engine remove FORD KUGA 2011 1.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 174 of 2057

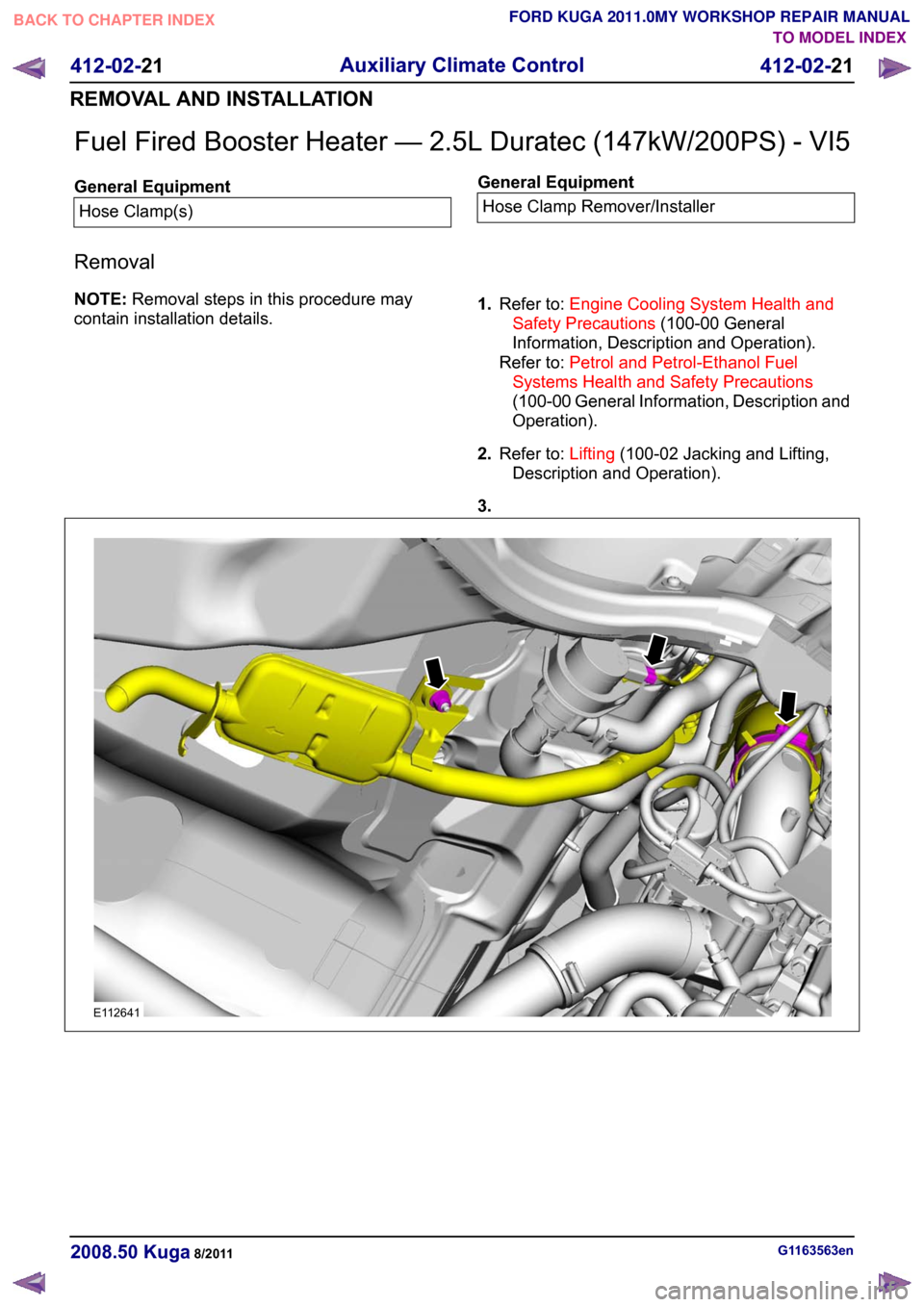

Fuel Fired Booster Heater — 2.5L Duratec (147kW/200PS) - VI5

General Equipment

Hose Clamp(s) General Equipment

Hose Clamp Remover/Installer

Removal

NOTE: Removal steps in this procedure may

contain installation details. 1.

Refer to: Engine Cooling System Health and

Safety Precautions (100-00 General

Information, Description and Operation).

Refer to: Petrol and Petrol-Ethanol Fuel

Systems Health and Safety Precautions

(100-00 General Information, Description and

Operation).

2. Refer to: Lifting(100-02 Jacking and Lifting,

Description and Operation).

3. G1163563en

2008.50 Kuga 8/2011 412-02-21

Auxiliary Climate Control

412-02-21

REMOVAL AND INSTALLATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE112641

