spring FORD KUGA 2011 1.G Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1549 of 2057

Engine – System Operation and Component Description

System Operation

The variable camshaft timing occurs

electro-hydraulically and individually for both

camshafts.

The camshaft adjusters work according to the vane

cell principle and have an adjustment range of 52°

crank angle on the intake side and 47° crank angle

on the exhaust side. On starting the engine and

during idling, both camshafts are mechanically

locked in their starting positions. The exhaust

camshaft is in the early position and the intake

camshaft is in the late position. The camshaftadjuster on the exhaust side has a torsion spring

which compensates the camshaft drive torque.

This ensures that the assembly can return to the

starting position under all operating conditions and

when the engine is turned off.

Internal exhaust gas recirculation can be realized

through continuous adjustment of the timings. This

results in better fuel consumption and more

favorable combustion temperatures which produce

less pollutants. This means that pollutant level IV

can be adhered to with a 3-way catalytic converter.

The variable timings also make it possible to

optimize performance with wide open throttle.

G1032416en2008.50 Kuga8/2011

303-01-

16

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

16

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1550 of 2057

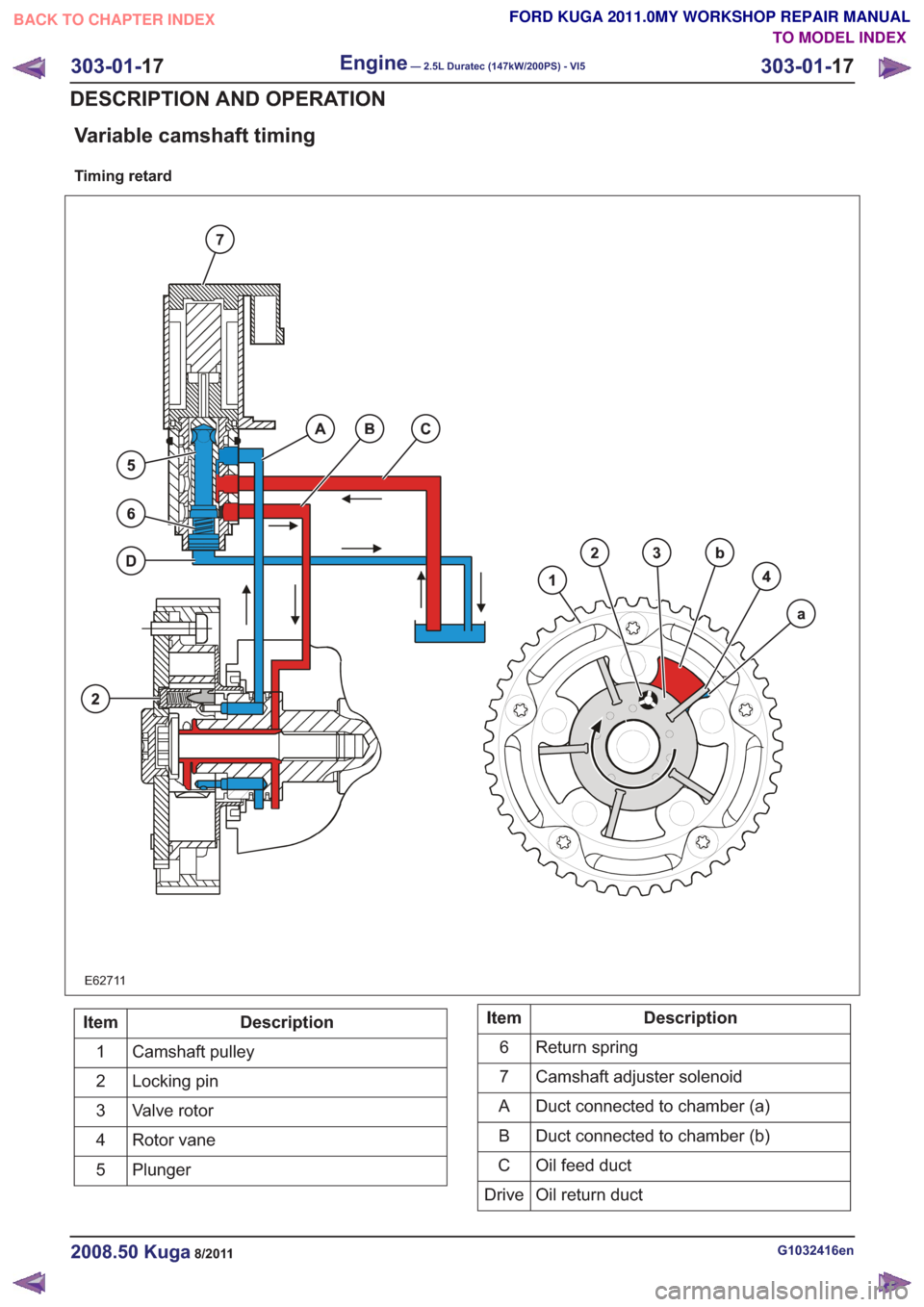

Variable camshaft timing

Timing retard

E62711

Description

Item

Camshaft pulley

1

Locking pin

2

Valve rotor

3

Rotor vane

4

Plunger

5Description

Item

Return spring

6

Camshaft adjuster solenoid

7

Duct connected to chamber (a)

A

Duct connected to chamber (b)

B

Oil feed duct

C

Oil return duct

Drive

G1032416en2008.50 Kuga8/2011

303-01- 17

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

17

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1556 of 2057

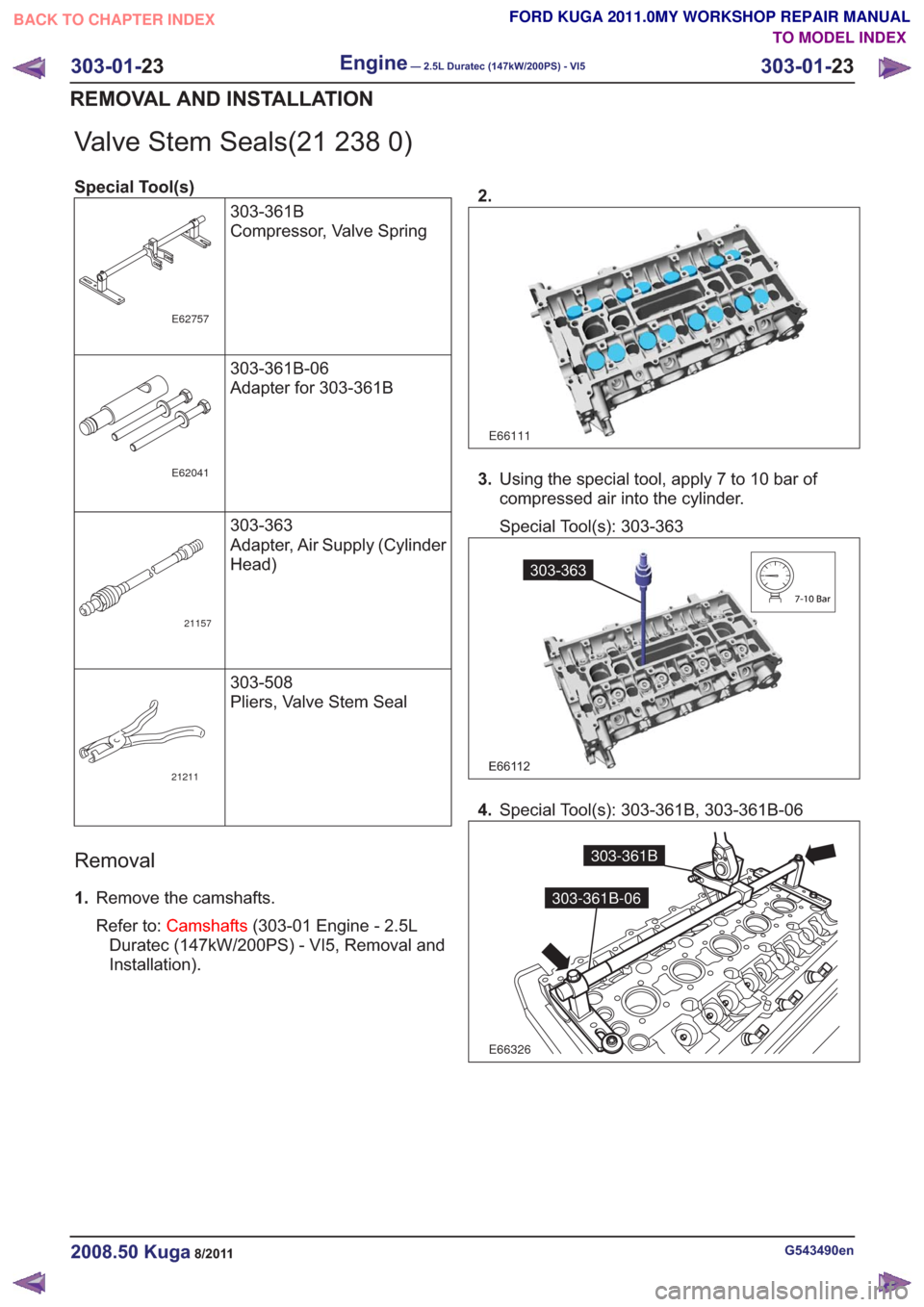

Valve Stem Seals(21 238 0)

Special Tool(s)303-361B

Compressor, Valve Spring

E62757

303-361B-06

Adapter for 303-361B

E62041

303-363

Adapter, Air Supply (Cylinder

Head)

21157

303-508

Pliers, Valve Stem Seal

21211

Removal

1.Remove the camshafts.

Refer to: Camshafts (303-01 Engine - 2.5L

Duratec (147kW/200PS) - VI5, Removal and

Installation). 2.

E66111

3.

Using the special tool, apply 7 to 10 bar of

compressed air into the cylinder.

Special Tool(s): 303-363

E66112

303-363

4.Special Tool(s): 303-361B, 303-361B-06

E66326

303-361B

303-361B-06

G543490en2008.50 Kuga8/2011

303-01- 23

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

23

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1560 of 2057

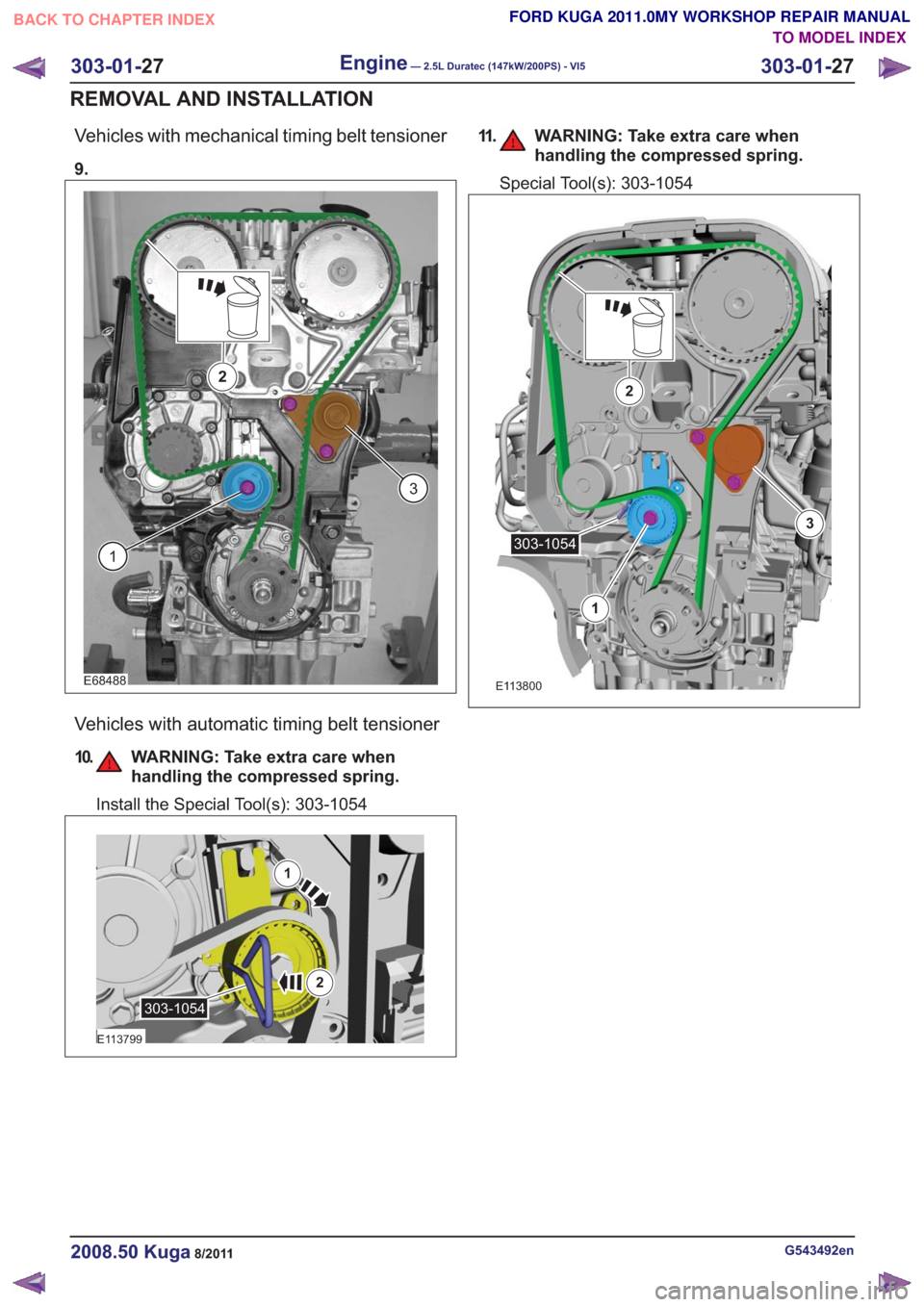

Vehicles with mechanical timing belt tensioner

9.

E68488

1

3

2

Vehicles with automatic timing belt tensioner

10. WARNING: Take extra care whenhandling the compressed spring.

Install the Special Tool(s): 303-1054

1

2

E113799

303-1054

11. WARNING: Take extra care whenhandling the compressed spring.

Special Tool(s): 303-1054

E113800

1

2

3

303-1054

G543492en2008.50 Kuga8/2011

303-01- 27

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

27

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1561 of 2057

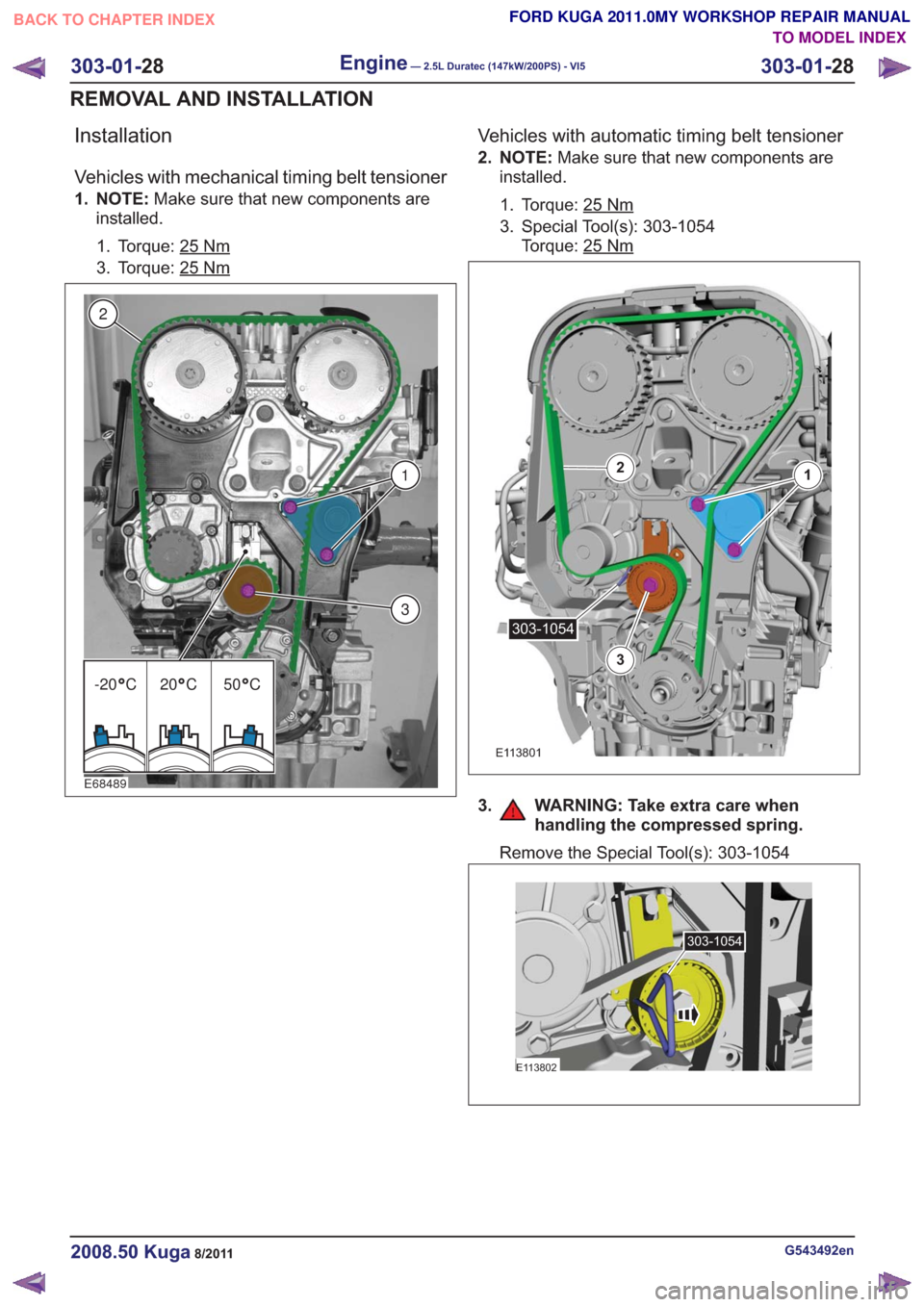

Installation

Vehicles with mechanical timing belt tensioner

1. NOTE:Make sure that new components are

installed.

1. Torque: 25

Nm

3. Torque: 25Nm

E68489

3

1

2

-20 C 20 C 50 C

Vehicles with automatic timing belt tensioner

2. NOTE: Make sure that new components are

installed.

1. Torque: 25

Nm

3. Special Tool(s): 303-1054 Torque: 25

Nm

E113801

12

3

303-1054

3. WARNING: Take extra care when handling the compressed spring.

Remove the Special Tool(s): 303-1054

E113802

303-1054

G543492en2008.50 Kuga8/2011

303-01- 28

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

28

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1573 of 2057

Vehicles with automatic timing belt tensioner

7. NOTE:Make sure that new components are

installed.

1. Torque: 25

Nm

3. Special Tool(s): 303-1054 Torque: 25

Nm

E113801

12

3

303-1054

8. WARNING: Take extra care when handling the compressed spring.

Remove the Special Tool(s): 303-1054

E113802

303-1054

All vehicles

9.Torque: 120Nm

E68746

10.Remove the Special Tool(s): 303-1178

E66324

303-1178

11 .Remove the Special Tool(s): 303-1182

E66328

303-1182

G1166799en2008.50 Kuga8/2011

303-01- 40

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

40

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1618 of 2057

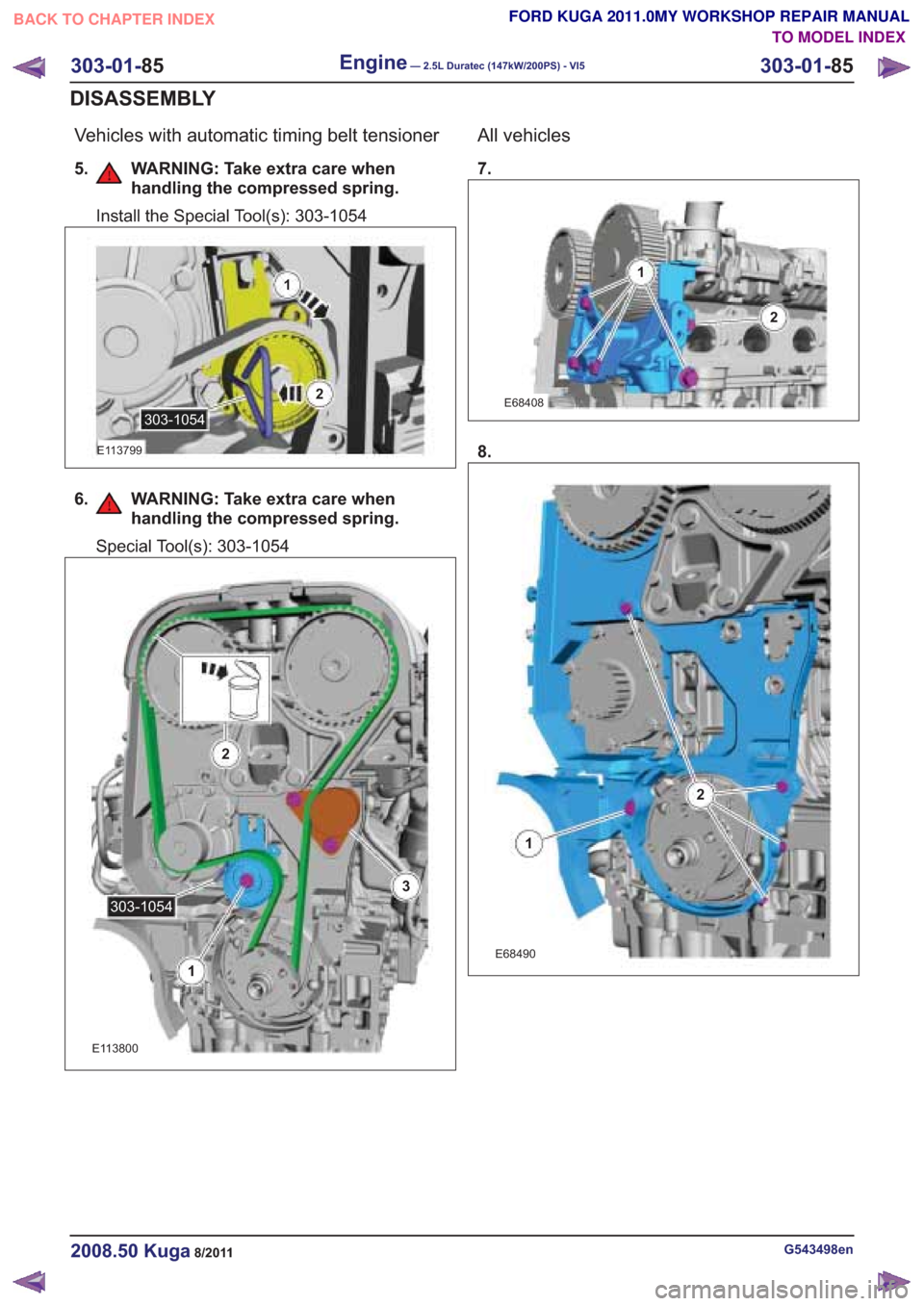

Vehicles with automatic timing belt tensioner

5. WARNING: Take extra care whenhandling the compressed spring.

6. WARNING: Take extra care whenhandling the compressed spring.

All vehicles

7.

G543498en2008.50 Kuga8/2011

303-01- 85

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

85

DISASSEMBLY

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Install the Special Tool(s): 303-1054

1

2

E113799

303-1054

Special Tool(s): 303-1054

E113800

1

2

3

303-1054

E68408

1

2

8.

E68490

1

2

Page 1626 of 2057

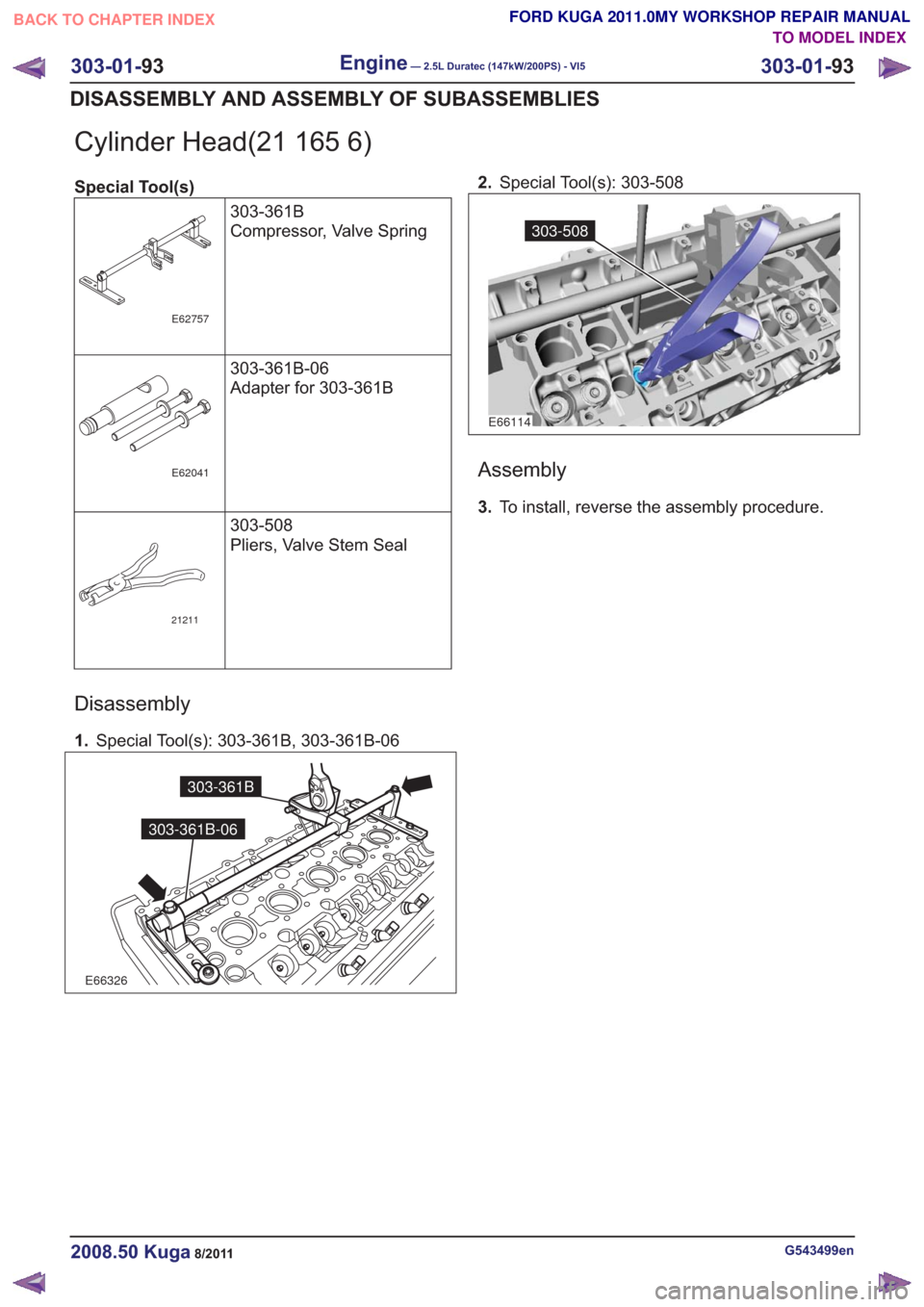

Cylinder Head(21 165 6)

Special Tool(s)303-361B

Compressor, Valve Spring

E62757

303-361B-06

Adapter for 303-361B

E62041

303-508

Pliers, Valve Stem Seal

21211

Disassembly

1.Special Tool(s): 303-361B, 303-361B-06

E66326

303-361B

303-361B-06

2.Special Tool(s): 303-508

E66114

303-508

Assembly

3.To install, reverse the assembly procedure.

G543499en2008.50 Kuga8/2011

303-01- 93

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

93

DISASSEMBLY AND ASSEMBLY OF SUBASSEMBLIES

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1641 of 2057

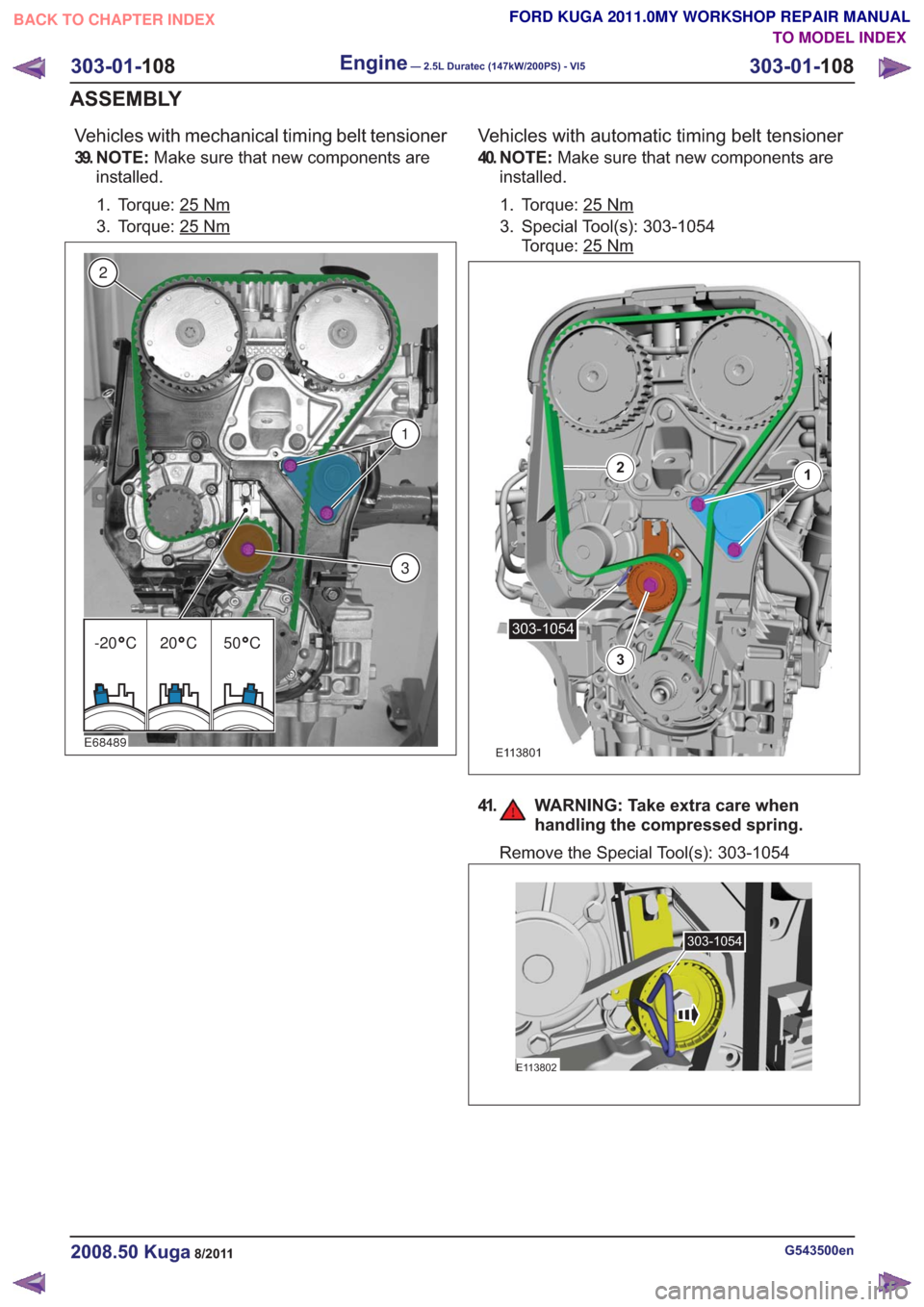

Vehicles with mechanical timing belt tensioner

39. N O T E :Make sure that new components are

installed.

1. Torque: 25

Nm

3. Torque: 25Nm

E68489

3

1

2

-20 C 20 C 50 C

Vehicles with automatic timing belt tensioner

40. N O T E : Make sure that new components are

installed.

1. Torque: 25

Nm

3. Special Tool(s): 303-1054 Torque: 25

Nm

E113801

12

3

303-1054

41. WARNING: Take extra care when handling the compressed spring.

Remove the Special Tool(s): 303-1054

E113802

303-1054

G543500en2008.50 Kuga8/2011

303-01- 108

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

108

ASSEMBLY

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1720 of 2057

Turbocharger – Overview

Turbocharger(s)

CAUTION: Do not switch off the engine

while it is running at high speed. If the

engine is switched off while it is running

at high speed, the turbocharger will

continue to run after the engine oil

pressure has already dropped to zero. This

will cause premature wear in the

turbocharger bearings.

A TC consists of an exhaust turbine located in the

exhaust gas flow, this turbine is connected to a

compressor by a shaft. The turbine is made to

rotate by the exhaust gas flow from the engine and

thus drives the compressor. The compressor

increases the pressure in the engine intake tract

so that a greater mass of air enters the cylinder

during the intake stroke.

The turbine housing of the TC is integrated into the

exhaust manifold. This construction offers

thermodynamic advantages compared with the

usual construction, the maximum exhaust

temperature is up to 1050°C.

The maximum boost pressure is 0.65 bar.

The exhaust manifold is secured to the exhaust

side of the cylinder head with 12 self-locking nuts.

The exhaust manifold gasket is a multi-layer steel

gasket and cannot be reused. In order to

compensate for the thermal expansion of the

exhaust manifold, the flange of the TC is provided

with two grooves.

The TC and the exhaust manifold are joined by a

hose clip. The hose clip must not be loosened or

removed. The TC and the exhaust manifold are

not available as separate replacement parts,

exchange is only possible as a complete unit.

The turbocharger heat shield is secured to the

exhaust manifold by four bolts. Two of the bolts

have spring washers underneath their heads.

During removal, make a note of the installation

location of the spring washers to refer to during

installation.

The recirculated air valve is built into the TC

housing and cannot be changed.

The Ford diagnostic unit can test the operation of

the wastegate control valve using actuator

diagnosis.

The boost pressure regulator is set in the factory.

Adjustments to the boost pressure regulator must never be attempted. A red colored seal is applied

to the adjustment nut of the operating rod, in order

to monitor the factory setting of the boost pressure.

The bearings of the TC are lubricated with engine

oil. The engine oil passes from the cylinder block

through the oil supply pipe to the TC. The oil is

returned to the oil pan through the oil return pipe,

The TC is cooled by the engine coolant circuit.

When installing hoses and lines, make certain that

their ends are free of oil residues and dirt.

G1032425en2008.50 Kuga8/2011

303-04B-

4

Fuel Charging and Controls - Turbocharger

—

2.5L Duratec (147kW/200PS) - VI5

303-04B- 4

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL