axle FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 350 of 413

07-03-10

FMX Transmission

07-03-10

Too/-T69P-7B793-A

ADJUSTING SCREW

REAR SERVO \ LOCK NUT

Tool—7795-C

D1329-A

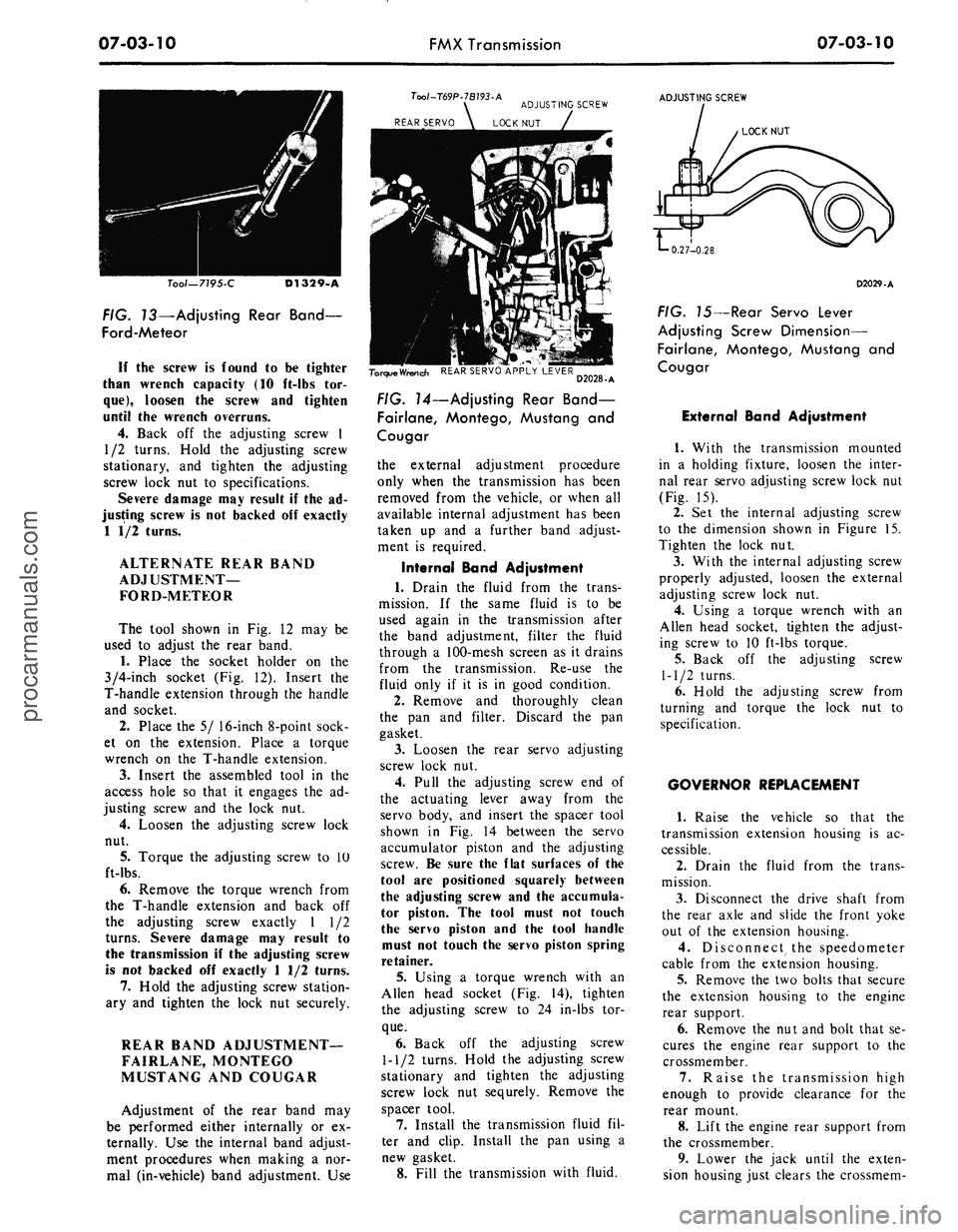

FIG. 13—Adjusting Rear Band—

Ford-Meteor

If

the

screw

is

found

to be

tighter

than

wrench

capacity

(10

ft-lbs

tor-

que),

loosen

the

screw

and

tighten

until

the

wrench

overruns.

4.

Back off the adjusting screw 1

1/2 turns. Hold the adjusting screw

stationary, and tighten the adjusting

screw lock nut to specifications.

Severe damage may result if the ad-

justing screw is not backed off exactly

1 1/2 turns.

ALTERNATE REAR BAND

ADJUSTMENT—

FORD-METEOR

The tool shown in Fig. 12 may be

used to adjust the rear band.

1.

Place the socket holder on the

3/4-inch socket (Fig. 12). Insert the

T-handle extension through the handle

and socket.

2.

Place the 5/ 16-inch 8-point sock-

et on the extension. Place a torque

wrench on the T-handle extension.

3.

Insert the assembled tool in the

access hole so that it engages the ad-

justing screw and the lock nut.

4.

Loosen the adjusting screw lock

nut.

5.

Torque the adjusting screw to 10

ft-lbs.

6. Remove the torque wrench from

the T-handle extension and back off

the adjusting screw exactly 1 1/2

turns.

Severe

damage

may

result

to

the

transmission

if the

adjusting

screw

is

not

backed

off

exactly

11/2

turns.

7.

Hold the adjusting screw station-

ary and tighten the lock nut securely.

REAR BAND ADJUSTMENT—

FAIRLANE, MONTEGO

MUSTANG AND COUGAR

Adjustment of the rear band may

be performed either internally or ex-

ternally. Use the internal band adjust-

ment procedures when making a nor-

mal (in-vehicle) band adjustment. Use

ADJUSTING SCREW

LOCK NUT

I

IN

TorqueWrench REAR SERVO APPLY LEVER

D2028-A

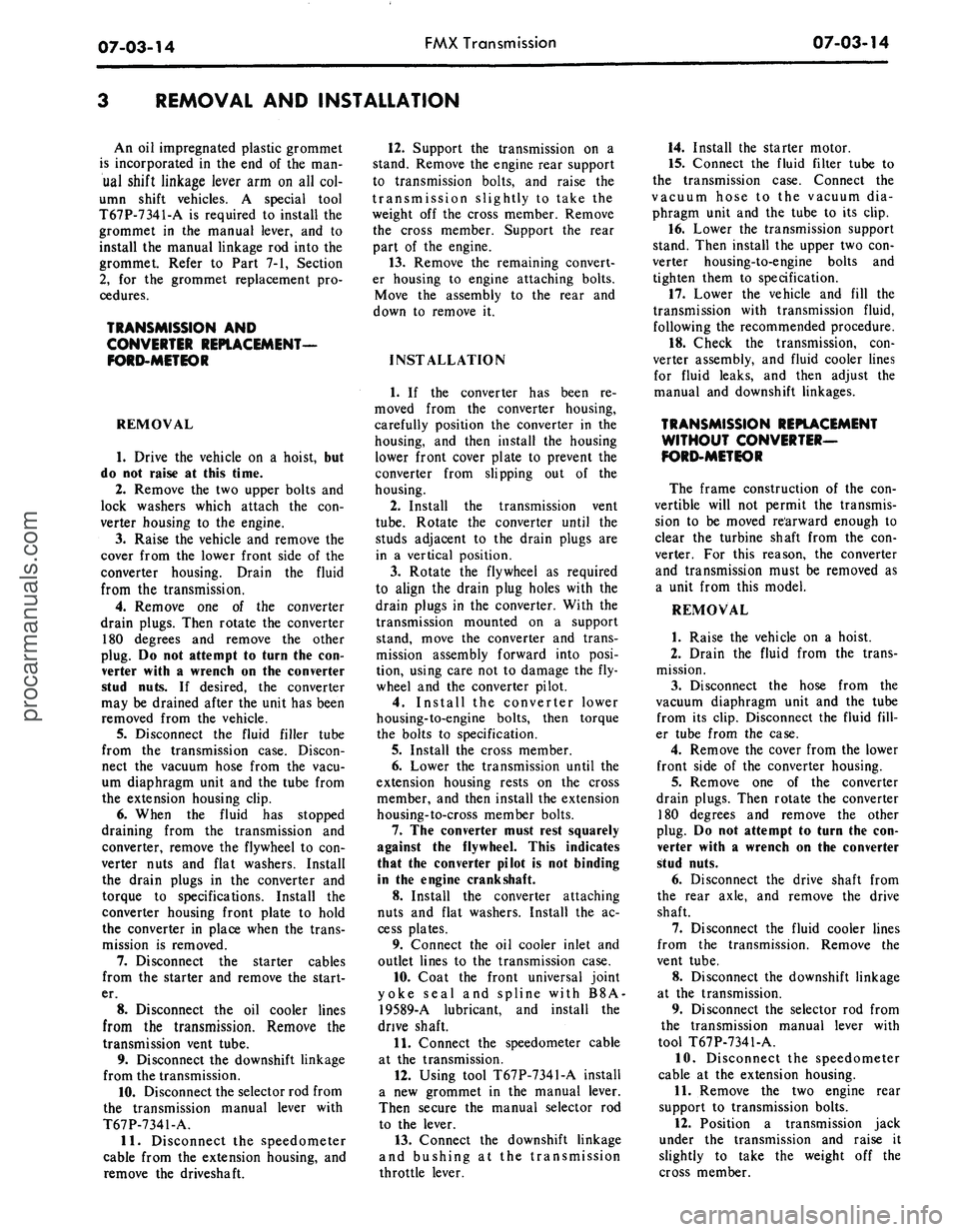

FIG. 14—Adjusting Rear Band—

Fairlane, Montego, Mustang and

Cougar

the external adjustment procedure

only when the transmission has been

removed from the vehicle, or when all

available internal adjustment has been

taken up and a further band adjust-

ment is required.

Internal Band Adjustment

1.

Drain the fluid from the trans-

mission. If the same fluid is to be

used again in the transmission after

the band adjustment, filter the fluid

through a 100-mesh screen as it drains

from the transmission. Re-use the

fluid only if it is in good condition.

2.

Remove and thoroughly clean

the pan and filter. Discard the pan

gasket.

3.

Loosen the rear servo adjusting

screw lock nut.

4.

Pull the adjusting screw end of

the actuating lever away from the

servo body, and insert the spacer tool

shown in Fig. 14 between the servo

accumulator piston and the adjusting

screw.

Be

sure

the

flat

surfaces

of the

tool

are

positioned

squarely

between

the

adjusting

screw

and the

accumula-

tor

piston.

The

tool must

not

touch

the servo

piston

and the

tool

handle

must

not

touch

the

servo

piston

spring

retainer.

5.

Using a torque wrench with an

Allen head socket (Fig. 14), tighten

the adjusting screw to 24 in-lbs tor-

que.

6. Back off the adjusting screw

1-1/2 turns. Hold the adjusting screw

stationary and tighten the adjusting

screw lock nut sequrely. Remove the

spacer tool.

7.

Install the transmission fluid fil-

ter and clip. Install the pan using a

new gasket.

8. Fill the transmission with fluid.

D2029-A

FIG. 15—Rear Servo Lever

Adjusting Screw Dimension—

Fairlane, Montego, Mustang and

Cougar

External Band Adjustment

1.

With the transmission mounted

in a holding fixture, loosen the inter-

nal rear servo adjusting screw lock nut

(Fig. 15).

2.

Set the internal adjusting screw

to the dimension shown in Figure 15.

Tighten the lock nut.

3.

With the internal adjusting screw

properly adjusted, loosen the external

adjusting screw lock nut.

4.

Using a torque wrench with an

Allen head socket, tighten the adjust-

ing screw to 10 ft-lbs torque.

5.

Back off the adjusting screw

1-1/2 turns.

6. Hold the adjusting screw from

turning and torque the lock nut to

specification.

GOVERNOR REPLACEMENT

1.

Raise the vehicle so that the

transmission extension housing is ac-

cessible.

2.

Drain the fluid from the trans-

mission.

3.

Disconnect the drive shaft from

the rear axle and slide the front yoke

out of the extension housing.

4.

Disconnect the speedometer

cable from the extension housing.

5.

Remove the two bolts that secure

the extension housing to the engine

rear support.

6. Remove the nut and bolt that se-

cures the engine rear support to the

crossmember.

7.

Raise the transmission high

enough to provide clearance for the

rear mount.

8. Lift the engine rear support from

the crossmember.

9. Lower the jack until the exten-

sion housing just clears the crossmem-procarmanuals.com

Page 354 of 413

07-03-14

FMX Transmission

07-03-14

REMOVAL AND INSTALLATION

An oil impregnated plastic grommet

is incorporated in the end of the man-

ual shift linkage lever arm on all col-

umn shift vehicles. A special tool

T67P-7341-A is required to install the

grommet in the manual lever, and to

install the manual linkage rod into the

grommet. Refer to Part 7-1, Section

2,

for the grommet replacement pro-

cedures.

TRANSMISSION AND

CONVERTER REPLACEMENT—

FORD-METEOR

REMOVAL

1.

Drive the vehicle on a hoist, but

do not raise at this time.

2.

Remove the two upper bolts and

lock washers which attach the con-

verter housing to the engine.

3.

Raise the vehicle and remove the

cover from the lower front side of the

converter housing. Drain the fluid

from the transmission.

4.

Remove one of the converter

drain plugs. Then rotate the converter

180 degrees and remove the other

plug. Do not attempt to turn the con-

verter with a wrench on the converter

stud nuts. If desired, the converter

may be drained after the unit has been

removed from the vehicle.

5.

Disconnect the fluid filler tube

from the transmission case. Discon-

nect the vacuum hose from the vacu-

um diaphragm unit and the tube from

the extension housing clip.

6. When the fluid has stopped

draining from the transmission and

converter, remove the flywheel to con-

verter nuts and flat washers. Install

the drain plugs in the converter and

torque to specifications. Install the

converter housing front plate to hold

the converter in place when the trans-

mission is removed.

7.

Disconnect the starter cables

from the starter and remove the start-

er.

8. Disconnect the oil cooler lines

from the transmission. Remove the

transmission vent tube.

9. Disconnect the downshift linkage

from the transmission.

10.

Disconnect the selector rod from

the transmission manual lever with

T67P-7341-A.

11.

Disconnect the speedometer

cable from the extension housing, and

remove the driveshaft.

12.

Support the transmission on a

stand. Remove the engine rear support

to transmission bolts, and raise the

transmission slightly to take the

weight off the cross member. Remove

the cross member. Support the rear

part of the engine.

13.

Remove the remaining convert-

er housing to engine attaching bolts.

Move the assembly to the rear and

down to remove it.

INSTALLATION

1.

If the converter has been re-

moved from the converter housing,

carefully position the converter in the

housing, and then install the housing

lower front cover plate to prevent the

converter from slipping out of the

housing.

2.

Install the transmission vent

tube.

Rotate the converter until the

studs adjacent to the drain plugs are

in a vertical position.

3.

Rotate the flywheel as required

to align the drain plug holes with the

drain plugs in the converter. With the

transmission mounted on a support

stand, move the converter and trans-

mission assembly forward into posi-

tion, using care not to damage the fly-

wheel and the converter pilot.

4.

Install the converter lower

housing-to-engine bolts, then torque

the bolts to specification.

5.

Install the cross member.

6. Lower the transmission until the

extension housing rests on the cross

member, and then install the extension

housing-to-cross member bolts.

7.

The converter must rest squarely

against the flywheel. This indicates

that the converter pilot is not binding

in the engine crankshaft.

8. Install the converter attaching

nuts and flat washers. Install the ac-

cess plates.

9. Connect the oil cooler inlet and

outlet lines to the transmission case.

10.

Coat the front universal joint

yoke seal and spline with B8A-

19589-A lubricant, and install the

drive shaft.

11.

Connect the speedometer cable

at the transmission.

12.

Using tool T67P-7341-A install

a new grommet in the manual lever.

Then secure the manual selector rod

to the lever.

13.

Connect the downshift linkage

and bushing at the transmission

throttle lever.

14.

Install the starter motor.

15.

Connect the fluid filter tube to

the transmission case. Connect the

vacuum hose to the vacuum dia-

phragm unit and the tube to its clip.

16.

Lower the transmission support

stand. Then install the upper two con-

verter housing-to-engine bolts and

tighten them to specification.

17.

Lower the vehicle and fill the

transmission with transmission fluid,

following the recommended procedure.

18.

Check the transmission, con-

verter assembly, and fluid cooler lines

for fluid leaks, and then adjust the

manual and downshift linkages.

TRANSMISSION REPLACEMENT

WITHOUT CONVERTER—

FORD-METEOR

The frame construction of the con-

vertible will not permit the transmis-

sion to be moved rearward enough to

clear the turbine shaft from the con-

verter. For this reason, the converter

and transmission must be removed as

a unit from this model.

REMOVAL

1.

Raise the vehicle on a hoist.

2.

Drain the fluid from the trans-

mission.

3.

Disconnect the hose from the

vacuum diaphragm unit and the tube

from its clip. Disconnect the fluid fill-

er tube from the case.

4.

Remove the cover from the lower

front side of the converter housing.

5.

Remove one of the converter

drain plugs. Then rotate the converter

180 degrees and remove the other

plug. Do not attempt to turn the con-

verter with a wrench on the converter

stud nuts.

6. Disconnect the drive shaft from

the rear axle, and remove the drive

shaft.

7.

Disconnect the fluid cooler lines

from the transmission. Remove the

vent tube.

8. Disconnect the downshift linkage

at the transmission.

9. Disconnect the selector rod from

the transmission manual lever with

tool T67P-7341-A.

10.

Disconnect the speedometer

cable at the extension housing.

11.

Remove the two engine rear

support to transmission bolts.

12.

Position a transmission jack

under the transmission and raise it

slightly to take the weight off the

cross member.procarmanuals.com

Page 370 of 413

07-04-01

C-6 Automatic Transmission

07-04-01

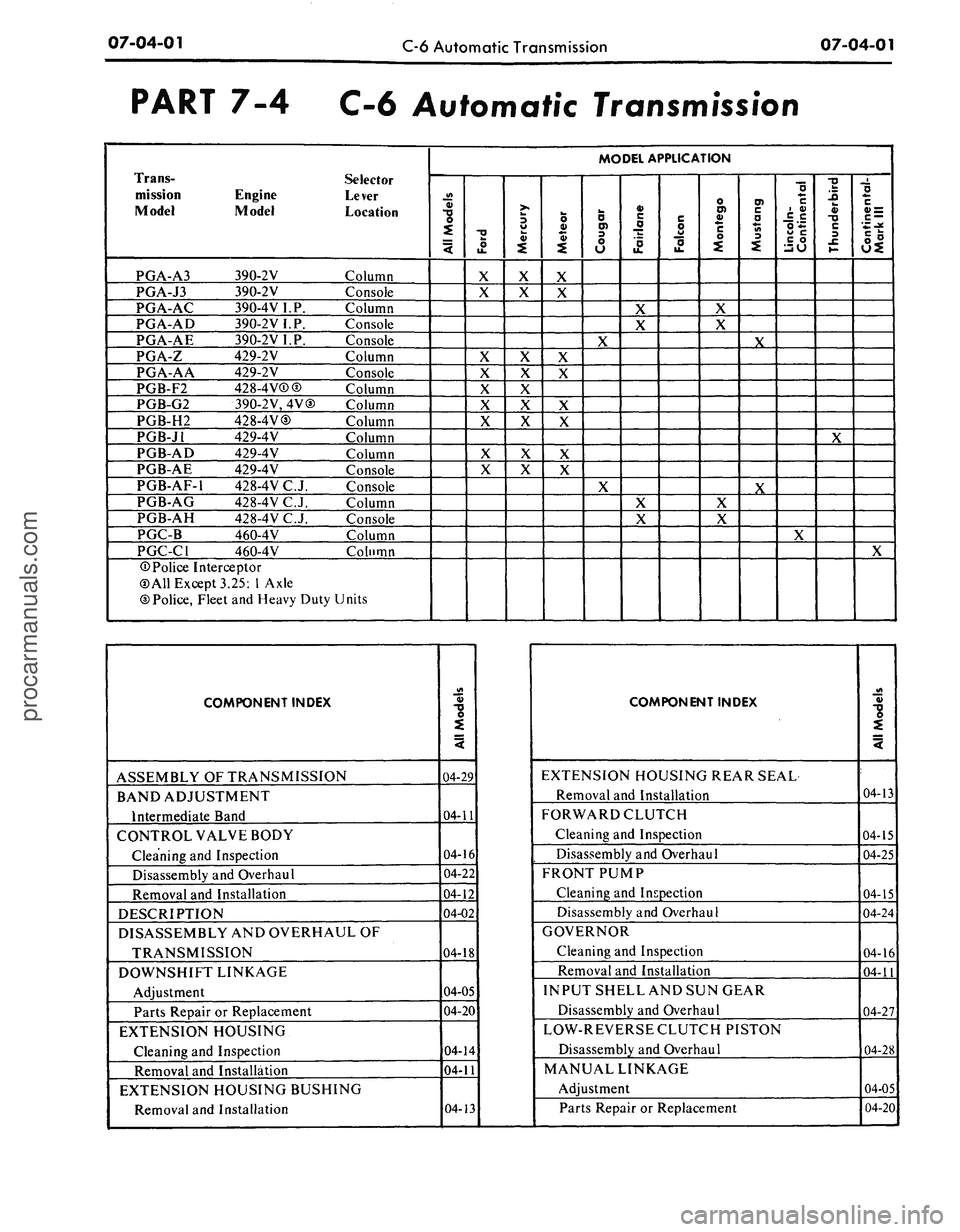

PART 7-4 C-6 Automatic Transmission

Trans-

Selector

mission Engine Lever

Model Model Location

PGA-A3 390-2V Column

PGA-J3 390-2V Console

PGA-AC 390-4VI.P. Column

PGA-AD 390-2VI.P. Console

PGA-AE 390-2V I.P. Console

PGA-Z 429-2V Column

PGA-AA 429-2V Console

PGB-F2 428-4 V®@ Column

PGB-G2 390-2V,4V© Column

PGB-H2 428-4V® Column

PGB-J1 429-4V Column

PGB-AD 429-4V Column

PGB-AE 429-4V Console

PGB-AF-1 428-4VC.J. Console

PGB-AG 428-4V C. J. Column

PGB-AH 428-4V C.J. Console

PGC-B 460-4V Column

PGC-C1 460-4V Column

©Police Interceptor

©All Except 3.25:

1

Axle

©Police, Fleet and Heavy Duty Units

MODEL APPLICATION

All

Models

Ford

X

X

X

X

X

X

X

X

X

Mercury

x

X

X

X

X

X

X

X

Meteor

X

X

X

X

X

X

X

X

Cougar

X

X

Fairlane

X

X

X

X

Falcon

Montego

X

X

X

X

Mustang

X

X

Lincoln-

Continental

X

Thunderbird

X

1

Continental-

Mark

III

X

COMPONENT INDEX

ASSEMBLY OF TRANSMISSION

BAND ADJUSTMENT

Intermediate Band

CONTROL VALVE BODY

Cleaning and Inspection

Disassembly and Overhaul

Removal and Installation

DESCRIPTION

DISASSEMBLY AND OVERHAUL OF

TRANSMISSION

DOWNSHIFT LINKAGE

Adjustment

Parts Repair or Replacement

EXTENSION HOUSING

Cleaning and Inspection

Removal and Installation

EXTENSION HOUSING BUSHING

Removal and Installation

All

Models

04-29

04-11

04-16

04-22

04-12

04-02

04-18

04-05

04-20

04-14

04-11

04-13

COMPONENT INDEX

EXTENSION HOUSING REAR SEAL

Removal and Installation

FORWARD CLUTCH

Cleaning and Inspection

Disassembly and Overhaul

FRONT PUMP

Cleaning and Inspection

Disassembly and Overhaul

GOVERNOR

Cleaning and Inspection

Removal and Installation

INPUT SHELL AND SUN GEAR

Disassembly and Overhaul

LOW-REVERSE CLUTCH PISTON

Disassembly and Overhaul

MANUAL LINKAGE

Adjustment

Parts Repair or Replacement

All

Models

04-13

04-15

04-25

04-15

04-24

04-16

04-11

04-27

04-28

04-05

04-20

procarmanuals.com

Page 380 of 413

07-04-11

C-6 Automatic Transmission

07-04-11

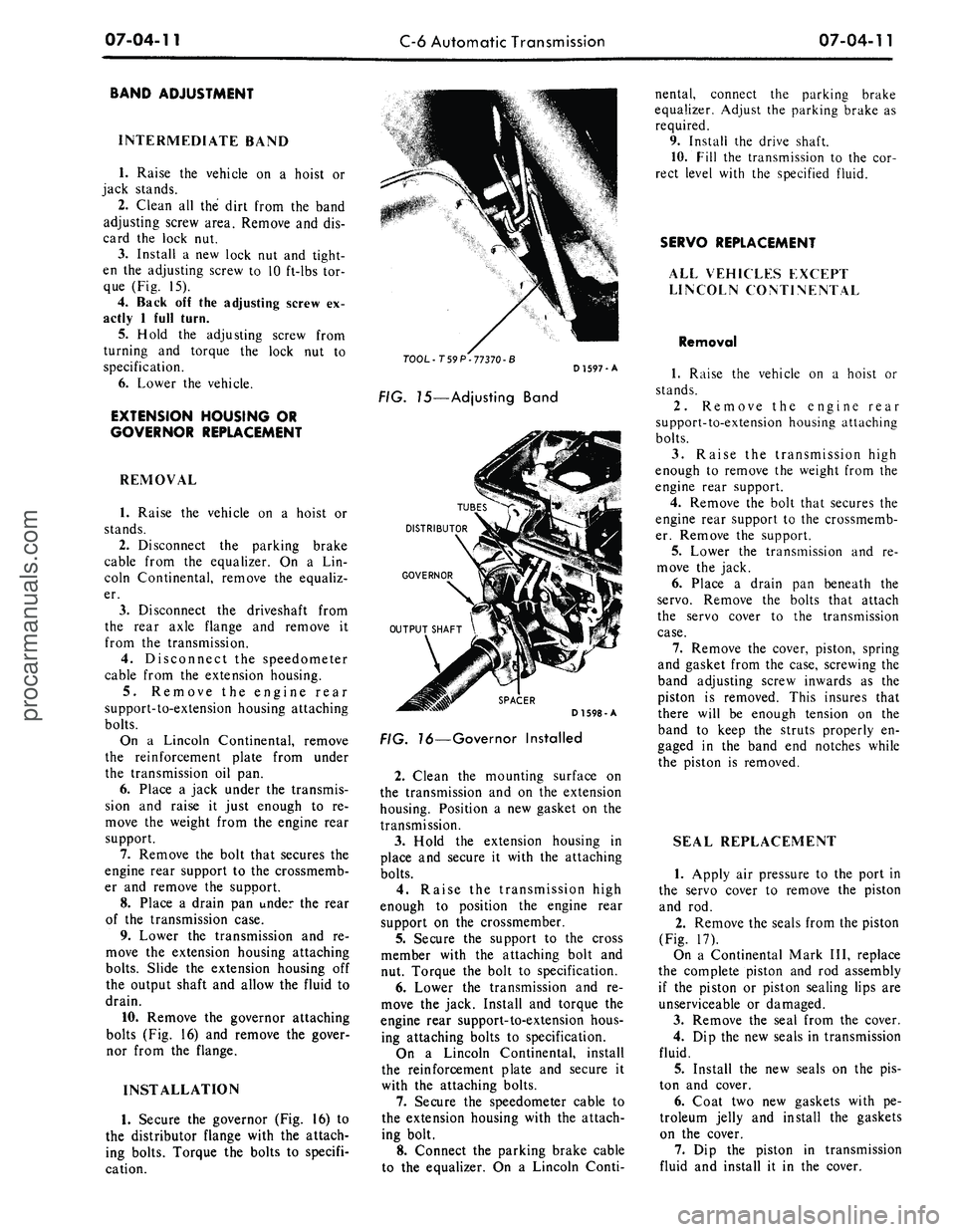

BAND ADJUSTMENT

INTERMEDIATE BAND

1.

Raise the vehicle on a hoist or

jack stands.

2.

Clean all the dirt from the band

adjusting screw area. Remove and dis-

card the lock nut.

3.

Install a new lock nut and tight-

en the adjusting screw to 10 ft-lbs tor-

que (Fig. 15).

4.

Back off the adjusting screw ex-

actly 1 full turn.

5.

Hold the adjusting screw from

turning and torque the lock nut to

specification.

6. Lower the vehicle.

EXTENSION HOUSING OR

GOVERNOR REPLACEMENT

REMOVAL

1.

Raise the vehicle on a hoist or

stands.

2.

Disconnect the parking brake

cable from the equalizer. On a Lin-

coln Continental, remove the equaliz-

er.

3.

Disconnect the driveshaft from

the rear axle flange and remove it

from the transmission.

4.

Disconnect the speedometer

cable from the extension housing.

5.

Remove the engine rear

support-to-extension housing attaching

bolts.

On a Lincoln Continental, remove

the reinforcement plate from under

the transmission oil pan.

6. Place a jack under the transmis-

sion and raise it just enough to re-

move the weight from the engine rear

support.

7.

Remove the bolt that secures the

engine rear support to the crossmemb-

er and remove the support.

8. Place a drain pan under the rear

of the transmission case.

9. Lower the transmission and re-

move the extension housing attaching

bolts.

Slide the extension housing off

the output shaft and allow the fluid to

drain.

10.

Remove the governor attaching

bolts (Fig. 16) and remove the gover-

nor from the flange.

INSTALLATION

1.

Secure the governor (Fig. 16) to

the distributor flange with the attach-

ing bolts. Torque the bolts to specifi-

cation.

TOOL-T59 P-77370-B

FIG. 75—Adjusting Band

D 1597-A

TUBES

DISTRIBUTOR

GOVERNOR

SPACER

D1598-A

FIG. 76—Governor Installed

2.

Clean the mounting surface on

the transmission and on the extension

housing. Position a new gasket on the

transmission.

3.

Hold the extension housing in

place and secure it with the attaching

bolts.

4.

Raise the transmission high

enough to position the engine rear

support on the crossmember.

5.

Secure the support to the cross

member with the attaching bolt and

nut. Torque the bolt to specification.

6. Lower the transmission and re-

move the jack. Install and torque the

engine rear support-to-extension hous-

ing attaching bolts to specification.

On a Lincoln Continental, install

the reinforcement plate and secure it

with the attaching bolts.

7.

Secure the speedometer cable to

the extension housing with the attach-

ing bolt.

8. Connect the parking brake cable

to the equalizer. On a Lincoln Conti-

nental, connect the parking brake

equalizer. Adjust the parking brake as

required.

9. Install the drive shaft.

10.

Fill the transmission to the cor-

rect level with the specified fluid.

SERVO REPLACEMENT

ALL VEHICLES EXCEPT

LINCOLN CONTINENTAL

Removal

1.

Raise the vehicle on a hoist or

stands.

2.

Remove the engine rear

support-to-extension housing attaching

bolts.

3.

Raise the transmission high

enough to remove the weight from the

engine rear support.

4.

Remove the bolt that secures the

engine rear support to the crossmemb-

er. Remove the support.

5.

Lower the transmission and re-

move the jack.

6. Place a drain pan beneath the

servo.

Remove the bolts that attach

the servo cover to the transmission

case.

7.

Remove the cover, piston, spring

and gasket from the case, screwing the

band adjusting screw inwards as the

piston is removed. This insures that

there will be enough tension on the

band to keep the struts properly en-

gaged in the band end notches while

the piston is removed.

SEAL REPLACEMENT

1.

Apply air pressure to the port in

the servo cover to remove the piston

and rod.

2.

Remove the seals from the piston

(Fig. 17).

On a Continental Mark III, replace

the complete piston and rod assembly

if the piston or piston sealing lips are

unserviceable or damaged.

3.

Remove the seal from the cover.

4.

Dip the new seals in transmission

fluid.

5.

Install the new seals on the pis-

ton and cover.

6. Coat two new gaskets with pe-

troleum jelly and install the gaskets

on the cover.

7.

Dip the piston in transmission

fluid and install it in the cover.procarmanuals.com

Page 382 of 413

07-04-13

C-6 Automatic Transmission

07-04-13

On a Lincoln Continental, install

the reinforcement plate and secure it

with the attaching bolts.

4.

Lower the vehicle and fill the

transmission to the correct level with

the specified fluid.

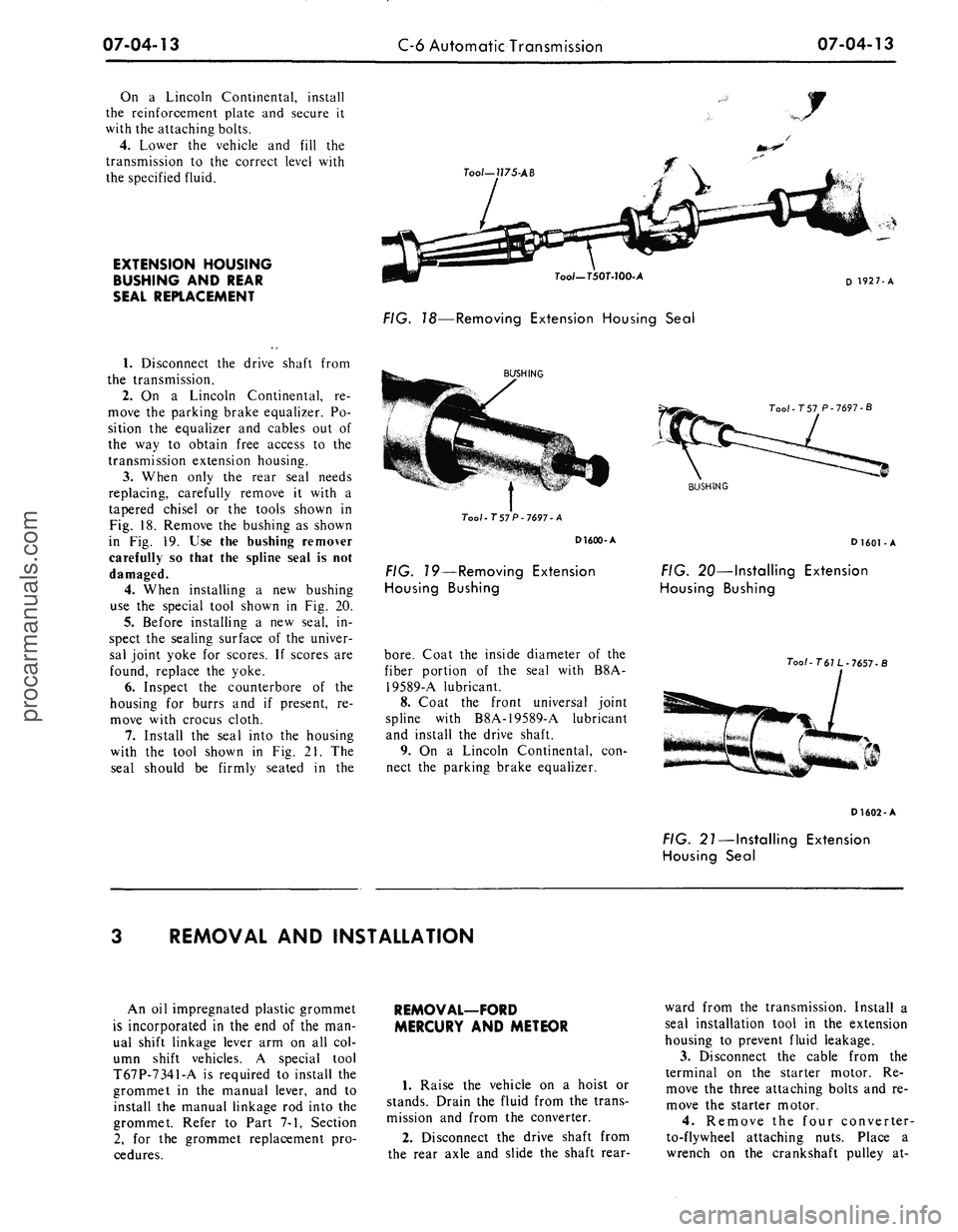

EXTENSION HOUSING

BUSHING AND REAR

SEAL REPLACEMENT

Too/—

1175-AB

Tool—750T-70O-A

D 1927-A

FIG. 18—Removing Extension Housing Seal

1.

Disconnect the drive shaft from

the transmission.

2.

On a Lincoln Continental, re-

move the parking brake equalizer. Po-

sition the equalizer and cables out of

the way to obtain free access to the

transmission extension housing.

3.

When only the rear seal needs

replacing, carefully remove it with a

tapered chisel or the tools shown in

Fig. 18. Remove the bushing as shown

in Fig. 19. Use the bushing remover

carefully so that the spline seal is not

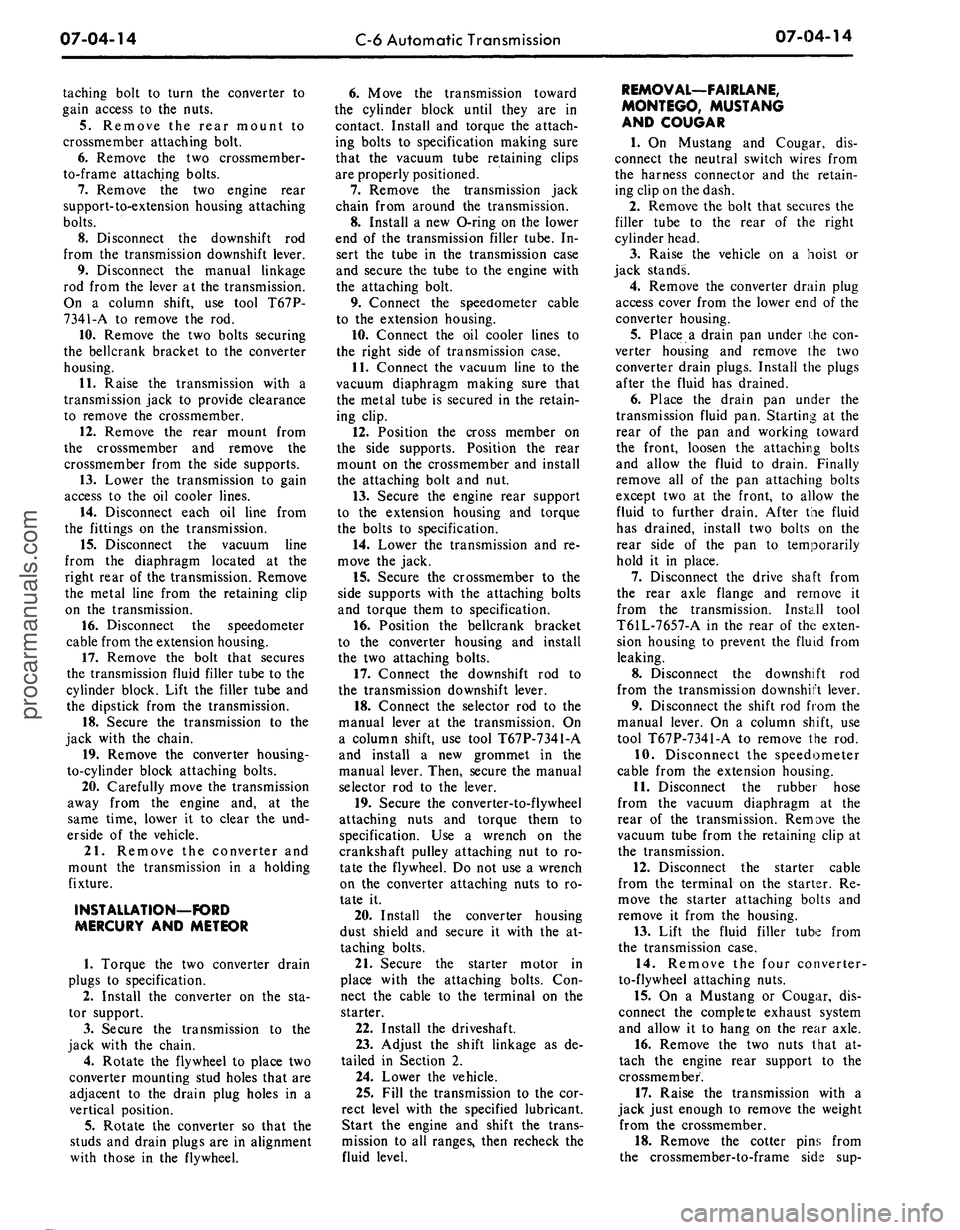

damaged.

4.

When installing a new bushing

use the special tool shown in Fig. 20.

5.

Before installing a new seal, in-

spect the sealing surface of the univer-

sal joint yoke for scores. If scores are

found, replace the yoke.

6. Inspect the counterbore of the

housing for burrs and if present, re-

move with crocus cloth.

7.

Install the seal into the housing

with the tool shown in Fig. 21. The

seal should be firmly seated in the

BUSHING

Too/-757 P-7697-A

D1600-A

FIG. 19—Removing Extension

Housing Bushing

bore.

Coat the inside diameter of the

fiber portion of the seal with B8A-

19589-A lubricant.

8. Coat the front universal joint

spline with B8A-19589-A lubricant

and install the drive shaft.

9. On a Lincoln Continental, con-

nect the parking brake equalizer.

Tool-T 57 P-7697-B

BUSHING

D

1601

-A

FIG. 20—Installing Extension

Housing Bushing

Tool-

T61 L

-

7657-

B

D1602-A

FIG. 21—Installing Extension

Housing Seal

REMOVAL AND INSTALLATION

An oil impregnated plastic grommet

is incorporated in the end of the man-

ual shift linkage lever arm on all col-

umn shift vehicles. A special tool

T67P-7341-A is required to install the

grommet in the manual lever, and to

install the manual linkage rod into the

grommet. Refer to Part 7-1, Section

2,

for the grommet replacement pro-

cedures.

REMOVAL—FORD

MERCURY AND METEOR

1.

Raise the vehicle on a hoist or

stands. Drain the fluid from the trans-

mission and from the converter.

2.

Disconnect the drive shaft from

the rear axle and slide the shaft rear-

ward from the transmission. Install a

seal installation tool in the extension

housing to prevent fluid leakage.

3.

Disconnect the cable from the

terminal on the starter motor. Re-

move the three attaching bolts and re-

move the starter motor.

4.

Remove the four converter-

to-flywheel attaching nuts. Place a

wrench on the crankshaft pulley at-procarmanuals.com

Page 383 of 413

07-04-14

C-6 Automatic Transmission

07-04-14

taching bolt to turn the converter to

gain access to the nuts.

5.

Remove the rear mount to

crossmember attaching bolt.

6. Remove the two crossmember-

to-frame attaching bolts.

7.

Remove the two engine rear

support-to-extension housing attaching

bolts.

8. Disconnect the downshift rod

from the transmission downshift lever.

9. Disconnect the manual linkage

rod from the lever at the transmission.

On a column shift, use tool T67P-

7341-A to remove the rod.

10.

Remove the two bolts securing

the bellcrank bracket to the converter

housing.

11.

Raise the transmission with a

transmission jack to provide clearance

to remove the crossmember.

12.

Remove the rear mount from

the crossmember and remove the

crossmember from the side supports.

13.

Lower the transmission to gain

access to the oil cooler lines.

14.

Disconnect each oil line from

the fittings on the transmission.

15.

Disconnect the vacuum line

from the diaphragm located at the

right rear of the transmission. Remove

the metal line from the retaining clip

on the transmission.

16.

Disconnect the speedometer

cable from the extension housing.

17.

Remove the bolt that secures

the transmission fluid filler tube to the

cylinder block. Lift the filler tube and

the dipstick from the transmission.

18.

Secure the transmission to the

jack with the chain.

19.

Remove the converter housing-

to-cylinder block attaching bolts.

20.

Carefully move the transmission

away from the engine and, at the

same time, lower it to clear the und-

erside of the vehicle.

21.

Remove the converter and

mount the transmission in a holding

fixture.

INSTALLATION—FORD

MERCURY AND METEOR

1.

Torque the two converter drain

plugs to specification.

2.

Install the converter on the sta-

tor support.

3.

Secure the transmission to the

jack with the chain.

4.

Rotate the flywheel to place two

converter mounting stud holes that are

adjacent to the drain plug holes in a

vertical position.

5.

Rotate the converter so that the

studs and drain plugs are in alignment

with those in the flywheel.

6. Move the transmission toward

the cylinder block until they are in

contact. Install and torque the attach-

ing bolts to specification making sure

that the vacuum tube retaining clips

are properly positioned.

7.

Remove the transmission jack

chain from around the transmission.

8. Install a new Oring on the lower

end of the transmission filler tube. In-

sert the tube in the transmission case

and secure the tube to the engine with

the attaching bolt.

9. Connect the speedometer cable

to the extension housing.

10.

Connect the oil cooler lines to

the right side of transmission case.

11.

Connect the vacuum line to the

vacuum diaphragm making sure that

the metal tube is secured in the retain-

ing clip.

12.

Position the cross member on

the side supports. Position the rear

mount on the crossmember and install

the attaching bolt and nut.

13.

Secure the engine rear support

to the extension housing and torque

the bolts to specification.

14.

Lower the transmission and re-

move the jack.

15.

Secure the crossmember to the

side supports with the attaching bolts

and torque them to specification.

16.

Position the bellcrank bracket

to the converter housing and install

the two attaching bolts.

17.

Connect the downshift rod to

the transmission downshift lever.

18.

Connect the selector rod to the

manual lever at the transmission. On

a column shift, use tool T67P-7341-A

and install a new grommet in the

manual lever. Then, secure the manual

selector rod to the lever.

19.

Secure the converter-to-flywheel

attaching nuts and torque them to

specification. Use a wrench on the

crankshaft pulley attaching nut to ro-

tate the flywheel. Do not use a wrench

on the converter attaching nuts to ro-

tate it.

20.

Install the converter housing

dust shield and secure it with the at-

taching bolts.

21.

Secure the starter motor in

place with the attaching bolts. Con-

nect the cable to the terminal on the

starter.

22.

Install the driveshaft.

23.

Adjust the shift linkage as de-

tailed in Section 2.

24.

Lower the vehicle.

25.

Fill the transmission to the cor-

rect level with the specified lubricant.

Start the engine and shift the trans-

mission to all ranges, then recheck the

fluid level.

REMOVAL—FAIRLANE,

MONTEGO, MUSTANG

AND COUGAR

1.

On Mustang and Cougar, dis-

connect the neutral switch wires from

the harness connector and the retain-

ing clip on the dash.

2.

Remove the bolt that secures the

filler tube to the rear of the right

cylinder head.

3.

Raise the vehicle on a hoist or

jack stands.

4.

Remove the converter drain plug

access cover from the lower end of the

converter housing.

5.

Place a drain pan under nhe con-

verter housing and remove the two

converter drain plugs. Install the plugs

after the fluid has drained.

6. Place the drain pan under the

transmission fluid pan. Starting at the

rear of the pan and working toward

the front, loosen the attaching bolts

and allow the fluid to drain. Finally

remove all of the pan attaching bolts

except two at the front, to allow the

fluid to further drain. After the fluid

has drained, install two bolts on the

rear side of the pan to temporarily

hold it in place.

7.

Disconnect the drive shaft from

the rear axle flange and remove it

from the transmission. Install tool

T61L-7657-A in the rear of the exten-

sion housing to prevent the fluid from

leaking.

8. Disconnect the downshift rod

from the transmission downshift lever.

9. Disconnect the shift rod from the

manual lever. On a column shift, use

tool T67P-7341-A to remove the rod.

10.

Disconnect the speedometer

cable from the extension housing.

11.

Disconnect the rubber hose

from the vacuum diaphragm at the

rear of the transmission. Remove the

vacuum tube from the retaining clip at

the transmission.

12.

Disconnect the starter cable

from the terminal on the starter. Re-

move the starter attaching bolts and

remove it from the housing.

13.

Lift the fluid filler tube from

the transmission case.

14.

Remove the four converter-

to-flywheel attaching nuts.

15.

On a Mustang or Cougar, dis-

connect the complete exhaust system

and allow it to hang on the rear axle.

16.

Remove the two nuts that at-

tach the engine rear support to the

crossmember.

17.

Raise the transmission with a

jack just enough to remove the weight

from the crossmember.

18.

Remove the cotter pins from

the crossmember-to-frame side sup-procarmanuals.com

Page 407 of 413

07-05-07

Specifications

07-05-07

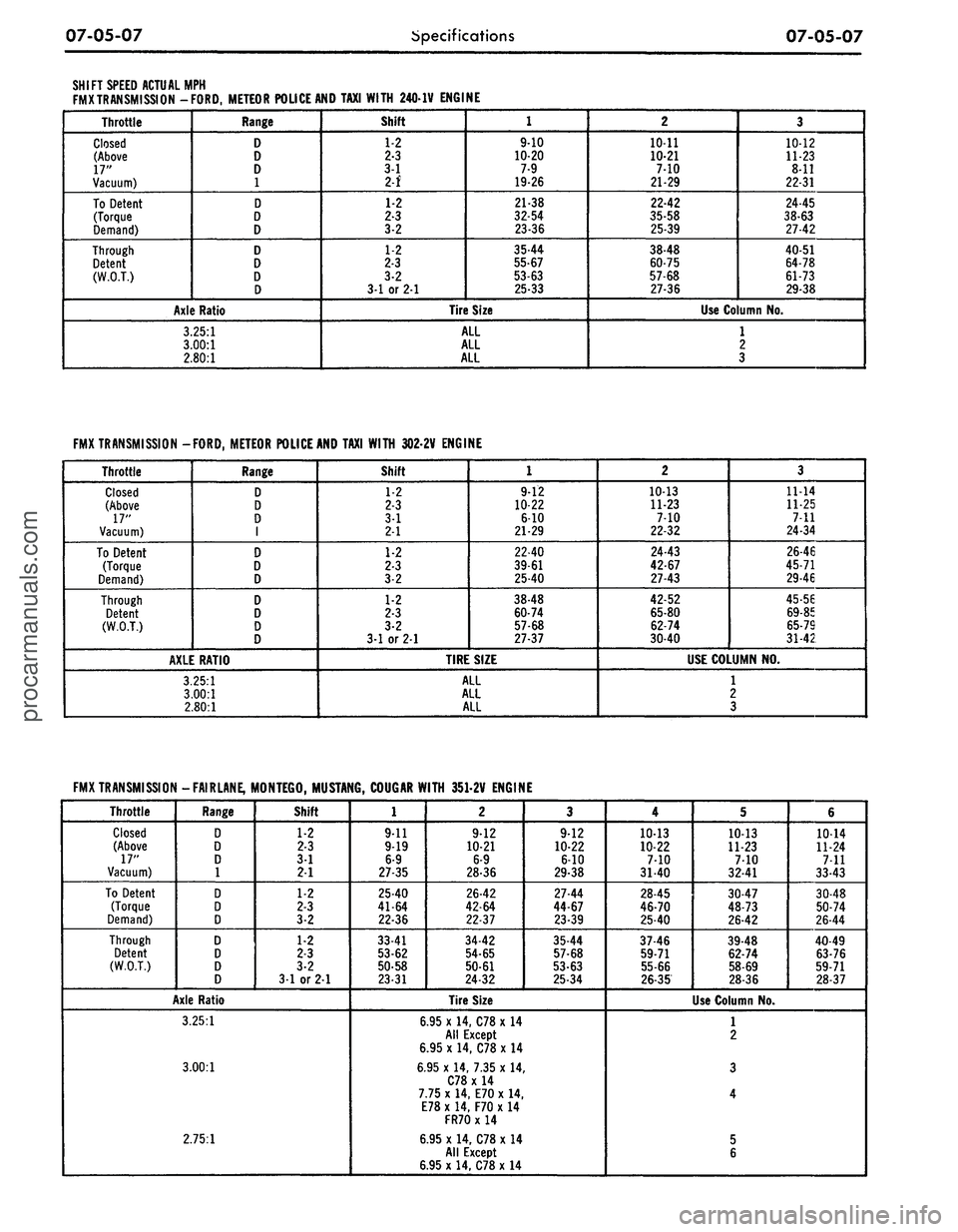

SHIFT SPEED ACTUAL

MPH

FMXTRANSMISSION -FORD, METEOR POLICE AND TAXI WITH 2401V ENGINE

Throttle

Closed

(Above

17"

Vacuum)

To Detent

(Torque

Demand)

Through

Detent

(W.O.T.)

Range

D

D

D

1

D

D

D

D

D

D

D

Axle Ratio

3.25:1

3.00:1

2.80:1

Shift

1-2

2-3

3-1

2-f

1-2

2-3

3-2

1-2

2-3

3-2

31

or 2-1

1

910

10-20

7-9

19-26

21-38

32-54

23-36

35-44

55-67

53-63

25-33

Tire Size

ALL

ALL

ALL

2

10-11

10-21

7-10

21-29

22-42

35-58

25-39

38-48

60-75

57-68

27-36

3

10-12

11-23

8-11

22-31

24-45

38-63

27-42

40-51

64-78

61-73

29-38

Use Column

No.

1

2

3

FMXTRANSMISSION -FORD, METEOR POLICE AND TAXI WITH 3022V ENGINE

Throttle

Closed

(Above

17"

Vacuum)

To Detent

(Torque

Demand)

Through

Detent

(W.O.T.)

Range

D

D

D

1

D

D

D

D

D

D

D

AXLE RATIO

3.25:1

3.00:1

2.80:1

Shift

1-2

2-3

3-1

2-1

1-2

2-3

3-2

1-2

2-3

3-2

3-1

or 21

1

9-12

10-22

6-10

21-29

22-40

39-61

25-40

38-48

60-74

57-68

27-37

TIRE SIZE

ALL

ALL

ALL

2

10-13

11-23

7-10

22-32

24-43

42-67

27-43

42-52

65-80

62-74

30-40

3

11-14

11-25

7-11

24-34

26-46

45-71

29-46

45-56

69-85

65-79

31-42

USE COLUMN

NO.

1

2

3

FMXTRANSMISSION

Throttle

Closed

(Above

17"

Vacuum)

To Detent

(Torque

Demand)

Through

Detent

(W.O.T.)

-FAIRLANE, MONTEGO, MUSTANG, COUGAR WITH 351-2V ENGINE

Range

D

D

D

1

D

D

D

D

D

D

D

Shift

1-2

2-3

3-1

21

1-2

2-3

3-2

1-2

2-3

3-2

3-1

or 2-1

Axle Ratio

3.25:1

3.00:1

2.75:1

1

9-11

9-19

6-9

27-35

25-40

41-64

22-36

33-41

53-62

50-58

23-31

2

9-12

10-21

6-9

28-36

26-42

42-64

22-37

34-42

54-65

50-61

24-32

3

9-12

10-22

6-10

29-38

27-44

44-67

23-39

35-44

57-68

53-63

25-34

Tire Size

6.95

x

14, C78 x

14

All Except

6.95

x

14, C78 x

14

6.95

x

14, 7.35

x 14,

C78 x

14

7.75

x

14, E70

x 14,

E78 x 14, F70 x

14

FR70

x 14

6.95 x 14, C78 x

14

All Except

6.95 x 14, C78 x

14

4

10-13

10-22

7-10

31-40

28-45

46-70

25-40

37-46

59-71

55-66

26-35

5

10-13

11-23

7-10

32-41

30-47

48-73

26-42

39-48

62-74

58-69

28-36

Use Column

No.

6

10-14

11-24

7-11

33-43

30-48

50-74

26-44

40-49

63-76

59-71

28-37

1

2

3

4

5

6procarmanuals.com

Page 408 of 413

07-05-08

Specifications

07-05-08

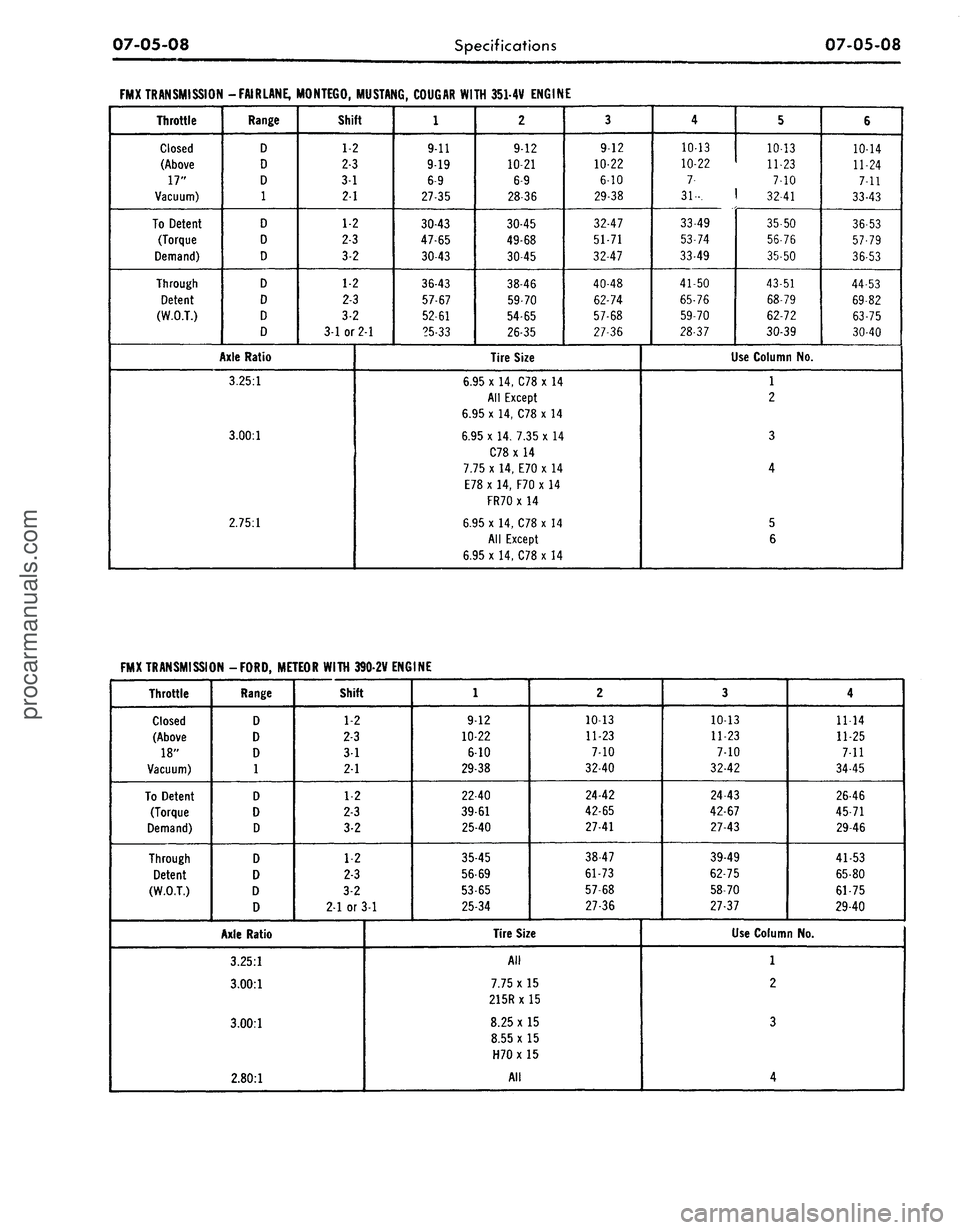

FMX TRANSMISSION

Throttle

Closed

(Above

17"

Vacuum)

To

Detent

(Torque

Demand)

Through

Detent

(W.O.T.)

-FAIRLANE,

1

Range

D

D

D

1

D

D

D

D

D

D

D

MONTEGO,

MUSTANG,

COUGAR

WITH 351-4V ENGINE

Shift

1-2

2-3

3-1

2-1

1-2

2-3

3-2

1-2

2-3

3-2

3-1 or 2-1

Axle Ratio

3.25:1

3.00:1

2.75:1

1

9-11

9-19

6-9

27-35

30-43

47-65

30-43

36-43

57-67

52-61

?5-33

2

9-12

10-21

6-9

28-36

30-45

49-68

30-45

38-46

59-70

54-65

26-35

3

9-12

10-22

6-10

29-38

32-47

51-71

32-47

40-48

62-74

57-68

27-36

Tire Size

6.95 x 14, C78 x

14

All

Except

6.95

x

14, C78

x

14

6.95

x

14. 7.35

x

14

C78

x

14

7.75

x

14, E70

x

14

E78

x

14, F70

x

14

FR70

x 14

6.95

x

14, C78

x

14

All

Except

6.95

x

14, C78

x

14

4

1013

10-22

7

31-.

33-49

53-74

33-49

41-50

65-76

59-70

28-37

5

10-13

11-23

7-10

32-41

35-50

56-76

35-50

43-51

68-79

62-72

30-39

6

10-14

11-24

7-11

33-43

36-53

57-79

36-53

44-53

69-82

63-75

30-40

Use

Column

No.

1

2

3

4

5

6

FMX TRANSMISSION -FORD, METEOR WITH 390-2V ENGINE

Throttle

Closed

(Above

18"

Vacuum)

To

Detent

(Torque

Demand)

Through

Detent

(W.O.T.)

Range

D

D

D

1

D

D

D

D

D

D

D

Shift

1-2

2-3

3-1

2-1

1-2

2-3

3-2

1-2

2-3

3-2

2-1 or 3-1

Axle Ratio

3.25:1

3.00:1

3.00:1

2.80:1

1

9-12

10-22

6-10

29-38

22-40

39-61

25-40

35-45

56-69

53-65

25-34

2

10-13

11-23

7-10

32-40

24-42

42-65

27-41

38-47

61-73

57-68

27-36

Tire Size

All

7.75x15

215R

x15

8.25 x

15

8.55

x

15

H70

x

15

All

3

10-13

11-23

7-10

32-42

24-43

42-67

27-43

39-49

62-75

58-70

27-37

4

11-14

11-25

7-11

34-45

26-46

45-71

29-46

41-53

65-80

61-75

29-40

Use

Column

No.

1

2

3

4procarmanuals.com

Page 409 of 413

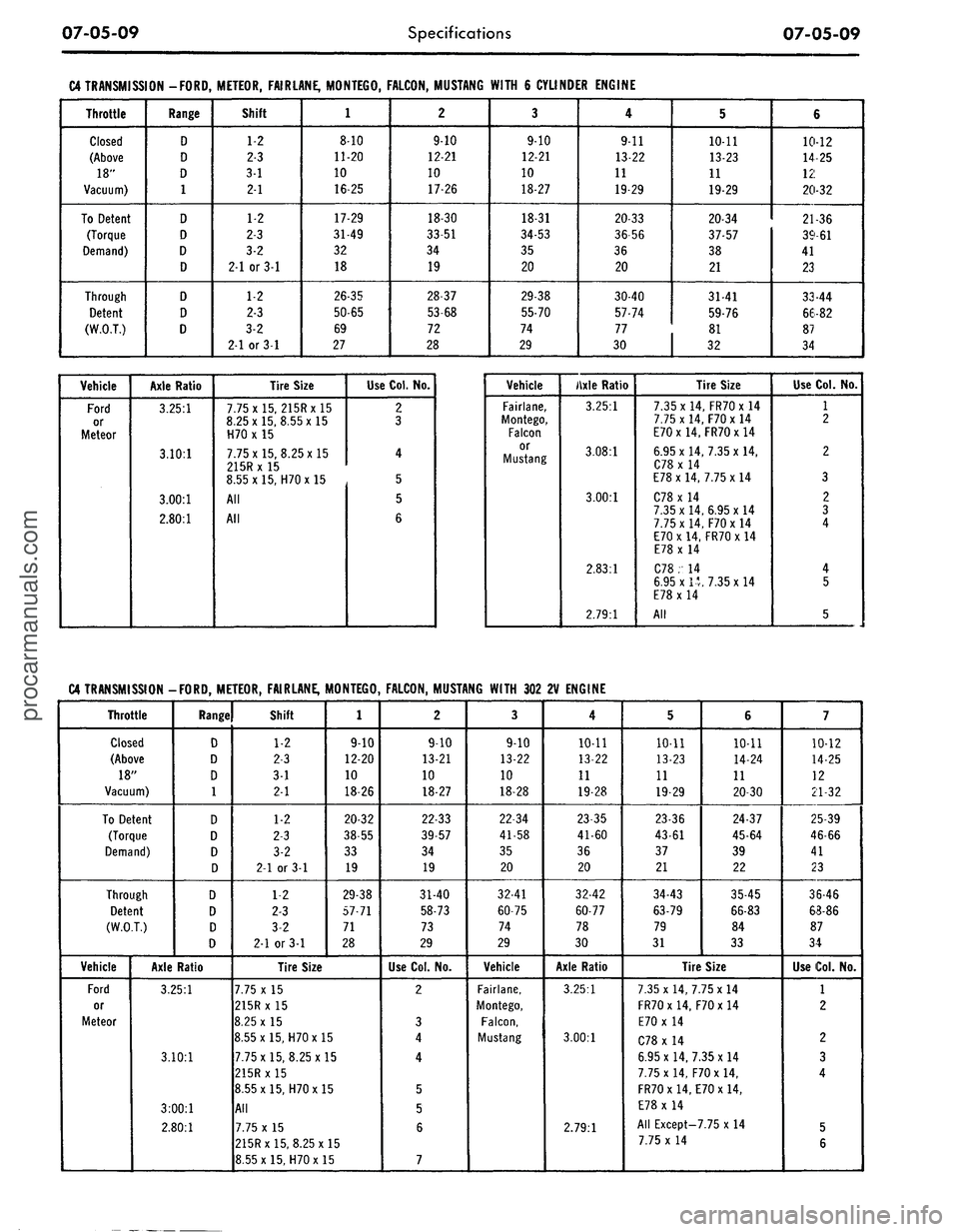

07-05-09

Specifications

07-05-09

C4 TRANSMISSION-FORD,

Throttle

Closed

(Above

18"

Vacuum)

To Detent

(Torque

Demand)

Through

Detent

(W.O.T.)

Range

D

D

D

1

D

D

D

D

D

D

D

METEOR, FAIRLANE, MONTEGO, FALCON, MUSTANG

Shift

1-2

2-3

3-1

2-1

1-2

2-3

3-2

2-1

or 3-1

1-2

2-3

3-2

2-1

or 3-1

1

8-10

11-20

10

16-25

17-29

31-49

32

18

26-35

50-65

69

27

2

9-10

12-21

10

17-26

18-30

33-51

34

19

28-37

53-68

72

28

WITH

6

CYLINDER ENGINE

3

9-10

12-21

10

18-27

18-31

34-53

35

20

29-38

55-70

74

29

4

9-11

13-22

11

19-29

20-33

36-56

36

20

30-40

57-74

77

30

5

10-11

13-23

11

19-29

20-34

37-57

38

21

31-41

59-76

81

32

6

10-12

14

25

12:

20-32

21-36

39-61

41

23

33-44

66-82

87

34

Vehicle

Ford

or

Meteor

Axle Ratio

3.25:1

3.10:1

3.00:1

2.80:1

Tire Size

7.75x15, 215Rx

15

8.25x15,8.55x15

H70

x

15

7.75x15,8.25x15

215Rx

15

8.55x15, H70x

15

All

All

Use Col.

No.

2

3

4

5

5

6

Vehicle

Fairlane,

Montego,

Falcon

or

Mustang

Axle Ratio

3.25:1

3.08:1

3.00:1

2.83:1

2.79:1

Tire Size

7.35x14, FR70x

14

7.75x14, F70x

14

E70xl4, FR70xl4

6.95x14,7.35x14,

C78 x

14

E78

x

14, 7.75 x 14

C78 x

14

7.35x14,6.95x14

7.75x14, F70 x

14

E70 x14, FR70

x14

E78

x 14

C78

:

14

6.95x1-:,

7.35x14

E78 x

14

All

Use Col.

No.

1

2

2

3

2

3

4

4

5

5

C4 TRANSMISSION -FORD, METEOR, FAIRLANE,

Throttle

Closed

(Above

18"

Vacuum)

To Detent

(Torque

Demand)

Through

Detent

(W.O.T.)

Vehicle

Ford

or

Meteor

Range

D

D

D

1

D

D

D

D

D

D

D

D

Axle Ratio

3.25:1

3.10:1

3:00:1

2.80:1

Shift

1-2

2-3

3-1

2-1

1-2

2-3

3-2

2-1

or 3-1

1-2

2-3

3-2

2-1

or 3-1

MONTEGO,

1

9-10

12-20

10

18-26

20-32

38-55

33

19

29-38

57-71

71

28

Tire Size

7.75

x 15

215R

x15

8.25x15

8.55x15, H70x

15

7.75x15,

8.25

x

215R

x15

15

8.55x15, H70x

15

All

7.75

x 15

215Rxl5,8.25x

15

8.55x15, H70x

15

FALCON, MUSTANG WITH

302

2

9-10

13-21

10

18-27

22-33

39-57

34

19

31-40

58-73

73

29

Use Col.

No.

2

3

4

4

5

5

6

7

3

9-10

13-22

10

18-28

22-34

41-58

35

20

32-41

60-75

74

29

Vehicle

Fairlane,

Montego,

Falcon,

Mustang

2V ENGINE

4

10-11

13-22

11

19-28

23-35

41-60

36

20

32-42

60-77

78

30

Axle Ratio

3.25:1

3.00:1

2.79:1

5

10-11

13-23

11

19-29

23-36

43-61

37

21

34-43

63-79

79

31

6

10-11

14-24

11

20-30

24-37

45-64

39

22

35-45

66-83

84

33

Tire Size

7.35x14,7.75x14

FR70 x14, F70

x14

E70

x 14

C78 x

14

6.95x14,7.35x14

7.75

x

14, F70xl4,

FR70xl4, E70xl4,

E78

x 14

All Except-7.75

x

14

7.75

x 14

7

10-12

14-25

12

21-32

25-39

46-66

41

23

36-46

63-86

87

34

Use Col. No.

1

2

2

3

4

5

6procarmanuals.com

Page 410 of 413

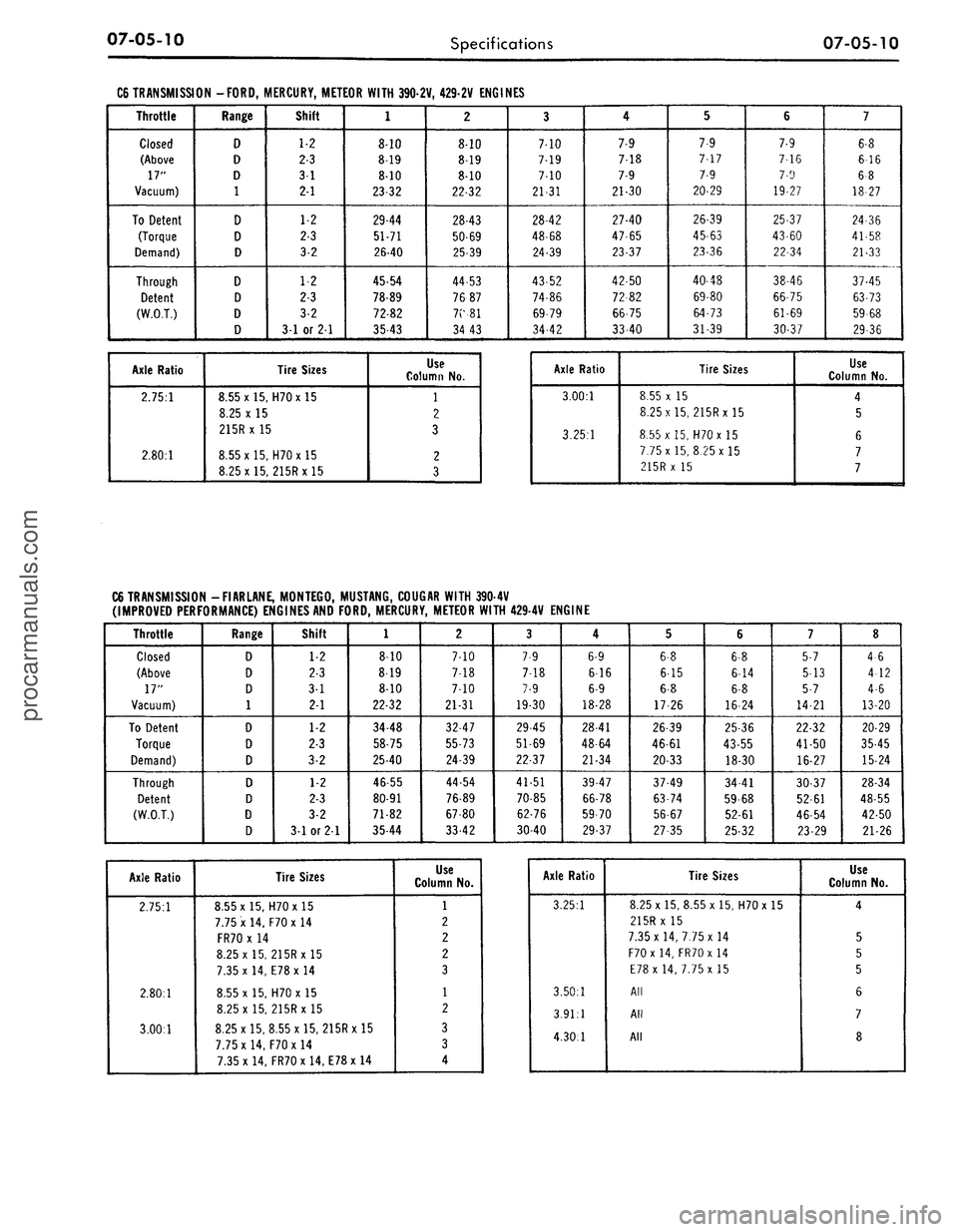

07-05-10

Specifications

07-05-10

C6 TRANSMISSION -FORD,

1

Throttle

Closed

(Above

17"

Vacuum)

To Detent

(Torque

Demand)

Through

Detent

(W.O.T.)

Range

D

D

D

1

D

D

D

D

D

D

D

MERCURY, METEOR WITH 390-2V, 429-2V ENGINES

Shift

1-2

2-3

3-1

2-1

1-2

2-3

3-2

1-2

2-3

3-2

3-1

or 21

1

8-10

8-19

8-10

23-32

29-44

51-71

26-40

45-54

78-89

72-82

35-43

2

8-10

8-19

8-10

22-32

28-43

50-69

25-39

44-53

7687

70

81

34

43

3

7-10

7-19

7-10

21-31

28-42

48-68

24-39

43-52

74-86

69-79

34-42

4

7-9

7-18

7-9

21-30

27-40

47-65

23-37

42-50

72-82

66-75

33-40

5

7-9

7-17

7-9

20-29

26-39

45-63

23-36

40-48

69-80

64-73

31-39

6

7-9

7-16

7-9

19-27

25-37

43-60

22-34

38-46

66-75

61-69

30-37

7

6-8

6-16

6-8

18-27

24-36

41-58

21-33

37-45

63-73

59

68

29-36

Axle Ratio

2.75:1

2.80:1

Tire Sizes

8.55x15,

H70x

15

8.25x15

215RX

15

8.55x15,

H70x

15

8.25x15,

215Rx

15

Use

Column

No.

1

2

3

2

3

Axle Ratio

3.00:1

3.25:1

Tire Sizes

8.55 x

15

8.25x15, 215Rx

15

8.55

x 15r

H70x

15

7.75x15,8.25x15

215R

x 15

Use

Column

No.

4

5

6

7

7

C6 TRANSMISSION -FIARLANE, MONTEGO, MUSTANG, COUGAR WITH 390-4V

(IMPROVED PERFORMANCE) ENGINES AND FORD, MERCURY, METEOR WITH 429-4V ENGINE

Throttle

Closed

(Above

17"

Vacuum)

To Detent

Torque

Demand)

Through

Detent

(W.O.T.)

Range

D

D

D

1

D

D

D

D

D

D

D

Shift

1-2

2-3

3-1

21

1-2

2-3

3-2

1-2

2-3

3-2

3-1 or 2-1

1

8-10

819

8-10

22-32

34-48

58-75

25-40

46-55

80-91

71-82

35-44

2

7-10

7-18

710

21-31

32-47

55-73

24-39

44-54

76-89

67-80

33-42

3

7-9

7-18

7-9

19-30

29-45

51-69

22-37

41-51

70-85

62-76

30-40

4

6-9

6-16

6-9

18-28

28-41

48-64

21-34

39-47

66-78

59-70

29-37

5

6-8

615

6-8

17-26

26-39

46-61

20-33

37-49

63-74

56-67

27-35

6

6-8

6-14

6-8

16-24

25-36

43-55

18-30

34-41

59-68

52-61

25-32

7

5-7

5-13

5-7

14-21

22-32

41-50

16-27

30-37

52-61

46-54

23-29

8

4 6

4 12

4-6

13-20

20-29

35-45

15-24

28-34

48-55

42-50

21-26

Axle Ratio

2.75:1

2.80:1

3.00:1

Tire Sizes

8.55x15, H70xl5

7.75 x 14, F70

x

14

FR70

x 14

8.25x15, 215Rx

15

7.35 x 14, E78 x

14

8.55

x 15,

H70x

15

8.25x15, 215Rx

15

8.25 x 15, 8.55 x 15, 215R x

15

7.75x14, F70x

14

7.35x14, FR70x

14,

E78

x 14

Use

Column

No.

1

2

2

2

3

1

2

3

3

4

Axle Ratio

3.25:1

3.50:1

3.91:1

4.30:1

Tire Sizes

8.25

x

15,

8.55 x

15, H70xl5

215Rx

15

7.35x14,7.75x14

F70x 14, FR70x

14

E78x 14,

7.75x15

All

All

All

Use

Column

No.

4

5

5

5

6

7

8procarmanuals.com