spring FORD KUGA 2011 1.G Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1724 of 2057

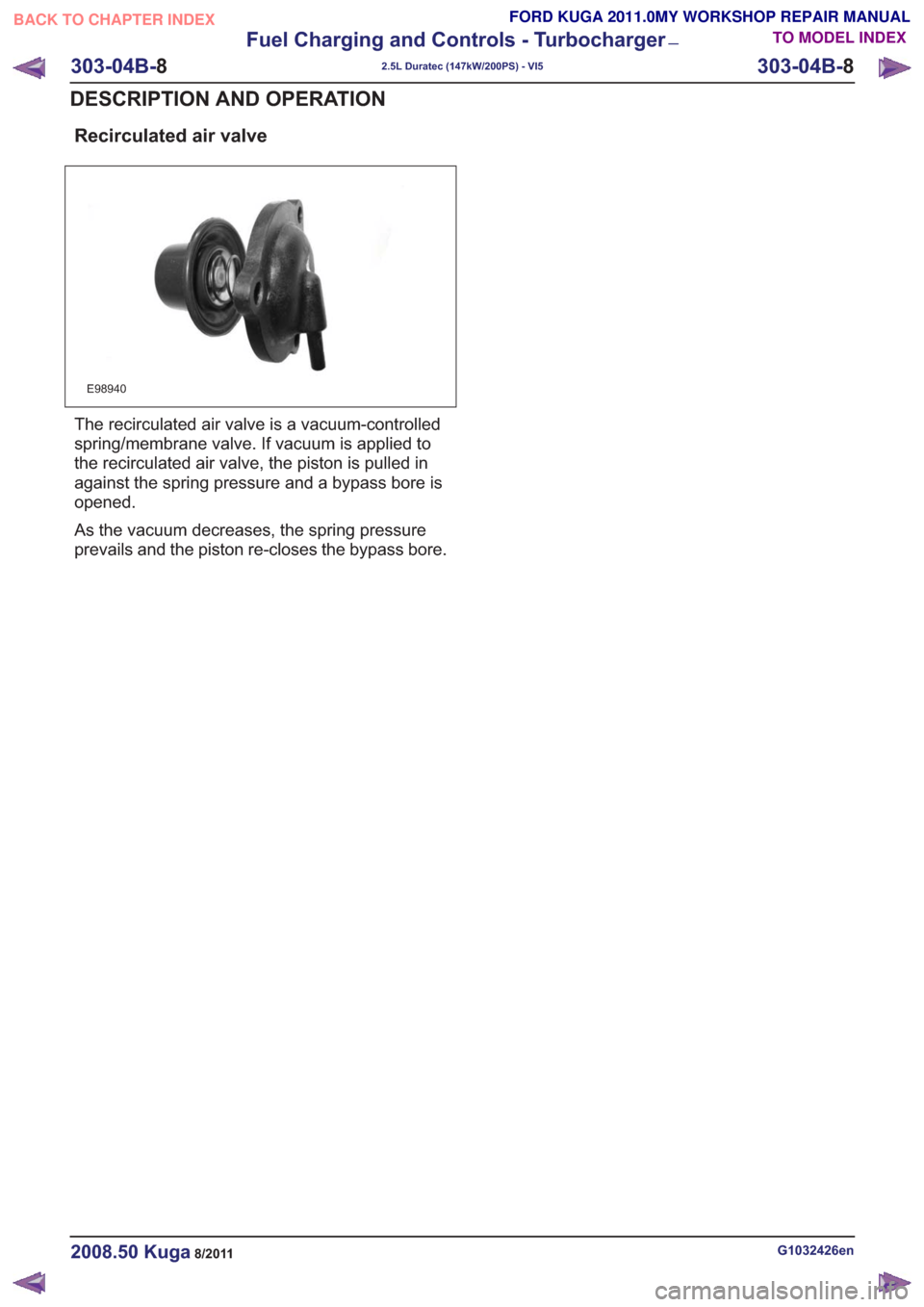

Recirculated air valve

E98940

The recirculated air valve is a vacuum-controlled

spring/membrane valve. If vacuum is applied to

the recirculated air valve, the piston is pulled in

against the spring pressure and a bypass bore is

opened.

As the vacuum decreases, the spring pressure

prevails and the piston re-closes the bypass bore.

G1032426en2008.50 Kuga8/2011

303-04B-8

Fuel Charging and Controls - Turbocharger

—

2.5L Duratec (147kW/200PS) - VI5

303-04B- 8

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1739 of 2057

Action

Possible Sources

Symptom

• CHECK the accessory drivebelt tensioner for correct opera-

tion or damage. REFER to the

Accessory Drive Belt Tensioner

Component Test in this

procedure. INSTALL a new

accessory drive belt tensioner

as necessary.

