engine remove FORD KUGA 2011 1.G Manual PDF

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1706 of 2057

Action

Possible Sources

Symptom

• CHECK for signs of contamina-tion such as strange odors from

the fuel tank.

• If contaminated fuel is found, DRAIN the complete fuel

system. FLUSH the fuel system

through with clean gasoline.

REFER to: Fuel Tank Draining

(310-00 Fuel System -

General Information, General

Procedures).

INSTALL a new fuel filter.

• INSPECT the fuel injectors. CLEAN the fuel injectors or

INSTALL a new set of injectors

as required only after the

checks have been carried out.

REFER to: Fuel Injectors (303-

04 Fuel Charging and

Controls - 2.5L Duratec

(147kW/200PS) - VI5,

Removal and Installation).

• INSTALL a new fuel rail.

REFER to: Fuel Rail(303-04

Fuel Charging and Controls -

2.5L Duratec (147kW/200PS)

- VI5, Removal and Installa-

tion).

• Incorrect or contaminated fuel.

• White smoke

• CARRY OUT a cooling systempressure test.

REFER to: Engine Cooling

(303-03 Engine Cooling,

Diagnosis and Testing).

• REMOVE the cylinder head. INSPECT the cylinder head,

cylinder head gasket and

cylinder bores for wear or

damage.

REFER to: Cylinder Head (303-

01 Engine - 2.5L Duratec

(147kW/200PS) - VI5,

Removal and Installation).

• Coolant in the combustion

chamber.

G1183441en2008.50 Kuga8/2011

303-04A- 15

Fuel Charging and Controls

— 2.5L Duratec (147kW/200PS) -

VI5

303-04A- 15

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1708 of 2057

Action

Possible Sources

Symptom

• INSPECT the fuel injectors.CLEAN the fuel injectors or

INSTALL a new set of injectors

as required only after the

checks have been carried out.

REFER to: Fuel Injectors (303-

04 Fuel Charging and

Controls - 2.5L Duratec

(147kW/200PS) - VI5,

Removal and Installation).

• Fuel injectors.

• Carry out a full enginediagnosis using the guided

diagnostic menu in the Ford

diagnostic equipment.

• Fuel rail fuel pressure sensor.

• CHECK the engine compres-sion.

REFER to: Engine(303-00

Engine System - General

Information, Diagnosis and

Testing).

• Low cylinder compression.

• REMOVE the cylinder head.INSPECT the cylinder head,

valves, tappets and camshafts

for signs of wear or damage.

REFER to: Cylinder Head (303-

01 Engine - 2.5L Duratec

(147kW/200PS) - VI5,

Removal and Installation).

• Worn or damaged valve(s),

tappet(s) or camshaft(s).

• REMOVE the cylinder head.INSPECT the cylinder head

gasket and cylinder bores for

wear or damage.

REFER to: Cylinder Head (303-

01 Engine - 2.5L Duratec

(147kW/200PS) - VI5,

Removal and Installation).

• Damaged cylinder head gasket.

• CHECK the engine oil level.REFILL as necessary.

• Low engine oil level.

• Engine knock at idle

G1183441en2008.50 Kuga8/2011

303-04A- 17

Fuel Charging and Controls

— 2.5L Duratec (147kW/200PS) -

VI5

303-04A- 17

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1710 of 2057

Action

Possible Sources

Symptom

• CHECK the valve timing.REFER to: Timing Belt (303-01

Engine - 2.5L Duratec

(147kW/200PS) - VI5,

Removal and Installation).

• Incorrect valve timing.

• REMOVE the cylinder head.INSPECT the cylinder head

and pistons for signs carbon

build up.

REFER to: Cylinder Head (303-

01 Engine - 2.5L Duratec

(147kW/200PS) - VI5,

Removal and Installation).

• Excessive carbon build up.

• INSPECT the engine compon-ents.

• Worn or damaged oil pump.

• Worn or damaged timing chain

or sprocket.

• Major mechanical engine failure.

• Carry out a full enginediagnosis using the guided

diagnostic menu in the Ford

diagnostic equipment.

• KS.

• Engine knock during accelera-

tion

• INSPECT the fuel injectors.CLEAN the fuel injectors or

INSTALL a new set of injectors

as required only after the

checks have been carried out.

REFER to: Fuel Injectors (303-

04 Fuel Charging and

Controls - 2.5L Duratec

(147kW/200PS) - VI5,

Removal and Installation).

• Fuel injectors.

• REFER to:Engine(303-00

Engine System - General

Information, Diagnosis and

Testing).

• Major mechanical engine

failure.

• CHECK the braking system.REFER to: Brake System (206-

00 Brake System - General

Information, Diagnosis and

Testing).

• Brakes binding.

• Excessive fuel consumption

• ADVISE the customer aboutthe effects of overloading the

vehicle and wind resistance on

the fuel consumption.

• Vehicle overloaded, or

excessive wind resistance (roof

racks, towing etc).

• INSTALL a new air cleanerelement.

• Air cleaner element blocked.

G1183441en2008.50 Kuga8/2011

303-04A-

19

Fuel Charging and Controls

— 2.5L Duratec (147kW/200PS) -

VI5

303-04A- 19

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1720 of 2057

Turbocharger – Overview

Turbocharger(s)

CAUTION: Do not switch off the engine

while it is running at high speed. If the

engine is switched off while it is running

at high speed, the turbocharger will

continue to run after the engine oil

pressure has already dropped to zero. This

will cause premature wear in the

turbocharger bearings.

A TC consists of an exhaust turbine located in the

exhaust gas flow, this turbine is connected to a

compressor by a shaft. The turbine is made to

rotate by the exhaust gas flow from the engine and

thus drives the compressor. The compressor

increases the pressure in the engine intake tract

so that a greater mass of air enters the cylinder

during the intake stroke.

The turbine housing of the TC is integrated into the

exhaust manifold. This construction offers

thermodynamic advantages compared with the

usual construction, the maximum exhaust

temperature is up to 1050°C.

The maximum boost pressure is 0.65 bar.

The exhaust manifold is secured to the exhaust

side of the cylinder head with 12 self-locking nuts.

The exhaust manifold gasket is a multi-layer steel

gasket and cannot be reused. In order to

compensate for the thermal expansion of the

exhaust manifold, the flange of the TC is provided

with two grooves.

The TC and the exhaust manifold are joined by a

hose clip. The hose clip must not be loosened or

removed. The TC and the exhaust manifold are

not available as separate replacement parts,

exchange is only possible as a complete unit.

The turbocharger heat shield is secured to the

exhaust manifold by four bolts. Two of the bolts

have spring washers underneath their heads.

During removal, make a note of the installation

location of the spring washers to refer to during

installation.

The recirculated air valve is built into the TC

housing and cannot be changed.

The Ford diagnostic unit can test the operation of

the wastegate control valve using actuator

diagnosis.

The boost pressure regulator is set in the factory.

Adjustments to the boost pressure regulator must never be attempted. A red colored seal is applied

to the adjustment nut of the operating rod, in order

to monitor the factory setting of the boost pressure.

The bearings of the TC are lubricated with engine

oil. The engine oil passes from the cylinder block

through the oil supply pipe to the TC. The oil is

returned to the oil pan through the oil return pipe,

The TC is cooled by the engine coolant circuit.

When installing hoses and lines, make certain that

their ends are free of oil residues and dirt.

G1032425en2008.50 Kuga8/2011

303-04B-

4

Fuel Charging and Controls - Turbocharger

—

2.5L Duratec (147kW/200PS) - VI5

303-04B- 4

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1727 of 2057

Turbocharger(23 612 0)

General EquipmentCable Ties

Hose Clamp Remover/Installer

Materials

Specification

Name

SA-M1C9107-A / YS5J-

M1C9107-AA

Grease KS-PS

Removal

NOTE:

Removal steps in this procedure may

contain installation details.

1. Refer to: Battery Disconnect and Connect

(414-01 Battery, Mounting and Cables,

General Procedures).

2. Refer to: Cooling System Draining and Vacuum

Filling (303-03 Engine Cooling, General

Procedures).

3. Refer to: Cowl Panel Grille (501-02 Front End

Body Panels, Removal and Installation).

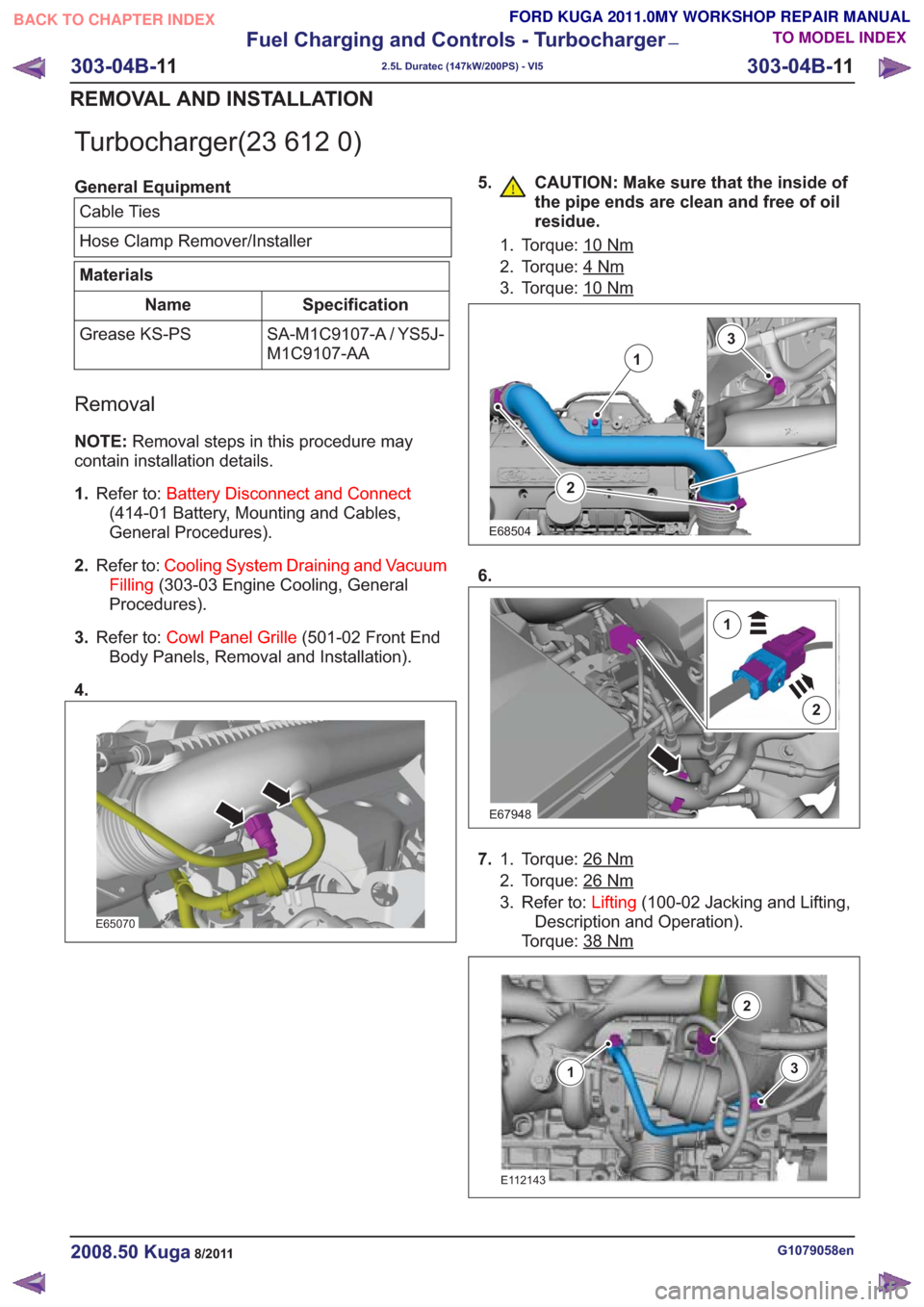

4.

E65070

5. CAUTION: Make sure that the inside of the pipe ends are clean and free of oil

residue.

1. Torque: 10Nm

2. Torque: 4Nm

3. Torque: 10Nm

2

1

3

E68504

6.

E67948

2

1

7.Torque: 26Nm1.

2. Torque: 26

Nm

3. Refer to: Lifting(100-02 Jacking and Lifting,

Description and Operation).

Torque: 38

Nm

E112143

3

2

1

G1079058en2008.50 Kuga8/2011

303-04B- 11

Fuel Charging and Controls - Turbocharger

—

2.5L Duratec (147kW/200PS) - VI5

303-04B- 11

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1736 of 2057

VUE0037806

4. If the cause is not visually evident, verify thesymptom and refer to the Symptom Chart.

Symptom Chart

Action

Possible Sources

Symptom

• CHECK the system with theengine running and the

accessory drive belt removed

(only run the engine for a very

short period). If a noise is

apparent, the cause is not the

accessory drive system. If a

noise is not apparent, the

cause is the accessory drive

system. CHECK where the

noise is coming from. Use a

stethoscope or other listening

device to determine the source

of the noise. INSTALL new

components as necessary.

TEST the system for normal

operation.

• Accessory drive system

• Accessory drive belt noise

• CHECK the accessory drivebelt is correctly installed in the

pulley grooves. INSTALL a new

accessory drive belt as neces-

sary.

REFER to: Accessory Drive

Belt (303-05 Accessory Drive

- 2.5L Duratec

(147kW/200PS) - VI5,

Removal and Installation).

and/or

REFER to: Air Conditioning

(A/C) Compressor Belt (303-

05 Accessory Drive - 2.5L

Duratec (147kW/200PS) -

VI5, Removal and Installa-

tion).

TEST the system for normal

operation.

• Accessory drive belt incorrectly

installed.

G1183443en2008.50 Kuga8/2011

303-05- 6

Accessory Drive— 2.5L Duratec (147kW/200PS) - VI5303-05-

6

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1738 of 2057

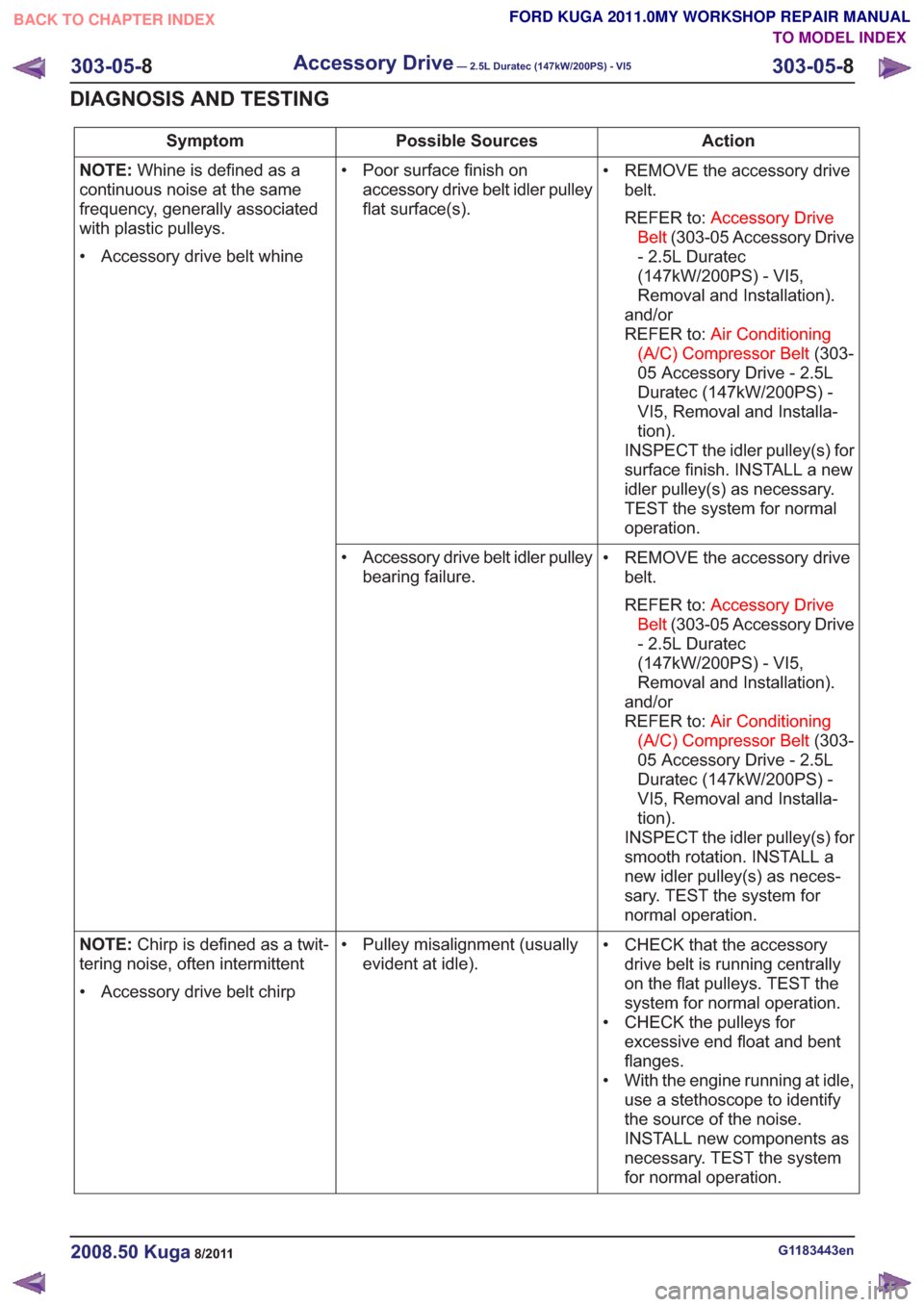

Action

Possible Sources

Symptom

• REMOVE the accessory drivebelt.

REFER to: Accessory Drive

Belt (303-05 Accessory Drive

- 2.5L Duratec

(147kW/200PS) - VI5,

Removal and Installation).

and/or

REFER to: Air Conditioning

(A/C) Compressor Belt (303-

05 Accessory Drive - 2.5L

Duratec (147kW/200PS) -

VI5, Removal and Installa-

tion).

INSPECT the idler pulley(s) for

surface finish. INSTALL a new

idler pulley(s) as necessary.

TEST the system for normal

operation.

• Poor surface finish on

accessory drive belt idler pulley

flat surface(s).

NOTE:

Whine is defined as a

continuous noise at the same

frequency, generally associated

with plastic pulleys.

• Accessory drive belt whine

• REMOVE the accessory drivebelt.

REFER to: Accessory Drive

Belt (303-05 Accessory Drive

- 2.5L Duratec

(147kW/200PS) - VI5,

Removal and Installation).

and/or

REFER to: Air Conditioning

(A/C) Compressor Belt (303-

05 Accessory Drive - 2.5L

Duratec (147kW/200PS) -

VI5, Removal and Installa-

tion).

INSPECT the idler pulley(s) for

smooth rotation. INSTALL a

new idler pulley(s) as neces-

sary. TEST the system for

normal operation.

• Accessory drive belt idler pulley

bearing failure.

• CHECK that the accessorydrive belt is running centrally

on the flat pulleys. TEST the

system for normal operation.

• CHECK the pulleys for excessive end float and bent

flanges.

• With the engine running at idle, use a stethoscope to identify

the source of the noise.

INSTALL new components as

necessary. TEST the system

for normal operation.

• Pulley misalignment (usually

evident at idle).

NOTE:

Chirp is defined as a twit-

tering noise, often intermittent

• Accessory drive belt chirp

G1183443en2008.50 Kuga8/2011

303-05- 8

Accessory Drive— 2.5L Duratec (147kW/200PS) - VI5303-05-

8

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1782 of 2057

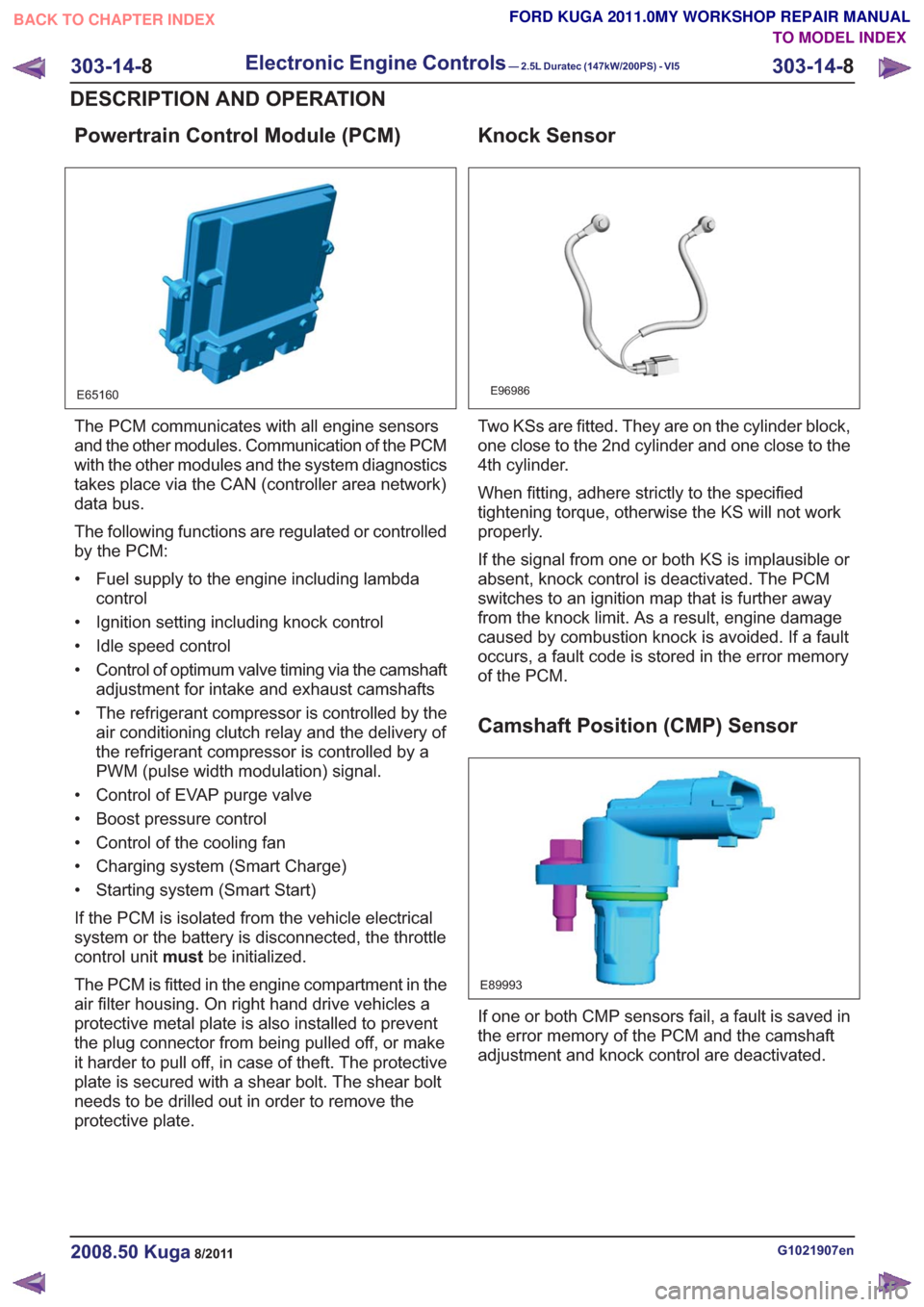

Powertrain Control Module (PCM)

E65160

The PCM communicates with all engine sensors

and the other modules. Communication of the PCM

with the other modules and the system diagnostics

takes place via the CAN (controller area network)

data bus.

The following functions are regulated or controlled

by the PCM:

• Fuel supply to the engine including lambdacontrol

• Ignition setting including knock control

• Idle speed control

• Control of optimum valve timing via the camshaft adjustment for intake and exhaust camshafts

• The refrigerant compressor is controlled by the air conditioning clutch relay and the delivery of

the refrigerant compressor is controlled by a

PWM (pulse width modulation) signal.

• Control of EVAP purge valve

• Boost pressure control

• Control of the cooling fan

• Charging system (Smart Charge)

• Starting system (Smart Start)

If the PCM is isolated from the vehicle electrical

system or the battery is disconnected, the throttle

control unit mustbe initialized.

The PCM is fitted in the engine compartment in the

air filter housing. On right hand drive vehicles a

protective metal plate is also installed to prevent

the plug connector from being pulled off, or make

it harder to pull off, in case of theft. The protective

plate is secured with a shear bolt. The shear bolt

needs to be drilled out in order to remove the

protective plate.

Knock Sensor

E96986

Two KSs are fitted. They are on the cylinder block,

one close to the 2nd cylinder and one close to the

4th cylinder.

When fitting, adhere strictly to the specified

tightening torque, otherwise the KS will not work

properly.

If the signal from one or both KS is implausible or

absent, knock control is deactivated. The PCM

switches to an ignition map that is further away

from the knock limit. As a result, engine damage

caused by combustion knock is avoided. If a fault

occurs, a fault code is stored in the error memory

of the PCM.

Camshaft Position (CMP) Sensor

E89993

If one or both CMP sensors fail, a fault is saved in

the error memory of the PCM and the camshaft

adjustment and knock control are deactivated.

G1021907en2008.50 Kuga8/2011

303-14- 8

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

8

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1797 of 2057

Calculation of valve timing adjustment

angle

The 2.5L Duratec (VI5) engine has two camshaft

adjustment units which work independently of each

other.

One camshaft adjustment solenoid is installed for

each intake camshaft and exhaust camshaft.

This allows the PCM to continuously adjust the

intake and exhaust-side camshaft adjustments

independently of one another. The timing is

adjusted by the PCM using curves; adjustment is

primarily done as a function of engine load and

engine speed.

In this way the engine performance is increased

and internal exhaust gas recirculation is realized.

The advantages of camshaft adjustment are as

follows:

• Higher torque and improved torquecharacteristics

• Reduced fuel consumption

• Improved emissions performance

The camshaft adjustment solenoids are actuated

by the PWM by means of a PCM signal.

Continuous adjustment of the camshafts by the

PCM is achieved by means of the camshaft

adjustment solenoids, the camshaft adjustment

units and two CMP sensors. A defined quantity of

engine is oil is supplied to or drained from the

adjustment units via the camshaft adjustment

solenoids. The existing EOP (engine oil pressure)

is taken into account in the process. In this way

the valve timings are adjusted according to the

operating condition of the engine. The camshaft

adjusters work according to the vane-cell principle.

On starting the engine, both camshafts are

mechanically locked in their starting positions. The

intake camshaft is in the maximum late position

and the exhaust camshaft in the maximum early

position.

Control is divided into four main areas:

• Low engine speed and low load

• Partial load

• Low engine speed and high load

• High engine speed and high load

At low engine speed and low load, the exhaust

valves open early and the intake valves open late.

The result is reduced fuel consumption and more

uniform idling. In the partial load range, the exhaust valves and

the intake valves open late. The late opening of

the exhaust valves results in a good utilization of

the expanding gases in the cylinder. Closing the

exhaust valves after Top Dead Center allows

internal exhaust gas recirculation through aspiration

of exhaust gases into the combustion chamber.

Moreover, the intake valves close after Bottom

Dead Centre, allowing the fresh air/fuel mixture

and exhaust gases to flow back into the intake

tract. The result is reduced fuel consumption and

low emissions.

At low engine speed and high engine load, the

exhaust valves open late and the intake valves

open early. Due to the resulting valve opening

overlap at Top Dead Centre, the pulsating gas

column within the combustion chamber is utilized

to achieve better charging of the combustion

chamber. The result is increased torque at lower

RPM.

At high engine speeds and high engine load, the

exhaust valves open early and the intake valves

close late. Because a rapid gas exchange must be

achieved at high engine speeds, the early opening

of the exhaust valves achieves better expulsion of

the exhaust gas and the late closing of the intake

valves improves cylinder charge efficiency.

Optimum power output is achieved.

Many other camshaft positions are possible in

addition to these settings.

In order to avoid a malfunction in the camshaft

adjustment units at excessively low ambient or

engine-oil temperatures, they are activated by the

PCM with a time delay via the camshaft adjustment

solenoids. The PCM receives the information

required for this from the ECT sensor and the

outside air temperature sensor.

When idling and during deceleration, the camshaft

adjustment solenoids are activated repeatedly by

the PCM in order to remove any dirt which may be

on the bore holes and ring grooves.

Boost pressure control

Optimum regulation is achieved by means of an

electronically-controlled solenoid valve, the boost

control solenoid valve.

Refer to:

Turbocharger (303-04 Fuel Charging and

Controls - Turbocharger - 2.5L Duratec

(147kW/200PS) - VI5, Description and

Operation).

G1021908en2008.50 Kuga8/2011

303-14- 23

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

23

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1815 of 2057

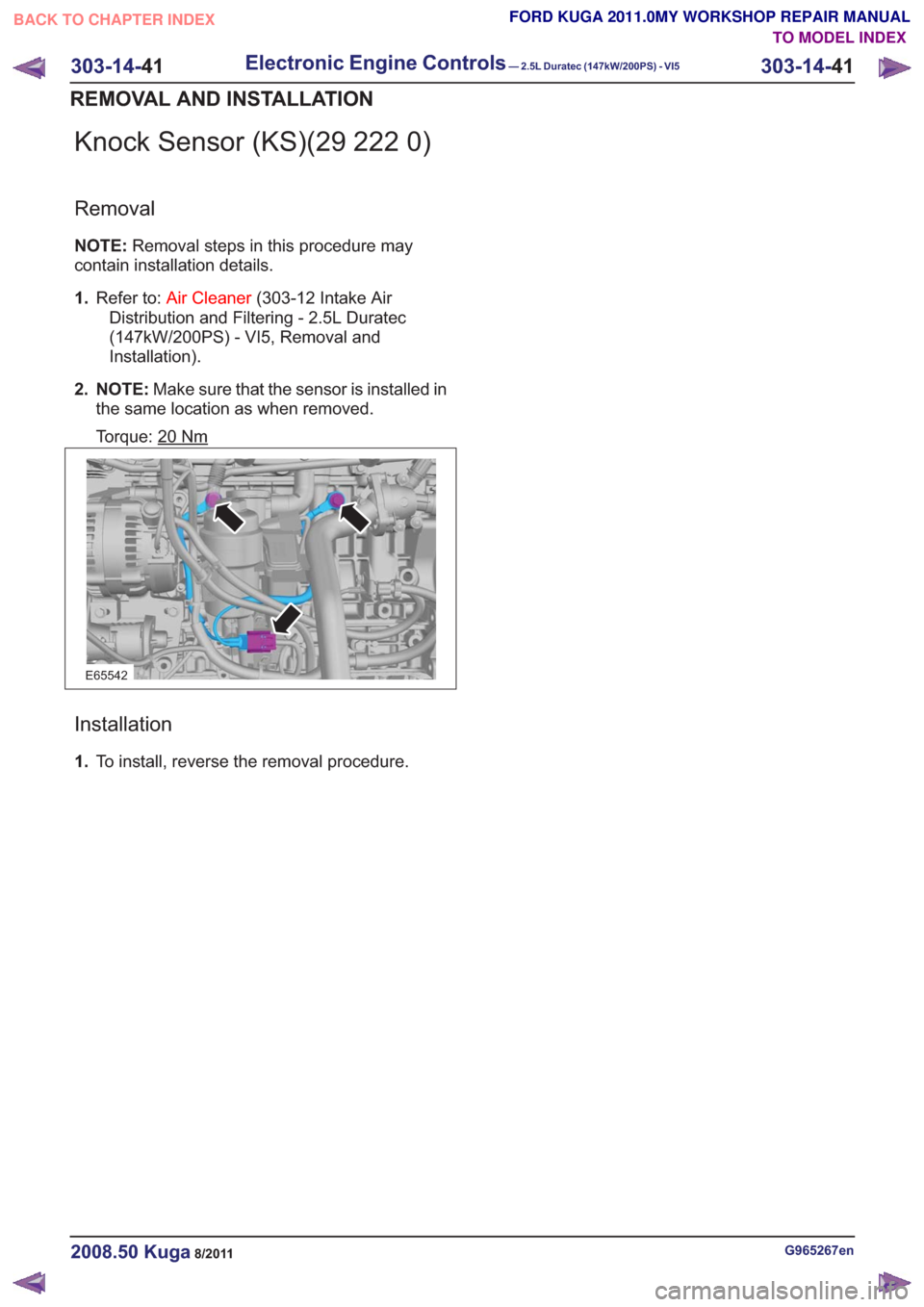

Knock Sensor (KS)(29 222 0)

Removal

NOTE:Removal steps in this procedure may

contain installation details.

1. Refer to: Air Cleaner (303-12 Intake Air

Distribution and Filtering - 2.5L Duratec

(147kW/200PS) - VI5, Removal and

Installation).

2. NOTE: Make sure that the sensor is installed in

the same location as when removed.

Torque: 20

Nm

E65542

Installation

1. To install, reverse the removal procedure.

G965267en2008.50 Kuga8/2011

303-14- 41

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

41

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL