battery FORD GRANADA 1985 Service Manual PDF

[x] Cancel search | Manufacturer: FORD, Model Year: 1985, Model line: GRANADA, Model: FORD GRANADA 1985Pages: 255, PDF Size: 14.98 MB

Page 131 of 255

Models covered in this Manual have disc

brakes fitted all round. The footbrake operates

hydraulically on all four wheels, and the

handbrake operates mechanically on the rear

wheels. Both footbrake and handbrake are

self-adjusting in use.

Ford’s anti-lock braking system (ABS) is

fitted to all models. The system monitors the

rotational speed of each roadwheel. When a

wheel begins to lock under heavy braking, the

ABS reduces the hydraulic pressure to that

wheel, so preventing it from locking. When this

happens a pulsating effect will be noticed at

the brake pedal. On some road surfaces the

tyres may squeal when braking hard even

though the wheels are not locked.

The main components of the system are the

hydraulic unit, the calipers, pads and discs,

the wheel sensors and the “brain” or control

module. The hydraulic unit contains the

elements of a traditional master cylinder, plus

an electric motor and pump, a pressure

accumulator and control valves. The pump is

the source of pressure for the system and

does away with the need for a vacuum servo.

The hydraulic circuit is split front and rear,

as is normal practice with rear-wheel drive

vehicles. In the event that the hydraulic pump

fails, unassisted braking effort is still available

on the front calipers only.

Warning lights inform the driver of low brake

fluid level, ABS failure and (on some models)

brake pad wear. The low fluid level light

doubles as a “handbrake on” light; if it

illuminates at the same time as the ABS

warning light, it warns of low hydraulic

pressure.

ABS cannot overturn the laws of physics:

stopping distances will inevitably be greater on

loose or slippery surfaces. However, the system

should allow even inexperienced drivers to

retain directional control under panic braking.

From August 1986 the following

modifications were made to the braking

system.

a)The relays differ from earlier versions.b)The hydraulic pump is constructed of iron

rather than alloy.

c)A new pressure warning switch is used.

d)The earlier high pressure rubber hose is

replaced by a steel pipe.

To overcome the problem of excessive rear

brake pad wear, Ford introduced a differential

valve which is screwed into the ABS valve

block.The valve limits the pressure applied to

the rear brake calipers and so reduces brake

pad wear. From 1988 onwards, the valve has

been fitted during production. The differential

valve can also be fitted to earlier models. Refer

to your Ford dealer for further information.

From April 1992 onwards, the models

covered in this Manual were equipped with a

new Teves MK IV anti-lock braking system

instead of the Teves MK II system fitted to the

earlier models.

The Teves MK IV system differs from the

earlier MK II system in the following ways.

a)The source of hydraulic pressure for the

system is a conventional master cylinder

and vacuum servo assembly.

b)A valve block and pump assembly is used

instead of the hydraulic control unit. The

block contains the inlet and outlet

solenoid valves that control the hydraulic

system. There are three pairs of valves,

one for each brake circuit (paragraph c).

c)The hydraulic braking system consists of

three separate circuits; one for each front

brake (which are totally independent of

each other), and a joint circuit which

operates both rear brakes.

d)A G (gravity) switch is incorporated in the

system. This is an inertia type switch and

informs the control module when the

vehicle is decelerating rapidly.

e)A Pedal Travel Sensor (PTS) is fitted to the

vacuum servo unit. The PTS informs the

control module of the position of the brake

pedal when the anti-lock sequence starts

and ensures that a constant pedal height

is maintained during the sequence.

The MK IV system operates as follows.

During normal operation the system

functions in the same way as a non-ABS

system would. During this time the three inlet

valves in the valve block are open and theoutlet valves are closed, allowing full hydraulic

pressure present in the master cylinder to act

on the main braking circuit. If the control

module receives a signal from one of the

wheel sensors and senses that a wheel is

about to lock, it closes the relevant inlet valve

in the valve block which then isolates the

brake caliper on the wheel which is about to

lock from the master cylinder, effectively

sealing in the hydraulic pressure. If the speed

of rotation of the wheel continues to decrease

at an abnormal rate, the control module will

then open the relevant outlet valve in the valve

block; this allows the fluid from the relevant

hydraulic circuit to return to the master

cylinder reservoir, releasing pressure on the

brake caliper so that the brake is released. The

pump in the valve block also operates to assist

in the quick release of pressure. Once the

speed of rotation of the wheel returns to an

acceptable rate the pump stops, the outlet

valve closes and the inlet valve is opened,

allowing the hydraulic master cylinder

pressure to return to the caliper which then

reapplies the brake. This cycle can be carried

many times a second. The solenoid valves

connected to the front calipers operate

independently, but the valve connected to the

rear calipers operates both calipers

simultaneously.

The operation of the ABS system is entirely

dependent on electrical signals. To prevent

the system responding to any inaccurate

signals, a built-in safety circuit monitors all

signals received by the control module. If an

inaccurate signal or low battery voltage is

detected, the ABS system is automatically

shut down and the warning lamp on the

instrument cluster is illuminated to inform the

driver that the ABS system is not operational.

Whilst in this state the system functions in the

same way as a non-ABS system would. If a

fault does develop in the ABS system, the car

must be taken to a Ford dealer for fault

diagnosis and repair. The system is equipped

with a diagnostic plug into which a special

diagnostic (STAR) tester can be plugged. This

allows faults to be easily traced.

1General information

10•2Braking system

Torque wrench settingsNmlbf ft

Front caliper:

To stub axle carrier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51 to 6138 to 45

Slide bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 2515 to 18

Rear caliper:

Bracket to carrier plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51 to 6138 to 45

Slide bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31 to 3523 to 26

Hydraulic unit to bulkhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41 to 5130 to 38

Accumulator to pump body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35 to 4526 to 33

Pump mounting bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 to 95 to 7

High pressure hose banjo bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16 to 2412 to 18

Reservoir mounting bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 to 63 to 4

Wheel sensor fixing bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 116 to 8

Vacuum servo unit retaining nuts (Teves MK IV) . . . . . . . . . . . . . . . . . .35 to 4526 to 33

Master cylinder retaining nuts (Teves MK IV) . . . . . . . . . . . . . . . . . . . . .20 to 2515 to 18

Valve block and pump assembly mounting nuts (Teves MK IV) . . . . . . .21 to 2815 to 21

procarmanuals.com

Page 137 of 255

17Refit the washer, spring and spring cover.

Compress the spring and refit the circlip, then

release the spring compressor.

18Lubricate the caliper bore with clean

hydraulic fluid and fit a new piston seal.

19Reassemble the piston components.

Lubricate the contact face of the adjuster nut

with a little brake grease, then fit the adjuster

nut (with new seal), thrust bearing,

thrustwasher, wave washer and the second

thrustwasher. Secure with the circlip.

20Fit a new dust boot. The manufacturers

recommend that it be fitted to the caliper

groove and the piston fitted afterwards; it is

also possible to fit the boot to the piston first

and engage it in the caliper groove afterwards.

Either way it is a fiddly business.

21Refit the piston and screw it into the

caliper, then fit whichever lip of the dust boot

was left free (see illustration).22Renew the slide pin gaiters and apply a

little anti-seize compound to the slide pins

when reassembling the caliper to the bracket.

The splash shield is retained by the rear hub

bolts. Proceed as described in Chapter 11 for

removal and refitting of the rear hub.

1Disconnect the battery negative lead.

2Depressurise the hydraulic system by

pumping the brake pedal at least 20 times, or

until it becomes hard.

3Remove the under-dash trim on the driver’s

side.

4Remove the spring clip which secures the

hydraulic unit pushrod to the brake pedal. Also

remove the clip from the brake pedal shaft

(see illustration).

5Withdraw the brake pedal shaft towards the

left of the vehicle - through the clutch pedal,

when applicable - until the brake pedal is free.

6Remove the pedal, noting the fitted

sequence of bushes, spacers and washers.

7Refit by reversing the removal operations.

Check the correct functioning of the stop-light

and (if applicable) cruise control switches

before refitting the trim. See Chapter 13.1Disconnect the battery negative lead.

2Depressurise the hydraulic system by

pumping the brake pedal at least 20 times, or

until it becomes hard.

3Disconnect the six multi-plugs from the

hydraulic unit. They are all different, so there is

no need to label them. When a plug has a

spring clip retainer, lift the clip before pulling

out the plug. To release the pump plug, pull

back the rubber boot and the plug sleeve (see

illustrations).

4Unbolt the earth strap from the unit (see

illustration).

5Make arrangements to catch spilt hydraulic

15Hydraulic unit - removal and

refitting

14Brake pedal - removal and

refitting

13Rear disc splash shield -

removal and refitting

10•8Braking system

12.21 Dust boot fitted to caliper and piston

15.3d Disconnecting the pressure switch

multi-plug15.3e Disconnecting the pump motor plug15.4 Earth strap (arrowed) bolted to

hydraulic unit

14.4 Pushrod spring clip (A) and brake

pedal shaft clip (B)

15.3a Disconnect the valve block multi-

plug. Lift the clip and pull off the plug15.3b Disconnecting a fluid level sensor

plug15.3c Disconnecting the main valve plug

procarmanuals.com

Page 138 of 255

fluid. Identify the hydraulic pipes and

disconnect them from the base of the unit.

