warning FORD KUGA 2011 1.G Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1979 of 2057

Fuel Tank Draining

General EquipmentFluid Container

Fuel Tank Draining Equipment

Hose Clamp Remover/Installer

Activation

CAUTION: If the fuel tank has been filled

with the wrong type of fuel, the engine

must not be started.

NOTE: Removal steps in this procedure may

contain installation details.

6. Refer to: Petrol and Petrol-Ethanol Fuel

Systems Health and Safety Precautions

(100-00 General Information, Description and

Operation).

7. Refer to: Lifting(100-02 Jacking and Lifting,

Description and Operation).

8. WARNINGS:

Fuel may still be present in the fuel tank

after draining.

Be prepared to collect escaping fluids.

CAUTION: Use suitable paper to absorb

any escaping fluid. NOTE:

Make sure that a new component is

installed.

• General Equipment: Hose Clamp Remover/Installer

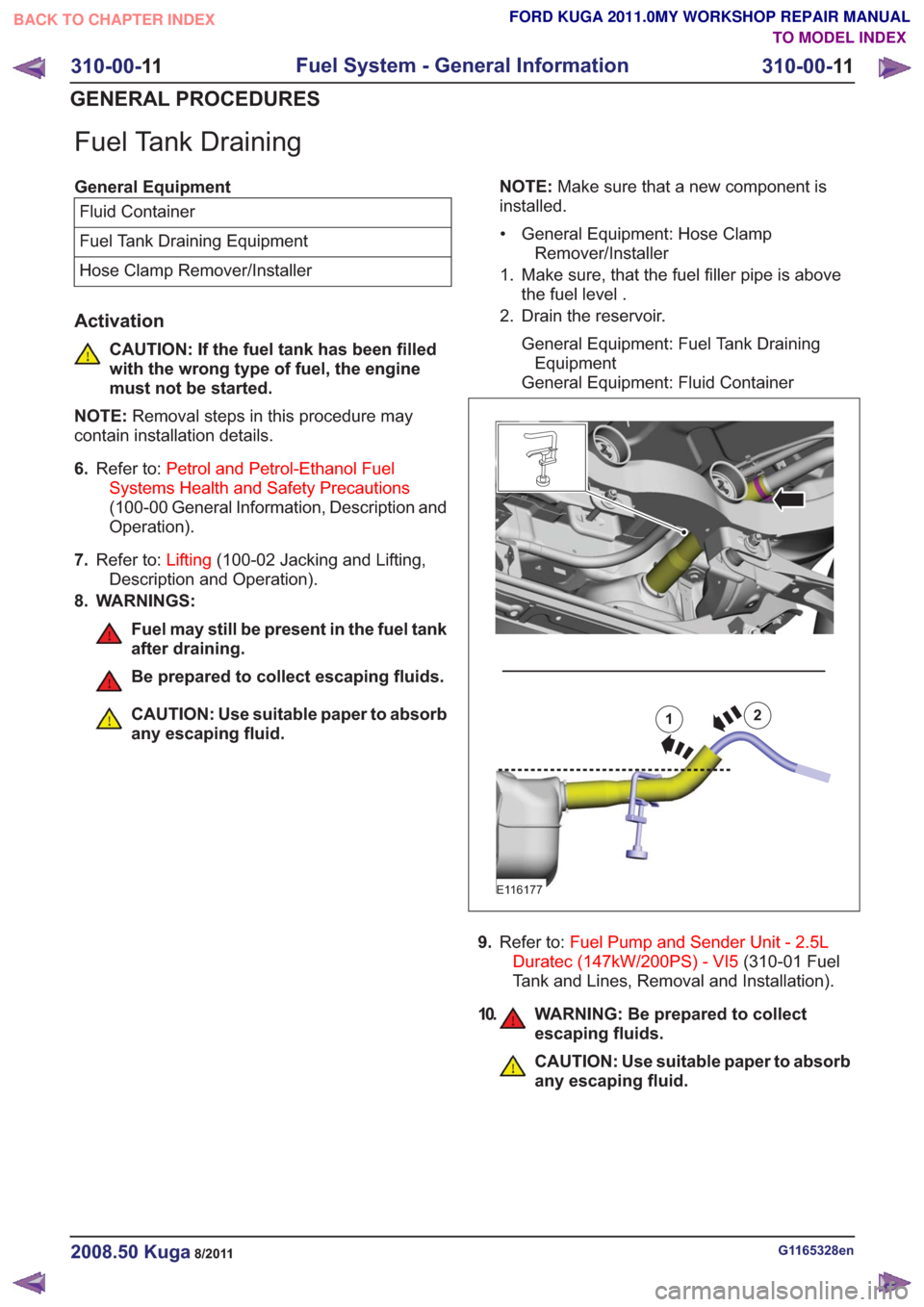

1. Make sure, that the fuel filler pipe is above the fuel level .

2. Drain the reservoir.

General Equipment: Fuel Tank DrainingEquipment

General Equipment: Fluid Container12

E116177

9. Refer to: Fuel Pump and Sender Unit - 2.5L

Duratec (147kW/200PS) - VI5 (310-01 Fuel

Tank and Lines, Removal and Installation).

10. WARNING: Be prepared to collect escaping fluids.

CAUTION: Use suitable paper to absorb

any escaping fluid.

G1165328en2008.50 Kuga8/2011

310-00- 11

Fuel System - General Information

310-00- 11

GENERAL PROCEDURES

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1988 of 2057

Fuel Tank — 2.5L Duratec (147kW/200PS) - VI5

Removal

WARNING: Avoid flames, sparks or lighted

substances.

NOTE: Removal steps in this procedure may

contain installation details.

1. Refer to: Battery Disconnect and Connect

(414-01 Battery, Mounting and Cables,

General Procedures).

4x4

2. Refer to: Driveshaft (205-01 Driveshaft,

Removal and Installation).

All vehicles

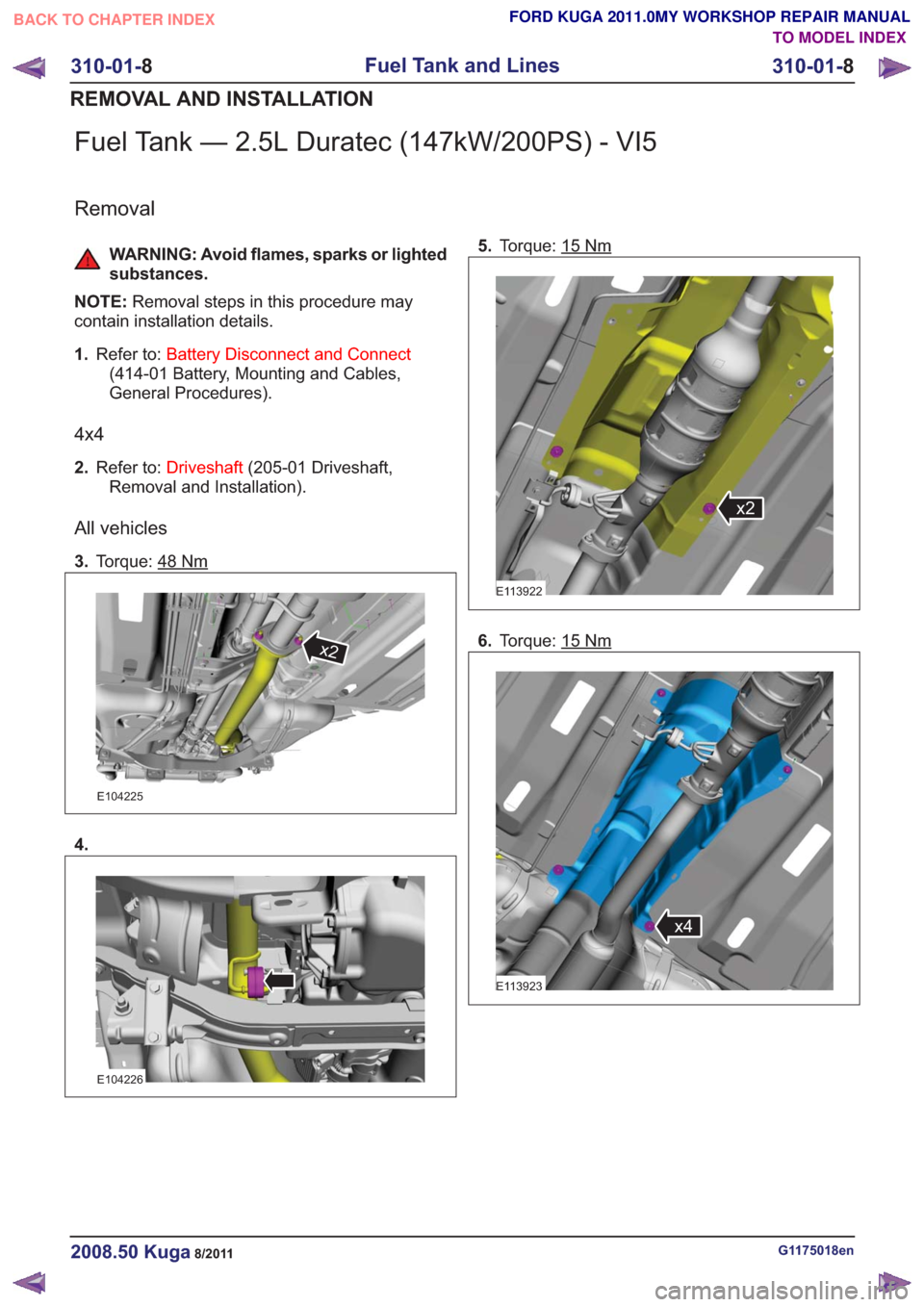

3. Torque: 48Nm

x2x2

E104225

4.

E104226

5.Torque: 15Nm

E113922

x2

6.Torque: 15Nm

x4x4

E113923

G1175018en2008.50 Kuga8/2011

310-01- 8

Fuel Tank and Lines

310-01- 8

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1989 of 2057

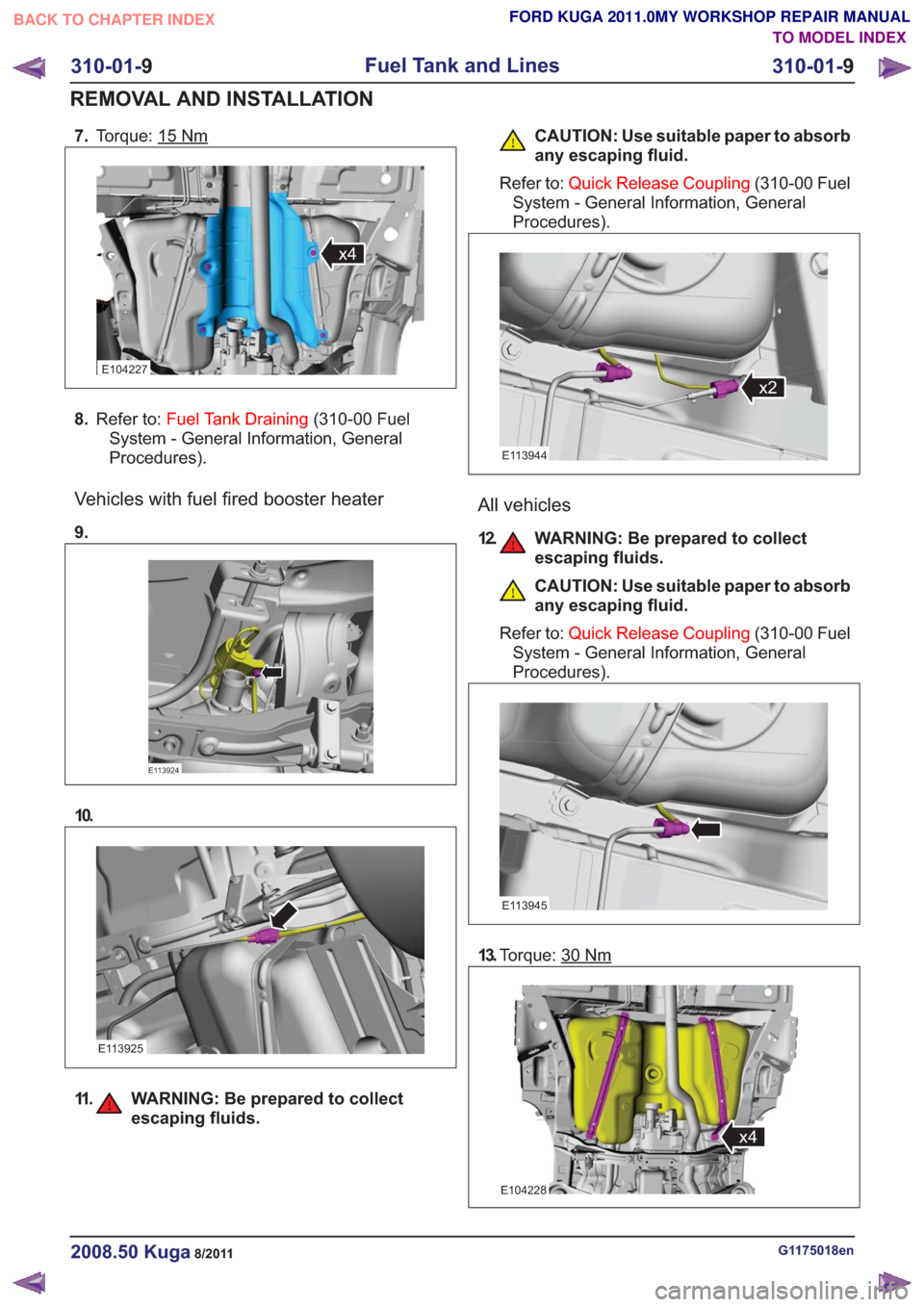

7.Torque: 15Nm

x4x4

E104227

8.Refer to: Fuel Tank Draining (310-00 Fuel

System - General Information, General

Procedures).

Vehicles with fuel fired booster heater

9.

E113924

10.

E113925

11. WARNING: Be prepared to collect escaping fluids.

CAUTION: Use suitable paper to absorb

any escaping fluid.

Refer to: Quick Release Coupling (310-00 Fuel

System - General Information, General

Procedures).

x2x2

E113944

All vehicles

12. WARNING: Be prepared to collect escaping fluids.

CAUTION: Use suitable paper to absorb

any escaping fluid.

Refer to: Quick Release Coupling (310-00 Fuel

System - General Information, General

Procedures).

E113945

13. Torque: 30Nm

x4x4

E104228

G1175018en2008.50 Kuga8/2011

310-01- 9

Fuel Tank and Lines

310-01- 9

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1990 of 2057

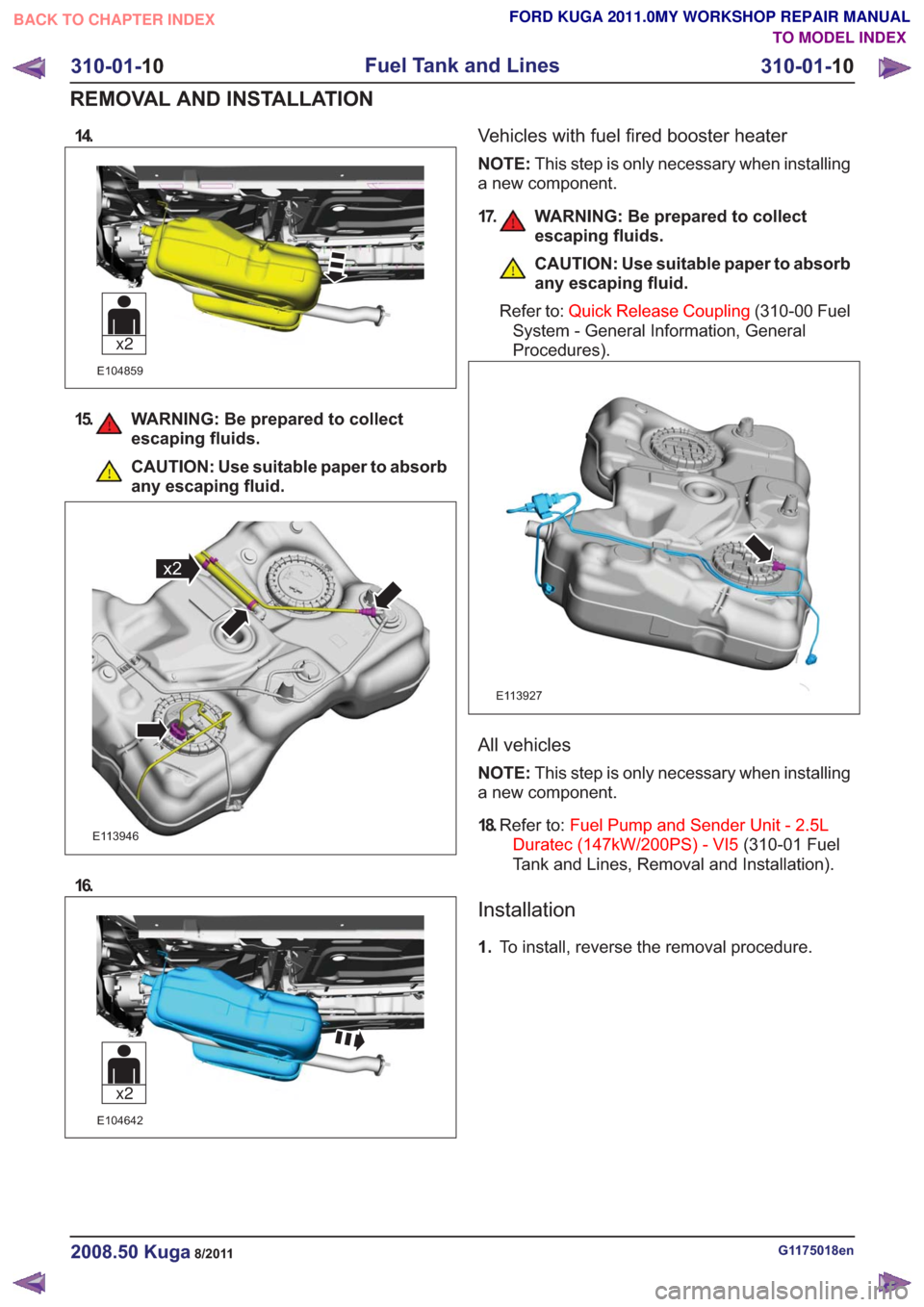

14.

E104859

x2

15. WARNING: Be prepared to collectescaping fluids.

CAUTION: Use suitable paper to absorb

any escaping fluid.

x2x2

E113946

16.

E104642

x2

Vehicles with fuel fired booster heater

NOTE:This step is only necessary when installing

a new component.

17. WARNING: Be prepared to collect escaping fluids.

CAUTION: Use suitable paper to absorb

any escaping fluid.

Refer to: Quick Release Coupling (310-00 Fuel

System - General Information, General

Procedures).

E113927

All vehicles

NOTE: This step is only necessary when installing

a new component.

18. Refer to: Fuel Pump and Sender Unit - 2.5L

Duratec (147kW/200PS) - VI5 (310-01 Fuel

Tank and Lines, Removal and Installation).

Installation

1. To install, reverse the removal procedure.

G1175018en2008.50 Kuga8/2011

310-01- 10

Fuel Tank and Lines

310-01- 10

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1992 of 2057

Fuel Tank Filler Pipe

General EquipmentFluid ContainerGeneral EquipmentFuel Tank Draining Equipment

Hose Clamp Remover/Installer

Removal

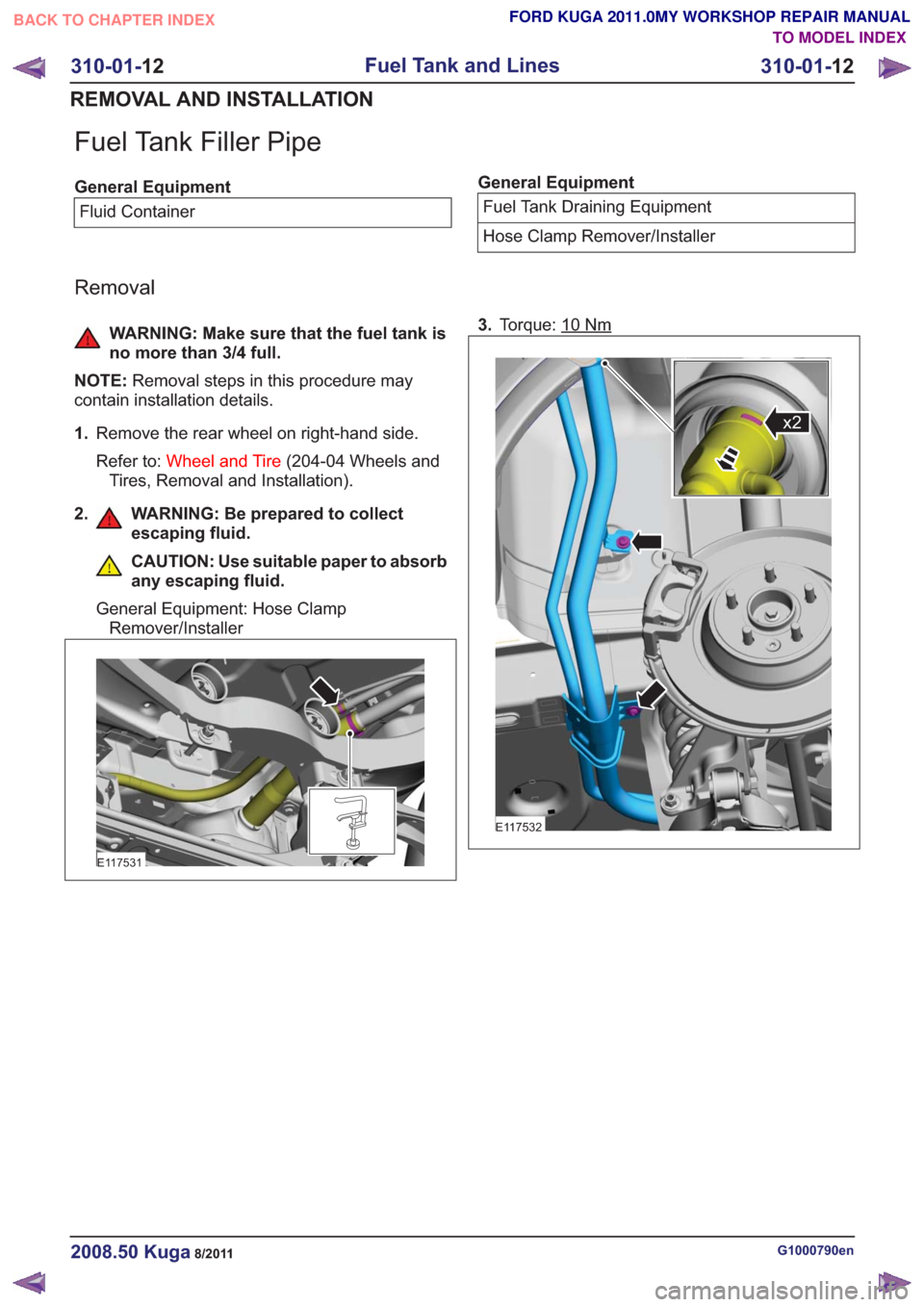

WARNING: Make sure that the fuel tank is

no more than 3/4 full.

NOTE: Removal steps in this procedure may

contain installation details.

1. Remove the rear wheel on right-hand side.

Refer to: Wheel and Tire (204-04 Wheels and

Tires, Removal and Installation).

2. WARNING: Be prepared to collect escaping fluid.

CAUTION: Use suitable paper to absorb

any escaping fluid.

General Equipment: Hose Clamp Remover/Installer

E117531

3. Torque: 10Nm

x2x2

E117532

G1000790en2008.50 Kuga8/2011

310-01- 12

Fuel Tank and Lines

310-01- 12

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1993 of 2057

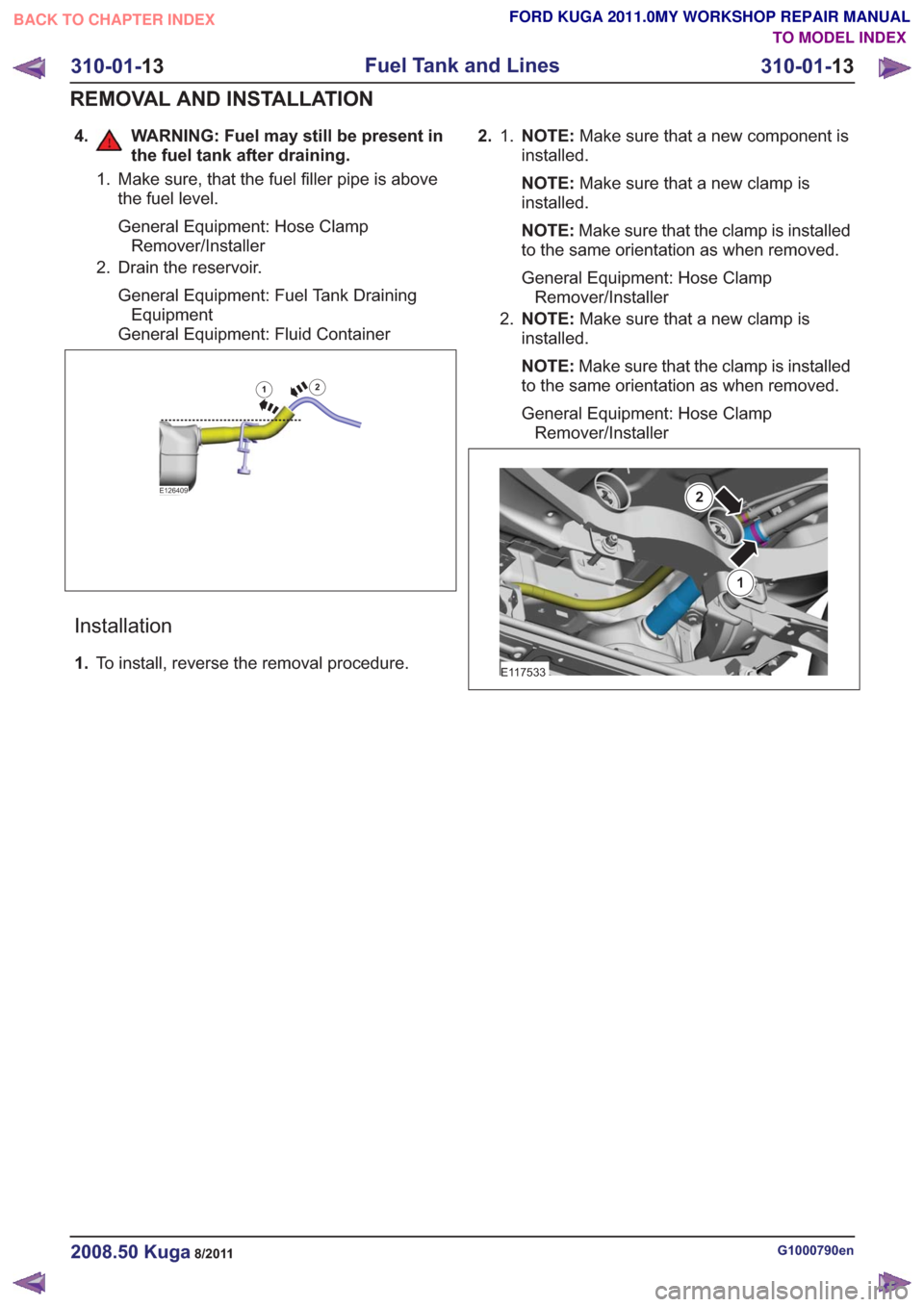

4. WARNING: Fuel may still be present inthe fuel tank after draining.

1. Make sure, that the fuel filler pipe is abovethe fuel level.

General Equipment: Hose ClampRemover/Installer

2. Drain the reservoir.

General Equipment: Fuel Tank DrainingEquipment

General Equipment: Fluid Container

E126409

12

Installation

1. To install, reverse the removal procedure. 2. NOTE:

Make sure that a new component is

installed.

1.

NOTE: Make sure that a new clamp is

installed.

NOTE: Make sure that the clamp is installed

to the same orientation as when removed.

General Equipment: Hose Clamp Remover/Installer

2. NOTE: Make sure that a new clamp is

installed.

NOTE: Make sure that the clamp is installed

to the same orientation as when removed.

General Equipment: Hose Clamp Remover/Installer

1

2

E117533

G1000790en2008.50 Kuga8/2011

310-01- 13

Fuel Tank and Lines

310-01- 13

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1994 of 2057

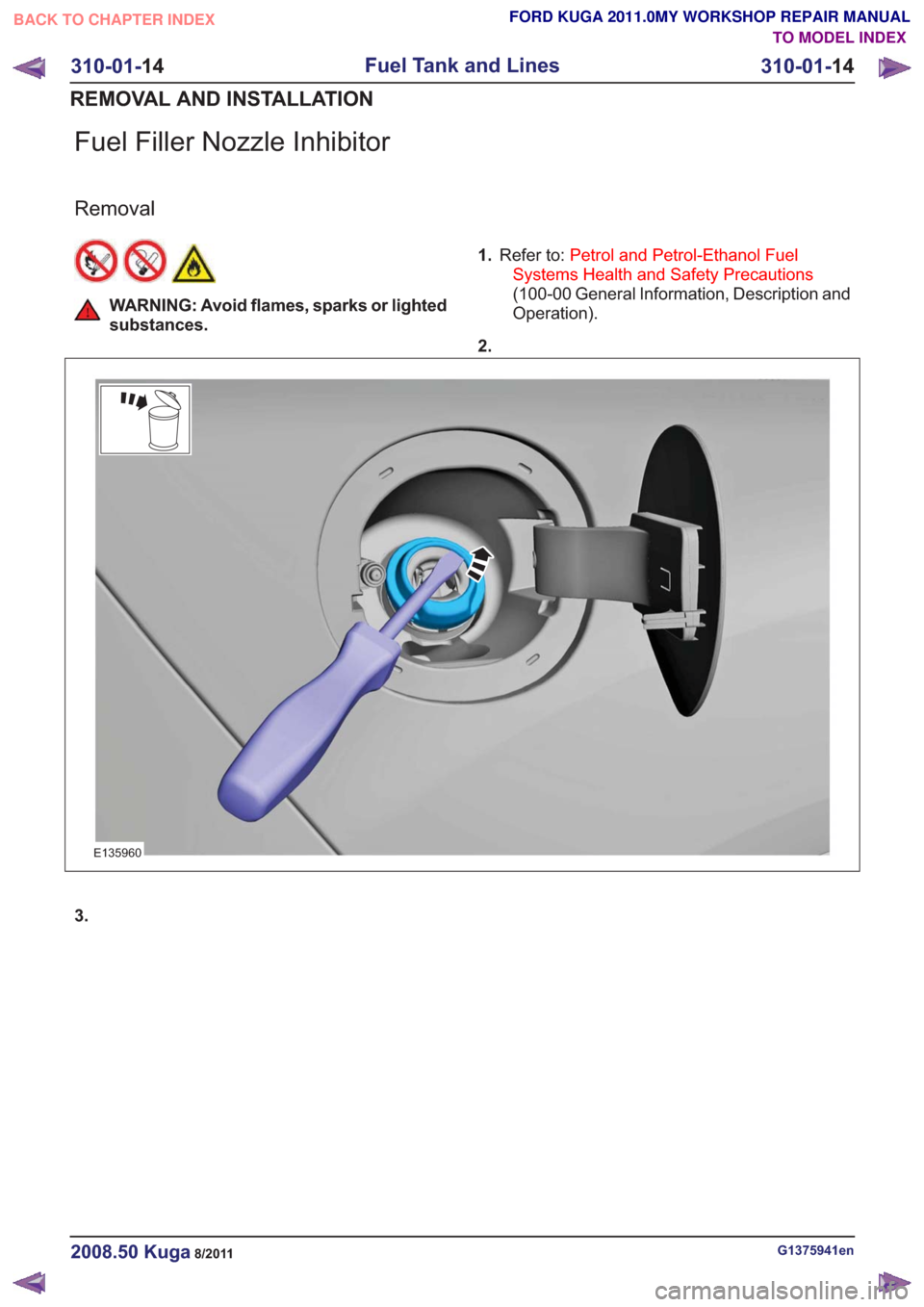

Fuel Filler Nozzle Inhibitor

Removal

WARNING: Avoid flames, sparks or lighted

substances.1.

Refer to: Petrol and Petrol-Ethanol Fuel

Systems Health and Safety Precautions

(100-00 General Information, Description and

Operation).

2.

E135960

3.

G1375941en2008.50 Kuga8/2011

310-01- 14

Fuel Tank and Lines

310-01- 14

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1999 of 2057

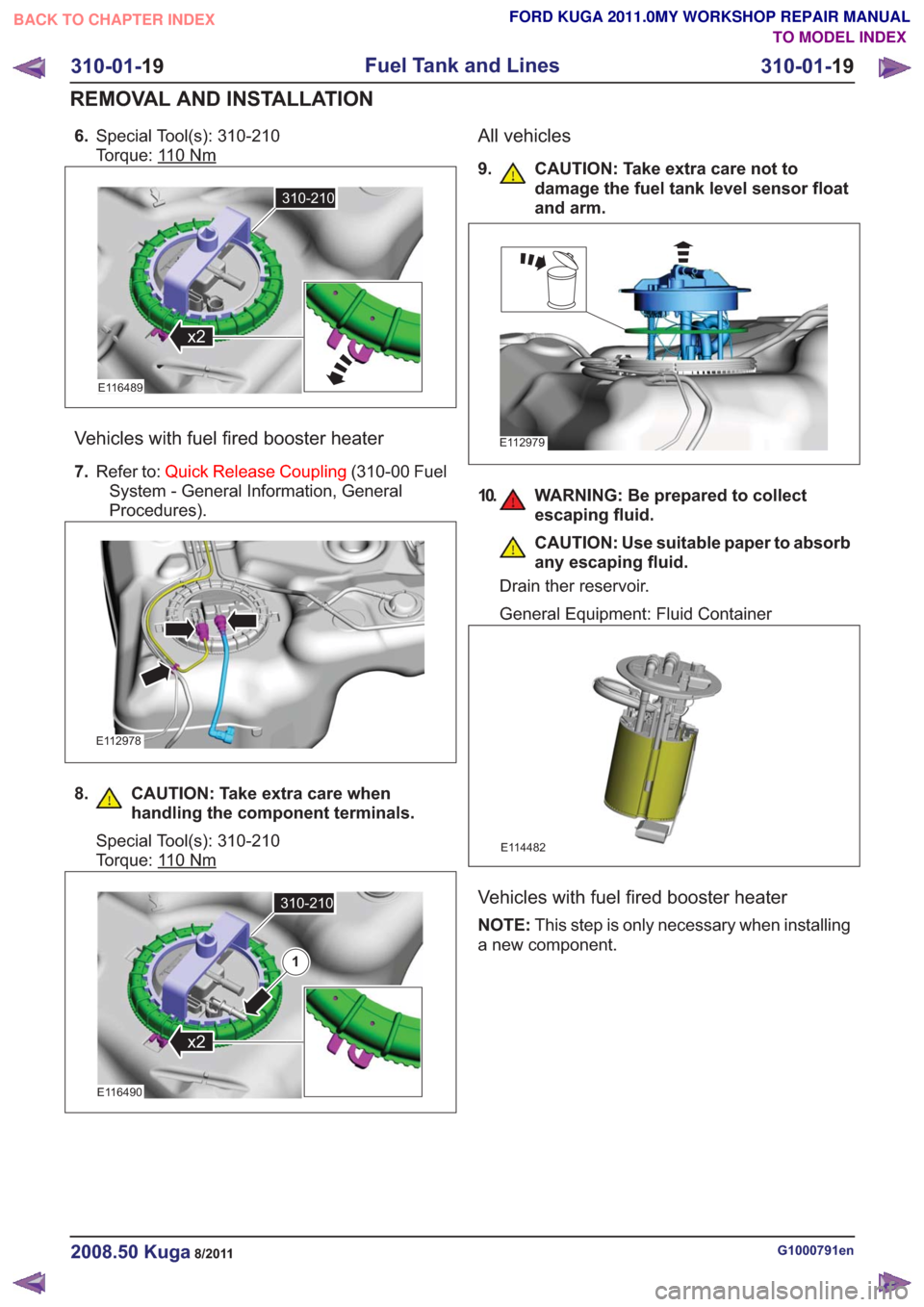

6.Special Tool(s): 310-210

Torque: 1

10Nm

310-210

x2

310-210

x2

E116489

Vehicles with fuel fired booster heater

7.Refer to: Quick Release Coupling (310-00 Fuel

System - General Information, General

Procedures).

E112978

8. CAUTION: Take extra care when handling the component terminals.

Special Tool(s): 310-210

Torque: 1

10Nm

310-210

x2

310-210

x2

E116490

1

All vehicles

9. CAUTION: Take extra care not todamage the fuel tank level sensor float

and arm.

E112979

10. WARNING: Be prepared to collectescaping fluid.

CAUTION: Use suitable paper to absorb

any escaping fluid.

Drain ther reservoir.

General Equipment: Fluid Container

E114482

Vehicles with fuel fired booster heater

NOTE: This step is only necessary when installing

a new component.

G1000791en2008.50 Kuga8/2011

310-01- 19

Fuel Tank and Lines

310-01- 19

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 2005 of 2057

Speed Control – Overview

Speed Control

The cruise control system keeps the vehicle to a

target speed selected by the driver. The cruise

control system is controlled by the PCM (powertrain

control module)

WARNING: The cruise control system may

not be used in heavy traffic, on winding

roads or on a slippery road surface.

To remove the buttons for the cruise control

system, the airbag must be removed. The buttons

for the two control switch units cannot be replaced

individually.

G1015505en2008.50 Kuga8/2011

310-03- 2

Speed Control

310-03- 2

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 2014 of 2057

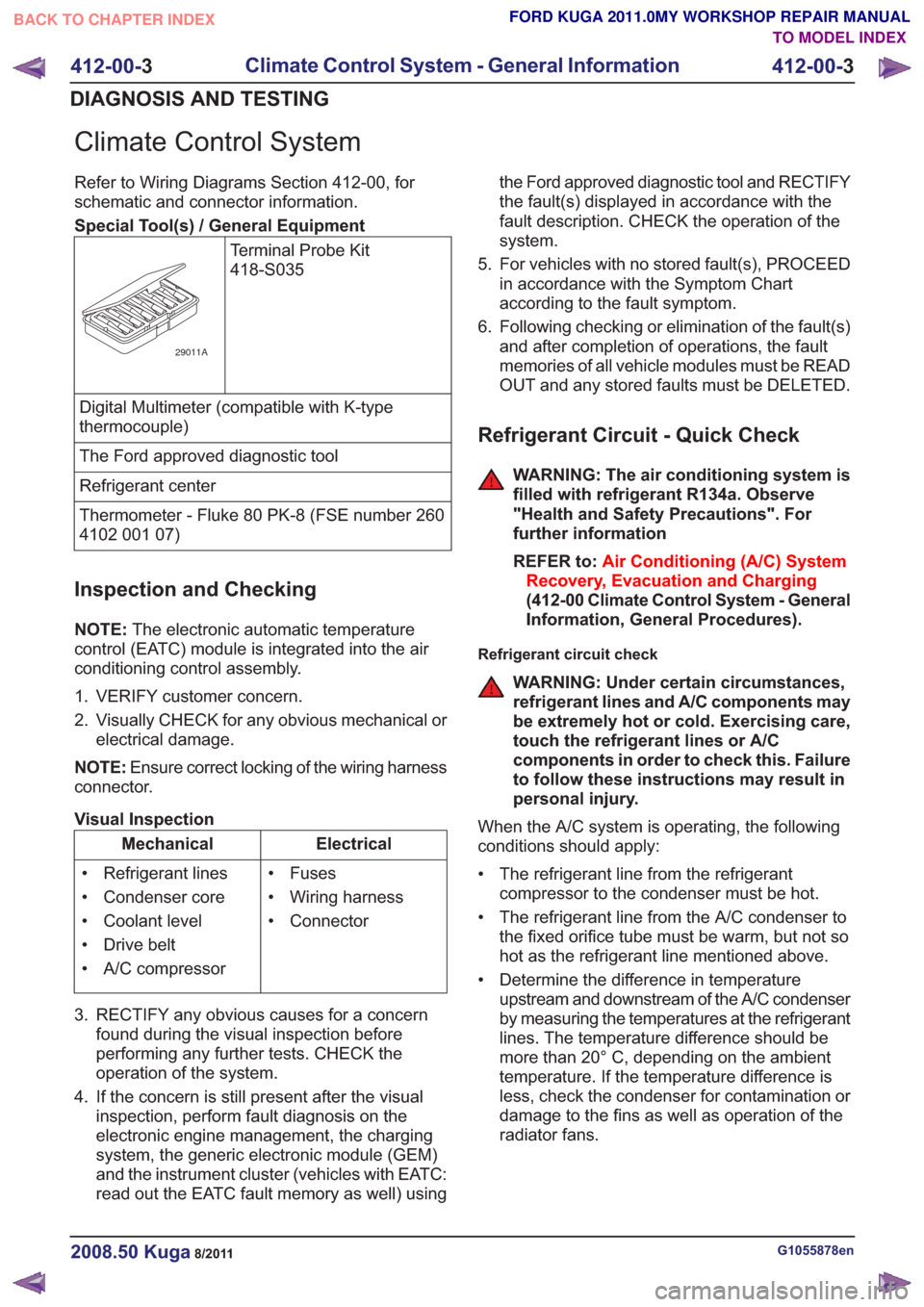

Climate Control System

Refer to Wiring Diagrams Section 412-00, for

schematic and connector information.

Special Tool(s) / General EquipmentTerminal Probe Kit

418-S035

29011A

Digital Multimeter (compatible with K-type

thermocouple)

The Ford approved diagnostic tool

Refrigerant center

Thermometer - Fluke 80 PK-8 (FSE number 260

4102 001 07)

Inspection and Checking

NOTE:The electronic automatic temperature

control (EATC) module is integrated into the air

conditioning control assembly.

1. VERIFY customer concern.

2. Visually CHECK for any obvious mechanical or electrical damage.

NOTE: Ensure correct locking of the wiring harness

connector.

Visual Inspection

Electrical

Mechanical

• Fuses

• Wiring harness

• Connector

• Refrigerant lines

• Condenser core

• Coolant level

• Drive belt

• A/C compressor

3. RECTIFY any obvious causes for a concern found during the visual inspection before

performing any further tests. CHECK the

operation of the system.

4. If the concern is still present after the visual inspection, perform fault diagnosis on the

electronic engine management, the charging

system, the generic electronic module (GEM)

and the instrument cluster (vehicles with EATC:

read out the EATC fault memory as well) using the Ford approved diagnostic tool and RECTIFY

the fault(s) displayed in accordance with the

fault description. CHECK the operation of the

system.

5. For vehicles with no stored fault(s), PROCEED in accordance with the Symptom Chart

according to the fault symptom.

6. Following checking or elimination of the fault(s) and after completion of operations, the fault

memories of all vehicle modules must be READ

OUT and any stored faults must be DELETED.

Refrigerant Circuit - Quick Check

WARNING: The air conditioning system is

filled with refrigerant R134a. Observe

"Health and Safety Precautions". For

further information

REFER to: Air Conditioning (A/C) System

Recovery, Evacuation and Charging

(412-00 Climate Control System - General

Information, General Procedures).

Refrigerant circuit check

WARNING: Under certain circumstances,

refrigerant lines and A/C components may

be extremely hot or cold. Exercising care,

touch the refrigerant lines or A/C

components in order to check this. Failure

to follow these instructions may result in

personal injury.

When the A/C system is operating, the following

conditions should apply:

• The refrigerant line from the refrigerant compressor to the condenser must be hot.

• The refrigerant line from the A/C condenser to the fixed orifice tube must be warm, but not so

hot as the refrigerant line mentioned above.

• Determine the difference in temperature upstream and downstream of the A/C condenser

by measuring the temperatures at the refrigerant

lines. The temperature difference should be

more than 20° C, depending on the ambient

temperature. If the temperature difference is

less, check the condenser for contamination or

damage to the fins as well as operation of the

radiator fans.

G1055878en2008.50 Kuga8/2011

412-00- 3

Climate Control System - General Information

412-00- 3

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL