oil change FORD KUGA 2011 1.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1797 of 2057

Calculation of valve timing adjustment

angle

The 2.5L Duratec (VI5) engine has two camshaft

adjustment units which work independently of each

other.

One camshaft adjustment solenoid is installed for

each intake camshaft and exhaust camshaft.

This allows the PCM to continuously adjust the

intake and exhaust-side camshaft adjustments

independently of one another. The timing is

adjusted by the PCM using curves; adjustment is

primarily done as a function of engine load and

engine speed.

In this way the engine performance is increased

and internal exhaust gas recirculation is realized.

The advantages of camshaft adjustment are as

follows:

• Higher torque and improved torquecharacteristics

• Reduced fuel consumption

• Improved emissions performance

The camshaft adjustment solenoids are actuated

by the PWM by means of a PCM signal.

Continuous adjustment of the camshafts by the

PCM is achieved by means of the camshaft

adjustment solenoids, the camshaft adjustment

units and two CMP sensors. A defined quantity of

engine is oil is supplied to or drained from the

adjustment units via the camshaft adjustment

solenoids. The existing EOP (engine oil pressure)

is taken into account in the process. In this way

the valve timings are adjusted according to the

operating condition of the engine. The camshaft

adjusters work according to the vane-cell principle.

On starting the engine, both camshafts are

mechanically locked in their starting positions. The

intake camshaft is in the maximum late position

and the exhaust camshaft in the maximum early

position.

Control is divided into four main areas:

• Low engine speed and low load

• Partial load

• Low engine speed and high load

• High engine speed and high load

At low engine speed and low load, the exhaust

valves open early and the intake valves open late.

The result is reduced fuel consumption and more

uniform idling. In the partial load range, the exhaust valves and

the intake valves open late. The late opening of

the exhaust valves results in a good utilization of

the expanding gases in the cylinder. Closing the

exhaust valves after Top Dead Center allows

internal exhaust gas recirculation through aspiration

of exhaust gases into the combustion chamber.

Moreover, the intake valves close after Bottom

Dead Centre, allowing the fresh air/fuel mixture

and exhaust gases to flow back into the intake

tract. The result is reduced fuel consumption and

low emissions.

At low engine speed and high engine load, the

exhaust valves open late and the intake valves

open early. Due to the resulting valve opening

overlap at Top Dead Centre, the pulsating gas

column within the combustion chamber is utilized

to achieve better charging of the combustion

chamber. The result is increased torque at lower

RPM.

At high engine speeds and high engine load, the

exhaust valves open early and the intake valves

close late. Because a rapid gas exchange must be

achieved at high engine speeds, the early opening

of the exhaust valves achieves better expulsion of

the exhaust gas and the late closing of the intake

valves improves cylinder charge efficiency.

Optimum power output is achieved.

Many other camshaft positions are possible in

addition to these settings.

In order to avoid a malfunction in the camshaft

adjustment units at excessively low ambient or

engine-oil temperatures, they are activated by the

PCM with a time delay via the camshaft adjustment

solenoids. The PCM receives the information

required for this from the ECT sensor and the

outside air temperature sensor.

When idling and during deceleration, the camshaft

adjustment solenoids are activated repeatedly by

the PCM in order to remove any dirt which may be

on the bore holes and ring grooves.

Boost pressure control

Optimum regulation is achieved by means of an

electronically-controlled solenoid valve, the boost

control solenoid valve.

Refer to:

Turbocharger (303-04 Fuel Charging and

Controls - Turbocharger - 2.5L Duratec

(147kW/200PS) - VI5, Description and

Operation).

G1021908en2008.50 Kuga8/2011

303-14- 23

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

23

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1807 of 2057

Description

Item

Coil-on-plug ignition coil

1

Spark plug connector

2

Low-voltage connection

3

Laminated soft-iron core

4Description

Item

Primary winding

5

Secondary winding

6

Spark plug

7

High-voltage connection via spring contact

8

In an ignition system with coil-on-plug ignition coils,

each cylinder is actuated individually and only once

per cycle (working stroke). The coil-on-plug ignition

coils are mounted directly on the spark plugs,

therefore no ignition cables are required between

the ignition coils and the spark plugs.

Each individual ignition coil is actuated on the

low-voltage side by the PCM. The power

end-stages are incorporated into the coil-on-plug

ignition coils. Only the actuating current for these

power end-stages is controlled by the PCM.

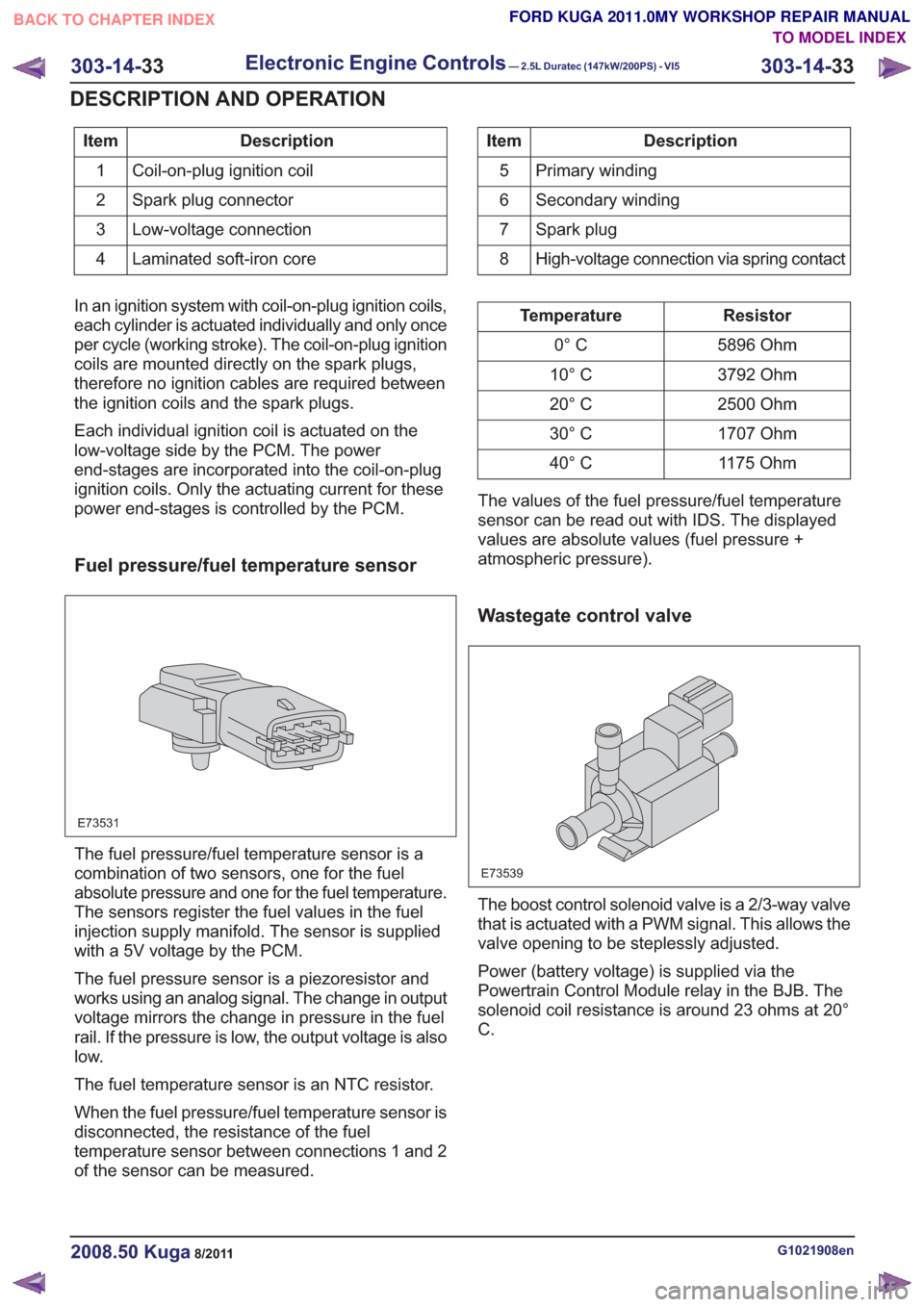

Fuel pressure/fuel temperature sensor

E73531

The fuel pressure/fuel temperature sensor is a

combination of two sensors, one for the fuel

absolute pressure and one for the fuel temperature.

The sensors register the fuel values in the fuel

injection supply manifold. The sensor is supplied

with a 5V voltage by the PCM.

The fuel pressure sensor is a piezoresistor and

works using an analog signal. The change in output

voltage mirrors the change in pressure in the fuel

rail. If the pressure is low, the output voltage is also

low.

The fuel temperature sensor is an NTC resistor.

When the fuel pressure/fuel temperature sensor is

disconnected, the resistance of the fuel

temperature sensor between connections 1 and 2

of the sensor can be measured.

Resistor

Temperature

5896 Ohm

0° C

3792 Ohm

10° C

2500 Ohm

20° C

1707 Ohm

30° C

1175 Ohm

40° C

The values of the fuel pressure/fuel temperature

sensor can be read out with IDS. The displayed

values are absolute values (fuel pressure +

atmospheric pressure).

Wastegate control valve

E73539

The boost control solenoid valve is a 2/3-way valve

that is actuated with a PWM signal. This allows the

valve opening to be steplessly adjusted.

Power (battery voltage) is supplied via the

Powertrain Control Module relay in the BJB. The

solenoid coil resistance is around 23 ohms at 20°

C.

G1021908en2008.50 Kuga8/2011

303-14- 33

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

33

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1808 of 2057

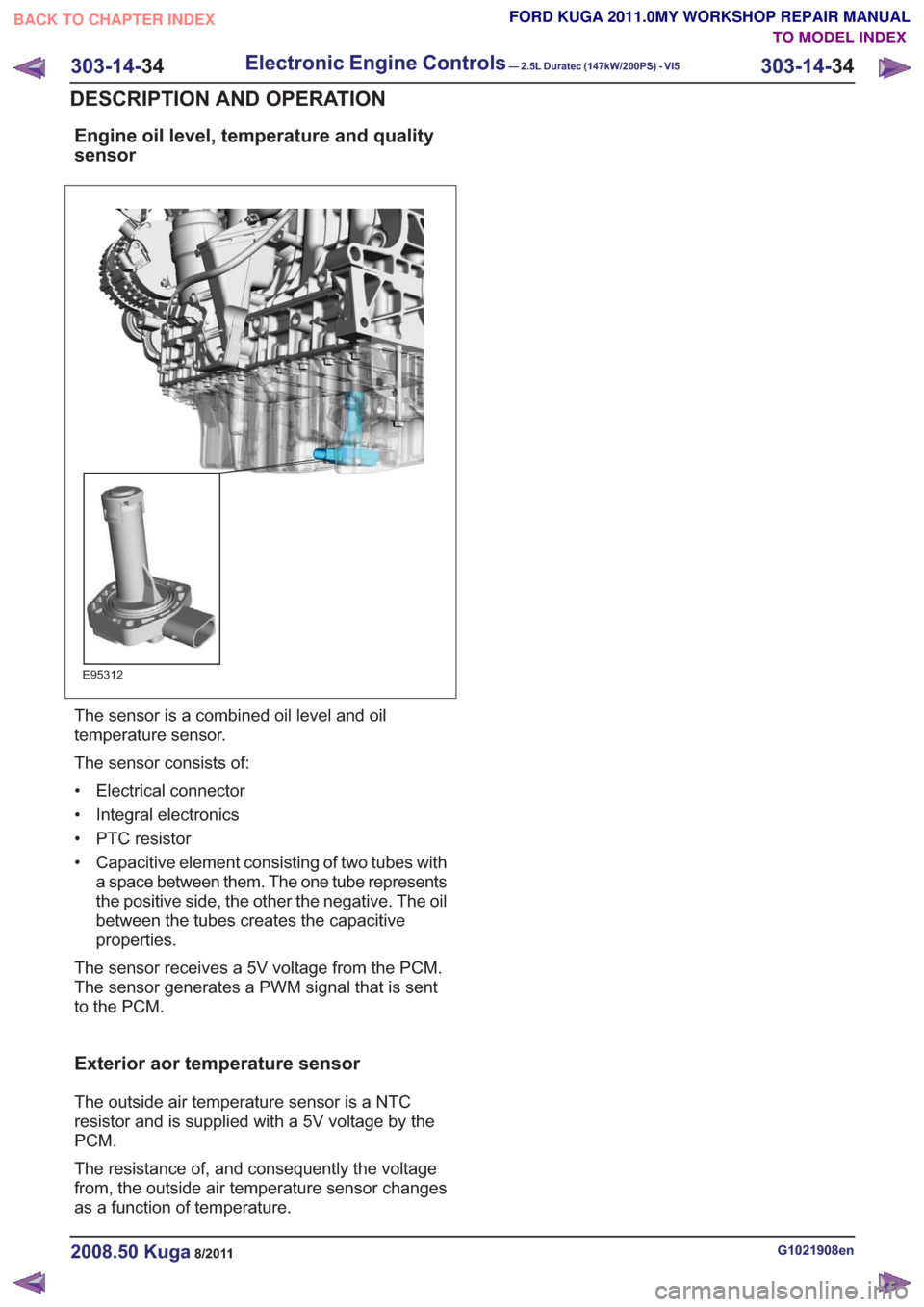

Engine oil level, temperature and quality

sensor

E95312

The sensor is a combined oil level and oil

temperature sensor.

The sensor consists of:

• Electrical connector

• Integral electronics

• PTC resistor

• Capacitive element consisting of two tubes witha space between them. The one tube represents

the positive side, the other the negative. The oil

between the tubes creates the capacitive

properties.

The sensor receives a 5V voltage from the PCM.

The sensor generates a PWM signal that is sent

to the PCM.

Exterior aor temperature sensor

The outside air temperature sensor is a NTC

resistor and is supplied with a 5V voltage by the

PCM.

The resistance of, and consequently the voltage

from, the outside air temperature sensor changes

as a function of temperature.