Hint: Plug or cap the open unions to keep

fluid in and dirt out.

6Remove the under-dash trim on the driver’s

side. Disconnect the spring clip which secures

the hydraulic unit pushrod to the brake pedal.

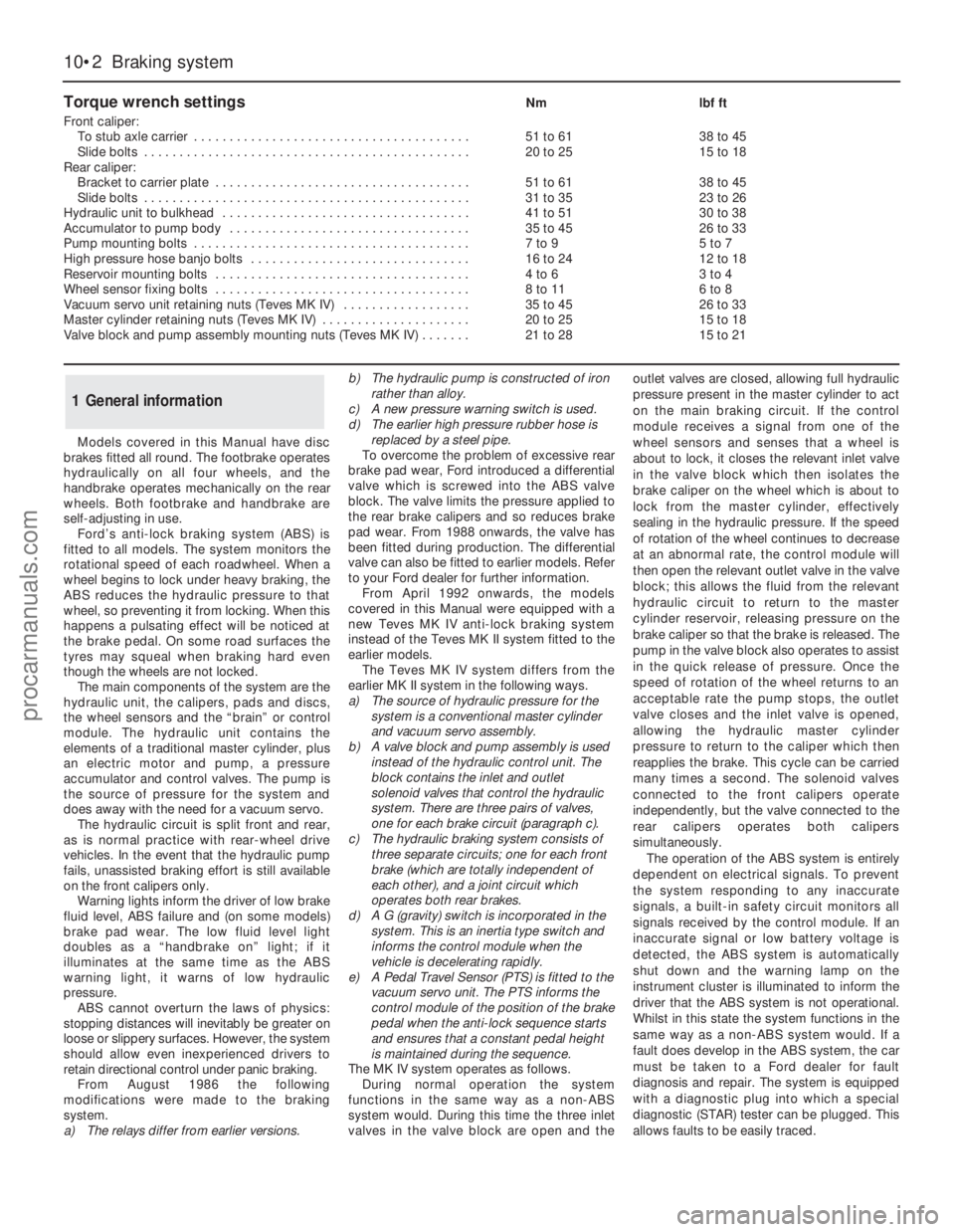

7Have an assistant support the hydraulic

unit. Remove the four nuts which hold the unit

to the bulkhead (see illustration). Withdraw

the unit from under the bonnet.

8Recover the sealing compound from the

unit and the bulkhead.

9Drain the hydraulic fluid from the reservoir.

Do not actuate the pushrod with the unit

removed.

10Dismantling of the hydraulic unit should be

limited to the operations described in thefollowing Sections. These operations can all

be carried out without removing the unit from

the vehicle if wished.

11Refit by reversing the removal operations,

noting the following points:

a)Do not refill the reservoir until the end of

refitting

b)Use new sealing compound between the

unit and the bulkhead

c)Make sure that the hydraulic pipes are

reconnected to the correct unions

d)Bleed the complete hydraulic system on

completion - see Section 2

1Disconnect the battery negative lead.

2Depressurise the hydraulic system by

pumping the brake pedal at least 20 times, or

until it becomes hard.

3Disconnect the multi-plugs and remove the

reservoir cap.

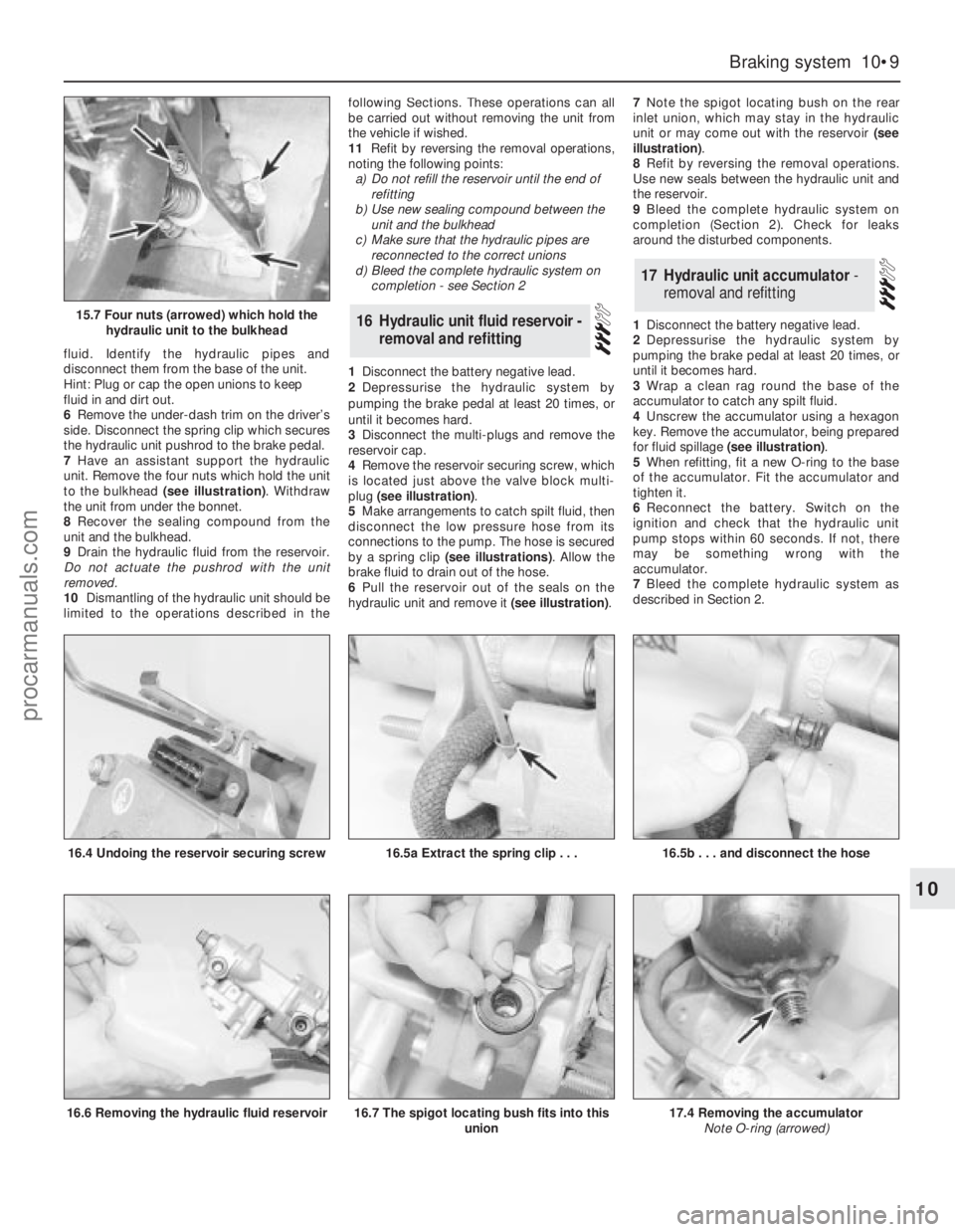

4Remove the reservoir securing screw, which

is located just above the valve block multi-

plug (see illustration).

5Make arrangements to catch spilt fluid, then

disconnect the low pressure hose from its

connections to the pump. The hose is secured

by a spring clip (see illustrations). Allow the

brake fluid to drain out of the hose.

6Pull the reservoir out of the seals on the

hydraulic unit and remove it (see illustration).7Note the spigot locating bush on the rear

inlet union, which may stay in the hydraulic

unit or may come out with the reservoir (see

illustration).

8Refit by reversing the removal operations.

Use new seals between the hydraulic unit and

the reservoir.

9Bleed the complete hydraulic system on

completion (Section 2). Check for leaks

around the disturbed components.

1Disconnect the battery negative lead.

2Depressurise the hydraulic system by

pumping the brake pedal at least 20 times, or

until it becomes hard.

3Wrap a clean rag round the base of the

accumulator to catch any spilt fluid.

4Unscrew the accumulator using a hexagon

key. Remove the accumulator, being prepared

for fluid spillage (see illustration).

5When refitting, fit a new O-ring to the base

of the accumulator. Fit the accumulator and

tighten it.

6Reconnect the battery. Switch on the

ignition and check that the hydraulic unit

pump stops within 60 seconds. If not, there

may be something wrong with the

accumulator.

7Bleed the complete hydraulic system as

described in Section 2.

17Hydraulic unit accumulator -

removal and refitting

16Hydraulic unit fluid reservoir -

removal and refitting

Braking system 10•9

10

15.7 Four nuts (arrowed) which hold the

hydraulic unit to the bulkhead

16.4 Undoing the reservoir securing screw16.5a Extract the spring clip . . .

16.6 Removing the hydraulic fluid reservoir

16.5b . . . and disconnect the hose

16.7 The spigot locating bush fits into this

union17.4 Removing the accumulator

Note O-ring (arrowed)

procarmanuals.com

Page 139 of 255

1Remove the accumulator (Section 17).

2Disconnect the high pressure hose from the

pump. Be prepared for fluid spillage.

3Disconnect the low pressure hose from the

pump. Allow the fluid to drain out of the

reservoir through the hose.

4Disconnect the multi-plugs from the

pressure switch and the pump motor.

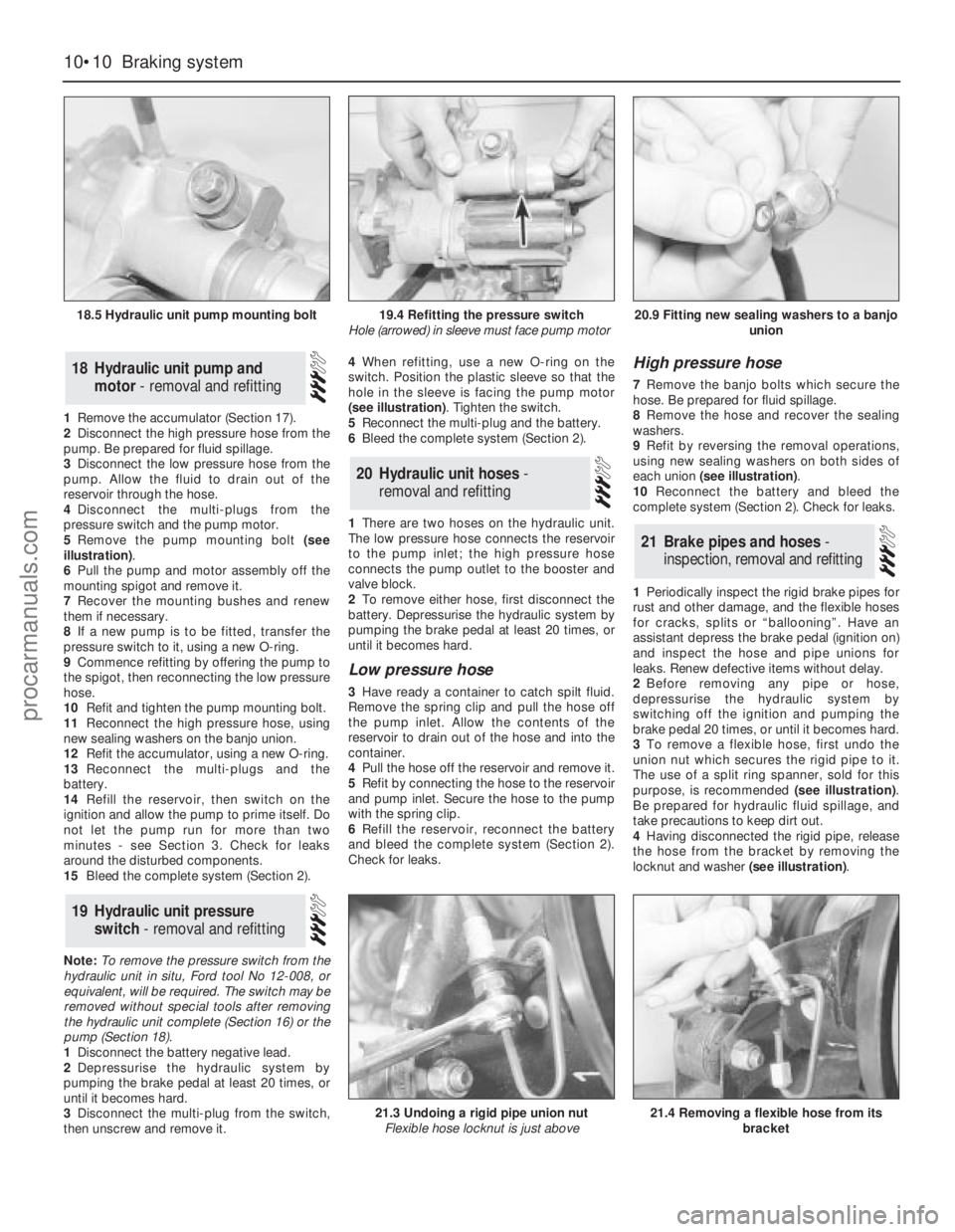

5Remove the pump mounting bolt (see

illustration).

6Pull the pump and motor assembly off the

mounting spigot and remove it.

7Recover the mounting bushes and renew

them if necessary.

8If a new pump is to be fitted, transfer the

pressure switch to it, using a new O-ring.

9Commence refitting by offering the pump to

the spigot, then reconnecting the low pressure

hose.

10Refit and tighten the pump mounting bolt.

11Reconnect the high pressure hose, using

new sealing washers on the banjo union.

12Refit the accumulator, using a new O-ring.

13Reconnect the multi-plugs and the

battery.

14Refill the reservoir, then switch on the

ignition and allow the pump to prime itself. Do

not let the pump run for more than two

minutes - see Section 3. Check for leaks

around the disturbed components.

15Bleed the complete system (Section 2).

Note: To remove the pressure switch from the

hydraulic unit in situ, Ford tool No 12-008, or

equivalent, will be required. The switch may be

removed without special tools after removing

the hydraulic unit complete (Section 16) or the

pump (Section 18).

1Disconnect the battery negative lead.

2Depressurise the hydraulic system by

pumping the brake pedal at least 20 times, or

until it becomes hard.

3Disconnect the multi-plug from the switch,

then unscrew and remove it.4When refitting, use a new O-ring on the

switch. Position the plastic sleeve so that the

hole in the sleeve is facing the pump motor

(see illustration). Tighten the switch.

5Reconnect the multi-plug and the battery.

6Bleed the complete system (Section 2).

1There are two hoses on the hydraulic unit.

The low pressure hose connects the reservoir

to the pump inlet; the high pressure hose

connects the pump outlet to the booster and

valve block.

2To remove either hose, first disconnect the

battery. Depressurise the hydraulic system by

pumping the brake pedal at least 20 times, or

until it becomes hard.

Low pressure hose

3Have ready a container to catch spilt fluid.

Remove the spring clip and pull the hose off

the pump inlet. Allow the contents of the

reservoir to drain out of the hose and into the

container.

4Pull the hose off the reservoir and remove it.

5Refit by connecting the hose to the reservoir

and pump inlet. Secure the hose to the pump

with the spring clip.

6Refill the reservoir, reconnect the battery

and bleed the complete system (Section 2).

Check for leaks.

High pressure hose

7Remove the banjo bolts which secure the

hose. Be prepared for fluid spillage.

8Remove the hose and recover the sealing

washers.

9Refit by reversing the removal operations,

using new sealing washers on both sides of

each union (see illustration).

10Reconnect the battery and bleed the

complete system (Section 2). Check for leaks.

1Periodically inspect the rigid brake pipes for

rust and other damage, and the flexible hoses

for cracks, splits or “ballooning”. Have an

assistant depress the brake pedal (ignition on)

and inspect the hose and pipe unions for

leaks. Renew defective items without delay.

2Before removing any pipe or hose,

depressurise the hydraulic system by

switching off the ignition and pumping the

brake pedal 20 times, or until it becomes hard.

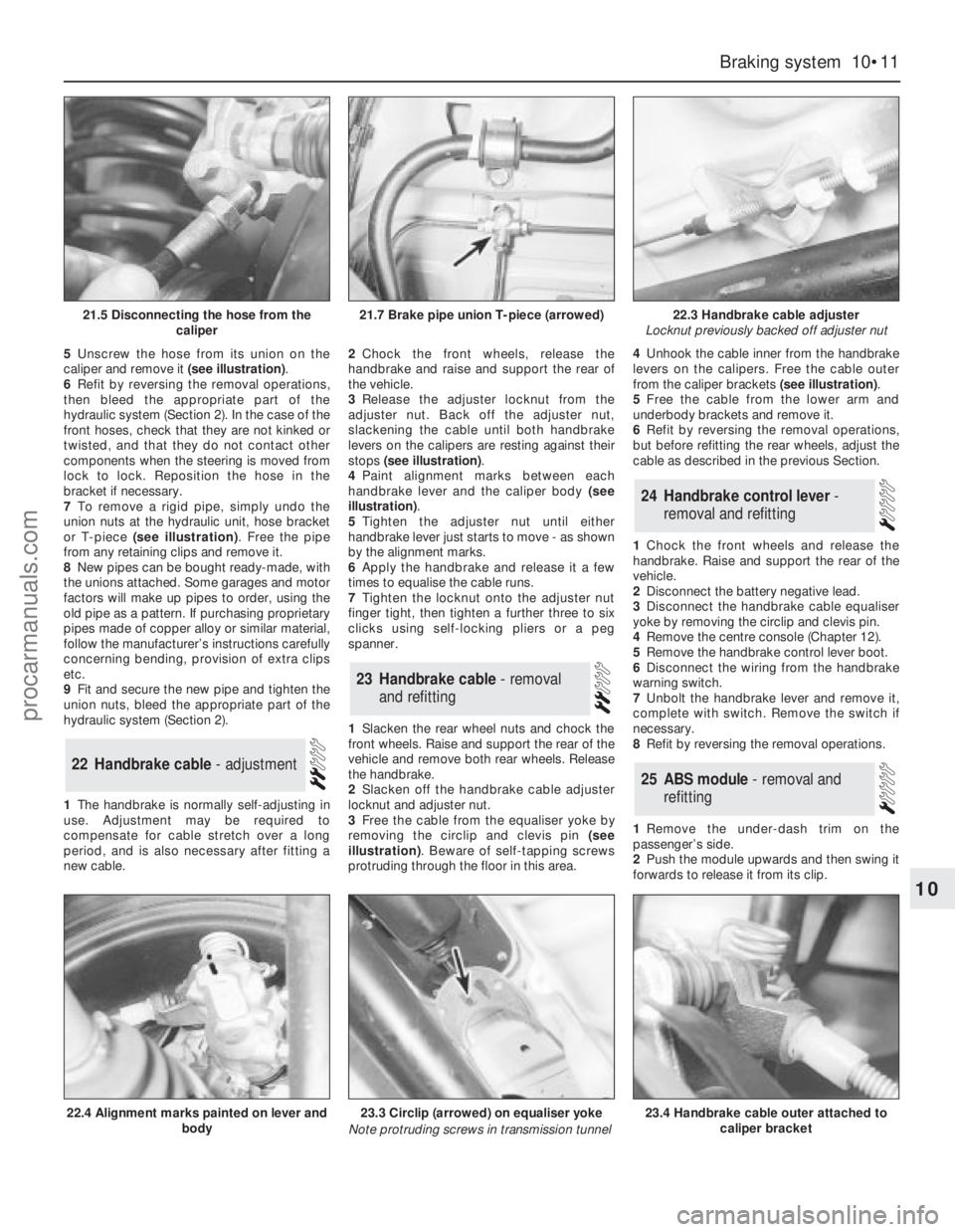

3To remove a flexible hose, first undo the

union nut which secures the rigid pipe to it.

The use of a split ring spanner, sold for this

purpose, is recommended (see illustration).

Be prepared for hydraulic fluid spillage, and

take precautions to keep dirt out.

4Having disconnected the rigid pipe, release

the hose from the bracket by removing the

locknut and washer (see illustration).

21Brake pipes and hoses -

inspection, removal and refitting

20Hydraulic unit hoses -

removal and refitting

19Hydraulic unit pressure

switch - removal and refitting

18Hydraulic unit pump and

motor - removal and refitting

10•10Braking system

18.5 Hydraulic unit pump mounting bolt

21.3 Undoing a rigid pipe union nut

Flexible hose locknut is just above21.4 Removing a flexible hose from its

bracket

19.4 Refitting the pressure switch

Hole (arrowed) in sleeve must face pump motor20.9 Fitting new sealing washers to a banjo

union

procarmanuals.com

Page 140 of 255

5Unscrew the hose from its union on the

caliper and remove it (see illustration).

6Refit by reversing the removal operations,

then bleed the appropriate part of the

hydraulic system (Section 2). In the case of the

front hoses, check that they are not kinked or

twisted, and that they do not contact other

components when the steering is moved from

lock to lock. Reposition the hose in the

bracket if necessary.

7To remove a rigid pipe, simply undo the

union nuts at the hydraulic unit, hose bracket

or T-piece (see illustration). Free the pipe

from any retaining clips and remove it.

8New pipes can be bought ready-made, with

the unions attached. Some garages and motor

factors will make up pipes to order, using the

old pipe as a pattern. If purchasing proprietary

pipes made of copper alloy or similar material,

follow the manufacturer’s instructions carefully

concerning bending, provision of extra clips

etc.

9Fit and secure the new pipe and tighten the

union nuts, bleed the appropriate part of the

hydraulic system (Section 2).

1The handbrake is normally self-adjusting in

use. Adjustment may be required to

compensate for cable stretch over a long

period, and is also necessary after fitting a

new cable.2Chock the front wheels, release the

handbrake and raise and support the rear of

the vehicle.

3Release the adjuster locknut from the

adjuster nut. Back off the adjuster nut,

slackening the cable until both handbrake

levers on the calipers are resting against their

stops (see illustration).

4Paint alignment marks between each

handbrake lever and the caliper body (see

illustration).

5Tighten the adjuster nut until either

handbrake lever just starts to move - as shown

by the alignment marks.

6Apply the handbrake and release it a few

times to equalise the cable runs.

7Tighten the locknut onto the adjuster nut

finger tight, then tighten a further three to six

clicks using self-locking pliers or a peg

spanner.

1Slacken the rear wheel nuts and chock the

front wheels. Raise and support the rear of the

vehicle and remove both rear wheels. Release

the handbrake.

2Slacken off the handbrake cable adjuster

locknut and adjuster nut.

3Free the cable from the equaliser yoke by

removing the circlip and clevis pin (see

illustration). Beware of self-tapping screws

protruding through the floor in this area.4Unhook the cable inner from the handbrake

levers on the calipers. Free the cable outer

from the caliper brackets (see illustration).

5Free the cable from the lower arm and

underbody brackets and remove it.

6Refit by reversing the removal operations,

but before refitting the rear wheels, adjust the

cable as described in the previous Section.

1Chock the front wheels and release the

handbrake. Raise and support the rear of the

vehicle.

2Disconnect the battery negative lead.

3Disconnect the handbrake cable equaliser

yoke by removing the circlip and clevis pin.

4Remove the centre console (Chapter 12).

5Remove the handbrake control lever boot.

6Disconnect the wiring from the handbrake

warning switch.

7Unbolt the handbrake lever and remove it,

complete with switch. Remove the switch if

necessary.

8Refit by reversing the removal operations.

1Remove the under-dash trim on the

passenger’s side.

2Push the module upwards and then swing it

forwards to release it from its clip.

25ABS module - removal and

refitting

24Handbrake control lever -

removal and refitting

23Handbrake cable - removal

and refitting

22Handbrake cable - adjustment

Braking system 10•11

10

21.5 Disconnecting the hose from the

caliper21.7 Brake pipe union T-piece (arrowed)22.3 Handbrake cable adjuster

Locknut previously backed off adjuster nut

22.4 Alignment marks painted on lever and

body23.3 Circlip (arrowed) on equaliser yoke

Note protruding screws in transmission tunnel23.4 Handbrake cable outer attached to

caliper bracket

procarmanuals.com

Page 141 of 255

3Press the multi-plug locking lever,

disconnect the multi-plug and unhook it from

the module. Remove the module.

4Refit by reversing the removal operations.

Make sure that the multi-plug is properly

engaged before refitting the module.

Front

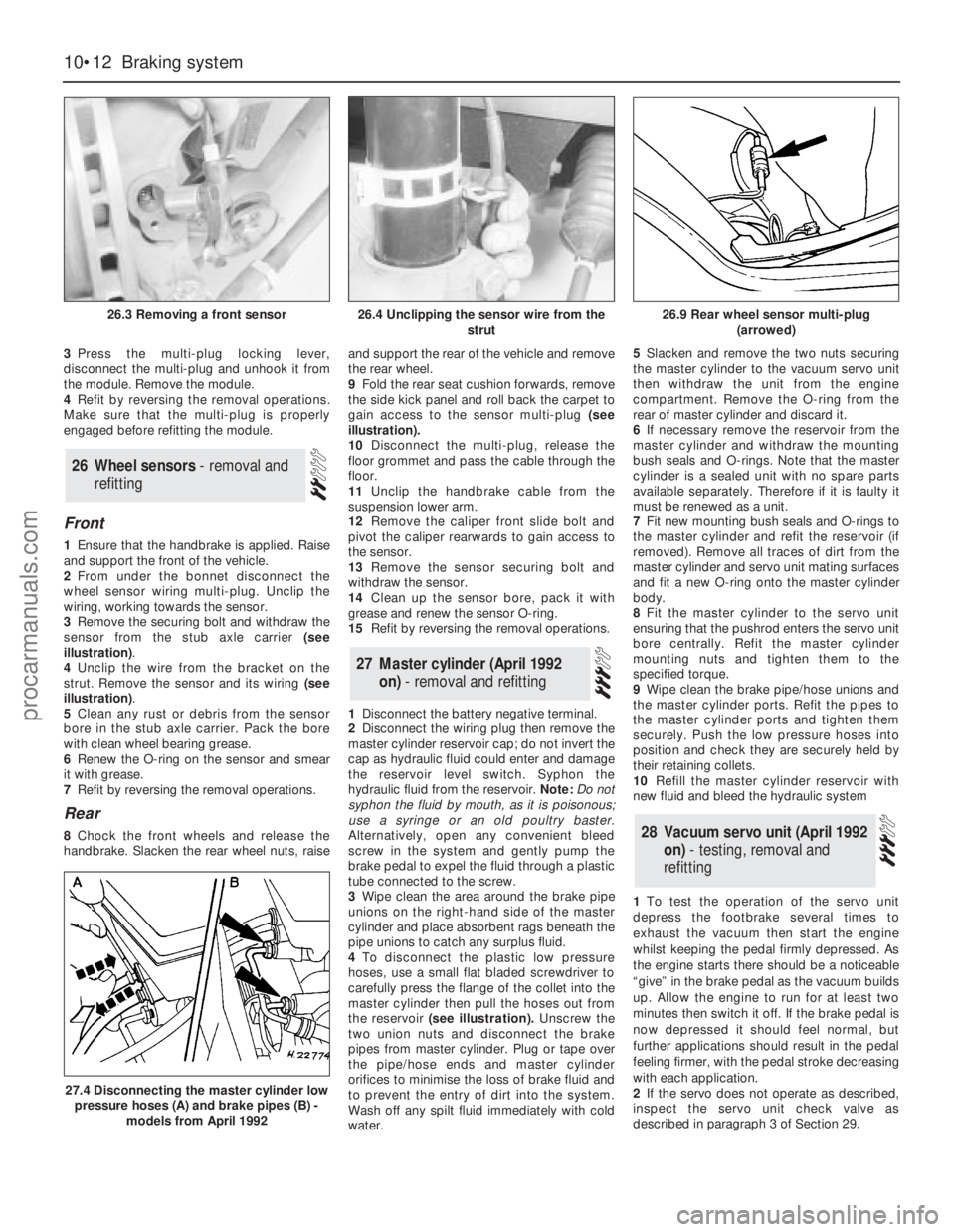

1Ensure that the handbrake is applied. Raise

and support the front of the vehicle.

2From under the bonnet disconnect the

wheel sensor wiring multi-plug. Unclip the

wiring, working towards the sensor.

3Remove the securing bolt and withdraw the

sensor from the stub axle carrier (see

illustration).

4Unclip the wire from the bracket on the

strut. Remove the sensor and its wiring (see

illustration).

5Clean any rust or debris from the sensor

bore in the stub axle carrier. Pack the bore

with clean wheel bearing grease.

6Renew the O-ring on the sensor and smear

it with grease.

7Refit by reversing the removal operations.

Rear

8Chock the front wheels and release the

handbrake. Slacken the rear wheel nuts, raiseand support the rear of the vehicle and remove

the rear wheel.

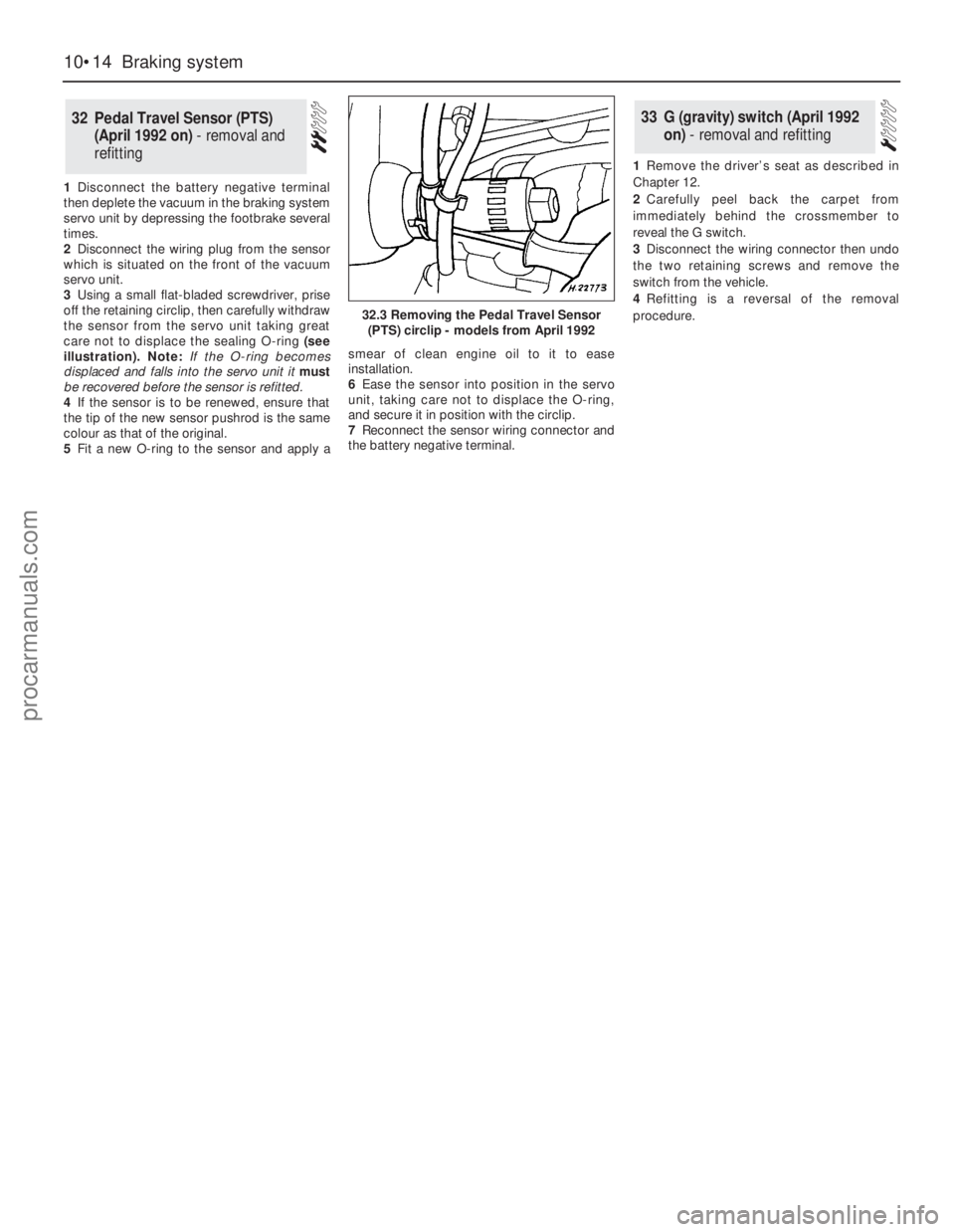

9Fold the rear seat cushion forwards, remove

the side kick panel and roll back the carpet to

gain access to the sensor multi-plug (see

illustration).

10Disconnect the multi-plug, release the

floor grommet and pass the cable through the

floor.

11Unclip the handbrake cable from the

suspension lower arm.

12Remove the caliper front slide bolt and

pivot the caliper rearwards to gain access to

the sensor.

13Remove the sensor securing bolt and

withdraw the sensor.

14Clean up the sensor bore, pack it with

grease and renew the sensor O-ring.

15Refit by reversing the removal operations.

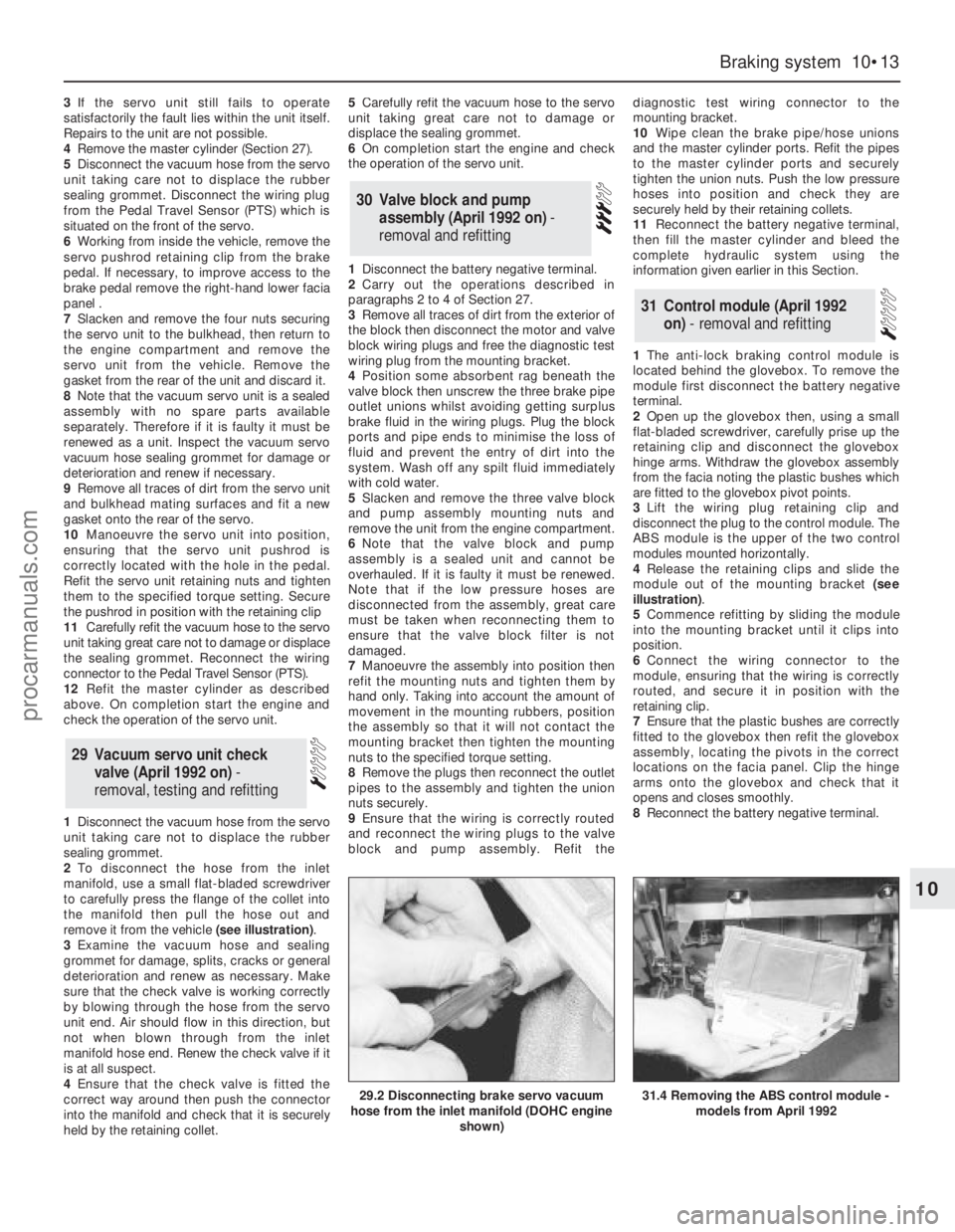

1Disconnect the battery negative terminal.

2Disconnect the wiring plug then remove the

master cylinder reservoir cap; do not invert the

cap as hydraulic fluid could enter and damage

the reservoir level switch. Syphon the

hydraulic fluid from the reservoir. Note: Do not

syphon the fluid by mouth, as it is poisonous;

use a syringe or an old poultry baster.

Alternatively, open any convenient bleed

screw in the system and gently pump the

brake pedal to expel the fluid through a plastic

tube connected to the screw.

3Wipe clean the area around the brake pipe

unions on the right-hand side of the master

cylinder and place absorbent rags beneath the

pipe unions to catch any surplus fluid.

4To disconnect the plastic low pressure

hoses, use a small flat bladed screwdriver to

carefully press the flange of the collet into the

master cylinder then pull the hoses out from

the reservoir(see illustration).Unscrew the

two union nuts and disconnect the brake

pipes from master cylinder. Plug or tape over

the pipe/hose ends and master cylinder

orifices to minimise the loss of brake fluid and

to prevent the entry of dirt into the system.

Wash off any spilt fluid immediately with cold

water.5Slacken and remove the two nuts securing

the master cylinder to the vacuum servo unit

then withdraw the unit from the engine

compartment. Remove the O-ring from the

rear of master cylinder and discard it.

6If necessary remove the reservoir from the

master cylinder and withdraw the mounting

bush seals and O-rings. Note that the master

cylinder is a sealed unit with no spare parts

available separately. Therefore if it is faulty it

must be renewed as a unit.

7Fit new mounting bush seals and O-rings to

the master cylinder and refit the reservoir (if

removed). Remove all traces of dirt from the

master cylinder and servo unit mating surfaces

and fit a new O-ring onto the master cylinder

body.

8Fit the master cylinder to the servo unit

ensuring that the pushrod enters the servo unit

bore centrally. Refit the master cylinder

mounting nuts and tighten them to the

specified torque.

9Wipe clean the brake pipe/hose unions and

the master cylinder ports. Refit the pipes to

the master cylinder ports and tighten them

securely. Push the low pressure hoses into

position and check they are securely held by

their retaining collets.

10Refill the master cylinder reservoir with

new fluid and bleed the hydraulic system

1To test the operation of the servo unit

depress the footbrake several times to

exhaust the vacuum then start the engine

whilst keeping the pedal firmly depressed. As

the engine starts there should be a noticeable

“give” in the brake pedal as the vacuum builds

up. Allow the engine to run for at least two

minutes then switch it off. If the brake pedal is

now depressed it should feel normal, but

further applications should result in the pedal

feeling firmer, with the pedal stroke decreasing

with each application.

2If the servo does not operate as described,

inspect the servo unit check valve as

describedin paragraph 3 of Section 29.28Vacuum servo unit (April 1992

on) - testing, removal and

refitting

27Master cylinder (April 1992

on) - removal and refitting

26Wheel sensors - removal and

refitting

10•12Braking system

26.3 Removing a front sensor

27.4 Disconnecting the master cylinder low

pressure hoses (A) and brake pipes (B) -

models from April 1992

26.4 Unclipping the sensor wire from the

strut26.9 Rear wheel sensor multi-plug

(arrowed)

procarmanuals.com

Page 142 of 255

3If the servo unit still fails to operate

satisfactorily the fault lies within the unit itself.

Repairs to the unit are not possible.

4Remove the master cylinder (Section 27).

5Disconnect the vacuum hose from the servo

unit taking care not to displace the rubber

sealing grommet. Disconnect the wiring plug

from the Pedal Travel Sensor (PTS) which is

situated on the front of the servo.

6Working from inside the vehicle, remove the

servo pushrod retaining clip from the brake

pedal. If necessary, to improve access to the

brake pedal remove the right-hand lower facia

panel .

7Slacken and remove the four nuts securing

the servo unit to the bulkhead, then return to

the engine compartment and remove the

servo unit from the vehicle. Remove the

gasket from the rear of the unit and discard it.

8Note that the vacuum servo unit is a sealed

assembly with no spare parts available

separately. Therefore if it is faulty it must be

renewed as a unit. Inspect the vacuum servo

vacuum hose sealing grommet for damage or

deterioration and renew if necessary.

9Remove all traces of dirt from the servo unit

and bulkhead mating surfaces and fit a new

gasket onto the rear of the servo.

10Manoeuvre the servo unit into position,

ensuring that the servo unit pushrod is

correctly located with the hole in the pedal.

Refit the servo unit retaining nuts and tighten

them to the specified torque setting. Secure

the pushrod in position with the retaining clip

11Carefully refit the vacuum hose to the servo

unit taking great care not to damage or displace

the sealing grommet. Reconnect the wiring

connector to the Pedal Travel Sensor (PTS).

12Refit the master cylinder as described

above. On completion start the engine and

check the operation of the servo unit.

1Disconnect the vacuum hose from the servo

unit taking care not to displace the rubber

sealing grommet.

2To disconnect the hose from the inlet

manifold, use a small flat-bladed screwdriver

to carefully press the flange of the collet into

the manifold then pull the hose out and

remove it from the vehicle (see illustration).

3Examine the vacuum hose and sealing

grommet for damage, splits, cracks or general

deterioration and renew as necessary. Make

sure that the check valve is working correctly

by blowing through the hose from the servo

unit end. Air should flow in this direction, but

not when blown through from the inlet

manifold hose end. Renew the check valve if it

is at all suspect.

4Ensure that the check valve is fitted the

correct way around then push the connector

into the manifold and check that it is securely

held by the retaining collet.5Carefully refit the vacuum hose to the servo

unit taking great care not to damage or

displace the sealing grommet.

6On completion start the engine and check

the operation of the servo unit.

1Disconnect the battery negative terminal.

2Carry out the operations described in

paragraphs 2 to 4 of Section 27.

3Remove all traces of dirt from the exterior of

the block then disconnect the motor and valve

block wiring plugs and free the diagnostic test

wiring plug from the mounting bracket.

4Position some absorbent rag beneath the

valve block then unscrew the three brake pipe

outlet unions whilst avoiding getting surplus

brake fluid in the wiring plugs. Plug the block

ports and pipe ends to minimise the loss of

fluid and prevent the entry of dirt into the

system. Wash off any spilt fluid immediately

with cold water.

5Slacken and remove the three valve block

and pump assembly mounting nuts and

remove the unit from the engine compartment.

6Note that the valve block and pump

assembly is a sealed unit and cannot be

overhauled. If it is faulty it must be renewed.

Note that if the low pressure hoses are

disconnected from the assembly, great care

must be taken when reconnecting them to

ensure that the valve block filter is not

damaged.

7Manoeuvre the assembly into position then

refit the mounting nuts and tighten them by

hand only. Taking into account the amount of

movement in the mounting rubbers, position

the assembly so that it will not contact the

mounting bracket then tighten the mounting

nuts to the specified torque setting.

8Remove the plugs then reconnect the outlet

pipes to the assembly and tighten the union

nuts securely.

9Ensure that the wiring is correctly routed

and reconnect the wiring plugs to the valve

block and pump assembly. Refit thediagnostic test wiring connector to the

mounting bracket.

10Wipe clean the brake pipe/hose unions

and the master cylinder ports. Refit the pipes

to the master cylinder ports and securely

tighten the union nuts. Push the low pressure

hoses into position and check they are

securely held by their retaining collets.

11Reconnect the battery negative terminal,

then fill the master cylinder and bleed the

complete hydraulic system using the

information given earlier in this Section.

1The anti-lock braking control module is

located behind the glovebox. To remove the

module first disconnect the battery negative

terminal.

2Open up the glovebox then, using a small

flat-bladed screwdriver, carefully prise up the

retaining clip and disconnect the glovebox

hinge arms. Withdraw the glovebox assembly

from the facia noting the plastic bushes which

are fitted to the glovebox pivot points.

3Lift the wiring plug retaining clip and

disconnect the plug to the control module. The

ABS module is the upper of the two control

modules mounted horizontally.

4Release the retaining clips and slide the

module out of the mounting bracket (see

illustration).

5Commence refitting by sliding the module

into the mounting bracket until it clips into

position.

6Connect the wiring connector to the

module, ensuring that the wiring is correctly

routed, and secure it in position with the

retaining clip.

7Ensure that the plastic bushes are correctly

fitted to the glovebox then refit the glovebox

assembly, locating the pivots in the correct

locations on the facia panel. Clip the hinge

arms onto the glovebox and check that it

opens and closes smoothly.

8Reconnect the battery negative terminal.

31Control module (April 1992

on) - removal and refitting

30Valve block and pump

assembly (April 1992 on) -

removal and refitting

29 Vacuum servo unit check

valve (April 1992 on) -

removal, testing and refitting

Braking system 10•13

10

29.2 Disconnecting brake servo vacuum

hose from the inlet manifold (DOHC engine

shown)31.4 Removing the ABS control module -

models from April 1992

procarmanuals.com

Page 143 of 255

1Disconnect the battery negative terminal

then deplete the vacuum in the braking system

servo unit by depressing the footbrake several

times.

2Disconnect the wiring plug from the sensor

which is situated on the front of the vacuum

servo unit.

3Using a small flat-bladed screwdriver, prise

off the retaining circlip, then carefully withdraw

the sensor from the servo unit taking great

care not to displace the sealing O-ring (see

illustration).Note:If the O-ring becomes

displaced and falls into the servo unit it must

be recovered before the sensor is refitted.

4If the sensor is to be renewed, ensure that

the tip of the new sensor pushrod is the same

colour as that of the original.

5Fit a new O-ring to the sensor and apply asmear of clean engine oil to it to ease

installation.

6Ease the sensor into position in the servo

unit, taking care not to displace the O-ring,

and secure it in position with the circlip.

7Reconnect the sensor wiring connector and

the battery negative terminal.1Remove the driver’s seat as described in

Chapter 12.

2Carefully peel back the carpet from

immediately behind the crossmember to

reveal the G switch.

3Disconnect the wiring connector then undo

the two retaining screws and remove the

switch from the vehicle.

4Refitting is a reversal of the removal

procedure.

33G (gravity) switch (April 1992

on) - removal and refitting32Pedal Travel Sensor (PTS)

(April 1992 on) - removal and

refitting

10•14Braking system

32.3 Removing the Pedal Travel Sensor

(PTS) circlip - models from April 1992

procarmanuals.com

Page 147 of 255

13Refit the track rod ends to the steering

arms. Fit the balljoint nuts and tighten them to

the specified torque, then secure with new

split pins.

14Nip up the track rod end locknuts, but do

not tighten them fully yet.

15Refit the front wheels and wheel nuts.

Lower the vehicle and tighten the wheel nuts

to the specified torque.

16Check the toe setting as described in

Section 19. When toe is correct, tighten the

track rod end locknuts fully.

Power-assisted steering

17Proceed as described for manual steering

gear, but before removing the steering gear-

to-crossmember bolts, remove the clamp

plate bolt from the steering gear valve body

(see illustration).18Pull the fluid pipes out of the valve body.

Be prepared for fluid spillage. Plug or cap the

open pipes and orifices.

19The steering gear may now be removed.

20Refit in the reverse order to removal, using

new O-rings on the fluid pipes.

21Bleed the steering gear hydraulic system

on completion.

1Remove the track rod end on the side

concerned.Also remove the locknut.

2Remove the bellows retaining clips and slide

the bellows off the track rod (see illustration).

3On manual steering racks, apply a smear of

grease to the track rod 4Fit the new bellows and secure with new

clips. Make sure that the ends of the bellows

are located in their grooves. Do not tighten the

outer clip yet - leave it slack until toe has been

checked after refitting.

5Refit the track rod end locknut, followed by

the track rod end itself.

6Repeat on the other side of the vehicle if

necessary.

Models before April 1992

1Disconnect the battery negative lead.

2Prise off the horn push pad from the centre

of the steering wheel.

3Remove the three screws which secure the

horn switch plate. Withdraw the plate,

disconnect its wires and remove it.

4Engage the steering lock, then undo and

remove the steering wheel nut. Unlock the

steering again.

5Mark the relationship of the wheel to the

shaft, then pull the wheel off the shaft. Use a

puller if it cannot be removed by hand. Do not

use hammer blows, which may damage the

collapsible parts of the column and shaft.

6Recover the spacer from below the steering

wheel (see illustration).

7Refit by reversing the removal operations.

Tighten the steering wheel nut to the specified

torque.

Models from April 1992

8The steering wheel can be removed and

refitted as described above whilst ignoring the

5Steering wheel - removal and

refitting

4Steering rack bellows - renewal

in vehicle

11•4Steering and suspension

3.17 Clamp plate bolt (arrowed) is located

between two fluid pipes4.2 Steering rack bellows retaining clips

(arrowed)5.6 Spacer ring (arrowed) fits below

steering wheel

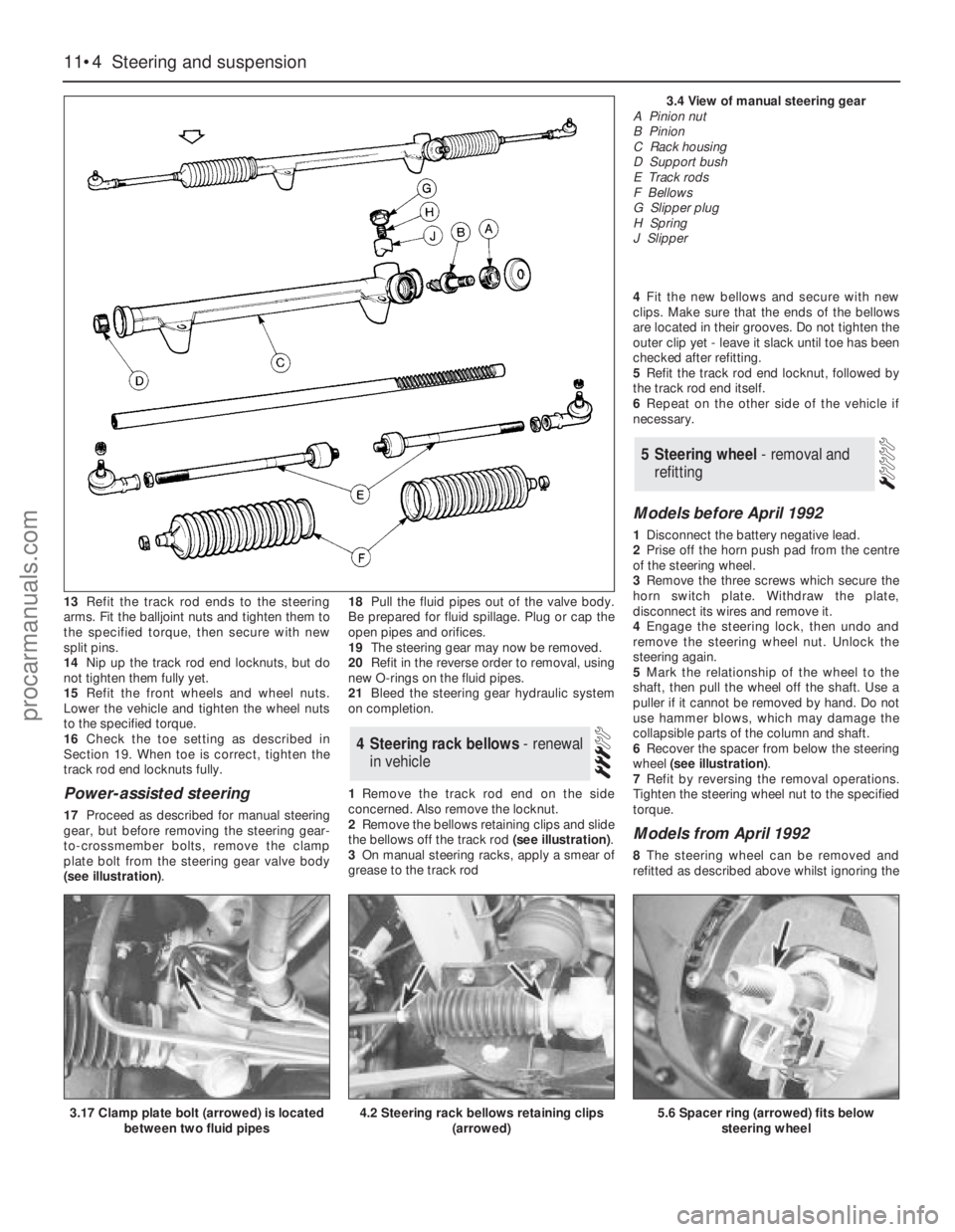

3.4 View of manual steering gearA Pinion nut

B Pinion

C Rack housing

D Support bush

E Track rods

F Bellows

G Slipper plug

H Spring

J Slipper

procarmanuals.com

Page 148 of 255

reference to horn switch plate retaining

screws. Note that the wheel is retained by a

bolt, not a nut as on earlier models. To gain

access to the bolt, prise out the horn button

and disconnect the wiring connectors.

1This operation is for correcting small errors

in steering wheel centralisation - up to 60°. For

larger errors, remove the steering wheel and

make a rough correction by repositioning the

wheel on refitting.

2Drive the vehicle in a straight line on a level

surface. Note the angle by which the steering

wheel deviates from the desired straight-

ahead position.

3Raise the front of the vehicle by driving it

onto ramps, or with a jack and axle stands

(see “Jacking”).

4Slacken both track rod end locknuts. Also

slacken the steering rack bellows outer clips.

5Make alignment marks between each track

rod end and its rod, so that the amount of

rotation applied can be accurately determined.

6Turn both track rodsin the same direction

to correct the steering wheel position. As a

rough guide, 19°of track rod rotation will

change the steering wheel position by 1°. To

correct error at the steering wheel, rotate both

track rods anti-clockwise (viewed from the

left-hand side of the vehicle), and the reverse

to correct as anti-clockwise errors. Both track

rods must be rotated by the same amount.

7Tighten the bellows clips and the track rod

end locknuts when adjustment is correct.

Lower the vehicle.

1Disconnect the battery negative lead.

2Position the steering in the straight-ahead

position.

3Remove the steering wheel. This is not

essential, but will improve access.

4Working under the bonnet, disconnect the

intermediate shaft universal joint from the

steering column shaft.5Remove the steering column shrouds and

disconnect the switch multi-plugs. Do not

forget the ignition/starter switch.

6Disconnect the bonnet release cable from the

operating lever on the underside of the column.

7Prise out the driver’s side air vent. Remove

the under-dash insulation and trim panel on

the driver’s side, unclipping the bulb failure

module, where applicable.

8Remove the three nuts which secure the

column height adjuster to the mounting bracket

(see illustration). Remove the column assembly

by drawing it into the vehicle. Do not drop it or

otherwise mistreat it if it is to be re-used.9When refitting, have an assistant guide the

column shaft into the intermediate shaft

universal joint. Secure the column with the

three nuts inside the vehicle and adjust it to

the minimum length position, then tighten the

coupling pinch-bolt.

10Complete refitting by reversing the

removal operations.

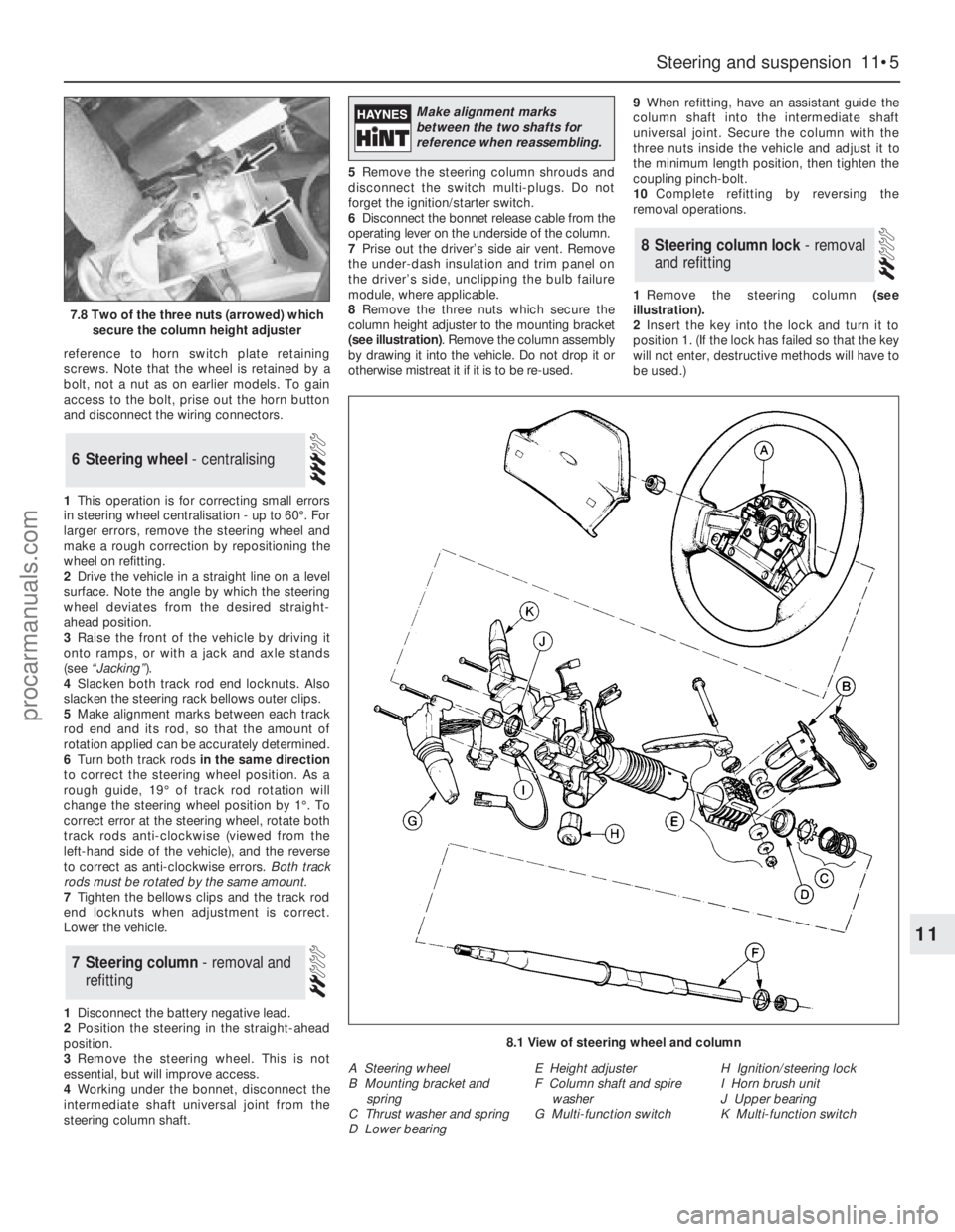

1Remove the steering column (see

illustration).

2Insert the key into the lock and turn it to

position 1. (If the lock has failed so that the key

will not enter, destructive methods will have to

be used.)

8Steering column lock - removal

and refitting

7Steering column - removal and

refitting

6Steering wheel - centralising

Steering and suspension 11•5

11

7.8 Two of the three nuts (arrowed) which

secure the column height adjuster

8.1 View of steering wheel and column

A Steering wheel

B Mounting bracket and

spring

C Thrust washer and spring

D Lower bearingE Height adjuster

F Column shaft and spire

washer

G Multi-function switchH Ignition/steering lock

I Horn brush unit

J Upper bearing

K Multi-function switch

Make alignment marks

between the two shafts for

reference when reassembling.

procarmanuals.com