engine remove FORD KUGA 2011 1.G Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 47 of 2057

Exhaust Fumes

These contain asphyxiating, harmful and toxic

chemicals and particles such as carbon oxides,

nitrogen oxides, aldehydes, lead and aromatic

hydrocarbons. Engines should be run only under

conditions of adequate exhaust extraction or

general ventilation and not in confined spaces.

Gasoline (petrol) engine

There may not be adequate warning of odor or of

irritation before toxic or harmful effects arise. These

may be immediate or delayed.

Diesel engine

Soot, discomfort and irritation usually give

adequate warning of hazardous fume

concentrations.

Fibre Insulation

See alsoDusts.

Used in noise and sound insulation.

The fibrous nature of surfaces and cut edges can

cause skin irritation. This is usually a physical and

not a chemical effect.

Precautions should be taken to avoid excessive

skin contact through careful organization of work

practices and the use of gloves.

Fire

See also Welding,Foams,Legal Aspects.

Many of the materials found on or associated with

the repair of vehicles are highly flammable. Some

give off toxic or harmful fumes if burnt.

Observe strict fire safety when storing and handling

flammable materials or solvents, particularly near

electrical equipment or welding processes.

Make sure, before using electrical or welding

equipment, that there is no fire hazard present.

Have a suitable fire extinguisher available when

using welding or heating equipment.

First Aid

Apart from meeting any legal requirements it is

desirable for someone in the workshop to be

trained in First Aid procedures.

Splashes in the eye should be flushed carefully

with clean water for at least ten minutes.

Soiled skin should be washed with soap and water.

In case of cold burns, from alternative fuels, place

affected area in cool to cold water.

Individuals affected by inhalation of gases and

fumes should be removed to fresh air immediately.

If effects persist, consult a doctor.

If liquids are swallowed inadvertently, consult a

doctor giving him the information on the container

or label. Do not induce vomiting unless this action

is indicated on the label.

Fluoroelastomer

See Viton.

Foams - Polyurethane

See also Fire.

Used in sound and noise insulation. Cured foams

used in seat and trim cushioning.

Follow manufacturers instructions.

Unreacted components are irritating and may be

harmful to the skin and eyes. Wear gloves and

goggles.

Individuals with chronic respiratory diseases,

asthma, bronchial medical problems, or histories

of allergic diseases should not work in or near

uncured materials.

The components, vapors or spray mists can cause

direct irritation, sensitivity reactions and may be

toxic or harmful.

Vapors and spray mists must not be inhaled. These

materials must be applied with adequate ventilation

and respiratory protection. Do not remove the

respirator immediately after spraying; wait until the

vapors/mists have cleared.

Burning of the uncured components and the cured

foams can generate toxic and harmful fumes.

Smoking, naked flames or the use of electrical

equipment during foaming operations and until

vapors/mists have cleared should not be allowed.

Any heat cutting of cured foams or partially cured

G566527en2008.50 Kuga8/2011

100-00- 46

General Information

100-00- 46

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 52 of 2057

dermatitis or be absorbed through the skin in

toxic or harmful quantities.

– Do not use emptied containers for other materials except when they have been cleaned

under supervised conditions.

– Do not sniff or smell chemical materials. Brief exposure to high concentrations of fumes can

be toxic or harmful.

Chlorofluorocarbons (CFC)

There is concern in the scientific community that

CFCs and Halons are depleting the upper ozone

layer which filters out harmful ultraviolet radiation.

Decreased filtration of ultraviolet radiation may

result in increases in skin cancer, cataracts and

immune system suppression in humans, as well

as decreased productivity of crops and aquatic

systems.

CFCs are used primarily as refrigerants in vehicle

air conditioning systems and as aerosol

propellants. Halons are used as fire extinguishants.

Clutch Fluids

See Brake fluids.

Clutch Linings and Pads

SeeAsbestos.

Corrosion Protection Materials

See also Solvents, Fire.

Highly flammable, flammable – observe No

Smoking policy.

These materials are varied and the manufacturers

instructions must be followed. They may contain

solvents, resins or petroleum products. Skin and

eye contact should be avoided. They should only

be sprayed in conditions of adequate ventilation

and not in confined spaces.

Cutting

See Welding.

Dewaxing

SeeSolvents andFuels (Kerosene).

Dusts

Powder, dusts or clouds may be irritant, harmful

or toxic. Avoid breathing dusts from powdery

chemical materials or those arising from dry

abrasion operations. Wear respiratory protection

if ventilation is inadequate.

Fine dusts of combustible material can present an

explosion hazard. Avoid explosive limits and

sources of ignition.

Electric Shock

Electric shock can result from the use of faulty

electrical equipment or from the misuse of

equipment in good condition.

Make sure that electrical equipment is maintained

in good condition and frequently tested. Faulty

equipment should be labeled and preferably

removed from the workstation.

Make sure that flexes, cables, plugs and sockets

are not frayed, kinked, cut, cracked or otherwise

damaged.

Make sure that electrical equipment and flexes do

not come into contact with water.

Make sure that electrical equipment is protected

by the correct rated fuse.

Never misuse electrical equipment and never use

equipment that is in any way faulty. The results

could be fatal.

Make sure that the cables of mobile electrical

equipment cannot get trapped and damaged, such

as in a vehicle hoist.

Make sure that the designated electrical workers

are trained in basic First Aid.

In cases of electrocution:

– switch off the power supply before approaching

the victim.

– if this is not possible push or drag the victim from the source of electricity using dry

non-conductive material.

– commence resuscitation if trained to do so.

– SUMMON MEDICAL ASSISTANCE.

Engine Oils

See Lubricants and Grease.

G566527en2008.50 Kuga8/2011

100-00- 45

General Information

100-00- 45

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 54 of 2057

Accidental eye contact should be dealt with as per

normal first aid practices, by flushing the eyes with

an eye wash or clean cool water for 10 minutes,

after which medical attention should be obtained.

Remove and launder clothing which becomes

contaminated with the fluids. Do not place rags

contaminated with fluid in clothing pockets.

Wash thoroughly after completing operations where

skin exposure may have occurred.

It is important that personnel do not smoke, eat or

drink whilst handling the fluids or affected

transmissions. These measures are designed to

limit the risk from accidental ingestion.

Label any decanted fluid properly/use an equivalent

label to that on original product containers.

Clean up any spills promptly using an inert

absorbent and wash down contaminated surfaces

with detergent and water.

Dispose of any waste fluids safely as hazardous

waste.

Safety Data Sheets

Safety Data Sheets, which detail specific material

handling instructions and precautions are available

from the respective national sales company, and

via internet www.msds.ford.com.

Used Engine Oil

Prolonged and repeated contact with mineral oil

will result in the removal of natural fats from the

skin, leading to dryness, irritation and dermatitis.

In addition, used engine oil contains potentially

harmful contaminants, which may cause skin

cancer. Adequate means of skin protection and

washing facilities must be provided.

Do not employ used engine oils as lubricants or

for any application where appreciable skin contact

is likely to occur.

Environmental Precautions

Burning used engine oil in small space heaters or

boilers can be recommended only for units of

approved design. If in doubt check with the

appropriate local authority and manufacturer of

approved appliances.

Dispose of used oil and used oil filters through

authorized waste disposal contractors or licensedwaste disposal sites, or to the waste oil reclamation

trade. If in doubt, contact the relevant local

authority for advice on disposal facilities.

It is illegal to pour used oil on to the ground, down

sewers or drains, or into watercourses.

Noise

Some operations may produce high noise levels,

which could, in time, damage hearing. In these

cases, suitable ear protection must be worn.

Noise Insulation Materials

See

Foams, Fibre Insulation.

O-Rings (Fluoroelastomer)

SeeViton.

Paints

See also Solvents, Chemical Materials.

Highly flammable, flammable - observe No

Smoking policy

One Pack

Can contain harmful or toxic pigments, driers and

other components as well as solvents. Spraying

should be carried out only with adequate

ventilation.

Two Pack

Can also contain harmful and toxic unreacted

resins and resin hardening agents. The

manufacturers instructions should be followed. See

also Resin-based Adhesives and Isocyanate

Adhesives and Sealers under Adhesives and

Sealers.

Spraying should preferably be carried out in

exhausted ventilated booths removing vapor and

spray mists from the breathing zone. Individuals

working in booths should wear appropriate

respiratory protection. Those doing small-scale

repair work in the open workshop should wear

air-fed respirators.

G566527en2008.50 Kuga8/2011

100-00- 49

General Information

100-00- 49

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 55 of 2057

Pressurized Equipment

See HighPressure Air, Lubrication and Oil Test

Equipment.

Solder

Solders are mixtures of metals such that the

melting point of the mixture is below that of the

constituent metals (normally lead and tin). Solder

application does not normally give rise to toxic lead

fumes, provided a gas/air flame is used.

Oxy-acetylene flames should not be used, as they

are much hotter and will cause lead fumes to be

produced.

Some fumes may be produced by the application

of any flame to surfaces coated with grease, and

inhalation of these should be avoided.

Removal of excess solder should be undertaken

with care, to make sure that fine lead dust is not

produced, which can give toxic effects if inhaled.

Respiratory protection may be necessary.

Solder spillage and filings should be collected and

removed promptly to prevent general air

contamination by lead.

High standards of personal hygiene are necessary

in order to avoid ingestion of lead or inhalation of

solder dust from clothing.

Solvents

See also Chemical Materials, Fuels (Kerosene),

Fire.

For example acetone, white spirit, toluene, xylene,

trichloroethane.

Used in cleaning and dewaxing materials, paints,

plastics, resins and thinners.

Some may be highly flammable or flammable.

Skin contact will degrease the skin and may result

in irritation and dermatitis following repeated or

prolonged contact. Some can be absorbed through

the skin in toxic or harmful quantities.

Splashes in the eye may cause severe irritation

and could lead to loss of vision.

Brief exposure of high concentrations of vapors or

mists will cause eye and throat irritation,

drowsiness, dizziness, headaches and, in the worst

circumstances, unconsciousness.

Repeated or prolonged exposure to excessive but

lower concentrations of vapors or mists, for which there might not be adequate warning indications,

can cause more serious toxic or harmful effects.

Aspiration into the lungs, for example through

vomiting, is the most serious consequence of

swallowing.

Avoid splashes to the skin, eyes and clothing. Wear

protective gloves, goggles and clothing if

necessary.

Make sure there is good ventilation when in use,

avoid breathing fumes, vapors and spray mists and

keep containers tightly sealed. Do not use in

confined spaces.

When spraying materials containing solvents, for

example paints, adhesive, coatings, use extraction

ventilation or personal respiratory protection in the

absence of adequate general ventilation.

Do not apply heat or flame except under specific

and detailed manufacturers instructions.

Sound Insulation

See

Fibre Insulation, Foams.

Suspended Loads

CAUTION: Never improvise lifting tackle.

There is always a danger when loads are lifted or

suspended. Never work under an unsupported,

suspended or raised load, for example a

suspended engine.

Always make sure that lifting equipment such as

jacks, hoists, axle stands and slings are adequate

and suitable for the job, in good condition and

regularly maintained.

Transmission Brake Bands

See Asbestos.

Underseal

SeeCorrosion Protection.

Viton

In common with many other manufacturers

vehicles, some components have O-rings, seals

or gaskets, which contain a material known as

`Viton'.

G566527en2008.50 Kuga8/2011

100-00- 50

General Information

100-00- 50

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 57 of 2057

SPECIAL PRECAUTIONS MUST BE TAKEN

BEFORE ANY WELDING OR CUTTING TAKES

PLACE ON VESSELS, WHICH HAVE

CONTAINED COMBUSTIBLE MATERIALS, FOR

EXAMPLE BOILING OR STEAMING OUT OF

FUEL TANKS.

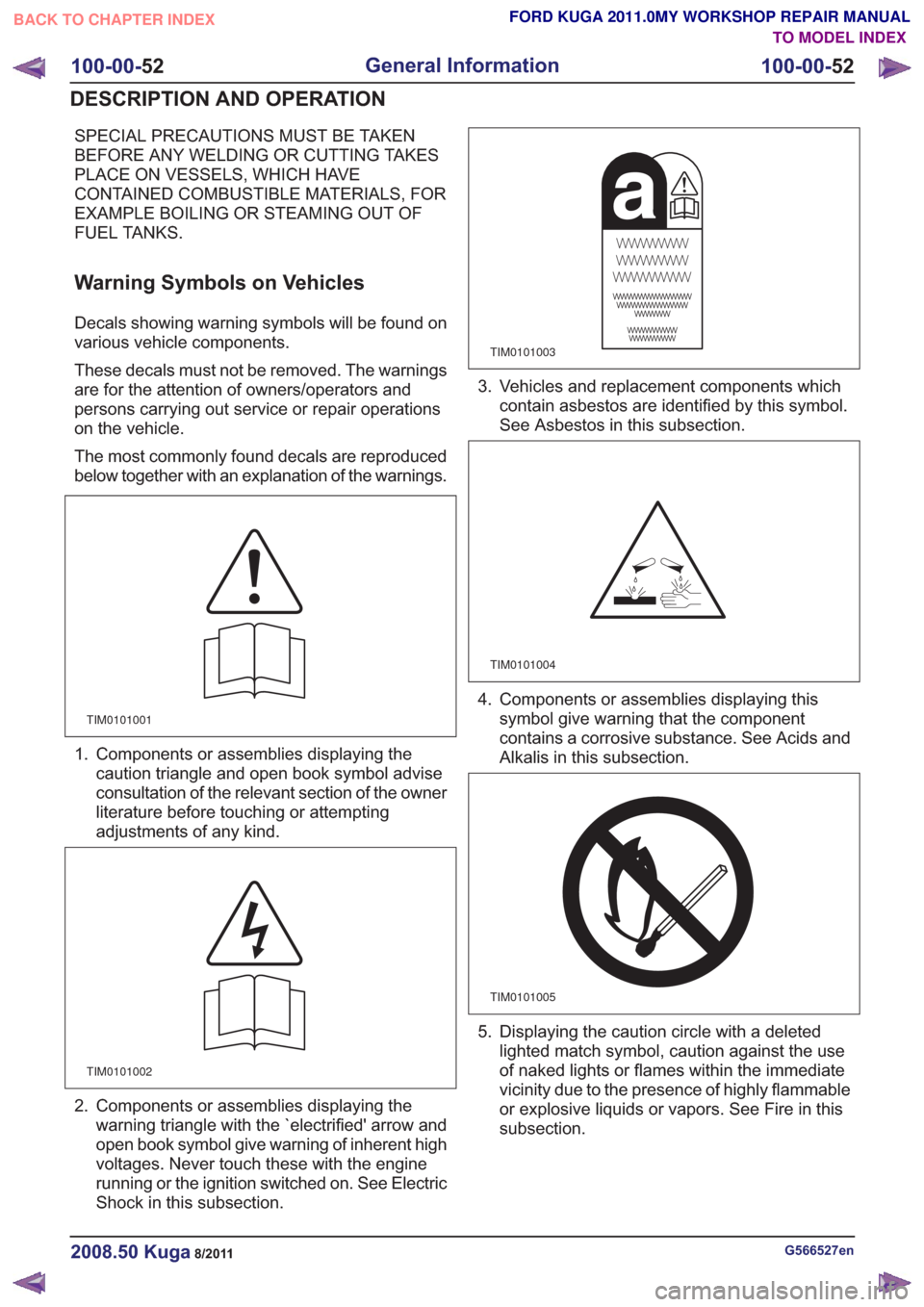

Warning Symbols on Vehicles

Decals showing warning symbols will be found on

various vehicle components.

These decals must not be removed. The warnings

are for the attention of owners/operators and

persons carrying out service or repair operations

on the vehicle.

The most commonly found decals are reproduced

below together with an explanation of the warnings.

TIM0101001

1. Components or assemblies displaying thecaution triangle and open book symbol advise

consultation of the relevant section of the owner

literature before touching or attempting

adjustments of any kind.

TIM0101002

2. Components or assemblies displaying thewarning triangle with the `electrified' arrow and

open book symbol give warning of inherent high

voltages. Never touch these with the engine

running or the ignition switched on. See Electric

Shock in this subsection.

TIM0101003

3. Vehicles and replacement components whichcontain asbestos are identified by this symbol.

See Asbestos in this subsection.

TIM0101004

4. Components or assemblies displaying thissymbol give warning that the component

contains a corrosive substance. See Acids and

Alkalis in this subsection.

TIM0101005

5. Displaying the caution circle with a deletedlighted match symbol, caution against the use

of naked lights or flames within the immediate

vicinity due to the presence of highly flammable

or explosive liquids or vapors. See Fire in this

subsection.

G566527en2008.50 Kuga8/2011

100-00- 52

General Information

100-00- 52

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 60 of 2057

Standard Workshop Practices

Vehicle in Workshop

When working on a vehicle in the workshop always

make sure that:

– the parking brake is applied or the wheels aresecurely chocked to prevent the vehicle moving

forwards or backwards.

– the key is removed from key operated hood locks before any work is carried out around the

front of the vehicle.

– if the engine is to be run, there is adequate ventilation, or an extraction hose to remove

exhaust fumes.

– there is adequate room to raise the vehicle and remove the wheels, if necessary.

– fender covers are always fitted if any work is to be carried out in the engine compartment.

– the battery is disconnected if working on the engine, underneath the vehicle, or if the vehicle

is raised.

CAUTION: When electric arc welding on a

vehicle, always disconnect the generator

wiring to prevent the possibility of a surge

of current causing damage to the internal

components of the generator.

– if using welding equipment on the vehicle, a suitable fire extinguisher is readily available.

Towing the Vehicle

WARNING: When the vehicle is being

towed, the ignition switch must be in

position II (steering lock released and

warning lamps illuminated). Only then will

the steering, turn signal lamps, horn and

stop lamps be operational. Failure to follow

these instructions may result in personal

injury.

NOTE: The removable towing eye (if equipped),

has a left-hand thread and must be fully tightened

before towing can commence.

When towing is necessary, the vehicle towing eyes

should be used. The rope must be securely

fastened to the towing eyes and must also be

attached to the other vehicle such that the rope will

not foul the bodywork.

When a vehicle with automatic transmission is

towed, the gear selector must be in position N (Neutral). Never tow a vehicle with automatic

transmission at a speed greater than 30 mph (50

km/h) or for a distance greater than 30 miles (50

km). If it is necessary to tow the vehicle a greater

distance, the drive wheels must be lifted clear off

the ground.

Alternatively the vehicle can be transported on a

low loader or a trailer.

Connecting a Slave Battery Using

Jumper Cables

WARNING: If the slave battery has recently

been charged and is gassing, cover the

vent plugs or covers with a damp cloth to

reduce the risk of explosion should arcing

occur when connecting the jumper cables.

Failure to follow these instructions may

result in personal injury.

CAUTIONS:

A discharged battery condition may have

been caused by an electrical short circuit.

If this condition exists there will be an

apparently live circuit on the vehicle even

when all normal circuits are switched off.

This can cause arcing when the jumper

cables are connected.

While it is not recommended that the

vehicle is jump started, it is recognized

that this may occasionally be the only

practical way to mobilize a vehicle. In such

an instance, the discharged battery must

be recharged immediately after jump

starting to avoid permanent damage.

– Always make sure that the jumper cables are adequate for the task. Heavy duty cables must

be used.

– Always make sure that the slave battery is of the same voltage as the vehicle battery. The

batteries must be connected in parallel.

– Always make sure that switched electric circuits are switched off before connecting jumper

cables. This reduces the risk of arcing occurring

when the final connection is made.

G17373en2008.50 Kuga8/2011

100-00- 54

General Information

100-00- 54

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 62 of 2057

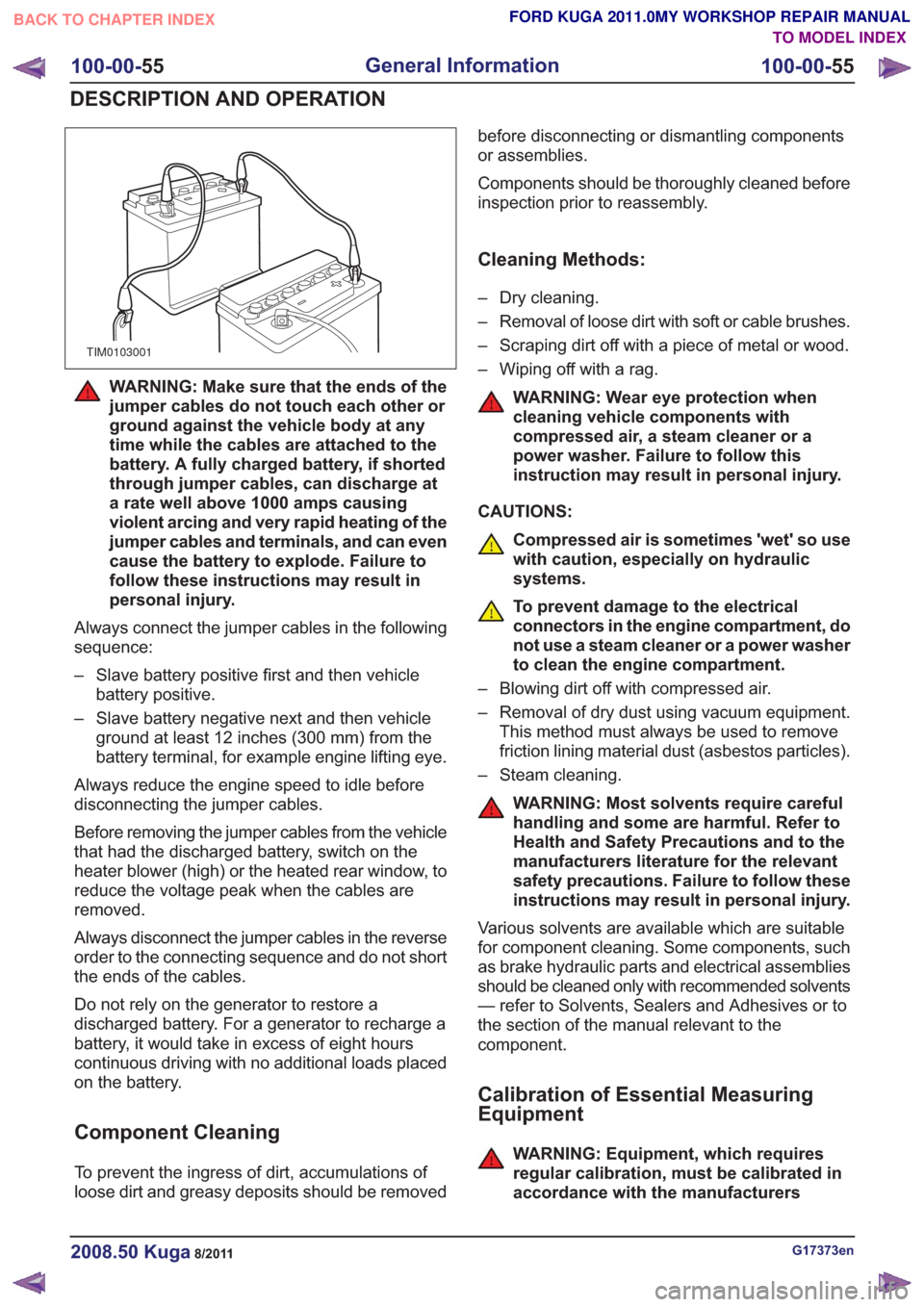

TIM0103001

WARNING: Make sure that the ends of the

jumper cables do not touch each other or

ground against the vehicle body at any

time while the cables are attached to the

battery. A fully charged battery, if shorted

through jumper cables, can discharge at

a rate well above 1000 amps causing

violent arcing and very rapid heating of the

jumper cables and terminals, and can even

cause the battery to explode. Failure to

follow these instructions may result in

personal injury.

Always connect the jumper cables in the following

sequence:

– Slave battery positive first and then vehicle battery positive.

– Slave battery negative next and then vehicle ground at least 12 inches (300 mm) from the

battery terminal, for example engine lifting eye.

Always reduce the engine speed to idle before

disconnecting the jumper cables.

Before removing the jumper cables from the vehicle

that had the discharged battery, switch on the

heater blower (high) or the heated rear window, to

reduce the voltage peak when the cables are

removed.

Always disconnect the jumper cables in the reverse

order to the connecting sequence and do not short

the ends of the cables.

Do not rely on the generator to restore a

discharged battery. For a generator to recharge a

battery, it would take in excess of eight hours

continuous driving with no additional loads placed

on the battery.

Component Cleaning

To prevent the ingress of dirt, accumulations of

loose dirt and greasy deposits should be removed before disconnecting or dismantling components

or assemblies.

Components should be thoroughly cleaned before

inspection prior to reassembly.

Cleaning Methods:

– Dry cleaning.

– Removal of loose dirt with soft or cable brushes.

– Scraping dirt off with a piece of metal or wood.

– Wiping off with a rag.

WARNING: Wear eye protection when

cleaning vehicle components with

compressed air, a steam cleaner or a

power washer. Failure to follow this

instruction may result in personal injury.

CAUTIONS:

Compressed air is sometimes 'wet' so use

with caution, especially on hydraulic

systems.

To prevent damage to the electrical

connectors in the engine compartment, do

not use a steam cleaner or a power washer

to clean the engine compartment.

– Blowing dirt off with compressed air.

– Removal of dry dust using vacuum equipment. This method must always be used to remove

friction lining material dust (asbestos particles).

– Steam cleaning.

WARNING: Most solvents require careful

handling and some are harmful. Refer to

Health and Safety Precautions and to the

manufacturers literature for the relevant

safety precautions. Failure to follow these

instructions may result in personal injury.

Various solvents are available which are suitable

for component cleaning. Some components, such

as brake hydraulic parts and electrical assemblies

should be cleaned only with recommended solvents

— refer to Solvents, Sealers and Adhesives or to

the section of the manual relevant to the

component.

Calibration of Essential Measuring

Equipment

WARNING: Equipment, which requires

regular calibration, must be calibrated in

accordance with the manufacturers

G17373en2008.50 Kuga8/2011

100-00- 55

General Information

100-00- 55

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 82 of 2057

sometimes noticed in the steering wheel/column,

seats, front floor panel, front door trim panel or

front end sheet metal. It is a low frequency

vibration (around 9-15 cycles per second). It

may or may not be increased by applying the

brakes lightly. REFER to Idle

Boom/Shake/Vibration in the Driveline Noise

and Vibration Symptom Chart.

3. High Speed: A vibration is felt in the front floor panel or seats with no visible shake, but with

an accompanying sound or rumble, buzz, hum,

drone or booming noise. Coast with the clutch

pedal depressed (manual transmission) or shift

control selector lever in "N" (NEUTRAL)

(automatic transmission) and engine idling. If

vibration is still evident, it may be related to

wheels, tires, front brake discs, wheel hubs or

front wheel bearings. REFER to Shake and

Vibration While Driving in the Driveline Noise

and Vibration Symptom Chart.

4. Engine rpm Sensitive: A vibration is felt whenever the engine reaches a particular rpm.

It will disappear in neutral coasts. The vibration

can be duplicated by operating the engine at

the problem rpm while the vehicle is stationary.

It can be caused by any component, from the

accessory drive belt to the clutch or torque

converter which turns at engine speed when the

vehicle is stopped. REFER to Shake and

Vibration While Driving in the Driveline Noise

and Vibration Symptom Chart.

5. Noise and Vibration While Turning: Clicking, popping or grinding noises may be due to the

following:

• worn, damaged or incorrectly installed front wheel bearing.

• damaged powertrain/drivetrain mounts.

Road Conditions

An experienced technician will always establish a

route that will be used for all NVH diagnosis road

tests. The road selected should be reasonably

smooth, level and free of undulations (unless a

particular condition needs to be identified). A

smooth asphalt road that allows driving over a

range of speeds is best. Gravel or bumpy roads

are unsuitable because of the additional road noise

produced. Once the route is established and consistently used, the road noise variable is

eliminated from the test results.

NOTE:

Some concerns may be apparent only on

smooth asphalt roads.

If a customer complains of a noise or vibration on

a particular road and only on a particular road, the

source of the concern may be the road surface. If

possible, try to test the vehicle on the same type

of road.

Vehicle Preparation

Carry out a thorough visual inspection of the

vehicle before carrying out the road test. Note

anything which is unusual. Do not repair or adjust

any condition until the road test is carried out,

unless the vehicle is inoperative or the condition

could pose a hazard to the technician. After

verifying that the condition has been corrected,

make sure all components removed have been

installed.

Power Steering Conditions

Check for the noise in the following conditions to

verify the customer concern.

• Check for the noise in several temperature conditions.

• Is the noise from when the vehicle was new?

• Can the noise be repeated constantly or is it random?

• Check the condition of the vehicle age, mileage and service record.

• Interview the customer to find the operating condition in which the noise will occur. Test the

vehicle based on the detail(s) from the customer

interview.

• Follow the power steering operation noise condition tables below, to find which condition

the noise will occur.

Power Steering Operation Noise Check

Step 1: Check for NVH concerns from non-steering

components, which may sound like noises coming

from the steering system.

G37349en2008.50 Kuga8/2011

100-04- 4

Noise, Vibration and Harshness

100-04- 4

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 107 of 2057

Blower Motor — RHD(34 374 0)

Special Tool(s)412-131

Remover/Installer, Blower

Engine

E42948

Removal

NOTE:Removal steps in this procedure may

contain installation details.

1. Refer to: Cowl Panel Grille (501-02 Front End

Body Panels, Removal and Installation).

2. Torque: 25

Nm

E101389

3.Refer to: Steering Column (211-04 Steering

Column, Removal and Installation).

4. Refer to: Floor Console Extension - Vehicles

With: Center Armrest (501-12 Instrument

Panel and Console, Removal and Installation).

5.

E102293

6. Torque: 25Nm

G1065500en2008.50 Kuga8/2011

412-01- 37

Climate Control

412-01- 37

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 170 of 2057

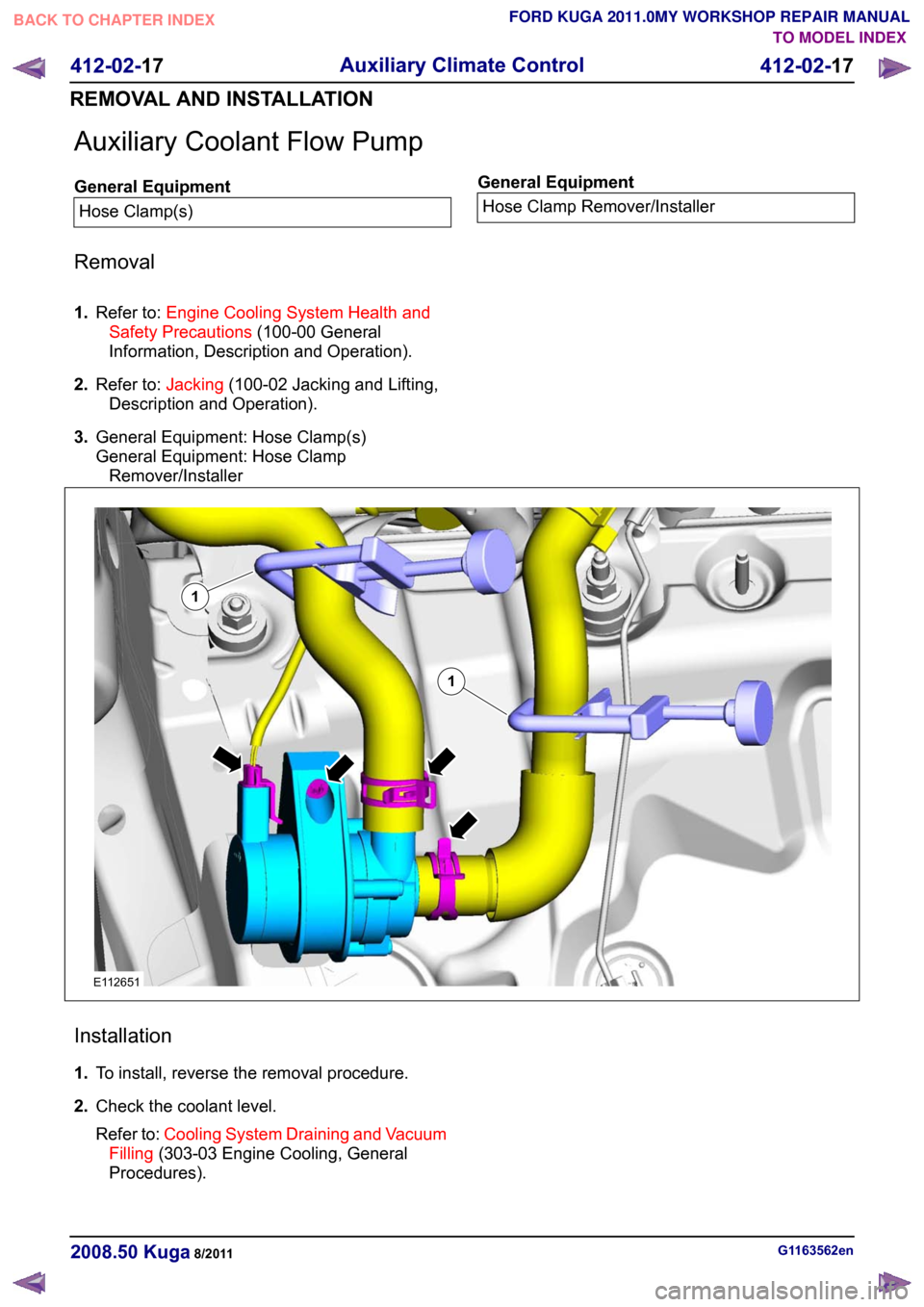

Auxiliary Coolant Flow Pump

General Equipment

Hose Clamp(s) General Equipment

Hose Clamp Remover/Installer

Removal

1. Refer to: Engine Cooling System Health and

Safety Precautions (100-00 General

Information, Description and Operation).

2. Refer to: Jacking(100-02 Jacking and Lifting,

Description and Operation).

3. General Equipment: Hose Clamp(s)

General Equipment: Hose Clamp

Remover/Installer Installation

1.

To install, reverse the removal procedure.

2. Check the coolant level.

Refer to: Cooling System Draining and Vacuum

Filling (303-03 Engine Cooling, General

Procedures). G1163562en

2008.50 Kuga 8/2011 412-02-17

Auxiliary Climate Control

412-02-17

REMOVAL AND INSTALLATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL11E112651