power FORD KUGA 2011 1.G Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 90 of 2057

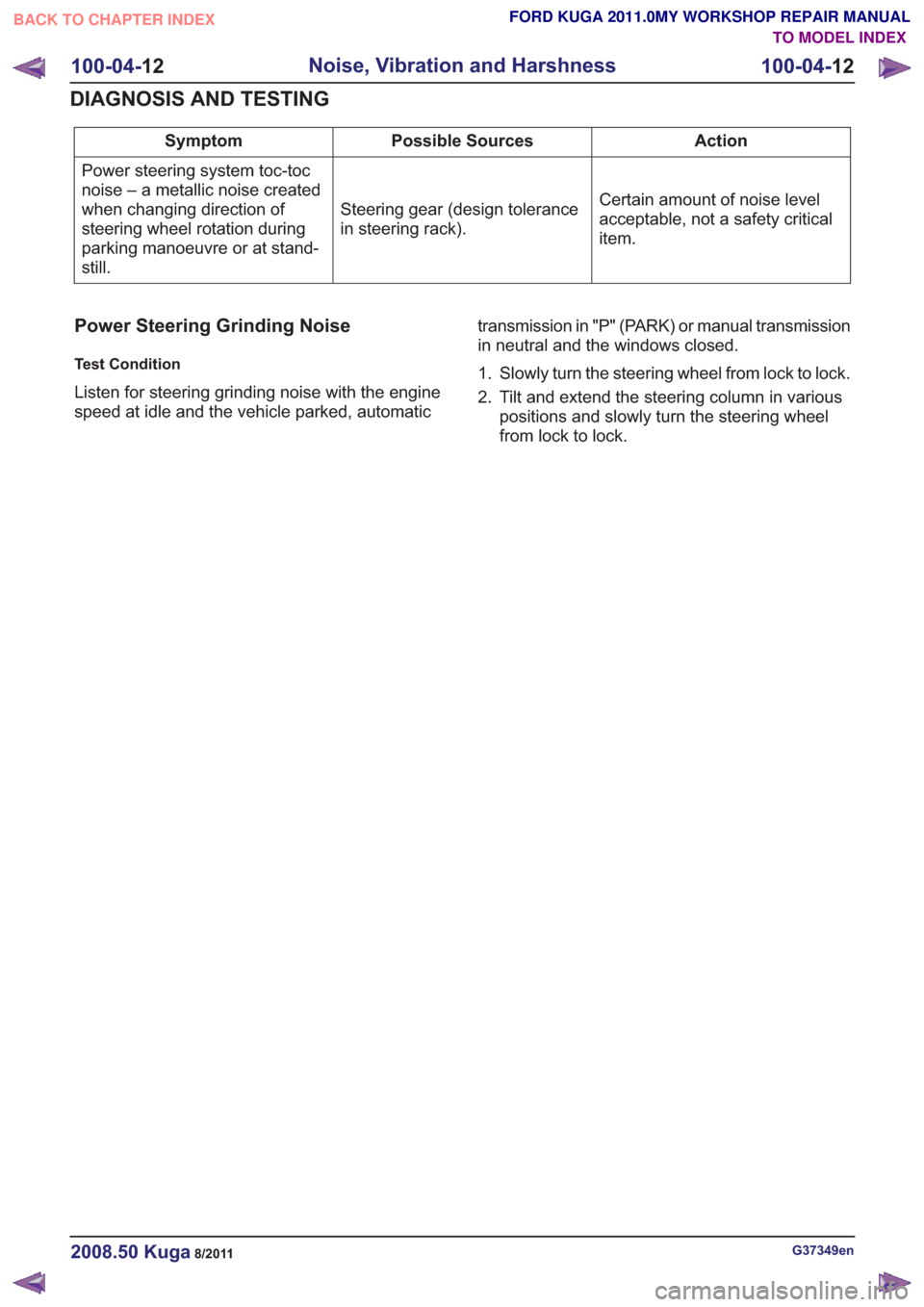

Action

Possible Sources

Symptom

Certain amount of noise level

acceptable, not a safety critical

item.

Steering gear (design tolerance

in steering rack).

Power steering system toc-toc

noise – a metallic noise created

when changing direction of

steering wheel rotation during

parking manoeuvre or at stand-

still.

Power Steering Grinding Noise

Test Condition

Listen for steering grinding noise with the engine

speed at idle and the vehicle parked, automatic transmission in "P" (PARK) or manual transmission

in neutral and the windows closed.

1. Slowly turn the steering wheel from lock to lock.

2. Tilt and extend the steering column in various

positions and slowly turn the steering wheel

from lock to lock.

G37349en2008.50 Kuga8/2011

100-04- 12

Noise, Vibration and Harshness

100-04- 12

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 91 of 2057

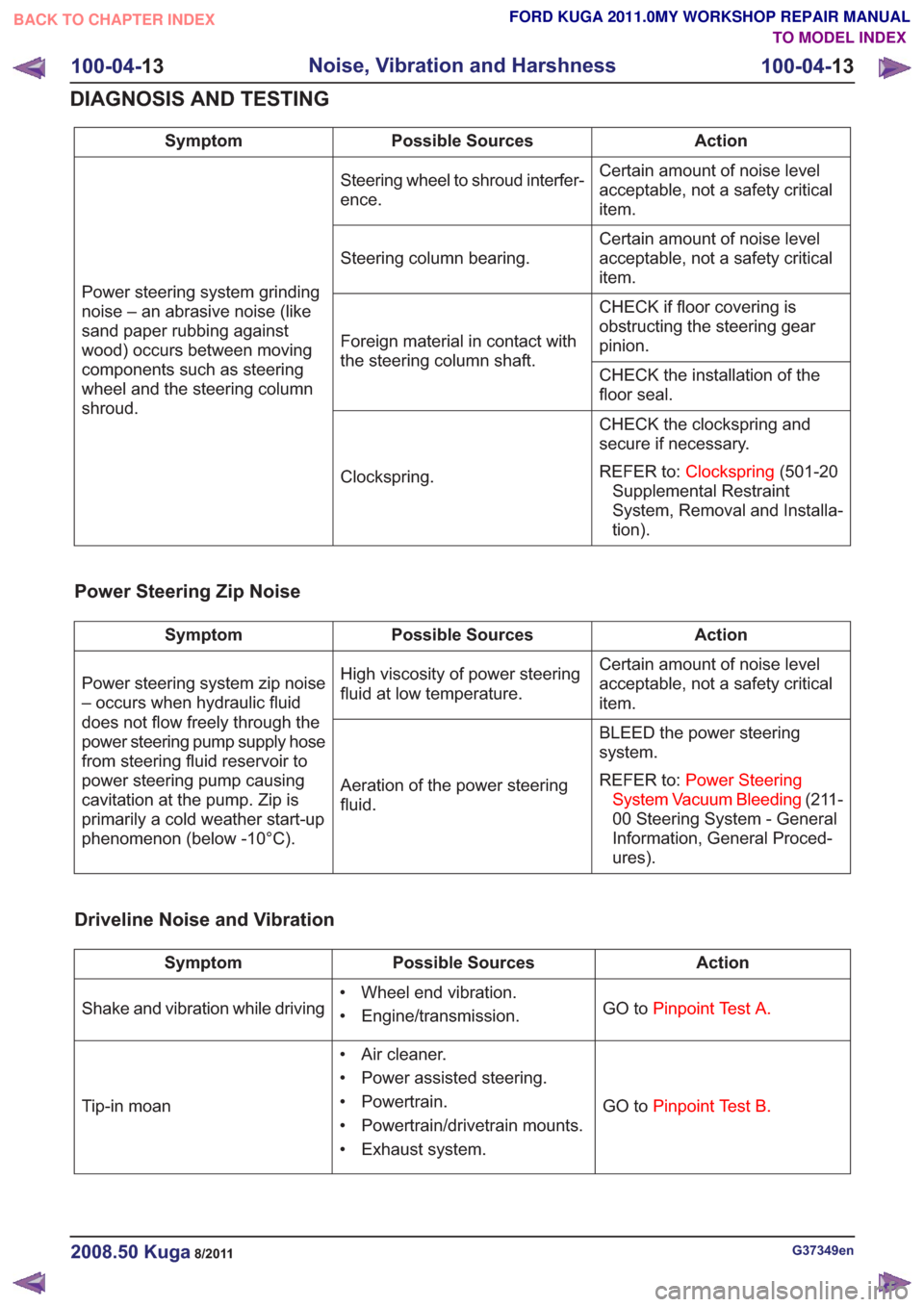

Action

Possible Sources

Symptom

Certain amount of noise level

acceptable, not a safety critical

item.

Steering wheel to shroud interfer-

ence.

Power steering system grinding

noise – an abrasive noise (like

sand paper rubbing against

wood) occurs between moving

components such as steering

wheel and the steering column

shroud. Certain amount of noise level

acceptable, not a safety critical

item.

Steering column bearing.

CHECK if floor covering is

obstructing the steering gear

pinion.

Foreign material in contact with

the steering column shaft.

CHECK the installation of the

floor seal.

CHECK the clockspring and

secure if necessary.

REFER to:Clockspring (501-20

Supplemental Restraint

System, Removal and Installa-

tion).

Clockspring.

Power Steering Zip Noise

Action

Possible Sources

Symptom

Certain amount of noise level

acceptable, not a safety critical

item.

High viscosity of power steering

fluid at low temperature.

Power steering system zip noise

– occurs when hydraulic fluid

does not flow freely through the

power steering pump supply hose

from steering fluid reservoir to

power steering pump causing

cavitation at the pump. Zip is

primarily a cold weather start-up

phenomenon (below -10°C). BLEED the power steering

system.

REFER to:

Power Steering

System Vacuum Bleeding (211-

00 Steering System - General

Information, General Proced-

ures).

Aeration of the power steering

fluid.

Driveline Noise and Vibration

Action

Possible Sources

Symptom

GO toPinpoint Test A.

• Wheel end vibration.

• Engine/transmission.

Shake and vibration while driving

GO toPinpoint Test B.

• Air cleaner.

• Power assisted steering.

• Powertrain.

• Powertrain/drivetrain mounts.

• Exhaust system.

Tip-in moan

G37349en2008.50 Kuga8/2011

100-04-

13

Noise, Vibration and Harshness

100-04- 13

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 92 of 2057

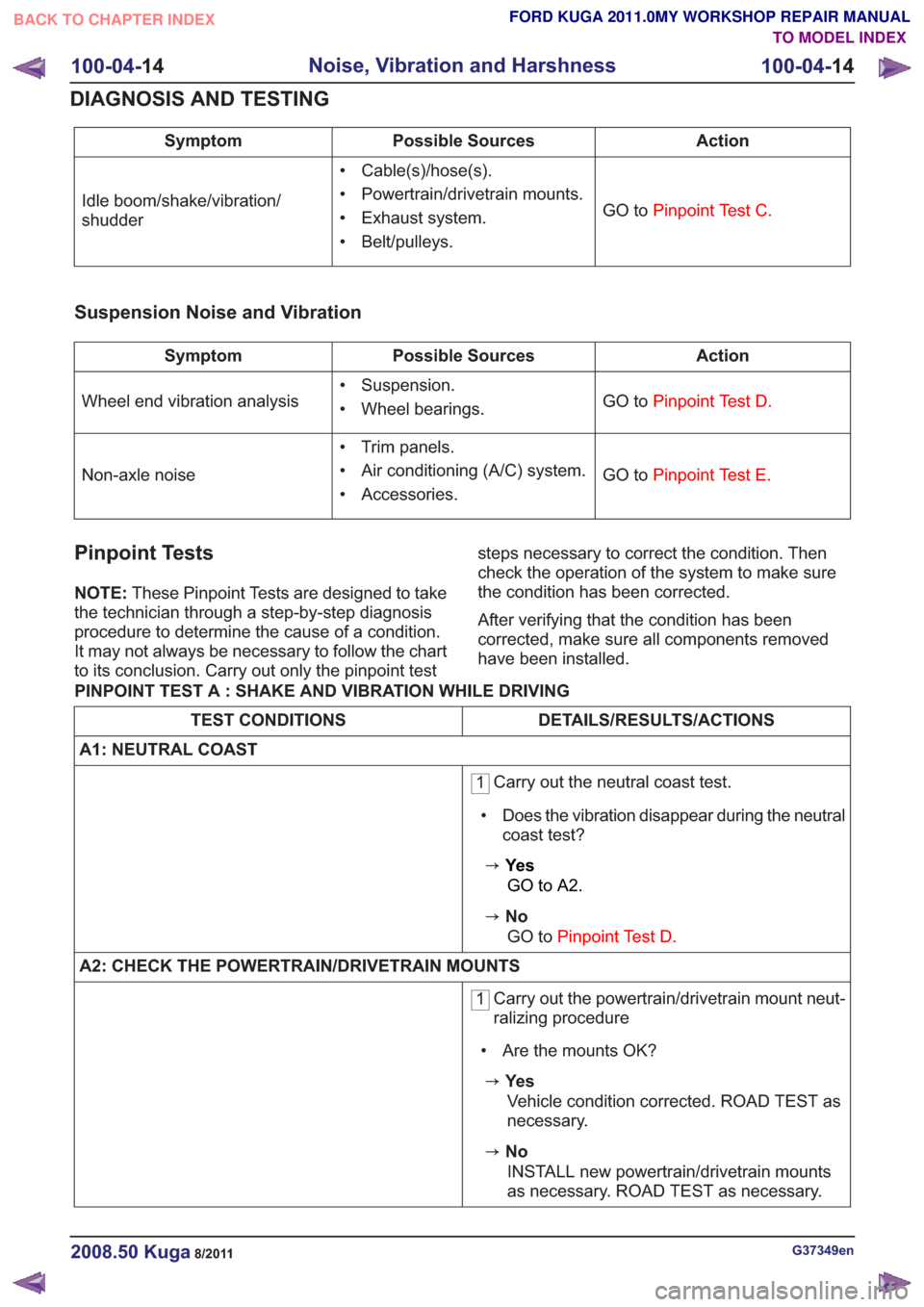

Action

Possible Sources

Symptom

GO toPinpoint Test C.

• Cable(s)/hose(s).

• Powertrain/drivetrain mounts.

• Exhaust system.

• Belt/pulleys.

Idle boom/shake/vibration/

shudder

Suspension Noise and Vibration

Action

Possible Sources

Symptom

GO toPinpoint Test D.

• Suspension.

• Wheel bearings.

Wheel end vibration analysis

GO toPinpoint Test E.

• Trim panels.

• Air conditioning (A/C) system.

• Accessories.

Non-axle noise

Pinpoint Tests

NOTE:

These Pinpoint Tests are designed to take

the technician through a step-by-step diagnosis

procedure to determine the cause of a condition.

It may not always be necessary to follow the chart

to its conclusion. Carry out only the pinpoint test steps necessary to correct the condition. Then

check the operation of the system to make sure

the condition has been corrected.

After verifying that the condition has been

corrected, make sure all components removed

have been installed.

PINPOINT TEST A : SHAKE AND VIBRATION WHILE DRIVING

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

A1: NEUTRAL COAST

1 Carry out the neutral coast test.

• Does the vibration disappear during the neutral coast test?

zYe s

GO to A2.

zNoGO to Pinpoint Test D.

A2: CHECK THE POWERTRAIN/DRIVETRAIN MOUNTS

1 Carry out the powertrain/drivetrain mount neut-

ralizing procedure

• Are the mounts OK?

zYe s Vehicle condition corrected. ROAD TEST as

necessary.

zNoINSTALL new powertrain/drivetrain mounts

as necessary. ROAD TEST as necessary.

