Slacken the nut a few

16Front stub axle carrier -

removal and refitting

15Front suspension

crossmember - removal and

refitting

14Front wheel alignment -

checking and adjusting

Steering and suspension 11•7

11

13.4 Using a balljoint separator

14.1 Front wheel toe-in (greatly

exaggerated)15.3 Front suspension lower arm pivot bolt

procarmanuals.com

Page 152 of 255

1Raise the vehicle on ramps or on a hoist, so

that the weight is still on the wheels.

2Remove the lower arm pivot nut and bolt

(see illustration).

3Remove the anti-roll bar end nut, dished

washer and plastic cover. Note which way

round these components are fitted.

4Now raise and support the vehicle so that

the front wheels are off the ground.

5Remove the split pin from the lower arm

balljoint nut. Back off the nut a few turns,

break the taper with a balljoint separator, then

remove the nut and free the balljoint from the

stub axle carrier.

6Pull the lower arm off the anti-roll bar and

remove it.

7If the balljoint is defective, the whole arm

must be renewed. The dust boot can be

renewed separately if required.

8The anti-roll bar bushes (compliance

bushes) can be removed by cutting off their

flanges with a chisel, then pressing or tapping

out the remains. Fit new bushes by tapping

them home with a tube or socket.

9The pivot bush can be pressed out using a

bench vice and a couple of large sockets or

suitable pieces of tube. The new pivot bush

should be lubricated with soap or glycerine

(notoil or grease) before being fitted in a

similar fashion. Do not keep the new bush

compressed in the tube for longer than

necessary, in case it becomes permanently

distorted.

10Commence refitting by offering the arm to

the anti-roll bar. Make sure that the shallow

dished washer and the plastic cover are fitted

on the inboard side of the bar (furthest from

the nut).

11Refit the balljoint to the stub axle carrier.

Tighten the castellated nut to the specified

torque and secure it with a new split pin.

12Fit the pivot end of the arm into the

crossmember and secure it with the pivot nut

and bolt. Jacking the vehicle up or down to

vary the loading on the wheels may help to get

the holes lined up. Do not tighten the pivot nut

and bolt yet.

13Lower the vehicle back onto its wheels.14Fit the deep dished washer and the plastic

cover over the end of the anti-roll bar. Fit the

nut and tighten it to the specified torque.

15Tighten the lower arm pivot nut and bolt to

the specified torque.

1Raise the vehicle on ramps or a hoist, so

that the weight is still on the wheels.

2Unbolt the two anti-roll bar clamps (see

illustration).

3Now raise and support the vehicle with the

wheels free.

4Remove the two nuts which hold the ends

of the anti-roll bar to the lower arms. Recover

the plastic covers and deep dished washers.

5Remove one lower arm pivot nut and bolt.

Prise the lower arm out of the crossmember

and work the anti-roll bar free from it.

6Pull the anti-roll bar out of the other lower

arm and remove it. Recover the other

compliance bush covers and washers.

7Refit by reversing the removal operations,

but do not finally tighten any fastenings until

the weight of the vehicle is back on the

wheels. Tighten in the following order:

a)Anti-roll bar clamps

b)Anti-roll bar-to lower arm nuts

c)Lower arm pivot nut and bolt

8Make sure that the anti-roll bar clamp

bushes are not twisted on completion.

Compliance bushes

1These are described in Section 18. It is not

strictly necessary to remove the lower arms to

renew these bushes, though obviously access

is not good with the arms installed.

Clamp bushes

2Although it is possible to remove and refit

the clamp bushes without removing the anti-

roll bar, since the bushes are split, this is not

recommended by the makers.

3Remove the anti-roll bar as described in the

previous Section.4Slide the clamp bushes off the anti-roll bar,

if necessary prising them open a little first.

5Lubricate the new bushes with glycerine or

soap and slide them into position with the split

facing forwards.

6Refit the anti-roll bar.

1Slacken the front wheel nuts, raise and

support the vehicle and remove the front

wheel.

2Disconnect the battery negative lead.

3Unbolt the brake caliper and suspend it

nearby so that the flexible hose is not strained.

4Remove the ABS sensor from the stub axle

carrier.

5Separate the track rod end and suspension

lower arm balljoints from the stub axle carrier.

6Unclip the ABS/brake pad wear wiring from

the strut.

7Remove the dust cover from the top of the

strut.

8Have an assistant support the strut.

Remove the three nuts which secure the strut

to the turret (see illustration).Do notundo

the centre nut.

9Lower the strut out of the turret and remove

it.

10Refit by reversing the removal operations.

Do not fully tighten the strut-to-turret nuts until

the weight of the vehicle is back on its wheels.

21Front suspension strut -

removal and refitting

20Front anti-roll bar bushes -

renewal

19Front anti-roll bar - removal

and refitting

18Front suspension lower arm -

removal, overhaul and refitting

Steering and suspension 11•9

11

19.2 A front anti-roll bar clamp

21.8 Two of the three nuts (arrowed)

securing the suspension strut to the turret

18.2 Front suspension lower arm components

A Anti-roll bar

B Rear dished washer and cover

C Bushes

D Balljoint

E Front dished washer and cover

F Locknut

G Pivot bush

procarmanuals.com

Page 156 of 255

cornering or braking. Control circuitry also

prevents the compressor being energised for

more than five minutes continuously, as could

otherwise happen if the system sprang a leak.

No repairs to individual components are

possible. Apparent control faults should be

referred to a Ford dealer before embarking on

an expensive programme of testing by

substitution. Always use new O-rings on the

pipe unions once they have been disturbed.

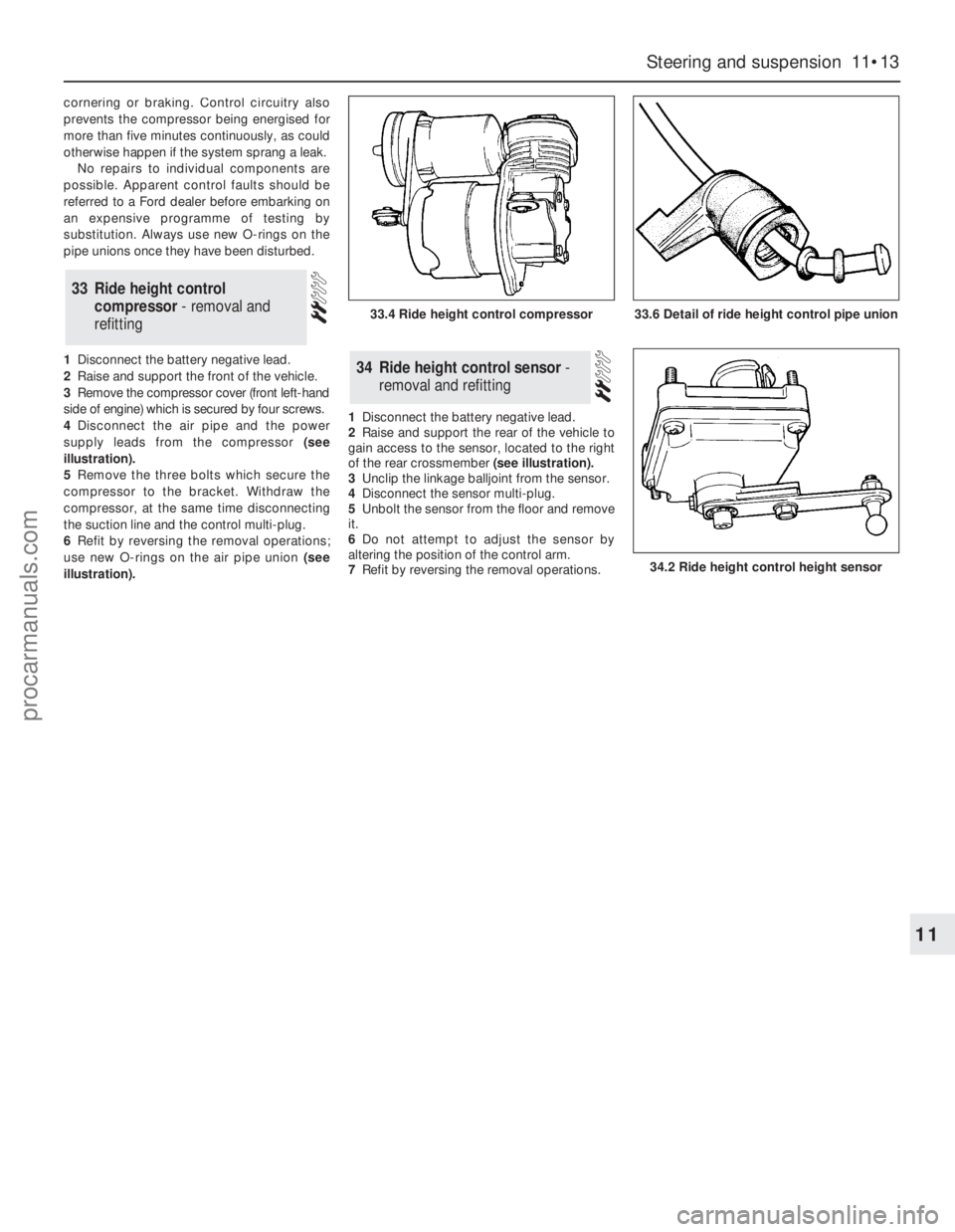

1Disconnect the battery negative lead.

2Raise and support the front of the vehicle.

3Remove the compressor cover (front left-hand

side of engine) which is secured by four screws.

4Disconnect the air pipe and the power

supply leads from the compressor (see

illustration).

5Remove the three bolts which secure the

compressor to the bracket. Withdraw the

compressor, at the same time disconnecting

the suction line and the control multi-plug.

6Refit by reversing the removal operations;

use new O-rings on the air pipe union(see

illustration).1Disconnect the battery negative lead.

2Raise and support the rear of the vehicle to

gain access to the sensor, located to the right

of the rear crossmember (see illustration).

3Unclip the linkage balljoint from the sensor.

4Disconnect the sensor multi-plug.

5Unbolt the sensor from the floor and remove

it.

6Do not attempt to adjust the sensor by

altering the position of the control arm.

7Refit by reversing the removal operations.

34Ride height control sensor -

removal and refitting

33Ride height control

compressor - removal and

refitting

Steering and suspension 11•13

11

33.4 Ride height control compressor33.6 Detail of ride height control pipe union

34.2 Ride height control height sensor

procarmanuals.com

Page 164 of 255

the door through the large cut-out. Further

displacement or removal of the foamrubber

sheet may be necessary.

7Refit in the reverse order to removal, noting

the following points:

a)Apply a little grease to the interior handle

rods where they pass through the plastic

bushes

b)When securing the interior handle, have

the locking lever in the “unlocked”

position, hold the assembly forwards as

far as itwill go and tighten the securing

screw

c)Check all functions before refitting the trim

panel.

Door weatherstrip

1Open the door and remove the weatherstrip

securing screw from the latch end. In the case

of the rear door, also remove the screw from

the hinge end.

2Carefully lift the latch end of the

weatherstrip and pull it off the door.

3Refit by reversing the removal operations,

using your palm to seat the weatherstrip.

Aperture weatherstrip

4Open the door. Remove the scuff plate

securing screws from the bottom of the door

aperture.

5Pull the old weatherstrip out of the door

aperture.

6Fit the new weatherstrip, starting at the

right-angled corner at the top. Fit the

weatherstrip to the other corners and bends,

leaving the straight sections until last.

7Refit the scuff, plate securing screws.

All models except Estate

1Disconnect the battery negative lead.

2Remove the tailgate interior trim panel,

which is secured by eleven screws.

3Remove the six nuts which secure the

tailgate handle. Remove the handle and

recover the gasket.

4Disconnect the tailgate lock switch multi-

plug. Release the switch locking tab and

remove the switch.

5Disconnect the operating rod from the lock

lever (see illustration). Extract the U-clip and

remove the lock barrel.

6Refit by reversing the removal operations.

Estate models

7The tailgate lock barrel can be removed and

refitted as described above, bearing in mind

the notes made in Section 8 when removing

the interior trim panels and noting that the lock

assembly is retained by two Torx bolts.1Open up the boot lid and remove the trim

panel from the inside of the lid.

2Unscrew the four boot lid exterior trim

retaining panel bolts (two situated on each

side of the lock) then carefully prise out the

nine panel retaining clips and remove the

panel from the boot lid.

3Undo the two lock barrel retaining nuts then

partially withdraw the barrel and disconnect the

wiring connector and lock operating rod from

the barrel. Remove the lock barrel from the lid.

4Undo the four lid lock retaining bolts then

withdraw the lock assembly from the boot lid,

disconnecting the central locking and warning

switch wiring plugs (see illustration).

5Refitting is a reversal of the removal

procedure tightening all retaining bolts

securely. On completion check the operation

of the boot lid lock and lock barrel before

refitting the trim panel.

1Disconnect the battery negative lead.

2Remove the tailgate interior trim panel,

which is secured by eleven screws.

3Unhook the operating rod from the tailgate

latch. Also disconnect the lock switch and

solenoid multi-plugs.4Remove the three bolts which secure the

tailgate latch. Remove the latch.

5Refit by reversing the removal operations.

1Open the tailgate and support it with a piece

of wood.

2Release the strut from its mountings by

raising the spring clips with a small

screwdriver, then pulling the strut off the ball-

stands. Do not raise the clips more than 4 mm

(0.16 in) if the strut is to be re-used.

3Do not attempt to dismantle a strut, and

dispose of it safely. It contains gas under

pressure.

4To refit a strut, position it over the ball-

studs. Push on each end in turn until it snaps

home.

1Open the fuel filler flap. Remove the key.

2Apply pressure to the lock barrel at the key

slot, using the thumb of one hand. With the

other hand insert a screwdriver into the cut-

out in the filler flap to release the lock barrel

retaining spring. As the spring is released,

thumb pressure will eject the lock barrel into

the petrol tank (see illustration).

3To refit, push the lock barrel into the flap

until the retaining spring clicks home.

Front door

1Open the door and remove the screws

which secure the front and rear edges of the

trim panel (see illustration).

2Remove the two screws from under the

covers on the door pocket. Unclip and remove

the pocket.

3On models with electrically-operated

windows and mirrors, prise out and disconnect

the window and mirror switches. The window

switch multi-plugs on the driver’s side are

22Door interior trim panel -

removal and refitting

21Fuel filler lock barrel -

removal and refitting

20Tailgate strut - removal and

refitting

19Tailgate latch assembly -

removal and refitting

18Boot lid lock barrel - removal

and refitting

17Tailgate lock barrel - removal

and refitting

16Door weatherstrip - removal

and refitting

Bodywork and fittings 12•7

12

17.5 Operating rod (arrowed) connected to

tailgate lock lever18.4 Boot lid lock retaining bolts (arrowed)

- Saloon models

21.2 Removing the fuel filler flap lock barrel

procarmanuals.com

Page 169 of 255

10Remove the securing screws and detach

the C and D-pillar trim panels.

11Remove the top of the facia panel.

12Remove the securing screw from the base

of the A-pillar trim on each side. Detach the A-

pillar trim panels.

13Remove the headlining through the

tailgate, peeling it back from around the sliding

roof (when applicable - see paragraph 15).

14Refitting is essentially a reversal of the

removal procedure. The services of an

assistant will be required during the initial

stages of refitting.

15When a sliding roof is fitted, the headlining

is secured around the aperture with double-

sided adhesive tape.

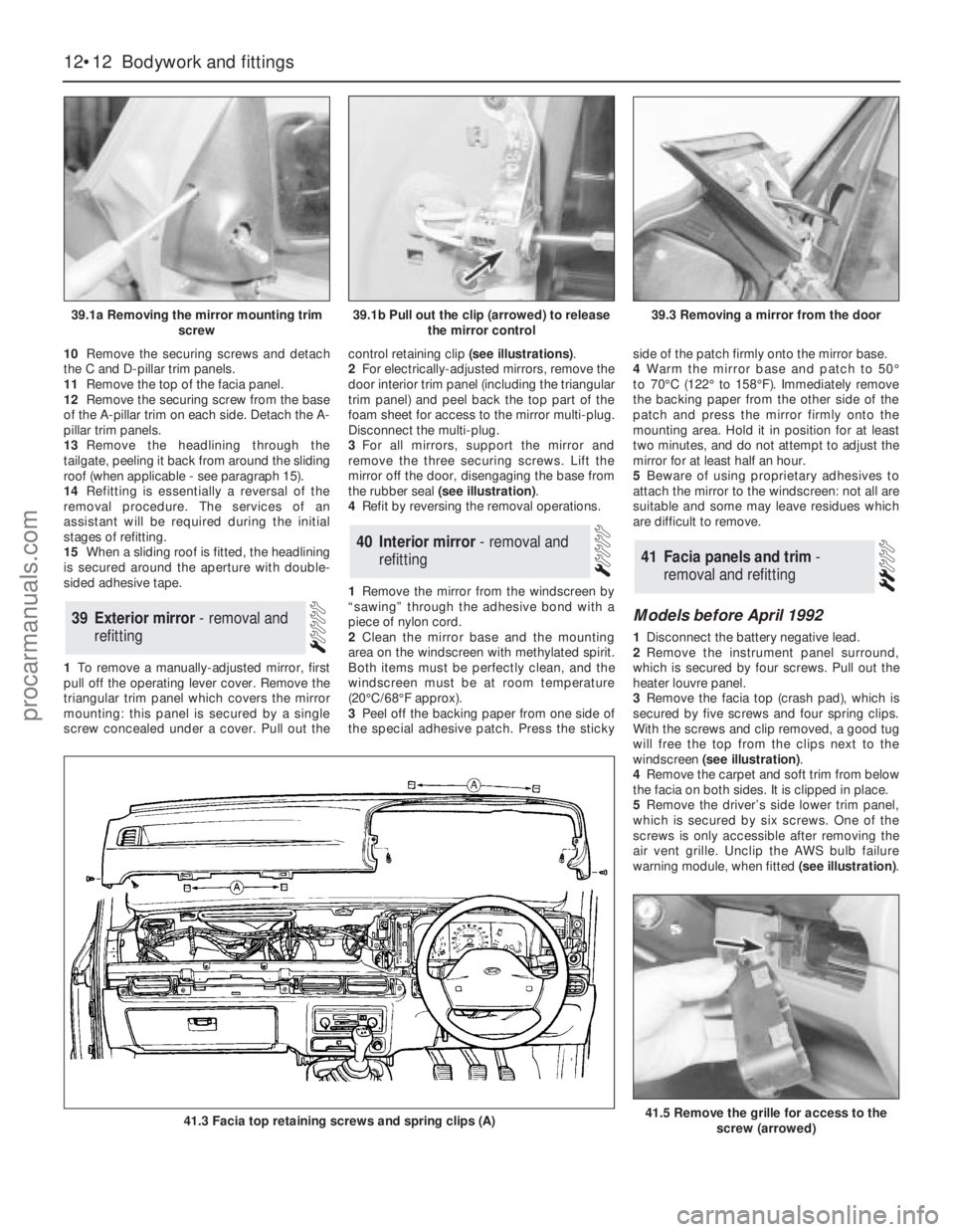

1To remove a manually-adjusted mirror, first

pull off the operating lever cover. Remove the

triangular trim panel which covers the mirror

mounting: this panel is secured by a single

screw concealed under a cover. Pull out thecontrol retaining clip (see illustrations).

2For electrically-adjusted mirrors, remove the

door interior trim panel (including the triangular

trim panel) and peel back the top part of the

foam sheet for access to the mirror multi-plug.

Disconnect the multi-plug.

3For all mirrors, support the mirror and

remove the three securing screws. Lift the

mirror off the door, disengaging the base from

the rubber seal (see illustration).

4Refit by reversing the removal operations.

1Remove the mirror from the windscreen by

“sawing” through the adhesive bond with a

piece of nylon cord.

2Clean the mirror base and the mounting

area on the windscreen with methylated spirit.

Both items must be perfectly clean, and the

windscreen must be at room temperature

(20°C/68°F approx).

3Peel off the backing paper from one side of

the special adhesive patch. Press the stickyside of the patch firmly onto the mirror base.

4Warm the mirror base and patch to 50°

to 70°C (122°to 158°F). Immediately remove

the backing paper from the other side of the

patch and press the mirror firmly onto the

mounting area. Hold it in position for at least

two minutes, and do not attempt to adjust the

mirror for at least half an hour.

5Beware of using proprietary adhesives to

attach the mirror to the windscreen: not all are

suitable and some may leave residues which

are difficult to remove.

Models before April 1992

1Disconnect the battery negative lead.

2Remove the instrument panel surround,

which is secured by four screws. Pull out the

heater louvre panel.

3Remove the facia top (crash pad), which is

secured by five screws and four spring clips.

With the screws and clip removed, a good tug

will free the top from the clips next to the

windscreen (see illustration).

4Remove the carpet and soft trim from below

the facia on both sides. It is clipped in place.

5Remove the driver’s side lower trim panel,

which is secured by six screws. One of the

screws is only accessible after removing the

air vent grille. Unclip the AWS bulb failure

warning module, when fitted (see illustration).

41Facia panels and trim -

removal and refitting40Interior mirror - removal and

refitting

39Exterior mirror - removal and

refitting

12•12Bodywork and fittings

39.1a Removing the mirror mounting trim

screw

41.3 Facia top retaining screws and spring clips (A)41.5 Remove the grille for access to the

screw (arrowed)

39.1b Pull out the clip (arrowed) to release

the mirror control39.3 Removing a mirror from the door

procarmanuals.com

Page 170 of 255

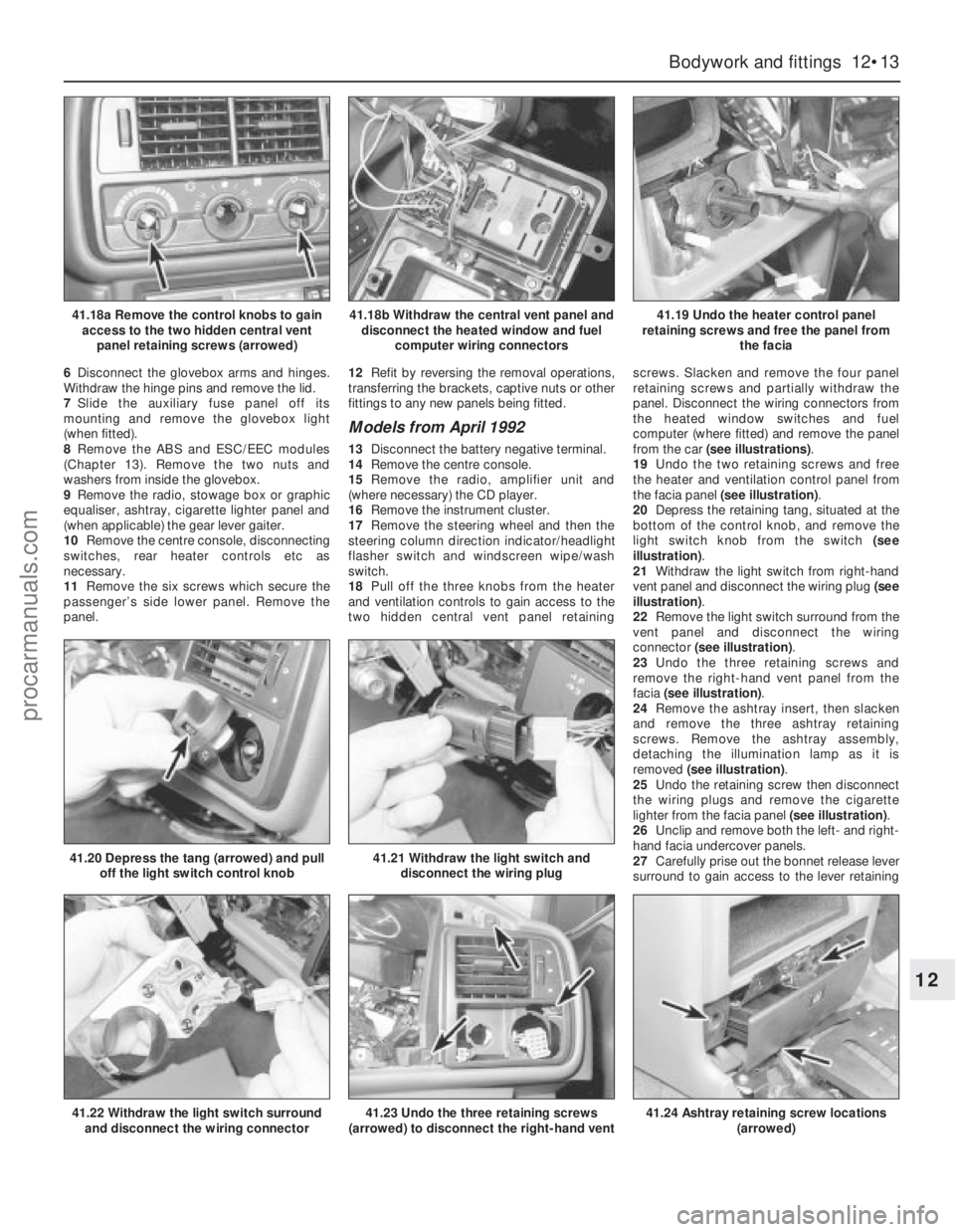

6Disconnect the glovebox arms and hinges.

Withdraw the hinge pins and remove the lid.

7Slide the auxiliary fuse panel off its

mounting and remove the glovebox light

(when fitted).

8Remove the ABS and ESC/EEC modules

(Chapter 13). Remove the two nuts and

washers from inside the glovebox.

9Remove the radio, stowage box or graphic

equaliser, ashtray, cigarette lighter panel and

(when applicable) the gear lever gaiter.

10Remove the centre console, disconnecting

switches, rear heater controls etc as

necessary.

11Remove the six screws which secure the

passenger’s side lower panel. Remove the

panel. 12Refit by reversing the removal operations,

transferring the brackets, captive nuts or other

fittings to any new panels being fitted.

Models from April 1992

13Disconnect the battery negative terminal.

14Remove the centre console.

15Remove the radio, amplifier unit and

(where necessary) the CD player.

16Remove the instrument cluster.

17Remove the steering wheel and then the

steering column direction indicator/headlight

flasher switch and windscreen wipe/wash

switch.

18Pull off the three knobs from the heater

and ventilation controls to gain access to the

two hidden central vent panel retainingscrews. Slacken and remove the four panel

retaining screws and partially withdraw the

panel. Disconnect the wiring connectors from

the heated window switches and fuel

computer (where fitted) and remove the panel

from the car (see illustrations).

19Undo the two retaining screws and free

the heater and ventilation control panel from

the facia panel (see illustration).

20Depress the retaining tang, situated at the

bottom of the control knob, and remove the

light switch knob from the switch (see

illustration).

21Withdraw the light switch from right-hand

vent panel and disconnect the wiring plug (see

illustration).

22Remove the light switch surround from the

vent panel and disconnect the wiring

connector (see illustration).

23Undo the three retaining screws and

remove the right-hand vent panel from the

facia (see illustration).

24Remove the ashtray insert, then slacken

and remove the three ashtray retaining

screws. Remove the ashtray assembly,

detaching the illumination lamp as it is

removed (see illustration).

25Undo the retaining screw then disconnect

the wiring plugs and remove the cigarette

lighter from the facia panel (see illustration).

26Unclip and remove both the left- and right-

hand facia undercover panels.

27Carefully prise out the bonnet release lever

surround to gain access to the lever retaining

Bodywork and fittings 12•13

12

41.18a Remove the control knobs to gain

access to the two hidden central vent

panel retaining screws (arrowed)41.18b Withdraw the central vent panel and

disconnect the heated window and fuel

computer wiring connectors41.19 Undo the heater control panel

retaining screws and free the panel from

the facia

41.22 Withdraw the light switch surround

and disconnect the wiring connector

41.20 Depress the tang (arrowed) and pull

off the light switch control knob41.21 Withdraw the light switch and

disconnect the wiring plug

41.23 Undo the three retaining screws

(arrowed) to disconnect the right-hand vent41.24 Ashtray retaining screw locations

(arrowed)

procarmanuals.com

Page 172 of 255

screws. Undo the three screws then withdraw

the lever. Remove the cable retaining clip and

detach the operating lever from the cable (see

illustrations).

28Slacken and remove the five right-hand

lower facia panel retaining screws and remove

the panel from the vehicle (see illustration).

29Open up the glovebox then, using a small

flat-bladed screwdriver, carefully prise up the

retaining clip and disconnect the glovebox

hinge arms. Withdraw the glovebox assembly

from the facia noting the plastic bushes which

are fitted to the glovebox pivot points.

Withdraw the glovebox illumination light,

disconnect the wiring connector and remove it

from the facia (see illustrations).

30Slacken and remove the three screws

securing the passenger side lower kick panel

in position and remove the panel (see

illustration).

31Carefully prise the upper end of the left-

hand A-pillar trim out of position until all the

retaining clips are released. Lift the panel up to

disengage the lower tab from the pillar and

remove the trim panel (see illustrations).

Repeat the procedure for the right-hand panel.

32Disconnect the alarm warning LED wiring

connector which is accessed via the

instrument cluster aperture (see illustration).

33Carefully prise the windscreen vent panel

out from the top of the facia to gain access to

the upper facia retaining screws (see

illustration).

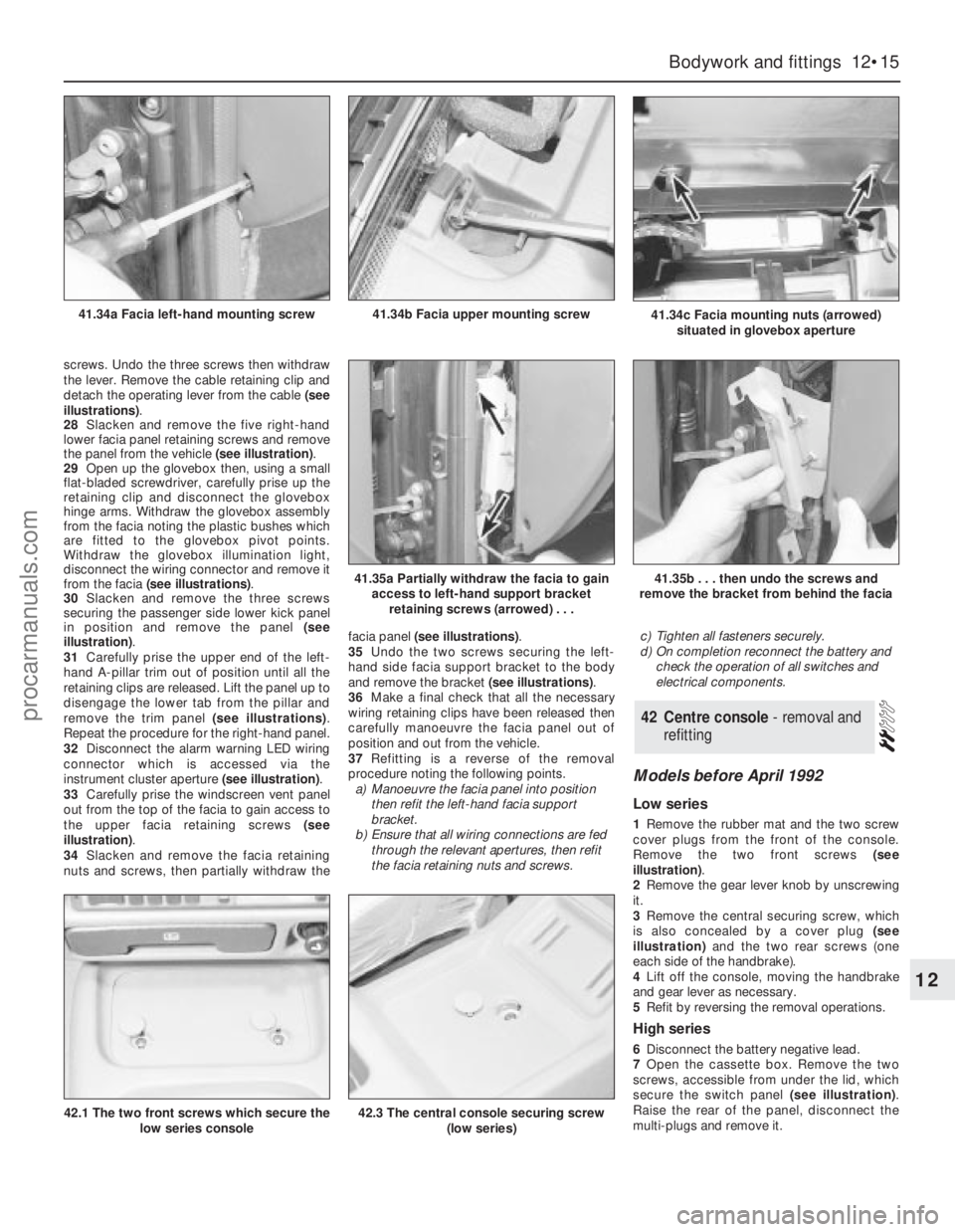

34Slacken and remove the facia retaining

nuts and screws, then partially withdraw thefacia panel (see illustrations).

35Undo the two screws securing the left-

hand side facia support bracket to the body

and remove the bracket (see illustrations).

36Make a final check that all the necessary

wiring retaining clips have been released then

carefully manoeuvre the facia panel out of

position and out from the vehicle.

37Refitting is a reverse of the removal

procedure noting the following points.

a)Manoeuvre the facia panel into position

then refit the left-hand facia support

bracket.

b)Ensure that all wiring connections are fed

through the relevant apertures, then refit

the facia retaining nuts and screws.c)Tighten all fasteners securely.

d)On completion reconnect the battery and

check the operation of all switches and

electrical components.

Models before April 1992

Low series

1Remove the rubber mat and the two screw

cover plugs from the front of the console.

Remove the two front screws (see

illustration).

2Remove the gear lever knob by unscrewing

it.

3Remove the central securing screw, which

is also concealed by a cover plug (see

illustration)and the two rear screws (one

each side of the handbrake).

4Lift off the console, moving the handbrake

and gear lever as necessary.

5Refit by reversing the removal operations.

High series

6Disconnect the battery negative lead.

7Open the cassette box. Remove the two

screws, accessible from under the lid, which

secure the switch panel (see illustration).

Raise the rear of the panel, disconnect the

multi-plugs and remove it.

42Centre console - removal and

refitting

Bodywork and fittings 12•15

12

41.34c Facia mounting nuts (arrowed)

situated in glovebox aperture41.34b Facia upper mounting screw41.34a Facia left-hand mounting screw

41.35a Partially withdraw the facia to gain

access to left-hand support bracket

retaining screws (arrowed) . . .41.35b . . . then undo the screws and

remove the bracket from behind the facia

42.1 The two front screws which secure the

low series console42.3 The central console securing screw

(low series)

procarmanuals.com

Page 173 of 255

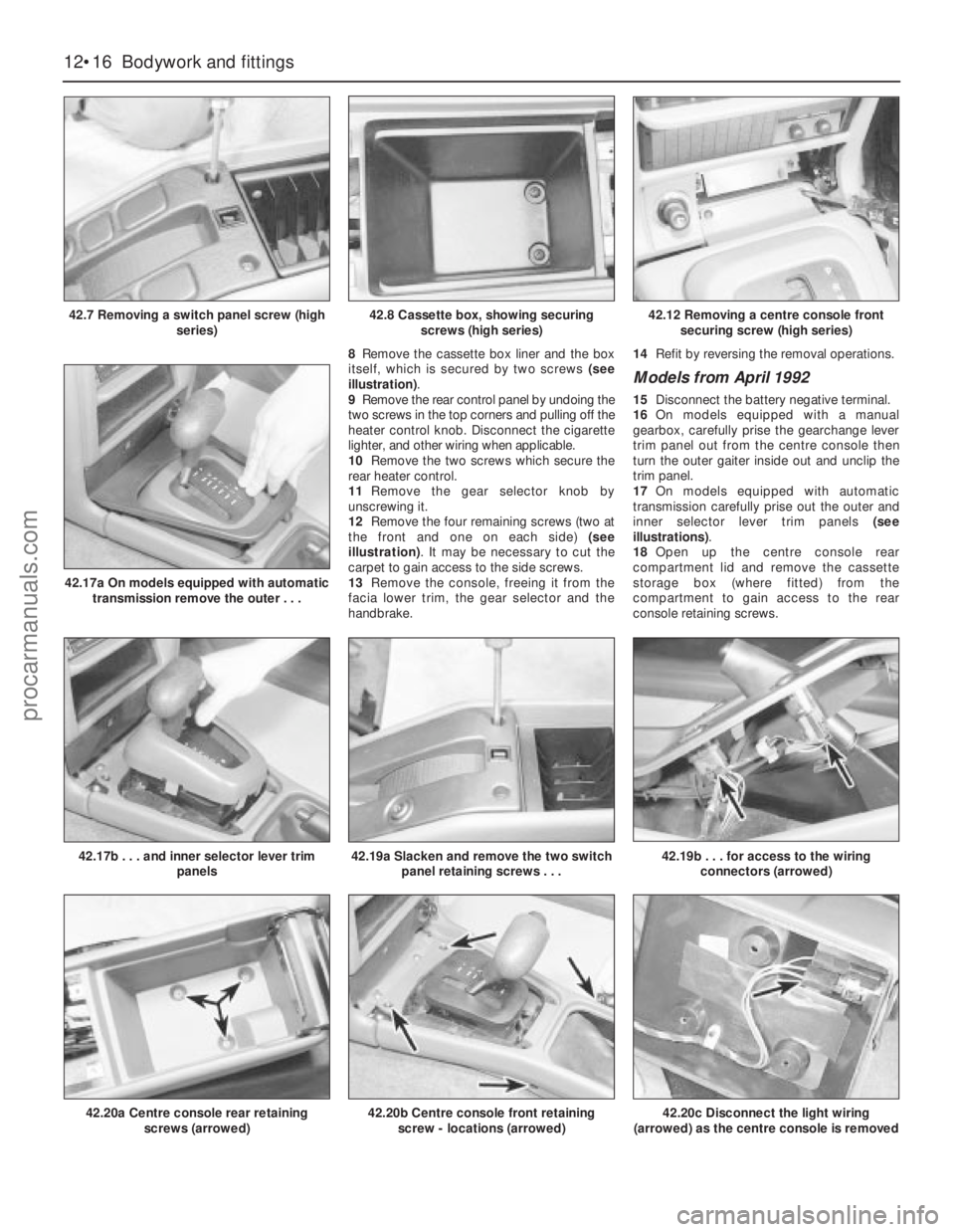

8Remove the cassette box liner and the box

itself, which is secured by two screws (see

illustration).

9Remove the rear control panel by undoing the

two screws in the top corners and pulling off the

heater control knob. Disconnect the cigarette

lighter, and other wiring when applicable.

10Remove the two screws which secure the

rear heater control.

11Remove the gear selector knob by

unscrewing it.

12Remove the four remaining screws (two at

the front and one on each side) (see

illustration). It may be necessary to cut the

carpet to gain access to the side screws.

13Remove the console, freeing it from the

facia lower trim, the gear selector and the

handbrake.14Refit by reversing the removal operations.

Models from April 1992

15Disconnect the battery negative terminal.

16On models equipped with a manual

gearbox, carefully prise the gearchange lever

trim panel out from the centre console then

turn the outer gaiter inside out and unclip the

trim panel.

17On models equipped with automatic

transmission carefully prise out the outer and

inner selector lever trim panels (see

illustrations).

18Open up the centre console rear

compartment lid and remove the cassette

storage box (where fitted) from the

compartment to gain access to the rear

console retaining screws.

12•16Bodywork and fittings

42.7 Removing a switch panel screw (high

series)

42.20a Centre console rear retaining

screws (arrowed)

42.17b . . . and inner selector lever trim

panels

42.17a On models equipped with automatic

transmission remove the outer . . .

42.19a Slacken and remove the two switch

panel retaining screws . . .42.19b . . . for access to the wiring

connectors (arrowed)

42.20b Centre console front retaining

screw - locations (arrowed)42.20c Disconnect the light wiring

(arrowed) as the centre console is removed

42.8 Cassette box, showing securing

screws (high series)42.12 Removing a centre console front

securing screw (high series)

procarmanuals.com

Page 174 of 255

19Slacken and remove the two switch panel

retaining screws then carefully slide the panel

up over the handbrake lever until the switch

wiring connectors can be accessed (see

illustrations). Disconnect the wiring

connectors from all the switches, then release

the loom from any relevant retaining clips and

manoeuvre the switch panel off the handbrake

lever.

20Slacken and remove the seven centre

console retaining screws (two at the front, one

on each side and three at the rear) then lift up

the console and disconnect the wiring

connector from the rear cigarette lighter.

Remove the console assembly from the car

(see illustrations).

21Refitting is a reverse of the removal

procedure.

1Disconnect the battery negative lead.

2Remove the interior light by carefully prising

it out of the console and disconnecting it.

3Remove the sliding roof control handle or

switches (as applicable).

4Remove the two retaining screws from the

front of the console. Pull the front of the

console down and then slide the assembly

rearwards to release it from the two clips (see

illustrations). These clips may be quite tight.

Disconnect the clock.

5Refit by reversing the removal operations.1Move the seat rearwards as far as possible,

then remove the two front retaining bolts (see

illustration).

2Disconnect the assist spring from under the

driver’s seat. (Moving the seat forwards will

reduce the tension on this spring, but also

makes it harder to get at.)

3When applicable, disconnect the seat

heating and/or adjustment motor multi-plugs.

4Move the seat fully forwards and remove the

three rear retaining bolts. These bolts are

under plastic covers (see illustrations).

5Lift out the seat, complete with adjustment

mechanism and seat belt buckle.

6If a new seat is being fitted, transfer the

adjustment mechanism and other components

to it.

7Refit by reversing the removal operations.

Tighten the seat retaining bolts to the

specified torque.

1Remove the front seat as described in the

previous Section.

2Remove the side trim pieces from the seat.

Free the air tube by removing Its two securing

screws.

3Separate the backrest from the base of theseat by removing the four retaining bolts.

4Remove the backrest cover by unbending

its retaining tags and sliding it off.

5Expose the air cushion by lifting up the foam

padding. Cut the hog rings (wire loops) which

secure the corners of the cushion and remove

it with the air hoses.

6When refitting, use new hog rings. Position

the cut-out in the cushion level with the

second spring in the backrest.

7The remainder of refitting is a reversal of the

removal procedure.

1All models are fitted with inertia reel front

seat belts as standard. Rear seat belts are

available as an extra.

2Maintenance is limited to periodic

inspection of the belts for fraying or other

damage. Also check the operation of the

buckles and retractor mechanisms. In case of

damage or malfunction the belt must be

renewed.

3If it is wished to clean the belts, use only an

approved upholstery cleaner or a weak

solution of detergent, followed by rinsing with

water. Do not use solvents, strong detergents,

dyes or bleaches. Keep the belt extended until

it is dry.

4Belts which have been subjected to impact

loads must be renewed.

1Remove the cover from the belt top anchor.

With the adjustable type of anchor(see

illustration)the cover is removed by levering

out the adjuster button and removing two

screws.

2Remove the anchor bolt or nut and detach

the seat belt runner from it. Note the position

of any washers or spacers.

3Carefully pull out the door aperture

weatherstrips (front and rear) from the B-pillar

(see illustration). Unclip the pillar trim.

4Remove the screws which secure the

retractor cover trim, pull away more of the

47Front seats belts - removal

and refitting

46Seat belts - care and

maintenance

45Front seat air cushion -

removal and refitting

44Front seat - removal and

refitting

43Overhead console - removal

and refitting

Bodywork and fittings 12•17

12

43.4a One of the overhead console

retaining screws43.4b Slide the console rearwards to

release the clips (arrowed)44.1 Removing a front seat retaining bolt

44.4a Front seat outboard rear retaining

bolt44.4b The other two rear retaining bolts are

under the cover

procarmanuals.com