REFER to: Accessory Drive

Belt Tensioner (303-05

Accessory Drive - 2.5L

Duratec (147kW/200PS) -

VI5, Removal and Installa-

tion).

or

REFER to: Air Conditioning

(A/C) Compressor Belt

Tensioner (303-05 Accessory

Drive - 2.5L Duratec

(147kW/200PS) - VI5,

Removal and Installation).

TEST the system for normal

operation.

• Accessory drive belt tensioner

hitting the end stops.

NOTE:

Rattle is defined as a

metallic knocking noise

• Accessory drive belt rattle

• CHECK the components orhardware for correct installation

and tighten as necessary.

TEST the system for normal

operation.

• Loose components or hard-

ware.

Component Tests

Accessory Drive Belt Tensioner - Static

Check

The accessory drive belt tensioner may be checked

statically as follows:

1. Inspect the area surrounding the accessorydrive belt tensioner for lubricant or other

contamination. Rectify any leaks before

installing a new accessory drive belt tensioner.

If the accessory drive belt tensioner is

contaminated, do not attempt to clean it as the

damping mechanism inside may be damaged.

INSTALL a new accessory drive belt tensioner

as necessary.

REFER to: Accessory Drive Belt Tensioner

(303-05 Accessory Drive - 2.5L Duratec

(147kW/200PS) - VI5, Removal and

Installation). or

REFER to:

Air Conditioning (A/C) Compressor

Belt Tensioner (303-05 Accessory Drive - 2.5L

Duratec (147kW/200PS) - VI5, Removal and

Installation).

TEST the system for normal operation.

2. Detach the accessory drive belt in the area of the accessory drive belt tensioner.

3. NOTE: The accessory drive belt tensioner has a damping feature, which is usually a

friction device, therefore some friction within

the system is normal.

Using the correct tool, move the accessory drive

belt tensioner from its relaxed position through

its full stroke and back to the relaxed position

to make sure there is no excessive stick, grab

or bind, and to make sure there is tension on

the accessory drive belt tensioner spring.

4. Rotate the accessory drive belt tensioner pulley and check for damage, freedom of rotation and

G1183443en2008.50 Kuga8/2011

303-05- 9

Accessory Drive— 2.5L Duratec (147kW/200PS) - VI5303-05-

9

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1796 of 2057

current value is reached. The PCM then

permanently connects the heating element to earth.

The catalyst monitor sensor is used by the PCM

to measure the oxygen content in the exhaust gas

in the TWC. If all the conditions for catalyst

diagnostics are met, based on this information the

PCM can check that the TWC is working

satisfactorily. The information is also used to

improve the air/fuel mixture adjustment.

The catalyst monitor sensor is similar in function

to an HO2S. The signal transmitted by the catalyst

monitor sensor changes sharply if the oxygen

content in the exhaust gas changes. For this

reason, catalyst monitor sensors are also called

"jump lambda sensors".

Fuel tank purging

The EVAP purge valve is only actuated by the PCM

if the coolant temperature is at least 60°C.

Actuation is done ground side by means of a PWM

signal. This makes it possible to have the full range

of opening widths, from fully closed to fully open.

The PCM determines from the operating conditions

when and how wide to open the EVAP tank purge

valve. If the EVAP purge valve is opened, the

engine sucks in ambient air through the activated

charcoal in the evaporative emission canister as

a result of the vacuum in the intake manifold. In

this way the adsorbed hydrocarbons are led to the

combustion chamber of the engine.

The EVAP tank purge valve is not actuated and

system cleaning is interrupted if the engine

switches to idle and/or a closed-loop control

process is initiated.

Power (battery voltage) is supplied via the

Powertrain Control Module relay in the BJB. The

solenoid coil resistance is between 17 and 24 ohms

at 20°C.

Engine speed control

The APP sensor provides the PCM with information

about the driver's request for acceleration.

The throttle control unit receives a corresponding

input signal from the PCM. An electric motor then

moves the throttle valve shaft by means of a set

of gears. The position of the throttle is continuously

recorded by the TP sensor. Information on throttle

position is processed and monitored by the PCM.

The TP sensor comprises two potentiometers.

These work in opposite ways to each other. In one

potentiometer, the resistance increases when the

throttle is opened, in the other it decreases. Thisallows the operation of the potentiometers to be

checked. The signal from the TP sensor is

amplified in the lower range (idle to a quarter open)

by the PCM to enable more precise control of the

throttle in this range. This is necessary because

the engine is very sensitive to changes in throttle

angle in this throttle opening range.

With the throttle valve position kept constant, the

ignition angle and the injected fuel quantity are

then varied to meet the torque demands.

Depending on the operating state of the engine, a

change in the position of the throttle flap may not

be necessary when the APP sensor changes.

If a fault develops in the throttle control unit, a

standby function is executed. This standby function

allows a slight opening of the throttle flap, so that

enough air passes through to allow limited engine

operation. For this purpose, there is a throttle flap

adjustment screw on the throttle housing. The

return spring closes the throttle flap until the stop

of the toothed segment touches the stop screw. In

this way a defined throttle flap gap is formed for

limp home mode.

The stop screw has a spring loaded pin, which

holds the throttle flap open for limp home mode.

In normal operating mode, this spring loaded pin

is pushed in by the force of the electric motor when

the throttle flap must be closed past the limp home

position (e.g. for idle speed control or overrun

shutoff).

Oil monitoring

The engine does not have an oil pressure

switch.

The oil level and oil quality are calculated.

Calculating the engine oil level

The oil level is determined by continuous

measurement of the capacitance (i.e. the ability to

store an electrical charge) between the two

capacitive elements of the engine oil

level/temperature/quality sensor. The different oil

levels cause the capacitance between the elements

to change. The data are recorded by the PCM and

converted into an oil level value. Temporary

fluctuations in oil level are automatically filtered out

by the PCM.

Calculating oil quality

The PCM calculates the oil quality from the oil level

measurement and the oil temperature measured

by the sensor, plus the engine speed and the

average fuel consumption. The driver is informed

about when an oil change is due.

G1021908en2008.50 Kuga8/2011

303-14- 22

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

22

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1801 of 2057

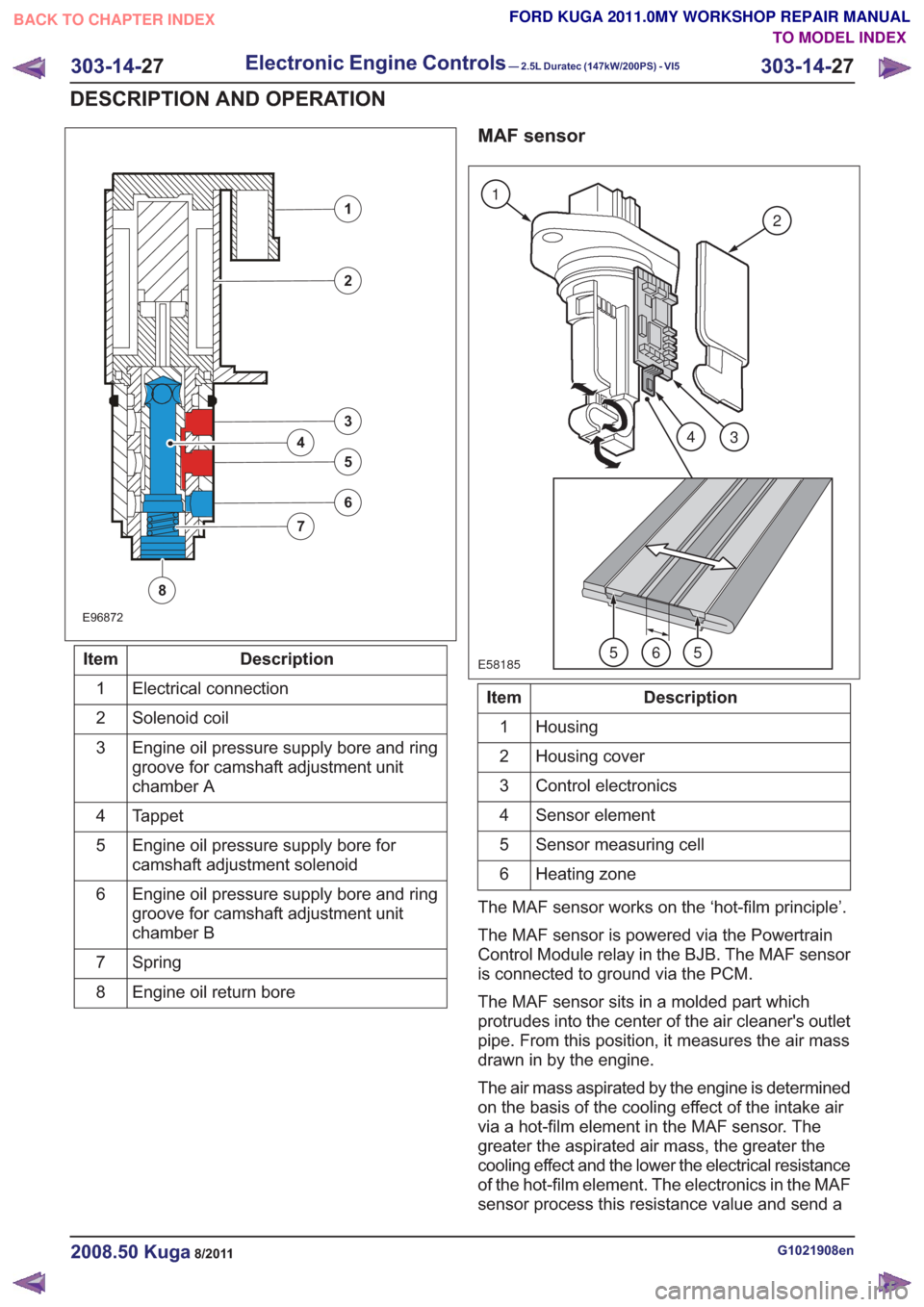

E96872

1

2

3

5

4

6

7

8

Description

Item

Electrical connection

1

Solenoid coil

2

Engine oil pressure supply bore and ring

groove for camshaft adjustment unit

chamber A

3

Tappet

4

Engine oil pressure supply bore for

camshaft adjustment solenoid

5

Engine oil pressure supply bore and ring

groove for camshaft adjustment unit

chamber B

6

Spring

7

Engine oil return bore

8

MAF sensor

E58185

1

2

43

565

Description

Item

Housing

1

Housing cover

2

Control electronics

3

Sensor element

4

Sensor measuring cell

5

Heating zone

6

The MAF sensor works on the ‘hot-film principle’.

The MAF sensor is powered via the Powertrain

Control Module relay in the BJB. The MAF sensor

is connected to ground via the PCM.

The MAF sensor sits in a molded part which

protrudes into the center of the air cleaner's outlet

pipe. From this position, it measures the air mass

drawn in by the engine.

The air mass aspirated by the engine is determined

on the basis of the cooling effect of the intake air

via a hot-film element in the MAF sensor. The

greater the aspirated air mass, the greater the

cooling effect and the lower the electrical resistance

of the hot-film element. The electronics in the MAF

sensor process this resistance value and send a

G1021908en2008.50 Kuga8/2011

303-14- 27

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

27

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1805 of 2057

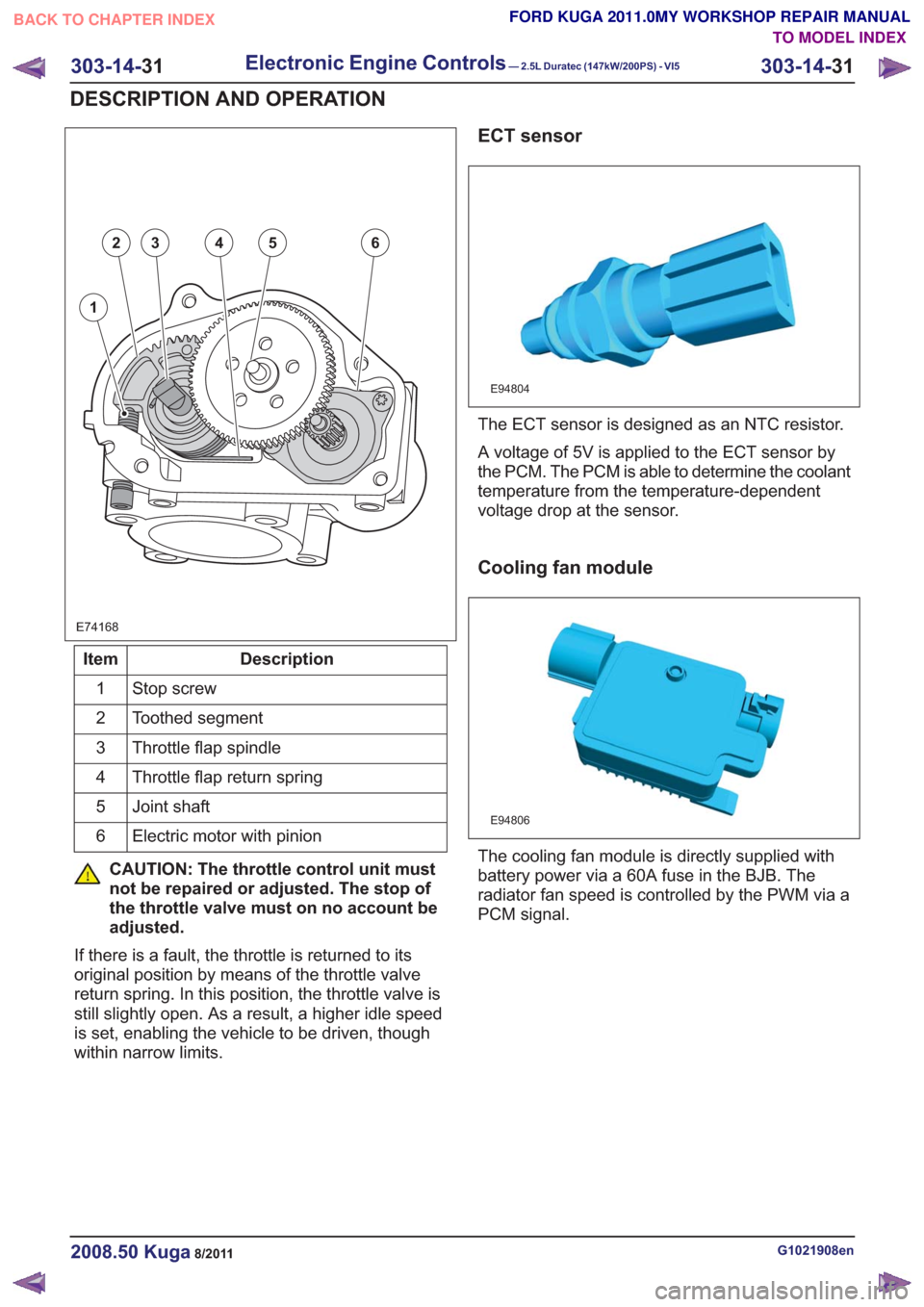

E74168

1

23456

Description

Item

Stop screw

1

Toothed segment

2

Throttle flap spindle

3

Throttle flap return spring

4

Joint shaft

5

Electric motor with pinion

6

CAUTION: The throttle control unit must

not be repaired or adjusted. The stop of

the throttle valve must on no account be

adjusted.

If there is a fault, the throttle is returned to its

original position by means of the throttle valve

return spring. In this position, the throttle valve is

still slightly open. As a result, a higher idle speed

is set, enabling the vehicle to be driven, though

within narrow limits.

ECT sensor

E94804

The ECT sensor is designed as an NTC resistor.

A voltage of 5V is applied to the ECT sensor by

the PCM. The PCM is able to determine the coolant

temperature from the temperature-dependent

voltage drop at the sensor.

Cooling fan module

E94806

The cooling fan module is directly supplied with

battery power via a 60A fuse in the BJB. The

radiator fan speed is controlled by the PWM via a

PCM signal.

G1021908en2008.50 Kuga8/2011

303-14- 31

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

31

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1806 of 2057

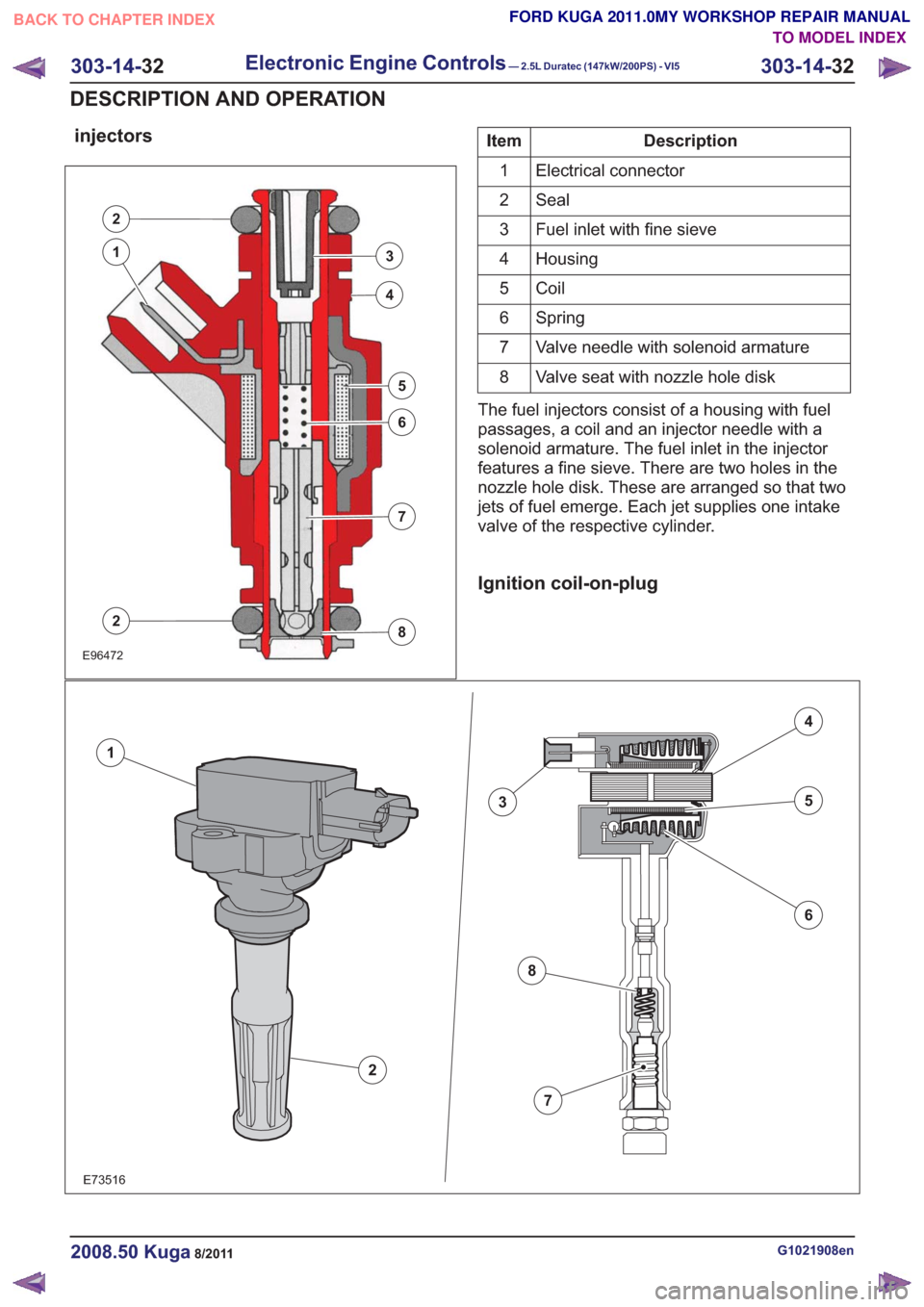

injectors

E96472

2

3

4

5

6

7

8

1

2

Description

Item

Electrical connector

1

Seal

2

Fuel inlet with fine sieve

3

Housing

4

Coil

5

Spring

6

Valve needle with solenoid armature

7

Valve seat with nozzle hole disk

8

The fuel injectors consist of a housing with fuel

passages, a coil and an injector needle with a

solenoid armature. The fuel inlet in the injector

features a fine sieve. There are two holes in the

nozzle hole disk. These are arranged so that two

jets of fuel emerge. Each jet supplies one intake

valve of the respective cylinder.

Ignition coil-on-plug

E73516

2

1

3

4

5

6

7

8

G1021908en2008.50 Kuga8/2011

303-14- 32

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

32

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1807 of 2057

Description

Item

Coil-on-plug ignition coil

1

Spark plug connector

2

Low-voltage connection

3

Laminated soft-iron core

4Description

Item

Primary winding

5

Secondary winding

6

Spark plug

7

High-voltage connection via spring contact

8

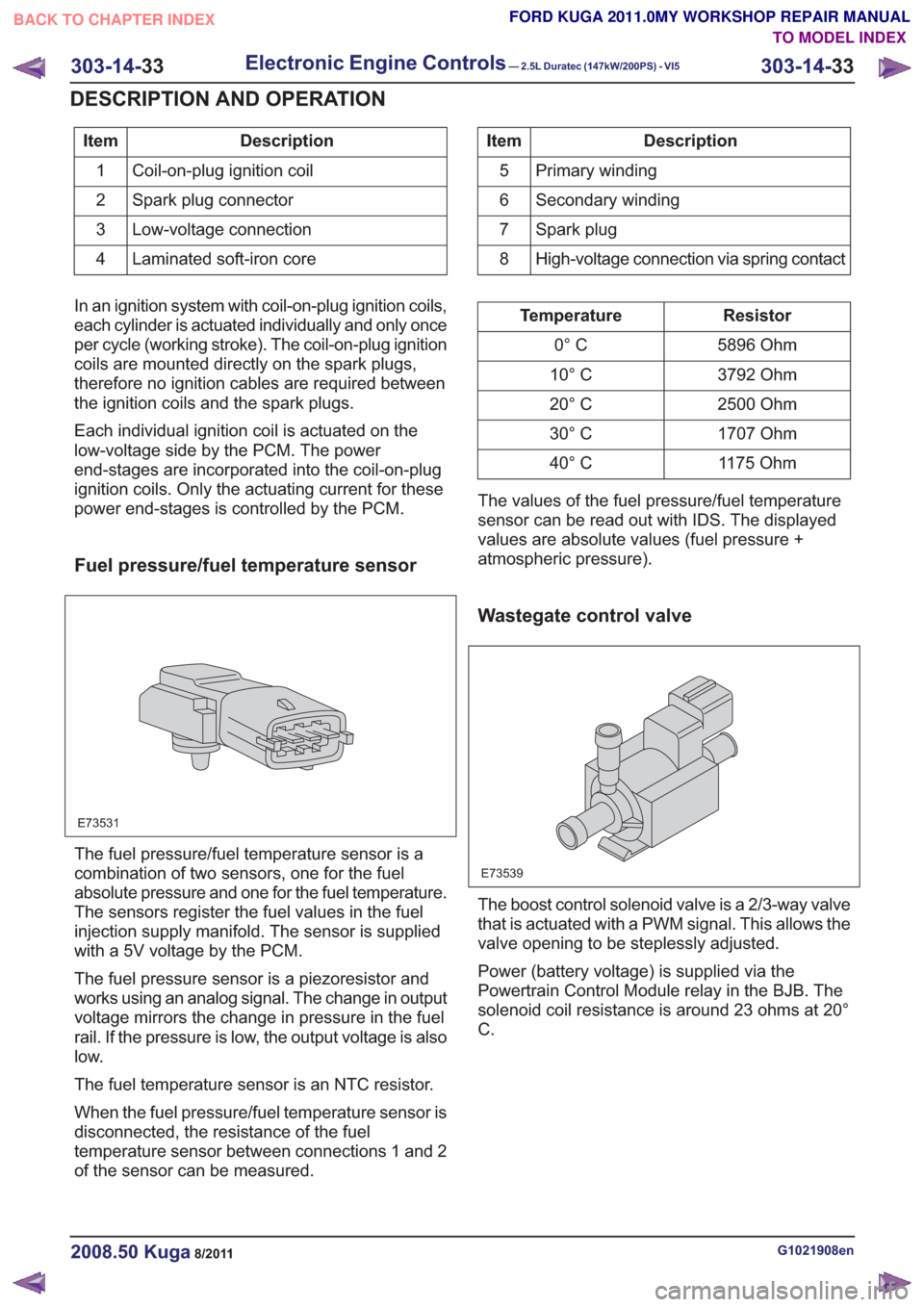

In an ignition system with coil-on-plug ignition coils,

each cylinder is actuated individually and only once

per cycle (working stroke). The coil-on-plug ignition

coils are mounted directly on the spark plugs,

therefore no ignition cables are required between

the ignition coils and the spark plugs.

Each individual ignition coil is actuated on the

low-voltage side by the PCM. The power

end-stages are incorporated into the coil-on-plug

ignition coils. Only the actuating current for these

power end-stages is controlled by the PCM.

Fuel pressure/fuel temperature sensor

E73531

The fuel pressure/fuel temperature sensor is a

combination of two sensors, one for the fuel

absolute pressure and one for the fuel temperature.

The sensors register the fuel values in the fuel

injection supply manifold. The sensor is supplied

with a 5V voltage by the PCM.

The fuel pressure sensor is a piezoresistor and

works using an analog signal. The change in output

voltage mirrors the change in pressure in the fuel

rail. If the pressure is low, the output voltage is also

low.

The fuel temperature sensor is an NTC resistor.

When the fuel pressure/fuel temperature sensor is

disconnected, the resistance of the fuel

temperature sensor between connections 1 and 2

of the sensor can be measured.

Resistor

Temperature

5896 Ohm

0° C

3792 Ohm

10° C

2500 Ohm

20° C

1707 Ohm

30° C

1175 Ohm

40° C

The values of the fuel pressure/fuel temperature

sensor can be read out with IDS. The displayed

values are absolute values (fuel pressure +

atmospheric pressure).

Wastegate control valve

E73539

The boost control solenoid valve is a 2/3-way valve

that is actuated with a PWM signal. This allows the

valve opening to be steplessly adjusted.

Power (battery voltage) is supplied via the

Powertrain Control Module relay in the BJB. The

solenoid coil resistance is around 23 ohms at 20°

C.

G1021908en2008.50 Kuga8/2011

303-14- 33

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

33

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1969 of 2057

SECTION 310-00 Fuel System - General Information

VEHICLE APPLICATION:2008.50 Kuga

PA G E

CONTENTS

DIAGNOSIS AND TESTING

310-00-2

Fuel System — Vehicles With: Fuel Additive Tank .............................................................

310-00-2

Principles of Operation ........................................................................\

...............................

310-00-2

Inspection and Verification ........................................................................\

..........................

GENERAL PROCEDURES 310-00-3

Spring Lock Couplings ........................................................................\

................................

310-00-3

Disconnect ........................................................................\

..................................................

310-00-5

Connect ........................................................................\

......................................................

310-00-6

Quick Release Coupling ........................................................................\

.............................

310-00-6

Disconnect ........................................................................\

..................................................

310-00-7

Connect ........................................................................\

......................................................

310-00-8

Fuel System Pressure Check — 2.5L Duratec (162kW/220PS) - VI5 ................................

310-00-10

Fuel System Pressure Release ........................................................................\

..................

310-00-10

Release ........................................................................\

......................................................

310-00-11

Fuel Tank Draining ........................................................................\

......................................

310-00-1

Fuel System - General Information

310-00- 1

.

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1971 of 2057

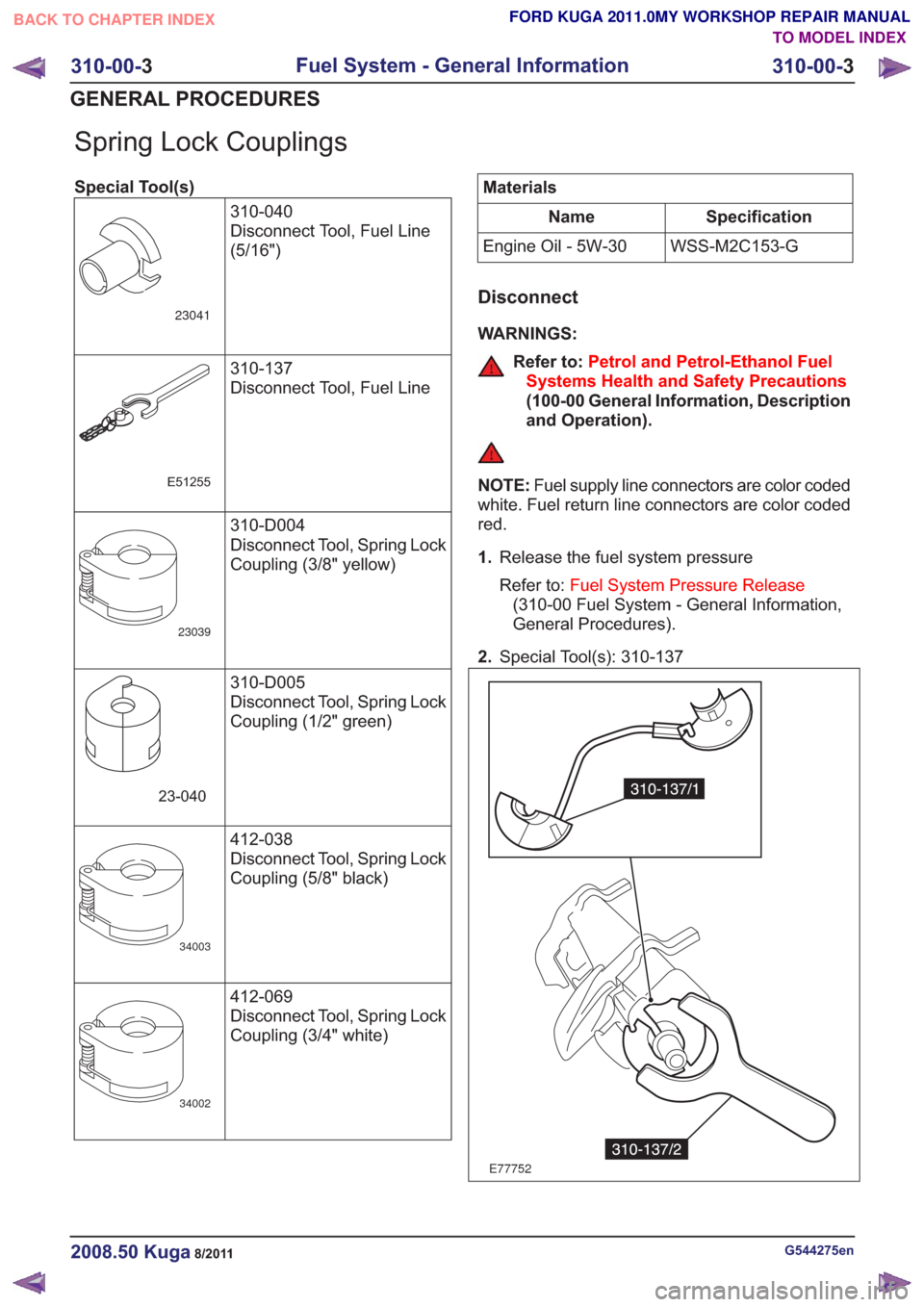

Spring Lock Couplings

Special Tool(s)310-040

Disconnect Tool, Fuel Line

(5/16")

23041

310-137

Disconnect Tool, Fuel Line

E51255

310-D004

Disconnect Tool, Spring Lock

Coupling (3/8" yellow)

23039

310-D005

Disconnect Tool, Spring Lock

Coupling (1/2" green)

23-040

412-038

Disconnect Tool, Spring Lock

Coupling (5/8" black)

34003

412-069

Disconnect Tool, Spring Lock

Coupling (3/4" white)

34002

Materials

Specification

Name

WSS-M2C153-G

Engine Oil - 5W-30

Disconnect

WARNINGS:

Refer to: Petrol and Petrol-Ethanol Fuel

Systems Health and Safety Precautions

(100-00 General Information, Description

and Operation).

NOTE: Fuel supply line connectors are color coded

white. Fuel return line connectors are color coded

red.

1. Release the fuel system pressure

Refer to: Fuel System Pressure Release

(310-00 Fuel System - General Information,

General Procedures).

2. Special Tool(s): 310-137

E77752

G544275en2008.50 Kuga8/2011

310-00- 3

Fuel System - General Information

310-00- 3

GENERAL PROCEDURES

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1987 of 2057

Description

Item

Latch mechanism

1

Housing, capless fuel filler pipe

2

Overflow

3Description

Item

Gasket

4

Filler nozzle

5

A spring-loaded fuel filler door closes off the upper

end of the fuel tank filler pipe in place of the filler

cap. The spring-loaded fuel filler door features a

latching mechanism. The release mechanism is

matched to the size of the filler nozzle. If the correct

filler nozzle is inserted, the release lugs are pushed

back. This releases the slide which can move

upwards and opens the way to the spring-loaded

fuel filler door for the filler nozzle.

G1090887en2008.50 Kuga8/2011

310-01- 7

Fuel Tank and Lines

310-01- 7

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL