light FORD MONDEO 1993 Service Manual PDF

[x] Cancel search | Manufacturer: FORD, Model Year: 1993, Model line: MONDEO, Model: FORD MONDEO 1993Pages: 279, PDF Size: 12.71 MB

Page 144 of 279

Ignition timing and base idle

speed check

Note:The following procedure is a check only,

essentially of the ECU. Both the ignition timing

and the base idle speed are controlled by the

ECU. The ignition timing is not adjustable at

all; the base idle speed is set in production,

and should not be altered.

38If the fault code read-out (with any checks

resulting from it) has not eliminated the fault,

the next step is to check the ECU’s control of

the ignition timing and the base idle speed.

This task requires the use of a Ford STAR

tester (a proprietary fault code reader can be

used only if it is capable of inducing the ECU

to enter its “Service Adjustment Programme”),

coupled with an accurate tachometer and a

good-quality timing light. Without this

equipment, the task is not possible; the

vehicle must be taken to a Ford dealer for

attention.

39To make the check, apply the handbrake,

switch off the air conditioning (where fitted)

and any other electrical loads (lights, heated

rear window, etc), then select neutral (manual

transmission) or the “P” position (automatic

transmission). Start the engine, and warm it

up to normal operating temperature. The

radiator electric cooling fan must be running

continuously while the check is made; this

should be activated by the ECU, when

prompted by the tester. Switch off the engine,

and connect the test equipment as directed

by the manufacturer - refer to paragraph 26

above for details of STAR tester connection.

40Raise and support the front of the vehicle

securely, and remove the auxiliary drivebelt

cover (see Chapter 1). Emphasise the two

pairs of notches in the inner and outer rims of

the crankshaft pulley, using white paint. Note

that an ignition timing reference mark is not

provided on the pulley - in the normal

direction of crankshaft rotation (clockwise,

seen from the right-hand side of the vehicle)

the first pair of notches are irrelevant to the

vehicles covered in this manual, while the

second pair indicate Top Dead Centre (TDC)

when aligned with the rear edge of the raised

mark on the sump; when checking the ignition

timing, therefore, the (rear edge of the) sumpmark should appear just before the TDC

notches (see Part A of Chapter 2, Section 4,

for further information if required).

41Start the engine and allow it to idle. Work

through the engine-running test procedure

until the ECU enters its “Service Adjustment

Programme” - see paragraph 35 above.

42Use the timing light to check that the

timing marks appear approximately as

outlined above at idle speed. Do not spend

too much time on this check; if the timing

appears to be incorrect, the system may have

a fault, and a full system test must be carried

out (see below) to establish its cause.

43Using the tachometer, check that the

base idle speed is as given in the

Specifications Section of Chapter 4.

44If the recorded speed differs significantly

from the specified value, check for air leaks,

as described in the preliminary checks

(paragraphs 15 to 18 above), or any other

faults which might cause the discrepancy.

45The base idle speed is set in production

by means of an air bypass screw (located in

the front right-hand corner of the throttle

housing) which controls the amount of air that

is allowed to pass through a bypass passage,

past the throttle valve when it is fully closed in

the idle position; the screw is then sealed with

a white tamperproof plug (see illustration). In

service, the idle speed is controlled by the

ECU, which has the ability to compensate for

engine wear, build-up of dirt in the throttle

housing, and other factors which might

require changes in idle speed. The air bypass

screw setting should not, therefore, be

altered. If any alterations are made, a blue

tamperproof plug must be fitted, and the

engine should be allowed to idle for at least

five minutes on completion, so that the ECU

can re-learn its idle values.

46When both checks have been made and

the “Service Adjustment Programme” is

completed, follow the tester instructions to

return to the fault code read-out, and

establish whether the fault has been cured or

not.

Basic check of ignition system

47If the checks so far have not eliminated

the fault, the next step is to carry out a basic

check of the ignition system components,

using an engine analyser with an oscilloscope

- without such equipment, the only tests

possible are to remove and check each spark

plug in turn, to check the spark plug (HT) lead

connections and resistances, and to check

the connections and resistances of the

ignition coil. Refer to the relevant Sections of

Chapters 1 and 5.

Basic check of fuel system

48If the checks so far have not eliminated

the fault, the next step is to carry out a basic

check of the fuel system components.

49Assuming that the preliminary checks

have established that the fuel pump is

operating correctly, that the fuel filter isunlikely to be blocked, and also that there are

no leaks in the system, the next step is to

check the fuel pressure (see Chapter 4). If this

is correct, check the injectors (see Chapter 4)

and the Positive Crankcase Ventilation system

(see Chapter 1).

System test

50The final element of the Ford testing

procedure is to carry out a system test, using

a break-out box - this is a device that is

connected between the ECU and its electrical

connector, so that the individual circuits

indicated by the fault code read-out can be

tested while connected to the system, if

necessary with the engine running. In the case

of many of the system’s components, this

enables their output voltages to be measured

- a more accurate means of testing.

51In addition to the break-out box and the

adaptors required to connect it, several items

of specialist equipment are needed to

complete these tests. This puts them quite

beyond the scope of many smaller dealers, let

alone the DIY owner; the vehicle should be

taken to a Ford dealer for attention.

Note:This Section is concerned principally

with the sensors which give the ECU the

information it needs to control the various

engine management sub-systems - for further

details of those systems and their other

components, refer to the relevant Chapter of

this manual.

General

ECU (Electronic Control Unit)

1This component is the heart of the entire

engine management system, controlling the

fuel injection, ignition and emissions control

systems. It also controls sub-systems such as

the radiator cooling fan, air conditioning and

automatic transmission, where appropriate.

Refer to Section 2 of this Chapter for an

illustration of how it works.

Air mass meter

2This uses a “hot-wire” system, sending the

ECU a constantly-varying (analogue) voltage

signal corresponding to the mass of air

passing into the engine. Since air mass varies

with temperature (cold air being denser than

warm), measuring air mass provides the ECU

with a very accurate means of determining the

correct amount of fuel required to achieve the

ideal air/fuel mixture ratio.

Crankshaft speed/position sensor

3This is an inductive pulse generator bolted

(in a separate bracket) to the cylinder

block/crankcase, to scan the ridges between

36 holes machined in the inboard (right-hand)

face of the flywheel/driveplate. As each ridge

4 Information sensors -

general information, testing,

removal and refitting

6•10 Emissions control systems

3.45 Throttle housing air bypass screw is

sealed on production with a white

tamperproof plug (arrowed)

procarmanuals.com

Page 146 of 279

Vehicle speed sensor

29Testing of this component is beyond the

scope of the DIY mechanic, and should be left

to a Ford dealer.

Power steering pressure switch

30Unplug the electrical connector from the

sensor.

31Using an ohmmeter, measure the

resistance between the switch terminals. With

the engine switched off, or idling with the

roadwheels in the straight-ahead position,

little or no resistance should be measured.

With the engine running and the steering on

full-lock, the pressure increase in the system

should open the switch contacts, so that

infinite resistance is now measured.

32If the results obtained show the switch to

be faulty, renew it.

Exhaust gas pressure differential

sensor

33Testing of this component is beyond the

scope of the DIY mechanic, and should be left

to a Ford dealer.

Oxygen sensor

34Testing of this component can be done

only by attaching special diagnostic

equipment to the sensor wiring, and checking

that the voltage varies from low to high values

when the engine is running; do notattempt to

“test” any part of the system with anything

other than the correct test equipment. This is

beyond the scope of the DIY mechanic, and

should be left to a Ford dealer.

Removal and refitting

General

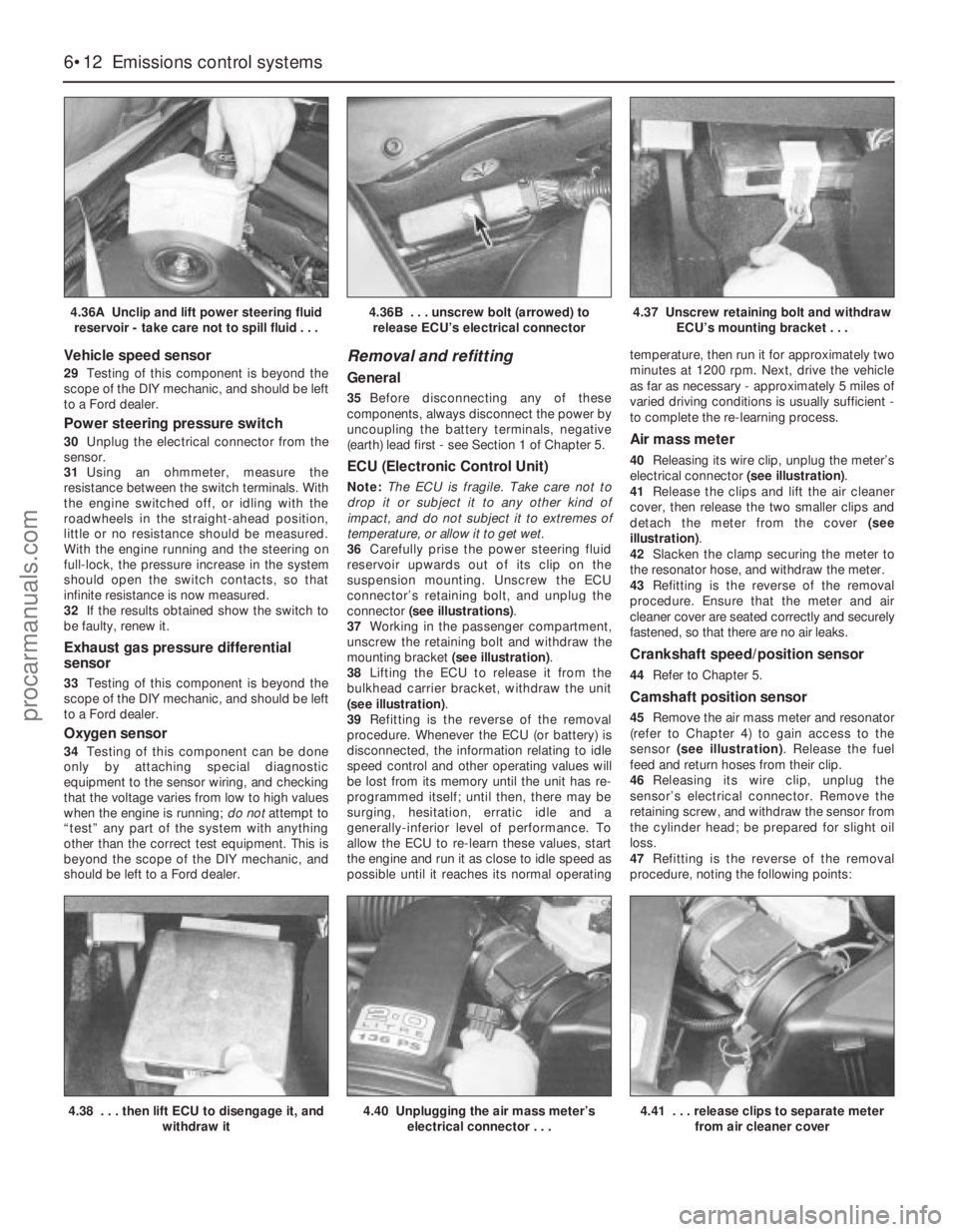

35Before disconnecting any of these

components, always disconnect the power by

uncoupling the battery terminals, negative

(earth) lead first - see Section 1 of Chapter 5.

ECU (Electronic Control Unit)

Note:The ECU is fragile. Take care not to

drop it or subject it to any other kind of

impact, and do not subject it to extremes of

temperature, or allow it to get wet.

36Carefully prise the power steering fluid

reservoir upwards out of its clip on the

suspension mounting. Unscrew the ECU

connector’s retaining bolt, and unplug the

connector (see illustrations).

37Working in the passenger compartment,

unscrew the retaining bolt and withdraw the

mounting bracket (see illustration).

38Lifting the ECU to release it from the

bulkhead carrier bracket, withdraw the unit

(see illustration).

39Refitting is the reverse of the removal

procedure. Whenever the ECU (or battery) is

disconnected, the information relating to idle

speed control and other operating values will

be lost from its memory until the unit has re-

programmed itself; until then, there may be

surging, hesitation, erratic idle and a

generally-inferior level of performance. To

allow the ECU to re-learn these values, start

the engine and run it as close to idle speed as

possible until it reaches its normal operatingtemperature, then run it for approximately two

minutes at 1200 rpm. Next, drive the vehicle

as far as necessary - approximately 5 miles of

varied driving conditions is usually sufficient -

to complete the re-learning process.

Air mass meter

40Releasing its wire clip, unplug the meter’s

electrical connector (see illustration).

41Release the clips and lift the air cleaner

cover, then release the two smaller clips and

detach the meter from the cover (see

illustration).

42Slacken the clamp securing the meter to

the resonator hose, and withdraw the meter.

43Refitting is the reverse of the removal

procedure. Ensure that the meter and air

cleaner cover are seated correctly and securely

fastened, so that there are no air leaks.

Crankshaft speed/position sensor

44Refer to Chapter 5.

Camshaft position sensor

45Remove the air mass meter and resonator

(refer to Chapter 4) to gain access to the

sensor (see illustration). Release the fuel

feed and return hoses from their clip.

46Releasing its wire clip, unplug the

sensor’s electrical connector. Remove the

retaining screw, and withdraw the sensor from

the cylinder head; be prepared for slight oil

loss.

47Refitting is the reverse of the removal

procedure, noting the following points:

6•12 Emissions control systems

4.36A Unclip and lift power steering fluid

reservoir - take care not to spill fluid . . .4.36B . . . unscrew bolt (arrowed) to

release ECU’s electrical connector4.37 Unscrew retaining bolt and withdraw

ECU’s mounting bracket . . .

4.40 Unplugging the air mass meter’s

electrical connector . . .4.38 . . . then lift ECU to disengage it, and

withdraw it4.41 . . . release clips to separate meter

from air cleaner cover

procarmanuals.com

Page 149 of 279

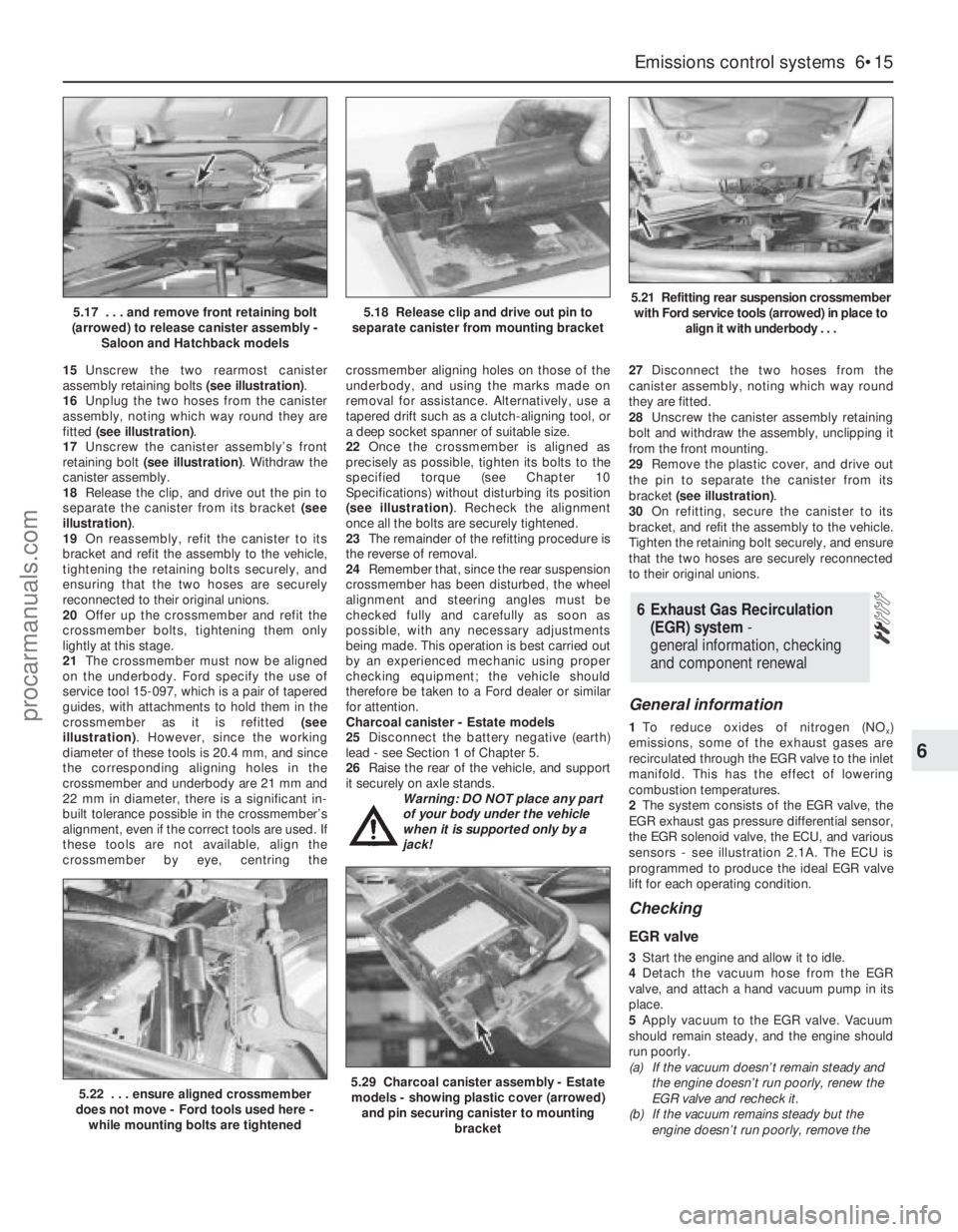

15Unscrew the two rearmost canister

assembly retaining bolts (see illustration).

16Unplug the two hoses from the canister

assembly, noting which way round they are

fitted (see illustration).

17Unscrew the canister assembly’s front

retaining bolt (see illustration). Withdraw the

canister assembly.

18Release the clip, and drive out the pin to

separate the canister from its bracket (see

illustration).

19On reassembly, refit the canister to its

bracket and refit the assembly to the vehicle,

tightening the retaining bolts securely, and

ensuring that the two hoses are securely

reconnected to their original unions.

20Offer up the crossmember and refit the

crossmember bolts, tightening them only

lightly at this stage.

21The crossmember must now be aligned

on the underbody. Ford specify the use of

service tool 15-097, which is a pair of tapered

guides, with attachments to hold them in the

crossmember as it is refitted (see

illustration). However, since the working

diameter of these tools is 20.4 mm, and since

the corresponding aligning holes in the

crossmember and underbody are 21 mm and

22 mm in diameter, there is a significant in-

built tolerance possible in the crossmember’s

alignment, even if the correct tools are used. If

these tools are not available, align the

crossmember by eye, centring thecrossmember aligning holes on those of the

underbody, and using the marks made on

removal for assistance. Alternatively, use a

tapered drift such as a clutch-aligning tool, or

a deep socket spanner of suitable size.

22Once the crossmember is aligned as

precisely as possible, tighten its bolts to the

specified torque (see Chapter 10

Specifications) without disturbing its position

(see illustration). Recheck the alignment

once all the bolts are securely tightened.

23The remainder of the refitting procedure is

the reverse of removal.

24Remember that, since the rear suspension

crossmember has been disturbed, the wheel

alignment and steering angles must be

checked fully and carefully as soon as

possible, with any necessary adjustments

being made. This operation is best carried out

by an experienced mechanic using proper

checking equipment; the vehicle should

therefore be taken to a Ford dealer or similar

for attention.

Charcoal canister - Estate models

25Disconnect the battery negative (earth)

lead - see Section 1 of Chapter 5.

26Raise the rear of the vehicle, and support

it securely on axle stands.

Warning: DO NOT place any part

of your body under the vehicle

when it is supported only by a

jack!27Disconnect the two hoses from the

canister assembly, noting which way round

they are fitted.

28Unscrew the canister assembly retaining

bolt and withdraw the assembly, unclipping it

from the front mounting.

29Remove the plastic cover, and drive out

the pin to separate the canister from its

bracket (see illustration).

30On refitting, secure the canister to its

bracket, and refit the assembly to the vehicle.

Tighten the retaining bolt securely, and ensure

that the two hoses are securely reconnected

to their original unions.

General information

1To reduce oxides of nitrogen (NOx)

emissions, some of the exhaust gases are

recirculated through the EGR valve to the inlet

manifold. This has the effect of lowering

combustion temperatures.

2The system consists of the EGR valve, the

EGR exhaust gas pressure differential sensor,

the EGR solenoid valve, the ECU, and various

sensors - see illustration 2.1A. The ECU is

programmed to produce the ideal EGR valve

lift for each operating condition.

Checking

EGR valve

3Start the engine and allow it to idle.

4Detach the vacuum hose from the EGR

valve, and attach a hand vacuum pump in its

place.

5Apply vacuum to the EGR valve. Vacuum

should remain steady, and the engine should

run poorly.

(a) If the vacuum doesn’t remain steady and

the engine doesn’t run poorly, renew the

EGR valve and recheck it.

(b) If the vacuum remains steady but the

engine doesn’t run poorly, remove the

6 Exhaust Gas Recirculation

(EGR) system-

general information, checking

and component renewal

Emissions control systems 6•15

6

5.22 . . . ensure aligned crossmember

does not move - Ford tools used here -

while mounting bolts are tightened5.29 Charcoal canister assembly - Estate

models - showing plastic cover (arrowed)

and pin securing canister to mounting

bracket

5.17 . . . and remove front retaining bolt

(arrowed) to release canister assembly -

Saloon and Hatchback models5.18 Release clip and drive out pin to

separate canister from mounting bracket5.21 Refitting rear suspension crossmember

with Ford service tools (arrowed) in place to

align it with underbody . . .

procarmanuals.com

Page 159 of 279

Since most of the procedures dealt with in

this Chapter involve jacking up the vehicle

and working underneath it, a good pair of axle

stands will be needed. A hydraulic trolley jack

is the preferred type of jack to lift the vehicle,

and it can also be used to support certain

components during removal and refitting

operations.

Warning: Never, under any

circumstances, rely on a jack to

support the vehicle while working

beneath it. When jacking up the vehicle, do

not lift or support it beneath the front or

rear subframes.

Removal

1Apply the handbrake. Remove the wheel

cover from the relevant front wheel, and

loosen (but do not remove) the driveshaft/hub

nut. This nut is very tight.

2Loosen the front wheel nuts, jack up the

front of the vehicle and support it on axle

stands. Remove the front wheel.

3Extract the split pin from the track rod end

balljoint nut. Unscrew the nut, and detach the

rod from the arm on the steering knuckle

using a conventional balljoint removal tool.

Take care not to damage the balljoint seal.

4Remove the ABS sensor (when fitted) as

described in Chapter 9.

5Remove the brake caliper and brake disc as

described in Chapter 9, but do not disconnect

the flexible hose from the caliper. Suspend

the caliper from a suitable point under the

wheel arch, taking care not to strain the hose.

6Unscrew and remove the driveshaft/hub

nut. Note that the nut is of special laminated

design, and should only be re-used a

maximum of 5 times. (It is a good idea to file a

small notch on the nut every time it is

removed.) Obtain a new nut if necessary.

7Note which way round the lower arm

balljoint clamp bolt is fitted, then unscrew and

remove it from the knuckle assembly. Lever

the balljoint down from the knuckle; if it is

tight, prise the clamp open using a large flat-

bladed tool. Take care not to damage the

balljoint seal during the separation procedure.

8Unscrew and remove the pinch-bolt

securing the steering knuckle assembly to the

front suspension strut, noting which way

round it is fitted. Prise open the clamp using a

wedge-shaped tool, and release the knuckle

from the strut. If necessary, tap the knuckle

downwards with a soft-headed mallet to

separate the two components. Support the

knuckle on an axle stand.

9Pull the steering knuckle and hub assembly

from the driveshaft splines. If it is tight,

connect a universal puller to the hub flange,

and withdraw it from the driveshaft. When the

driveshaft is free, support it on an axle stand,

or suspend it from a suitable point under thewheel arch, making sure that the inner

constant velocity joint is not turned through

more than 18°. (Damage may occur if the joint

is turned through too great an angle.)

Refitting

10Lift the steering knuckle and hub

assembly onto the driveshaft splines, and

support the assembly on an axle stand.

11Locate the assembly on the front

suspension strut. Insert the pinch-bolt with its

head facing forwards. Fit the nut and tighten it

to the specified torque.

12Refit the lower arm balljoint to the knuckle

assembly, and insert the clamp bolt with its

head facing forwards. Refit the nut and tighten

it to the specified torque.

13Refit the driveshaft/hub nut, and tighten it

moderately at this stage. Final tightening of

the nut is made with the vehicle lowered to the

ground.

14Refit the brake caliper and brake disc as

described in Chapter 9.

15Where fitted, refit the ABS sensor as

described in Chapter 9.

16Reconnect the track rod end balljoint to

the steering arm, and tighten the nut to the

specified torque. Check that the split pin

holes are aligned; if necessary, turn the nut to

the nearest alignment, making sure that the

torque wrench setting is still within the

specified range. Insert a new split pin, and

bend it back to secure.

17Refit the front wheel, and lower the

vehicle to the ground. Tighten the wheel nuts

to the specified torque.

18Tighten the driveshaft/hub nut to the

specified torque, and refit the wheel cover.

Inspection

1The front hub bearings are non-adjustable,

and are supplied already greased.

2To check the bearings for excessive wear,

apply the handbrake, jack up the front of the

vehicle and support it on axle stands.

3Grip the front wheel at top and bottom, and

attempt to rock it. If excessive movement is

noted, it may be that the hub bearings are

worn. Do not confuse wear in the driveshaft

outer joint or front suspension lower arm

balljoint with wear in the bearings. Hub

bearing wear will show up as roughness or

vibration when the wheel is spun; it will also

be noticeable as a rumbling or growling noise

when driving.

Renewal

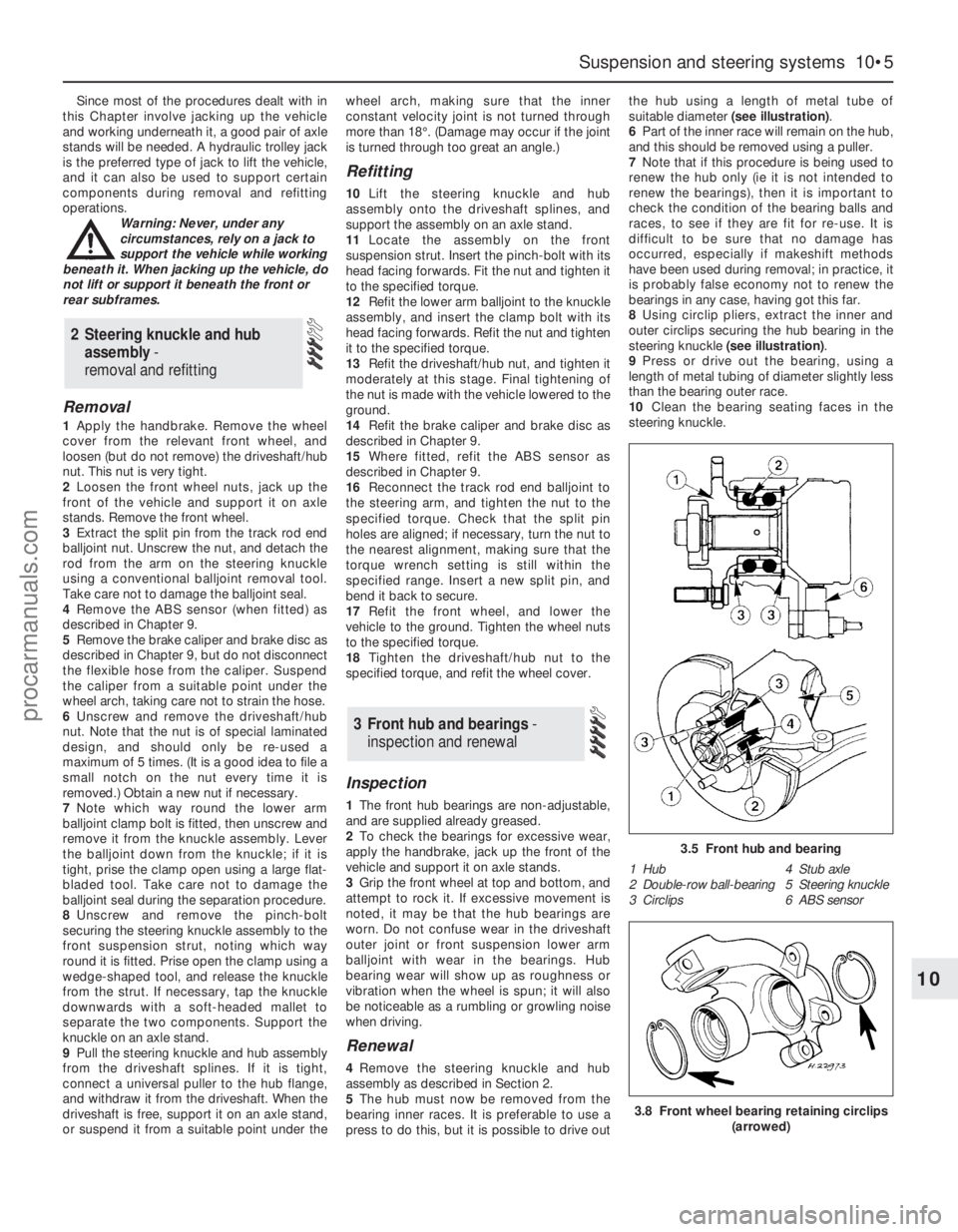

4Remove the steering knuckle and hub

assembly as described in Section 2.

5The hub must now be removed from the

bearing inner races. It is preferable to use a

press to do this, but it is possible to drive outthe hub using a length of metal tube of

suitable diameter (see illustration).

6Part of the inner race will remain on the hub,

and this should be removed using a puller.

7Note that if this procedure is being used to

renew the hub only (ie it is not intended to

renew the bearings), then it is important to

check the condition of the bearing balls and

races, to see if they are fit for re-use. It is

difficult to be sure that no damage has

occurred, especially if makeshift methods

have been used during removal; in practice, it

is probably false economy not to renew the

bearings in any case, having got this far.

8Using circlip pliers, extract the inner and

outer circlips securing the hub bearing in the

steering knuckle (see illustration).

9Press or drive out the bearing, using a

length of metal tubing of diameter slightly less

than the bearing outer race.

10Clean the bearing seating faces in the

steering knuckle.

3 Front hub and bearings -

inspection and renewal

2 Steering knuckle and hub

assembly -

removal and refitting

Suspension and steering systems 10•5

10

3.5 Front hub and bearing

1 Hub 4 Stub axle

2 Double-row ball-bearing 5 Steering knuckle

3 Circlips 6 ABS sensor

3.8 Front wheel bearing retaining circlips

(arrowed)

procarmanuals.com

Page 160 of 279

11Locate one of the circlips in the outer

groove of the knuckle.

12Press or drive the new bearing into the

knuckle until it contacts the circlip, using a

length of metal tube of diameter slightly less

than the outer race. Do not apply any

pressure to the inner race.

13Locate the remaining circlip in the inner

groove of the knuckle.

14Support the inner race on a length of

metal tube, then press or drive the hub fully

into the bearing.

15Refit the steering knuckle and hub

assembly as described in Section 2.

Removal

1Apply the handbrake, then jack up the front

of the vehicle and support it on axle stands.

Remove the appropriate front wheel.

2Unbolt the brake hose support bracket from

the front of the suspension strut (see

illustration).

3Remove the brake caliper as described in

Chapter 9, but do not disconnect the flexible

hydraulic hose from the caliper. Suspend the

caliper from a suitable point under the wheel

arch, taking care not to strain the hose.

4Extract the split pin from the track rod end

balljoint nut. Unscrew the nut, and detach the

rod from the arm on the steering knuckleusing a conventional balljoint removal tool.

Take care not to damage the balljoint seal.

5Remove the ABS sensor (when fitted) from

the steering knuckle, as described in Chapter 9.

6Remove the clip securing the driveshaft

inner gaiter to the inner CV joint. Disconnect

the gaiter from the CV joint housing.

7Remove the nut and disconnect the anti-roll

bar link from the strut. Note that, on models

fitted with ABS, the ABS wheel sensor wiring

support bracket is located beneath the nut

(see illustration).

8Note which way round the lower arm

balljoint clamp bolt is fitted, then unscrew and

remove it from the knuckle assembly. Lever

the balljoint down from the knuckle; if it is

tight, prise the clamp open carefully using a

large flat-bladed tool. Take care not to

damage the balljoint seal during the

separation procedure.

9Where applicable, disconnect the adaptive

damping wiring multi-plug at the strut, and

unclip the wire.

10Support the strut and steering knuckle on

an axle stand. Working inside the engine

compartment, remove the strut cap (if fitted).

Unscrew and remove the front suspension

strut upper mounting nut, holding the piston

rod stationary with an 8 mm Allen key (see

illustration).

11Lower the suspension strut, together with

the driveshaft and steering knuckle, from

under the wheel arch, withdrawing the tripod

on the inner end of the driveshaft from the CV

joint housing.12Unscrew and remove the pinch-bolt

securing the steering knuckle assembly to the

front suspension strut, noting which way

round it is fitted. Prise open the clamp using a

wedge-shaped tool, and release the knuckle

from the strut (see illustrations).

Refitting

13With the clamp prised open, locate the

front suspension strut on the steering knuckle,

and refit the pinch-bolt with its head facing

forwards. Tighten the bolt to the specified

torque.

14Locate the suspension strut (together with

the driveshaft and steering knuckle) in its

upper mounting, and loosely screw on the

nut.

15Locate the tripod on the inner end of the

driveshaft in the CV joint housing, then

manipulate the gaiter onto the housing, and fit

a new clip.

16Where applicable, reconnect the adaptive

damping multi-plug, and fit the wire in the clip.

17Locate the lower arm balljoint fully in the

bottom of the steering knuckle. Refit the

clamp bolt and tighten it to the specified

torque.

18Reconnect the anti-roll bar link to the

strut, and tighten the nut to the specified

torque. On models fitted with ABS, do not

forget to locate the sensor wiring support

bracket beneath the nut.

19Where fitted, refit the ABS sensor as

described in Chapter 9.

20Refit the track rod end balljoint to the

steering knuckle, and tighten the nut to the

specified torque. Check that the split pin

holes are aligned; if necessary, turn the nut to

the nearest alignment, making sure that the

torque wrench setting is still within the

specified range. Insert a new split pin, and

bend it back to secure.

21Refit the brake caliper as described in

Chapter 9.

22Refit the brake hose support bracket to

the strut, and tighten the bolt.

23Refit the wheel, and lower the vehicle to

the ground. Tighten the wheel nuts to the

specified torque.

24Tighten the suspension strut upper

mounting nut to the specified torque, while

4 Front suspension strut -

removal and refitting

10•6 Suspension and steering systems

4.2 Removing the brake hose support

bracket from the front of the front

suspension strut4.7 Removing the anti-roll bar link and

ABS sensor wiring bracket4.10 Front suspension strut upper

mounting nut

4.12A Steering knuckle-to-strut pinch-bolt4.12B Releasing the knuckle from the strut

procarmanuals.com

Page 165 of 279

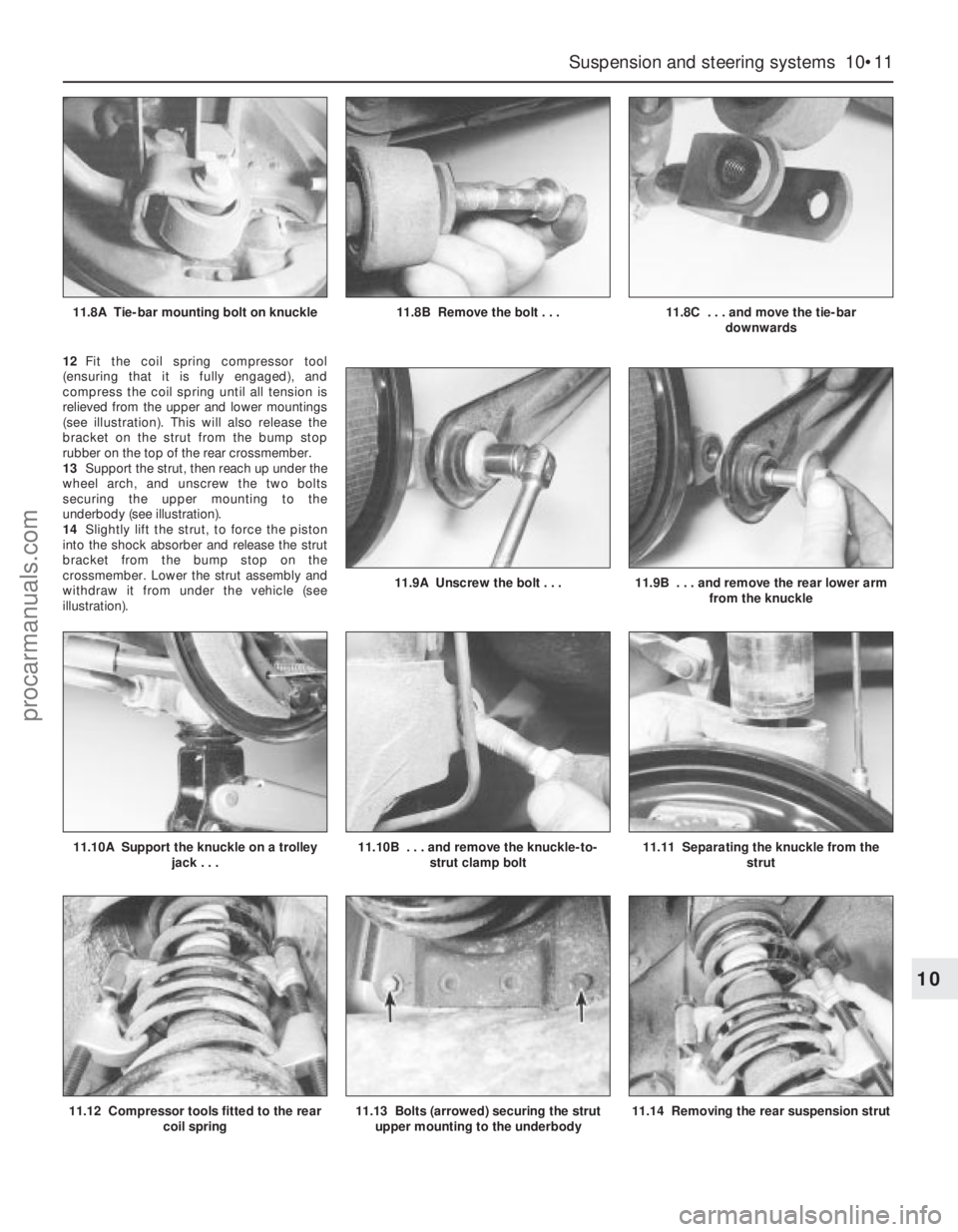

12Fit the coil spring compressor tool

(ensuring that it is fully engaged), and

compress the coil spring until all tension is

relieved from the upper and lower mountings

(see illustration). This will also release the

bracket on the strut from the bump stop

rubber on the top of the rear crossmember.

13Support the strut, then reach up under the

wheel arch, and unscrew the two bolts

securing the upper mounting to the

underbody (see illustration).

14Slightly lift the strut, to force the piston

into the shock absorber and release the strut

bracket from the bump stop on the

crossmember. Lower the strut assembly and

withdraw it from under the vehicle (see

illustration).

Suspension and steering systems 10•11

10

11.12 Compressor tools fitted to the rear

coil spring11.13 Bolts (arrowed) securing the strut

upper mounting to the underbody11.14 Removing the rear suspension strut

11.10A Support the knuckle on a trolley

jack . . .11.10B . . . and remove the knuckle-to-

strut clamp bolt11.11 Separating the knuckle from the

strut

11.9A Unscrew the bolt . . .11.9B . . . and remove the rear lower arm

from the knuckle

11.8A Tie-bar mounting bolt on knuckle11.8B Remove the bolt . . .11.8C . . . and move the tie-bar

downwards

procarmanuals.com

Page 172 of 279

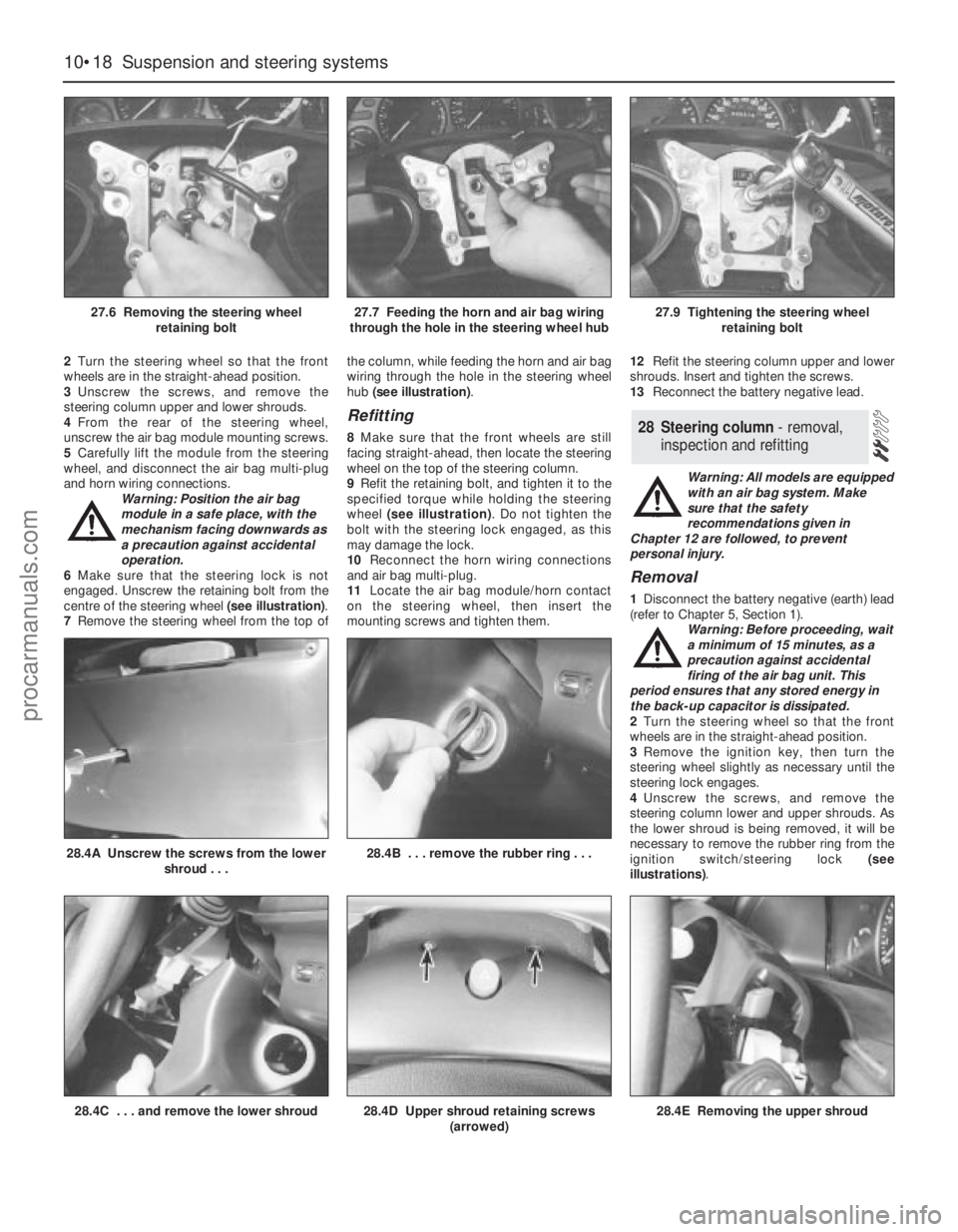

2Turn the steering wheel so that the front

wheels are in the straight-ahead position.

3Unscrew the screws, and remove the

steering column upper and lower shrouds.

4From the rear of the steering wheel,

unscrew the air bag module mounting screws.

5Carefully lift the module from the steering

wheel, and disconnect the air bag multi-plug

and horn wiring connections.

Warning: Position the air bag

module in a safe place, with the

mechanism facing downwards as

a precaution against accidental

operation.

6Make sure that the steering lock is not

engaged. Unscrew the retaining bolt from the

centre of the steering wheel (see illustration).

7Remove the steering wheel from the top ofthe column, while feeding the horn and air bag

wiring through the hole in the steering wheel

hub (see illustration).

Refitting

8Make sure that the front wheels are still

facing straight-ahead, then locate the steering

wheel on the top of the steering column.

9Refit the retaining bolt, and tighten it to the

specified torque while holding the steering

wheel (see illustration). Do not tighten the

bolt with the steering lock engaged, as this

may damage the lock.

10Reconnect the horn wiring connections

and air bag multi-plug.

11Locate the air bag module/horn contact

on the steering wheel, then insert the

mounting screws and tighten them.12Refit the steering column upper and lower

shrouds. Insert and tighten the screws.

13Reconnect the battery negative lead.

Warning: All models are equipped

with an air bag system. Make

sure that the safety

recommendations given in

Chapter 12 are followed, to prevent

personal injury.

Removal

1Disconnect the battery negative (earth) lead

(refer to Chapter 5, Section 1).

Warning: Before proceeding, wait

a minimum of 15 minutes, as a

precaution against accidental

firing of the air bag unit. This

period ensures that any stored energy in

the back-up capacitor is dissipated.

2Turn the steering wheel so that the front

wheels are in the straight-ahead position.

3Remove the ignition key, then turn the

steering wheel slightly as necessary until the

steering lock engages.

4Unscrew the screws, and remove the

steering column lower and upper shrouds. As

the lower shroud is being removed, it will be

necessary to remove the rubber ring from the

ignition switch/steering lock (see

illustrations).

28 Steering column - removal,

inspection and refitting

10•18 Suspension and steering systems

27.6 Removing the steering wheel

retaining bolt27.7 Feeding the horn and air bag wiring

through the hole in the steering wheel hub27.9 Tightening the steering wheel

retaining bolt

28.4C . . . and remove the lower shroud28.4D Upper shroud retaining screws

(arrowed)

28.4A Unscrew the screws from the lower

shroud . . .28.4B . . . remove the rubber ring . . .

28.4E Removing the upper shroud

procarmanuals.com

Page 174 of 279

15Locate the steering column shaft on the

flexible coupling, swivel the clamp plate

round, then insert the bolt and tighten to the

specified torque.

16Refit the driver’s side lower trim panel.

17Refit the steering column upper and lower

shrouds.

18Reconnect the battery negative lead.

Removal

1Disconnect the battery negative (earth) lead

(refer to Chapter 5, Section 1).

2Turn the steering wheel so that the front

wheels are in the straight-ahead position.

Remove the ignition key, then turn the

steering wheel slightly as necessary until the

steering lock engages.

3Unscrew the clamp plate bolt securing the

steering column shaft to the flexible coupling.

Swivel the clamp plate around, and disengage

it from the flexible coupling stub.

4Carefully prise the rubber boot from the

bulkhead, and withdraw it into the passenger

compartment. Take care not to damage the

sealing lip of the boot.

5Using an Allen key, unscrew the clamp bolt

securing the flexible coupling to the pinion

shaft on the steering gear, and withdraw the

coupling from inside the vehicle.

Refitting

6Refitting is a reversal of the removal

procedure, but tighten the clamp bolts to the

specified torque. Make sure that the rubber

boot engages correctly in the bulkhead and

on the flexible coupling.

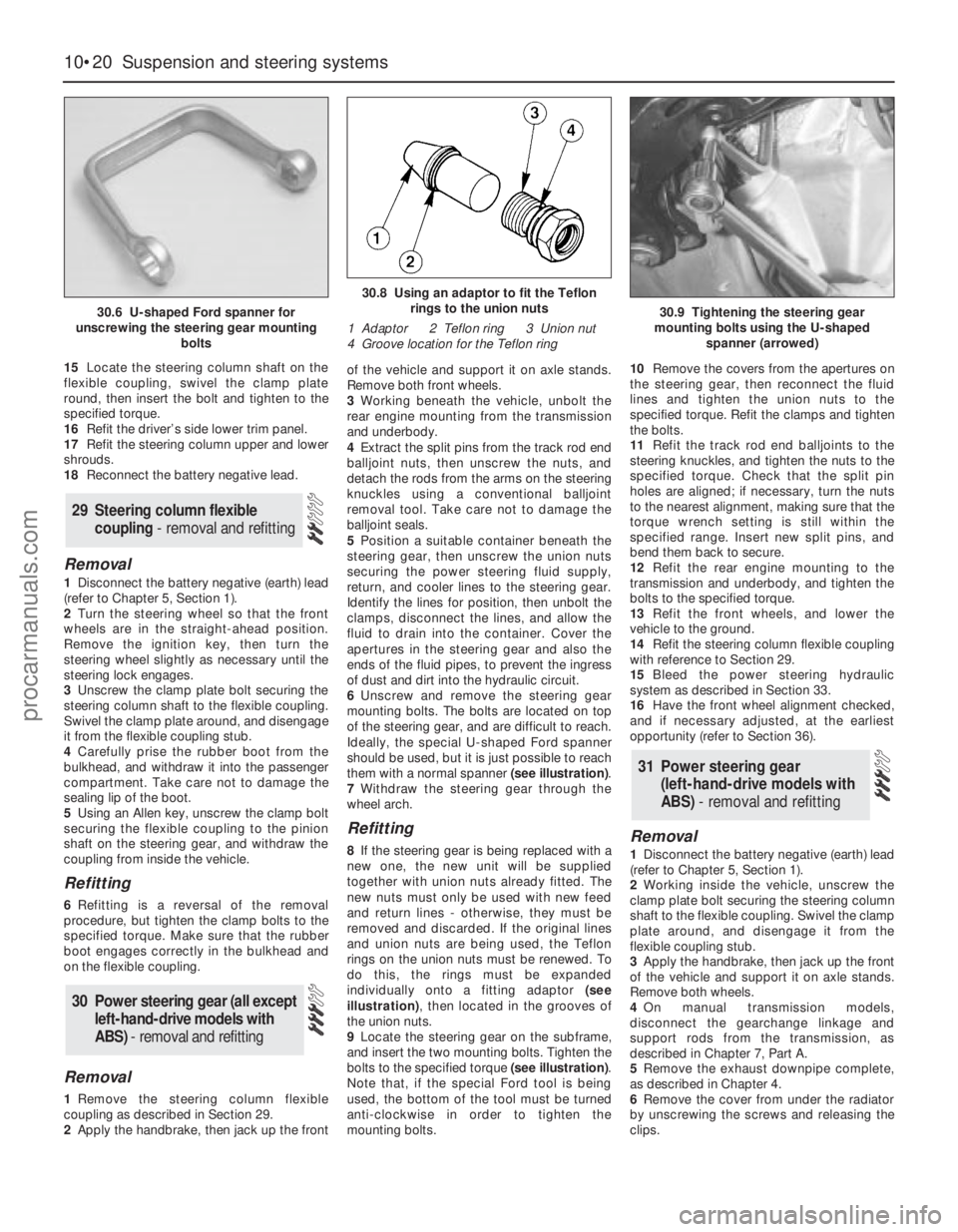

Removal

1Remove the steering column flexible

coupling as described in Section 29.

2Apply the handbrake, then jack up the frontof the vehicle and support it on axle stands.

Remove both front wheels.

3Working beneath the vehicle, unbolt the

rear engine mounting from the transmission

and underbody.

4Extract the split pins from the track rod end

balljoint nuts, then unscrew the nuts, and

detach the rods from the arms on the steering

knuckles using a conventional balljoint

removal tool. Take care not to damage the

balljoint seals.

5Position a suitable container beneath the

steering gear, then unscrew the union nuts

securing the power steering fluid supply,

return, and cooler lines to the steering gear.

Identify the lines for position, then unbolt the

clamps, disconnect the lines, and allow the

fluid to drain into the container. Cover the

apertures in the steering gear and also the

ends of the fluid pipes, to prevent the ingress

of dust and dirt into the hydraulic circuit.

6Unscrew and remove the steering gear

mounting bolts. The bolts are located on top

of the steering gear, and are difficult to reach.

Ideally, the special U-shaped Ford spanner

should be used, but it is just possible to reach

them with a normal spanner (see illustration).

7Withdraw the steering gear through the

wheel arch.

Refitting

8If the steering gear is being replaced with a

new one, the new unit will be supplied

together with union nuts already fitted. The

new nuts must only be used with new feed

and return lines - otherwise, they must be

removed and discarded. If the original lines

and union nuts are being used, the Teflon

rings on the union nuts must be renewed. To

do this, the rings must be expanded

individually onto a fitting adaptor (see

illustration), then located in the grooves of

the union nuts.

9Locate the steering gear on the subframe,

and insert the two mounting bolts. Tighten the

bolts to the specified torque (see illustration).

Note that, if the special Ford tool is being

used, the bottom of the tool must be turned

anti-clockwise in order to tighten the

mounting bolts.10Remove the covers from the apertures on

the steering gear, then reconnect the fluid

lines and tighten the union nuts to the

specified torque. Refit the clamps and tighten

the bolts.

11Refit the track rod end balljoints to the

steering knuckles, and tighten the nuts to the

specified torque. Check that the split pin

holes are aligned; if necessary, turn the nuts

to the nearest alignment, making sure that the

torque wrench setting is still within the

specified range. Insert new split pins, and

bend them back to secure.

12Refit the rear engine mounting to the

transmission and underbody, and tighten the

bolts to the specified torque.

13Refit the front wheels, and lower the

vehicle to the ground.

14Refit the steering column flexible coupling

with reference to Section 29.

15Bleed the power steering hydraulic

system as described in Section 33.

16Have the front wheel alignment checked,

and if necessary adjusted, at the earliest

opportunity (refer to Section 36).Removal

1Disconnect the battery negative (earth) lead

(refer to Chapter 5, Section 1).

2Working inside the vehicle, unscrew the

clamp plate bolt securing the steering column

shaft to the flexible coupling. Swivel the clamp

plate around, and disengage it from the

flexible coupling stub.

3Apply the handbrake, then jack up the front

of the vehicle and support it on axle stands.

Remove both wheels.

4On manual transmission models,

disconnect the gearchange linkage and

support rods from the transmission, as

described in Chapter 7, Part A.

5Remove the exhaust downpipe complete,

as described in Chapter 4.

6Remove the cover from under the radiator

by unscrewing the screws and releasing the

clips.

31 Power steering gear

(left-hand-drive models with

ABS) - removal and refitting

30 Power steering gear (all except

left-hand-drive models with

ABS) - removal and refitting

29 Steering column flexible

coupling - removal and refitting

10•20 Suspension and steering systems

30.6 U-shaped Ford spanner for

unscrewing the steering gear mounting

bolts

30.8 Using an adaptor to fit the Teflon

rings to the union nuts

1 Adaptor 2 Teflon ring 3 Union nut

4 Groove location for the Teflon ring

30.9 Tightening the steering gear

mounting bolts using the U-shaped

spanner (arrowed)

procarmanuals.com

Page 179 of 279

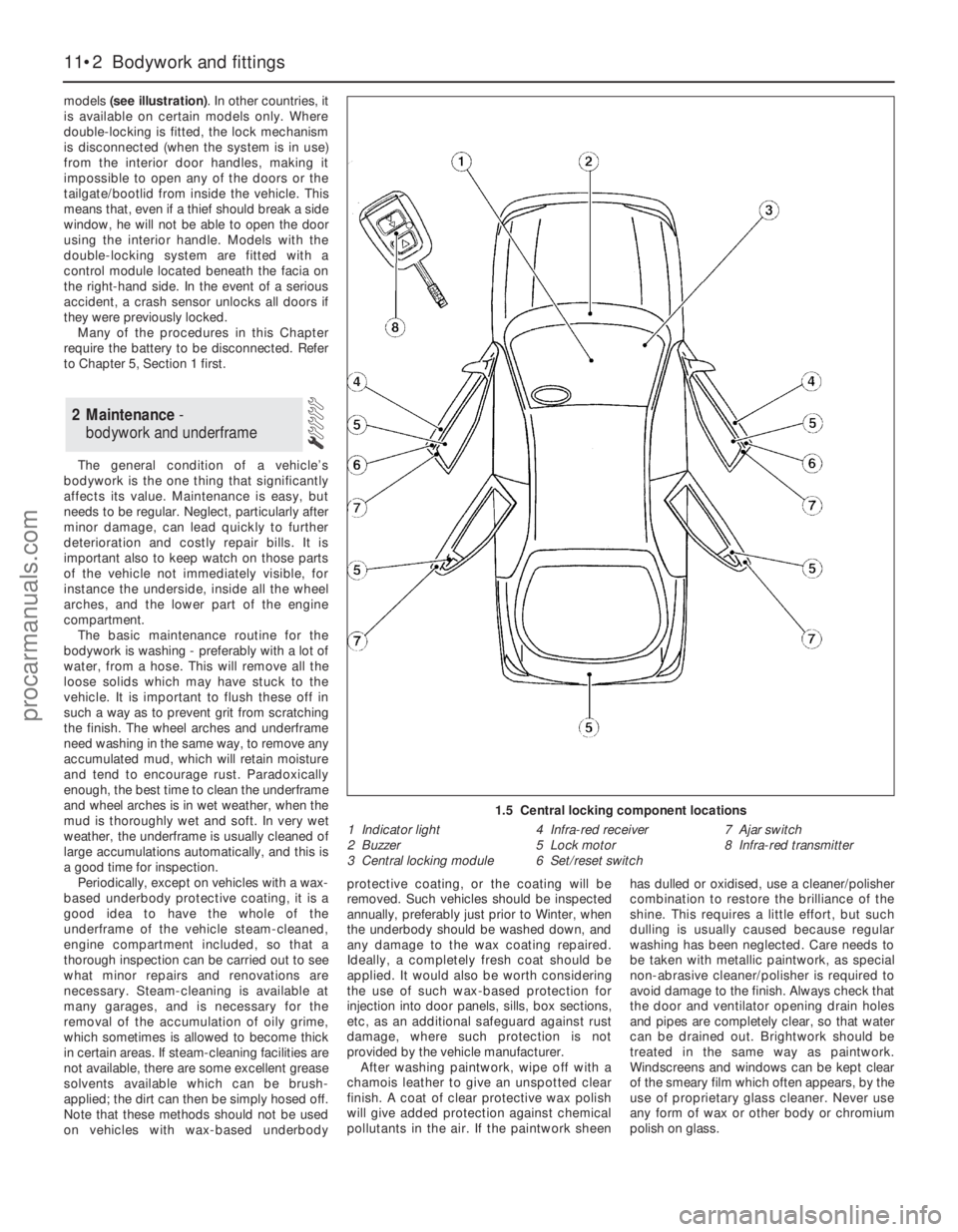

models (see illustration). In other countries, it

is available on certain models only. Where

double-locking is fitted, the lock mechanism

is disconnected (when the system is in use)

from the interior door handles, making it

impossible to open any of the doors or the

tailgate/bootlid from inside the vehicle. This

means that, even if a thief should break a side

window, he will not be able to open the door

using the interior handle. Models with the

double-locking system are fitted with a

control module located beneath the facia on

the right-hand side. In the event of a serious

accident, a crash sensor unlocks all doors if

they were previously locked.

Many of the procedures in this Chapter

require the battery to be disconnected. Refer

to Chapter 5, Section 1 first.

The general condition of a vehicle’s

bodywork is the one thing that significantly

affects its value. Maintenance is easy, but

needs to be regular. Neglect, particularly after

minor damage, can lead quickly to further

deterioration and costly repair bills. It is

important also to keep watch on those parts

of the vehicle not immediately visible, for

instance the underside, inside all the wheel

arches, and the lower part of the engine

compartment.

The basic maintenance routine for the

bodywork is washing - preferably with a lot of

water, from a hose. This will remove all the

loose solids which may have stuck to the

vehicle. It is important to flush these off in

such a way as to prevent grit from scratching

the finish. The wheel arches and underframe

need washing in the same way, to remove any

accumulated mud, which will retain moisture

and tend to encourage rust. Paradoxically

enough, the best time to clean the underframe

and wheel arches is in wet weather, when the

mud is thoroughly wet and soft. In very wet

weather, the underframe is usually cleaned of

large accumulations automatically, and this is

a good time for inspection.

Periodically, except on vehicles with a wax-

based underbody protective coating, it is a

good idea to have the whole of the

underframe of the vehicle steam-cleaned,

engine compartment included, so that a

thorough inspection can be carried out to see

what minor repairs and renovations are

necessary. Steam-cleaning is available at

many garages, and is necessary for the

removal of the accumulation of oily grime,

which sometimes is allowed to become thick

in certain areas. If steam-cleaning facilities are

not available, there are some excellent grease

solvents available which can be brush-

applied; the dirt can then be simply hosed off.

Note that these methods should not be used

on vehicles with wax-based underbodyprotective coating, or the coating will be

removed. Such vehicles should be inspected

annually, preferably just prior to Winter, when

the underbody should be washed down, and

any damage to the wax coating repaired.

Ideally, a completely fresh coat should be

applied. It would also be worth considering

the use of such wax-based protection for

injection into door panels, sills, box sections,

etc, as an additional safeguard against rust

damage, where such protection is not

provided by the vehicle manufacturer.

After washing paintwork, wipe off with a

chamois leather to give an unspotted clear

finish. A coat of clear protective wax polish

will give added protection against chemical

pollutants in the air. If the paintwork sheenhas dulled or oxidised, use a cleaner/polisher

combination to restore the brilliance of the

shine. This requires a little effort, but such

dulling is usually caused because regular

washing has been neglected. Care needs to

be taken with metallic paintwork, as special

non-abrasive cleaner/polisher is required to

avoid damage to the finish. Always check that

the door and ventilator opening drain holes

and pipes are completely clear, so that water

can be drained out. Brightwork should be

treated in the same way as paintwork.

Windscreens and windows can be kept clear

of the smeary film which often appears, by the

use of proprietary glass cleaner. Never use

any form of wax or other body or chromium

polish on glass.

2 Maintenance -

bodywork and underframe

11•2 Bodywork and fittings

1.5 Central locking component locations

1 Indicator light

2 Buzzer

3 Central locking module4 Infra-red receiver

5 Lock motor

6 Set/reset switch7 Ajar switch

8 Infra-red transmitter

procarmanuals.com

Page 180 of 279

Mats and carpets should be brushed or

vacuum-cleaned regularly, to keep them free

of grit. If they are badly stained, remove them

from the vehicle for scrubbing or sponging,

and make quite sure they are dry before

refitting. Seats and interior trim panels can be

kept clean by wiping with a damp cloth. If they

do become stained (which can be more

apparent on light-coloured upholstery), use a

little liquid detergent and a soft nail brush to

scour the grime out of the grain of the

material. Do not forget to keep the headlining

clean in the same way as the upholstery.

When using liquid cleaners inside the vehicle,

do not over-wet the surfaces being cleaned.

Excessive damp could get into the seams and

padded interior, causing stains, offensive

odours or even rot.

Note:For more detailed information about

bodywork repair, Haynes Publishing produce

a book by Lindsay Porter called “The Car

Bodywork Repair Manual”. This incorporates

information on such aspects as rust treatment,

painting and glass-fibre repairs, as well as

details on more ambitious repairs involving

welding and panel beating.

Repairs of minor scratches in

bodywork

If the scratch is very superficial, and does

not penetrate to the metal of the bodywork,

repair is very simple. Lightly rub the area of

the scratch with a paintwork renovator, or a

very fine cutting paste, to remove loose paint

from the scratch, and to clear the surrounding

bodywork of wax polish. Rinse the area with

clean water.

Apply touch-up paint to the scratch using a

fine paint brush; continue to apply fine layers

of paint until the surface of the paint in the

scratch is level with the surrounding

paintwork. Allow the new paint at least two

weeks to harden, then blend it into the

surrounding paintwork by rubbing the scratch

area with a paintwork renovator or a very fine

cutting paste. Finally, apply wax polish.

Where the scratch has penetrated right

through to the metal of the bodywork, causingthe metal to rust, a different repair technique

is required. Remove any loose rust from the

bottom of the scratch with a penknife, then

apply rust-inhibiting paint to prevent the

formation of rust in the future. Using a rubber

or nylon applicator, fill the scratch with

bodystopper paste. If required, this paste can

be mixed with cellulose thinners to provide a

very thin paste which is ideal for filling narrow

scratches. Before the stopper-paste in the

scratch hardens, wrap a piece of smooth

cotton rag around the top of a finger. Dip the

finger in cellulose thinners, and quickly sweep

it across the surface of the stopper-paste in

the scratch; this will ensure that the surface of

the stopper-paste is slightly hollowed. The

scratch can now be painted over as described

earlier in this Section.

Repairs of dents in bodywork

When deep denting of the vehicle’s

bodywork has taken place, the first task is to

pull the dent out, until the affected bodywork

almost attains its original shape. There is little

point in trying to restore the original shape

completely, as the metal in the damaged area

will have stretched on impact, and cannot be

reshaped fully to its original contour. It is

better to bring the level of the dent up to a

point which is about 3 mm below the level of

the surrounding bodywork. In cases where the

dent is very shallow anyway, it is not worth

trying to pull it out at all. If the underside of the

dent is accessible, it can be hammered out

gently from behind, using a mallet with a

wooden or plastic head. Whilst doing this,

hold a suitable block of wood firmly against

the outside of the panel, to absorb the impact

from the hammer blows and thus prevent a

large area of the bodywork from being

“belled-out”.

Should the dent be in a section of the

bodywork which has a double skin, or some

other factor making it inaccessible from

behind, a different technique is called for. Drill

several small holes through the metal inside

the area - particularly in the deeper section.

Then screw long self-tapping screws into the

holes, just sufficiently for them to gain a good

purchase in the metal. Now the dent can be

pulled out by pulling on the protruding heads

of the screws with a pair of pliers.

The next stage of the repair is the removal

of the paint from the damaged area, and from

an inch or so of the surrounding “sound”

bodywork. This is accomplished most easily

by using a wire brush or abrasive pad on a

power drill, although it can be done just as

effectively by hand, using sheets of abrasive

paper. To complete the preparation for filling,

score the surface of the bare metal with a

screwdriver or the tang of a file, or

alternatively, drill small holes in the affected

area. This will provide a really good “key” for

the filler paste.

To complete the repair, see the Section on

filling and respraying.

Repairs of rust holes or gashes in

bodywork

Remove all paint from the affected area,

and from an inch or so of the surrounding

“sound” bodywork, using an abrasive pad or a

wire brush on a power drill. If these are not

available, a few sheets of abrasive paper will

do the job most effectively. With the paint

removed, you will be able to judge the severity

of the corrosion, and therefore decide

whether to renew the whole panel (if this is

possible) or to repair the affected area. New

body panels are not as expensive as most

people think, and it is often quicker and more

satisfactory to fit a new panel than to attempt

to repair large areas of corrosion.

Remove all fittings from the affected area,

except those which will act as a guide to the

original shape of the damaged bodywork (eg

headlight shells etc). Then, using tin snips or a

hacksaw blade, remove all loose metal and any

other metal badly affected by corrosion.

Hammer the edges of the hole inwards, in order

to create a slight depression for the filler paste.

Wire-brush the affected area to remove the

powdery rust from the

surface of the remaining metal. Paint the

affected area with rust-inhibiting paint, if the

back of the rusted area is accessible, treat

this also.

Before filling can take place, it will be

necessary to block the hole in some way. This

can be achieved by the use of aluminium or

plastic mesh, or aluminium tape.

Aluminium or plastic mesh, or glass-fibre

matting, is probably the best material to use

for a large hole. Cut a piece to the

approximate size and shape of the hole to be

filled, then position it in the hole so that its

edges are below the level of the surrounding

bodywork. It can be retained in position by

several blobs of filler paste around its

periphery.

Aluminium tape should be used for small or

very narrow holes. Pull a piece off the roll, trim

it to the approximate size and shape required,

then pull off the backing paper (if used) and

stick the tape over the hole; it can be

overlapped if the thickness of one piece is

insufficient. Burnish down the edges of the

tape with the handle of a screwdriver or

similar, to ensure that the tape is securely

attached to the metal underneath.

Bodywork repairs - filling and

respraying

Before using this Section, see the Sections

on dent, deep scratch, rust holes and gash

repairs.

Many types of bodyfiller are available, but

generally speaking, those proprietary kits

which contain a tin of filler paste and a tube of

resin hardener are best for this type of repair.

A wide, flexible plastic or nylon applicator will

be found invaluable for imparting a smooth

and well-contoured finish to the surface of the

filler.

4 Minor body damage - repair

3 Maintenance -

upholstery and carpets

Bodywork and fittings 11•3

11

If the inside of the vehicle

gets wet accidentally, it is

worthwhile taking some

trouble to dry it out properly,

particularly where carpets are involved.

Do not leave oil or electric heaters

inside the vehicle for this purpose.

procarmanuals.com