G1021908en2008.50 Kuga8/2011

303-14- 34

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

34

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1875 of 2057

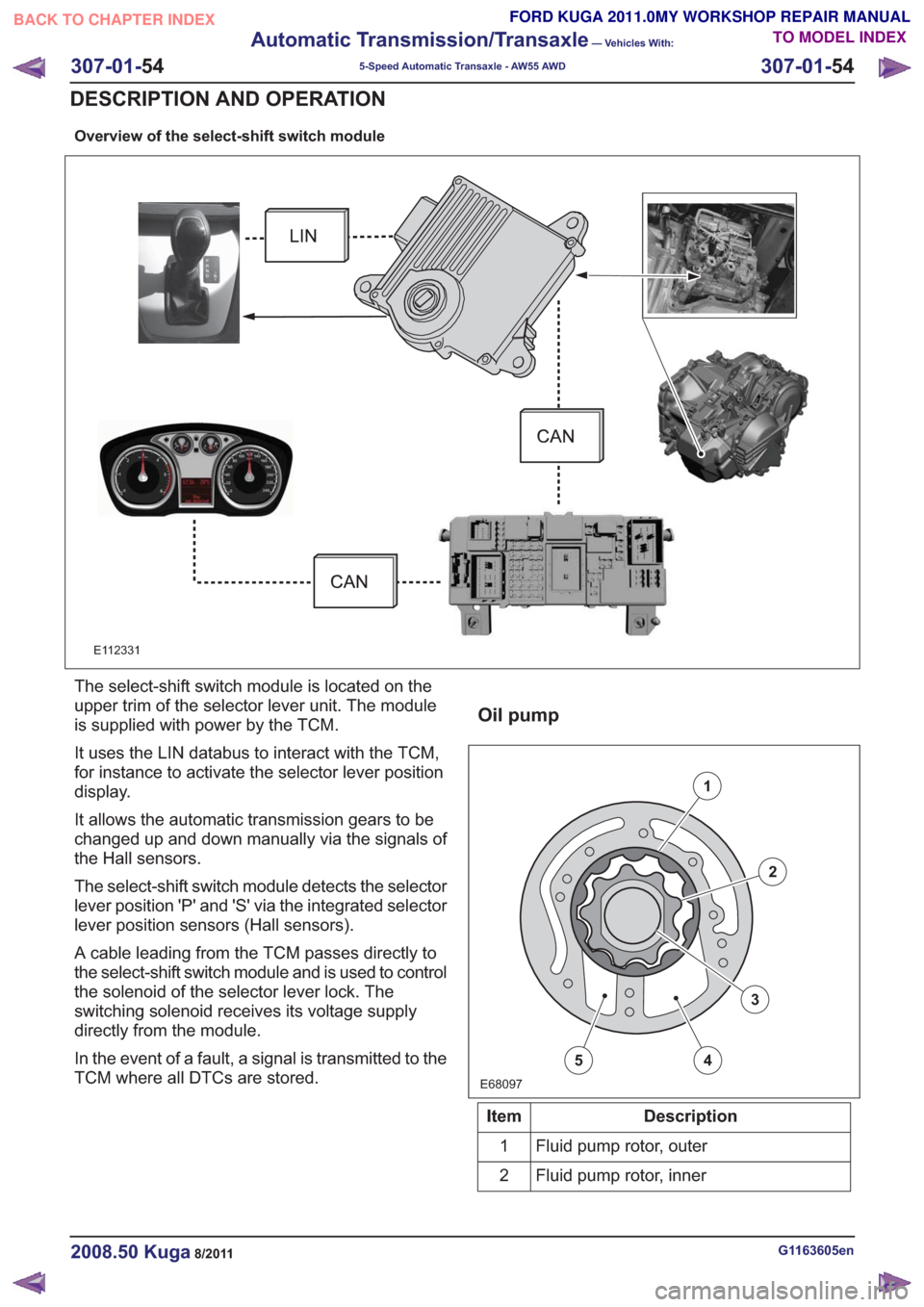

Overview of the select-shift switch module

E112331

The select-shift switch module is located on the

upper trim of the selector lever unit. The module

is supplied with power by the TCM.

It uses the LIN databus to interact with the TCM,

for instance to activate the selector lever position

display.

It allows the automatic transmission gears to be

changed up and down manually via the signals of

the Hall sensors.

The select-shift switch module detects the selector

lever position 'P' and 'S' via the integrated selector

lever position sensors (Hall sensors).

A cable leading from the TCM passes directly to

the select-shift switch module and is used to control

the solenoid of the selector lever lock. The

switching solenoid receives its voltage supply

directly from the module.

In the event of a fault, a signal is transmitted to the

TCM where all DTCs are stored.

Oil pump

E68097

1

2

3

45

Description

Item

Fluid pump rotor, outer

1

Fluid pump rotor, inner

2

G1163605en2008.50 Kuga8/2011

307-01- 54

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 54

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 2009 of 2057

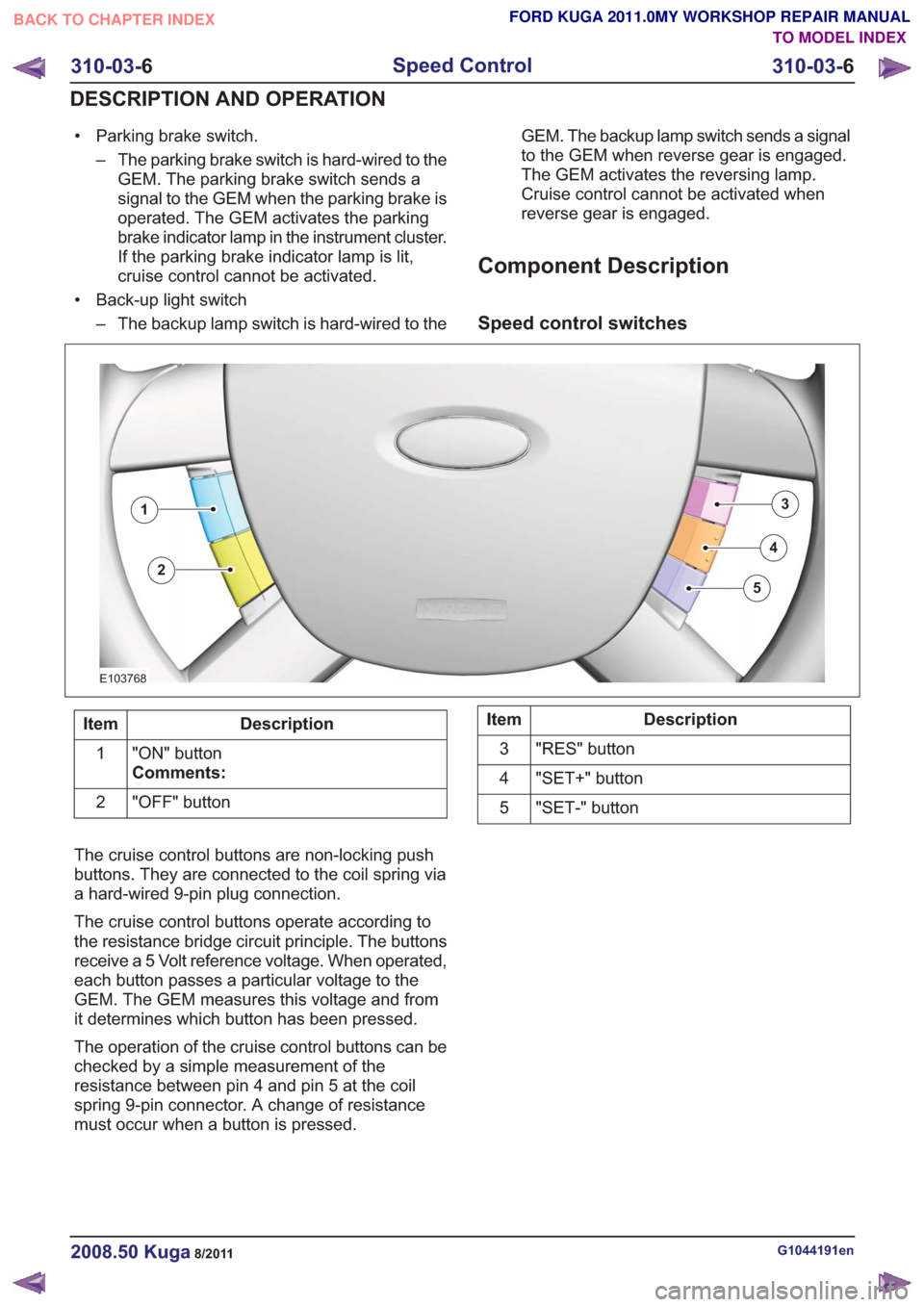

• Parking brake switch.– The parking brake switch is hard-wired to theGEM. The parking brake switch sends a

signal to the GEM when the parking brake is

operated. The GEM activates the parking

brake indicator lamp in the instrument cluster.

If the parking brake indicator lamp is lit,

cruise control cannot be activated.

• Back-up light switch – The backup lamp switch is hard-wired to the GEM. The backup lamp switch sends a signal

to the GEM when reverse gear is engaged.

The GEM activates the reversing lamp.

Cruise control cannot be activated when

reverse gear is engaged.

Component Description

Speed control switches

E103768

3

4

5

1

2

Description

Item

"ON" button

Comments:

1

"OFF" button

2Description

Item

"RES" button

3

"SET+" button

4

"SET-" button

5

The cruise control buttons are non-locking push

buttons. They are connected to the coil spring via

a hard-wired 9-pin plug connection.

The cruise control buttons operate according to

the resistance bridge circuit principle. The buttons

receive a 5 Volt reference voltage. When operated,

each button passes a particular voltage to the

GEM. The GEM measures this voltage and from

it determines which button has been pressed.

The operation of the cruise control buttons can be

checked by a simple measurement of the

resistance between pin 4 and pin 5 at the coil

spring 9-pin connector. A change of resistance

must occur when a button is pressed.

G1044191en2008.50 Kuga8/2011

310-03- 6

Speed Control

310-03- 6

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 2028 of 2057

SECTION 412-01 Climate Control

VEHICLE APPLICATION:2008.50 Kuga

PA G E

CONTENTS

SPECIFICATIONS

412-01-3

Specifications ........................................................................\

..............................................

DESCRIPTION AND OPERATION 412-01-4

Climate Control (Component Location) ........................................................................\

......

412-01-10

Climate Control (Overview) ........................................................................\

........................

412-01-10

Pollen filter ........................................................................\

..................................................

412-01-10

Heat exchanger ........................................................................\

..........................................

412-01-10

Evaporator assembly ........................................................................\

..................................

412-01-10

Blower motor ........................................................................\

..............................................

412-01-11

Fault Memory Interrogation without diagnostics unit - vehicles with automatic temperature

control ........................................................................\

.......................................................

412-01-11

Switch over from Celsius to Fahrenheit ........................................................................\

......

412-01-12

Climate Control (System Operation and Component Description) .....................................

412-01-12

System Diagram ........................................................................\

.........................................

412-01-19

System Operation ........................................................................\

.......................................

412-01-19

Climate control housing ........................................................................\

..........................

412-01-22

Climate control ........................................................................\

........................................

412-01-24

Component Description ........................................................................\

..............................

412-01-24

Air conditioning compressor ........................................................................\

...................

412-01-24

Pollen filter ........................................................................\

..............................................

412-01-24

Control assembly, climate control - vehicles with manual temperature control ..............

412-01-25

Control assembly, climate control - vehicles with automatic temperature control ...........

412-01-25

Control assembly, climate control - vehicles with DVD navigation system with a touch

screen........................................................................\

................................................... 412-01-25

Climate control module - vehicles with DVD navigation system with a touch screen.....

412-01-25

Sun sensor - vehicles with automatic temperature control .............................................

412-01-26

In-vehicle temperature sensor ........................................................................\

................

412-01-26

Ambient temperature sensor ........................................................................\

..................

412-01-26

Blower motor ........................................................................\

...........................................

412-01-26

Blower control module - vehicles equipped with automatic temperature control ............

REMOVAL AND INSTALLATION 412-01-28

(34 626 4)

Air Conditioning (A/C) Compressor — 2.5L Duratec (147kW/200PS) - VI5 ....

412-01-29

Air Conditioning (A/C) Compressor to Condenser Discharge Line .....................................

412-01-30

Air Conditioning (A/C) Compressor to Condenser Discharge Line — 2.5L Duratec

(147kW/200PS) - VI5 ........................................................................\

................................

412-01-31

Condenser ........................................................................\

..................................................

412-01-35

Clutch and Clutch Field Coil........................................................................\

.......................

412-01-36

Pollen Filter — RHD........................................................................\

...................................

412-01-37

(34

374 0)

Blower Motor — RHD ........................................................................\

.............

412-01-40

(34 382 0)

Blower Motor Resistor — Vehicles With: Manual Temperature Control, RHD .

412-01-41

(34 382 0)

Blower Motor Resistor — Vehicles With: Dual Automatic Temperature

Control ........................................................................\

..................................

412-01- 1

Climate Control

412-01- 1

.

TO MODEL INDEX

BACK TO CHAPTER INDEX

PAGE 1 OF 2 FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL