case FORD KUGA 2011 1.G Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 46 of 2057

Steering System Health and Safety Precautions

WARNINGS:

When handling the power steering fluid,

always wear protective goggles and gloves

made of nitril.

EYE CONTACT: Power steering fluid

contains long chain alkyl amine

thiophosphate. Avoid contact with the

eyes. Wash hands thoroughly after

handling. If power steering fluid comes into

contact with the eyes, flush the eyes with

plenty of cold running water for 15

minutes. Seek medical attention for any

persistent eye irritation or abnormality.

SKIN CONTACT: If power steering fluid

comes into contact with the skin, remove

contaminated clothing. Wash affected

areas of skin with soap and water. Seek

medical attention for any persistent skin

irritation or abnormality.

INHALED: If oil mist is inhaled, move a

victim to fresh air. Keep a victim warm and

at rest. Seek immediate medical attention

in cases of throat irritation or coughing.

SWALLOWED: Power steering fluid

contains long chain alkyl amine

thiophosphate. If swallowed, drink plenty

of water. Seek immediate medical attention.

CAUTION: If the power steering fluid is

spilled on the paintwork, the affected area

must be immediately washed down with

cold water.

G1185951en2008.50 Kuga8/2011

100-00-41

General Information

100-00- 41

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 47 of 2057

Exhaust Fumes

These contain asphyxiating, harmful and toxic

chemicals and particles such as carbon oxides,

nitrogen oxides, aldehydes, lead and aromatic

hydrocarbons. Engines should be run only under

conditions of adequate exhaust extraction or

general ventilation and not in confined spaces.

Gasoline (petrol) engine

There may not be adequate warning of odor or of

irritation before toxic or harmful effects arise. These

may be immediate or delayed.

Diesel engine

Soot, discomfort and irritation usually give

adequate warning of hazardous fume

concentrations.

Fibre Insulation

See alsoDusts.

Used in noise and sound insulation.

The fibrous nature of surfaces and cut edges can

cause skin irritation. This is usually a physical and

not a chemical effect.

Precautions should be taken to avoid excessive

skin contact through careful organization of work

practices and the use of gloves.

Fire

See also Welding,Foams,Legal Aspects.

Many of the materials found on or associated with

the repair of vehicles are highly flammable. Some

give off toxic or harmful fumes if burnt.

Observe strict fire safety when storing and handling

flammable materials or solvents, particularly near

electrical equipment or welding processes.

Make sure, before using electrical or welding

equipment, that there is no fire hazard present.

Have a suitable fire extinguisher available when

using welding or heating equipment.

First Aid

Apart from meeting any legal requirements it is

desirable for someone in the workshop to be

trained in First Aid procedures.

Splashes in the eye should be flushed carefully

with clean water for at least ten minutes.

Soiled skin should be washed with soap and water.

In case of cold burns, from alternative fuels, place

affected area in cool to cold water.

Individuals affected by inhalation of gases and

fumes should be removed to fresh air immediately.

If effects persist, consult a doctor.

If liquids are swallowed inadvertently, consult a

doctor giving him the information on the container

or label. Do not induce vomiting unless this action

is indicated on the label.

Fluoroelastomer

See Viton.

Foams - Polyurethane

See also Fire.

Used in sound and noise insulation. Cured foams

used in seat and trim cushioning.

Follow manufacturers instructions.

Unreacted components are irritating and may be

harmful to the skin and eyes. Wear gloves and

goggles.

Individuals with chronic respiratory diseases,

asthma, bronchial medical problems, or histories

of allergic diseases should not work in or near

uncured materials.

The components, vapors or spray mists can cause

direct irritation, sensitivity reactions and may be

toxic or harmful.

Vapors and spray mists must not be inhaled. These

materials must be applied with adequate ventilation

and respiratory protection. Do not remove the

respirator immediately after spraying; wait until the

vapors/mists have cleared.

Burning of the uncured components and the cured

foams can generate toxic and harmful fumes.

Smoking, naked flames or the use of electrical

equipment during foaming operations and until

vapors/mists have cleared should not be allowed.

Any heat cutting of cured foams or partially cured

G566527en2008.50 Kuga8/2011

100-00- 46

General Information

100-00- 46

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 49 of 2057

Solvent-based Adhesives/Sealers - See

Solvents

Follow manufacturers instructions.

Water-based Adhesives/Sealers

Those based on polymer emulsions and rubber

latexes may contain small amounts of volatile toxic

and harmful chemicals. Skin and eye contact

should be avoided and adequate ventilation

provided during use.

Hot Melt Adhesives

In the solid state, they are safe. In the molten state

they may cause burns and health hazards may

arise from the inhalation of toxic fumes.

Use appropriate protective clothing and a

thermostatically controlled heater with a thermal

cut-out and adequate extraction.

Resin-based Adhesives/Sealers, for

example Epoxide and Formaldehyde

Resin-based

Mixing should be carried out in well ventilated

areas, as harmful or toxic volatile chemicals may

be released.

Skin contact with uncured resins and hardeners

can result in irritation, dermatitis, and absorption

of toxic or harmful chemicals through the skin.

Splashes can damage the eyes.

Provide adequate ventilation and avoid skin and

eye contact.

Anaerobic, Cyanoacrylate (super-glues)

and other Acrylic Adhesives

Many are irritant, sensitizing or harmful to the skin

and respiratory tract. Some are eye irritants.

Skin and eye contact should be avoided and the

manufacturers instructions followed.

Cyanoacrylate adhesives (super-glues) MUST NOT

contact the skin or eyes. If skin or eye tissue is

bonded, cover with a clean moist pad and SEEK

IMMEDIATE MEDICAL ATTENTION. Do not

attempt to pull tissue apart. Use in well ventilated

areas as vapors can cause irritation to the nose

and eyes.For two-pack systems see Resin-based and

Isocyanate Adhesives/Sealers.

Isocyanate (Polyurethane)

Adhesives/Sealers

See also

Resin-based Adhesives.

Individuals suffering from asthma or respiratory

allergies should not work with or near these

materials as sensitivity reactions can occur.

Over exposure is irritating to the eyes and

respiratory system. Excessive concentrations may

produce effects on the nervous system including

drowsiness. In extreme cases, loss of

consciousness may result. Long term exposure to

vapor concentrations may result in adverse health

effects.

Prolonged contact with the skin may have a

defatting effect which may lead to skin irritation

and in some cases, dermatitis.

Splashes entering the eye will cause discomfort

and possible damage.

Any spraying should preferably be carried out in

exhaust ventilated booths, removing vapors and

spray droplets from the breathing zone.

Wear appropriate gloves, eye and respiratory

protection.

Antifreeze

See also Fire, Solvents.

For example isopropanol, ethylene glycol,

methanol.

Highly flammable, flammable, combustible.

Used in vehicle coolant systems, brake air pressure

systems, screenwash solutions.

For additional information, refer to: Engine Cooling

System Health and Safety Precautions (100-00

General Information, Description and Operation).

Asbestos

See also Warning Symbols on Vehicles at the end

of this subsection.

Breathing asbestos dust may cause lung damage

or, in some cases, cancer.

Used in brake and clutch linings, transmission

brake bands and gaskets.

G566527en2008.50 Kuga8/2011

100-00- 43

General Information

100-00- 43

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 52 of 2057

dermatitis or be absorbed through the skin in

toxic or harmful quantities.

– Do not use emptied containers for other materials except when they have been cleaned

under supervised conditions.

– Do not sniff or smell chemical materials. Brief exposure to high concentrations of fumes can

be toxic or harmful.

Chlorofluorocarbons (CFC)

There is concern in the scientific community that

CFCs and Halons are depleting the upper ozone

layer which filters out harmful ultraviolet radiation.

Decreased filtration of ultraviolet radiation may

result in increases in skin cancer, cataracts and

immune system suppression in humans, as well

as decreased productivity of crops and aquatic

systems.

CFCs are used primarily as refrigerants in vehicle

air conditioning systems and as aerosol

propellants. Halons are used as fire extinguishants.

Clutch Fluids

See Brake fluids.

Clutch Linings and Pads

SeeAsbestos.

Corrosion Protection Materials

See also Solvents, Fire.

Highly flammable, flammable – observe No

Smoking policy.

These materials are varied and the manufacturers

instructions must be followed. They may contain

solvents, resins or petroleum products. Skin and

eye contact should be avoided. They should only

be sprayed in conditions of adequate ventilation

and not in confined spaces.

Cutting

See Welding.

Dewaxing

SeeSolvents andFuels (Kerosene).

Dusts

Powder, dusts or clouds may be irritant, harmful

or toxic. Avoid breathing dusts from powdery

chemical materials or those arising from dry

abrasion operations. Wear respiratory protection

if ventilation is inadequate.

Fine dusts of combustible material can present an

explosion hazard. Avoid explosive limits and

sources of ignition.

Electric Shock

Electric shock can result from the use of faulty

electrical equipment or from the misuse of

equipment in good condition.

Make sure that electrical equipment is maintained

in good condition and frequently tested. Faulty

equipment should be labeled and preferably

removed from the workstation.

Make sure that flexes, cables, plugs and sockets

are not frayed, kinked, cut, cracked or otherwise

damaged.

Make sure that electrical equipment and flexes do

not come into contact with water.

Make sure that electrical equipment is protected

by the correct rated fuse.

Never misuse electrical equipment and never use

equipment that is in any way faulty. The results

could be fatal.

Make sure that the cables of mobile electrical

equipment cannot get trapped and damaged, such

as in a vehicle hoist.

Make sure that the designated electrical workers

are trained in basic First Aid.

In cases of electrocution:

– switch off the power supply before approaching

the victim.

– if this is not possible push or drag the victim from the source of electricity using dry

non-conductive material.

– commence resuscitation if trained to do so.

– SUMMON MEDICAL ASSISTANCE.

Engine Oils

See Lubricants and Grease.

G566527en2008.50 Kuga8/2011

100-00- 45

General Information

100-00- 45

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 54 of 2057

Accidental eye contact should be dealt with as per

normal first aid practices, by flushing the eyes with

an eye wash or clean cool water for 10 minutes,

after which medical attention should be obtained.

Remove and launder clothing which becomes

contaminated with the fluids. Do not place rags

contaminated with fluid in clothing pockets.

Wash thoroughly after completing operations where

skin exposure may have occurred.

It is important that personnel do not smoke, eat or

drink whilst handling the fluids or affected

transmissions. These measures are designed to

limit the risk from accidental ingestion.

Label any decanted fluid properly/use an equivalent

label to that on original product containers.

Clean up any spills promptly using an inert

absorbent and wash down contaminated surfaces

with detergent and water.

Dispose of any waste fluids safely as hazardous

waste.

Safety Data Sheets

Safety Data Sheets, which detail specific material

handling instructions and precautions are available

from the respective national sales company, and

via internet www.msds.ford.com.

Used Engine Oil

Prolonged and repeated contact with mineral oil

will result in the removal of natural fats from the

skin, leading to dryness, irritation and dermatitis.

In addition, used engine oil contains potentially

harmful contaminants, which may cause skin

cancer. Adequate means of skin protection and

washing facilities must be provided.

Do not employ used engine oils as lubricants or

for any application where appreciable skin contact

is likely to occur.

Environmental Precautions

Burning used engine oil in small space heaters or

boilers can be recommended only for units of

approved design. If in doubt check with the

appropriate local authority and manufacturer of

approved appliances.

Dispose of used oil and used oil filters through

authorized waste disposal contractors or licensedwaste disposal sites, or to the waste oil reclamation

trade. If in doubt, contact the relevant local

authority for advice on disposal facilities.

It is illegal to pour used oil on to the ground, down

sewers or drains, or into watercourses.

Noise

Some operations may produce high noise levels,

which could, in time, damage hearing. In these

cases, suitable ear protection must be worn.

Noise Insulation Materials

See

Foams, Fibre Insulation.

O-Rings (Fluoroelastomer)

SeeViton.

Paints

See also Solvents, Chemical Materials.

Highly flammable, flammable - observe No

Smoking policy

One Pack

Can contain harmful or toxic pigments, driers and

other components as well as solvents. Spraying

should be carried out only with adequate

ventilation.

Two Pack

Can also contain harmful and toxic unreacted

resins and resin hardening agents. The

manufacturers instructions should be followed. See

also Resin-based Adhesives and Isocyanate

Adhesives and Sealers under Adhesives and

Sealers.

Spraying should preferably be carried out in

exhausted ventilated booths removing vapor and

spray mists from the breathing zone. Individuals

working in booths should wear appropriate

respiratory protection. Those doing small-scale

repair work in the open workshop should wear

air-fed respirators.

G566527en2008.50 Kuga8/2011

100-00- 49

General Information

100-00- 49

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 56 of 2057

Viton is a fluoroelastomer, that is a synthetic rubber

type material, which contains Fluorine. It is

commonly used for O-rings, gaskets and seals of

all types. Although Viton is the most well known

fluoroelastomer, there are others, including Fluorel

and Tecmoflon.

When used under design conditions

fluoroelastomers are perfectly safe. If, however,

they are exposed to temperatures in excess of

400°C, the material will not burn, but will

decompose, and one of the products formed is

hydrofluoric acid.

This acid is extremely corrosive and may be

absorbed directly, through contact, into the general

body system.

O-rings, seals or gaskets which have been exposed

to very high temperatures will appear charred or

as a black sticky substance.

DO NOT; under any circumstances touch them or

the attached components.

Enquiries should be made to determine whether

Viton or any other fluoroelastomer has been used

in the affected O-ring, seal or gasket. If they are of

natural rubber or nitrile there is no hazard. If in

doubt, be cautious, as the material may be Viton

or any fluoroelastomer.

If Viton or any other fluoroelastomers have been

used, the affected area should be decontaminated

before the commencement of work.

Disposable heavy duty plastic gloves should be

worn at all times, and the affected area washed

down using wire wool and a limewater (calcium

hydroxide) solution to neutralize the acid before

disposing of the decomposed Viton residue and

final cleaning of the area. After use, the plastic

gloves should be discarded carefully and safely.

Welding

See alsoFire, Electric Shock, Gas Cylinders.

Welding processes include Resistance Welding

(Spot Welding), Arc Welding and Gas Welding.

Resistance Welding

This process may cause particles of molten metal

to be emitted at a high velocity, and the eyes and

skin must be protected.

Arc Welding

This process emits a high level of ultra-violet

radiation, which may cause arc-eye, and skin burns

to the operator and to other persons nearby.

Gas-shielded welding processes are particularly

hazardous in this respect. Personal protection must

be worn, and screens used to shield other people.

CONTACT LENS WEARERS ARE ADVISED TO

REVERT TO ORDINARY SPECTACLES WHEN

ARC WELDING as the arc spectrum is believed to

emit microwaves which dry out the fluid between

the lens and the eye. This may result in blindness

when the lens is removed from the eye.

Metal spatter will also occur, and appropriate eye

and skin protection is necessary.

The heat of the welding arc will produce fumes and

gases from the metals being welded, the rods and

from any applied coatings or contamination on the

surfaces being worked on. These gases and fumes

may be toxic and inhalation of these should be

avoided. The use of extraction ventilation to remove

the fumes from the working area may be necessary

particularly in cases where the general ventilation

is poor, or where considerable welding work is

anticipated. In extreme cases or confined spaces

where adequate ventilation cannot be provided,

air-fed respirators may be necessary.

Gas Welding (and Cutting)

Oxy-acetylene torches may be used for welding

and cutting, and special care must be taken to

prevent leakage of these gases, with consequent

risk of fire and explosion.

The process will produce metal spatter and eye

and skin protection is necessary.

The flame is bright, and eye protection should be

used, but the ultra-violet emission is much less

than that from arc welding, and lighter filters may

be used.

The process itself produces few toxic fumes, but

such fumes and gases may be produced from

coatings on the work, particularly during cutting

away of damaged body parts, and inhalation of the

fumes should be avoided.

In brazing, toxic fumes may be produced from the

metals in the brazing rod, and a severe hazard

may arise if brazing rods containing cadmium are

used. In this event particular care must be taken

to avoid inhalation of fumes and expert advice may

be required.

G566527en2008.50 Kuga8/2011

100-00- 51

General Information

100-00- 51

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 165 of 2057

System Operation

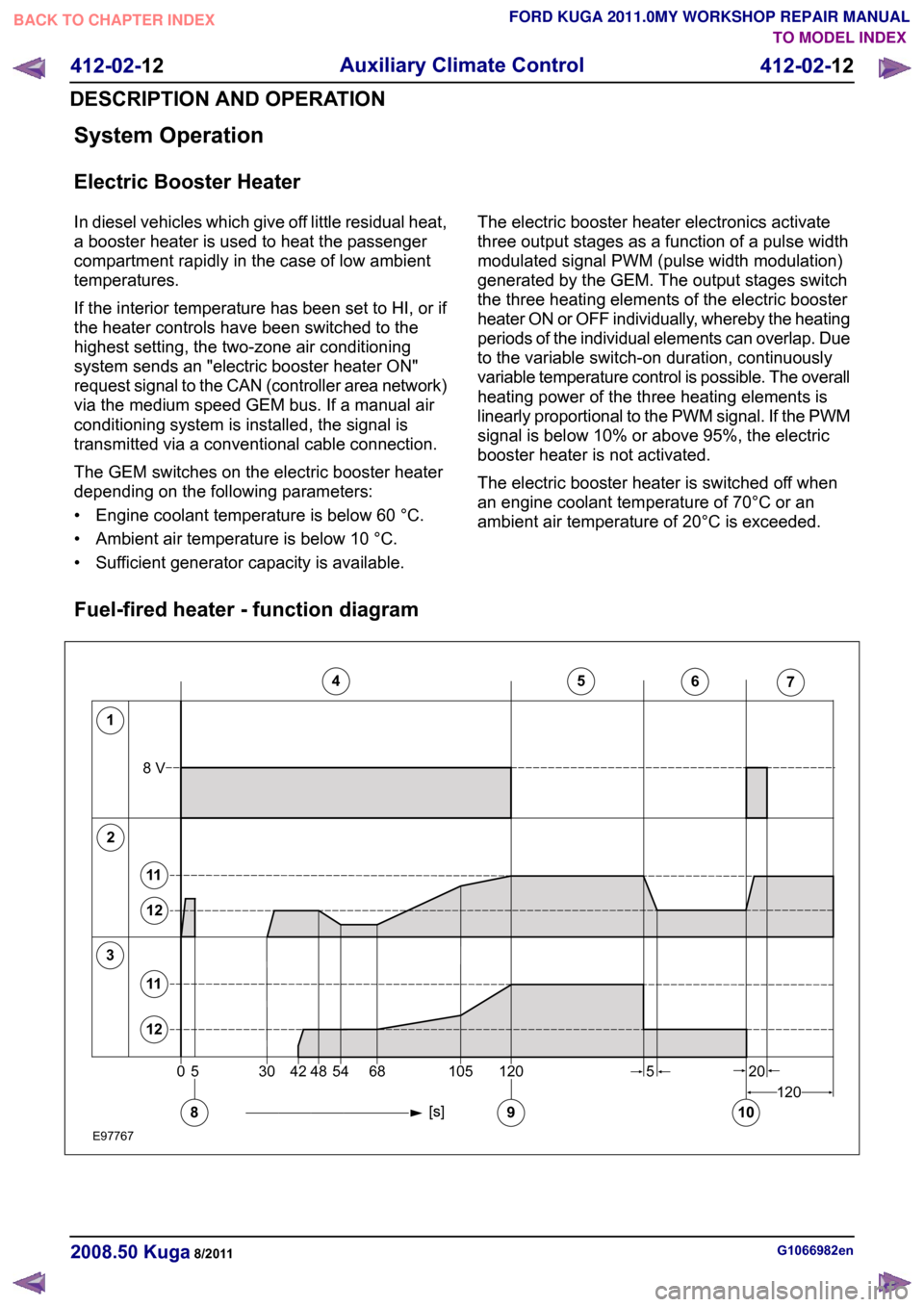

Electric Booster Heater

In diesel vehicles which give off little residual heat,

a booster heater is used to heat the passenger

compartment rapidly in the case of low ambient

temperatures.

If the interior temperature has been set to HI, or if

the heater controls have been switched to the

highest setting, the two-zone air conditioning

system sends an "electric booster heater ON"

request signal to the CAN (controller area network)

via the medium speed GEM bus. If a manual air

conditioning system is installed, the signal is

transmitted via a conventional cable connection.

The GEM switches on the electric booster heater

depending on the following parameters:

• Engine coolant temperature is below 60 °C.

• Ambient air temperature is below 10 °C.

• Sufficient generator capacity is available.

The electric booster heater electronics activate

three output stages as a function of a pulse width

modulated signal PWM (pulse width modulation)

generated by the GEM. The output stages switch

the three heating elements of the electric booster

heater ON or OFF individually, whereby the heating

periods of the individual elements can overlap. Due

to the variable switch-on duration, continuously

variable temperature control is possible. The overall

heating power of the three heating elements is

linearly proportional to the PWM signal. If the PWM

signal is below 10% or above 95%, the electric

booster heater is not activated.

The electric booster heater is switched off when

an engine coolant temperature of 70°C or an

ambient air temperature of 20°C is exceeded.

Fuel-fired heater - function diagram G1066982en

2008.50 Kuga 8/2011 412-02-12

Auxiliary Climate Control

412-02-12

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL12345671205304254481201056820108V58911121112E977670

Page 167 of 2057

reprogrammed. However, if the engine hasn't been

run since the last programmed start, the fuel-fired

booster heater will not start up the second time so

as to prevent the battery from being discharged.

The length of time required to pre-heat the vehicle

is calculated in the control unit of the fuel-fired

booster heater and is based on two temperature

values:

• Ambient air temperature: this message is taken

from the GEM via the CAN bus.

• Coolant temperature: this is determined via an internal sensor in the fuel-fired booster heater.

The maximum heating time is 30 minutes at an

outside air temperature of -10 °C or lower. The

heating time decreases proportionally with

increasing ambient temperature until the ambient

temperature is between +15 °C and +20 °C. Then

the minimum heating time is 10 minutes. The

parking heater is deactivated at temperatures

above +20 °C.

The sequence for a programmed start of the

booster heater is as follows:

• Two minutes before the start of the maximum heating time the driver information

system/instrument cluster sends an activation

message to the fuel-fired booster heater via the

CAN bus.

• The fuel-fired booster heater calculates the required heating time and, if necessary, sends

a delay request on the CAN bus.

• At the calculated time, the fuel-fired booster heater starts up. The conditions for start-up are:

engine not running and amount of fuel in the

fuel tank is above 14% of maximum.

• When the coolant temperature reaches +30 °C, the control unit of the fuel-fired booster heater

sends a request to switch on the passenger

compartment blower.

• Eight minutes after the programmed switch-off time, the booster heater stops heating mode

and starts a run-on operation to clean the

system's spark plugs.

• Ten minutes after the switch-off time, the post-cleaning operation is complete. The

additional ten minutes run-on time provides

some leeway in case the driver is late arriving.

After a programmed start-up of the booster heater

it is switched off again after the heating time has

elapsed (or if the fuel level in the fuel tank drops

below 8%). The booster heater stops within 2 minutes of the engine starting. This leaves enough

time to check whether the switch-on conditions for

boost heat mode have been met, thus preventing

the booster heater from having to switch off and

switch back on again. The heater can be switched

off manually at any time from the menu.

Whilst the fuel-fired booster heater is in additional

heating mode and/or parking heating mode, the

instrument cluster receives a fuel consumption

signal; this is used to re-calculate the vehicle's

remaining range and fuel consumption data.

Emergency shutoff

In the event of an accident in which the airbags

are deployed, the control unit of the fuel-fired

booster heater receives a message on the CAN

bus from the restraints control module (RCM).

When this message is received, the booster heater

system switches off immediately.

The booster heater control module deactivates the

system and does not respond to further messages

on the CAN bus. The booster heater control module

needs to be activated with WDS.

Component Description

Electric Booster Heater

The electric booster heater consists of three

individual heating elements, which are incorporated

into a single housing. It is controlled by the generic

electronic module (GEM), taking into account the

following factors:

Detailed illustration of fuel-fired heater

G1066982en

2008.50 Kuga 8/2011 412-02-14

Auxiliary Climate Control

412-02-14

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE97621

Page 263 of 2057

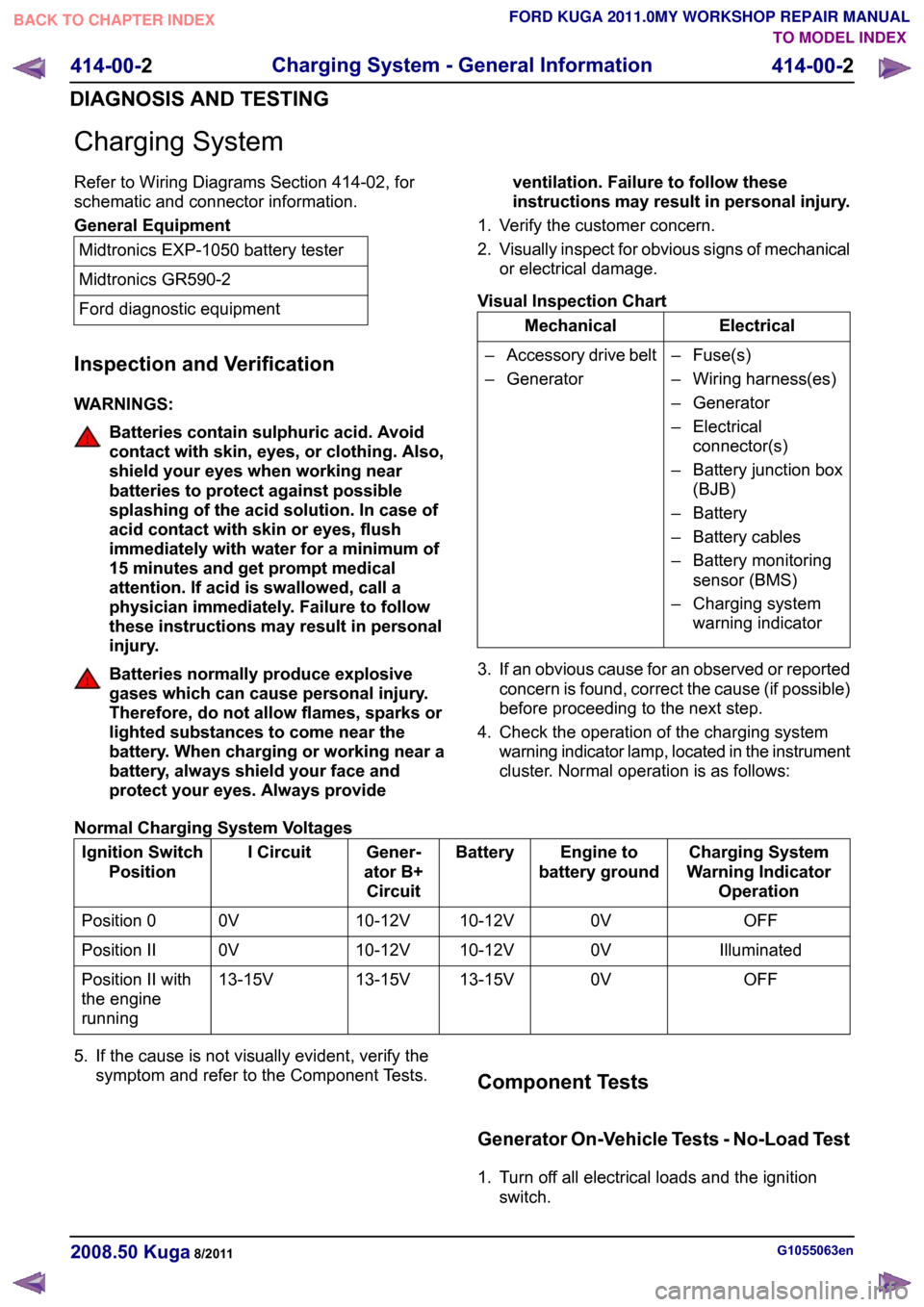

Charging System

Refer to Wiring Diagrams Section 414-02, for

schematic and connector information.

General Equipment

Midtronics EXP-1050 battery tester

Midtronics GR590-2

Ford diagnostic equipment

Inspection and Verification

WARNINGS: Batteries contain sulphuric acid. Avoid

contact with skin, eyes, or clothing. Also,

shield your eyes when working near

batteries to protect against possible

splashing of the acid solution. In case of

acid contact with skin or eyes, flush

immediately with water for a minimum of

15 minutes and get prompt medical

attention. If acid is swallowed, call a

physician immediately. Failure to follow

these instructions may result in personal

injury.

Batteries normally produce explosive

gases which can cause personal injury.

Therefore, do not allow flames, sparks or

lighted substances to come near the

battery. When charging or working near a

battery, always shield your face and

protect your eyes. Always provide

ventilation. Failure to follow these

instructions may result in personal injury.

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical

or electrical damage.

Visual Inspection Chart Electrical

Mechanical

– Fuse(s)

– Wiring harness(es)

– Generator

– Electricalconnector(s)

– Battery junction box (BJB)

– Battery

– Battery cables

– Battery monitoring sensor (BMS)

– Charging system warning indicator

–

Accessory drive belt

– Generator

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible)

before proceeding to the next step.

4. Check the operation of the charging system warning indicator lamp, located in the instrument

cluster. Normal operation is as follows:

Normal Charging System Voltages Charging System

Warning Indicator Operation

Engine to

battery ground

Battery

Gener-

ator B+ Circuit

I Circuit

Ignition Switch

Position

OFF

0V

10-12V

10-12V

0V

Position 0

Illuminated

0V

10-12V

10-12V

0V

Position II

OFF

0V

13-15V

13-15V

13-15V

Position II with

the engine

running

5. If the cause is not visually evident, verify the symptom and refer to the Component Tests. Component Tests

Generator On-Vehicle Tests - No-Load Test

1. Turn off all electrical loads and the ignition

switch. G1055063en

2008.50 Kuga 8/2011 414-00-2

Charging System - General Information

414-00-2

DIAGNOSIS AND TESTINGTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 266 of 2057

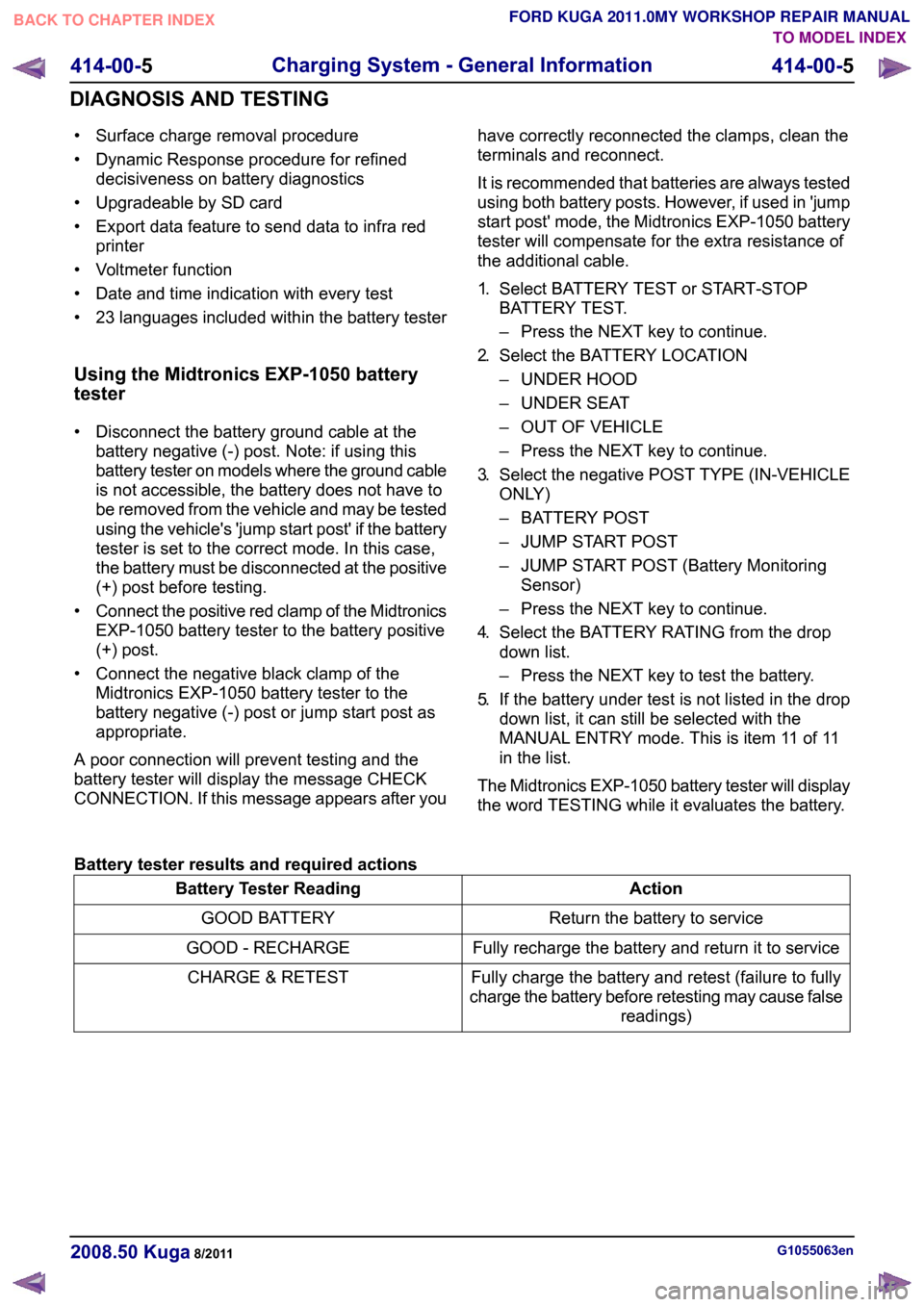

• Surface charge removal procedure

• Dynamic Response procedure for refined

decisiveness on battery diagnostics

• Upgradeable by SD card

• Export data feature to send data to infra red printer

• Voltmeter function

• Date and time indication with every test

• 23 languages included within the battery tester

Using the Midtronics EXP-1050 battery

tester

• Disconnect the battery ground cable at the battery negative (-) post. Note: if using this

battery tester on models where the ground cable

is not accessible, the battery does not have to

be removed from the vehicle and may be tested

using the vehicle's 'jump start post' if the battery

tester is set to the correct mode. In this case,

the battery must be disconnected at the positive

(+) post before testing.

• Connect the positive red clamp of the Midtronics

EXP-1050 battery tester to the battery positive

(+) post.

• Connect the negative black clamp of the Midtronics EXP-1050 battery tester to the

battery negative (-) post or jump start post as

appropriate.

A poor connection will prevent testing and the

battery tester will display the message CHECK

CONNECTION. If this message appears after you have correctly reconnected the clamps, clean the

terminals and reconnect.

It is recommended that batteries are always tested

using both battery posts. However, if used in 'jump

start post' mode, the Midtronics EXP-1050 battery

tester will compensate for the extra resistance of

the additional cable.

1.

Select BATTERY TEST or START-STOP

BATTERY TEST.

– Press the NEXT key to continue.

2. Select the BATTERY LOCATION

– UNDER HOOD

– UNDER SEAT

– OUT OF VEHICLE

– Press the NEXT key to continue.

3. Select the negative POST TYPE (IN-VEHICLE

ONLY)

– BATTERY POST

– JUMP START POST

– JUMP START POST (Battery Monitoring

Sensor)

– Press the NEXT key to continue.

4. Select the BATTERY RATING from the drop

down list.

– Press the NEXT key to test the battery.

5. If the battery under test is not listed in the drop

down list, it can still be selected with the

MANUAL ENTRY mode. This is item 11 of 11

in the list.

The Midtronics EXP-1050 battery tester will display

the word TESTING while it evaluates the battery.

Battery tester results and required actions Action

Battery Tester Reading

Return the battery to service

GOOD BATTERY

Fully recharge the battery and return it to service

GOOD - RECHARGE

Fully charge the battery and retest (failure to fully

charge the battery before retesting may cause false readings)

CHARGE & RETEST G1055063en

2008.50 Kuga 8/2011 414-00-5

Charging System - General Information

414-00-5

DIAGNOSIS AND TESTINGTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL