lock FORD GRANADA 1985 Service Manual Online

[x] Cancel search | Manufacturer: FORD, Model Year: 1985, Model line: GRANADA, Model: FORD GRANADA 1985Pages: 255, PDF Size: 14.98 MB

Page 123 of 255

multi-plug. Disconnect the plug, pulling on the

plug itself, not the wires (see illustration).

6Make alignment marks between the

distributor body and the engine, then remove

the distributor clamp bolt and clamp plate

(see illustration). On V6 models access is

poor, and a crow’s-foot spanner will be

needed. The clamp bolt may be covered insealant to discourage tampering - if so, scrape

it off. Unbolt the support bracket, when fitted.

7Lift out the distributor (see illustration).

Mark the position taken up by the rotor arm

after removal.

8If the distributor is mechanically or

electrically defective, it must be renewed. The

only spares available are the cap, rotor arm,

module (when applicable) and the shaft O-ring

(see illustration).

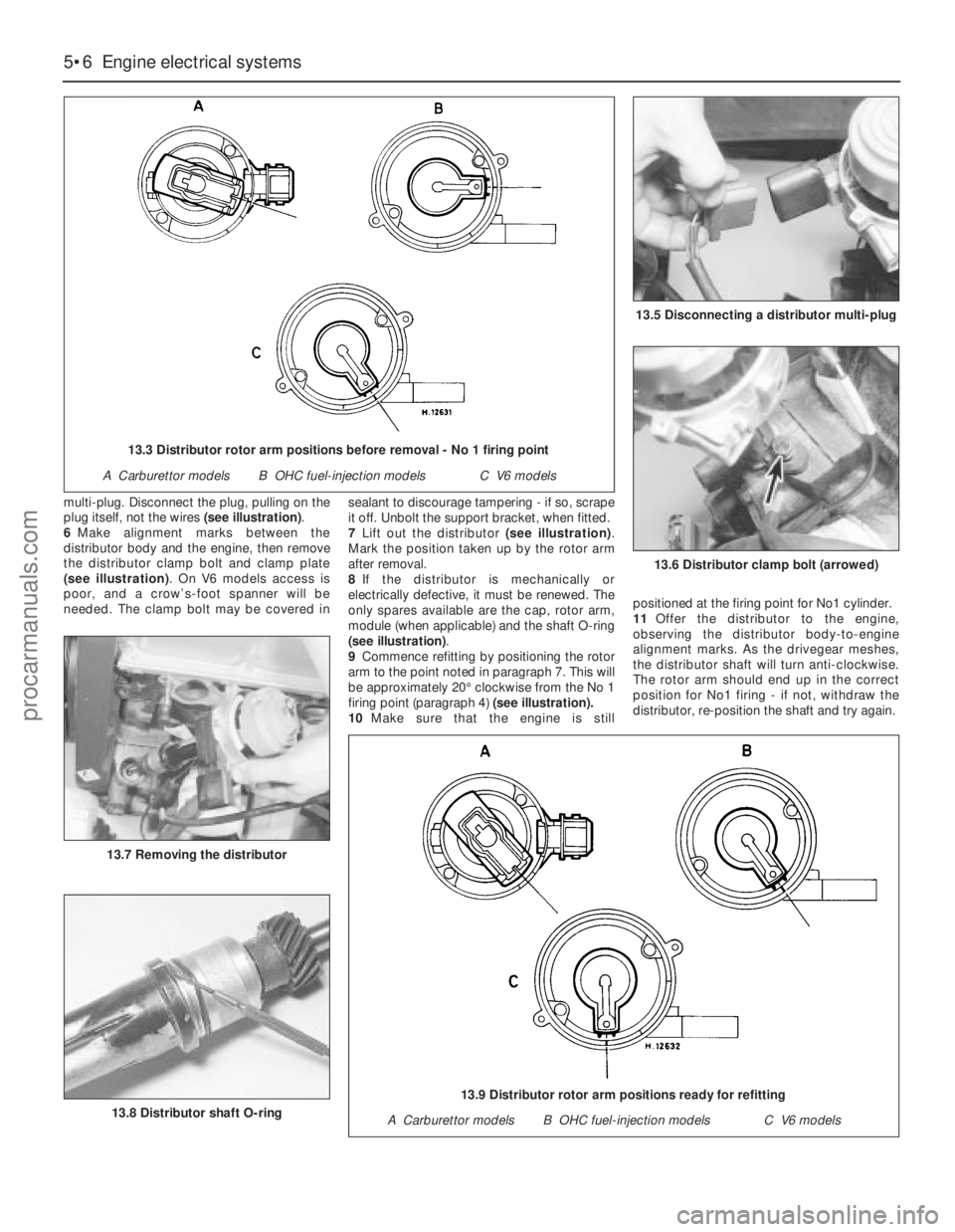

9Commence refitting by positioning the rotor

arm to the point noted in paragraph 7. This will

be approximately 20°clockwise from the No 1

firing point (paragraph 4)(see illustration).

10Make sure that the engine is stillpositioned at the firing point for No1 cylinder.

11Offer the distributor to the engine,

observing the distributor body-to-engine

alignment marks. As the drivegear meshes,

the distributor shaft will turn anti-clockwise.

The rotor arm should end up in the correct

position for No1 firing - if not, withdraw the

distributor, re-position the shaft and try again.

5•6Engine electrical systems

13.6 Distributor clamp bolt (arrowed)

13.8 Distributor shaft O-ring

13.7 Removing the distributor

13.5 Disconnecting a distributor multi-plug

13.3 Distributor rotor arm positions before removal - No 1 firing point

A Carburettor modelsB OHC fuel-injection modelsC V6 models

13.9 Distributor rotor arm positions ready for refitting

A Carburettor modelsB OHC fuel-injection modelsC V6 models

procarmanuals.com

Page 124 of 255

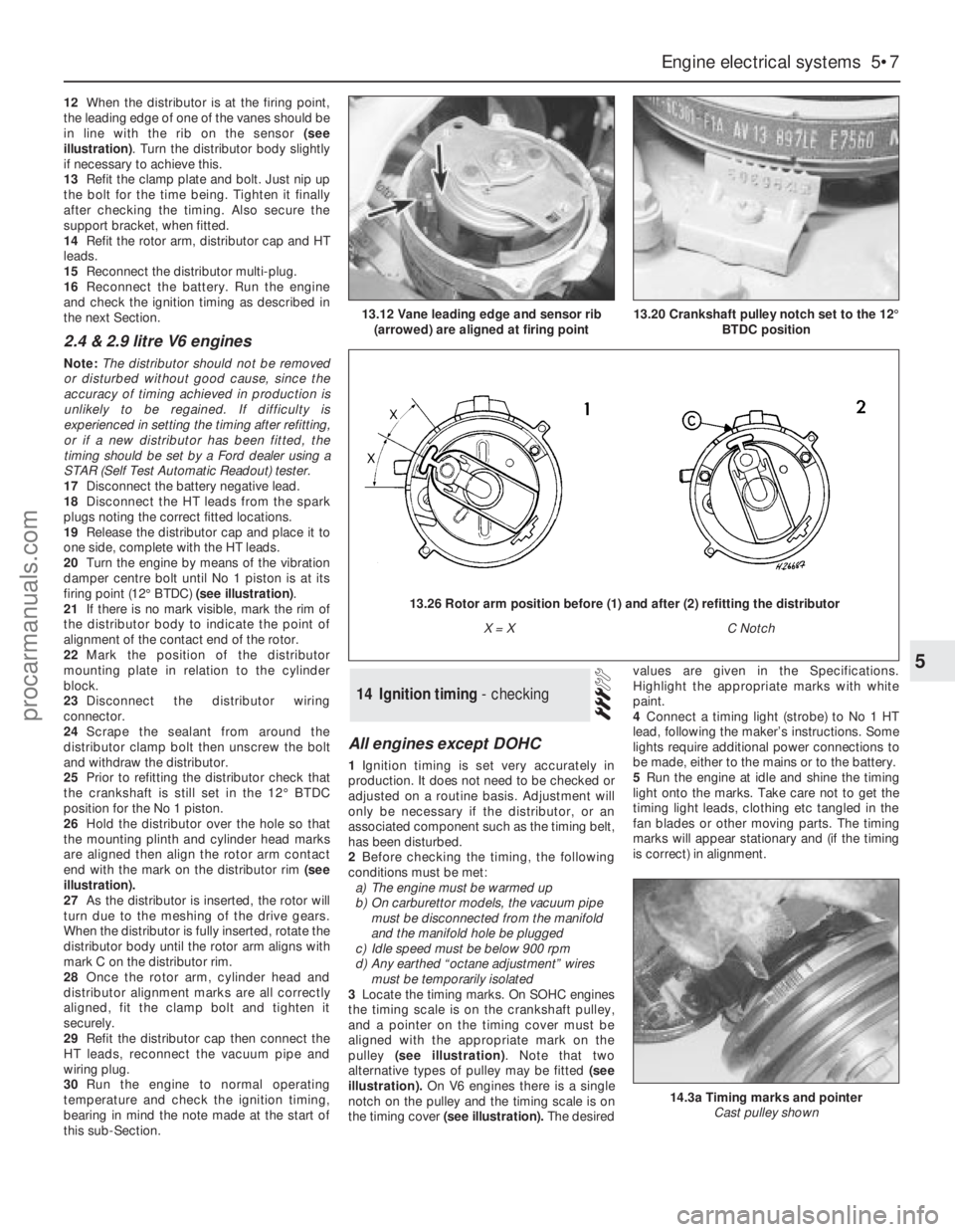

12When the distributor is at the firing point,

the leading edge of one of the vanes should be

in line with the rib on the sensor (see

illustration). Turn the distributor body slightly

if necessary to achieve this.

13Refit the clamp plate and bolt. Just nip up

the bolt for the time being. Tighten it finally

after checking the timing. Also secure the

support bracket, when fitted.

14Refit the rotor arm, distributor cap and HT

leads.

15Reconnect the distributor multi-plug.

16Reconnect the battery. Run the engine

and check the ignition timing as described in

the next Section.

2.4 & 2.9 litre V6 engines

Note: The distributor should not be removed

or disturbed without good cause, since the

accuracy of timing achieved in production is

unlikely to be regained. If difficulty is

experienced in setting the timing after refitting,

or if a new distributor has been fitted, the

timing should be set by a Ford dealer using a

STAR (Self Test Automatic Readout) tester.

17Disconnect the battery negative lead.

18Disconnect the HT leads from the spark

plugs noting the correct fitted locations.

19Release the distributor cap and place it to

one side, complete with the HT leads.

20Turn the engine by means of the vibration

damper centre bolt until No 1 piston is at its

firing point (12°BTDC) (see illustration).

21If there is no mark visible, mark the rim of

the distributor body to indicate the point of

alignment of the contact end of the rotor.

22Mark the position of the distributor

mounting plate in relation to the cylinder

block.

23Disconnect the distributor wiring

connector.

24Scrape the sealant from around the

distributor clamp bolt then unscrew the bolt

and withdraw the distributor.

25Prior to refitting the distributor check that

the crankshaft is still set in the 12°BTDC

position for the No 1 piston.

26Hold the distributor over the hole so that

the mounting plinth and cylinder head marks

are aligned then align the rotor arm contact

end with the mark on the distributor rim (see

illustration).

27As the distributor is inserted, the rotor will

turn due to the meshing of the drive gears.

When the distributor is fully inserted, rotate the

distributor body until the rotor arm aligns with

mark C on the distributor rim.

28Once the rotor arm, cylinder head and

distributor alignment marks are all correctly

aligned, fit the clamp bolt and tighten it

securely.

29Refit the distributor cap then connect the

HT leads, reconnect the vacuum pipe and

wiring plug.

30Run the engine to normal operating

temperature and check the ignition timing,

bearing in mind the note made at the start of

this sub-Section.

All engines except DOHC

1Ignition timing is set very accurately in

production. It does not need to be checked or

adjusted on a routine basis. Adjustment will

only be necessary if the distributor, or an

associated component such as the timing belt,

has been disturbed.

2Before checking the timing, the following

conditions must be met:

a)The engine must be warmed up

b)On carburettor models, the vacuum pipe

must be disconnected from the manifold

and the manifold hole be plugged

c)Idle speed must be below 900 rpm

d)Any earthed “octane adjustment” wires

must be temporarily isolated

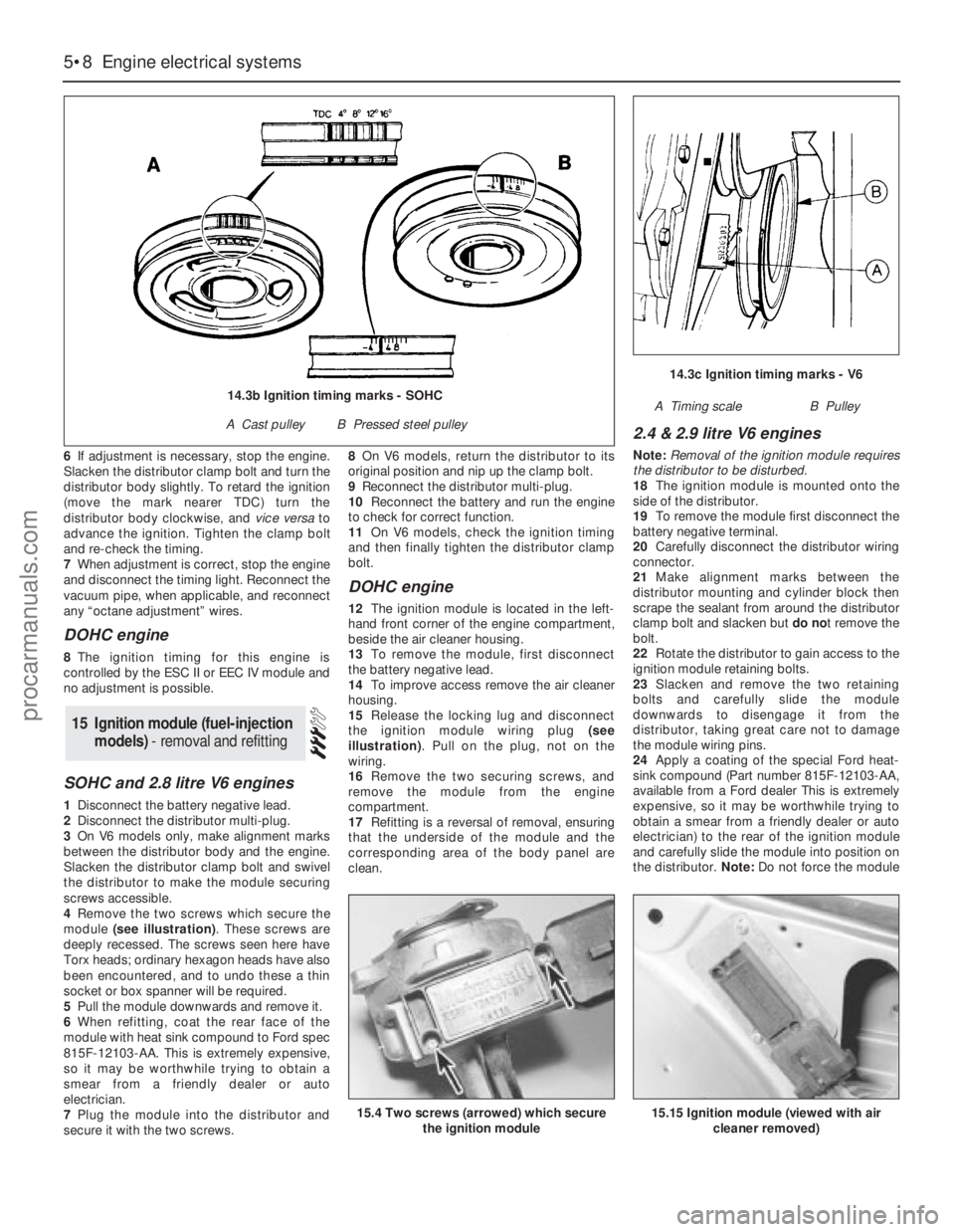

3Locate the timing marks. On SOHC engines

the timing scale is on the crankshaft pulley,

and a pointer on the timing cover must be

aligned with the appropriate mark on the

pulley (see illustration). Note that two

alternative types of pulley may be fitted (see

illustration).On V6 engines there is a single

notch on the pulley and the timing scale is on

the timing cover (see illustration).The desiredvalues are given in the Specifications.

Highlight the appropriate marks with white

paint.

4Connect a timing light (strobe) to No 1 HT

lead, following the maker’s instructions. Some

lights require additional power connections to

be made, either to the mains or to the battery.

5Run the engine at idle and shine the timing

light onto the marks. Take care not to get the

timing light leads, clothing etc tangled in the

fan blades or other moving parts. The timing

marks will appear stationary and (if the timing

is correct) in alignment.

14Ignition timing - checking

Engine electrical systems 5•7

5

13.12 Vane leading edge and sensor rib

(arrowed) are aligned at firing point13.20 Crankshaft pulley notch set to the 12°

BTDC position

14.3a Timing marks and pointer

Cast pulley shown

13.26 Rotor arm position before (1) and after (2) refitting the distributor

X = XC Notch

procarmanuals.com

Page 125 of 255

6If adjustment is necessary, stop the engine.

Slacken the distributor clamp bolt and turn the

distributor body slightly. To retard the ignition

(move the mark nearer TDC) turn the

distributor body clockwise, and vice versato

advance the ignition. Tighten the clamp bolt

and re-check the timing.

7When adjustment is correct, stop the engine

and disconnect the timing light. Reconnect the

vacuum pipe, when applicable, and reconnect

any “octane adjustment” wires.

DOHC engine

8The ignition timing for this engine is

controlled by the ESC II or EEC IV module and

no adjustment is possible.

SOHC and 2.8 litre V6 engines

1Disconnect the battery negative lead.

2Disconnect the distributor multi-plug.

3On V6 models only, make alignment marks

between the distributor body and the engine.

Slacken the distributor clamp bolt and swivel

the distributor to make the module securing

screws accessible.

4Remove the two screws which secure the

module (see illustration). These screws are

deeply recessed. The screws seen here have

Torx heads; ordinary hexagon heads have also

been encountered, and to undo these a thin

socket or box spanner will be required.

5Pull the module downwards and remove it.

6When refitting, coat the rear face of the

module with heat sink compound to Ford spec

815F-12103-AA. This is extremely expensive,

so it may be worthwhile trying to obtain a

smear from a friendly dealer or auto

electrician.

7Plug the module into the distributor and

secure it with the two screws.8On V6 models, return the distributor to its

original position and nip up the clamp bolt.

9Reconnect the distributor multi-plug.

10Reconnect the battery and run the engine

to check for correct function.

11On V6 models, check the ignition timing

and then finally tighten the distributor clamp

bolt.

DOHC engine

12The ignition module is located in the left-

hand front corner of the engine compartment,

beside the air cleaner housing.

13To remove the module, first disconnect

the battery negative lead.

14To improve access remove the air cleaner

housing.

15Release the locking lug and disconnect

the ignition module wiring plug (see

illustration). Pull on the plug, not on the

wiring.

16Remove the two securing screws, and

remove the module from the engine

compartment.

17Refitting is a reversal of removal, ensuring

that the underside of the module and the

corresponding area of the body panel are

clean.

2.4 & 2.9 litre V6 engines

Note: Removal of the ignition module requires

the distributor to be disturbed.

18The ignition module is mounted onto the

side of the distributor.

19To remove the module first disconnect the

battery negative terminal.

20Carefully disconnect the distributor wiring

connector.

21Make alignment marks between the

distributor mounting and cylinder block then

scrape the sealant from around the distributor

clamp bolt and slacken but do not remove the

bolt.

22Rotate the distributor to gain access to the

ignition module retaining bolts.

23Slacken and remove the two retaining

bolts and carefully slide the module

downwards to disengage it from the

distributor, taking great care not to damage

the module wiring pins.

24Apply a coating of the special Ford heat-

sink compound (Part number 815F-12103-AA,

available from a Ford dealer This is extremely

expensive, so it may be worthwhile trying to

obtain a smear from a friendly dealer or auto

electrician) to the rear of the ignition module

and carefully slide the module into position on

the distributor. Note: Do not force the module

15Ignition module (fuel-injection

models) - removal and refitting

5•8Engine electrical systems

15.4 Two screws (arrowed) which secure

the ignition module15.15 Ignition module (viewed with air

cleaner removed)

14.3c Ignition timing marks - V6

A Timing scaleB Pulley14.3b Ignition timing marks - SOHC

A Cast pulleyB Pressed steel pulley

procarmanuals.com

Page 126 of 255

into position or the wiring pins will be

damaged.

25Refit the module retaining bolts and

tighten them securely.

26Rotate the distributor until the marks made

on removal are aligned then securely tighten

the clamp bolt.

27Reconnect the distributor wiring

connector and the battery negative terminal.

28Run the engine to normal operating

temperature and check the ignition timing.

All engines except DOHC fuel-

injection

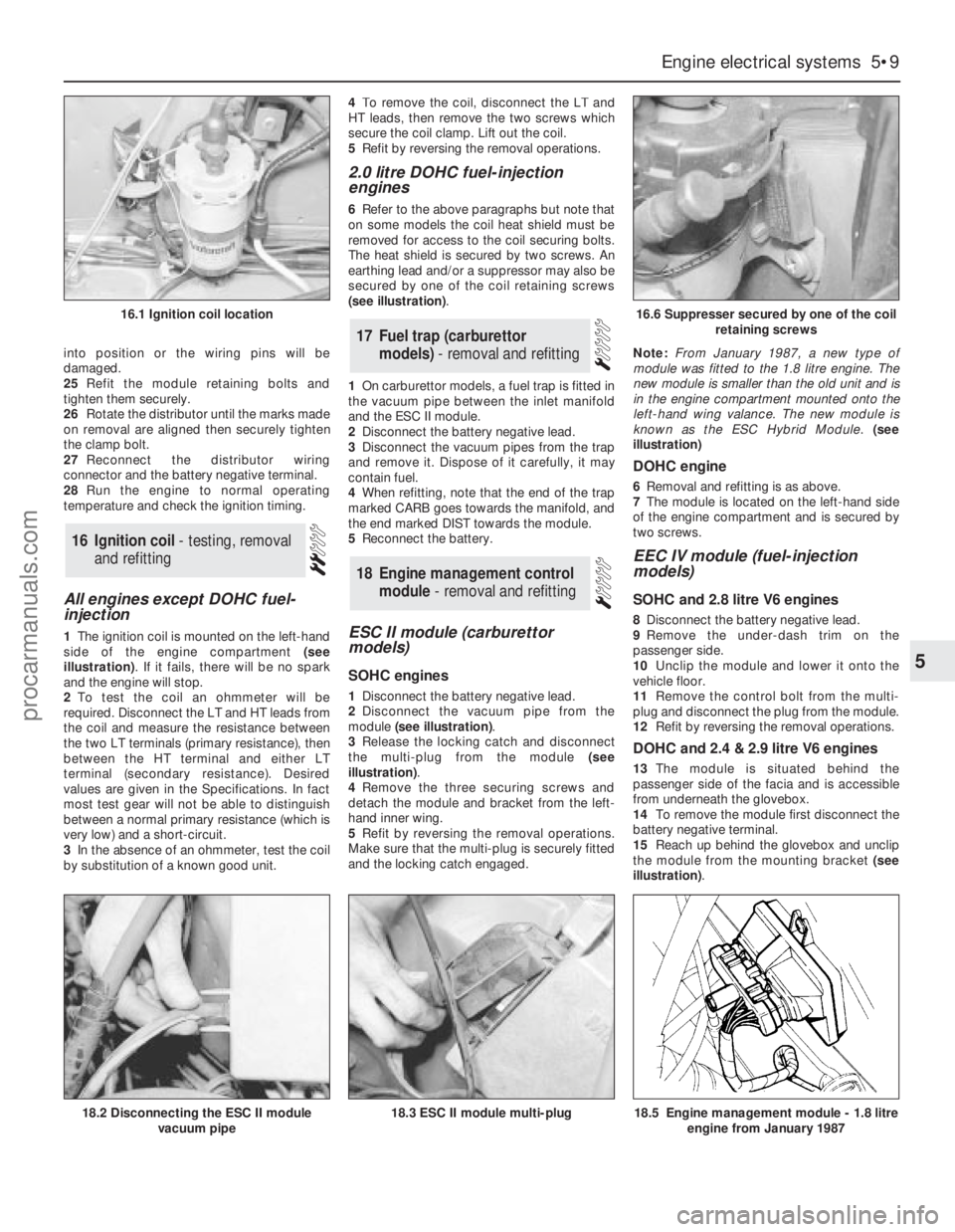

1The ignition coil is mounted on the left-hand

side of the engine compartment (see

illustration). If it fails, there will be no spark

and the engine will stop.

2To test the coil an ohmmeter will be

required. Disconnect the LT and HT leads from

the coil and measure the resistance between

the two LT terminals (primary resistance), then

between the HT terminal and either LT

terminal (secondary resistance). Desired

values are given in the Specifications. In fact

most test gear will not be able to distinguish

between a normal primary resistance (which is

very low) and a short-circuit.

3In the absence of an ohmmeter, test the coil

by substitution of a known good unit.4To remove the coil, disconnect the LT and

HT leads, then remove the two screws which

secure the coil clamp. Lift out the coil.

5Refit by reversing the removal operations.

2.0 litre DOHC fuel-injection

engines

6Refer to the above paragraphs but note that

on some models the coil heat shield must be

removed for access to the coil securing bolts.

The heat shield is secured by two screws. An

earthing lead and/or a suppressor may also be

secured by one of the coil retaining screws

(see illustration).

1On carburettor models, a fuel trap is fitted in

the vacuum pipe between the inlet manifold

and the ESC II module.

2Disconnect the battery negative lead.

3Disconnect the vacuum pipes from the trap

and remove it. Dispose of it carefully, it may

contain fuel.

4When refitting, note that the end of the trap

marked CARB goes towards the manifold, and

the end marked DIST towards the module.

5Reconnect the battery.

ESC II module (carburettor

models)

SOHC engines

1Disconnect the battery negative lead.

2Disconnect the vacuum pipe from the

module (see illustration).

3Release the locking catch and disconnect

the multi-plug from the module (see

illustration).

4Remove the three securing screws and

detach the module and bracket from the left-

hand inner wing.

5Refit by reversing the removal operations.

Make sure that the multi-plug is securely fitted

and the locking catch engaged.Note: From January 1987, a new type of

module was fitted to the 1.8 litre engine. The

new module is smaller than the old unit and is

in the engine compartment mounted onto the

left-hand wing valance. The new module is

known as the ESC Hybrid Module.(see

illustration)

DOHC engine

6Removal and refitting is as above.

7The module is located on the left-hand side

of the engine compartment and is secured by

two screws.

EEC IV module (fuel-injection

models)

SOHC and 2.8 litre V6 engines

8Disconnect the battery negative lead.

9Remove the under-dash trim on the

passenger side.

10Unclip the module and lower it onto the

vehicle floor.

11Remove the control bolt from the multi-

plug and disconnect the plug from the module.

12Refit by reversing the removal operations.

DOHC and 2.4 & 2.9 litre V6 engines

13The module is situated behind the

passenger side of the facia and is accessible

from underneath the glovebox.

14To remove the module first disconnect the

battery negative terminal.

15Reach up behind the glovebox and unclip

the module from the mounting bracket (see

illustration).

18Engine management control

module - removal and refitting

17Fuel trap (carburettor

models) - removal and refitting

16Ignition coil - testing, removal

and refitting

Engine electrical systems 5•9

5

16.1 Ignition coil location16.6 Suppresser secured by one of the coil

retaining screws

18.2 Disconnecting the ESC II module

vacuum pipe18.5 Engine management module - 1.8 litre

engine from January 198718.3 ESC II module multi-plug

procarmanuals.com

Page 127 of 255

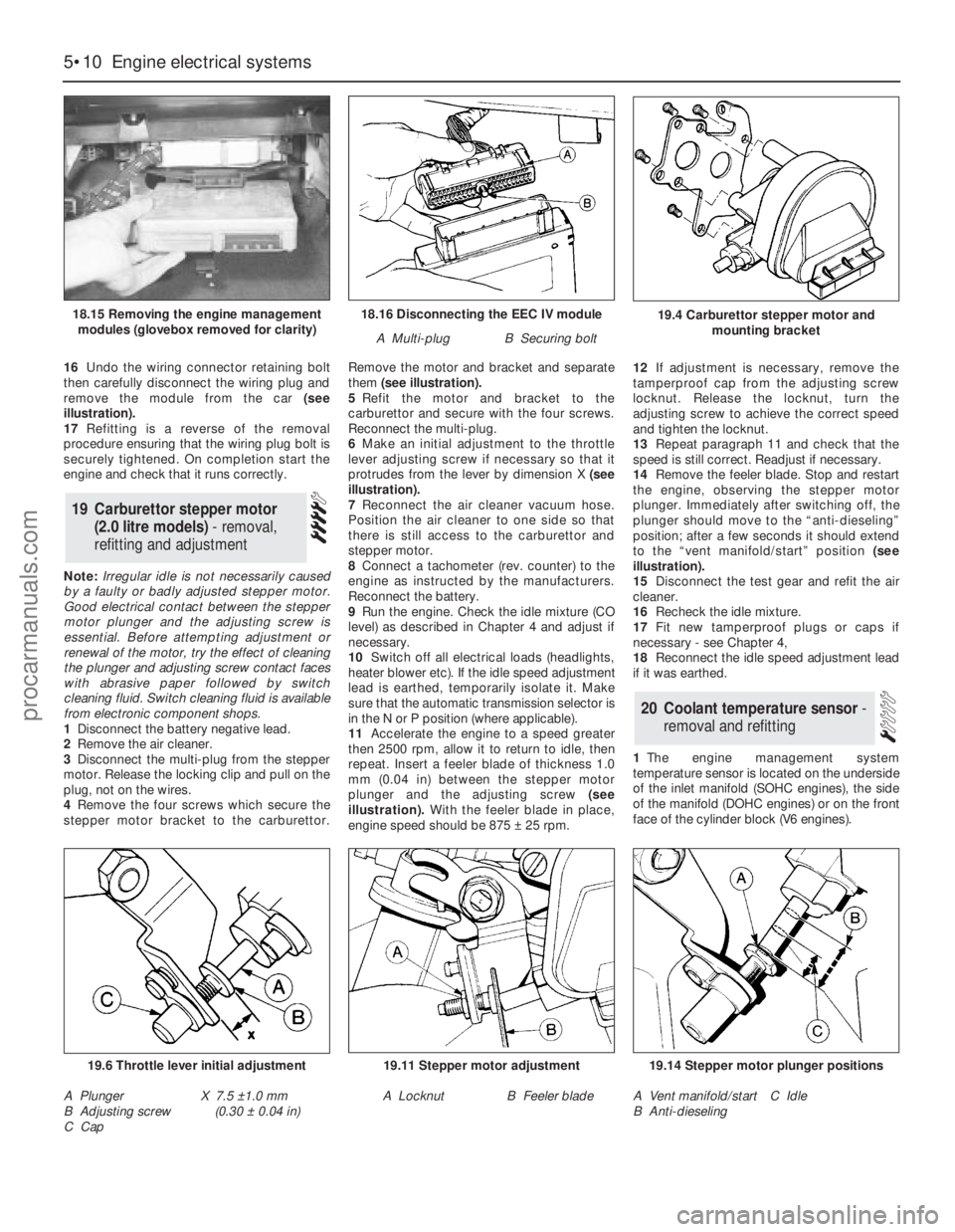

16Undo the wiring connector retaining bolt

then carefully disconnect the wiring plug and

remove the module from the car (see

illustration).

17Refitting is a reverse of the removal

procedure ensuring that the wiring plug bolt is

securely tightened. On completion start the

engine and check that it runs correctly.

Note: Irregular idle is not necessarily caused

by a faulty or badly adjusted stepper motor.

Good electrical contact between the stepper

motor plunger and the adjusting screw is

essential. Before attempting adjustment or

renewal of the motor, try the effect of cleaning

the plunger and adjusting screw contact faces

with abrasive paper followed by switch

cleaning fluid. Switch cleaning fluid is available

from electronic component shops.

1Disconnect the battery negative lead.

2Remove the air cleaner.

3Disconnect the multi-plug from the stepper

motor. Release the locking clip and pull on the

plug, not on the wires.

4Remove the four screws which secure the

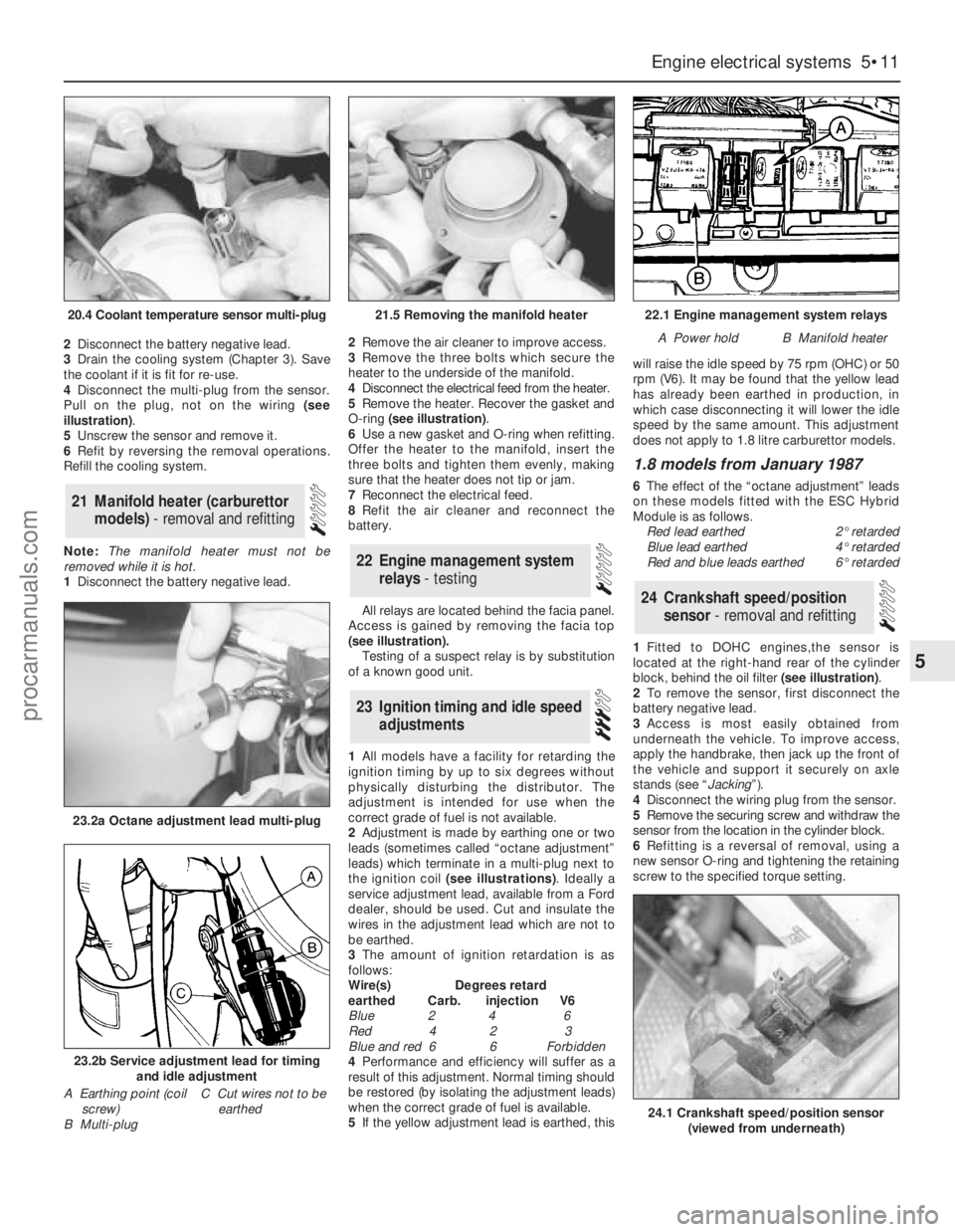

stepper motor bracket to the carburettor.Remove the motor and bracket and separate

them (see illustration).

5Refit the motor and bracket to the

carburettor and secure with the four screws.

Reconnect the multi-plug.

6Make an initial adjustment to the throttle

lever adjusting screw if necessary so that it

protrudes from the lever by dimension X (see

illustration).

7Reconnect the air cleaner vacuum hose.

Position the air cleaner to one side so that

there is still access to the carburettor and

stepper motor.

8Connect a tachometer (rev. counter) to the

engine as instructed by the manufacturers.

Reconnect the battery.

9Run the engine. Check the idle mixture (CO

level) as described in Chapter 4 and adjust if

necessary.

10Switch off all electrical loads (headlights,

heater blower etc). If the idle speed adjustment

lead is earthed, temporarily isolate it. Make

sure that the automatic transmission selector is

in the N or P position (where applicable).

11Accelerate the engine to a speed greater

then 2500 rpm, allow it to return to idle, then

repeat. Insert a feeler blade of thickness 1.0

mm (0.04 in) between the stepper motor

plunger and the adjusting screw(see

illustration).With the feeler blade in place,

engine speed should be 875 ±25 rpm. 12If adjustment is necessary, remove the

tamperproof cap from the adjusting screw

locknut. Release the locknut, turn the

adjusting screw to achieve the correct speed

and tighten the locknut.

13Repeat paragraph 11 and check that the

speed is still correct. Readjust if necessary.

14Remove the feeler blade. Stop and restart

the engine, observing the stepper motor

plunger. Immediately after switching off, the

plunger should move to the “anti-dieseling”

position; after a few seconds it should extend

to the “vent manifold/start” position (see

illustration).

15Disconnect the test gear and refit the air

cleaner.

16Recheck the idle mixture.

17Fit new tamperproof plugs or caps if

necessary - see Chapter 4,

18Reconnect the idle speed adjustment lead

if it was earthed.

1The engine management system

temperature sensor is located on the underside

of the inlet manifold (SOHC engines), the side

of the manifold (DOHC engines) or on the front

face of the cylinder block (V6 engines).

20Coolant temperature sensor -

removal and refitting

19Carburettor stepper motor

(2.0 litre models) - removal,

refitting and adjustment

5•10Engine electrical systems

18.16 Disconnecting the EEC IV module

A Multi-plugB Securing bolt

19.6 Throttle lever initial adjustment

A Plunger

B Adjusting screw

C CapX 7.5 ±1.0 mm

(0.30 ±0.04 in)

19.11 Stepper motor adjustment

A LocknutB Feeler blade

19.14 Stepper motor plunger positions

A Vent manifold/start

B Anti-dieselingC Idle

19.4 Carburettor stepper motor and

mounting bracket18.15 Removing the engine management

modules (glovebox removed for clarity)

procarmanuals.com

Page 128 of 255

2Disconnect the battery negative lead.

3Drain the cooling system (Chapter 3). Save

the coolant if it is fit for re-use.

4Disconnect the multi-plug from the sensor.

Pull on the plug, not on the wiring (see

illustration).

5Unscrew the sensor and remove it.

6Refit by reversing the removal operations.

Refill the cooling system.

Note: The manifold heater must not be

removed while it is hot.

1Disconnect the battery negative lead. 2Remove the air cleaner to improve access.

3Remove the three bolts which secure the

heater to the underside of the manifold.

4Disconnect the electrical feed from the heater.

5Remove the heater. Recover the gasket and

O-ring (see illustration).

6Use a new gasket and O-ring when refitting.

Offer the heater to the manifold, insert the

three bolts and tighten them evenly, making

sure that the heater does not tip or jam.

7Reconnect the electrical feed.

8Refit the air cleaner and reconnect the

battery.

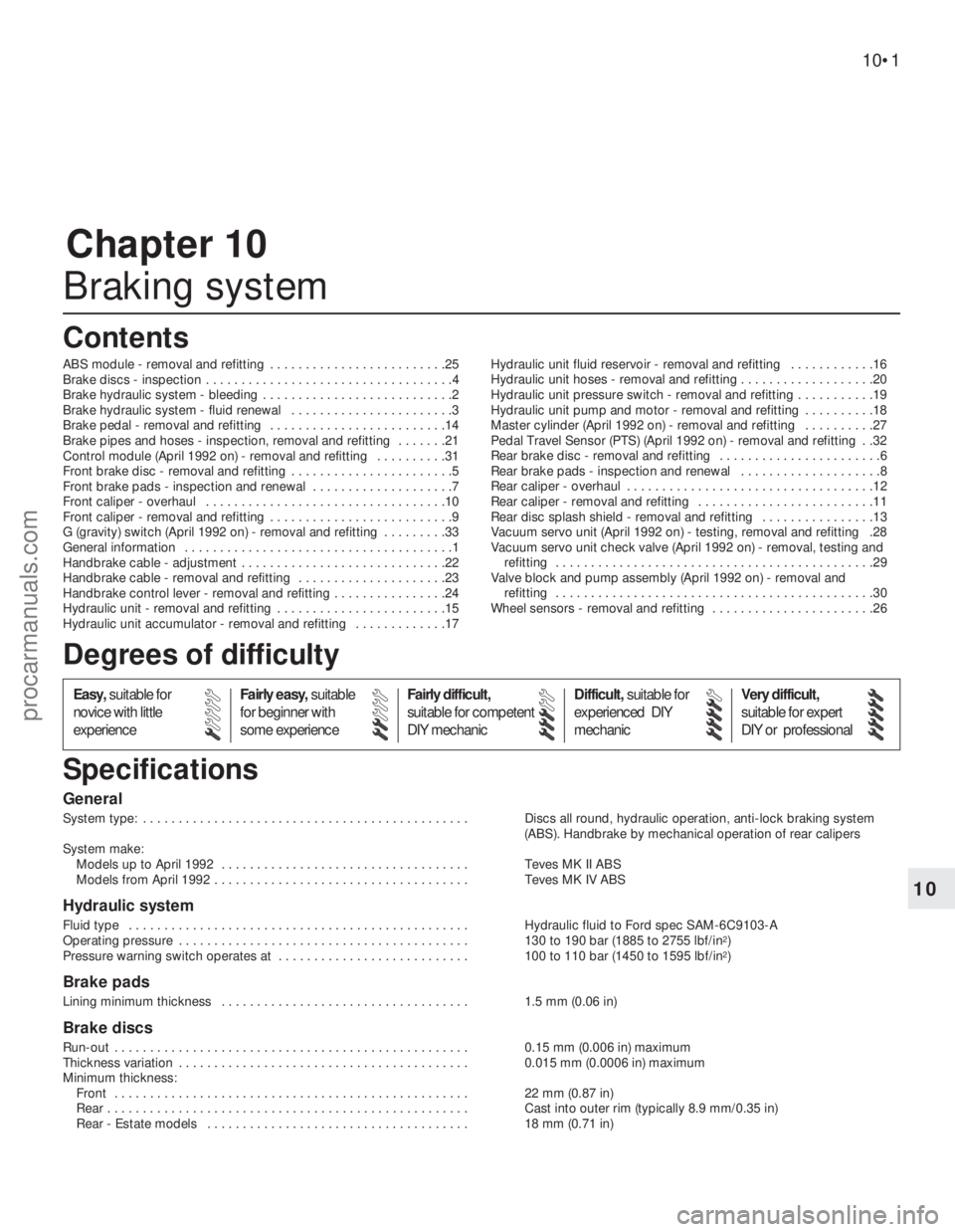

All relays are located behind the facia panel.

Access is gained by removing the facia top

(see illustration).

Testing of a suspect relay is by substitution

of a known good unit.

1All models have a facility for retarding the

ignition timing by up to six degrees without

physically disturbing the distributor. The

adjustment is intended for use when the

correct grade of fuel is not available.

2Adjustment is made by earthing one or two

leads (sometimes called “octane adjustment”

leads) which terminate in a multi-plug next to

the ignition coil (see illustrations). Ideally a

service adjustment lead, available from a Ford

dealer, should be used. Cut and insulate the

wires in the adjustment lead which are not to

be earthed.

3The amount of ignition retardation is as

follows:

Wire(s) Degrees retard

earthed Carb. injection V6

Blue 2 4 6

Red 4 2 3

Blue and red 6 6 Forbidden

4Performance and efficiency will suffer as a

result of this adjustment. Normal timing should

be restored (by isolating the adjustment leads)

when the correct grade of fuel is available.

5If the yellow adjustment lead is earthed, thiswill raise the idle speed by 75 rpm (OHC) or 50

rpm (V6). It may be found that the yellow lead

has already been earthed in production, in

which case disconnecting it will lower the idle

speed by the same amount. This adjustment

does not apply to 1.8 litre carburettor models.

1.8 models from January 1987

6The effect of the “octane adjustment” leads

on these models fitted with the ESC Hybrid

Module is as follows.

Red lead earthed2°retarded

Blue lead earthed4°retarded

Red and blue leads earthed6°retarded

1Fitted to DOHC engines,the sensor is

located at the right-hand rear of the cylinder

block, behind the oil filter (see illustration).

2To remove the sensor, first disconnect the

battery negative lead.

3Access is most easily obtained from

underneath the vehicle. To improve access,

apply the handbrake, then jack up the front of

the vehicle and support it securely on axle

stands (see “Jacking”).

4Disconnect the wiring plug from the sensor.

5Remove the securing screw and withdraw the

sensor from the location in the cylinder block.

6Refitting is a reversal of removal, using a

new sensor O-ring and tightening the retaining

screw to the specified torque setting.

24Crankshaft speed/position

sensor - removal and refitting

23Ignition timing and idle speed

adjustments

22Engine management system

relays - testing

21Manifold heater (carburettor

models) - removal and refitting

Engine electrical systems 5•11

5

20.4 Coolant temperature sensor multi-plug21.5 Removing the manifold heater22.1 Engine management system relays

A Power holdB Manifold heater

23.2a Octane adjustment lead multi-plug

23.2b Service adjustment lead for timing

and idle adjustment

A Earthing point (coil

screw)

B Multi-plugC Cut wires not to be

earthed

24.1 Crankshaft speed/position sensor

(viewed from underneath)

procarmanuals.com

Page 130 of 255

Chapter 10

Braking system

ABS module - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . .25

Brake discs - inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Brake hydraulic system - bleeding . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Brake hydraulic system - fluid renewal . . . . . . . . . . . . . . . . . . . . . . .3

Brake pedal - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . .14

Brake pipes and hoses - inspection, removal and refitting . . . . . . .21

Control module (April 1992 on) - removal and refitting . . . . . . . . . .31

Front brake disc - removal and refitting . . . . . . . . . . . . . . . . . . . . . . .5

Front brake pads - inspection and renewal . . . . . . . . . . . . . . . . . . . .7

Front caliper - overhaul . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Front caliper - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . .9

G (gravity) switch (April 1992 on) - removal and refitting . . . . . . . . .33

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Handbrake cable - adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Handbrake cable - removal and refitting . . . . . . . . . . . . . . . . . . . . .23

Handbrake control lever - removal and refitting . . . . . . . . . . . . . . . .24

Hydraulic unit - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . .15

Hydraulic unit accumulator - removal and refitting . . . . . . . . . . . . .17Hydraulic unit fluid reservoir - removal and refitting . . . . . . . . . . . .16

Hydraulic unit hoses - removal and refitting . . . . . . . . . . . . . . . . . . .20

Hydraulic unit pressure switch - removal and refitting . . . . . . . . . . .19

Hydraulic unit pump and motor - removal and refitting . . . . . . . . . .18

Master cylinder (April 1992 on) - removal and refitting . . . . . . . . . .27

Pedal Travel Sensor (PTS) (April 1992 on) - removal and refitting . .32

Rear brake disc - removal and refitting . . . . . . . . . . . . . . . . . . . . . . .6

Rear brake pads - inspection and renewal . . . . . . . . . . . . . . . . . . . .8

Rear caliper - overhaul . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Rear caliper - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . .11

Rear disc splash shield - removal and refitting . . . . . . . . . . . . . . . .13

Vacuum servo unit (April 1992 on) - testing, removal and refitting .28

Vacuum servo unit check valve (April 1992 on) - removal, testing and

refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Valve block and pump assembly (April 1992 on) - removal and

refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Wheel sensors - removal and refitting . . . . . . . . . . . . . . . . . . . . . . .26

General

System type: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Discs all round, hydraulic operation, anti-lock braking system

(ABS). Handbrake by mechanical operation of rear calipers

System make:

Models up to April 1992 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Teves MK II ABS

Models from April 1992 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Teves MK IV ABS

Hydraulic system

Fluid type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hydraulic fluid to Ford spec SAM-6C9103-A

Operating pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130 to 190 bar (1885 to 2755 lbf/in2)

Pressure warning switch operates at . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 to 110 bar (1450 to 1595 lbf/in2)

Brake pads

Lining minimum thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 mm (0.06 in)

Brake discs

Run-out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.15 mm (0.006 in) maximum

Thickness variation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.015 mm (0.0006 in) maximum

Minimum thickness:

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 mm (0.87 in)

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Cast into outer rim (typically 8.9 mm/0.35 in)

Rear - Estate models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 mm (0.71 in)

10•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanicDifficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Specifications Contents

10

procarmanuals.com

Page 131 of 255

Models covered in this Manual have disc

brakes fitted all round. The footbrake operates

hydraulically on all four wheels, and the

handbrake operates mechanically on the rear

wheels. Both footbrake and handbrake are

self-adjusting in use.

Ford’s anti-lock braking system (ABS) is

fitted to all models. The system monitors the

rotational speed of each roadwheel. When a

wheel begins to lock under heavy braking, the

ABS reduces the hydraulic pressure to that

wheel, so preventing it from locking. When this

happens a pulsating effect will be noticed at

the brake pedal. On some road surfaces the

tyres may squeal when braking hard even

though the wheels are not locked.

The main components of the system are the

hydraulic unit, the calipers, pads and discs,

the wheel sensors and the “brain” or control

module. The hydraulic unit contains the

elements of a traditional master cylinder, plus

an electric motor and pump, a pressure

accumulator and control valves. The pump is

the source of pressure for the system and

does away with the need for a vacuum servo.

The hydraulic circuit is split front and rear,

as is normal practice with rear-wheel drive

vehicles. In the event that the hydraulic pump

fails, unassisted braking effort is still available

on the front calipers only.

Warning lights inform the driver of low brake

fluid level, ABS failure and (on some models)

brake pad wear. The low fluid level light

doubles as a “handbrake on” light; if it

illuminates at the same time as the ABS

warning light, it warns of low hydraulic

pressure.

ABS cannot overturn the laws of physics:

stopping distances will inevitably be greater on

loose or slippery surfaces. However, the system

should allow even inexperienced drivers to

retain directional control under panic braking.

From August 1986 the following

modifications were made to the braking

system.

a)The relays differ from earlier versions.b)The hydraulic pump is constructed of iron

rather than alloy.

c)A new pressure warning switch is used.

d)The earlier high pressure rubber hose is

replaced by a steel pipe.

To overcome the problem of excessive rear

brake pad wear, Ford introduced a differential

valve which is screwed into the ABS valve

block.The valve limits the pressure applied to

the rear brake calipers and so reduces brake

pad wear. From 1988 onwards, the valve has

been fitted during production. The differential

valve can also be fitted to earlier models. Refer

to your Ford dealer for further information.

From April 1992 onwards, the models

covered in this Manual were equipped with a

new Teves MK IV anti-lock braking system

instead of the Teves MK II system fitted to the

earlier models.

The Teves MK IV system differs from the

earlier MK II system in the following ways.

a)The source of hydraulic pressure for the

system is a conventional master cylinder

and vacuum servo assembly.

b)A valve block and pump assembly is used

instead of the hydraulic control unit. The

block contains the inlet and outlet

solenoid valves that control the hydraulic

system. There are three pairs of valves,

one for each brake circuit (paragraph c).

c)The hydraulic braking system consists of

three separate circuits; one for each front

brake (which are totally independent of

each other), and a joint circuit which

operates both rear brakes.

d)A G (gravity) switch is incorporated in the

system. This is an inertia type switch and

informs the control module when the

vehicle is decelerating rapidly.

e)A Pedal Travel Sensor (PTS) is fitted to the

vacuum servo unit. The PTS informs the

control module of the position of the brake

pedal when the anti-lock sequence starts

and ensures that a constant pedal height

is maintained during the sequence.

The MK IV system operates as follows.

During normal operation the system

functions in the same way as a non-ABS

system would. During this time the three inlet

valves in the valve block are open and theoutlet valves are closed, allowing full hydraulic

pressure present in the master cylinder to act

on the main braking circuit. If the control

module receives a signal from one of the

wheel sensors and senses that a wheel is

about to lock, it closes the relevant inlet valve

in the valve block which then isolates the

brake caliper on the wheel which is about to

lock from the master cylinder, effectively

sealing in the hydraulic pressure. If the speed

of rotation of the wheel continues to decrease

at an abnormal rate, the control module will

then open the relevant outlet valve in the valve

block; this allows the fluid from the relevant

hydraulic circuit to return to the master

cylinder reservoir, releasing pressure on the

brake caliper so that the brake is released. The

pump in the valve block also operates to assist

in the quick release of pressure. Once the

speed of rotation of the wheel returns to an

acceptable rate the pump stops, the outlet

valve closes and the inlet valve is opened,

allowing the hydraulic master cylinder

pressure to return to the caliper which then

reapplies the brake. This cycle can be carried

many times a second. The solenoid valves

connected to the front calipers operate

independently, but the valve connected to the

rear calipers operates both calipers

simultaneously.

The operation of the ABS system is entirely

dependent on electrical signals. To prevent

the system responding to any inaccurate

signals, a built-in safety circuit monitors all

signals received by the control module. If an

inaccurate signal or low battery voltage is

detected, the ABS system is automatically

shut down and the warning lamp on the

instrument cluster is illuminated to inform the

driver that the ABS system is not operational.

Whilst in this state the system functions in the

same way as a non-ABS system would. If a

fault does develop in the ABS system, the car

must be taken to a Ford dealer for fault

diagnosis and repair. The system is equipped

with a diagnostic plug into which a special

diagnostic (STAR) tester can be plugged. This

allows faults to be easily traced.

1General information

10•2Braking system

Torque wrench settingsNmlbf ft

Front caliper:

To stub axle carrier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51 to 6138 to 45

Slide bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 2515 to 18

Rear caliper:

Bracket to carrier plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51 to 6138 to 45

Slide bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31 to 3523 to 26

Hydraulic unit to bulkhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41 to 5130 to 38

Accumulator to pump body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35 to 4526 to 33

Pump mounting bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 to 95 to 7

High pressure hose banjo bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16 to 2412 to 18

Reservoir mounting bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 to 63 to 4

Wheel sensor fixing bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 116 to 8

Vacuum servo unit retaining nuts (Teves MK IV) . . . . . . . . . . . . . . . . . .35 to 4526 to 33

Master cylinder retaining nuts (Teves MK IV) . . . . . . . . . . . . . . . . . . . . .20 to 2515 to 18

Valve block and pump assembly mounting nuts (Teves MK IV) . . . . . . .21 to 2815 to 21

procarmanuals.com

Page 134 of 255

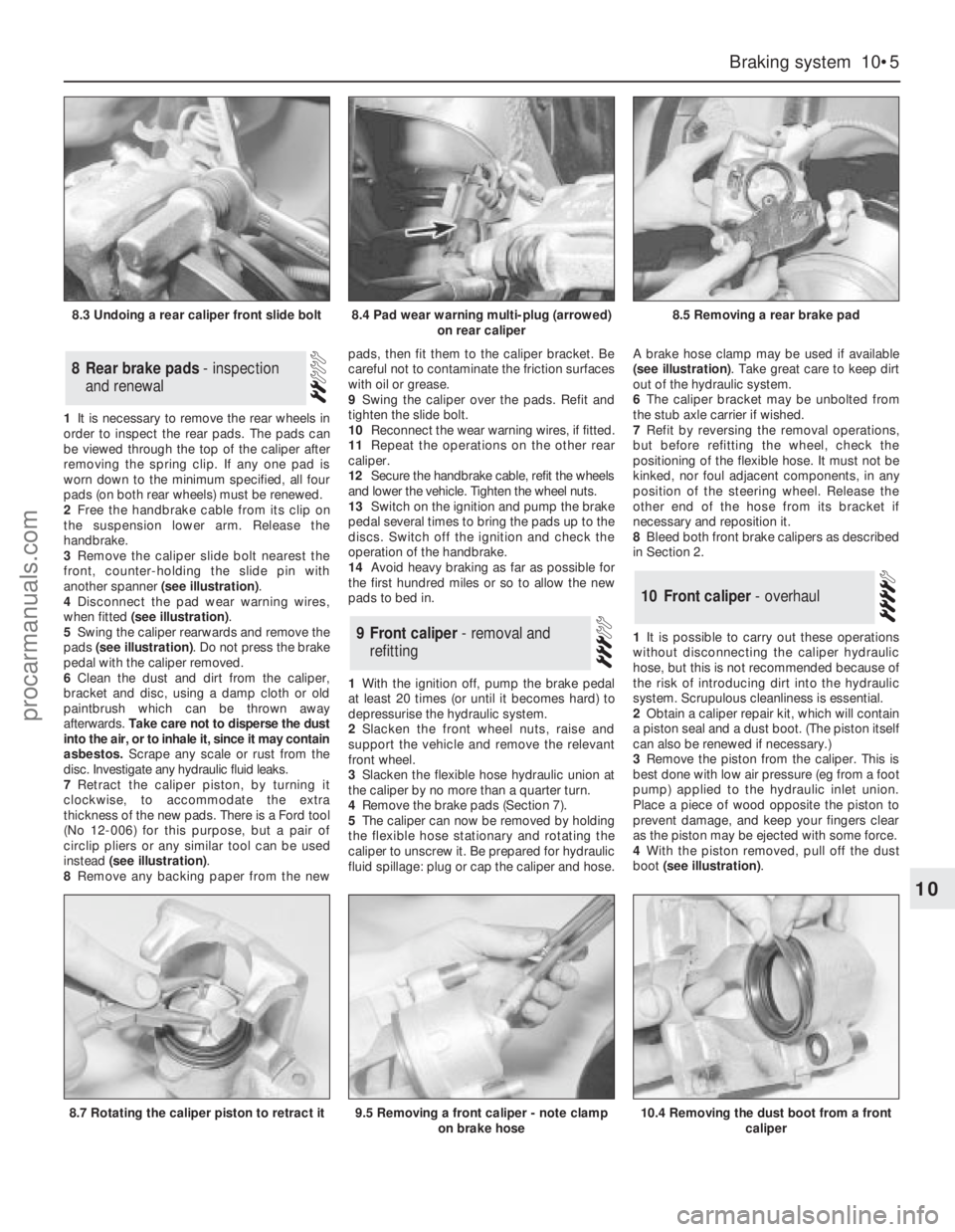

1It is necessary to remove the rear wheels in

order to inspect the rear pads. The pads can

be viewed through the top of the caliper after

removing the spring clip. If any one pad is

worn down to the minimum specified, all four

pads (on both rear wheels) must be renewed.

2Free the handbrake cable from its clip on

the suspension lower arm. Release the

handbrake.

3Remove the caliper slide bolt nearest the

front, counter-holding the slide pin with

another spanner (see illustration).

4Disconnect the pad wear warning wires,

when fitted (see illustration).

5Swing the caliper rearwards and remove the

pads (see illustration). Do not press the brake

pedal with the caliper removed.

6Clean the dust and dirt from the caliper,

bracket and disc, using a damp cloth or old

paintbrush which can be thrown away

afterwards. Take care not to disperse the dust

into the air, or to inhale it, since it may contain

asbestos. Scrape any scale or rust from the

disc. Investigate any hydraulic fluid leaks.

7Retract the caliper piston, by turning it

clockwise, to accommodate the extra

thickness of the new pads. There is a Ford tool

(No 12-006) for this purpose, but a pair of

circlip pliers or any similar tool can be used

instead (see illustration).

8Remove any backing paper from the newpads, then fit them to the caliper bracket. Be

careful not to contaminate the friction surfaces

with oil or grease.

9Swing the caliper over the pads. Refit and

tighten the slide bolt.

10Reconnect the wear warning wires, if fitted.

11Repeat the operations on the other rear

caliper.

12Secure the handbrake cable, refit the wheels

and lower the vehicle. Tighten the wheel nuts.

13Switch on the ignition and pump the brake

pedal several times to bring the pads up to the

discs. Switch off the ignition and check the

operation of the handbrake.

14Avoid heavy braking as far as possible for

the first hundred miles or so to allow the new

pads to bed in.

1With the ignition off, pump the brake pedal

at least 20 times (or until it becomes hard) to

depressurise the hydraulic system.

2Slacken the front wheel nuts, raise and

support the vehicle and remove the relevant

front wheel.

3Slacken the flexible hose hydraulic union at

the caliper by no more than a quarter turn.

4Remove the brake pads (Section 7).

5The caliper can now be removed by holding

the flexible hose stationary and rotating the

caliper to unscrew it. Be prepared for hydraulic

fluid spillage: plug or cap the caliper and hose.A brake hose clamp may be used if available

(see illustration). Take great care to keep dirt

out of the hydraulic system.

6The caliper bracket may be unbolted from

the stub axle carrier if wished.

7Refit by reversing the removal operations,

but before refitting the wheel, check the

positioning of the flexible hose. It must not be

kinked, nor foul adjacent components, in any

position of the steering wheel. Release the

other end of the hose from its bracket if

necessary and reposition it.

8Bleed both front brake calipers as described

in Section 2.

1It is possible to carry out these operations

without disconnecting the caliper hydraulic

hose, but this is not recommended because of

the risk of introducing dirt into the hydraulic

system. Scrupulous cleanliness is essential.

2Obtain a caliper repair kit, which will contain

a piston seal and a dust boot. (The piston itself

can also be renewed if necessary.)

3Remove the piston from the caliper. This is

best done with low air pressure (eg from a foot

pump) applied to the hydraulic inlet union.

Place a piece of wood opposite the piston to

prevent damage, and keep your fingers clear

as the piston may be ejected with some force.

4With the piston removed, pull off the dust

boot (see illustration).

10Front caliper - overhaul

9Front caliper - removal and

refitting

8Rear brake pads - inspection

and renewal

Braking system 10•5

10

8.3 Undoing a rear caliper front slide bolt8.4 Pad wear warning multi-plug (arrowed)

on rear caliper8.5 Removing a rear brake pad

8.7 Rotating the caliper piston to retract it9.5 Removing a front caliper - note clamp

on brake hose10.4 Removing the dust boot from a front

caliper

procarmanuals.com

Page 135 of 255

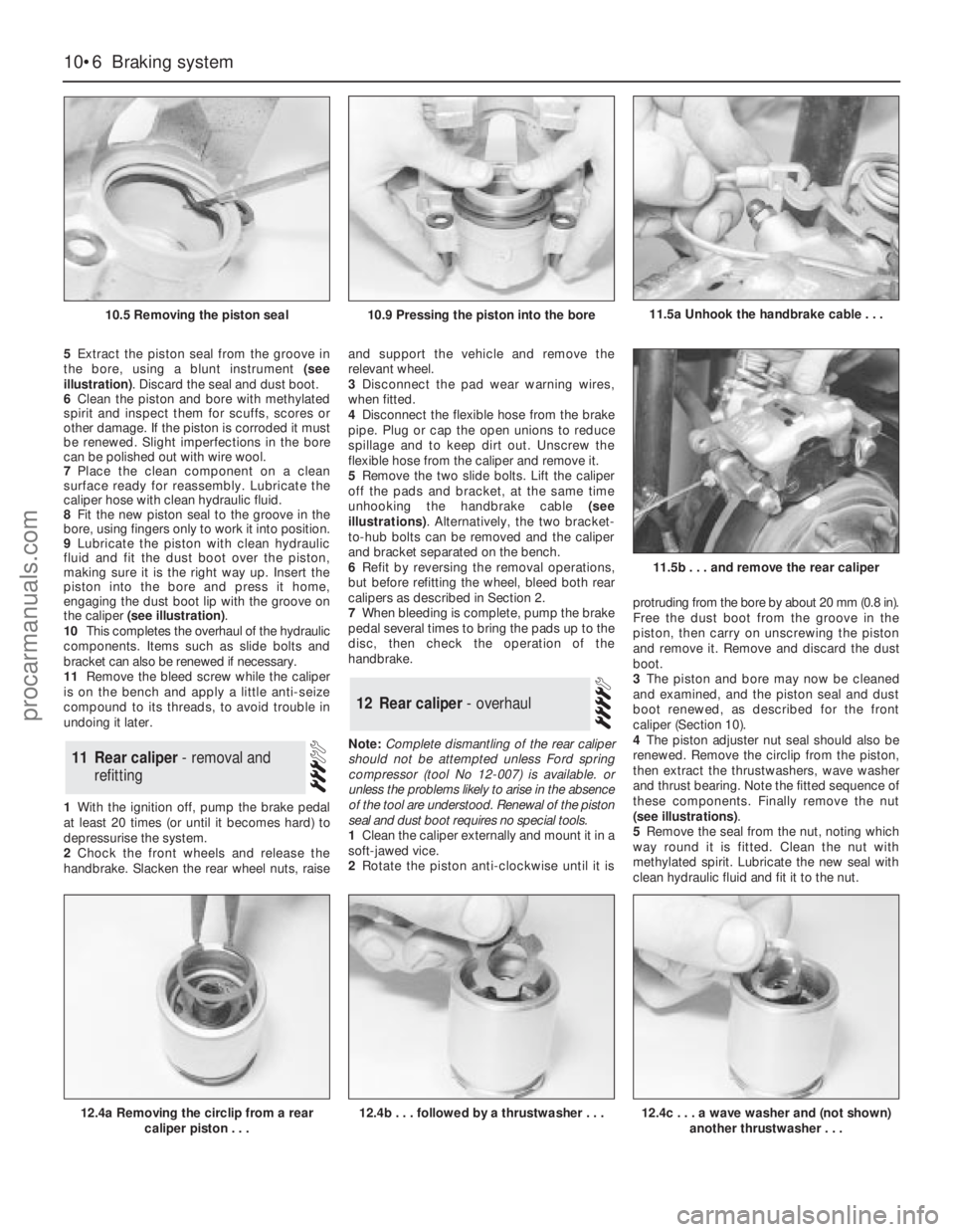

5Extract the piston seal from the groove in

the bore, using a blunt instrument (see

illustration). Discard the seal and dust boot.

6Clean the piston and bore with methylated

spirit and inspect them for scuffs, scores or

other damage. If the piston is corroded it must

be renewed. Slight imperfections in the bore

can be polished out with wire wool.

7Place the clean component on a clean

surface ready for reassembly. Lubricate the

caliper hose with clean hydraulic fluid.

8Fit the new piston seal to the groove in the

bore, using fingers only to work it into position.

9Lubricate the piston with clean hydraulic

fluid and fit the dust boot over the piston,

making sure it is the right way up. Insert the

piston into the bore and press it home,

engaging the dust boot lip with the groove on

the caliper (see illustration).

10This completes the overhaul of the hydraulic

components. Items such as slide bolts and

bracket can also be renewed if necessary.

11Remove the bleed screw while the caliper

is on the bench and apply a little anti-seize

compound to its threads, to avoid trouble in

undoing it later.

1With the ignition off, pump the brake pedal

at least 20 times (or until it becomes hard) to

depressurise the system.

2Chock the front wheels and release the

handbrake. Slacken the rear wheel nuts, raiseand support the vehicle and remove the

relevant wheel.

3Disconnect the pad wear warning wires,

when fitted.

4Disconnect the flexible hose from the brake

pipe. Plug or cap the open unions to reduce

spillage and to keep dirt out. Unscrew the

flexible hose from the caliper and remove it.

5Remove the two slide bolts. Lift the caliper

off the pads and bracket, at the same time

unhooking the handbrake cable (see

illustrations). Alternatively, the two bracket-

to-hub bolts can be removed and the caliper

and bracket separated on the bench.

6Refit by reversing the removal operations,

but before refitting the wheel, bleed both rear

calipers as described in Section 2.

7When bleeding is complete, pump the brake

pedal several times to bring the pads up to the

disc, then check the operation of the

handbrake.

Note: Complete dismantling of the rear caliper

should not be attempted unless Ford spring

compressor (tool No 12-007) is available. or

unless the problems likely to arise in the absence

of the tool are understood. Renewal of the piston

seal and dust boot requires no special tools.

1Clean the caliper externally and mount it in a

soft-jawed vice.

2Rotate the piston anti-clockwise until it isprotruding from the bore by about 20 mm (0.8 in).

Free the dust boot from the groove in the

piston, then carry on unscrewing the piston

and remove it. Remove and discard the dust

boot.

3The piston and bore may now be cleaned

and examined, and the piston seal and dust

boot renewed, as described for the front

caliper (Section 10).

4The piston adjuster nut seal should also be

renewed. Remove the circlip from the piston,

then extract the thrustwashers, wave washer

and thrust bearing. Note the fitted sequence of

these components. Finally remove the nut

(see illustrations).

5Remove the seal from the nut, noting which

way round it is fitted. Clean the nut with

methylated spirit. Lubricate the new seal with

clean hydraulic fluid and fit it to the nut.

12Rear caliper - overhaul

11Rear caliper - removal and

refitting

10•6Braking system

10.5 Removing the piston seal

12.4a Removing the circlip from a rear

caliper piston . . .12.4b . . . followed by a thrustwasher . . .

11.5b . . . and remove the rear caliper

10.9 Pressing the piston into the bore11.5a Unhook the handbrake cable . . .

12.4c . . . a wave washer and (not shown)

another thrustwasher . . .

procarmanuals.com