light FORD MONDEO 1993 Service Manual Online

[x] Cancel search | Manufacturer: FORD, Model Year: 1993, Model line: MONDEO, Model: FORD MONDEO 1993Pages: 279, PDF Size: 12.71 MB

Page 181 of 279

Mix up a little filler on a clean piece of card

or board - measure the hardener carefully

(follow the maker’s instructions on the pack),

otherwise the filler will set too rapidly or too

slowly. Using the applicator, apply the filler

paste to the prepared area; draw the

applicator across the surface of the filler to

achieve the correct contour and to level the

surface. As soon as a contour that

approximates to the correct one is achieved,

stop working the paste - if you carry on too

long, the paste will become sticky and begin

to “pick-up” on the applicator. Continue to

add thin layers of filler paste at 20-minute

intervals, until the level of the filler is just

proud of the surrounding bodywork.

Once the filler has hardened, the excess

can be removed using a metal plane or file.

From then on, progressively-finer grades of

abrasive paper should be used, starting with a

40-grade production paper, and finishing with

a 400-grade wet-and-dry paper. Always wrap

the abrasive paper around a flat rubber, cork,

or wooden block - otherwise the surface of

the filler will not be completely flat. During the

smoothing of the filler surface, the wet-and-

dry paper should be periodically rinsed in

water. This will ensure that a very smooth

finish is imparted to the filler at the final stage.

At this stage, the “dent” should be

surrounded by a ring of bare metal, which in

turn should be encircled by the finely

“feathered” edge of the good paintwork.

Rinse the repair area with clean water, until all

of the dust produced by the rubbing-down

operation has gone.

Spray the whole area with a light coat of

primer - this will show up any imperfections in

the surface of the filler. Repair these

imperfections with fresh filler paste or

bodystopper, and once more smooth the

surface with abrasive paper. Repeat this

spray-and-repair procedure until you are

satisfied that the surface of the filler, and the

feathered edge of the paintwork, are perfect.

Clean the repair area with clean water, and

allow to dry fully.

The repair area is now ready for final

spraying. Paint spraying must be carried out

in a warm, dry, windless and dust-free

atmosphere. This condition can be created

artificially if you have access to a large indoor

working area, but if you are forced to work in

the open, you will have to pick your day very

carefully. If you are working indoors, dousing

the floor in the work area with water will help

to settle the dust which would otherwise be in

the atmosphere. If the repair area is confined

to one body panel, mask off the surrounding

panels; this will help to minimise the effects ofa slight mis-match in paint colours. Bodywork

fittings (eg chrome strips, door handles etc)

will also need to be masked off. Use genuine

masking tape, and several thicknesses of

newspaper, for the masking operations.

Before commencing to spray, agitate the

aerosol can thoroughly, then spray a test area

(an old tin, or similar) until the technique is

mastered. Cover the repair area with a thick

coat of primer; the thickness should be built

up using several thin layers of paint, rather

than one thick one. Using 400-grade wet-and-

dry paper, rub down the surface of the primer

until it is really smooth. While doing this, the

work area should be thoroughly doused with

water, and the wet-and-dry paper periodically

rinsed in water. Allow to dry before spraying

on more paint.

Spray on the top coat, again building up the

thickness by using several thin layers of paint.

Start spraying at one edge of the repair area,

and then, using a side-to-side motion, work

until the whole repair area and about 2 inches

of the surrounding original paintwork is

covered. Remove all masking material 10 to

15 minutes after spraying on the final coat of

paint.

Allow the new paint at least two weeks to

harden, then, using a paintwork renovator, or

a very fine cutting paste, blend the edges of

the paint into the existing paintwork. Finally,

apply wax polish.

Plastic components

With the use of more and more plastic body

components by the vehicle manufacturers (eg

bumpers. spoilers, and in some cases major

body panels), rectification of more serious

damage to such items has become a matter

of either entrusting repair work to a specialist

in this field, or renewing complete

components. Repair of such damage by the

DIY owner is not really feasible, owing to the

cost of the equipment and materials required

for effecting such repairs. The basic technique

involves making a groove along the line of the

crack in the plastic, using a rotary burr in a

power drill. The damaged part is then welded

back together, using a hot-air gun to heat up

and fuse a plastic filler rod into the groove.

Any excess plastic is then removed, and the

area rubbed down to a smooth finish. It is

important that a filler rod of the correct plastic

is used, as body components can be made of

a variety of different types (eg polycarbonate,

ABS, polypropylene).

Damage of a less serious nature (abrasions,

minor cracks etc) can be repaired by the DIY

owner using a two-part epoxy filler repair

material. Once mixed in equal proportions,

this is used in similar fashion to the bodywork

filler used on metal panels. The filler is usually

cured in twenty to thirty minutes, ready for

sanding and painting.

If the owner is renewing a complete

component himself, or if he has repaired it

with epoxy filler, he will be left with theproblem of finding a suitable paint for finishing

which is compatible with the type of plastic

used. At one time, the use of a universal paint

was not possible, owing to the complex range

of plastics encountered in body component

applications. Standard paints, generally

speaking, will not bond to plastic or rubber

satisfactorily. However, it is now possible to

obtain a plastic body parts finishing kit which

consists of a pre-primer treatment, a primer

and coloured top coat. Full instructions are

normally supplied with a kit, but basically, the

method of use is to first apply the pre-primer

to the component concerned, and allow it to

dry for up to 30 minutes. Then the primer is

applied, and left to dry for about an hour

before finally applying the special-coloured

top coat. The result is a correctly-coloured

component, where the paint will flex with the

plastic or rubber, a property that standard

paint does not normally posses.

Where serious damage has occurred, or

large areas need renewal due to neglect, it

means that complete new panels will need

welding-in; this is best left to professionals. If

the damage is due to impact, it will also be

necessary to check completely the alignment

of the bodyshell; this can only be carried out

accurately by a Ford dealer, using special jigs.

If the body is left misaligned, it is primarily

dangerous, as the car will not handle properly,

and secondly, uneven stresses will be

imposed on the steering, suspension and

possibly transmission, causing abnormal wear

or complete failure, particularly to items such

as the tyres.

Removal

Front bumper

1Apply the handbrake, jack up the front of

the vehicle and support it on axle stands.

2Where applicable, remove the foglights

from the front bumper (Chapter 12).

3Where applicable, disconnect the tubing

from the headlight washer jets.

4Unscrew the screws securing the wheel

arch liners to the front bumper (see

illustration).

5Unscrew the bumper mounting nuts, and

withdraw the bumper forwards from the

vehicle, at the same time disconnecting the

guides from the side pins (see illustrations).

Rear bumper

6Chock the front wheels, jack up the rear of

the vehicle and support it on axle stands.

6 Bumpers - removal and refitting

5 Major body damage - repair

11•4 Bodywork and fittings

If bodystopper is used, it can

be mixed with cellulose

thinners, to form a really thin

paste which is ideal for filling

small holes.

procarmanuals.com

Page 182 of 279

7Disconnect the rear exhaust mounting

rubber, and support the exhaust system on an

axle stand.

8Remove the screws securing the wheel

arch liners to the rear bumper.

9Unscrew the bumper mounting nuts, and

withdraw the bumper rearwards from the

vehicle, at the same time disconnecting the

guides from the side pins (see illustration).

Refitting

Front and rear bumpers

10Refitting is a reversal of the removal

procedure. Make sure that the guides locate

correctly on the side pins.

Removal

1Support the bonnet in the open position.

2Using a Torx key, unscrew the radiator grille

mounting screws (see illustration).

3Unclip the radiator grille from the front

panel (see illustration).

Refitting

4Refitting is a reversal of the removal

procedure.

Removal

1Open the bonnet, and support it in the open

position using the stay.

2Disconnect the battery negative (earth) lead

(Chapter 5, Section 1).

3Prise out the clips from the insulator on the

underside of the bonnet, for access to the

windscreen washer hoses and engine

compartment light. It is not necessary to

completely remove the insulator.

4Disconnect the wiring from the engine

compartment light, and unclip the wiring from

the bonnet.5Unbolt the earth lead from the bonnet (see

illustration).

6Disconnect the windscreen washer hoses

from the bottom of the jets, and unclip the

hose from the bonnet.

7To assist in correctly realigning the bonnet

when refitting it, mark the outline of the hinges

with a soft pencil. Loosen the two hinge

retaining bolts on each side (see illustration).

8With the help of an assistant, unscrew the

four bolts, release the stay, and lift the bonnet

from the vehicle (see illustration).

Refitting

9Refitting is a reversal of the removal

procedure. Position the bonnet hinges within

the outline marks made during removal, but if

necessary alter its position to provide a

8 Bonnet - removal,

refitting and adjustment

7 Radiator grille-

removal and refitting

Bodywork and fittings 11•5

11

7.3 Unclipping the radiator grille from the

front panel

8.5 Earth lead and washer hoses on the

underside of the bonnet

6.9 Rear bumper mounting nuts7.2 Removing a radiator grille mounting

screw

8.7 Mark around the bonnet hinges with a

soft pencil before removal

6.4 Screw (arrowed) securing the wheel

arch liner to the front bumper6.5A Front bumper mounting bolt

(arrowed)6.5B Disconnecting the front bumper from

the side guides

procarmanuals.com

Page 188 of 279

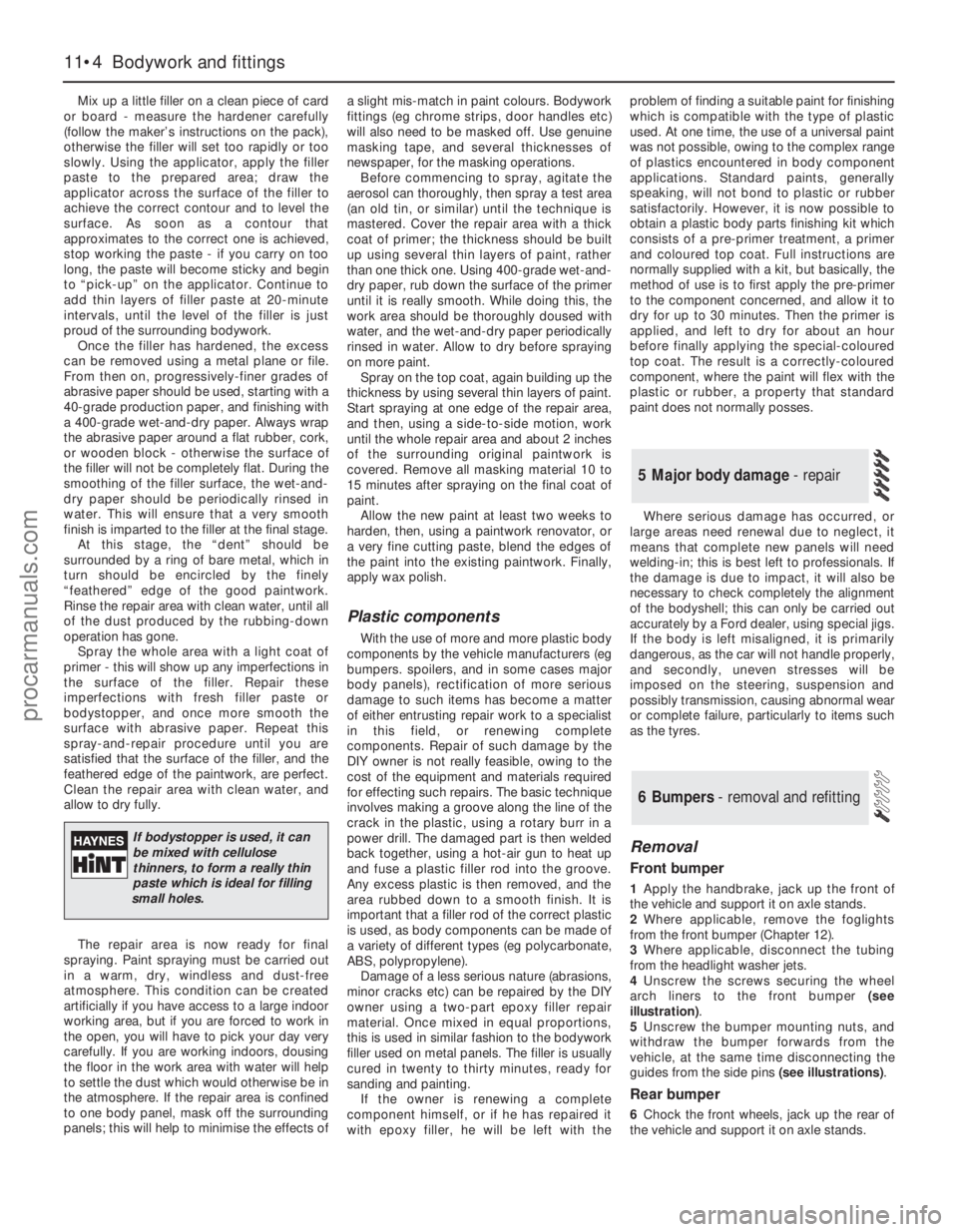

4Unscrew and remove the lock mounting

bolts on the inner rear edge of the door, and

remove the plate. Also remove the additional

support screw (see illustrations).

5Unclip and disconnect the wiring multi-

plugs for the central locking and alarm

systems (see illustration).

6Disconnect the wiring multi-plug from the

door lock.

7Disconnect the inner handle illumination

light. Undo the screws and remove the inner

handle. Disconnect the operating cable from

the inner handle, as described later in this

Section (see illustrations).

8Manipulate the lock and handle assembly

as necessary, and disconnect the wiring

multi-plugs for the alarm sensor and central

locking. Withdraw the complete assembly

from inside the door (see illustrations).

9To disconnect the handle assembly from

the lock bracket, slide the rubber posts

inwards, and push out the assembly (see

illustration).

10To remove the handle itself, twist the door

handle through a quarter-turn, and pull out the

connecting rods (see illustration).

11Remove the alarm sensor and the central

locking “Set-reset” sensor (see illustration).

Rear door exterior handle

12Remove the door inner trim panel (Sec-

tion 11).

13Use a knife to cut through the adhesive

Bodywork and fittings 11•11

11

14.8B Front door lock and exterior handle

assembly removed from the vehicle14.9 Disconnecting the handle assembly

from the lock bracket14.10 Pulling out the handle connecting

rods

14.4A Unscrew the lock mounting

bolts . . .14.4B . . . and remove the plate14.4C Removing the additional support

screw

14.5 Disconnecting the central locking

and alarm system wiring multi-plugs14.7A Removing the inner handle

14.7B Disconnecting the operating cable

from the inner handle14.8A Removing the lock and exterior

handle assembly from inside the door

procarmanuals.com

Page 189 of 279

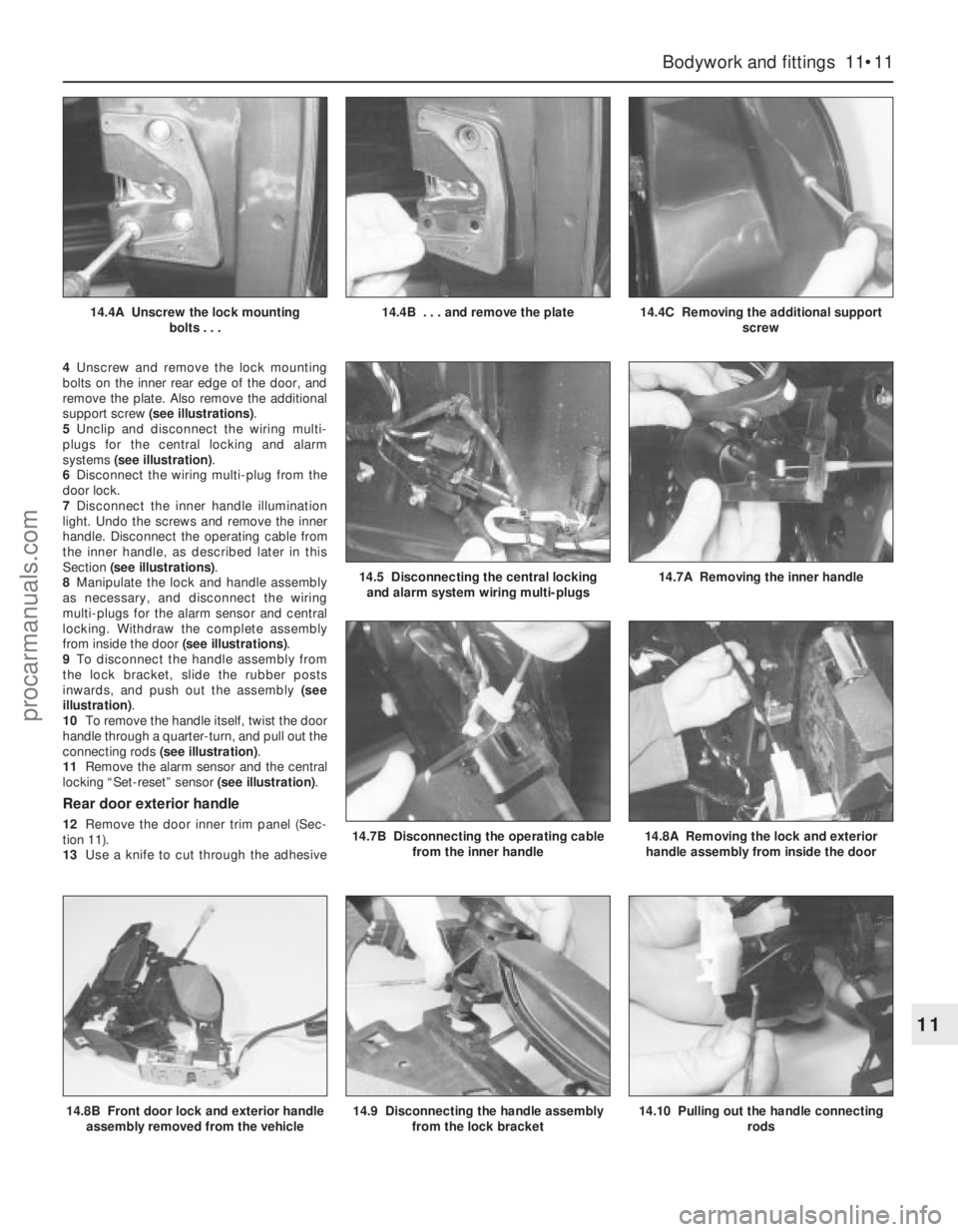

strip, so that the foam insulator can be peeled

back for access to the lock. Do notpeel back

the foam insulator without first cutting through

the adhesive strip. To ensure a good seal

when the insulator is pressed back, do not

touch the adhesive strip.

14Prise out the plug from the rear edge of

the door, then unscrew the handle mounting

nuts (see illustrations).

15Prise up the clip, and disconnect the

operating rod from the lock (see illustration).

16Withdraw the handle from the outside of

the door (see illustration).

Interior handle

17Remove the door inner trim panel (Sec-

tion 11).

18Use a knife to cut through the adhesive

strip, so that the foam insulator can be peeledback for access to the lock. Do notpeel back

the foam insulator without first cutting through

the adhesive strip. To ensure a good seal

when the insulator is pressed back, do not

touch the adhesive strip.

19Disconnect the interior handle illumination

light.

20Undo the screws and remove the interior

handle.

21To remove the cable, first pull back the

plastic outer cable end and blanking piece.

Apply light inward pressure to the control

lever, with the lever in the locked position,

until the inner cable is aligned with the release

slot in the bottom of the cable holder.

22Push down on the cable ferrule, and

disconnect the inner cable. Remove the

handle assembly.

Lock barrel

23Remove the exterior handle as described

earlier in this Section.

24Prise out the barrel retaining tab from the

handle body, using a small screwdriver (see

illustration).

25Insert the key, turn it so that it engages

the barrel, then pull out the barrel (see

illustration).

Lock motor - front door26Remove the exterior handle as described

earlier in this Section.

27Extract the clip, and pull out the operating

rod.

28Remove the operating rod from the plastic

bush, by turning it through a quarter-turn.

29Release the sensor wiring loom from the

clip.

11•12 Bodywork and fittings

14.11 Removing the central locking “Set-

reset” sensor14.14A Prise out the plug . . .14.14B . . . and unscrew the handle

mounting nuts

14.25 . . . and pull out the lock barrel14.31 Unclipping the door-ajar sensor14.32 Removing the plastic shield from the

locating post

14.15 Disconnect the operating rod from

the lock14.16 Removing the rear door exterior

handle14.24 Prise out the barrel retaining tab . . .

procarmanuals.com

Page 190 of 279

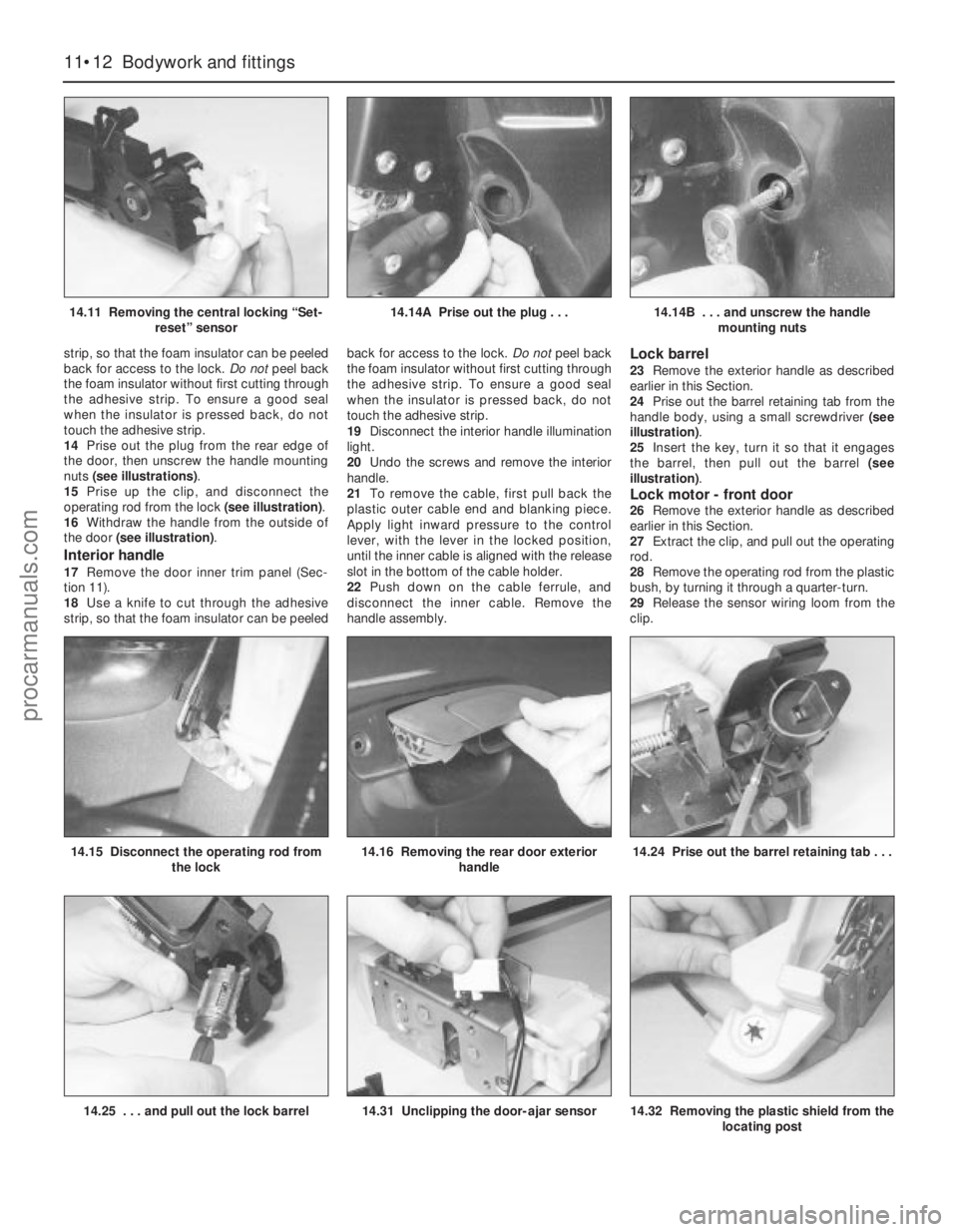

30Detach the mounting plate from the lock.

31Release the door-ajar sensor from the clip

(see illustration).

32Prise the plastic shield from the locating

post (see illustration).

33Slide the outer cable from the lock

bracket (see illustration), then turn the inner

cable through a quarter-turn to remove it from

the bell crank.

34Unscrew the mounting screws and

remove the lock motor (see illustration).

Lock motor - rear door

35Remove the exterior handle as described

earlier in this Section.

36Unscrew and remove the three lock

mounting screws.

37Release the sensor wiring loom from the

clip on the door.

38Disconnect the wiring multi-plug from the

door lock.

39Disconnect the interior handle illumination

light.

40Remove the screws, and remove the

interior handle.

41Remove the lock assembly.

42Release the door-ajar sensor from the

clip.

43Prise the plastic shield from the locating

post.

44Slide the outer cable from the lock

bracket, then turn the inner cable through a

quarter-turn to remove it from the bell crank.

45Unscrew the mounting screws andremove the lock motor.

Striker

46Using a pencil, mark the position of the

striker.

47Undo the mounting screws using a Torx

key, and remove the striker.

Check strap

48Disconnect the battery negative (earth)

lead (Chapter 5, Section 1).

49Using a Torx key, unscrew and remove

the check strap mounting screw(s). On the

front door, there are two screws; on the rear

door, there is only one.

50Prise the rubber grommet from the door

aperture, then unscrew the mounting nuts and

withdraw the check strap from the door.

Refitting

Handles (exterior and interior)

51Refitting is a reversal of the removal

procedure.

Lock barrel

52Check that the retaining clip is fitted

correctly.

53Align the grooves on the barrel with the

grooves on the body and operating lever, then

carefully push the barrel into the handle until it

engages the clip.

54The remaining refitting procedure is a

reversal of removal.

Lock motor

55Refitting is a reversal of the removal

procedure.

Striker

56Refitting is a reversal of the removal

procedure, but check that the door lock

passes over the striker centrally. If necessary,

re-position the striker before fully tightening

the mounting screws.

Check strap

59Refitting is a reversal of the removal

procedure.

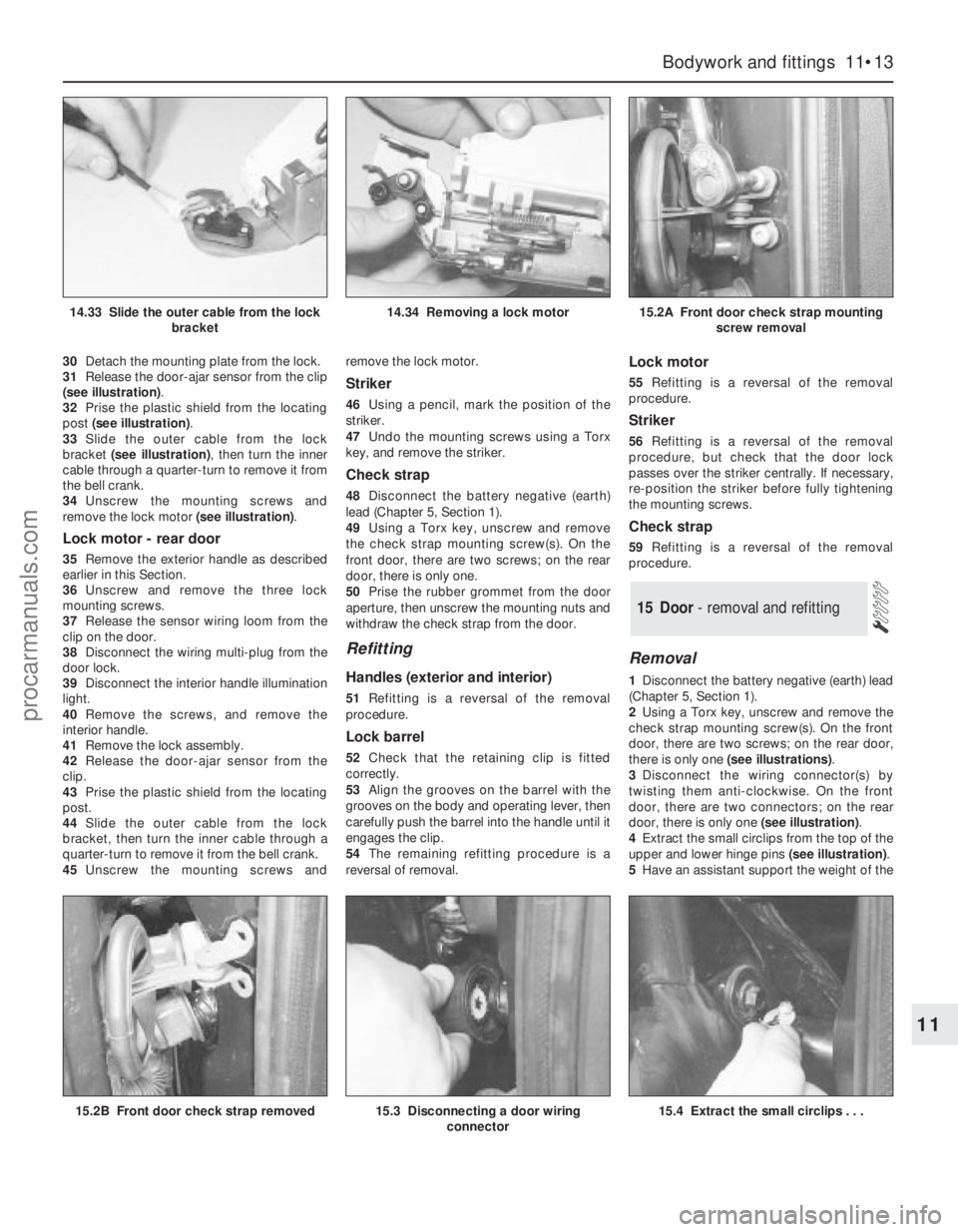

Removal

1Disconnect the battery negative (earth) lead

(Chapter 5, Section 1).

2Using a Torx key, unscrew and remove the

check strap mounting screw(s). On the front

door, there are two screws; on the rear door,

there is only one (see illustrations).

3Disconnect the wiring connector(s) by

twisting them anti-clockwise. On the front

door, there are two connectors; on the rear

door, there is only one (see illustration).

4Extract the small circlips from the top of the

upper and lower hinge pins (see illustration).

5Have an assistant support the weight of the

15 Door - removal and refitting

Bodywork and fittings 11•13

11

15.2B Front door check strap removed15.3 Disconnecting a door wiring

connector15.4 Extract the small circlips . . .

14.33 Slide the outer cable from the lock

bracket14.34 Removing a lock motor15.2A Front door check strap mounting

screw removal

procarmanuals.com

Page 192 of 279

Removal

Lock barrel

1Disconnect the battery negative (earth) lead

(Chapter 5, Section 1).

2With the boot lid open, remove the luggage

space trim from the right-hand rear corner.

3Remove the screws, and prise out the rear

light trim cover from the guides.

4Release the door-ajar sensor from the clip

near the lock.

5Slide the outer cable from the lock bracket.

Raise the inner cable until it is aligned with the

slot in the barrel lever, and disconnect it.

6Pull out the lock locating spring clip.

7Detach the cable mounting bracket from

the barrel, and remove the barrel.

Lock

8Disconnect the battery negative (earth) lead

(Chapter 5, Section 1).

9With the boot lid open, prise out the clips

and remove the trim from inside the boot lid.

10Release the door-ajar sensor from the clip

near the lock.

11Using a Torx key, unscrew the lock

mounting screws, and withdraw the lock for

access to the cables.

12Disconnect both the inner and outer

cables from the lock bracket.13Prise open the plastic lip, and remove the

central locking control rod.

14Withdraw the lock assembly.

Refitting

Lock barrel and lock

15Refitting is a reversal of the removal

procedure.

Removal

Hatchback

1Disconnect the battery negative (earth) lead

(Chapter 5, Section 1). Open the tailgate.

2The tailgate may be unbolted from the

hinges and the hinges left in position, or the

hinges may be detached from the roof panel

by unscrewing the mounting nuts. In the latter

case, carefully pull down the rear edge of the

headlining for access to the nuts. Take care

not to damage the headlining.

3Remove the parcel shelf left-hand support

bracket as follows. Fold the rear seat

forwards, and disconnect the left-hand seat

pull cable from the bracket and clips.

Unscrew the screws and remove the bracket.

4Pull up the rear seat side bolster, then

carefully remove the side trim from the left-

hand side of the luggage area. On low-series

models, the bolster is retained with a screw.5Separate the tailgate wiring loom multi-

plugs, located on the left-hand side of the

luggage compartment, on top of the wheel

arch.

6Unclip and remove the upper trim panel

from the inside of the tailgate. Also remove

the rear shelf cord plastic post (see

illustrations).

7Prise out the rubber grommet from the top

of the tailgate aperture, and pull the wiring

loom out through the hole in the body (see

illustration).

8Disconnect the rear window washer tube

from the jet.

9Prise out the rubber grommet from the

right-hand side of the tailgate aperture, and

pull out the washer tube.

10Have an assistant support the tailgate in

its open position.

11Using a small screwdriver, prise off the

clips securing the struts to the tailgate. Pull

the sockets from the ball-studs, and move the

struts downwards.

12If the headlining has been pulled back,

unscrew and remove the hinge nuts from the

roof panel. Otherwise, unscrew the bolts

securing the tailgate to the hinges (see

illustration).

13Withdraw the tailgate from the body

aperture, taking care not to damage the

paintwork.

Estate

14Disconnect the battery negative (earth)

lead (Chapter 5, Section 1).

15The tailgate may be unbolted from the

hinges and the hinges left in position, or the

hinges may be detached from the rear roof

panel by unscrewing the mounting nuts. In the

latter case, carefully pull down the rear edge

of the headlining for access to the nuts. Take

care not to damage the headlining.

16Unscrew the retaining screws, then unclip

the “D” pillar trim panels from both sides (see

illustration).

17Unclip and remove the upper trim panel

from inside the tailgate.

18Carefully remove the side trim from the

left-hand side of the luggage area, and

separate the tailgate wiring loom multi-plugs

in the rear light cluster housing.

20 Tailgate -

removal and refitting

19 Boot lid lock components-

removal and refitting

Bodywork and fittings 11•15

11

20.12 Unscrewing the bolts securing the

tailgate to the hinges20.16 “D” pillar trim panel retaining

screws (arrowed) - Estate models

20.6A Unclipping the upper trim panel

from the tailgate20.6B Shelf cord post removal20.7 Removing the wiring loom rubber

grommet

procarmanuals.com

Page 193 of 279

19Attach a strong fine cord to the end of the

wiring loom, to act as an aid to guiding the

wiring through the tailgate when it is refitted.

20Prise the rubber grommet from the top

left-hand side of the tailgate aperture, and pull

out the wiring loom. Untie the cord, leaving it

in position in the “D” pillar.

21Disconnect the rear window washer tube

from the jet. Pull out the rubber grommet, and

remove the tube.

22Have an assistant support the tailgate in

its open position.

23Using a small screwdriver, prise off the

clip securing the struts to the tailgate. Pull the

sockets from the ball-studs, and move the

struts downwards.

24Unscrew and remove the hinge nuts from

the roof panel, or the hinge bolts from thehinge, as desired (see illustration). Withdraw

the tailgate from the body aperture, taking

care not to damage the paintwork.

Refitting

Hatchback and Estate

25Refitting is a reversal of the removal

procedure, but check that the tailgate is

located centrally in the body aperture, and

that the striker enters the lock centrally. If

necessary, loosen the mounting nuts and re-

position the tailgate as required.

Removal

1Support the tailgate in its open position.

2Prise off the upper spring clip securing the

strut to the tailgate, then pull the socket from

the ball-stud (see illustration).

3Similarly prise off the bottom clip (see

illustration), and pull the socket from the ball-

stud. Withdraw the strut.

Refitting

4Refitting is a reversal of the removal

procedure, but make sure that the piston end

of the strut is fitted on the body (ie

downwards).

Removal

Lock barrel (Hatchback)

1Disconnect the battery negative (earth) lead

(Chapter 5, Section 1).

2With the tailgate open, pull up the

weatherstrip for access to the lock. Remove

the screws and clips, and remove the trim

panel from the rear of the luggage

compartment.

3Unhook the parcel net, then remove the

screws and clips, and remove the rear

crossmember trim.

4Remove the screws, and prise out the rear

light trim cover from the guides.

5Release the door-ajar sensor from the clip

near the lock.

6Slide the outer cable from the lock bracket.

Raise the inner cable until it is aligned with the

slot in the barrel lever, and disconnect it (see

illustration).

7Pull out the lock barrel locating spring clip.

8Detach the cable mounting bracket from

the barrel, and remove the barrel and cylinder

(see illustrations).

Lock barrel (Estate)

9Disconnect the battery negative (earth) lead

(Chapter 5, Section 1).

10Unclip and remove the tailgate trim panel.

Undo the three screws and remove the lock

shield, then unclip the door-ajar sensor.

11Working through the aperture in the

tailgate inner panel, pull out the lock barrel

locating spring clip. Unhook the operating rod

and withdraw the lock barrel.

Lock (Hatchback)

12Disconnect the battery negative (earth)

lead (Chapter 5, Section 1).

13With the tailgate open, pull up the

weatherstrip for access to the lock. Remove

the screws and clips, and remove the trim

panel from the rear of the luggage

compartment.

22 Tailgate lock components -

removal and refitting

21 Tailgate support strut-

removal and refitting

11•16 Bodywork and fittings

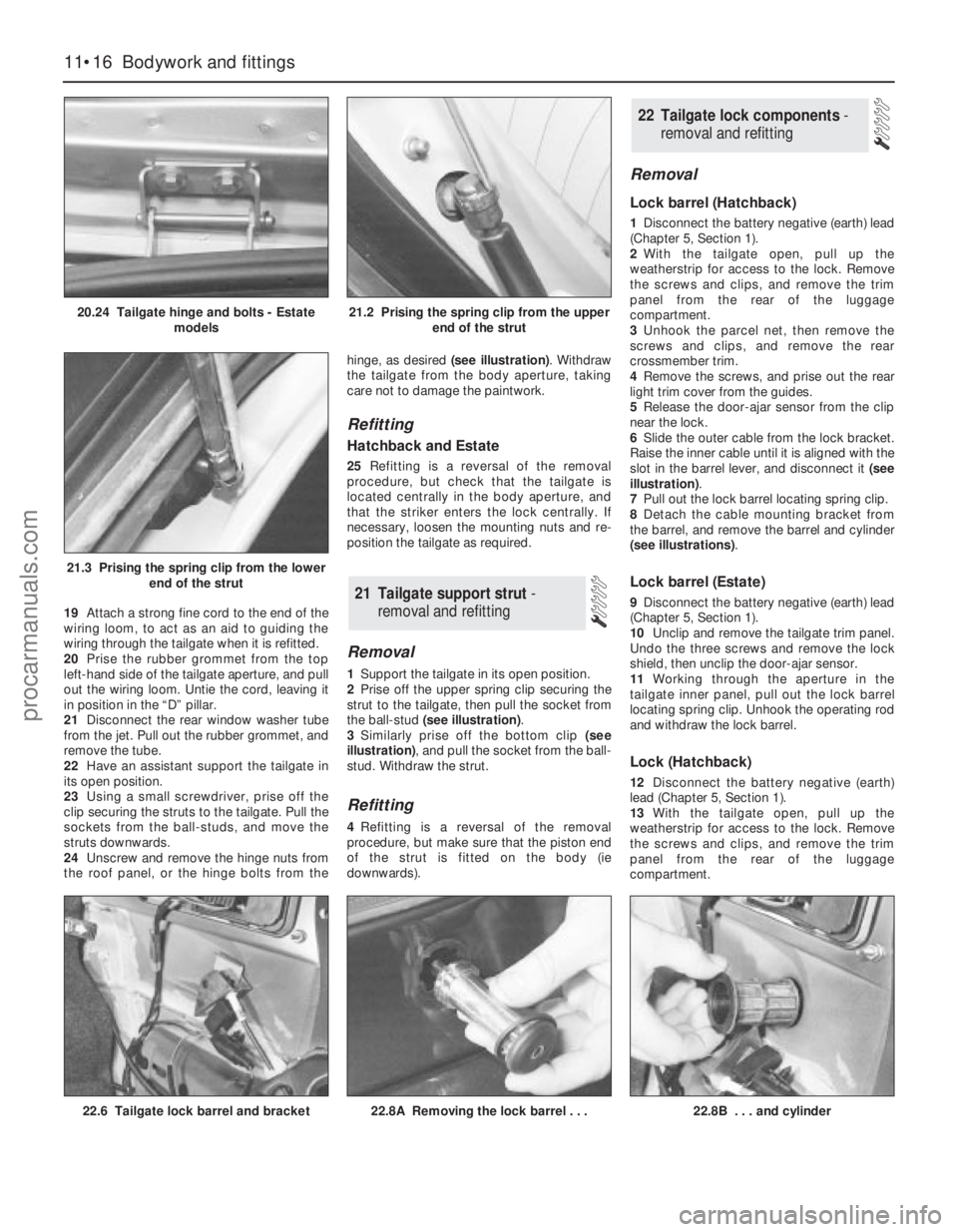

20.24 Tailgate hinge and bolts - Estate

models21.2 Prising the spring clip from the upper

end of the strut

21.3 Prising the spring clip from the lower

end of the strut

22.6 Tailgate lock barrel and bracket22.8A Removing the lock barrel . . .22.8B . . . and cylinder

procarmanuals.com

Page 197 of 279

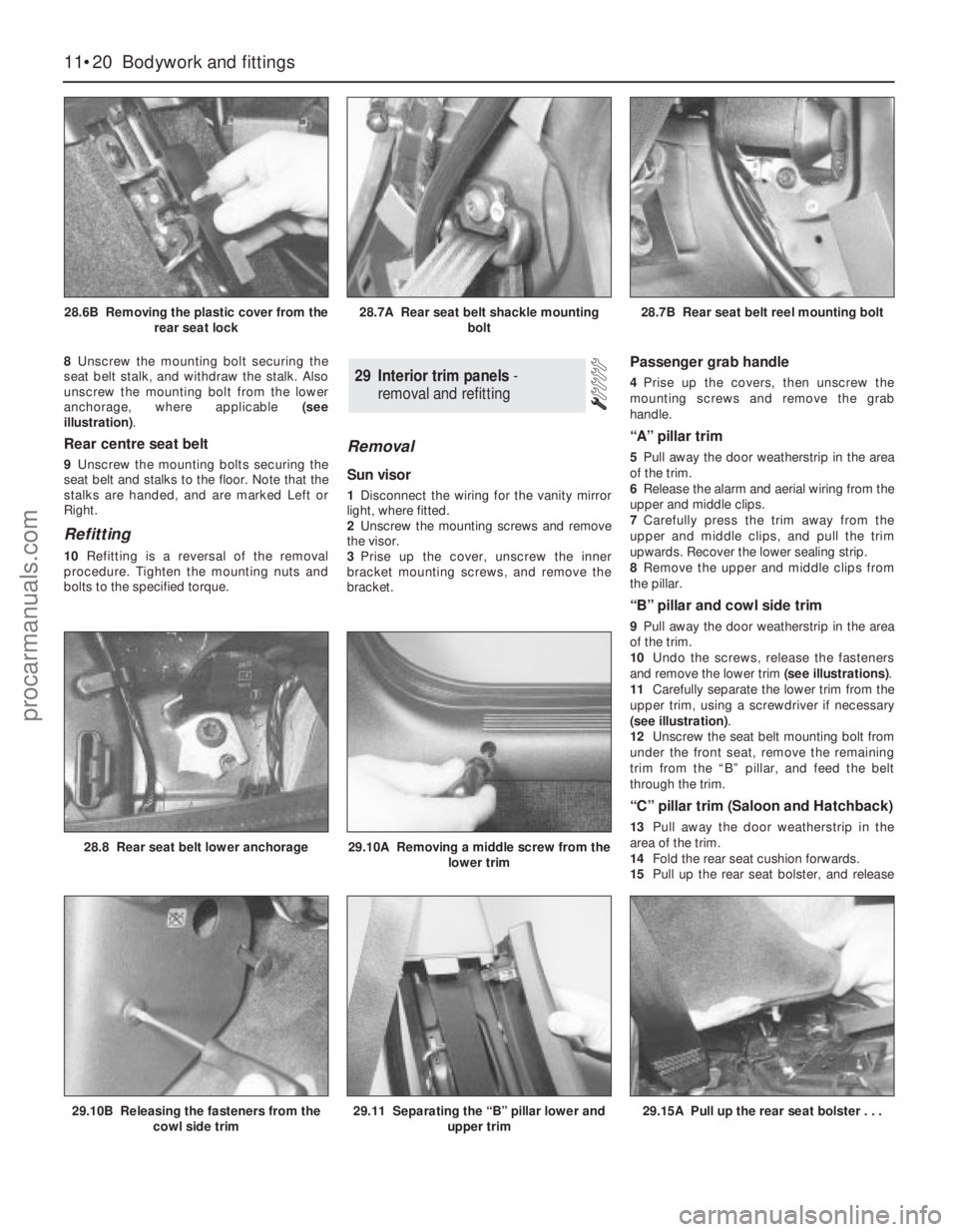

8Unscrew the mounting bolt securing the

seat belt stalk, and withdraw the stalk. Also

unscrew the mounting bolt from the lower

anchorage, where applicable (see

illustration).

Rear centre seat belt

9Unscrew the mounting bolts securing the

seat belt and stalks to the floor. Note that the

stalks are handed, and are marked Left or

Right.

Refitting

10Refitting is a reversal of the removal

procedure. Tighten the mounting nuts and

bolts to the specified torque.

Removal

Sun visor

1Disconnect the wiring for the vanity mirror

light, where fitted.

2Unscrew the mounting screws and remove

the visor.

3Prise up the cover, unscrew the inner

bracket mounting screws, and remove the

bracket.

Passenger grab handle

4Prise up the covers, then unscrew the

mounting screws and remove the grab

handle.

“A” pillar trim

5Pull away the door weatherstrip in the area

of the trim.

6Release the alarm and aerial wiring from the

upper and middle clips.

7Carefully press the trim away from the

upper and middle clips, and pull the trim

upwards. Recover the lower sealing strip.

8Remove the upper and middle clips from

the pillar.

“B” pillar and cowl side trim

9Pull away the door weatherstrip in the area

of the trim.

10Undo the screws, release the fasteners

and remove the lower trim (see illustrations).

11Carefully separate the lower trim from the

upper trim, using a screwdriver if necessary

(see illustration).

12Unscrew the seat belt mounting bolt from

under the front seat, remove the remaining

trim from the “B” pillar, and feed the belt

through the trim.

“C” pillar trim (Saloon and Hatchback)

13Pull away the door weatherstrip in the

area of the trim.

14Fold the rear seat cushion forwards.

15Pull up the rear seat bolster, and release

29 Interior trim panels-

removal and refitting

11•20 Bodywork and fittings

28.6B Removing the plastic cover from the

rear seat lock28.7A Rear seat belt shackle mounting

bolt28.7B Rear seat belt reel mounting bolt

29.10B Releasing the fasteners from the

cowl side trim29.11 Separating the “B” pillar lower and

upper trim

28.8 Rear seat belt lower anchorage29.10A Removing a middle screw from the

lower trim

29.15A Pull up the rear seat bolster . . .

procarmanuals.com

Page 199 of 279

6Prise off the plastic caps, then unscrew the

centre console mounting screws. These are

located on each side, on the front top, and

inside the cassette storage box. The screws

with the washers go on the side of the

console; the front screws are smaller than the

others, and black in colour (see illustrations).

7Fully apply the handbrake lever. Withdraw

the centre console, at the same time passing

the gaiter over the handbrake lever (see

illustrations).

8Disconnect the cigar lighter wiring (see

illustration).

Refitting

9Refitting is a reversal of the removal

procedure.

Removal

1Disconnect the battery negative (earth) lead

(Chapter 5, Section 1).

2When applicable, remove the sunroof

switch (Chapter 12).

3When applicable, remove the sunroof

handle, after undoing the securing screw (see

illustration).

3Push the console towards the windscreen,

to disengage it from the clips.

Refitting

4Refitting is a reversal of the removal

procedure.

Removal

1Open the glovebox. Using a screwdriver,

carefully press in one side of the glovebox

near the hinge, to release it from the plastic

clip (see illustration).

2Withdraw the glovebox and, where

necessary, disconnect the wiring multi-plug

for the light.

3If necessary, the lock may be removed by

unscrewing the mounting screws and removing

the lock plate and spring (see illustration).

4To remove the lock barrel, depress the

spring tabs.

Refitting

5Locate the barrel in the lock plate, making

sure that the clips are fully engaged.

6Hold the latch pins together, and engage

the right-hand pin of the lock plate.

7Refit the spring, and engage the left-hand

pin of the lock plate.

8Refit the lock plate, and tighten the screws.

9Reconnect the wiring multi-plug and refit

the glovebox, making sure that it is fully

inserted in the plastic clips.

32 Glovebox -

removal and refitting

31 Overhead console -

removal and refitting

11•22 Bodywork and fittings

30.6C . . . at the sides . . .30.6D . . . and inside the cassette storage

box30.7A Withdrawing the front of the

console from the facia

31.3 Removing the sunroof handle

securing screw32.1 Glovebox removal

30.8 Disconnecting the cigar lighter wiring

30.7B Passing the gaiter over the

handbrake lever

32.3 Glovebox lock mounting screws

(arrowed)

procarmanuals.com

Page 200 of 279

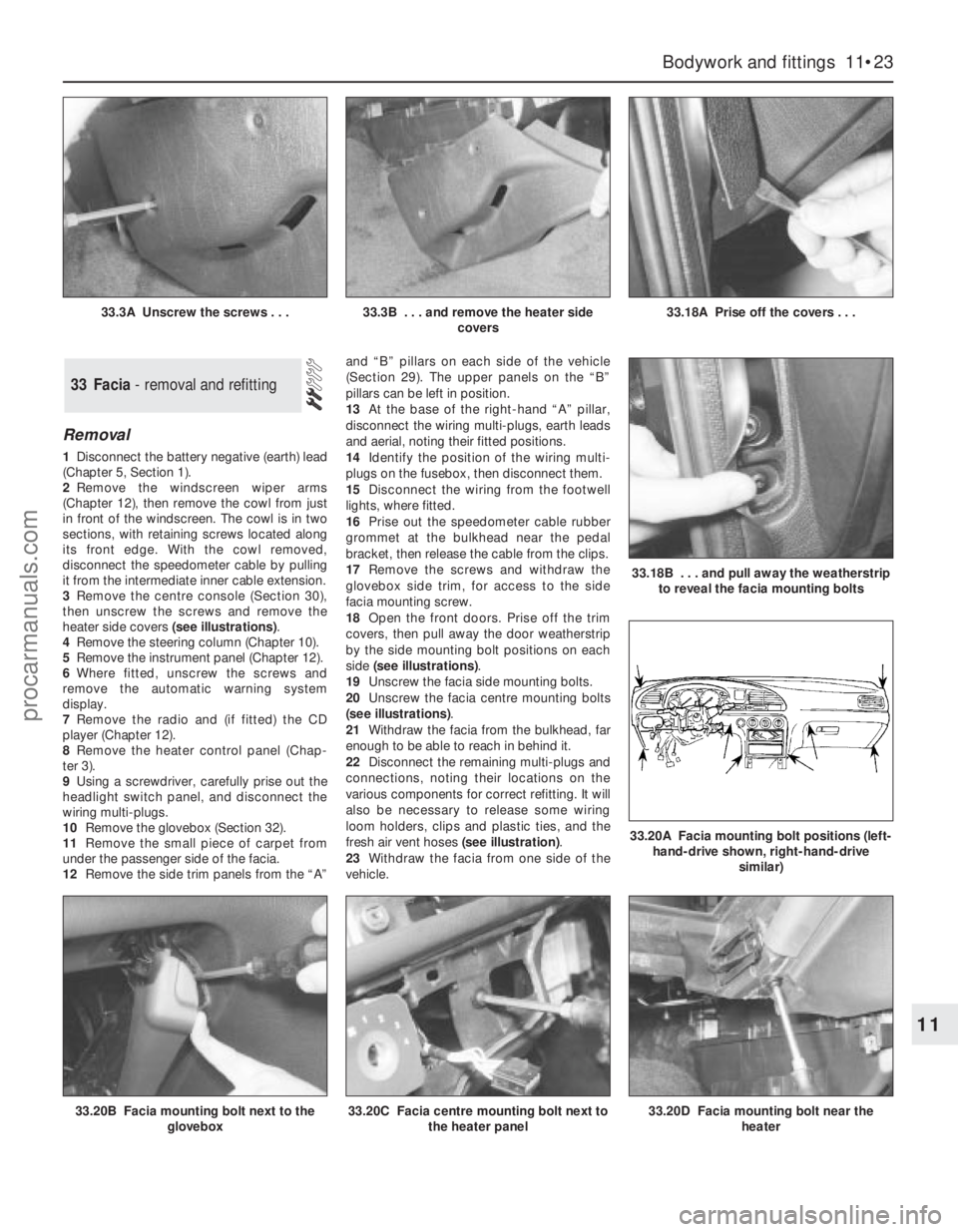

Removal

1Disconnect the battery negative (earth) lead

(Chapter 5, Section 1).

2Remove the windscreen wiper arms

(Chapter 12), then remove the cowl from just

in front of the windscreen. The cowl is in two

sections, with retaining screws located along

its front edge. With the cowl removed,

disconnect the speedometer cable by pulling

it from the intermediate inner cable extension.

3Remove the centre console (Section 30),

then unscrew the screws and remove the

heater side covers (see illustrations).

4Remove the steering column (Chapter 10).

5Remove the instrument panel (Chapter 12).

6Where fitted, unscrew the screws and

remove the automatic warning system

display.

7Remove the radio and (if fitted) the CD

player (Chapter 12).

8Remove the heater control panel (Chap-

ter 3).

9Using a screwdriver, carefully prise out the

headlight switch panel, and disconnect the

wiring multi-plugs.

10Remove the glovebox (Section 32).

11Remove the small piece of carpet from

under the passenger side of the facia.

12Remove the side trim panels from the “A”and “B” pillars on each side of the vehicle

(Section 29). The upper panels on the “B”

pillars can be left in position.

13At the base of the right-hand “A” pillar,

disconnect the wiring multi-plugs, earth leads

and aerial, noting their fitted positions.

14Identify the position of the wiring multi-

plugs on the fusebox, then disconnect them.

15Disconnect the wiring from the footwell

lights, where fitted.

16Prise out the speedometer cable rubber

grommet at the bulkhead near the pedal

bracket, then release the cable from the clips.

17Remove the screws and withdraw the

glovebox side trim, for access to the side

facia mounting screw.

18Open the front doors. Prise off the trim

covers, then pull away the door weatherstrip

by the side mounting bolt positions on each

side (see illustrations).

19Unscrew the facia side mounting bolts.

20Unscrew the facia centre mounting bolts

(see illustrations).

21Withdraw the facia from the bulkhead, far

enough to be able to reach in behind it.

22Disconnect the remaining multi-plugs and

connections, noting their locations on the

various components for correct refitting. It will

also be necessary to release some wiring

loom holders, clips and plastic ties, and the

fresh air vent hoses (see illustration).

23Withdraw the facia from one side of the

vehicle.

33 Facia - removal and refitting

Bodywork and fittings 11•23

11

33.20B Facia mounting bolt next to the

glovebox33.20C Facia centre mounting bolt next to

the heater panel33.20D Facia mounting bolt near the

heater

33.3A Unscrew the screws . . .33.3B . . . and remove the heater side

covers33.18A Prise off the covers . . .

33.18B . . . and pull away the weatherstrip

to reveal the facia mounting bolts

33.20A Facia mounting bolt positions (left-

hand-drive shown, right-hand-drive

similar)

procarmanuals.com