G37349en2008.50 Kuga8/2011

100-04- 14

Noise, Vibration and Harshness

100-04- 14

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 93 of 2057

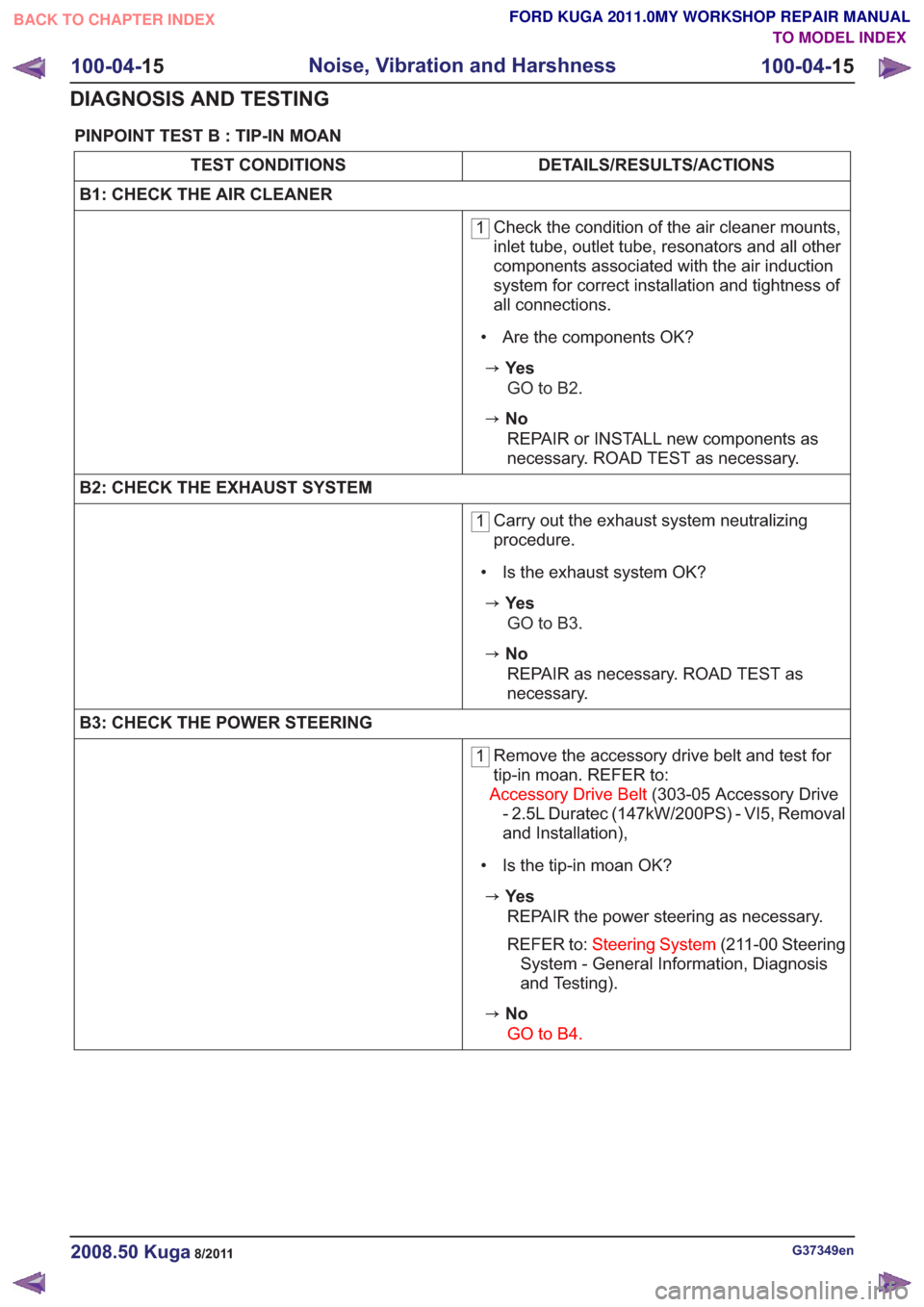

PINPOINT TEST B : TIP-IN MOAN

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

B1: CHECK THE AIR CLEANER

1 Check the condition of the air cleaner mounts,

inlet tube, outlet tube, resonators and all other

components associated with the air induction

system for correct installation and tightness of

all connections.

• Are the components OK?

zYe s GO to B2.

zNoREPAIR or INSTALL new components as

necessary. ROAD TEST as necessary.

B2: CHECK THE EXHAUST SYSTEM

1 Carry out the exhaust system neutralizing

procedure.

• Is the exhaust system OK?

zYe s GO to B3.

zNoREPAIR as necessary. ROAD TEST as

necessary.

B3: CHECK THE POWER STEERING

1 Remove the accessory drive belt and test for

tip-in moan. REFER to:

Accessory Drive Belt (303-05 Accessory Drive

- 2.5L Duratec (147kW/200PS) - VI5, Removal

and Installation),

• Is the tip-in moan OK?

zYe s REPAIR the power steering as necessary.

REFER to: Steering System (211-00 Steering

System - General Information, Diagnosis

and Testing).

zNo

GO to B4.

G37349en2008.50 Kuga8/2011

100-04- 15

Noise, Vibration and Harshness

100-04- 15

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 94 of 2057

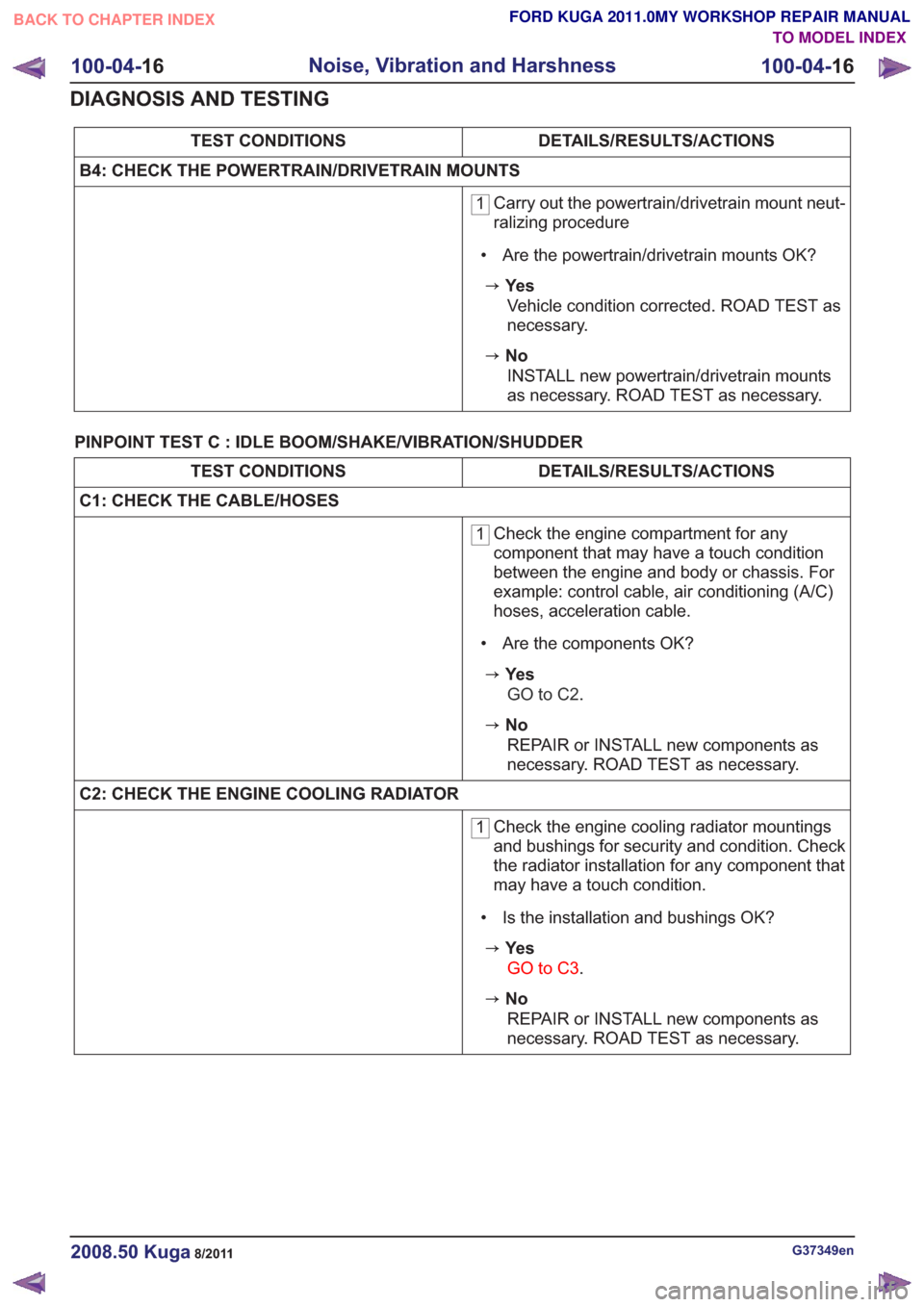

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

B4: CHECK THE POWERTRAIN/DRIVETRAIN MOUNTS

1 Carry out the powertrain/drivetrain mount neut-

ralizing procedure

• Are the powertrain/drivetrain mounts OK?

zYe s Vehicle condition corrected. ROAD TEST as

necessary.

zNoINSTALL new powertrain/drivetrain mounts

as necessary. ROAD TEST as necessary.

PINPOINT TEST C : IDLE BOOM/SHAKE/VIBRATION/SHUDDER

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

C1: CHECK THE CABLE/HOSES

1 Check the engine compartment for any

component that may have a touch condition

between the engine and body or chassis. For

example: control cable, air conditioning (A/C)

hoses, acceleration cable.

• Are the components OK?

zYe s GO to C2 .

zNo

REPAIR or INSTALL new components as

necessary. ROAD TEST as necessary.

C2: CHECK THE ENGINE COOLING RADIATOR

1 Check the engine cooling radiator mountings

and bushings for security and condition. Check

the radiator installation for any component that

may have a touch condition.

• Is the installation and bushings OK?

zYe s GO to C3 .

zNo

REPAIR or INSTALL new components as

necessary. ROAD TEST as necessary.

G37349en2008.50 Kuga8/2011

100-04- 16

Noise, Vibration and Harshness

100-04- 16

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 95 of 2057

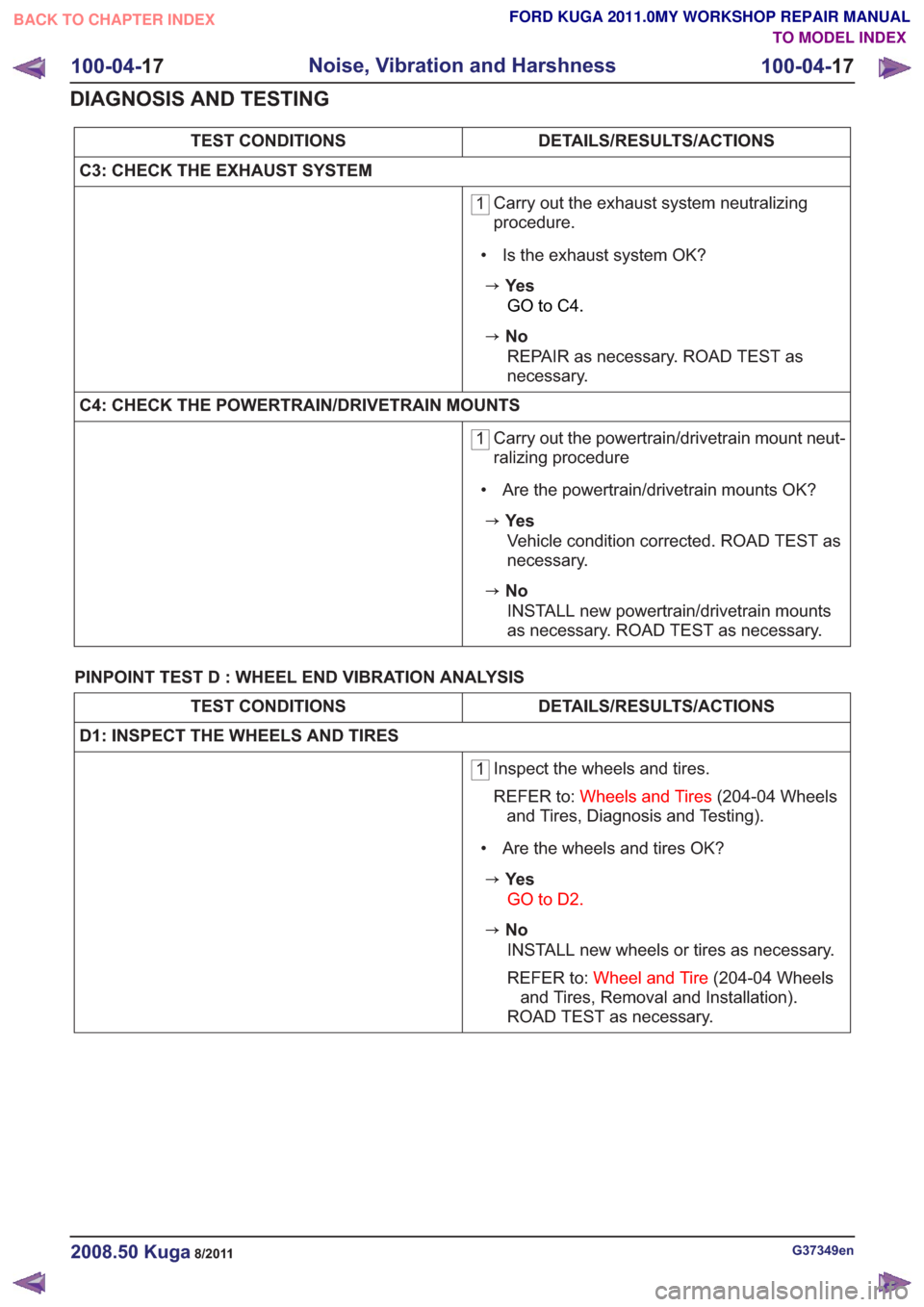

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

C3: CHECK THE EXHAUST SYSTEM

1 Carry out the exhaust system neutralizing

procedure.

• Is the exhaust system OK?

zYe s GO to C4 .

zNo

REPAIR as necessary. ROAD TEST as

necessary.

C4: CHECK THE POWERTRAIN/DRIVETRAIN MOUNTS

1 Carry out the powertrain/drivetrain mount neut-

ralizing procedure

• Are the powertrain/drivetrain mounts OK?

zYe s Vehicle condition corrected. ROAD TEST as

necessary.

zNoINSTALL new powertrain/drivetrain mounts

as necessary. ROAD TEST as necessary.

PINPOINT TEST D : WHEEL END VIBRATION ANALYSIS

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

D1: INSPECT THE WHEELS AND TIRES

1 Inspect the wheels and tires.

REFER to:

Wheels and Tires (204-04 Wheels

and Tires, Diagnosis and Testing).

• Are the wheels and tires OK?

zYe s GO to D2 .

zNo

INSTALL new wheels or tires as necessary.

REFER to: Wheel and Tire (204-04 Wheels

and Tires, Removal and Installation).

ROAD TEST as necessary.

G37349en2008.50 Kuga8/2011

100-04- 17

Noise, Vibration and Harshness

100-04- 17

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 156 of 2057

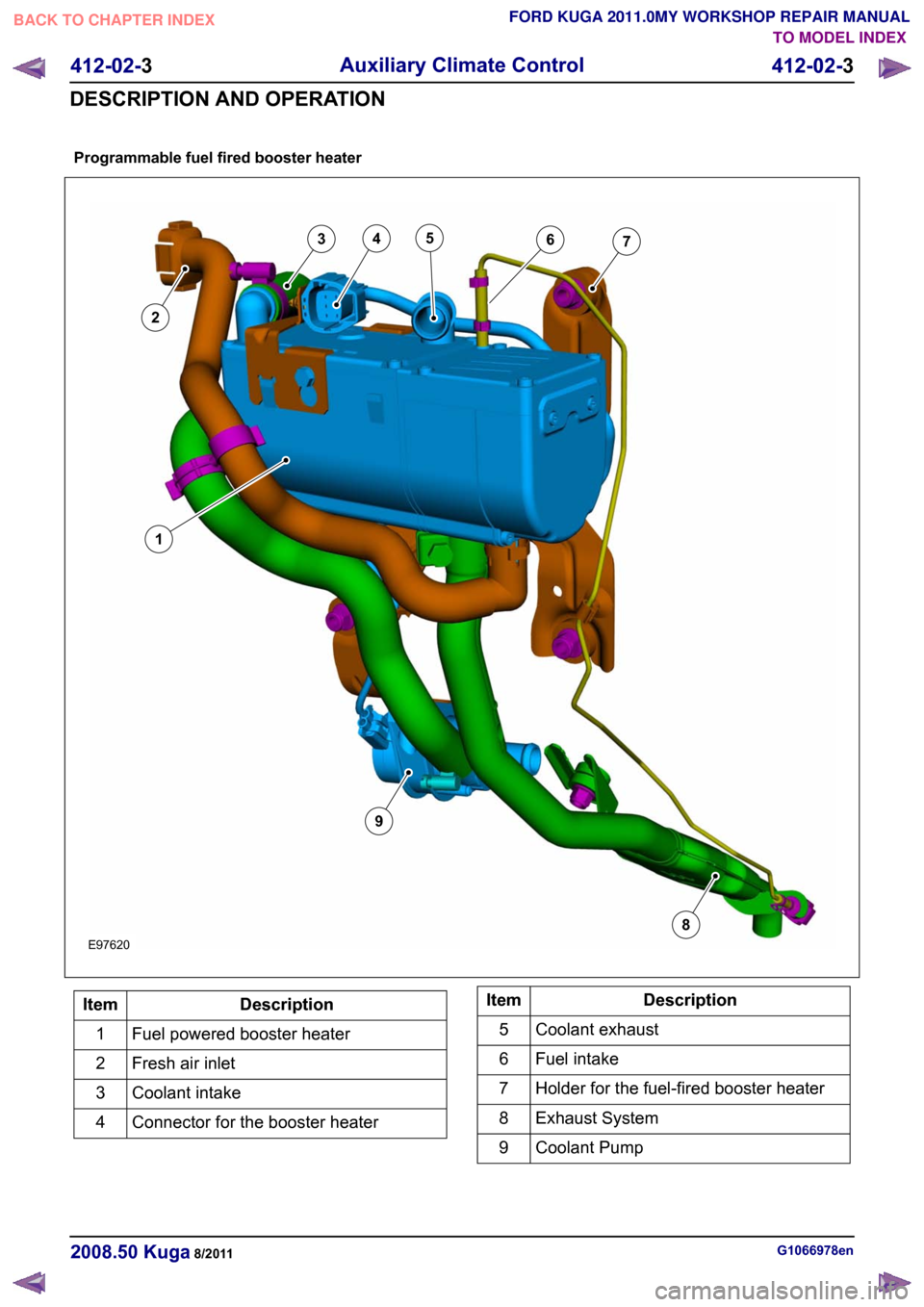

Programmable fuel fired booster heater

Description

Item

Fuel powered booster heater

1

Fresh air inlet

2

Coolant intake

3

Connector for the booster heater

4 Description

Item

Coolant exhaust

5

Fuel intake

6

Holder for the fuel-fired booster heater

7

Exhaust System

8

Coolant Pump

9 G1066978en

2008.50 Kuga 8/2011 412-02-3

Auxiliary Climate Control

412-02-3

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL269835471E97620

Page 160 of 2057

Description

Item

Electric Booster HeaterRefer to Component Description: (page

?)

1

GEM (generic electronic module)

2

Outside temperature sensor

3

Climate control system control assembly

4 Description

Item

Generator and Alternator

5

PCM (powertrain control module)

6

Coolant temperature sensor (ECT (engine

coolant temperature) sensor)Refer to Component Description: ECT

(page ?)

7

instrument cluster

8 G1066982en

2008.50 Kuga 8/2011 412-02-7

Auxiliary Climate Control

412-02-7

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 165 of 2057

System Operation

Electric Booster Heater

In diesel vehicles which give off little residual heat,

a booster heater is used to heat the passenger

compartment rapidly in the case of low ambient

temperatures.

If the interior temperature has been set to HI, or if

the heater controls have been switched to the

highest setting, the two-zone air conditioning

system sends an "electric booster heater ON"

request signal to the CAN (controller area network)

via the medium speed GEM bus. If a manual air

conditioning system is installed, the signal is

transmitted via a conventional cable connection.

The GEM switches on the electric booster heater

depending on the following parameters:

• Engine coolant temperature is below 60 °C.

• Ambient air temperature is below 10 °C.

• Sufficient generator capacity is available.

The electric booster heater electronics activate

three output stages as a function of a pulse width

modulated signal PWM (pulse width modulation)

generated by the GEM. The output stages switch

the three heating elements of the electric booster

heater ON or OFF individually, whereby the heating

periods of the individual elements can overlap. Due

to the variable switch-on duration, continuously

variable temperature control is possible. The overall

heating power of the three heating elements is

linearly proportional to the PWM signal. If the PWM

signal is below 10% or above 95%, the electric

booster heater is not activated.

The electric booster heater is switched off when

an engine coolant temperature of 70°C or an

ambient air temperature of 20°C is exceeded.

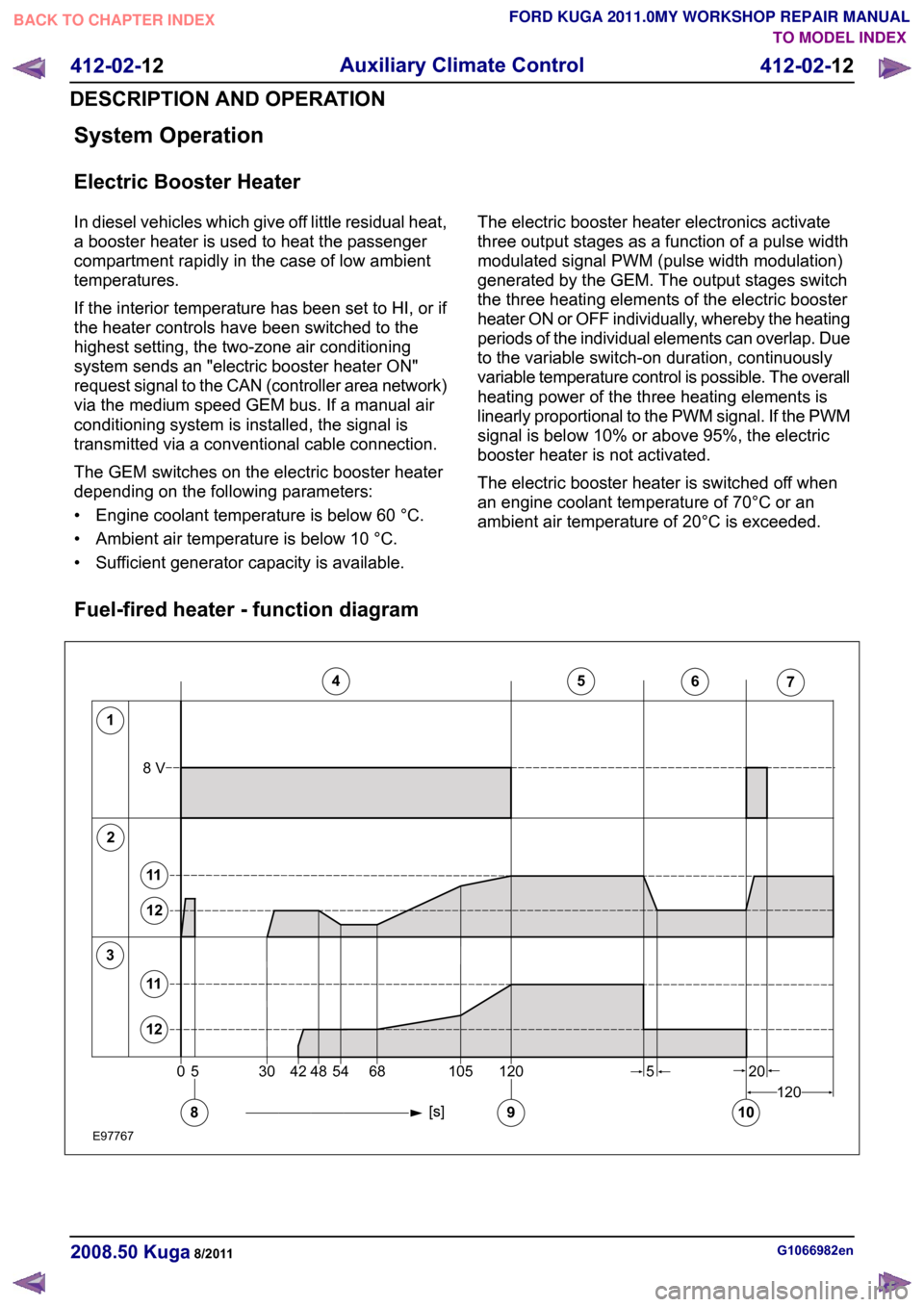

Fuel-fired heater - function diagram G1066982en

2008.50 Kuga 8/2011 412-02-12

Auxiliary Climate Control

412-02-12

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL12345671205304254481201056820108V58911121112E977670

Page 187 of 2057

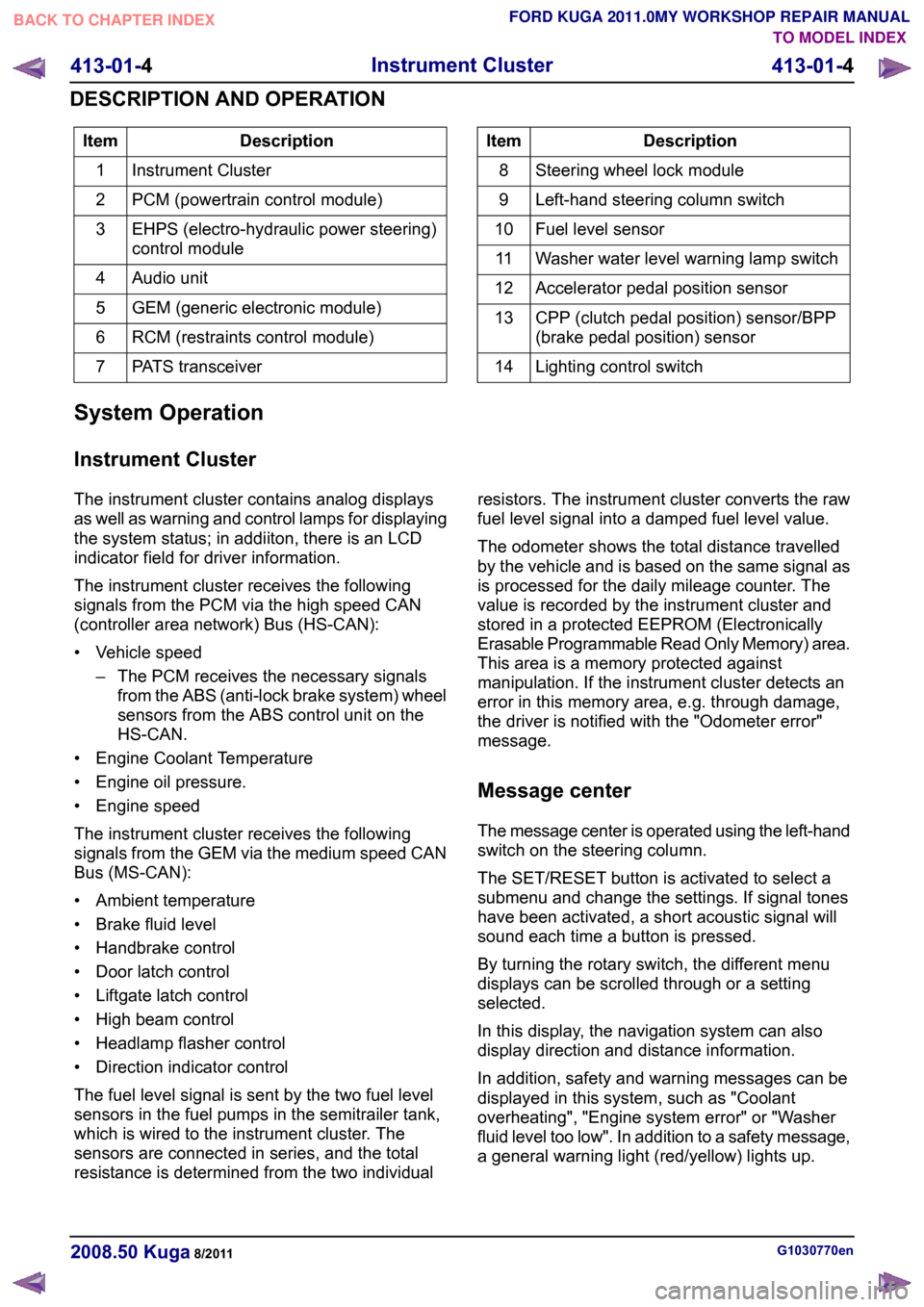

Description

Item

Instrument Cluster

1

PCM (powertrain control module)

2

EHPS (electro-hydraulic power steering)

control module

3

Audio unit

4

GEM (generic electronic module)

5

RCM (restraints control module)

6

PATS transceiver

7 Description

Item

Steering wheel lock module

8

Left-hand steering column switch

9

Fuel level sensor

10

Washer water level warning lamp switch

11

Accelerator pedal position sensor

12

CPP (clutch pedal position) sensor/BPP

(brake pedal position) sensor

13

Lighting control switch

14

System Operation

Instrument Cluster

The instrument cluster contains analog displays

as well as warning and control lamps for displaying

the system status; in addiiton, there is an LCD

indicator field for driver information.

The instrument cluster receives the following

signals from the PCM via the high speed CAN

(controller area network) Bus (HS-CAN):

• Vehicle speed – The PCM receives the necessary signalsfrom the ABS (anti-lock brake system) wheel

sensors from the ABS control unit on the

HS-CAN.

• Engine Coolant Temperature

• Engine oil pressure.

• Engine speed

The instrument cluster receives the following

signals from the GEM via the medium speed CAN

Bus (MS-CAN):

• Ambient temperature

• Brake fluid level

• Handbrake control

• Door latch control

• Liftgate latch control

• High beam control

• Headlamp flasher control

• Direction indicator control

The fuel level signal is sent by the two fuel level

sensors in the fuel pumps in the semitrailer tank,

which is wired to the instrument cluster. The

sensors are connected in series, and the total

resistance is determined from the two individual resistors. The instrument cluster converts the raw

fuel level signal into a damped fuel level value.

The odometer shows the total distance travelled

by the vehicle and is based on the same signal as

is processed for the daily mileage counter. The

value is recorded by the instrument cluster and

stored in a protected EEPROM (Electronically

Erasable Programmable Read Only Memory) area.

This area is a memory protected against

manipulation. If the instrument cluster detects an

error in this memory area, e.g. through damage,

the driver is notified with the "Odometer error"

message.

Message center

The message center is operated using the left-hand

switch on the steering column.

The SET/RESET button is activated to select a

submenu and change the settings. If signal tones

have been activated, a short acoustic signal will

sound each time a button is pressed.

By turning the rotary switch, the different menu

displays can be scrolled through or a setting

selected.

In this display, the navigation system can also

display direction and distance information.

In addition, safety and warning messages can be

displayed in this system, such as "Coolant

overheating", "Engine system error" or "Washer

fluid level too low". In addition to a safety message,

a general warning light (red/yellow) lights up.

G1030770en

2008.50 Kuga 8/2011 413-01-4

Instrument Cluster

413-01-4

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL