service FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 390 of 413

07-04-21

C-6 Automatic Transmission

07-04-21

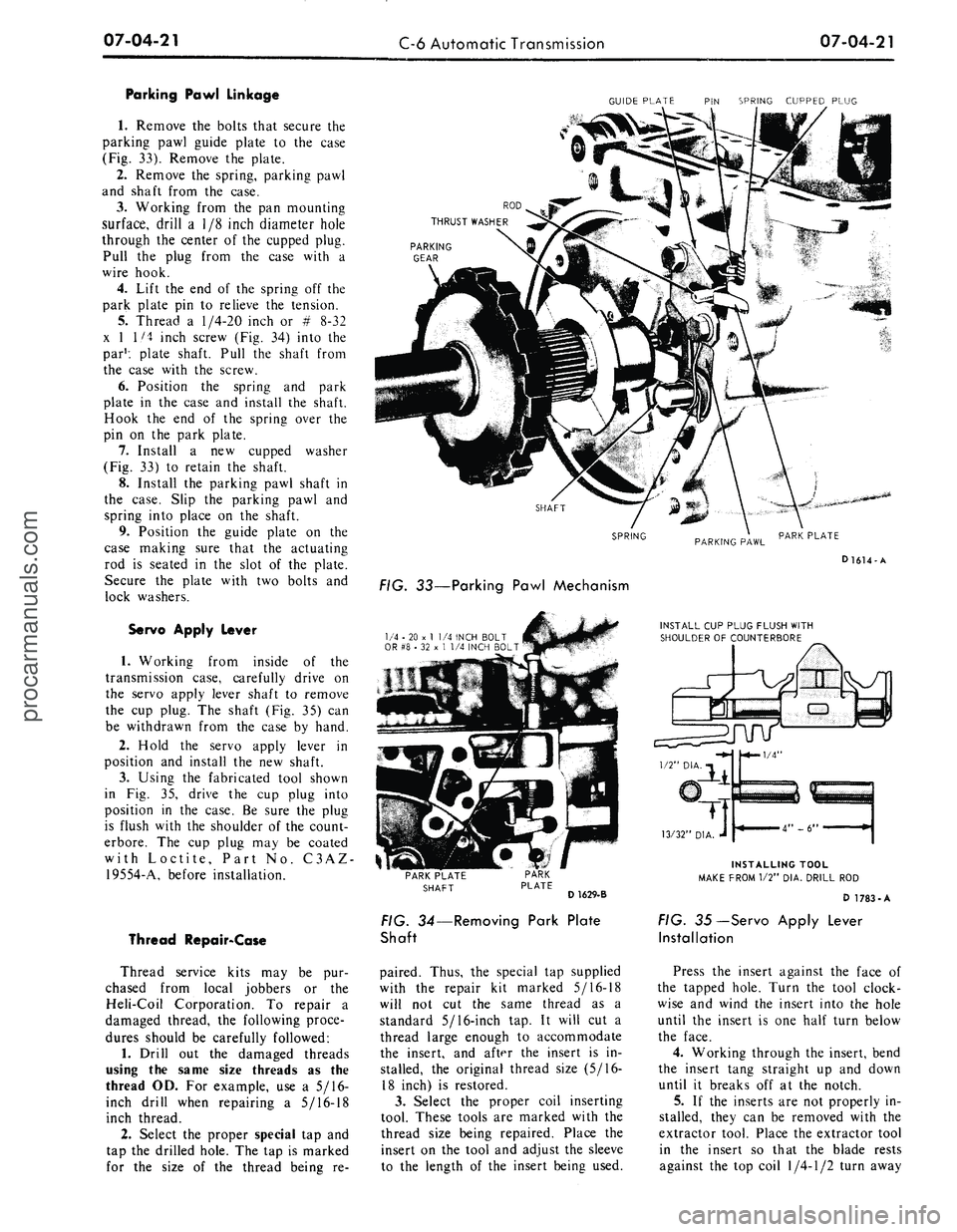

Parking Pawl Linkage

1.

Remove the bolts that secure the

parking pawl guide plate to the case

(Fig. 33). Remove the plate.

2.

Remove the spring, parking pawl

and shaft from the case.

3.

Working from the pan mounting

surface, drill a 1/8 inch diameter hole

through the center of the cupped plug.

Pull the plug from the case with a

wire hook.

4.

Lift the end of the spring off the

park plate pin to relieve the tension.

5.

Thread a

1/4-20

inch or # 8-32

x 1 1/4 inch screw (Fig. 34) into the

par1: plate shaft. Pull the shaft from

the case with the screw.

6. Position the spring and park

plate in the case and install the shaft.

Hook the end of the spring over the

pin on the park plate.

7.

Install a new cupped washer

(Fig. 33) to retain the shaft.

8. Install the parking pawl shaft in

the case. Slip the parking pawl and

spring into place on the shaft.

9. Position the guide plate on the

case making sure that the actuating

rod is seated in the slot of the plate.

Secure the plate with two bolts and

lock washers.

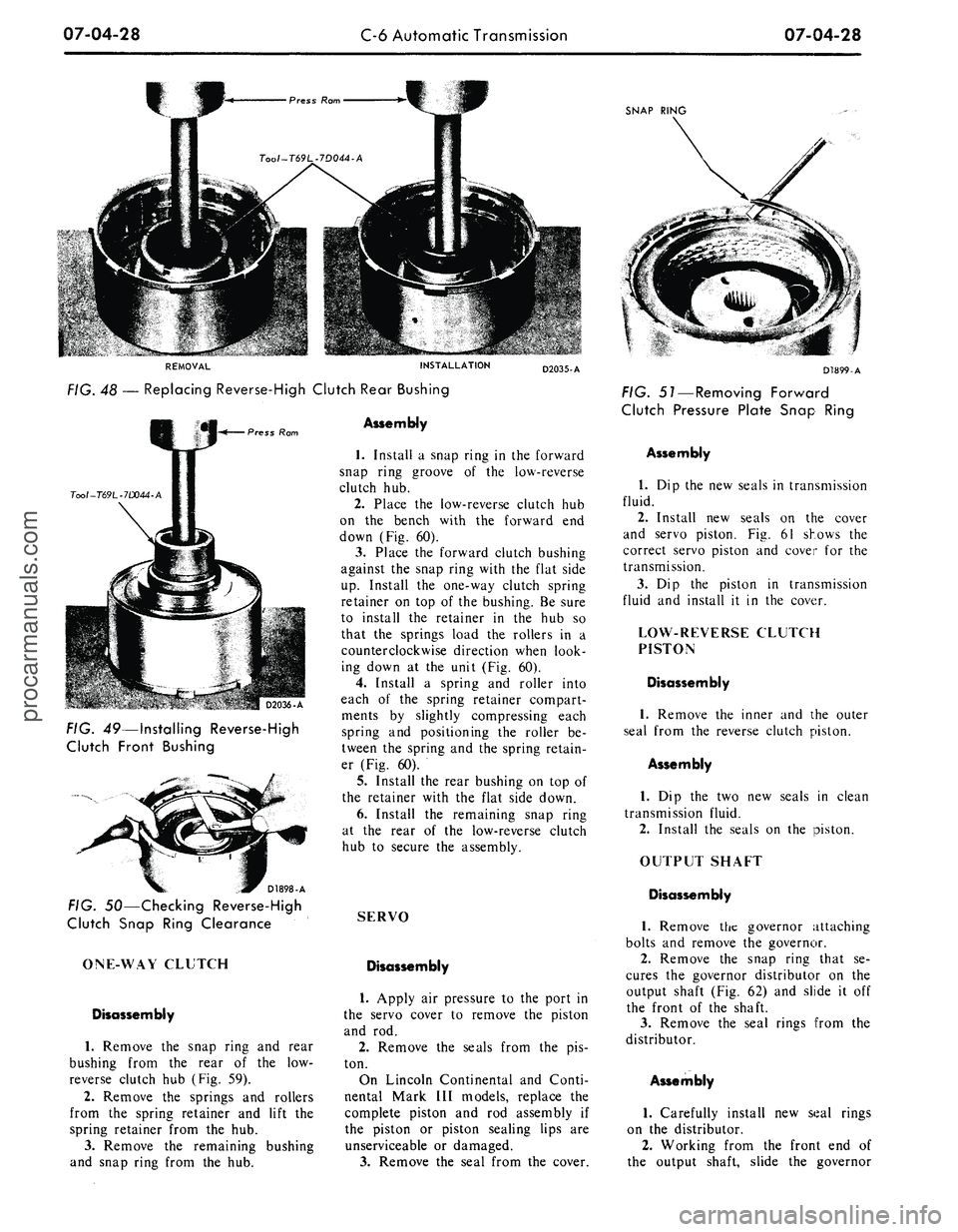

Servo Apply Lever

1.

Working from inside of the

transmission case, carefully drive on

the servo apply lever shaft to remove

the cup plug. The shaft (Fig. 35) can

be withdrawn from the case by hand.

2.

Hold the servo apply lever in

position and install the new shaft.

3.

Using the fabricated tool shown

in Fig. 35, drive the cup plug into

position in the case. Be sure the plug

is flush with the shoulder of the count-

erbore. The cup plug may be coated

with Loctite, Part No. C3AZ-

19554-A, before installation.

Thread Repair-Case

Thread service kits may be pur-

chased from local jobbers or the

Heli-Coil Corporation. To repair a

damaged thread, the following proce-

dures should be carefully followed:

1.

Drill out the damaged threads

using the same size threads as the

thread OD. For example, use a 5/16-

inch drill when repairing a 5/16-18

inch thread.

2.

Select the proper special tap and

tap the drilled hole. The tap is marked

for the size of the thread being re-

GUIDE PLATE PIN SPRING CUPPED PLUG

PARKING

GEAR

SHAFT

SPRING

PARKING PAWL

PARK PLATE

D1614-A

FIG. 33—Parking Pawl Mechanism

1/4 - 20 x

1

1/4 INCH BOLT

OR #8 • 32 x 1 1/4 INCH BOLT

INSTALL CUP PLUG FLUSH WITH

SHOULDER OF COUNTERBORE

PARK PLATE

SHAFT

D 1629-B

FIG. 34—Removing Park Plate

Shaft

paired. Thus, the special tap supplied

with the repair kit marked 5/16-18

will not cut the same thread as a

standard 5/16-inch tap. It will cut a

thread large enough to accommodate

the insert, and after the insert is in-

stalled, the original thread size (5/16-

18 inch) is restored.

3.

Select the proper coil inserting

tool. These tools are marked with the

thread size being repaired. Place the

insert on the tool and adjust the sleeve

to the length of the insert being used.

INSTALLING TOOL

MAKE FROM 1/2" DIA. DRILL ROD

D 1783-A

FIG. 35—Servo Apply Lever

Installation

Press the insert against the face of

the tapped hole. Turn the tool clock-

wise and wind the insert into the hole

until the insert is one half turn below

the face.

4.

Working through the insert, bend

the insert tang straight up and down

until it breaks off at the notch.

5.

If the inserts are not properly in-

stalled, they can be removed with the

extractor tool. Place the extractor tool

in the insert so that the blade rests

against the top coil

1/4-1/2

turn awayprocarmanuals.com

Page 397 of 413

07-04-28

C-6 Automatic Transmission

07-04-28

SNAP RING

REMOVAL INSTALLATION

FIG. 48 — Replacing Reverse-High Clutch Rear Bushing

D2035-A

Press Ram

Tool-T69L-7D044-A

D2036-A

FIG. 49—Installing Reverse-High

Clutch Front Bushing

D1898-A

FIG. 50—Checking Reverse-High

Clutch Snap Ring Clearance

ONE-WAY CLUTCH

Disassembly

1.

Remove the snap ring and rear

bushing from the rear of the low-

reverse clutch hub (Fig. 59).

2.

Remove the springs and rollers

from the spring retainer and lift the

spring retainer from the hub.

3.

Remove the remaining bushing

and snap ring from the hub.

Assembly

1.

Install a snap ring in the forward

snap ring groove of the low-reverse

clutch hub.

2.

Place the low-reverse clutch hub

on the bench with the forward end

down (Fig. 60).

3.

Place the forward clutch bushing

against the snap ring with the flat side

up.

Install the one-way clutch spring

retainer on top of the bushing. Be sure

to install the retainer in the hub so

that the springs load the rollers in a

counterclockwise direction when look-

ing down at the unit (Fig. 60).

4.

Install a spring and roller into

each of the spring retainer compart-

ments by slightly compressing each

spring and positioning the roller be-

tween the spring and the spring retain-

er (Fig. 60).

5.

Install the rear bushing on top of

the retainer with the flat side down.

6. Install the remaining snap ring

at the rear of the low-reverse clutch

hub to secure the assembly.

SERVO

Disassembly

1.

Apply air pressure to the port in

the servo cover to remove the piston

and rod.

2.

Remove the seals from the pis-

ton.

On Lincoln Continental and Conti-

nental Mark III models, replace the

complete piston and rod assembly if

the piston or piston sealing lips are

unserviceable or damaged.

3.

Remove the seal from the cover.

D1899-A

FIG. 51—Removing Forward

Clutch Pressure Plate Snap Ring

Assembly

1.

Dip the new seals in transmission

fluid.

2.

Install new seals on the cover

and servo piston. Fig. 61 shows the

correct servo piston and cover for the

transmission.

3.

Dip the piston in transmission

fluid and install it in the cover.

LOW-REVERSE CLUTCH

PISTON

Disassembly

1.

Remove the inner and the outer

seal from the reverse clutch piston.

Assembly

1.

Dip the two new seals in clean

transmission fluid.

2.

Install the seals on the piston.

OUTPUT SHAFT

Disassembly

1.

Remove the governor attaching

bolts and remove the governor.

2.

Remove the snap ring that se-

cures the governor distributor on the

output shaft (Fig. 62) and slide it off

the front of the shaft.

3.

Remove the seal rings from the

distributor.

Assembly

1.

Carefully install new seal rings

on the distributor.

2.

Working from the front end of

the output shaft, slide the governorprocarmanuals.com

Page 401 of 413

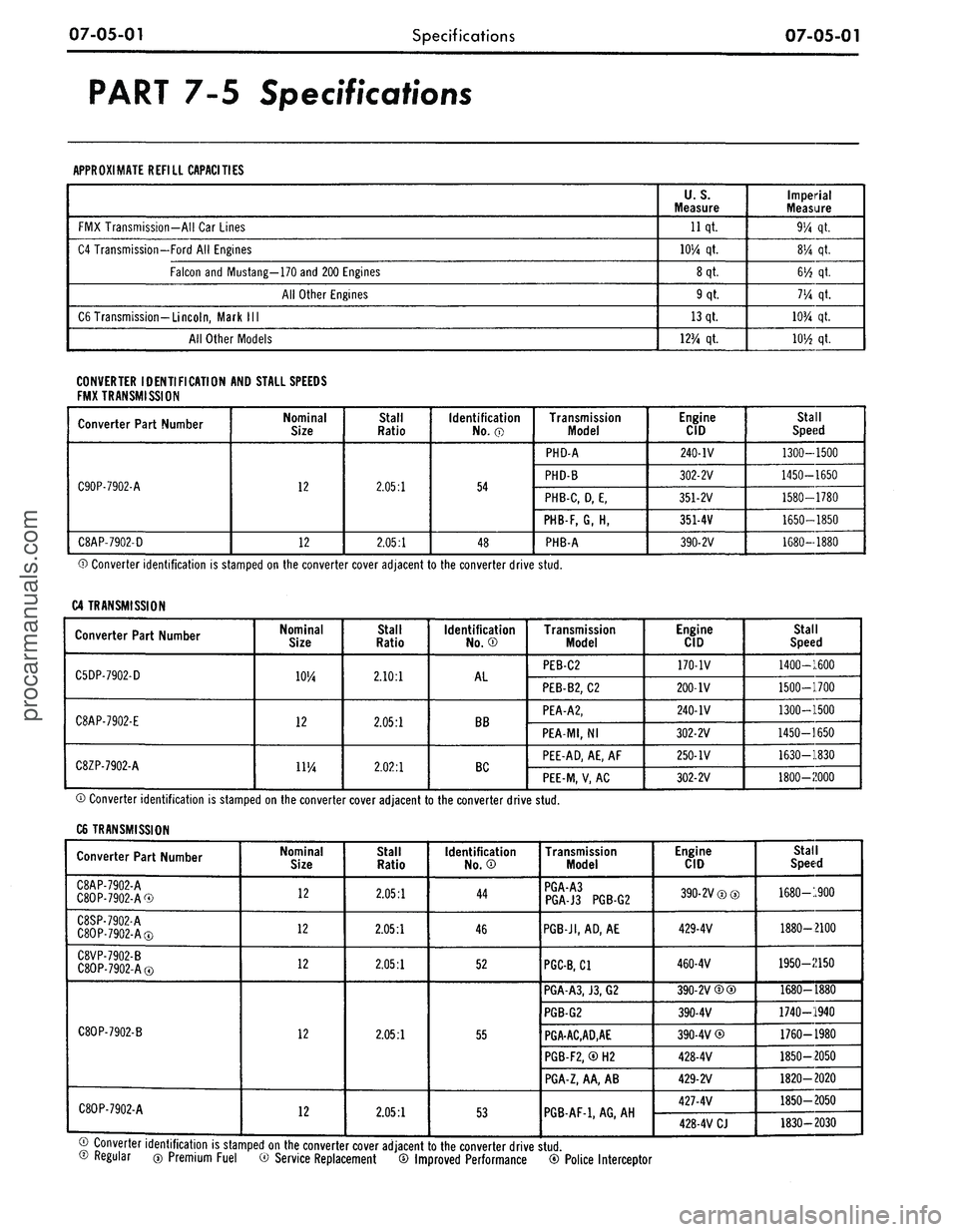

07-05-01

Specifications

07-05-01

PART

7-5

Specifications

APPROXIMATE

REFILL

CAPACITIES

FMX

Transmission—All

Car

Lines

C4

Transmission—Ford

All

Engines

Falcon

and

Mustang—170

and 200

Engines

All Other

Engines

C6Transmission—Lincoln,

Mark

III

All Other Models

U.S.

Measure

11

qt.

WA

qt.

8

qt.

9

qt.

13

qt.

123/4

qt.

Imperial

Measure

9M

qt.

8Va

qt.

V/i

qt.

7%

qt.

103/4

qt.

10VS

qt.

CONVERTER IDENTIFICATION

AND

STALL SPEEDS

FMX

TRANSMISSION

Converter Part Number

C90P-7902-A

C8AP-7902-D

Nominal

Size

12

12

Stall

Ratio

2.05:1

2.05:1

Identification

No.

0

54

48

Transmission

Model

PHD-A

PHD-B

PHB-C,

D, E,

PHB-F,

G, H,

PHB-A

Engine

CID

240-IV

302-2V

351-2V

351-4V

390-2V

Stall

Speed

1300-1500

1450-1650

1580-1780

1650-1850

1680-1880

®

Converter identification

is

stamped

on the

converter cover adjacent

to the

converter drive

stud.

C4

TRANSMISSION

Converter Part Number

C5DP-7902-D

C8AP-7902-E

C8ZP-7902-A

Nominal

Size

ioy4

12

11V4

Stall

Ratio

2.10:1

2.05:1

2.02:1

Identification

No.®

AL

BB

BC

Transmission

Model

PEB-C2

PEB-B2,

C2

PEA-A2,

PEA-MI,

Nl

PEE-AD,

AE,

AF

PEE-M,

V, AC

Engine

CID

170-1V

200-IV

240-IV

302-2

V

250-IV

302-2V

Stall

Speed

1400-1600

1500-1700

1300-1500

1450-1650

1630-1830

1800-2000

®

Converter identification

is

stamped

on the

converter cover adjacent

to the

converter drive

stud.

C6

TRANSMISSION

Converter Part Number

C8AP-7902-A

C8OP-7902-A®

C8SP-7902-A

C8OP-7902-A®

C8VP-7902-B

C8OP-79O2-A0

C8OP-7902-B

C8OP-7902-A

Nominal

Size

12

12

12

12

12

Stall

Ratio

2.05:1

2.05:1

2.05:1

2.05:1

2.05:1

Identification

No.®

44

46

52

55

53

Transmission

Model

PGA-A3

PGA-J3 PGB-G2

PGB-JI,

AD, AE

PGC-B,

Cl

PGA-A3,

J3, G2

PGB-G2

PGA-AC,AD,AE

PGB-F2,

®

H2

PGA-Z, AA, AB

PGB-AF-1,

AG, AH

Engine

CID

390-2V©®

429-4V

460-4V

390-2V®®

390-4V

390-4V

©

428-4V

429-2V

427-4V

428-4V

CJ

Stall

Speed

1680-:,900

1880-2100

1950-2150

1680-1880

1740-1940

1760-1980

1850-2050

1820-2020

1850-2050

1830-2030

D

Converter identification

is

stamped

on the

converter cover adjacent

to the

converter drive

stud.

v

Regular

©

Premium Fuel

0

Service Replacement

®

Improved Performance

®

Poli

Police Interceptorprocarmanuals.com

Page 405 of 413

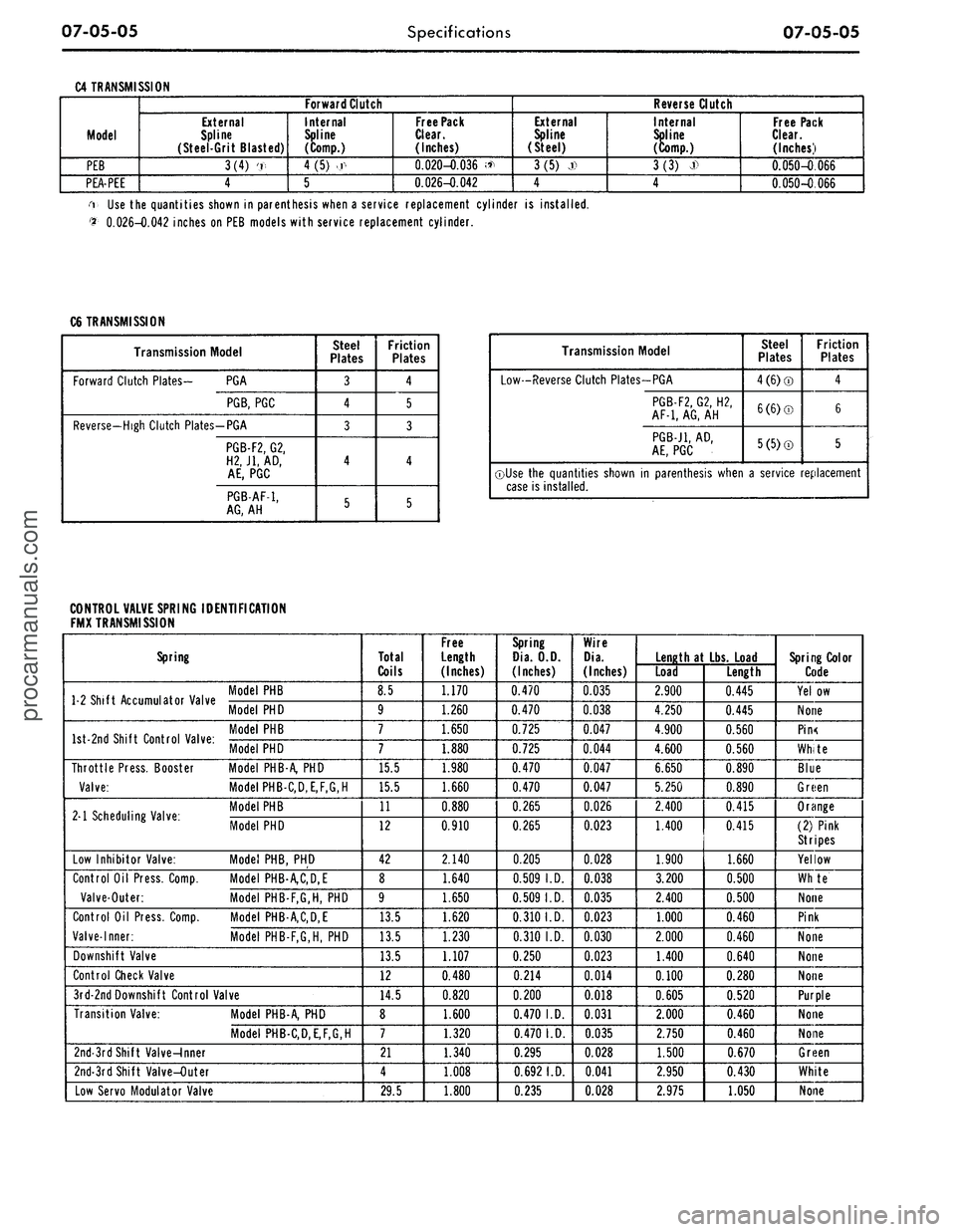

07-05-05

Specifications

07-05-05

C4 TRANSMISSION

Model

PEB

PEA-PEE

Forward Clutch

External

Spline

(Steel-Grit Blasted)

3(4) '.,

4

Internal

Spline

(Comp.)

4

(5)

>.r<

5

Free Pack

Clear.

(Inches)

0.020-0.036 <*

0.026-0.042

Reverse Clutch

External

Spline

(Steel)

3(5) j)

4

Internal

Spline

(Comp.)

3(3)

J>

4

Free Pack

Clear.

(Inches)

0.050-0.066

0.050-0.066

i Use the quantities shown in parenthesis when a service replacement cylinder is installed.

$•

0.026-0.042 inches on PEB models with service replacement cylinder.

C6 TRANSMISSION

Transmission Model

Forward Clutch Plates- PGA

PGB,

PGC

Reverse-High Clutch Plates-PGA

PGB-F2,

G2,

H2J1,

AD,

AE,

PGC

PGB-AF-1,

AG,

AH

Steel

Plates

3

4

3

4

5

Friction

Plates

4

5

3

4

5

Transmission Model

Low-Reverse Clutch Plates-PGA

PGB-F2,

G2, H2,

AF-1,

AG,

AH

PGB-J1,

AD,

AE,

PGC

Steel

Plates

4(6)®

6(6)©

5(5)®

Friction

Plates

4

6

5

©Use the quantities shown in parenthesis when a service replacement

case is installed.

CONTROL VALVE SPRING IDENTIFICATION

FMX TRANSMISSION

Spring

1 2 Shift Accumulator Valve '° C

Model

PHD

W °nri Shift Pnntrnl Vilur

Model PHD

Throttle Press. Booster Model PHB-A, PHD

Valve:

Model PHB-C,D,E,F,G,H

M Scheduling Valve-

M°delPHB

. 1 Scheduling Valve. Mode, PHD

Low Inhibitor Valve: Model PHB, PHD

Control Oil Press. Comp. Model PHB-A,C,D,E

Valve-Outer: Model PHB-F,G,H, PHD

Control Oil Press. Comp. Model PHB-A,C,D,E

Valve-Inner: Model PHB-F,G,H, PHD

Downshift Valve

Control Check Valve

3rd-2ndDownshift Control Valve

Transition Valve: Model PHB-A, PHD

Model PHB-C,D,E,F,G,H

2nd-3rd Shift Valve-Inner

2nd-3rd Shift Valve-Outer

Low Servo Modulator Valve

Total

Coils

8.5

9

7

7

15.5

15.5

11

12

42

8

9

13.5

13.5

13.5

12

14.5

8

7

21

4

29.5

Free

Length

(Inches)

1.170

1.260

1.650

1.880

1.980

1.660

0.880

0.910

2.140

1.640

1.650

1.620

1.230

1.107

0.480

0.820

1.600

1.320

1.340

1.008

1.800

Spring

Dia.

O.D.

(Inches)

0.470

0.470

0.725

0.725

0.470

0.470

0.265

0.265

0.205

0.509

I.D.

0.509

I.D.

0.310

I.D.

0.310 I.D.

0.250

0.214

0.200

0.470

I.D.

0.470

I.D.

0.295

0.692

I.D.

0.235

Wire

Dia.

(Inches)

0.035

0.038

0.047

0.044

0.047

0.047

0.026

0.023

0.028

0.038

0.035

0.023

0.030

0.023

0.014

0.018

0.031

0.035

0.028

0.041

0.028

Length

at Lbs.

Load

Load

2.900

4.250

4.900

4.600

6.650

5.250

2.400

1.400

1.900

3.200

2.400

1.000

2.000

1.400

0.100

0.605

2.000

2.750

1.500

2.950

2.975

Length

0.445

0.445

0.560

0.560

0.890

0.890

0.415

0.415

1.660

0.500

0.500

0.460

0.460

0.640

0.280

0.520

0.460

0.460

0.670

0.430

1.050

Spring Color

Code

Yel.ow

None

Pin<

White

Blue

Green

Orange

(2) Pink

Stripes

Yellow

Whte

None

Pink

None

None

None

Purple

None

None

Green

White

Noneprocarmanuals.com