light FORD MONDEO 1993 Service Manual PDF

[x] Cancel search | Manufacturer: FORD, Model Year: 1993, Model line: MONDEO, Model: FORD MONDEO 1993Pages: 279, PDF Size: 12.71 MB

Page 123 of 279

5Support the caliper in one hand, and

prevent the hydraulic hose from turning with

the other hand. Unscrew the caliper from the

hose, making sure that the hose is not twisted

unduly or strained. Once the caliper is

detached, plug the open hydraulic unions in

the caliper and hose, to keep out dust and

dirt.

6If required, the caliper carrier bracket can

be unbolted and removed from the steering

knuckle (see illustration).

Overhaul

7With the caliper on the bench, brush away

all traces of dust and dirt, but take care not to

inhale any dust, as it may be injurious to

health.

8Pull the dust-excluding rubber seal from the

end of the piston.

9Apply low air pressure to the fluid inlet

union, and eject the piston. Only low air

pressure is required for this, such as is

produced by a foot-operated tyre pump.

Caution: The piston may be

ejected with some force.

10Using a suitable blunt instrument (for

instance a knitting needle or a crochet hook),

prise the piston seal from the groove in the

cylinder bore. Take care not to scratch the

surface of the bore.

11Clean the piston and caliper body with

methylated spirit, and allow to dry. Examine the

surfaces of the piston and cylinder bore for wear,

damage and corrosion. If the piston alone is

unserviceable, a new piston must be obtained,

along with seals. If the cylinder bore is

unserviceable, the complete caliper must be

renewed. The seals must be renewed, regardless

of the condition of the other components.

12Coat the piston and seals with clean

brake fluid, then manipulate the piston seal

into the groove in the cylinder bore.13Push the piston squarely into its bore.

14Fit the dust-excluding rubber seal onto

the piston and caliper, then depress the

piston fully.

Refitting

15Refit the caliper, and where applicable the

carrier bracket, by reversing the removal

operations. Make sure that the flexible brake

hose is not twisted. Tighten the mounting

bolts and wheel nuts to the specified torque

(see illustration).

16Bleed the brake circuit according to the

procedure given in Section 15, remembering

to remove the brake hose clamp from the

flexible hose. Make sure there are no leaks

from the hose connections. Test the brakes

carefully before returning the vehicle to

normal service.

Note:To prevent uneven braking, BOTH front

brake discs should be renewed or reground at

the same time.

Inspection

1Apply the handbrake. Loosen the relevant

wheel nuts, jack up the front of the vehicle

and support it on axle stands. Remove the

wheel.

2Remove the front brake caliper and carrier

bracket with reference to Section 3, but do

not disconnect the flexible hose. Support the

caliper on an axle stand, or suspend it out of

the way with a piece of wire, taking care to

avoid straining the flexible hose.

3Temporarily refit two of the wheel nuts to

diagonally-opposite studs, with the flat sides

of the nuts against the disc. Tighten the nuts

progressively, to hold the disc firmly.

4Scrape any corrosion from the disc. Rotate

the disc, and examine it for deep scoring,

grooving or cracks. Using a micrometer,

measure the thickness of the disc in several

places. The minimum thickness is stamped on

the disc hub (see illustrations). Light wear

and scoring is normal, but if excessive, thedisc should be removed, and either reground

by a specialist, or renewed. If regrinding is

undertaken, the minimum thickness must be

maintained. Obviously, if the disc is cracked,

it must be renewed.

5Using a dial gauge or a flat metal block and

feeler gauges, check that the disc run-out

10 mm from the outer edge does not exceed

the limit given in the Specifications. To do

this, fix the measuring equipment, and rotate

the disc, noting the variation in measurement

as the disc is rotated (see illustration). The

difference between the minimum and

maximum measurements recorded is the disc

run-out.

6If the run-out is greater than the specified

amount, check for variations of the disc

thickness as follows. Mark the disc at eight

positions 45° apart, then using a micrometer,

measure the disc thickness at the eight

positions, 15 mm in from the outer edge. If the

variation between the minimum and maximum

readings is greater than the specified amount,

the disc should be renewed.

7The hub face run-out can also be checked

in a similar way. First remove the disc as

described later in this Section, fix the

measuring equipment, then slowly rotate the

hub, and check that the run-out does not

exceed the amount given in the

Specifications. If the hub face run-out is

excessive, this should be corrected (by

renewing the hub bearings - see Chapter 10)

before rechecking the disc run-out.

4 Front brake disc - inspection,

removal and refitting

Braking system 9•5

9

4.5 Measuring the disc run-out with a dial

gauge

3.15 Tightening the carrier bracket

mounting bolts4.4A Using a micrometer to measure the

thickness of the front brake disc4.4B Disc minimum thickness marking

Position a thin piece of wood

between the piston and the

caliper body, to prevent

damage to the end face of the

piston, in the event of it being ejected

suddenly.

procarmanuals.com

Page 126 of 279

6With the drum in position, refit the wheel,

then carry out the renewal procedure on the

remaining rear brake.

7Lower the vehicle to the ground, and

tighten the wheel nuts.

8Depress the brake pedal several times, in

order to operate the self-adjusting mechanism

and set the shoes at their normal operating

position.

9Make several forward and reverse stops,

and operate the handbrake fully two or three

times. Give the vehicle a road test, to make

sure that the brakes are functioning correctly,

and to bed-in the new linings to the contours

of the disc. Remember that the new linings

will not give full braking efficiency until they

have bedded-in.

Note:Before starting work, check on the

availability of parts (overhaul kit of seals). Also

bear in mind that if the brake shoes have been

contaminated by fluid leaking from the wheel

cylinder, they must be renewed. In principle,

the shoes on BOTH sides of the vehicle must

be renewed, even if they are only

contaminated on one side.

Removal

1Remove the brake drum as described in

Section 5.

2Minimise fluid loss either by removing the

master cylinder reservoir cap, and then

tightening it down onto a piece of polythene

to obtain an airtight seal, or by using a brake

hose clamp, a G-clamp, or similar tool, to

clamp the flexible hose at the nearest

convenient point to the wheel cylinder.

3Pull the brake shoes apart at their top ends,

so that they are just clear of the wheel

cylinder. The automatic adjuster will hold the

shoes in this position, so that the cylinder can

be withdrawn.

4Wipe away all traces of dirt around the

hydraulic union at the rear of the wheel

cylinder, then undo the union nut.5Unscrew the two bolts securing the wheel

cylinder to the backplate (see illustration).

6Withdraw the wheel cylinder from the

backplate so that it is clear of the brake

shoes. Plug the open hydraulic unions, to

prevent the entry of dirt, and to minimise

further fluid loss whilst the cylinder is

detached.

Overhaul

7Clean the external surfaces of the cylinder,

and unscrew the bleed screw.

8Carefully prise off the dust cover from each

end of the cylinder.

9Tap the wheel cylinder on a block of wood

to eject the pistons and seals, keeping them

identified for location. Finally remove the

spring.

10Clean the pistons and the cylinder by

washing in methylated spirit or fresh hydraulic

fluid. Do not use petrol, paraffin or any other

mineral-based fluid. Remove and discard the

old seals, noting which way round they are

fitted.

11Examine the surfaces of the pistons and

the cylinder bores, and look for any signs of

rust or scoring. If such damage is evident, the

complete wheel cylinder must be renewed.

12Reassemble by lubricating the first piston

in clean hydraulic fluid, then manipulating a

new seal into position, so that its raised lip

faces away from the brake shoe bearing face

of the piston.

13Insert the piston into the cylinder. As the

seal enters the bore, twist the piston back and

forth so that the seal lip is not trapped.

14Insert the spring, then refit the remaining

piston and seal, again making sure that the

seal lip is not trapped as it enters the bore.

15Fit new dust covers to the grooves in the

pistons and wheel cylinder body.

16Refit the bleed screw.

Refitting

17Wipe clean the backplate, and remove the

plug from the end of the hydraulic pipe. Fit the

cylinder onto the backplate, and screw in the

hydraulic union nut by hand, being careful not

to cross-thread it.18Tighten the mounting bolts, then fully

tighten the hydraulic union nut.

19Retract the automatic brake adjuster

mechanism, so that the brake shoes engage

with the pistons of the wheel cylinder. To do

this, prise the shoes apart slightly, turn the

automatic adjuster to its minimum position,

and release the shoes.

20Remove the clamp from the flexible brake

hose, or the polythene from the master

cylinder (as applicable).

21Refit the brake drum with reference to

Section 5.

22Bleed the brake hydraulic system as

described in Section 15. Providing suitable

precautions were taken to minimise loss of

fluid, it should only be necessary to bleed the

relevant rear brake.

23Test the brakes carefully before returning

the vehicle to normal service.

Warning: Disc brake pads must

be renewed on BOTH rear wheels

at the same time - never renew

the pads on only one wheel, as

uneven braking may result. Although

genuine Ford linings are asbestos-free, the

dust created by wear of non-genuine pads

may contain asbestos, which is a health

hazard. Never blow it out with compressed

air, and don’t inhale any of it. DO NOT use

petroleum-based solvents to clean brake

parts; use brake cleaner or methylated

spirit only. DO NOT allow any brake fluid,

oil or grease to contact the brake pads or

disc.

1Chock the front wheels, and engage 1st

gear (or “P”). Loosen the rear wheel nuts, jack

up the rear of the vehicle and support it on

axle stands.

2Remove the rear wheels. Work on one

brake assembly at a time, using the

assembled brake for reference if necessary.

3Inspect the rear brake disc as described in

Section 10.

4Extract the spring clip, and pull out the

retaining pin securing the caliper to the carrier

8 Rear brake pads - renewal

7 Rear wheel cylinder -

removal, overhaul and refitting

9•8 Braking system

6.2N Clean the backplate, and apply small

amounts of high-melting-point brake

grease to the brake shoe contact points.

Be careful not to get grease on any friction

surfaces6.2O Lubricate the sliding components of

the automatic adjuster with a little high-

melting-point brake grease, but leave the

serrations on the eccentric cam shown

here clean7.5 Bolts securing the wheel cylinder to

the backplate. Hydraulic union nut and

bleed screw cover are also visible

procarmanuals.com

Page 127 of 279

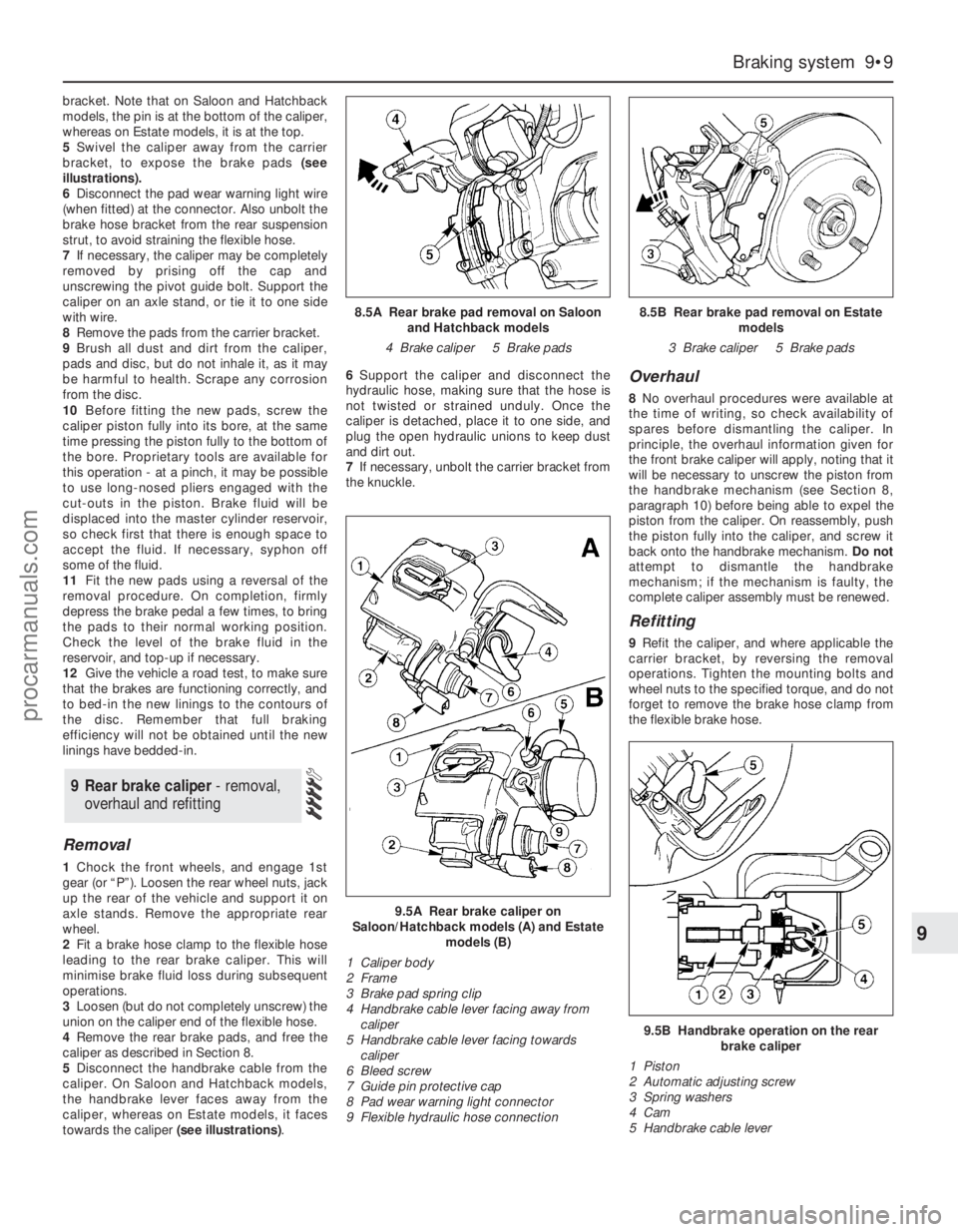

bracket. Note that on Saloon and Hatchback

models, the pin is at the bottom of the caliper,

whereas on Estate models, it is at the top.

5Swivel the caliper away from the carrier

bracket, to expose the brake pads (see

illustrations).

6Disconnect the pad wear warning light wire

(when fitted) at the connector. Also unbolt the

brake hose bracket from the rear suspension

strut, to avoid straining the flexible hose.

7If necessary, the caliper may be completely

removed by prising off the cap and

unscrewing the pivot guide bolt. Support the

caliper on an axle stand, or tie it to one side

with wire.

8Remove the pads from the carrier bracket.

9Brush all dust and dirt from the caliper,

pads and disc, but do not inhale it, as it may

be harmful to health. Scrape any corrosion

from the disc.

10Before fitting the new pads, screw the

caliper piston fully into its bore, at the same

time pressing the piston fully to the bottom of

the bore. Proprietary tools are available for

this operation - at a pinch, it may be possible

to use long-nosed pliers engaged with the

cut-outs in the piston. Brake fluid will be

displaced into the master cylinder reservoir,

so check first that there is enough space to

accept the fluid. If necessary, syphon off

some of the fluid.

11Fit the new pads using a reversal of the

removal procedure. On completion, firmly

depress the brake pedal a few times, to bring

the pads to their normal working position.

Check the level of the brake fluid in the

reservoir, and top-up if necessary.

12Give the vehicle a road test, to make sure

that the brakes are functioning correctly, and

to bed-in the new linings to the contours of

the disc. Remember that full braking

efficiency will not be obtained until the new

linings have bedded-in.

Removal

1Chock the front wheels, and engage 1st

gear (or “P”). Loosen the rear wheel nuts, jack

up the rear of the vehicle and support it on

axle stands. Remove the appropriate rear

wheel.

2Fit a brake hose clamp to the flexible hose

leading to the rear brake caliper. This will

minimise brake fluid loss during subsequent

operations.

3Loosen (but do not completely unscrew) the

union on the caliper end of the flexible hose.

4Remove the rear brake pads, and free the

caliper as described in Section 8.

5Disconnect the handbrake cable from the

caliper. On Saloon and Hatchback models,

the handbrake lever faces away from the

caliper, whereas on Estate models, it faces

towards the caliper (see illustrations).6Support the caliper and disconnect the

hydraulic hose, making sure that the hose is

not twisted or strained unduly. Once the

caliper is detached, place it to one side, and

plug the open hydraulic unions to keep dust

and dirt out.

7If necessary, unbolt the carrier bracket from

the knuckle.

Overhaul

8No overhaul procedures were available at

the time of writing, so check availability of

spares before dismantling the caliper. In

principle, the overhaul information given for

the front brake caliper will apply, noting that it

will be necessary to unscrew the piston from

the handbrake mechanism (see Section 8,

paragraph 10) before being able to expel the

piston from the caliper. On reassembly, push

the piston fully into the caliper, and screw it

back onto the handbrake mechanism. Do not

attempt to dismantle the handbrake

mechanism; if the mechanism is faulty, the

complete caliper assembly must be renewed.

Refitting

9Refit the caliper, and where applicable the

carrier bracket, by reversing the removal

operations. Tighten the mounting bolts and

wheel nuts to the specified torque, and do not

forget to remove the brake hose clamp from

the flexible brake hose.

9 Rear brake caliper - removal,

overhaul and refitting

Braking system 9•9

9

9.5A Rear brake caliper on

Saloon/Hatchback models (A) and Estate

models (B)

1 Caliper body

2 Frame

3 Brake pad spring clip

4 Handbrake cable lever facing away from

caliper

5 Handbrake cable lever facing towards

caliper

6 Bleed screw

7 Guide pin protective cap

8 Pad wear warning light connector

9 Flexible hydraulic hose connection

9.5B Handbrake operation on the rear

brake caliper

1 Piston

2 Automatic adjusting screw

3 Spring washers

4 Cam

5 Handbrake cable lever

8.5A Rear brake pad removal on Saloon

and Hatchback models

4 Brake caliper 5 Brake pads8.5B Rear brake pad removal on Estate

models

3 Brake caliper 5 Brake pads

procarmanuals.com

Page 128 of 279

10Bleed the brake circuit according to the

procedure given in Section 15. Make sure

there are no leaks from the hose connections.

Test the brakes carefully before returning the

vehicle to normal service.

Refer to Section 4 (front disc inspection).

Once the rear caliper is removed, the

procedure is the same.

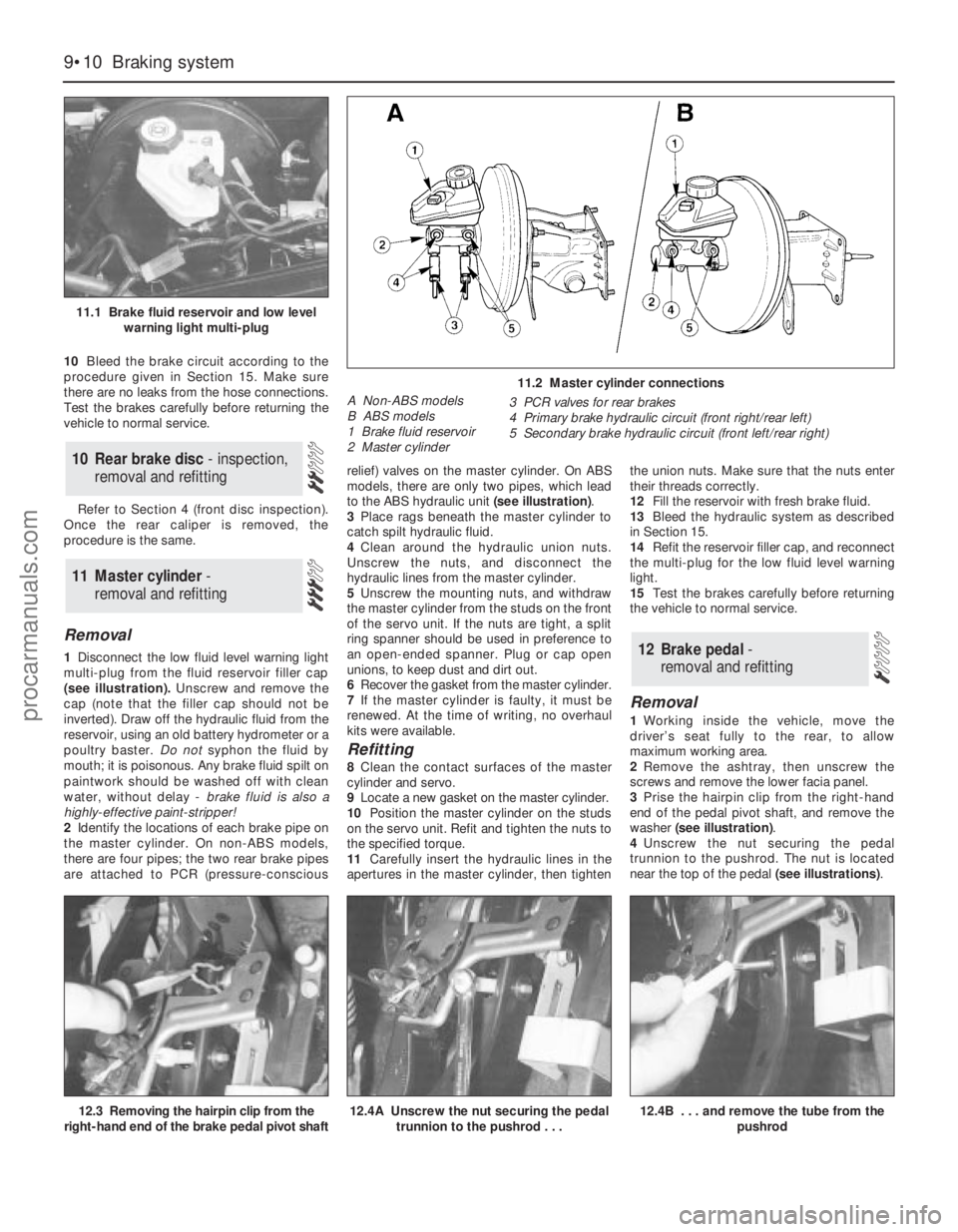

Removal

1Disconnect the low fluid level warning light

multi-plug from the fluid reservoir filler cap

(see illustration).Unscrew and remove the

cap (note that the filler cap should not be

inverted). Draw off the hydraulic fluid from the

reservoir, using an old battery hydrometer or a

poultry baster. Do notsyphon the fluid by

mouth; it is poisonous. Any brake fluid spilt on

paintwork should be washed off with clean

water, without delay - brake fluid is also a

highly-effective paint-stripper!

2Identify the locations of each brake pipe on

the master cylinder. On non-ABS models,

there are four pipes; the two rear brake pipes

are attached to PCR (pressure-consciousrelief) valves on the master cylinder. On ABS

models, there are only two pipes, which lead

to the ABS hydraulic unit (see illustration).

3Place rags beneath the master cylinder to

catch spilt hydraulic fluid.

4Clean around the hydraulic union nuts.

Unscrew the nuts, and disconnect the

hydraulic lines from the master cylinder.

5Unscrew the mounting nuts, and withdraw

the master cylinder from the studs on the front

of the servo unit. If the nuts are tight, a split

ring spanner should be used in preference to

an open-ended spanner. Plug or cap open

unions, to keep dust and dirt out.

6Recover the gasket from the master cylinder.

7If the master cylinder is faulty, it must be

renewed. At the time of writing, no overhaul

kits were available.

Refitting

8Clean the contact surfaces of the master

cylinder and servo.

9Locate a new gasket on the master cylinder.

10Position the master cylinder on the studs

on the servo unit. Refit and tighten the nuts to

the specified torque.

11Carefully insert the hydraulic lines in the

apertures in the master cylinder, then tightenthe union nuts. Make sure that the nuts enter

their threads correctly.

12Fill the reservoir with fresh brake fluid.

13Bleed the hydraulic system as described

in Section 15.

14Refit the reservoir filler cap, and reconnect

the multi-plug for the low fluid level warning

light.

15Test the brakes carefully before returning

the vehicle to normal service.

Removal

1Working inside the vehicle, move the

driver’s seat fully to the rear, to allow

maximum working area.

2Remove the ashtray, then unscrew the

screws and remove the lower facia panel.

3Prise the hairpin clip from the right-hand

end of the pedal pivot shaft, and remove the

washer (see illustration).

4Unscrew the nut securing the pedal

trunnion to the pushrod. The nut is located

near the top of the pedal (see illustrations).

12 Brake pedal-

removal and refitting

11 Master cylinder -

removal and refitting

10 Rear brake disc - inspection,

removal and refitting

9•10 Braking system

11.1 Brake fluid reservoir and low level

warning light multi-plug

11.2 Master cylinder connections

A Non-ABS models

B ABS models

1 Brake fluid reservoir

2 Master cylinder3 PCR valves for rear brakes

4 Primary brake hydraulic circuit (front right/rear left)

5 Secondary brake hydraulic circuit (front left/rear right)

12.3 Removing the hairpin clip from the

right-hand end of the brake pedal pivot shaft12.4A Unscrew the nut securing the pedal

trunnion to the pushrod . . .12.4B . . . and remove the tube from the

pushrod

procarmanuals.com

Page 131 of 279

and remove the clevis pin securing the servo

unit pushrod to the pedal cross-link arm.

7On left-hand drive models, unscrew the nut

securing the pedal trunnion to the servo unit

pushrod inside the passenger compartment.

The nut is located near the top of the pedal,

and is accessible through an access hole. For

improved access, remove the lower facia

panel first.

8Withdraw the servo unit from the bulkhead,

and remove it from the engine compartment.

On left-hand drive models, take care not to

damage the bulkhead rubber grommet as the

pushrod passes through it.

9Note that the servo unit cannot be

dismantled for repair or overhaul and, if faulty,

must be renewed.

Refitting

10Refitting is a reversal of the removal

procedure. Refer to Section 11 for details of

refitting the master cylinder.

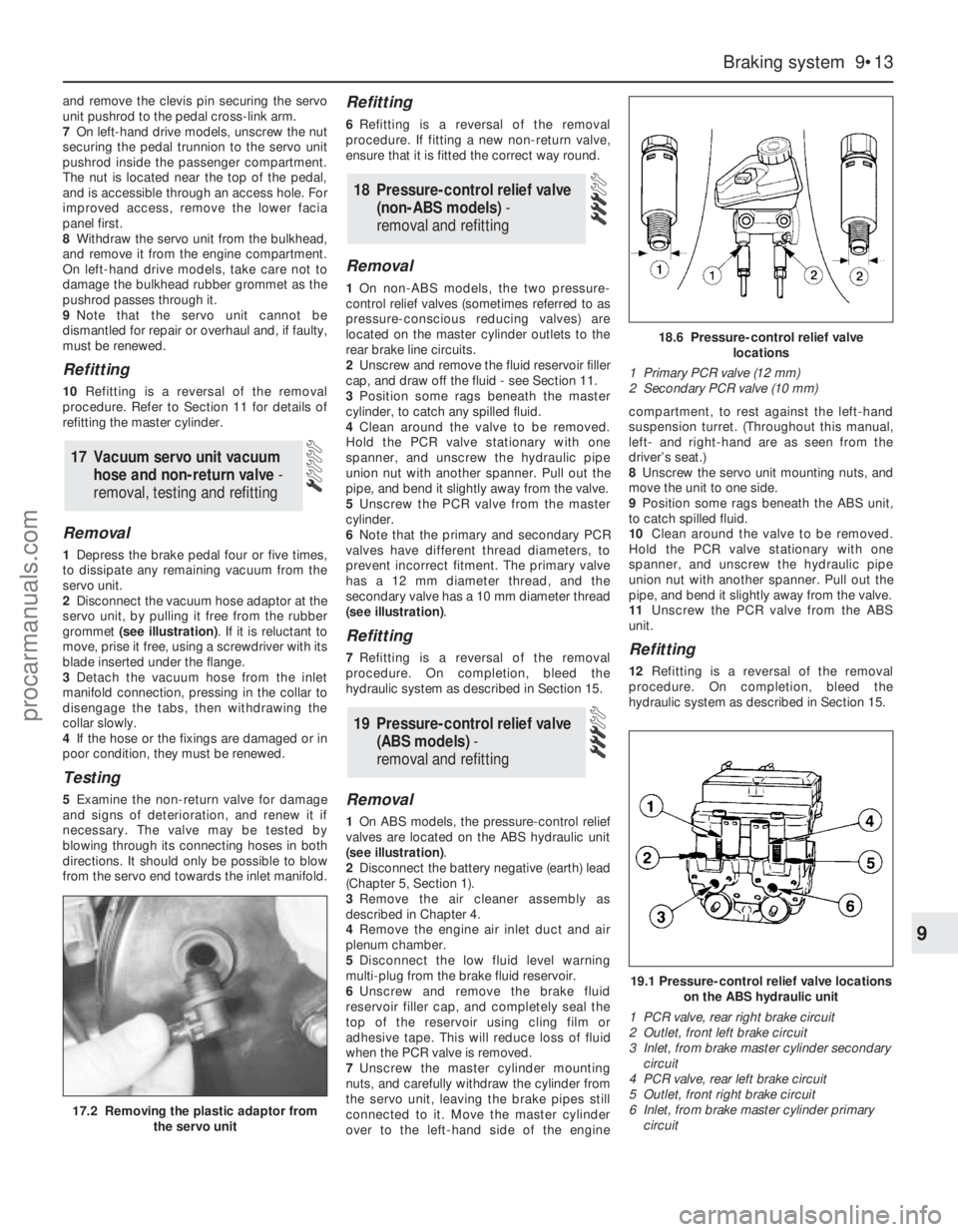

Removal

1Depress the brake pedal four or five times,

to dissipate any remaining vacuum from the

servo unit.

2Disconnect the vacuum hose adaptor at the

servo unit, by pulling it free from the rubber

grommet (see illustration). If it is reluctant to

move, prise it free, using a screwdriver with its

blade inserted under the flange.

3Detach the vacuum hose from the inlet

manifold connection, pressing in the collar to

disengage the tabs, then withdrawing the

collar slowly.

4If the hose or the fixings are damaged or in

poor condition, they must be renewed.

Testing

5Examine the non-return valve for damage

and signs of deterioration, and renew it if

necessary. The valve may be tested by

blowing through its connecting hoses in both

directions. It should only be possible to blow

from the servo end towards the inlet manifold.

Refitting

6Refitting is a reversal of the removal

procedure. If fitting a new non-return valve,

ensure that it is fitted the correct way round.

Removal

1On non-ABS models, the two pressure-

control relief valves (sometimes referred to as

pressure-conscious reducing valves) are

located on the master cylinder outlets to the

rear brake line circuits.

2Unscrew and remove the fluid reservoir filler

cap, and draw off the fluid - see Section 11.

3Position some rags beneath the master

cylinder, to catch any spilled fluid.

4Clean around the valve to be removed.

Hold the PCR valve stationary with one

spanner, and unscrew the hydraulic pipe

union nut with another spanner. Pull out the

pipe, and bend it slightly away from the valve.

5Unscrew the PCR valve from the master

cylinder.

6Note that the primary and secondary PCR

valves have different thread diameters, to

prevent incorrect fitment. The primary valve

has a 12 mm diameter thread, and the

secondary valve has a 10 mm diameter thread

(see illustration).

Refitting

7Refitting is a reversal of the removal

procedure. On completion, bleed the

hydraulic system as described in Section 15.

Removal

1On ABS models, the pressure-control relief

valves are located on the ABS hydraulic unit

(see illustration).

2Disconnect the battery negative (earth) lead

(Chapter 5, Section 1).

3Remove the air cleaner assembly as

described in Chapter 4.

4Remove the engine air inlet duct and air

plenum chamber.

5Disconnect the low fluid level warning

multi-plug from the brake fluid reservoir.

6Unscrew and remove the brake fluid

reservoir filler cap, and completely seal the

top of the reservoir using cling film or

adhesive tape. This will reduce loss of fluid

when the PCR valve is removed.

7Unscrew the master cylinder mounting

nuts, and carefully withdraw the cylinder from

the servo unit, leaving the brake pipes still

connected to it. Move the master cylinder

over to the left-hand side of the enginecompartment, to rest against the left-hand

suspension turret. (Throughout this manual,

left- and right-hand are as seen from the

driver’s seat.)

8Unscrew the servo unit mounting nuts, and

move the unit to one side.

9Position some rags beneath the ABS unit,

to catch spilled fluid.

10Clean around the valve to be removed.

Hold the PCR valve stationary with one

spanner, and unscrew the hydraulic pipe

union nut with another spanner. Pull out the

pipe, and bend it slightly away from the valve.

11Unscrew the PCR valve from the ABS

unit.

Refitting

12Refitting is a reversal of the removal

procedure. On completion, bleed the

hydraulic system as described in Section 15.

19 Pressure-control relief valve

(ABS models) -

removal and refitting

18 Pressure-control relief valve

(non-ABS models) -

removal and refitting

17 Vacuum servo unit vacuum

hose and non-return valve -

removal, testing and refitting

Braking system 9•13

9

17.2 Removing the plastic adaptor from

the servo unit

18.6 Pressure-control relief valve

locations

1 Primary PCR valve (12 mm)

2 Secondary PCR valve (10 mm)

19.1 Pressure-control relief valve locations

on the ABS hydraulic unit

1 PCR valve, rear right brake circuit

2 Outlet, front left brake circuit

3 Inlet, from brake master cylinder secondary

circuit

4 PCR valve, rear left brake circuit

5 Outlet, front right brake circuit

6 Inlet, from brake master cylinder primary

circuit

procarmanuals.com

Page 133 of 279

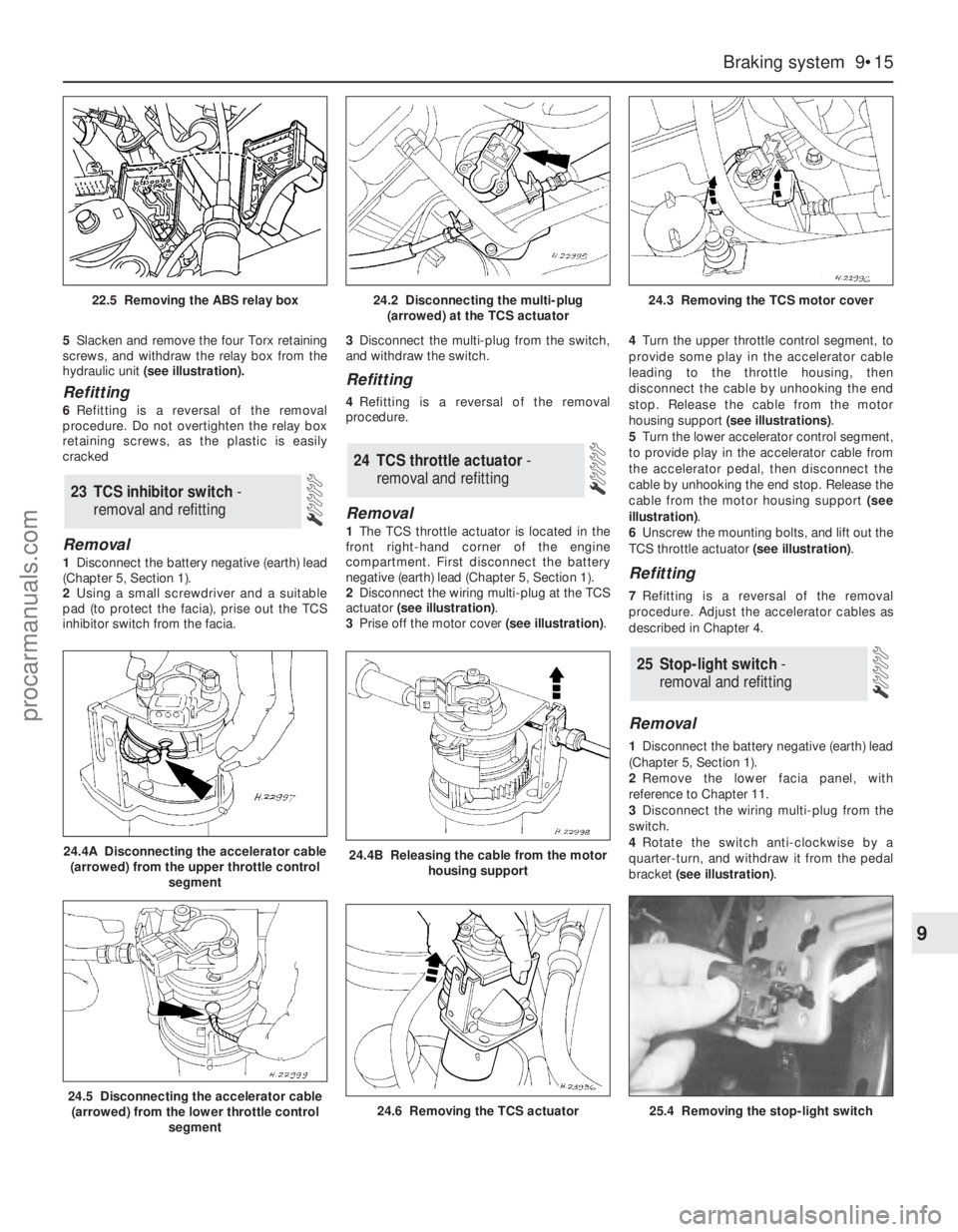

5Slacken and remove the four Torx retaining

screws, and withdraw the relay box from the

hydraulic unit (see illustration).

Refitting

6Refitting is a reversal of the removal

procedure. Do not overtighten the relay box

retaining screws, as the plastic is easily

cracked

Removal

1Disconnect the battery negative (earth) lead

(Chapter 5, Section 1).

2Using a small screwdriver and a suitable

pad (to protect the facia), prise out the TCS

inhibitor switch from the facia.3Disconnect the multi-plug from the switch,

and withdraw the switch.

Refitting

4Refitting is a reversal of the removal

procedure.

Removal

1The TCS throttle actuator is located in the

front right-hand corner of the engine

compartment. First disconnect the battery

negative (earth) lead (Chapter 5, Section 1).

2Disconnect the wiring multi-plug at the TCS

actuator (see illustration).

3Prise off the motor cover (see illustration).4Turn the upper throttle control segment, to

provide some play in the accelerator cable

leading to the throttle housing, then

disconnect the cable by unhooking the end

stop. Release the cable from the motor

housing support (see illustrations).

5Turn the lower accelerator control segment,

to provide play in the accelerator cable from

the accelerator pedal, then disconnect the

cable by unhooking the end stop. Release the

cable from the motor housing support (see

illustration).

6Unscrew the mounting bolts, and lift out the

TCS throttle actuator (see illustration).

Refitting

7Refitting is a reversal of the removal

procedure. Adjust the accelerator cables as

described in Chapter 4.

Removal

1Disconnect the battery negative (earth) lead

(Chapter 5, Section 1).

2Remove the lower facia panel, with

reference to Chapter 11.

3Disconnect the wiring multi-plug from the

switch.

4Rotate the switch anti-clockwise by a

quarter-turn, and withdraw it from the pedal

bracket (see illustration).

25 Stop-light switch -

removal and refitting

24 TCS throttle actuator -

removal and refitting

23 TCS inhibitor switch -

removal and refitting

Braking system 9•15

9

24.4B Releasing the cable from the motor

housing support24.4A Disconnecting the accelerator cable

(arrowed) from the upper throttle control

segment

24.5 Disconnecting the accelerator cable

(arrowed) from the lower throttle control

segment24.6 Removing the TCS actuator

22.5 Removing the ABS relay box24.2 Disconnecting the multi-plug

(arrowed) at the TCS actuator24.3 Removing the TCS motor cover

25.4 Removing the stop-light switch

procarmanuals.com

Page 134 of 279

Refitting and adjustment

5With the switch removed, reset it by fully

extending its plunger.

6Depress the brake pedal until the distance

between the pedal and mounting bracket is as

shown (see illustration).

7Hold the pedal in this position, and refit the

stop-light switch to the mounting bracket .

8With the switch securely clipped in position,

release the brake pedal, and gently pull it fully

back to the at-rest position. This will

automatically set the adjustment of the stop-

light switch.

9reconnect the wiring connector and the

battery, and check the operation of the switch

prior to refitting the lower facia panel (Chapter 11).

Removal

1Raise the front and rear of the vehicle, and

support it on axle stands. Fully release the

handbrake lever.

2Remove the centre console as described in

Chapter 11.

3Working beneath the vehicle, release the

exhaust system from the rubber mountings.

Lower the exhaust system as far as possible,

supporting it on blocks or more axle stands.

4Detach the exhaust heat shield from the

underbody.

5Unhook the secondary (rear) handbrake

cables from the equaliser bar.

6Working inside the vehicle, unscrew and

remove the two mounting bolts securing the

handbrake lever to the floor (see illustration).7Turn the handbrake lever upsidedown, then

disconnect the primary cable end from the

segment.

8Withdraw the handbrake from inside the

vehicle.

Refitting

9Refitting is a reversal of the removal

procedure, making sure that the primary cable

is correctly located in the segment. Check the

operation of the handbrake before returning

the vehicle to normal service.

Removal

Primary (front)

1Remove the handbrake lever as described

in Section 26.

2Prise the grommet from the underbody,

and withdraw the cable from beneath the

vehicle.

Secondary (rear)

3Chock the front wheels, and engage 1st

gear (or “P”). Jack up the rear of the vehicle

and support it on axle stands. Fully release

the handbrake lever.

4Remove the relevant rear wheel.5Working beneath the vehicle, release the

exhaust system from the rubber mountings.

Lower the exhaust system as far as possible,

supporting it on blocks or more axle stands.

6Unbolt the exhaust heat shield from the

underbody.

7Unhook the relevant cable from the

equaliser bar.

8On drum brake models, remove the rear

brake shoes on the relevant side as described

in Section 6, then remove the outer cable from

the backplate by compressing the three

retaining lugs (use a suitable ring spanner)

and pushing the cable through (see

illustration).

9On disc brake models, unhook the end of

the cable from the handbrake operating arm

on the rear caliper.

10Release the lugs securing the outer cable

to the underbody brackets, then release the

cable from the clips, and withdraw it from

under the vehicle (see illustrations).

Refitting

All cables

11Refitting is a reversal of the removal

procedure, but make sure that the cable end

fittings are correctly located. Check the

operation of the handbrake before returning

the vehicle to normal service.

27 Handbrake cables -

removal and refitting

26 Handbrake lever -

removal and refitting

9•16 Braking system

25.6 To ensure correct adjustment,

position the brake pedal as shown prior to

refitting the switch to its mounting bracket

26.6 Handbrake lever mounting bolts27.8 Using a ring spanner to compress the

retaining lugs securing the outer cable to

the backplate

27.10A Release the lugs using a ring

spanner . . .27.10B . . . and remove the outer cable

from the underbody brackets

procarmanuals.com

Page 138 of 279

constantly monitors the oxygen content of the

exhaust gas. If the percentage of oxygen in

the exhaust gas is incorrect, an electrical

signal is sent to the ECU. The ECU processes

this information, and then sends a command

to the fuel injection system, telling it to change

the air/fuel mixture; the end result is an air/fuel

mixture ratio which is constantly maintained

at a predetermined ratio, regardless of driving

conditions. This happens in a fraction of a

second, and goes on almost all the time while

the engine is running - the exceptions are that

the ECU cuts out the system and runs the

engine on values pre-programmed

(“mapped”) into its memory both while the

oxygen sensor is reaching its normal

operating temperature after the engine has

been started from cold, and when the throttle

is fully open for full acceleration.

In the event of a sensor malfunction, a

back-up circuit will take over, to provide

driveability until the problem is identified and

fixed.

Precautions

(a) Always disconnect the power by

uncoupling the battery terminals - see

Section 1 of Chapter 5 - before removing

any of the electronic control system’s

electrical connectors.

(b) When installing a battery, be particularly

careful to avoid reversing the positive and

negative battery leads.

(c) Do not subject any components of the

system (especially the ECU) to severe

impact during removal or installation.

(d) Do not be careless during fault diagnosis.

Even slight terminal contact can invalidate

a testing procedure, and damage one of

the numerous transistor circuits.

(e) Never attempt to work on the ECU, to test

it (with any kind of test equipment), or to

open its cover.

(f) If you are inspecting electronic control

system components during rainy weather,

make sure that water does not enter any

part. When washing the engine

compartment, do not spray these parts or

their electrical connectors with water.

General

The various components of the fuel, ignition

and emissions control systems (not forgetting

the same ECU’s control of sub-systems such

as the radiator cooling fan, air conditioning

and automatic transmission, where

appropriate) are so closely interlinked that

diagnosis of a fault in any one component is

virtually impossible using traditional methods.

Working on simpler systems in the past, the

experienced mechanic may well have been

able to use personal skill and knowledge

immediately to pinpoint the cause of a fault, or

quickly to isolate the fault, by elimination;however, with an engine management system

integrated to this degree, this is not likely to

be possible in most instances, because of the

number of symptoms that could arise from

even a minor fault.

So that the causes of faults can be quickly

and accurately traced and rectified, the ECU

is provided with a built-in self-diagnosis

facility, which detects malfunctions in the

system’s components. When a fault occurs,

three things happen: the ECU identifies the

fault, stores a corresponding code in its

memory, and (in most cases) runs the system

using back-up values pre-programmed

(“mapped”) into its memory; some form of

driveability is thus maintained, to enable the

vehicle to be driven to a garage for attention.

Any faults that may have occurred are

indicated in the form of three-digit codes

when the system is connected (via the built-in

diagnosis or self-test connectors, as

appropriate) to special diagnostic equipment -

this points the user in the direction of the

faulty circuit, so that further tests can pinpoint

the exact location of the fault.

Given below is the procedure that would be

followed by a Ford technician to trace a fault

from scratch. Should your vehicle’s engine

management system develop a fault, read

through the procedure and decide how much

you can attempt, depending on your skill and

experience and the equipment available to

you, or whether it would be simpler to have

the vehicle attended to by your local Ford

dealer. If you are concerned about the

apparent complexity of the system, however,

remember the comments made in the fourth

paragraph of Section 1 of this Chapter; the

preliminary checks require nothing but care,

patience and a few minor items of equipment,

and may well eliminate the majority of faults.

(a) Preliminary checks

(b) Fault code read-out *

(c) Check ignition timing and base idle

speed. Recheck fault codes to establish

whether fault has been cured or not *

(d) Carry out basic check of ignition system

components. Recheck fault codes to

establish whether fault has been cured or

not *

(e) Carry out basic check of fuel system

components. Recheck fault codes to

establish whether fault has been cured or

not *

(f) If fault is still not located, carry out system

test *

Note:Operations marked with an asterisk

require special test equipment.

Preliminary checks

Note:When carrying out these checks to

trace a fault, remember that if the fault has

appeared only a short time after any part of

the vehicle has been serviced or overhauled,

the first place to check is where that work was

carried out, however unrelated it may appear,

to ensure that no carelessly-refitted

components are causing the problem.If you are tracing the cause of a “partial”

engine fault, such as lack of performance, in

addition to the checks outlined below, check

the compression pressures (see Part A of

Chapter 2) and bear in mind the possibility

that one of the hydraulic tappets might be

faulty, producing an incorrect valve clearance.

Check also that the fuel filter has been

renewed at the recommended intervals.

If the system appears completely dead,

remember the possibility that the

alarm/inhibitor system may be responsible.

1The first check for anyone without special

test equipment is to switch on the ignition,

and to listen for the fuel pump (the sound of

an electric motor running, audible from

beneath the rear seats); assuming there is

sufficient fuel in the tank, the pump should

start and run for approximately one or two

seconds, then stop, each time the ignition is

switched on. If the pump runs continuously all

the time the ignition is switched on, the

electronic control system is running in the

back-up (or “limp-home”) mode referred to by

Ford as “Limited Operation Strategy” (LOS).

This almost certainly indicates a fault in the

ECU itself, and the vehicle should therefore be

taken to a Ford dealer for a full test of the

complete system using the correct diagnostic

equipment; do not waste time trying to test

the system without such facilities.

2If the fuel pump is working correctly (or not

at all), a considerable amount of fault

diagnosis is still possible without special test

equipment. Start the checking procedure as

follows.

3Open the bonnet and check the condition

of the battery connections - remake the

connections or renew the leads if a fault is

found (Chapter 5). Use the same techniques

to ensure that all earth points in the engine

compartment provide good electrical contact

through clean, metal-to-metal joints, and that

all are securely fastened. (In addition to the

earth connection at the engine lifting eye and

that from the transmission to the

body/battery, there is one earth connection

behind each headlight assembly, and one

below the power steering fluid reservoir.)

4Referring to the information given in

Chapter 12 and in the wiring diagrams at the

back of this manual, check that all fuses

protecting the circuits related to the engine

management system are in good condition.

Fit new fuses if required; while you are there,

check that all relays are securely plugged into

their sockets.

5Next work methodically around the engine

compartment, checking all visible wiring, and

the connections between sections of the

wiring loom. What you are looking for at this

stage is wiring that is obviously damaged by

chafing against sharp edges, or against

moving suspension/transmission components

and/or the auxiliary drivebelt, by being

trapped or crushed between carelessly-

refitted components, or melted by being

forced into contact with hot engine castings,

3 Diagnosis system -

general information

6•4 Emissions control systems

procarmanuals.com

Page 140 of 279

back again, as an assistant depresses the

accelerator pedal. If the valve shows any sign

of stiffness, sticking or otherwise-inhibited

movement (and the accelerator cable is

known from the previous check to be in good

condition), spray the throttle linkage with

penetrating lubricant, allow time for it to work,

and repeat the check; if no improvement is

obtained, the complete throttle housing must

be renewed (Chapter 4).

15Unclip the air cleaner cover, and check

that the air filter element and the crankcase

ventilation system filter are not clogged or

soaked. (A clogged air filter will obstruct the

intake air flow, causing a noticeable effect on

engine performance; a clogged crankcase

ventilation system filter will inhibit crankcase

“breathing”). Renew or clean the filter(s) as

appropriate; refer to the relevant Sections of

Chapter 1 for further information, if required.

Before refitting the air cleaner cover, check

that the air intake (located under the front left-

hand wing, opening behind the direction

indicator/headlight assembly) is clear. It

should be possible to blow through the intake,

or to probe it (carefully) as far as the rear of

the direction indicator light.

16Start the engine and allow it to idle.

Note:Working in the engine compartment

while the engine is running requires great care

if the risk of personal injury is to be avoided;

among the dangers are burns from contact

with hot components, or contact with moving

components such as the radiator cooling fan

or the auxiliary drivebelt. Refer to “Safety

first!” at the front of this manual before

starting, and ensure that your hands, and long

hair or loose clothing, are kept well clear of hot

or moving components at all times.

17Working from the air intake junction at the

inner wing panel, via the air cleaner assembly

and air mass meter, to the resonator, plenum

chamber, throttle housing and inlet manifold

(and including the various vacuum hoses and

pipes connected to these), check for air leaks.

Usually, these will be revealed by sucking or

hissing noises, but minor leaks may be traced

by spraying a solution of soapy water on to

the suspect joint; if a leak exists, it will be

shown by the change in engine note and the

accompanying air bubbles (or sucking-in of

the liquid, depending on the pressure

difference at that point). If a leak is found at

any point, tighten the fastening clamp and/or

renew the faulty components, as applicable.

18Similarly, work from the cylinder head, via

the manifold (and not forgetting the related

EGR and pulse-air system components) to the

tailpipe, to check that the exhaust system is

free from leaks. The simplest way of doing

this, if the vehicle can be raised and

supported safely and with complete security

while the check is made, is to temporarily

block the tailpipe while listening for the sound

of escaping exhaust gases; any leak should

be evident. If a leak is found at any point,

tighten the fastening clamp bolts and/or nuts,

renew the gasket, and/or renew the faultysection of the system, as necessary, to seal

the leak.

19It is possible to make a further check of

the electrical connections by wiggling each

electrical connector of the system in turn as

the engine is idling; a faulty connector will be

immediately evident from the engine’s

response as contact is broken and remade. A

faulty connector should be renewed to ensure

the future reliability of the system; note that

this may mean the renewal of that entire

section of the loom - see your local Ford

dealer for details.

20Switch off the engine. If the fault is not yet

identified, the next step is to check the

ignition voltages, using an engine analyser

with an oscilloscope - without such

equipment, the only tests possible are to

remove and check each spark plug in turn, to

check the spark plug (HT) lead connections

and resistances, and to check the

connections and resistances of the ignition

coil. Refer to the relevant Sections of

Chapters 1 and 5.

21The final step in these preliminary checks

would be to use an exhaust gas analyser to

measure the CO level at the exhaust tailpipe.This check cannot be made without special

test equipment - see your local Ford dealer for

details.

Fault code read-out

22As noted in the general comments at the

beginning of this Section, the preliminary

checks outlined above should eliminate the

majority of faults from the engine

management system. If the fault is not yet

identified, the next step is to connect a fault

code reader to the ECU, so that its self-

diagnosis facility can be used to identify the

faulty part of the system; further tests can

then be made to identify the exact cause of

the fault.

23In their basic form, fault code readers are

simply hand-held electronic devices, which

take data stored within an ECU’s memory and

display it when required as two- or three-digit

fault codes. The more sophisticated versions

now available can also control sensors and

actuators, to provide more effective testing;

some can store information, so that a road

test can be carried out, and any faults

encountered during the test can be displayed

afterwards.

6•6 Emissions control systems

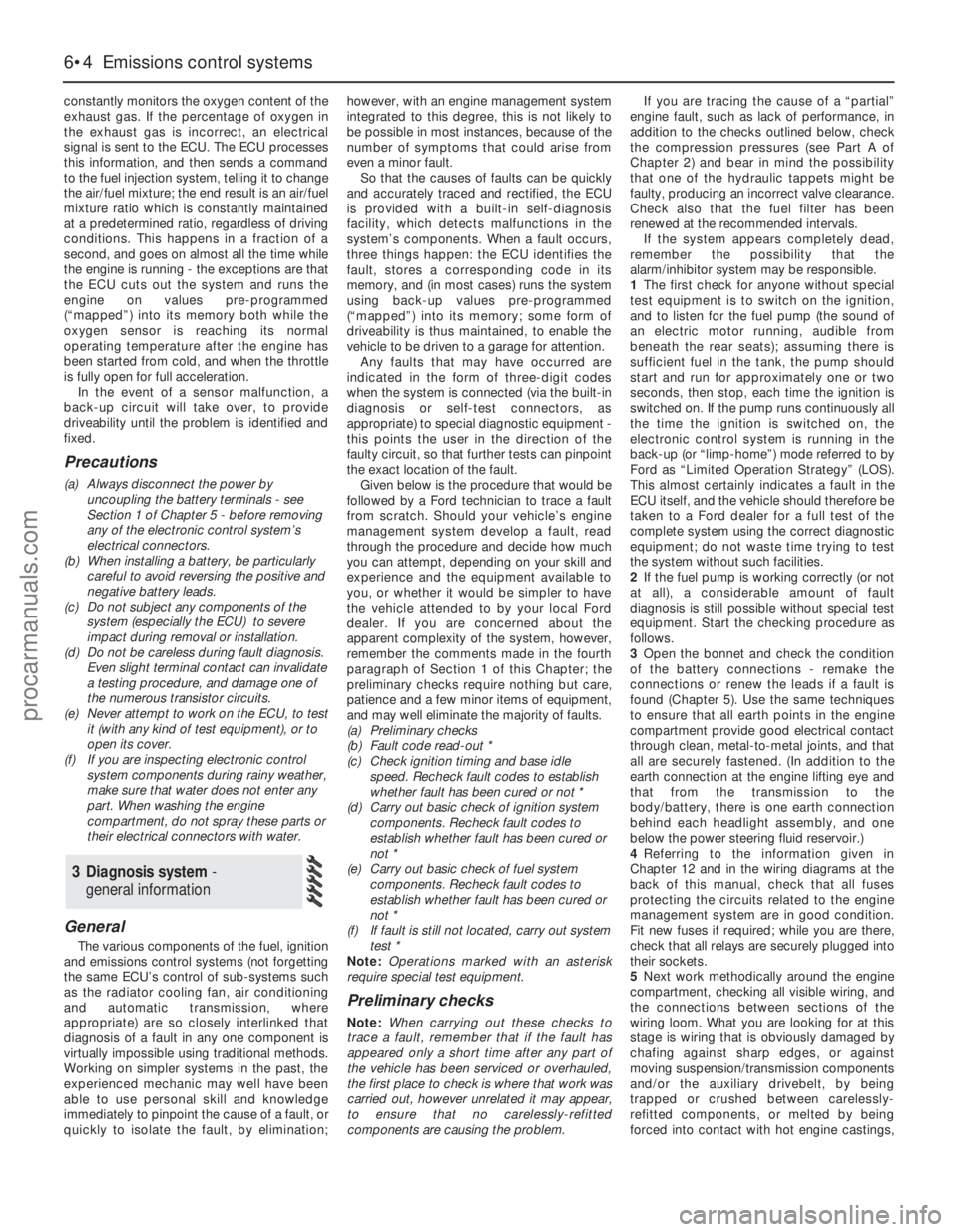

3.26 Location and terminal identification of engine management system self-test,

diagnosis and service connectors

1 Power steering fluid reservoir

2 Diagnosis connector - for Ford diagnostic equipment FDS 2000

3 Self-test connector - for fault code read-out - pin 17 is output terminal, pin 48 is input

terminal, pin 40/60 is earth

4 Service connector - for octane adjustment

5 Plug-in bridge - to suit 95 RON fuel

procarmanuals.com

Page 141 of 279

24Ford specify the use of their STAR (Self-

Test Automatic Readout) tester; most Ford

dealers should have such equipment, and the

staff trained to use it effectively. The only

alternatives are as follows:

(a) To obtain one of those proprietary readers

which can interpret EEC-IV three-digit

codes - at present, such readers are too

expensive for the DIY enthusiast, but are

becoming more popular with smaller

specialist garages.

(b) To use an analogue voltmeter, whereby

the stored codes are displayed as sweeps

of the voltmeter needle. This option limits

the operator to a read-out of any codes

stored - ie, there is no control of sensors

and/or actuators - but can still be useful in

pinpointing the faulty part of the engine

management system. The display is

interpreted as follows. Each code

(whether fault code or

command/separator) is marked by a

three-to-four second pause - code “538”

would therefore be shown as long (3 to

4 seconds) pause, five fast sweeps of the

needle, slight (1 second) pause, three fast

sweeps, slight pause, eight fast sweeps,

long pause.

(c) Owners without access to such

equipment must take the vehicle to a Ford

dealer, or to an expert who has similar

equipment and the skill to use it.

25Because of the variations in the design of

fault code readers, it is not possible to give

exact details of the sequence of tests; the

manufacturer’s instructions must be followed,

in conjunction with the codes given below.

The following ten paragraphs outline the

procedure to be followed using a version of

the Ford STAR tester, to illustrate the general

principles, as well as notes to guide the owner

using only a voltmeter.

26The vehicle must be prepared by applying

the handbrake, switching off the air

conditioning (where fitted) and any other

electrical loads (lights, heated rear window,

etc), then selecting neutral (manual

transmission) or the “P” position (automatic

transmission). Where the engine is required to

be running, it must be fully warmed-up to

normal operating temperature before the test

is started. Using any adaptors required,

connect the fault code reader to the system

via the (triangular, three-pin) self-test

connector on the right-hand end of the engine

compartment bulkhead (see illustration). If a

voltmeter is being used, connect its positive

lead to the battery positive terminal, and its

negative lead to the self-test connector’s

output terminal, pin 17. Have a pen and paper

ready to write down the codes displayed.

27Set the tester in operation. For the Ford

STAR tester, a display check will be carried

out and the test mode requirements must be

entered. If a voltmeter is being used, connect

a spare length of wire to earth the self-test

connector’s input terminal, pin 48. Be very

careful to ensure that you earth the correctterminal - the one with the white/green wire.

The first part of the test starts, with the

ignition switched on, but with the engine off.

On pressing the “Mem/test” button, the tester

displays “TEST” and the ready code “000”,

followed by a command code “010” - the

accelerator pedal must be fully depressed

within 10 seconds of the command code

appearing, or fault codes “576” or “577” will

appear when they are called up later. If a

voltmeter is being used, code “000” will not

appear (except perhaps as a flicker of the

needle) and “010” will appear as a single

sweep - to ensure correct interpretation of the

display, watch carefully for the interval

between the end of one code and the

beginning of the next, otherwise you will

become confused and misinterpret the read-

out.

28The tester will then display the codes for

any faults in the system at the time of the test.

Each code is repeated once; if no faults are

present, code “111” will be displayed. If a

voltmeter is being used, the pause between

repetitions will vary according to the

equipment in use and the number of faults in

the system, but was found to be

approximately 3 to 4 seconds - it may be

necessary to start again, and to repeat the

read-out until you are familiar with what you

are seeing.

29Next the tester will display code “010”

(now acting as a separator), followed by the

codes for any faults stored in the ECU’s

memory; if no faults were stored, code “111”

will be displayed.

30When prompted by the tester, the

operator must next depress the accelerator

pedal fully; the tester then checks several

actuators. Further test modes include a

“wiggle test” facility, whereby the operator

can check the various connectors as

described in paragraph 19 above (in this case,

any fault will be logged and the appropriate

code will be displayed), a facility for recalling

codes displayed, and a means for clearing the

ECU’s memory at the end of the test

procedure when any faults have been

rectified.

31The next step when using the Ford STAR

tester is to conduct a test with the engine

running. With the tester set in operation (see

paragraph 26 above) the engine is started and

allowed to idle. On pressing the “Mem/test”

button, the tester displays “TEST”, followed

by one of two codes, as follows.

32If warning code “998” appears, followed

by the appropriate fault code, switch off and

check as indicated the coolant temperature

sensor, the intake air temperature sensor, the

air mass meter, the throttle potentiometer

and/or their related circuits, then restart the

test procedure.

33If command code “020” appears, carry

out the following procedure within ten

seconds:

(a) Depress the brake pedal fully.

(b) Turn the steering to full-lock (either way)and centre it again, to produce a signal

from the power steering pressure switch -

if no signal is sent, fault code “521” will

be displayed.

(c) If automatic transmission is fitted, switch

the overdrive cancel button on and off,

then do the same for the

“Economy/Sport” mode switch.

(d) Wait for separator code “010” to be

displayed, then within 10 seconds,

depress the accelerator pedal fully,

increasing engine speed rapidly above

3000 rpm - release the pedal.

34Any faults found in the system will be

logged and displayed. Each code is repeated

once; if no faults are present, code “111” will

be displayed.

35When the codes have been displayed for

all faults logged, the ECU enters its “Service

Adjustment Programme”, as follows:

(a) The programme lasts for 2 minutes.

(b) The idle speed control valve is

deactivated, and the idle speed is set to

its pre-programmed (unregulated) value. If

the appropriate equipment is connected,

the base idle speed can be checked

(note, however, that it is not adjustable).

(c) The ignition timing can be checked if a

timing light is connected (note, however,

that it is not adjustable).

(d) Pressing the accelerator pedal fully at any

time during this period will execute a

cylinder balance test. Each injector in turn

is switched off, and the corresponding

decrease in engine speed is logged -

code “090” will be displayed if the test is

successful.

(e) At the end of the 2 minutes, the

completion of the programme is shown

by the engine speed briefly rising, then

returning to normal idling speed as

the idle speed control valve is

reactivated.

36As with the engine-off test, further test

modes include a “wiggle test” facility,

whereby the operator can check the various

connectors as described in paragraph 19

above (in this case, any fault will be logged

and the appropriate code will be displayed), a

facility for recalling codes displayed, and a

means for clearing the ECU’s memory at the

end of the test procedure when any faults

have been rectified. If equipment other than

the Ford STAR tester is used, the ECU’s

memory can be cleared by disconnecting the

battery - if this is not done, the code will

reappear with any other codes in the event of

subsequent trouble, but remember that other

systems with memory (such as the clock and

audio equipment) will also be affected. Should

it become necessary to disconnect the

battery during work on any other part of the

vehicle, first check to see if any fault codes

have been logged.

37Given overleaf are the possible codes,

their meanings, and where relevant, the action

to be taken as a result of a code being

displayed.

Emissions control systems 6•7

6

procarmanuals.com