Page 464 of 2057

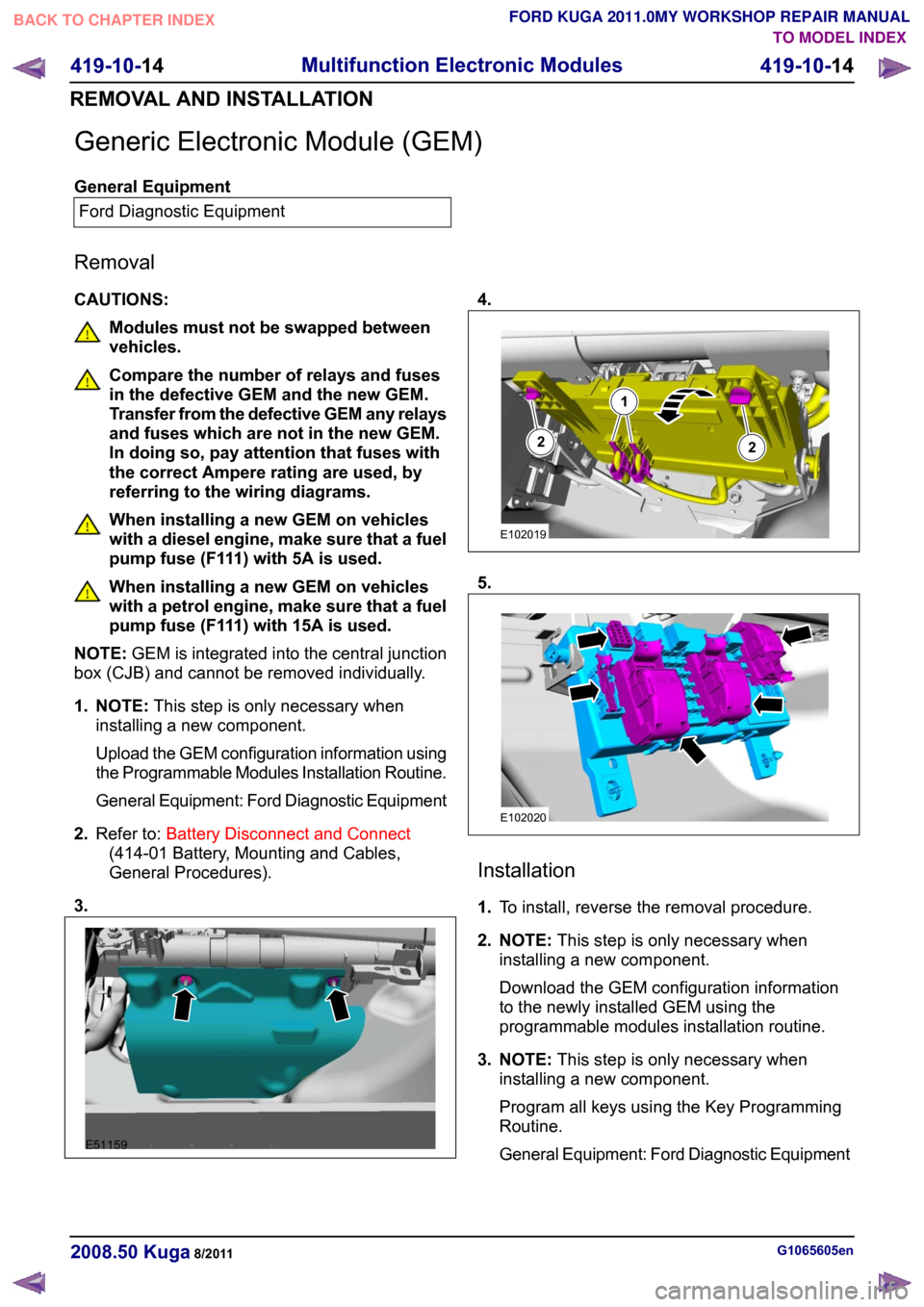

Generic Electronic Module (GEM)

General Equipment

Ford Diagnostic Equipment

Removal

CAUTIONS: Modules must not be swapped between

vehicles.

Compare the number of relays and fuses

in the defective GEM and the new GEM.

Transfer from the defective GEM any relays

and fuses which are not in the new GEM.

In doing so, pay attention that fuses with

the correct Ampere rating are used, by

referring to the wiring diagrams.

When installing a new GEM on vehicles

with a diesel engine, make sure that a fuel

pump fuse (F111) with 5A is used.

When installing a new GEM on vehicles

with a petrol engine, make sure that a fuel

pump fuse (F111) with 15A is used.

NOTE: GEM is integrated into the central junction

box (CJB) and cannot be removed individually.

1. NOTE: This step is only necessary when

installing a new component.

Upload the GEM configuration information using

the Programmable Modules Installation Routine.

General Equipment: Ford Diagnostic Equipment

2. Refer to: Battery Disconnect and Connect

(414-01 Battery, Mounting and Cables,

General Procedures).

3. 4.

5.

Installation

1.

To install, reverse the removal procedure.

2. NOTE: This step is only necessary when

installing a new component.

Download the GEM configuration information

to the newly installed GEM using the

programmable modules installation routine.

3. NOTE: This step is only necessary when

installing a new component.

Program all keys using the Key Programming

Routine.

General Equipment: Ford Diagnostic Equipment G1065605en

2008.50 Kuga 8/2011 419-10-14

Multifunction Electronic Modules

419-10-14

REMOVAL AND INSTALLATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE51159 122E102019 E102020

Page 1319 of 2057

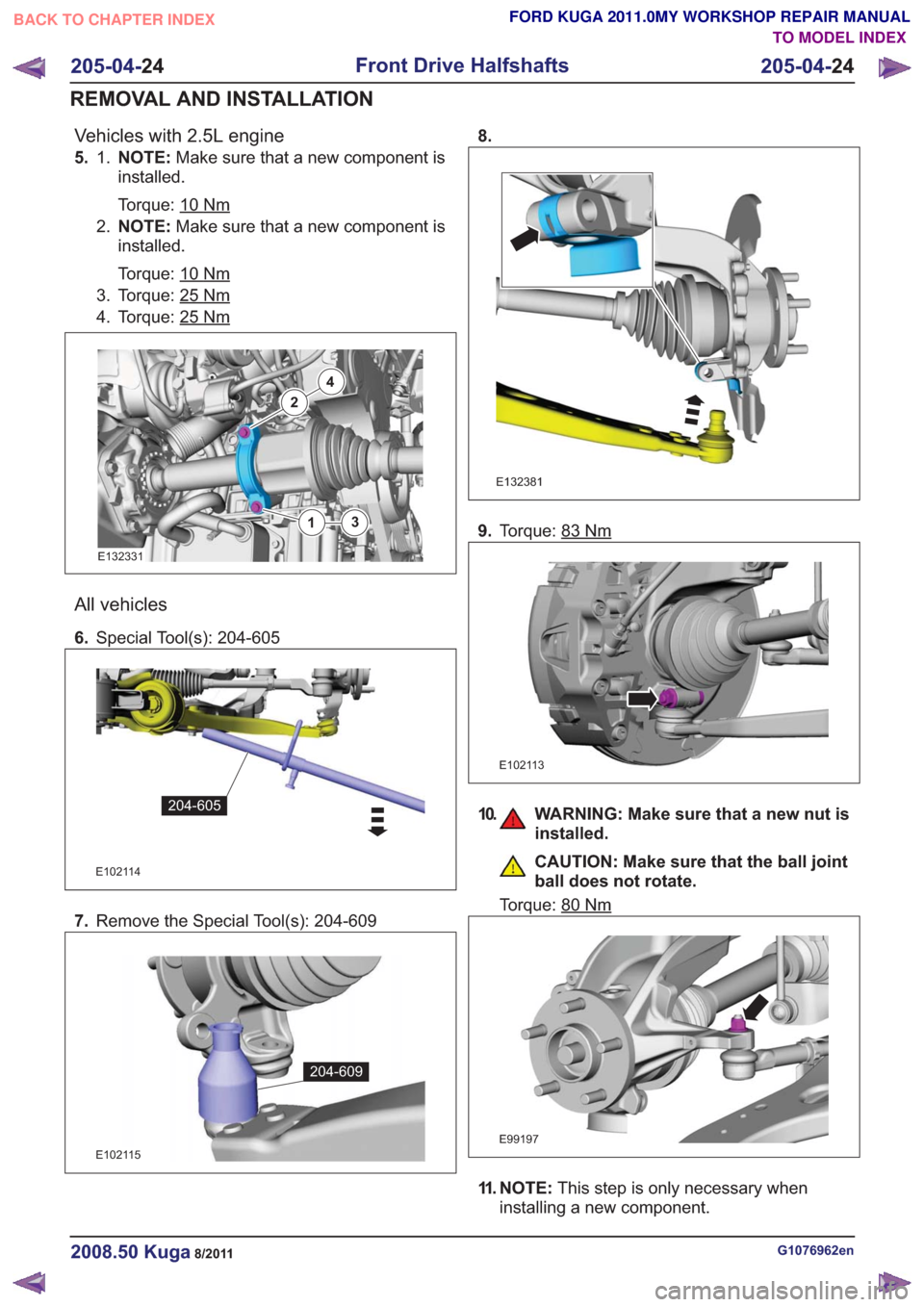

Vehicles with 2.5L engine

5. NOTE:Make sure that a new component is

installed.

Torque: 10

Nm

1.

2. NOTE: Make sure that a new component is

installed.

Torque: 10

Nm

3. Torque: 25Nm

4. Torque: 25Nm

2

4

13

2

4

13

E132331

All vehicles

6. Special Tool(s): 204-605

E102114

204-605

7.Remove the Special Tool(s): 204-609

E102115

204-609

8.

E132381

9.Torque: 83Nm

E102113

10. WARNING: Make sure that a new nut is

installed.

CAUTION: Make sure that the ball joint

ball does not rotate.

Torque: 80

Nm

E99197

11. NOTE: This step is only necessary when

installing a new component.

G1076962en2008.50 Kuga8/2011

205-04- 24

Front Drive Halfshafts

205-04- 24

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1354 of 2057

4. Remove the vacuum hose from the brakebooster. Manifold vacuum should be available

at the brake booster end of the hose with the

engine at idle speed and the transaxle in the

NEUTRAL position. Make sure that all unused

vacuum outlets are correctly capped, hose

connectors are correctly secured and vacuum

hoses are in good condition. When it is

established that manifold vacuum is available

to the brake booster, connect the vacuum hose

to the brake booster and repeat Step 3. If no

downward movement of the brake pedal is felt,

install a new brake booster.

5. Operate the engine a minimum of 10 seconds at approximately 1200 rpm. Stop the engine and

let the vehicle stand for 10 minutes. Then, apply

the brake pedal with approximately 89 N (20 lb)

force. The pedal feel (brake application) should

be the same as that noted with the engine

operating. If the brake pedal feels hard (no

power assist), install a new vacuum check valve

and then repeat the test. If the brake pedal still

feels hard, install a new brake booster. If the

brake pedal movement feels spongy, bleed the

brake system. REFER to: (206-00 Brake System

- General Information)

Brake System Bleeding (General Procedures),

Brake System Pressure Bleeding (General

Procedures),

Component Bleeding (General Procedures).

Brake Master Cylinder

Usually, the first and strongest indicator of anything

wrong with the braking system is a feeling through

the brake pedal. In diagnosing the condition of the

brake master cylinder, check pedal feel as

evidence of a brake concern. Check for the red

brake warning indicator illumination and the fluid

level in the master cylinder reservoir.

Normal Conditions

The following conditions are considered normal

and are not indications that the brake master

cylinder is in need of service.

– Modern brake systems are not designed to

produce as hard a pedal effort as in the past.

Complaints of light pedal efforts should be compared to pedal efforts of another vehicle, of

the same model and year.

– During normal operation of the brake pedal, the fluid level in the reservoir will rise during brake

pedal application and fall during release. The

net fluid level (i.e., after brake pedal application

and release) will remain unchanged.

– A trace of brake fluid will exists on the brake booster shell below the master cylinder

mounting flange. This results from the normal

lubricating action of the master cylinder bore

end seal.

– The fluid level will fall with brake shoe and lining wear.

Abnormal Conditions

NOTE: Prior to performing any diagnosis, make

sure the brake system warning indicator is

functional.

Changes in brake pedal feel or travel are indicators

that something could be wrong with the braking

system. The diagnostic procedure and techniques

use brake pedal feel, warning indicator illumination

and low brake fluid level as indicators in diagnosing

braking system concerns. The following conditions

are considered abnormal and indicate that the

brake master cylinder is in need of service.

– The brake pedal goes down fast. This could be caused by an external or internal leak.

– The brake pedal eases down slowly. This could be caused by an external or internal leak.

– The brake pedal is low and or feels spongy. This condition may be caused by no fluid in the brake

master cylinder reservoir, reservoir cap vent

holes clogged or air in the hydraulic system.

– The brake pedal effort is excessive. This may be caused by a bind or obstruction in the pedal

or linkage, clogged fluid control valve or

insufficient booster vacuum.

– The rear brakes lock up during light pedal force. This may be caused by incorrect tire pressures,

grease or fluid on the brake shoes and linings,

damaged brake shoes and linings, incorrectly

adjusted parking brake, or damaged or

contaminated brake pressure control valves.

– The brake pedal effort is erratic. This condition could be caused by a brake booster malfunction,

extreme caliper piston knock back or incorrectly

installed brake shoes and linings.

– The red brake warning indicator is ON. This may be caused by low fluid level, ignition wire routing

G1058975en2008.50 Kuga8/2011

206-00- 18

Brake System - General Information

206-00- 18

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1445 of 2057

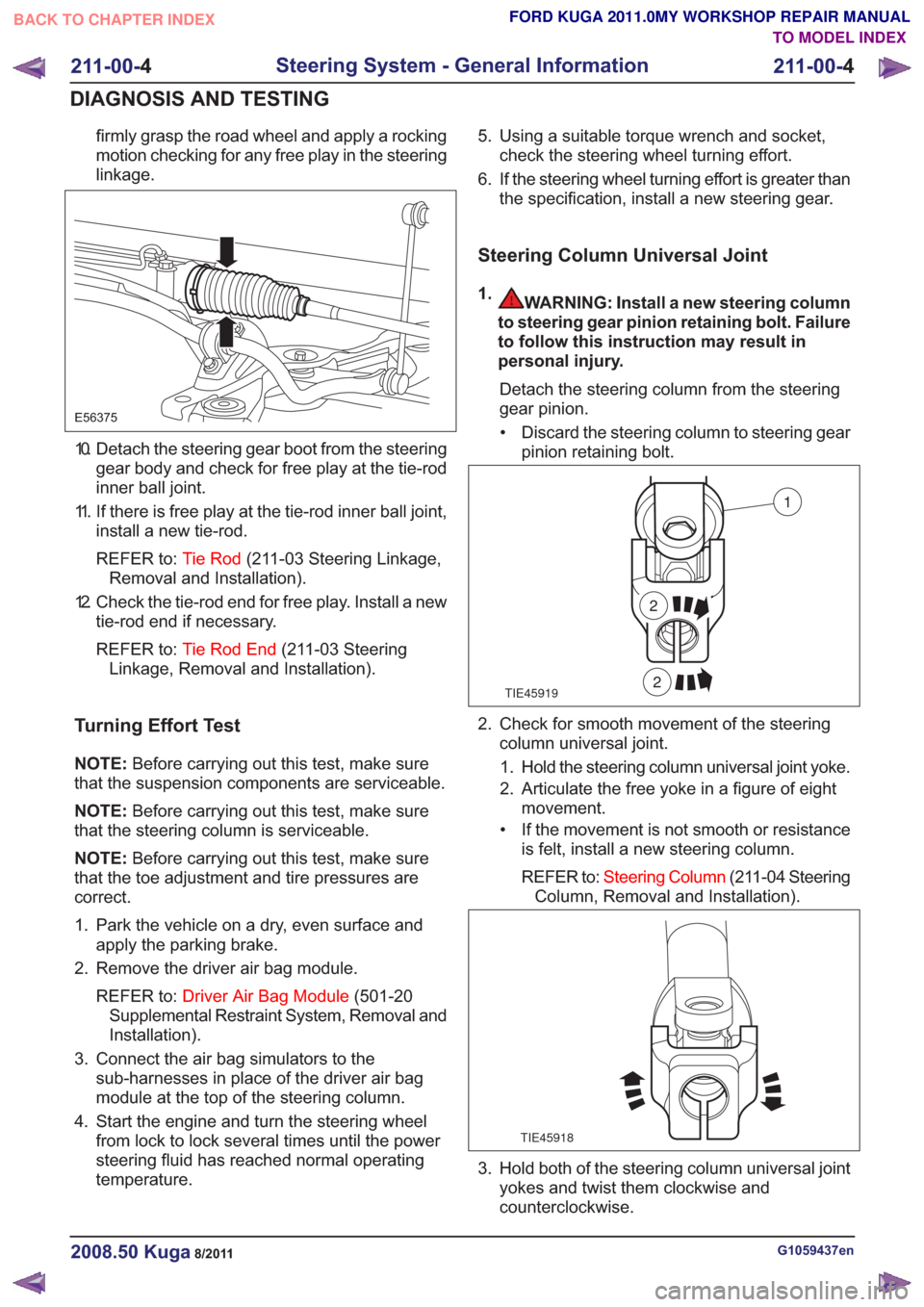

firmly grasp the road wheel and apply a rocking

motion checking for any free play in the steering

linkage.

E56375

10. Detach the steering gear boot from the steeringgear body and check for free play at the tie-rod

inner ball joint.

11. If there is free play at the tie-rod inner ball joint, install a new tie-rod.

REFER to: Tie Rod(211-03 Steering Linkage,

Removal and Installation).

12. Check the tie-rod end for free play. Install a new tie-rod end if necessary.

REFER to: Tie Rod End (211-03 Steering

Linkage, Removal and Installation).

Turning Effort Test

NOTE: Before carrying out this test, make sure

that the suspension components are serviceable.

NOTE: Before carrying out this test, make sure

that the steering column is serviceable.

NOTE: Before carrying out this test, make sure

that the toe adjustment and tire pressures are

correct.

1. Park the vehicle on a dry, even surface and apply the parking brake.

2. Remove the driver air bag module.

REFER to: Driver Air Bag Module (501-20

Supplemental Restraint System, Removal and

Installation).

3. Connect the air bag simulators to the sub-harnesses in place of the driver air bag

module at the top of the steering column.

4. Start the engine and turn the steering wheel from lock to lock several times until the power

steering fluid has reached normal operating

temperature. 5. Using a suitable torque wrench and socket,

check the steering wheel turning effort.

6. If the steering wheel turning effort is greater than the specification, install a new steering gear.

Steering Column Universal Joint

1.WARNING: Install a new steering column

to steering gear pinion retaining bolt. Failure

to follow this instruction may result in

personal injury.

Detach the steering column from the steering

gear pinion.• Discard the steering column to steering gear pinion retaining bolt.

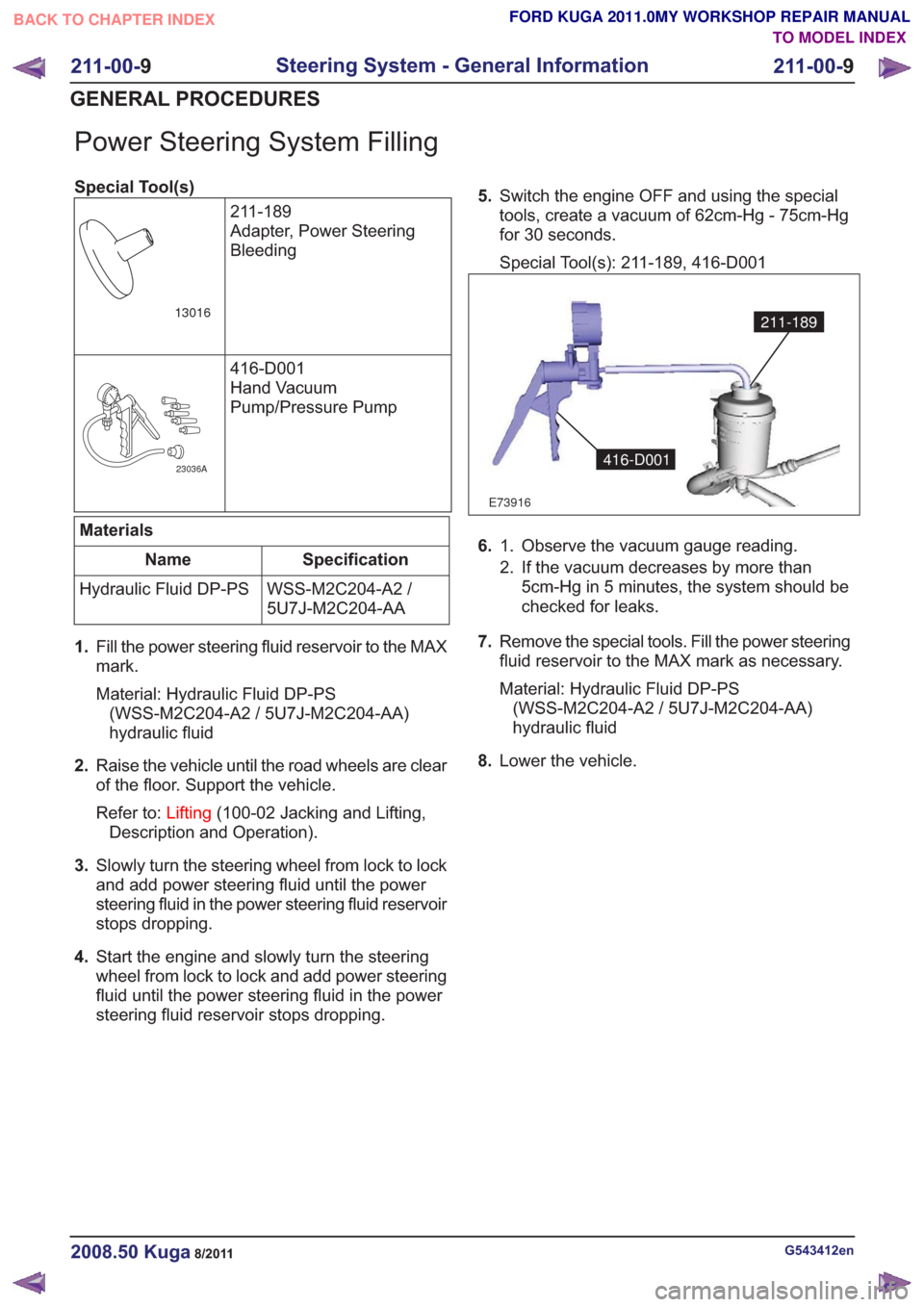

TIE45919

1

2

2

2. Check for smooth movement of the steeringcolumn universal joint.

1. Hold the steering column universal joint yoke.

2. Articulate the free yoke in a figure of eight movement.

• If the movement is not smooth or resistance is felt, install a new steering column.

REFER to: Steering Column (211-04 Steering

Column, Removal and Installation).

TIE45918

3. Hold both of the steering column universal joint yokes and twist them clockwise and

counterclockwise.

G1059437en2008.50 Kuga8/2011

211-00- 4

Steering System - General Information

211-00- 4

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1450 of 2057

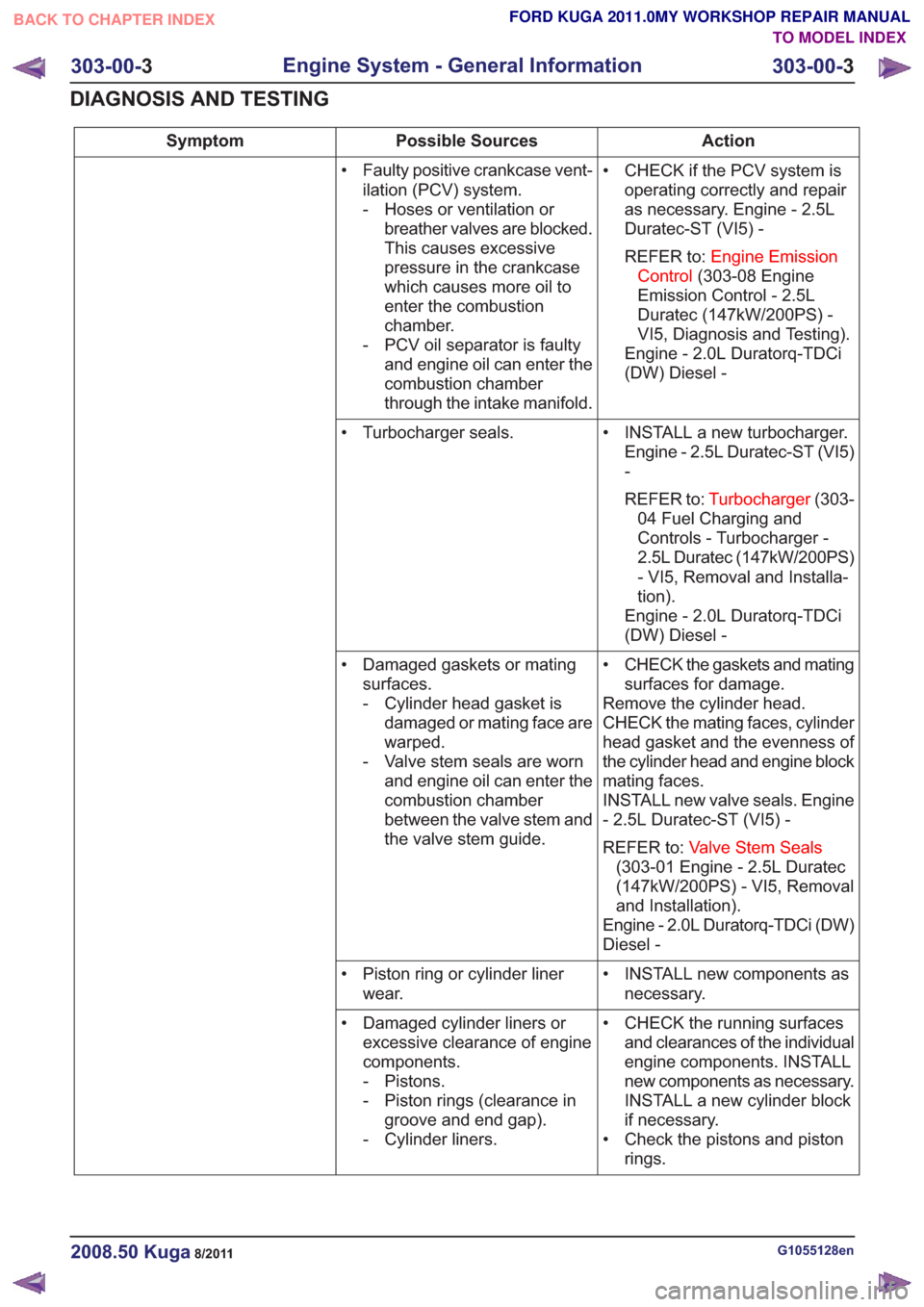

Power Steering System Filling

Special Tool(s)211-189

Adapter, Power Steering

Bleeding

13016

416-D001

Hand Vacuum

Pump/Pressure Pump

23036A

Materials

Specification

Name

WSS-M2C204-A2 /

5U7J-M2C204-AA

Hydraulic Fluid DP-PS

1. Fill the power steering fluid reservoir to the MAX

mark.

Material: Hydraulic Fluid DP-PS

(WSS-M2C204-A2 / 5U7J-M2C204-AA)

hydraulic fluid

2. Raise the vehicle until the road wheels are clear

of the floor. Support the vehicle.

Refer to: Lifting(100-02 Jacking and Lifting,

Description and Operation).

3. Slowly turn the steering wheel from lock to lock

and add power steering fluid until the power

steering fluid in the power steering fluid reservoir

stops dropping.

4. Start the engine and slowly turn the steering

wheel from lock to lock and add power steering

fluid until the power steering fluid in the power

steering fluid reservoir stops dropping. 5.

Switch the engine OFF and using the special

tools, create a vacuum of 62cm-Hg - 75cm-Hg

for 30 seconds.

Special Tool(s): 211-189, 416-D001

E73916

211-189

416-D001

6. Observe the vacuum gauge reading.

1.

2. If the vacuum decreases by more than

5cm-Hg in 5 minutes, the system should be

checked for leaks.

7. Remove the special tools. Fill the power steering

fluid reservoir to the MAX mark as necessary.

Material: Hydraulic Fluid DP-PS

(WSS-M2C204-A2 / 5U7J-M2C204-AA)

hydraulic fluid

8. Lower the vehicle.

G543412en2008.50 Kuga8/2011

211-00- 9

Steering System - General Information

211-00- 9

GENERAL PROCEDURES

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1519 of 2057

Action

Possible Sources

Symptom

• CHECK if the PCV system isoperating correctly and repair

as necessary. Engine - 2.5L

Duratec-ST (VI5) -

REFER to: Engine Emission

Control (303-08 Engine

Emission Control - 2.5L

Duratec (147kW/200PS) -

VI5, Diagnosis and Testing).

Engine - 2.0L Duratorq-TDCi

(DW) Diesel -

• Faulty positive crankcase vent-

ilation (PCV) system.

- Hoses or ventilation orbreather valves are blocked.

This causes excessive

pressure in the crankcase

which causes more oil to

enter the combustion

chamber.

- PCV oil separator is faulty and engine oil can enter the

combustion chamber

through the intake manifold.

• INSTALL a new turbocharger.Engine - 2.5L Duratec-ST (VI5)

-

REFER to: Turbocharger (303-

04 Fuel Charging and

Controls - Turbocharger -

2.5L Duratec (147kW/200PS)

- VI5, Removal and Installa-

tion).

Engine - 2.0L Duratorq-TDCi

(DW) Diesel -

• Turbocharger seals.

• CHECK the gaskets and matingsurfaces for damage.

Remove the cylinder head.

CHECK the mating faces, cylinder

head gasket and the evenness of

the cylinder head and engine block

mating faces.

INSTALL new valve seals. Engine

- 2.5L Duratec-ST (VI5) -

REFER to: Valve Stem Seals

(303-01 Engine - 2.5L Duratec

(147kW/200PS) - VI5, Removal

and Installation).

Engine - 2.0L Duratorq-TDCi (DW)

Diesel -

• Damaged gaskets or mating

surfaces.

- Cylinder head gasket isdamaged or mating face are

warped.

- Valve stem seals are worn and engine oil can enter the

combustion chamber

between the valve stem and

the valve stem guide.

• INSTALL new components asnecessary.

• Piston ring or cylinder liner

wear.

• CHECK the running surfacesand clearances of the individual

engine components. INSTALL

new components as necessary.

INSTALL a new cylinder block

if necessary.

• Check the pistons and piston rings.

• Damaged cylinder liners or

excessive clearance of engine

components.

- Pistons.

- Piston rings (clearance ingroove and end gap).

- Cylinder liners.

G1055128en2008.50 Kuga8/2011

303-00- 3

Engine System - General Information

303-00- 3

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1525 of 2057

Action

Possible Sources

Symptom

• CHECK the engine compon-ents for wear or damage. Make

sure that all components are

within specification. INSTALL

new components as necessary.

Engine - 2.5L Duratec-ST (VI5)

-

REFER to: Specifications (303-

01 Engine - 2.5L Duratec

(147kW/200PS) - VI5,

Specifications).

Engine - 2.0L Duratorq-TDCi

(DW) Diesel -

• Engine components

- Pistons.

- Piston rings.

- Connecting rod big end,main bearing or thrust

bearing journals.

- Connecting rods bent or damaged.

• Noisy running or engine noise

Engine - Oil Leaks

NOTE:

Before installing new gaskets or oil seals,

make sure that the fault is clearly established.

If the oil leak cannot be identified clearly by a visual

inspection, carry out an ultraviolet (UV) test:

Ultraviolet (UV) Testing

1. Clean the engine and transmission with a suitable cleaning fluid.

2. Pour the UV-test fluid in accordance with the quantity specified by the manufacturer through

the oil filler neck into the engine and install the

oil filler cap.

WARNING: Vehicles with manual transaxle,

shift the transaxle into Neutral. Failure to

follow this instruction may result in

personal injury.

3. Start the engine and let it run for about five minutes.

4. Switch off the engine.

NOTE: If no leak can be found, road test the

vehicle under various loads and check the engine

for leaks again.

5. Check the engine for oil leaks using a suitable UV lamp.

6. Rectify any leaks found and check the engine for oil leaks.

Measure the compression pressure

NOTE: The powertrain control module (PCM)

receives an error message when the fuel pump

relay is removed or electrical components are disconnected. This error message must be deleted

from the fault memory using the Ford diagnostic

equipment after completing the compression test.

NOTE:

Valve clearance must be set correctly

before performing a compression test. Make sure

the engine is at the normal operating temperature.

NOTE: The varying design of compression

checking devices and fluctuating starter motor

speeds normally only allows for a comparison to

be made of the compression pressures in all

cylinders.

G1055128en2008.50 Kuga8/2011

303-00- 9

Engine System - General Information

303-00- 9

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1526 of 2057

Measure the compression pressure

(Engine - 2.5L Duratec-ST (VI5))

TIE44608

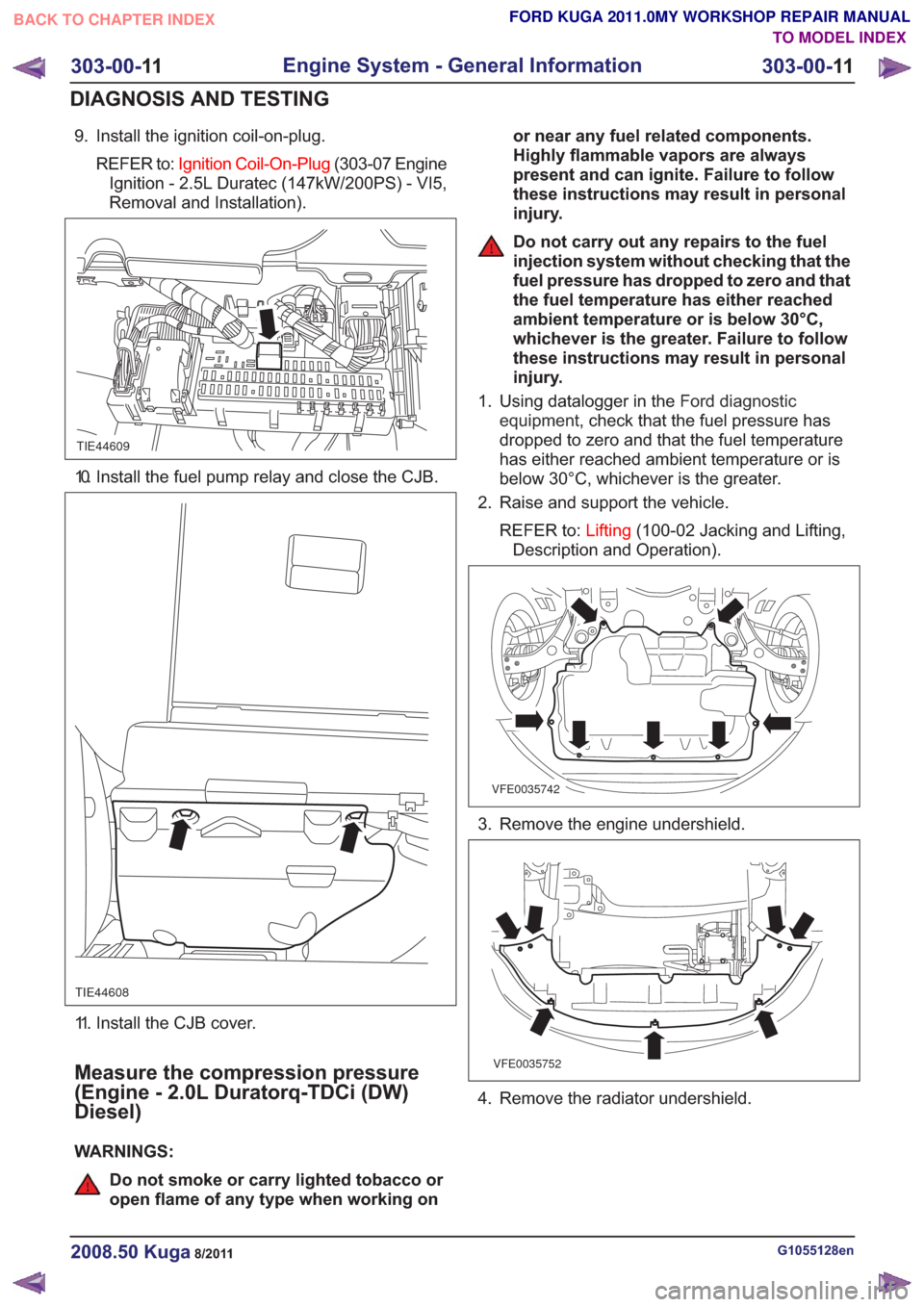

1. Remove the central junction box (CJB) cover.

TIE44609

2. Open the CJB and remove the fuel pump relay.

3. NOTE: The engine will start, run for a fewseconds and then stop.

Start the engine.

4. Remove the ignition coil-on-plug.

REFER to: Ignition Coil-On-Plug (303-07 Engine

Ignition - 2.5L Duratec (147kW/200PS) - VI5,

Removal and Installation). 5. Connect the battery ground cable.

REFER to: Battery Disconnect and Connect

(414-01 Battery, Mounting and Cables,

General Procedures).

E68679

x5

6. Using Special Tool 303-499, remove the spark plugs.

E68434

NOTE: Operate the starter motor with wide open

throttle until the pointer on the measuring device

stops rising.

7. Carry out the measurement in accordance with the instructions supplied with the measuring

device on every cylinder using a suitable

compression pressure recorder with a suitable

adapter.

E68680

28 Nm

8. Using Special Tool 303-499, install the sparkplugs.

G1055128en2008.50 Kuga8/2011

303-00- 10

Engine System - General Information

303-00- 10

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1527 of 2057

9. Install the ignition coil-on-plug.REFER to: Ignition Coil-On-Plug (303-07 Engine

Ignition - 2.5L Duratec (147kW/200PS) - VI5,

Removal and Installation).

TIE44609

10. Install the fuel pump relay and close the CJB.

TIE44608

11. Install the CJB cover.

Measure the compression pressure

(Engine - 2.0L Duratorq-TDCi (DW)

Diesel)

WARNINGS:

Do not smoke or carry lighted tobacco or

open flame of any type when working on or near any fuel related components.

Highly flammable vapors are always

present and can ignite. Failure to follow

these instructions may result in personal

injury.

Do not carry out any repairs to the fuel

injection system without checking that the

fuel pressure has dropped to zero and that

the fuel temperature has either reached

ambient temperature or is below 30°C,

whichever is the greater. Failure to follow

these instructions may result in personal

injury.

1. Using datalogger in the Ford diagnostic

equipment , check that the fuel pressure has

dropped to zero and that the fuel temperature

has either reached ambient temperature or is

below 30°C, whichever is the greater.

2. Raise and support the vehicle.

REFER to: Lifting(100-02 Jacking and Lifting,

Description and Operation).

VFE0035742

3. Remove the engine undershield.

VFE0035752

4. Remove the radiator undershield.

G1055128en2008.50 Kuga8/2011

303-00- 11

Engine System - General Information

303-00- 11

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL