brakes FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 24 of 413

02-02-05

Brake System

02-02-05

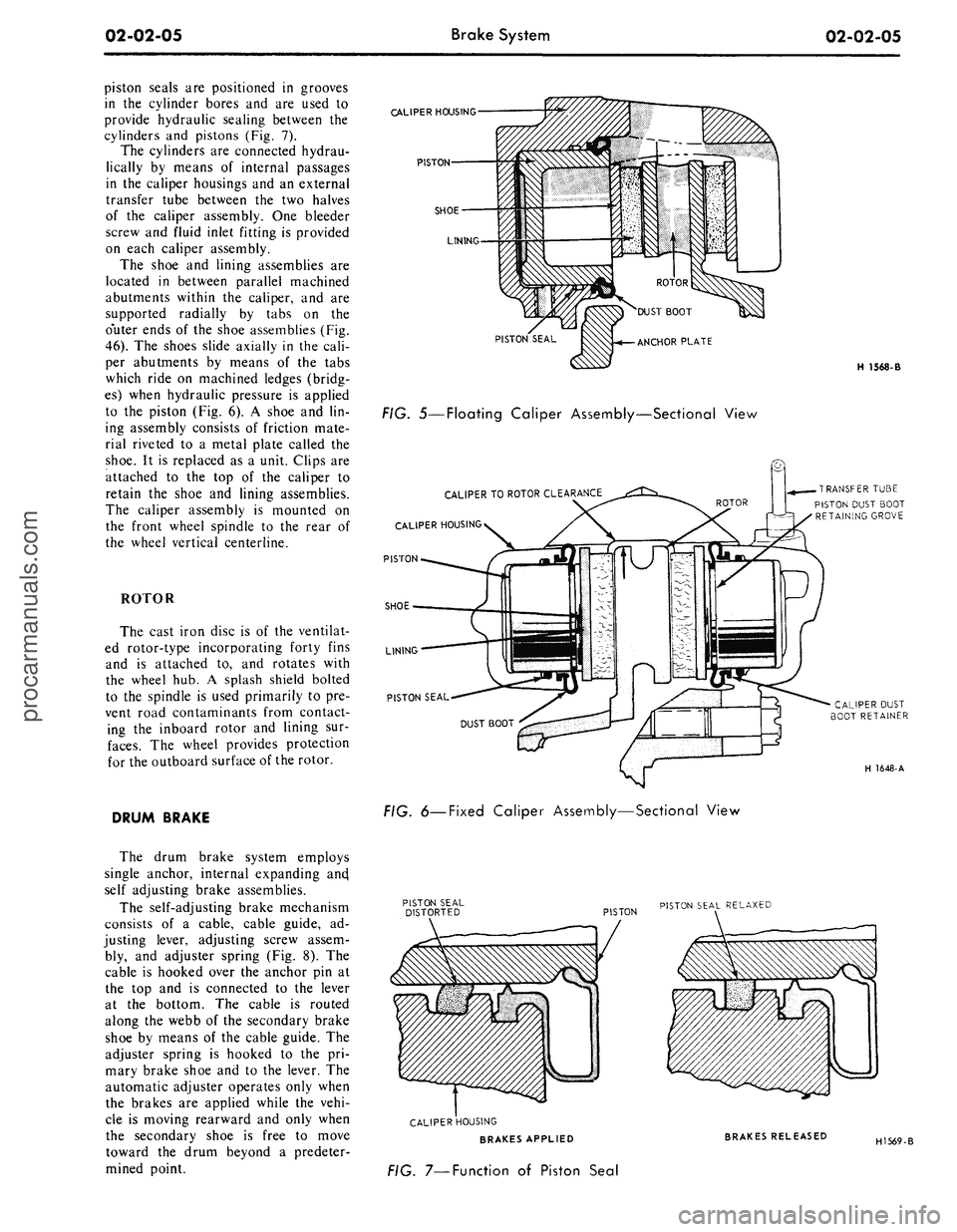

piston seals are positioned in grooves

in the cylinder bores and are used to

provide hydraulic sealing between the

cylinders and pistons (Fig. 7).

The cylinders are connected hydrau-

lically by means of internal passages

in the caliper housings and an external

transfer tube between the two halves

of the caliper assembly. One bleeder

screw and fluid inlet fitting is provided

on each caliper assembly.

The shoe and lining assemblies are

located in between parallel machined

abutments within the caliper, and are

supported radially by tabs on the

o'uter ends of the shoe assemblies (Fig.

46).

The shoes slide axially in the cali-

per abutments by means of the tabs

which ride on machined ledges (bridg-

es) when hydraulic pressure is applied

to the piston (Fig. 6). A shoe and lin-

ing assembly consists of friction mate-

rial riveted to a metal plate called the

shoe.

It is replaced as a unit. Clips are

attached to the top of the caliper to

retain the shoe and lining assemblies.

The caliper assembly is mounted on

the front wheel spindle to the rear of

the wheel vertical centerline.

ROTOR

The cast iron disc is of the ventilat-

ed rotor-type incorporating forty fins

and is attached to, and rotates with

the wheel hub. A splash shield bolted

to the spindle is used primarily to pre-

vent road contaminants from contact-

ing the inboard rotor and lining sur-

faces.

The wheel provides protection

for the outboard surface of the rotor.

DRUM BRAKE

The drum brake system employs

single anchor, internal expanding ancj

self adjusting brake assemblies.

The self-adjusting brake mechanism

consists of a cable, cable guide, ad-

justing lever, adjusting screw assem-

bly, and adjuster spring (Fig. 8). The

cable is hooked over the anchor pin at

the top and is connected to the lever

at the bottom. The cable is routed

along the webb of the secondary brake

shoe by means of the cable guide. The

adjuster spring is hooked to the pri-

mary brake shoe and to the lever. The

automatic adjuster operates only when

the brakes are applied while the vehi-

cle is moving rearward and only when

the secondary shoe is free to move

toward the drum beyond a predeter-

mined point.

CALIPER

HOUSING

PISTON

SHOE

LINING

PISTON SEAL

FIG. 5—Floating Caliper Assembly—Sectional View

CALIPER

TO

ROTOR

CLEARANCE

CALIPER

HOUSING

PISTON

SHOE

LINING

PISTON SEAL

H 1568-B

TRANSFER

TUBE

PISTON DUST BOOT

RETAINING

GROVE

CALIPER

DUST

BOOT

RETAINER

H 1648-A

FIG.

6—Fixed

Caliper Assembly—Sectional View

PISTON

PISTON SEAL

RELAXED

CALIPER

HOUSING

BRAKES APPLIED

FIG. 7—Function of Piston Seal

BRAKES RELEASED

H1569-Bprocarmanuals.com

Page 26 of 413

02-02-07

Brake System

02-02-07

ANTI-SKID CONTROL SYSTEM

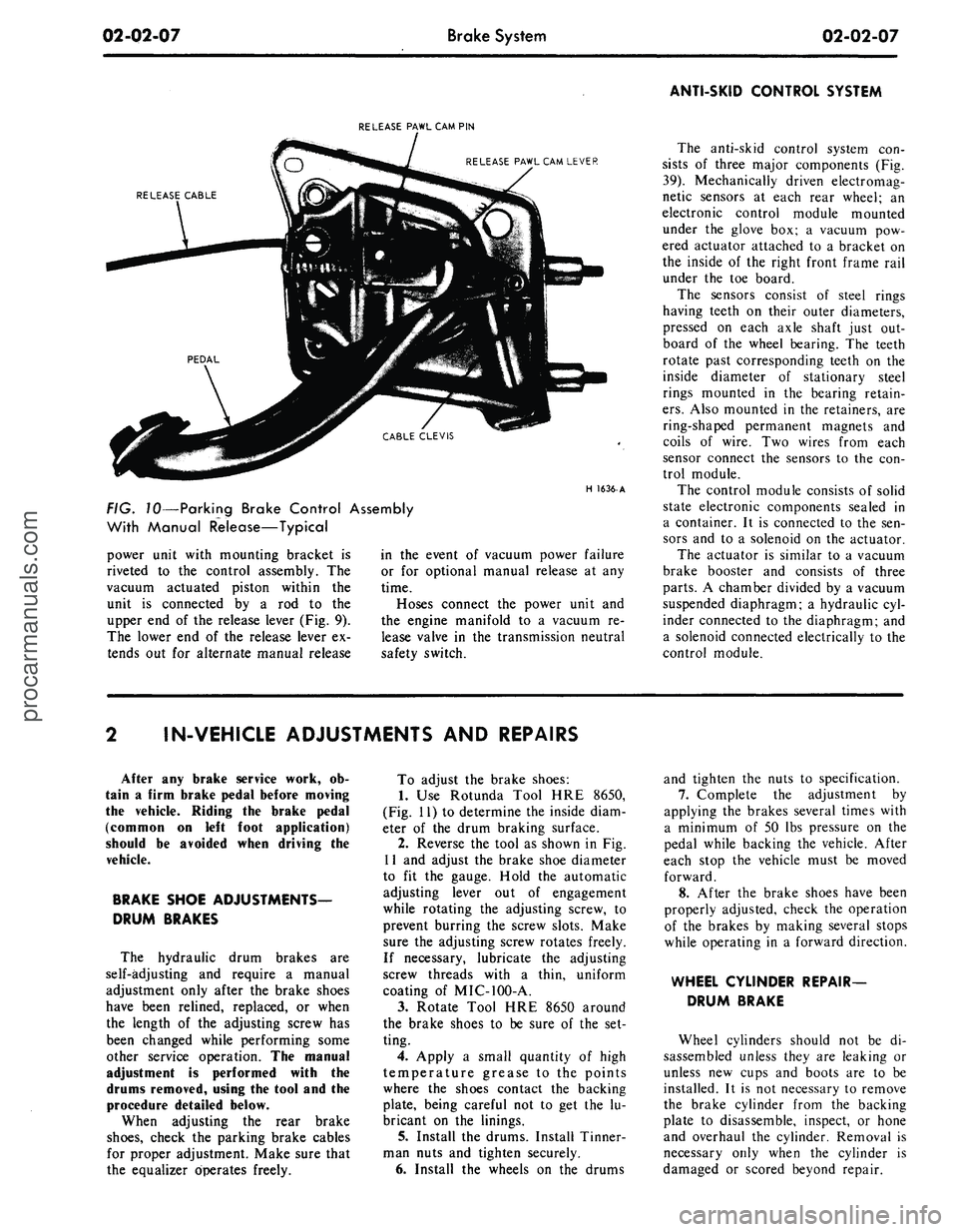

RELEASE PAWL CAM PIN

RELEASE PAWL CAM LEVER

RELEASE CABLE

H

1636-

A

FIG. 10—Parking Brake Control Assembly

With Manual Release—Typical

power unit with mounting bracket is

riveted to the control assembly. The

vacuum actuated piston within the

unit is connected by a rod to the

upper end of the release lever (Fig. 9).

The lower end of the release lever ex-

tends out for alternate manual release

in the event of vacuum power failure

or for optional manual release at any

time.

Hoses connect the power unit and

the engine manifold to a vacuum re-

lease valve in the transmission neutral

safety switch.

The anti-skid control system con-

sists of three major components (Fig.

39).

Mechanically driven electromag-

netic sensors at each rear wheel; an

electronic control module mounted

under the glove box; a vacuum pow-

ered actuator attached to a bracket on

the inside of the right front frame rail

under the toe board.

The sensors consist of steel rings

having teeth on their outer diameters,

pressed on each axle shaft just out-

board of the wheel bearing. The teeth

rotate past corresponding teeth on the

inside diameter of stationary steel

rings mounted in the bearing retain-

ers.

Also mounted in the retainers, are

ring-shaped permanent magnets and

coils of wire. Two wires from each

sensor connect the sensors to the con-

trol module.

The control module consists of solid

state electronic components sealed in

a container. It is connected to the sen-

sors and to a solenoid on the actuator.

The actuator is similar to a vacuum

brake booster and consists of three

parts.

A chamber divided by a vacuum

suspended diaphragm; a hydraulic cyl-

inder connected to the diaphragm; and

a solenoid connected electrically to the

control module.

IN-VEHICLE ADJUSTMENTS AND REPAIRS

After any brake service work, ob-

tain a firm brake pedal before moving

the vehicle. Riding the brake pedal

(common on left foot application)

should be avoided when driving the

vehicle.

BRAKE SHOE ADJUSTMENTS—

DRUM BRAKES

The hydraulic drum brakes are

self-adjusting and require a manual

adjustment only after the brake shoes

have been relined, replaced, or when

the length of the adjusting screw has

been changed while performing some

other service operation. The manual

adjustment is performed with the

drums removed, using the tool and the

procedure detailed below.

When adjusting the rear brake

shoes,

check the parking brake cables

for proper adjustment. Make sure that

the equalizer operates freely.

To adjust the brake shoes:

1.

Use Rotunda Tool HRE 8650,

(Fig. 11) to determine the inside diam-

eter of the drum braking surface.

2.

Reverse the tool as shown in Fig.

11 and adjust the brake shoe diameter

to fit the gauge. Hold the automatic

adjusting lever out of engagement

while rotating the adjusting screw, to

prevent burring the screw slots. Make

sure the adjusting screw rotates freely.

If necessary, lubricate the adjusting

screw threads with a thin, uniform

coating of MIC-100-A.

3.

Rotate Tool HRE 8650 around

the brake shoes to be sure of the set-

ting.

4.

Apply a small quantity of high

temperature grease to the points

where the shoes contact the backing

plate, being careful not to get the lu-

bricant on the linings.

5. Install the drums. Install Tinner-

man nuts and tighten securely.

6. Install the wheels on the drums

and tighten the nuts to specification.

7.

Complete the adjustment by

applying the brakes several times with

a minimum of 50 lbs pressure on the

pedal while backing the vehicle. After

each stop the vehicle must be moved

forward.

8. After the brake shoes have been

properly adjusted, check the operation

of the brakes by making several stops

while operating in a forward direction.

WHEEL CYLINDER REPAIR-

DRUM BRAKE

Wheel cylinders should not be di-

sassembled unless they are leaking or

unless new cups and boots are to be

installed. It is not necessary to remove

the brake cylinder from the backing

plate to disassemble, inspect, or hone

and overhaul the cylinder. Removal is

necessary only when the cylinder is

damaged or scored beyond repair.procarmanuals.com

Page 28 of 413

02-02-09

Brake System

02-02-09

REMOVAL AND INSTALLATION

FRONT BRAKE DRUM

REMOVAL

1.

Raise the vehicle until the wheel

and tire clear the floor. Remove the

wheel cover or hub cap, and remove

the wheel and tire from the drum.

2.

Remove the grease cap from the

hub.

Remove the cotter pin, nut lock,

adjusting nut, and flat washer from

the spindle. Remove the outer bearing

cone and roller assembly.

3.

Pull the drum off the wheel

spindle.

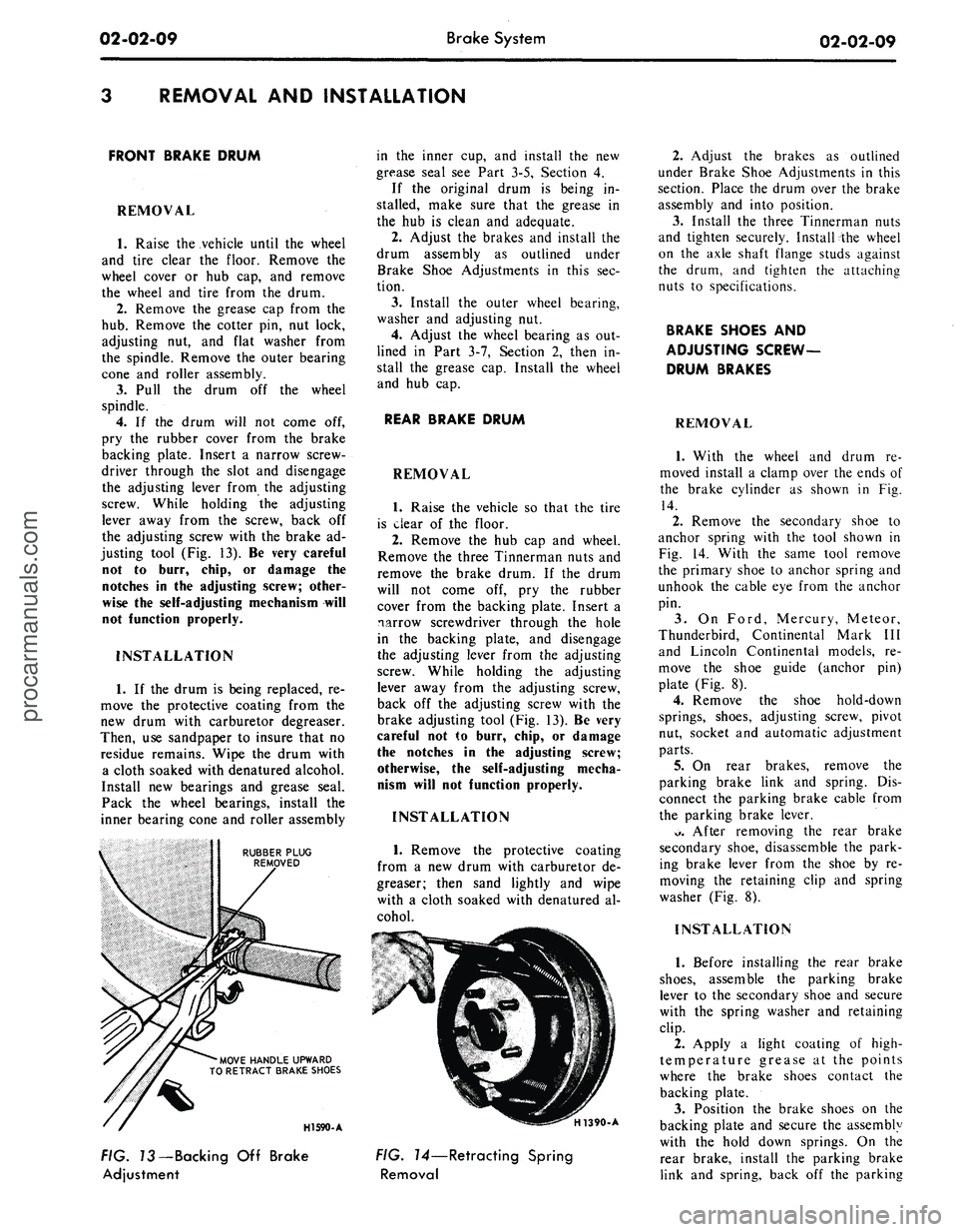

4.

If the drum will not come off,

pry the rubber cover from the brake

backing plate. Insert a narrow screw-

driver through the slot and disengage

the adjusting lever from the adjusting

screw. While holding the adjusting

lever away from the screw, back off

the adjusting screw with the brake ad-

justing tool (Fig. 13). Be very careful

not to burr, chip, or damage the

notches in the adjusting screw; other-

wise the self-adjusting mechanism will

not function properly.

INSTALLATION

1.

If the drum is being replaced, re-

move the protective coating from the

new drum with carburetor degreaser.

Then, use sandpaper to insure that no

residue remains. Wipe the drum with

a cloth soaked with denatured alcohol.

Install new bearings and grease seal.

Pack the wheel bearings, install the

inner bearing cone and roller assembly

RUBBER PLUG

REMOVED

'MOVE HANDLE UPWARD

TO RETRACT BRAKE SHOES

in the inner cup, and install the new

grease seal see Part 3-5, Section 4.

If the original drum is being in-

stalled, make sure that the grease in

the hub is clean and adequate.

2.

Adjust the brakes and install the

drum assembly as outlined under

Brake Shoe Adjustments in this sec-

tion.

3.

Install the outer wheel bearing,

washer and adjusting nut.

4.

Adjust the wheel bearing as out-

lined in Part 3-7, Section 2, then in-

stall the grease cap. Install the wheel

and hub cap.

REAR BRAKE DRUM

REMOVAL

1.

Raise the vehicle so that the tire

is clear of the floor.

2.

Remove the hub cap and wheel.

Remove the three Tinnerman nuts and

remove the brake drum. If the drum

will not come off, pry the rubber

cover from the backing plate. Insert a

narrow screwdriver through the hole

in the backing plate, and disengage

the adjusting lever from the adjusting

screw. While holding the adjusting

lever away from the adjusting screw,

back off the adjusting screw with the

brake adjusting tool (Fig. 13). Be very

careful not to burr, chip, or damage

the notches in the adjusting screw;

otherwise, the self-adjusting mecha-

nism will not function properly.

INSTALLATION

1.

Remove the protective coating

from a new drum with carburetor de-

greaser; then sand lightly and wipe

with a cloth soaked with denatured al-

cohol.

HI 590-A

H1390-A

FIG. 73—Backing Off Brake

Adjustment

FIG. 14—Retracting Spring

Removal

2.

Adjust the brakes as outlined

under Brake Shoe Adjustments in this

section. Place the drum over the brake

assembly and into position.

3.

Install the three Tinnerman nuts

and tighten securely. Install the wheel

on the axle shaft flange studs against

the drum, and tighten the attaching

nuts to specifications.

BRAKE SHOES AND

ADJUSTING SCREW-

DRUM BRAKES

REMOVAL

1.

With the wheel and drum re-

moved install a clamp over the ends of

the brake cylinder as shown in Fig.

14.

2.

Remove the secondary shoe to

anchor spring with the tool shown in

Fig. 14. With the same tool remove

the primary shoe to anchor spring and

unhook the cable eye from the anchor

pin.

3.

On Ford, Mercury, Meteor,

Thunderbird, Continental Mark III

and Lincoln Continental models, re-

move the shoe guide (anchor pin)

plate (Fig. 8).

4.

Remove the shoe hold-down

springs, shoes, adjusting screw, pivot

nut, socket and automatic adjustment

parts.

5.

On rear brakes, remove the

parking brake link and spring. Dis-

connect the parking brake cable from

the parking brake lever.

*>.

After removing the rear brake

secondary shoe, disassemble the park-

ing brake lever from the shoe by re-

moving the retaining clip and spring

washer (Fig. 8).

INSTALLATION

1.

Before installing the rear brake

shoes,

assemble the parking brake

lever to the secondary shoe and secure

with the spring washer and retaining

clip.

2.

Apply a light coating of high-

temperature grease at the points

where the brake shoes contact the

backing plate.

3.

Position the brake shoes on the

backing plate and secure the assembly

with the hold down springs. On the

rear brake, install the parking brake

link and spring, back off the parkingprocarmanuals.com

Page 29 of 413

02-02-10

Brake System

02-02-10

brake adjustment then connect the

parking brake cable to the parking

brake lever (Fig. 8).

4.

Install the shoe guide (anchor

pin) plate on the anchor pin when so

equipped.

5.

Place the cable eye over the an-

chor pin with the crimped side toward

the backing plate.

6. Install the primary shoe to an-

chor spring (Fig. 15).

H1391-A

FIG. 75—Retracting Spring

Installation

7.

Install the cable guide on the

secondary shoe web with the flanged

hole fitted into the hole in the second-

ary shoe web. Thread the cable

around the cable guide groove (Fig.

8).

It

is

imperative that

the

cable

be

positioned

in

this groove

and not be-

tween

the

guide

and the

shoe

web.

8.

Install the secondary shoe to an-

chor spring with the tool shown in

Fig. 15.

Be certain that

the

cable

eye is not

cocked

or

binding

on the

anchor

pin

when installed.

All

parts should

be

flat

on

the

anchor

pin.

Remove

the

brake

cylinder clamp.

9. Apply high-temperature grease

(MIC-100-A) to the threads and the

socket end of the adjusting screw.

Turn the adjusting screw into the ad-

justing pivot nut to the limit of the

threads and then back off 1/2 turn.

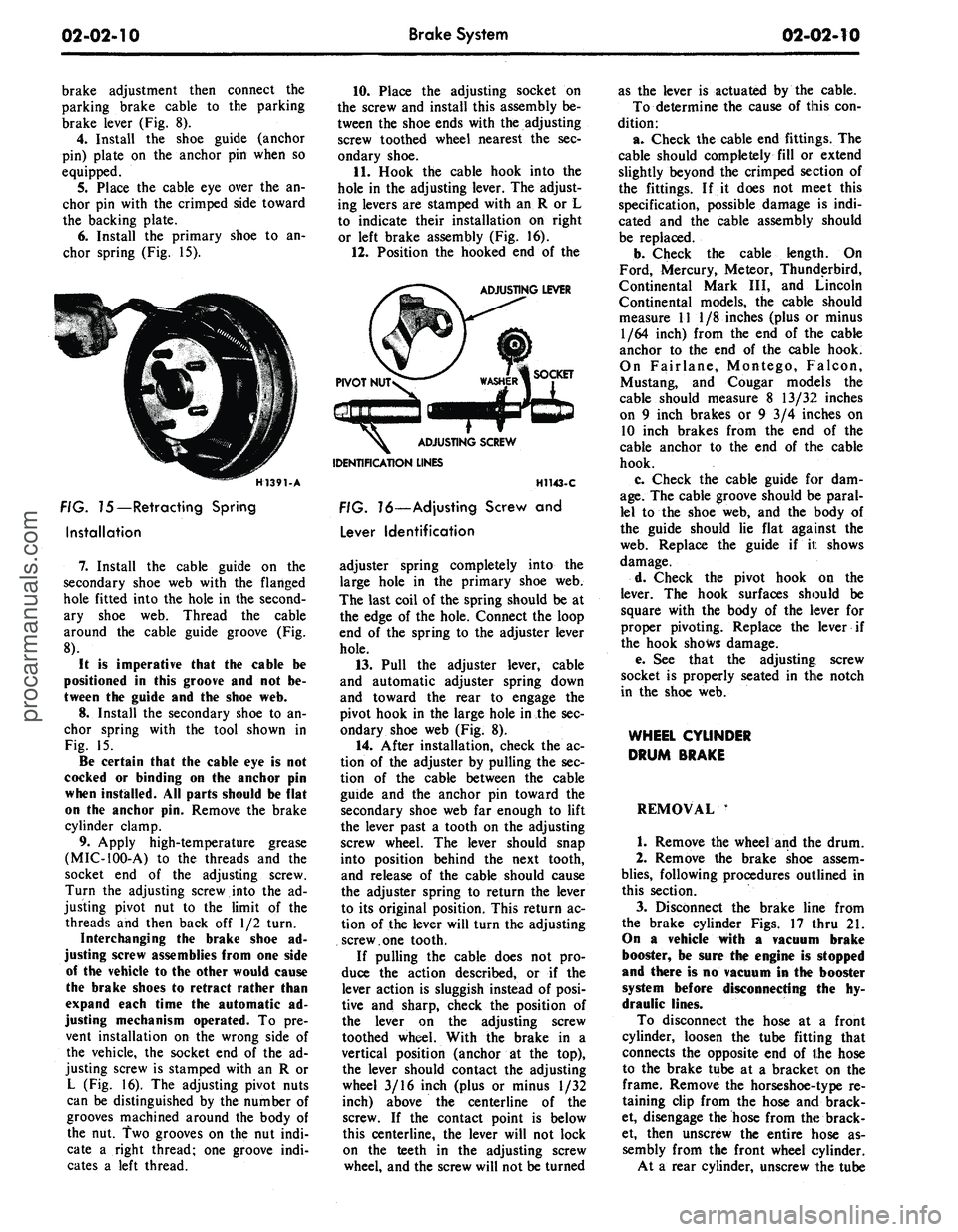

Interchanging

the

brake shoe

ad-

justing screw assemblies from

one

side

of

the

vehicle

to the

other would cause

the brake shoes

to

retract rather than

expand each time

the

automatic

ad-

justing mechanism operated.

To pre-

vent installation on the wrong side of

the vehicle, the socket end of the ad-

justing screw is stamped with an R or

L (Fig. 16). The adjusting pivot nuts

can be distinguished by the number of

grooves machined around the body of

the nut. Two grooves on the nut indi-

cate a right thread; one groove indi-

cates a left thread.

10.

Place the adjusting socket on

the screw and install this assembly be-

tween the shoe ends with the adjusting

screw toothed wheel nearest the sec-

ondary shoe.

11.

Hook the cable hook into the

hole in the adjusting lever. The adjust-

ing levers are stamped with an R or L

to indicate their installation on right

or left brake assembly (Fig. 16).

12.

Position the hooked end of the

ADJUSTING LEVER

IDENTIFICATION LINES

H1143-C

FIG. 16—Adjusting Screw

and

Lever Identification

adjuster spring completely into the

large hole in the primary shoe web.

The last coil of the spring should be at

the edge of the hole. Connect the loop

end of the spring to the adjuster lever

hole.

13.

Pull the adjuster lever, cable

and automatic adjuster spring down

and toward the rear to engage the

pivot hook in the large hole in the sec-

ondary shoe web (Fig. 8).

14.

After installation, check the ac-

tion of the adjuster by pulling the sec-

tion of the cable between the cable

guide and the anchor pin toward the

secondary shoe web far enough to lift

the lever past a tooth on the adjusting

screw wheel. The lever should snap

into position behind the next tooth,

and release of the cable should cause

the adjuster spring to return the lever

to its original position. This return ac-

tion of the lever will turn the adjusting

screw.one tooth.

If pulling the cable does not pro-

duce the action described, or if the

lever action is sluggish instead of posi-

tive and sharp, check the position of

the lever on the adjusting screw

toothed wheel. With the brake in a

vertical position (anchor at the top),

the lever should contact the adjusting

wheel 3/16 inch (plus or minus 1/32

inch) above the centerline of the

screw. If the contact point is below

this centerline, the lever will not lock

on the teeth in the adjusting screw

wheel, and the screw will not be turned

as the lever is actuated by the cable.

To determine the cause of this con-

dition:

a. Check the cable end fittings. The

cable should completely fill or extend

slightly beyond the crimped section of

the fittings. If it does not meet this

specification, possible damage is indi-

cated and the cable assembly should

be replaced.

b.

Check the cable length. On

Ford, Mercury, Meteor, Thunderbird,

Continental Mark III, and Lincoln

Continental models, the cable should

measure 11 1/8 inches (plus or minus

1/64 inch) from the end of the cable

anchor to the end of the cable hook.

On Fairlane, Montego, Falcon,

Mustang, and Cougar models the

cable should measure 8 13/32 inches

on 9 inch brakes or 9 3/4 inches on

10 inch brakes from the end of the

cable anchor to the end of the cable

hook.

c. Check the cable guide for dam-

age.

The cable groove should be paral-

lel to the shoe web, and the body of

the guide should lie flat against the

web.

Replace the guide if it shows

damage.

d. Check the pivot hook on the

lever. The hook surfaces should be

square with the body of the lever for

proper pivoting. Replace the lever if

the hook shows damage.

e. See that the adjusting; screw

socket is properly seated in the notch

in the shoe web.

WHEEL CYLINDER

DRUM BRAKE

REMOVAL '

1.

Remove the wheel and the drum.

2.

Remove the brake shoe assem-

blies,

following procedures outlined in

this section.

3.

Disconnect the brake line from

the brake cylinder Figs. 17 thru 21.

On

a

vehicle with

a

vacuum brake

booster,

be

sure

the

engine

is

stopped

and there

is no

vacuum

in the

booster

system before disconnecting

the hy-

draulic lines.

To disconnect the hose at a front

cylinder, loosen the tube fitting that

connects the opposite end of the hose

to the brake tube at a bracket on the

frame. Remove the horseshoe-type re-

taining clip from the hose and brack-

et, disengage the hose from the brack-

et, then unscrew the entire hose as-

sembly from the front wheel cylinder.

At a rear cylinder, unscrew the tubeprocarmanuals.com

Page 31 of 413

02-02-12

Brake System

02-02-12

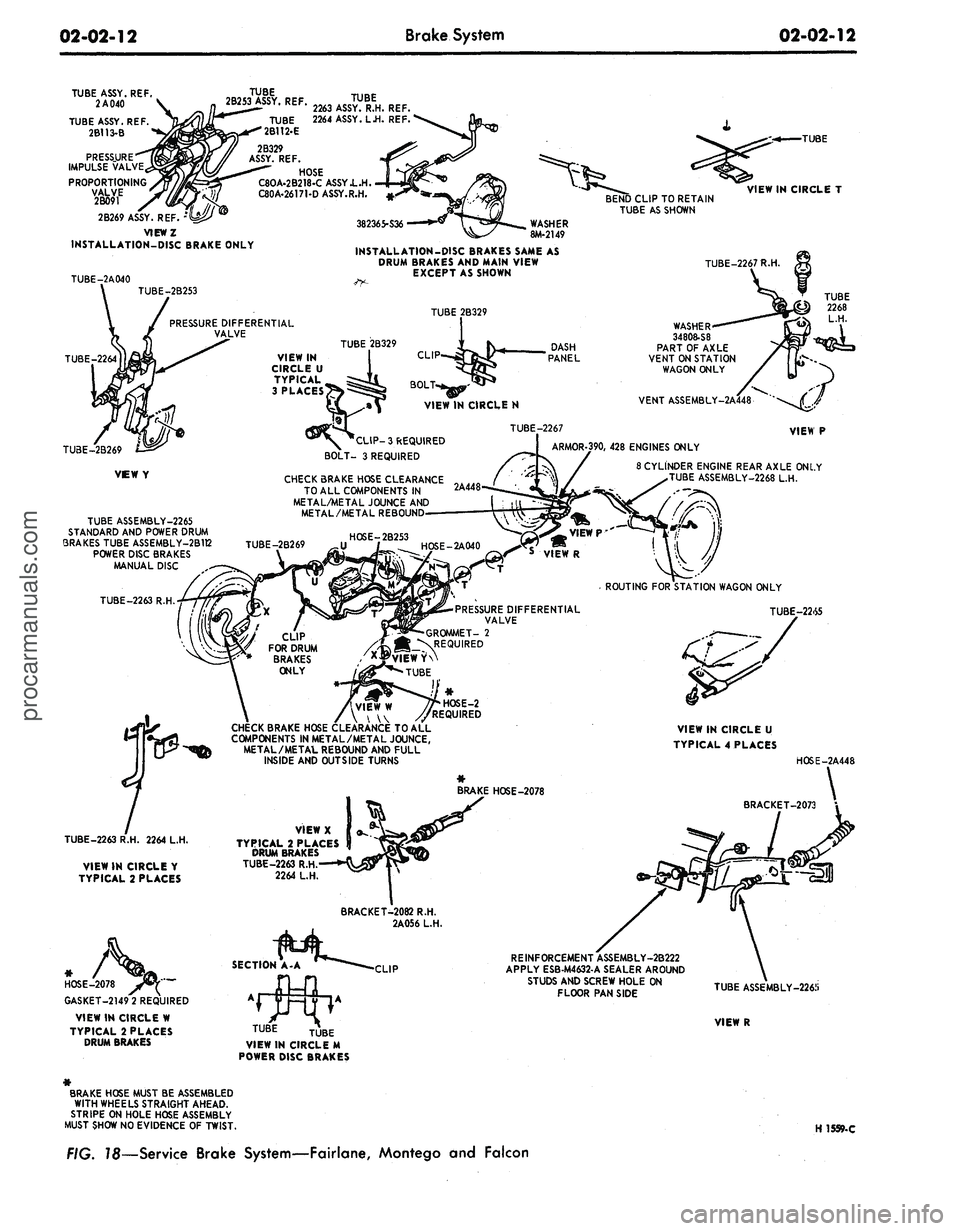

TUBE ASSY. REF.

2 A 040

TUBE ASSY. REF.

2B113-B

PRESSURE

IMPULSE VALVE

PROPORTIONING

TUBE

>Y.

2B253 ASSY REF TUBE

/W W '

Kth#

2263 ASSY. R.H. REF.

TUBE

2B112-E

2264 ASSY. L.H. REF.

2B329

ASSY. REF.

HOSE

C8OA-2B218-C ASSY.L.H.

C80A-26171-D ASSY.R.H.

2B269 ASSY. REF.

VIEWZ

INSTALLATION-DISC BRAKE ONLY

BEND CLIP TO RETAIN

TUBE AS SHOWN

-TUBE

VIEW IN CIRCLE T

382365-S36

WASHER

8M-2149

TUBE-2A040

INSTALLATION-DISC BRAKES SAME AS

DRUM BRAKES AND MAIN VIEW

EXCEPT AS SHOWN

TUBE-2267 R.H.

TUBE-2B253

TUBE 2B329

PRESSURE DIFFERENTIAL

VALVE

TUBE 2B329

VIEW IN

CIRCLE U

TYPICAL ^,

CES^^

CLI

BOLT-

VIEW IN CIRCLE N

WASHER

34808-S8

PART OF AXLE

VENT ON STATION

WAGON ONLY

VENT ASSEMBLY

TUBE ASSEMBLY-2265

STANDARD AND POWER DRUM

3RAKES TUBE ASSEMBLY-2B1T2

POWER DISC BRAKES

MANUAL DISC

TUBE-2263 R.H.

3 REQUIRED

BOLT- 3 REQUIRED

CHECK BRAKE HOSE CLEARANCE „

TO ALL COMPONENTS IN

2A448"

METAL/METAL JOUNCE AND

METAL/METAL REBOUND-

TUBE-2267

ARMOR-390, 428 ENGINES ONLY

8 CYLINDER ENGINE REAR AXLE ONLY

TUBE ASSEMBLY-2268 L.H.

PRESSURE DIFFERENTIAL

VALVE

- GROMMET- 2

jl^REQUIRED

EWYN

TUBE

VIEW P

ROUTING FOR STATION WAGON ONLY

TUBE-22.S5

TUBE-2263 R.H. 2264 L.H.

VIEW IN CIRCLE Y

TYPICAL 2 PLACES

CHECK BRAKE HOSE CLEARANCE TO ALL

COMPONENTS IN METAL/METAL JOUNCE,

METAL/METAL REBOUND AND FULL

INSIDE AND OUTSIDE TURNS

VIEWX

TYPICAL 2 PLACES

DRUM BRAKES

TUBE-2263 R.H

2264 L.H.

VIEW IN CIRCLE U

TYPICAL 4 PLACES

HOSE-2A448

BRAKE HOSE-2078

GASKET-2149 2 REQUIRED

VIEW IN CIRCLE W

TYPICAL 2 PLACES

DRUM BRAKES

LIP

REINFORCEMENT ASSEMBLY-2B222

APPLY ESB-M4632-A SEALER AROUND

STUDS AND SCREW HOLE ON

FLOOR PAN SIDE

TUBE

TUBE ASSEMBLY-226J)

VIEW R

TUBE

VIEW IN CIRCLE M

POWER DISC BRAKES

BRAKE HOSE MUST BE ASSEMBLED

WITH WHEELS STRAIGHT AHEAD.

STRIPE ON HOLE HOSE ASSEMBLY

MUST SHOW NO EVIDENCE OF TWIST.

H 1559-C

—Service Brake

System—Fairlane,

Montego

and

Falconprocarmanuals.com

Page 32 of 413

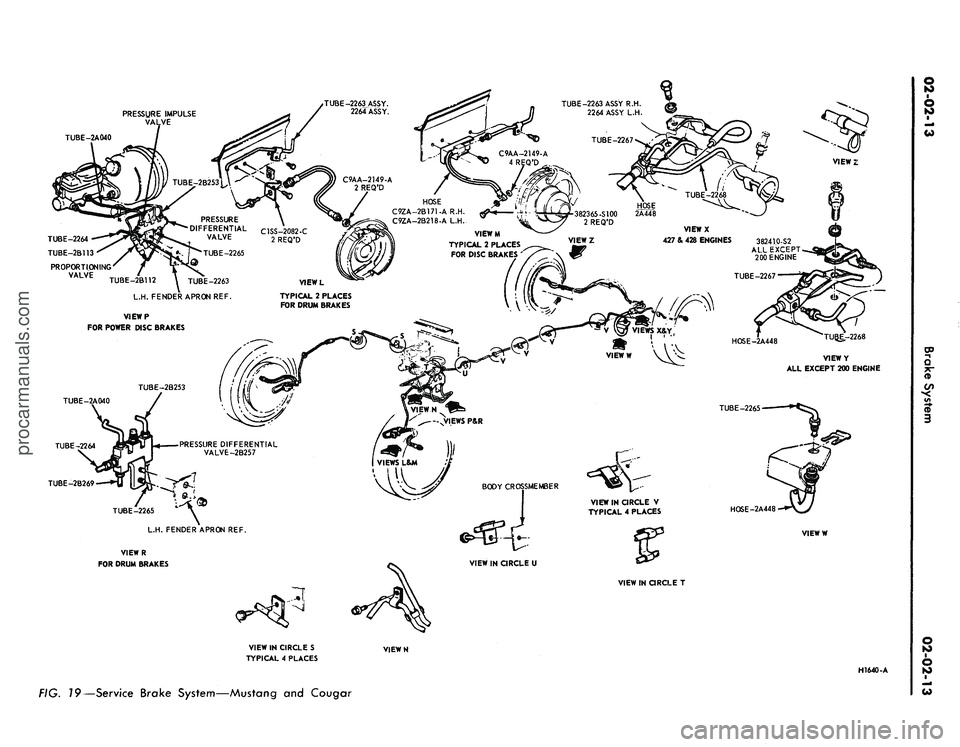

PRESSURE IMPULSE

VALVE

TUBE-2A040

TUBE-2B253

TUBE-2263 ASSY R.H.

2264 ASSY L.H.

TUBE-2267

PRESSURE

DIFFERENTIAL

VALVE

TUBE-2265

PROPORTIONING

VALVE

TUBE-2B112 \ TUBE-2263

L.H. FENDER APRON REF.

VIEWP

FOR POWER DISC BRAKES

TUBE-2B253

TUBE-

TUBE-22 64

TUBE-2B269

VIEWX

427 & 428 ENGINES 382410-S2

ALL EXCEPT

200 ENGINE

TUBE-2267

HOSE-2A448

TUBE-2265

TUBJ,-2268

VIEWY

ALL EXCEPT 200 ENGINE

PRESSURE DIFFERENTIAL

VALVE -2B257

VIEWS L&M //

BODY CROSSMEMBER

TUBE-2265

L.H. FENDER APRON REF.

VIEWR

FOR DRUM BRAKES

VIEW IN CIRCLE V

TYPICAL 4 PLACES

HOSE-2A448

VIEW IN CIRCLE U

VIEWW

VIEW IN CIRCLE T

VIEW IN CIRCLE S

TYPICAL 4 PLACES

VIEWN

H1640-A

FIG. 19—Service Brake System—Mustang and Cougarprocarmanuals.com

Page 35 of 413

02-02-16

Brake System

02-02-16

fitting that connects the tube to the

cylinder. Do not pull the metal tube

away from the cylinder. Pulling the

tube out of the cylinder connection

will bend the metal tube and make in-

stallation difficult. The tube will sepa-

rate from the cylinder when the cylin-

der is removed from the backing

plate.

4.

On all except the front wheels on

Ford, Mercury, and Meteor models,

remove the wheel cylinder attaching

bolts and lock washers and remove the

cylinder. On the front wheel of Ford,

Mercury and Meteor models, remove

the nut and washer that attaches the

cylinder to the anchor pin. Remove

the cylinder from the anchor pin.

INSTALLATION

Wipe the end(s) of the hydraulic

line to remove any foreign matter be-

fore making connections.

1.

On all models except Ford, Mer-

cury and Meteor, to install a front

wheel cylinder, position the cylinder to

the backing plate. Install the two lock

washers and attaching bolts. Torque

them to specifications.

On Ford, Mercury and Meteor

models, to install a front wheel cylin-

der, position the cylinder on the an-

chor pin against the backing plate. In-

stall the washer and cylinder attaching

nut on the anchor pin, and torque it

to specification. Lock the washer re-

tainer securely.

2.

Install a new copper gasket over

the hose fitting. Thread the hose into

the cylinder and tighten it to specified

torque.

3.

Engage the opposite end of the

hose to the bracket on the frame. In-

stall the horseshoe-type retaining clip,

and connect the brake tube to the

hose with the tube fitting nut. Tighten

the nut to specification with tool

1112-144.

4.

To install a rear wheel cylinder,

place the rear wheel cylinder into po-

sition. Enter the tubing into the cylin-

der, and start the tube fitting nut into

the threads of the cylinder.

5.

Secure the cylinder to the back-

ing plate by installing the attaching

bolts and lock washers.

6. Tighten the tube fitting nut to

specification with tool 1112-144.

7.

Install the links in the ends of

the wheel cylinder, install the shoes

and adjuster assemblies, and adjust

the shoes as outlined in this section.

8. Adjust the brakes (Part 2-2, Sec-

tion 2). Install the brake drum and

wheel. Bleed the brakes and centralize

the differential valve as outlined in

Part 2-1, Section 2.

BRAKE BACKING PLATE

DRUM BRAKE

REMOVAL

1.

Remove the wheel and brake

drum. Disconnect the brake line from

the brake cylinder.

2.

Remove the brake shoe and ad-

juster assemblies and the wheel cylin-

der as outlined in this section. On the

rear wheels, disconnect the parking

brake lever from the cable.

3.

If the rear backing plate is being

replaced, remove the axle shaft from

the applicable rear axle as outlined in

Group 4, Part 4-2— Rear Axle, Sec-

tion 2, disengage parking brake cable

retainer from backing plate. Remove

the backing plate and gasket.

If the front backing plate is being

replaced, remove the bolts and nuts

that secure the backing plate to the

front wheel spindle and remove the

plate and gasket.

INSTALLATION

If a rear backing plate is to be re-

placed, position a new rear backing

plate and gasket on the attaching

bolts in the axle housing flange. Insert

parking brake cable into backing plate

and secure retaining fingers. Install

the rear axle shaft for applicable rear

axle.

Refer to Group 4, Part 4-2 —

Rear Axle, Section 2 for the proper

installation procedure.

1.

If the front brake backing plate

is to be replaced, position a new front

backing plate and gasket to the wheel

spindle and install the attaching bolts

and nuts.

2.

Install the wheel cylinder and

connect the brake line as outlined in

this section.

3.

Install the brake shoe and ad-

juster assemblies as outlined in this

section. On a rear brake, connect the

parking brake cable to the lever.

4.

Adjust the brake shoes (Section

2),

and install the brake drums and

wheels. Bleed the brake system and

centralize the differential valve as out-

lined in Part 2-1, Section 2.

DISC BRAKE CALIPER

ASSEMBLY

ALL MODELS EXCEPT

LINCOLN CONTINENTAL

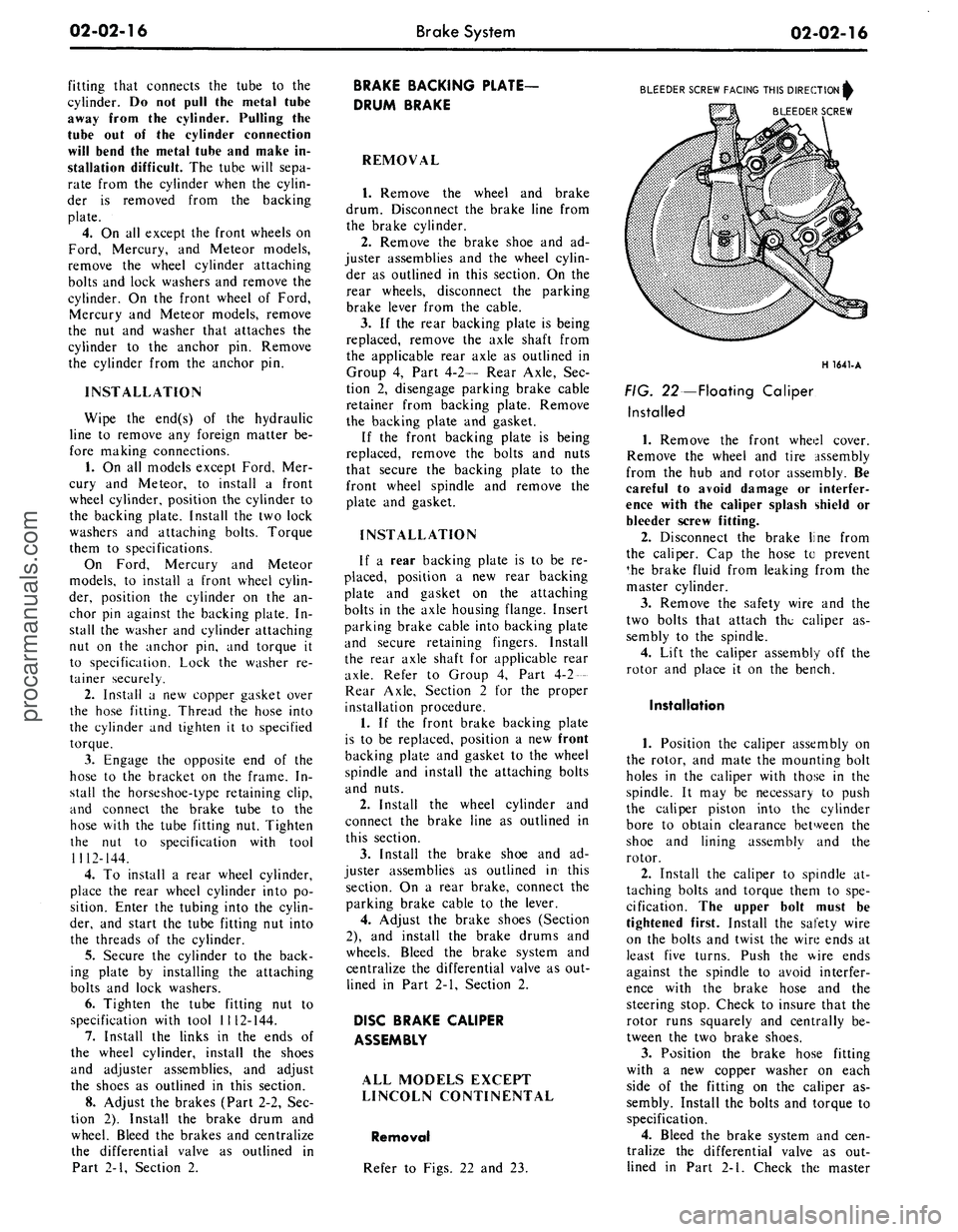

Removal

Refer to Figs. 22 and 23.

BLEEDER SCREW FACING THIS DIRECTION^

BLEEDER SCREW

H 1641-A

FIG. 22—Floating Caliper

Installed

1.

Remove the front wheel cover.

Remove the wheel and tire assembly

from the hub and rotor assembly. Be

careful to avoid damage or interfer-

ence with the caliper splash shield or

bleeder screw fitting.

2.

Disconnect the brake line from

the caliper. Cap the hose to prevent

*he brake fluid from leaking from the

master cylinder.

3.

Remove the safety wire and the

two bolts that attach the caliper as-

sembly to the spindle.

4.

Lift the caliper assembly off the

rotor and place it on the bench.

Installation

1.

Position the caliper assembly on

the rotor, and mate the mounting bolt

holes in the caliper with those in the

spindle. It may be necessary to push

the caliper piston into the cylinder

bore to obtain clearance between the

shoe and lining assembly and the

rotor.

2.

Install the caliper to spindle at-

taching bolts and torque them to spe-

cification. The upper bolt must be

tightened first. Install the safety wire

on the bolts and twist the wire ends at

least five turns. Push the wire ends

against the spindle to avoid interfer-

ence with the brake hose and the

steering stop. Check to insure that the

rotor runs squarely and centrally be-

tween the two brake shoes.

3.

Position the brake hose fitting

with a new copper washer on each

side of the fitting on the caliper as-

sembly. Install the bolts and torque to

specification.

4.

Bleed the brake system and cen-

tralize the differential valve as out-

lined in Part 2-1. Check the masterprocarmanuals.com

Page 38 of 413

02-02-19

Brake System

02-02-19

that the tabs on the shoe flanges seat

fully against the caliper bridges (Fig.

25).

2.

Install the caliper splash shield

and secure the shield to the caliper

with two retaining bolts (Fig. 4).

3.

Pump the brake pedal several

times until a firm pedal is obtained

and the shoe and lining assemblies are

properly seated.

4.

Install the wheel and tire assem-

bly on the hub and rotor assembly.

5.

Check and refill the master cyl-

inder reservoir with specified brake

fluid as required.

6. Road test the car.

It should not be necessary to bleed

the system after a shoe and lining re-

placement.

FRONT WHEEL HUB AND

ROTOR ASSEMBLY-

DISC BRAKES

REMOVAL

1.

Remove the wheel and tire from

the hub (Figs. 23 and 24). Be careful

to avoid damage or interference with

the bleeder screw fitting. On Lincoln

Continental models be careful to avoid

damage to the caliper splash shield or

transfer tube.

2.

Remove the caliper assembly

from the spindle and the rotor. If the

caliper does not require servicing, it is

not necessary to disconnect the brake

hose or remove the caliper from the

vehicle. Position the caliper out of the

way, and support it with a wire to

avoid damaging the caliper or stretch-

ing the hose. Insert a clean cardboard

spacer between the linings to prevent

the piston from coming out of the cyl-

inder bore while the caliper is re-

moved.

Handle the rotor and caliper assem-

blies in such a way as to avoid defor-

mation of the rotor and nicking,

scratching or contamination of the

brake linings.

3.

Remove the grease cap from the

hub.

Remove the cotter pin, nut lock,

adjusting nut, and flat washer from

the spindle. Remove the outer bearing

cone and roller assembly.

4.

Remove the hub and rotor as-

sembly from the spindle.

INSTALLATION

1.

If the rotor is being replaced, re-

move the protective coating from the

new rotor with carburetor degreaser.

Pack a new set of bearings with speci-

fied grease (M-1C75B), and install the

inner bearing cone and roller assembly

in the inner cup. Pack grease lightly

between the lips of a new grease seal

and install the seal (Figs. 23 and 24).

If the original rotor is being in-

stalled, make sure that the grease in

the hub is clean and adequate, that

the inner bearing and grease seal are

lubricated and in good condition, and

that the rotor braking surfaces are

clean.

2.

Install the hub and rotor assem-

bly on the spindle.

3.

Lubricate and install the outer

wheel bearing, washer and adjusting

nut.

4.

Adjust the wheel bearings to

specification, and then install the nut

lock, cotter pin, and grease cap. The

wheel bearing adjustment is especially

important with disc brakes.

5. Mount the caliper assembly on

the spindle following the Disc Brake

Caliper Assembly Installation proce-

dure in this section.

DISC BRAKE ROTOR

SPLASH SHIELD

REMOVAL

1.

Remove the caliper and the hub

and rotor assembly as outlined under

Removal in the foregoing procedure

(it is not necessary to disconnect hy-

draulic connections).

2.

Remove the three bolts that at-

tach the splash shield to the spindle,

and remove the shield (Figs. 23 and

24).

3.

Remove and discard the splash

shield to spindle gasket.

INSTALLATION

1.

Install a new splash shield to

spindle gasket.

2.

If the shield is bent, straighten it

out before installation. Position the

shield to the mounting bracket, install

the attaching bolts, nuts and torque

them to specification.

3.

Install the hub and rotor assem-

bly and the caliper as outlined under

Installation in the foregoing proce-

dure.

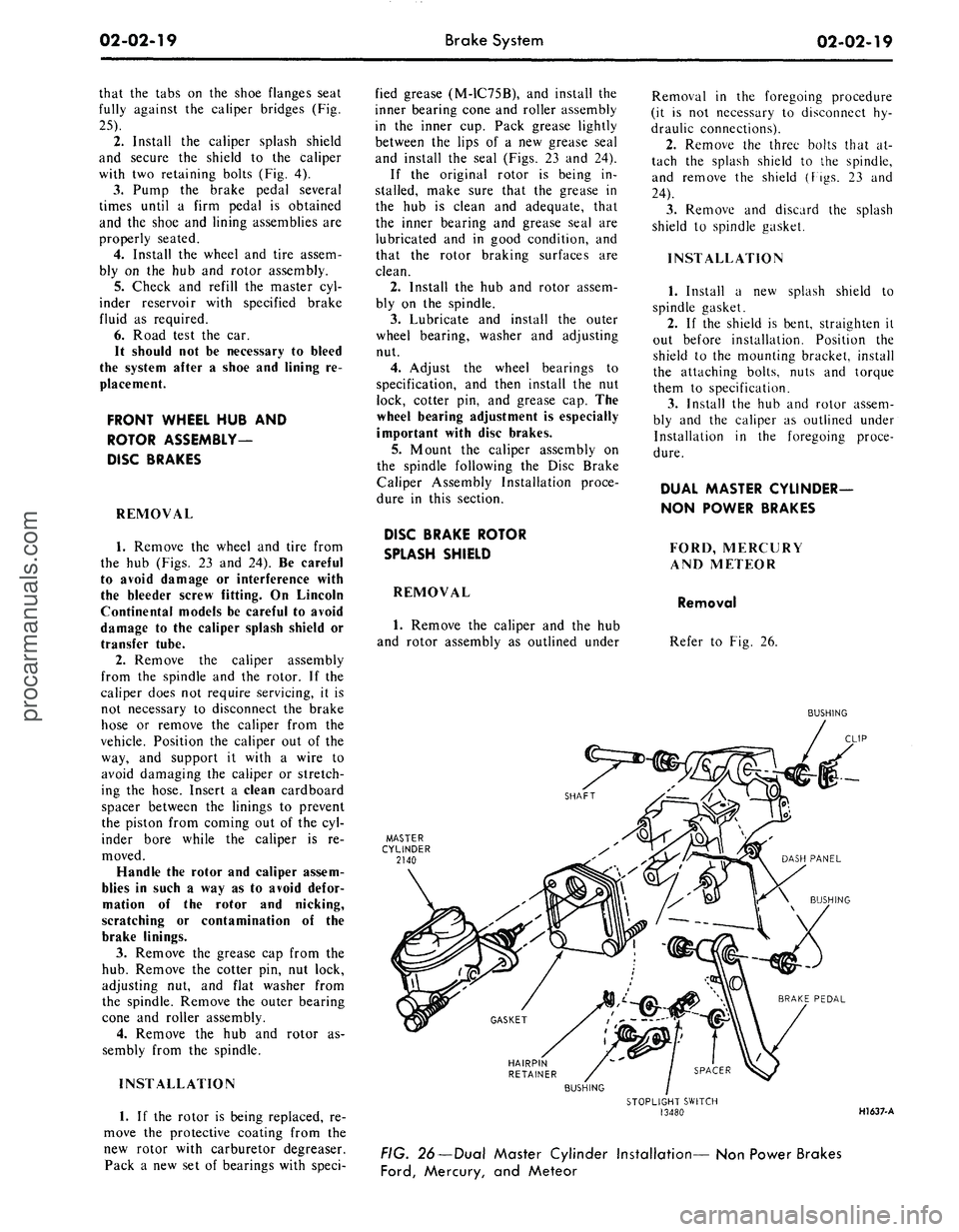

DUAL MASTER CYLINDER—

NON POWER BRAKES

FORD, MERCURY

AND METEOR

Removal

Refer to Fig. 26.

BUSHING

HAIRPIN

RETAINER

BUSHING

STOPLIGHT SWITCH

13480

HI 637-A

FIG. 26—Dual Master Cylinder Installation— Non Power Brakes

Ford,

Mercury, and Meteorprocarmanuals.com

Page 39 of 413

02-02-20

Brake System

02-02-20

1.

Disconnect the stoplight switch

wires at the connector. Remove the

spring retainer. Slide the stop light

switch off the brake pedal pin just far

enough to clear the end of the pin,

then liftfthe switch straight upward

from the pin. Use care to avoid switch

damage during removal.

2.

Slide the master cylinder push

rod and the nylon washers and bush-

ings off the brake pedal pin.

3.

Remove the brake tube from the

primary and secondary outlet ports of

the master cylinder.

4.

Remove the cap screws and lock-

washers that secure the master cylin-

der to the dirSh panel and lift the cyl-

inder forward and upward from the

vehicle.

Installation

1.

Position the boot on the push

rod and secure the boot to the master

cylinder. Carefully insert the master

cylinder push rod and boot through

the dash panel opening and position

the master cylinder on the panel.

2.

Install the cap screws at the dash

panel and torque them to specifica-

tion.

3.

Coat the nylon bushings with

SAE 10W oil. Install the nylon wash-

er and bushing on the brake pedal pin.

4.

Position the stop light switch on

the brake pedal pin, install the nylon

bushing and washer and secure them

in position with the spring retainer.

5.

Connect the wires at the stop

light switch connector.

6. Connect the brake lines to the

master cylinder leaving the brake line

fittings loose.

7.

Fill the master cylinder with the

specified brake fluid to within 1/4

inch of the top of the dual reservoirs.

Use Ford Brake Fluid— Extra Heavy

Duty-Part Number C6AZ-19542-A

(ESA-M6C25-A) or equivalent for all

drum brake applications. The extra

heavy duty brake system fluid is col-

ored blue for identification. Do not

mix low temperature brake fluids with

the specified fluid for the power disc

brake system.

8. Bleed the dual-master cylinder

and the primary and secondary brake

systems. Centralize the pressure dif-

ferential valve. Refer to Hydraulic

System Bleeding and Centralizing of

the Differential Valve, Part 2-1, Sec-

tion 2 for proper procedure.

9. Operate the brakes several times,

then check for external hydraulic

leaks.

FAIRLANE, MONTEGO,

FALCON, MUSTANG AND

COUGAR

Removal

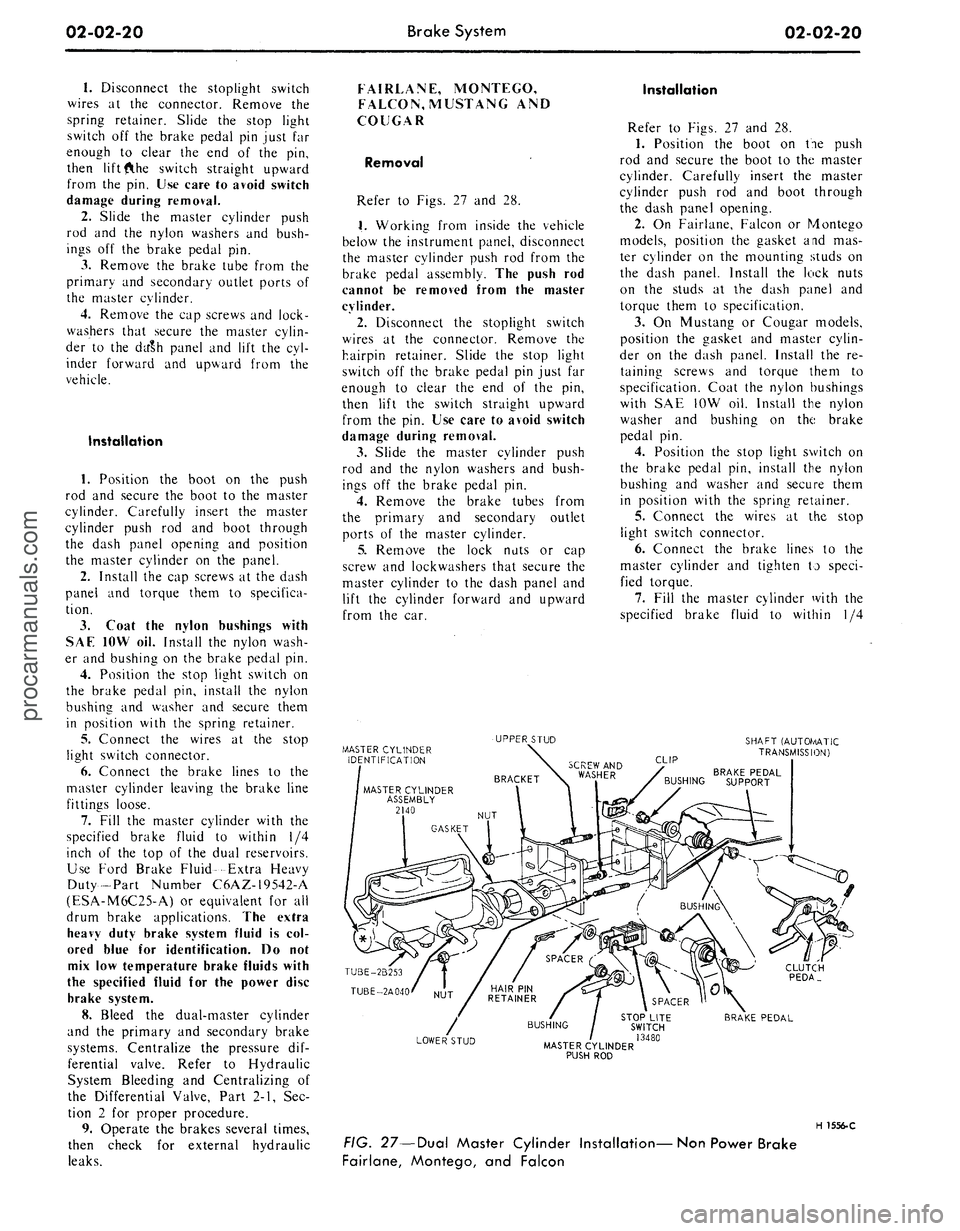

Refer to Figs. 27 and 28.

1.

Working from inside the vehicle

below the instrument panel, disconnect

the master cylinder push rod from the

brake pedal assembly. The push rod

cannot be removed from the master

cylinder.

2.

Disconnect the stoplight switch

wires at the connector. Remove the

hairpin retainer. Slide the stop light

switch off the brake pedal pin just far

enough to clear the end of the pin,

then lift the switch straight upward

from the pin. Use care to avoid switch

damage during removal.

3.

Slide the master cylinder push

rod and the nylon washers and bush-

ings off the brake pedal pin.

4.

Remove the brake tubes from

the primary and secondary outlet

ports of the master cylinder.

5.

Remove the lock nuts or cap

screw and lockwashers that secure the

master cylinder to the dash panel and

lift the cylinder forward and upward

from the car.

Installation

Refer to Figs. 27 and 28.

1.

Position the boot on tie push

rod and secure the boot to the master

cylinder. Carefully insert the master

cylinder push rod and boot through

the dash panel opening.

2.

On Fairlane, Falcon or Montego

models, position the gasket and mas-

ter cylinder on the mounting studs on

the dash panel. Install the lock nuts

on the studs at the dash panel and

torque them to specification.

3.

On Mustang or Cougar models,

position the gasket and master cylin-

der on the dash panel. Install the re-

taining screws and torque them to

specification. Coat the nylon bushings

with SAE 10W oil. Install the nylon

washer and bushing on the brake

pedal pin.

4.

Position the stop light switch on

the brake pedal pin, install the nylon

bushing and washer and secure them

in position with the spring retainer.

5.

Connect the wires at the stop

light switch connector.

6. Connect the brake lines to the

master cylinder and tighten to speci-

fied torque.

7.

Fill the master cylinder with the

specified brake fluid to within 1/4

MASTER CYLINDER

IDENTIFICATION

UPPER STUD

SHAFT (AUTOf/lATIC

TRANSMISSION)

CLIP

BRAKE PEDAL

BUSHING SUPPORT

TUBE-2B253

TUBE-2A040

CLUTCH

PEDA_

LOWER STUD

STOP LITE

SWITCH

/ 13480

MASTER CYLINDER

PUSH ROD

BRAKE PEDAL

H 1556-C

FIG. 27—Dual Master Cylinder Installation—Non Power Brake

Fairlane, Montego, and Falconprocarmanuals.com

Page 40 of 413

02-02-21

Brake System

02-02-21

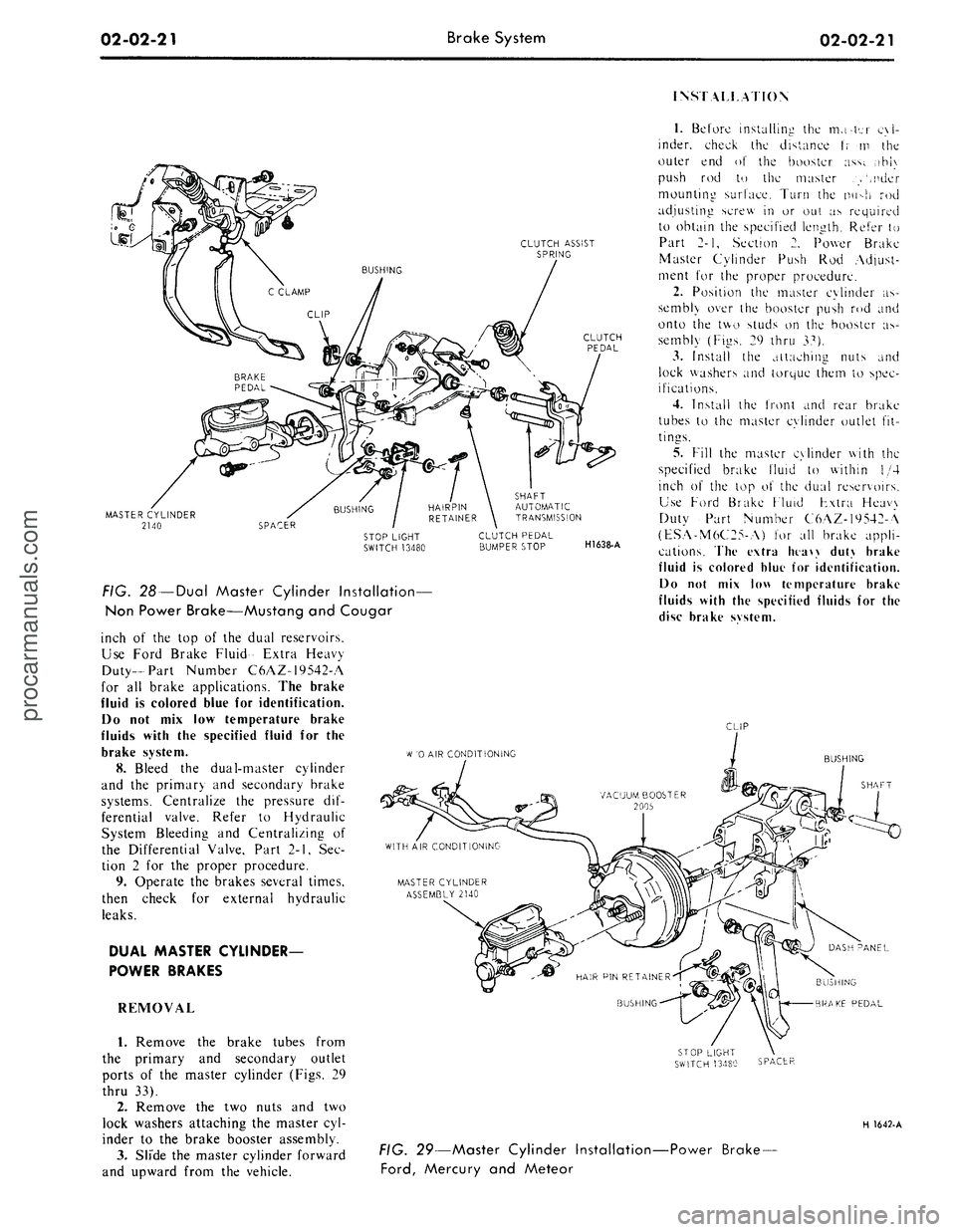

INSTALLATION

CLUTCH ASSIST

SPRING

MASTER CYLINDER

2140

FIG. 28 —Dual Master Cylinder Installation—

Non Power Brake—Mustang and Cougar

inch of the top of the dual reservoirs.

Use Ford Brake Fluid- Extra Heavy

Duty-Part Number C6AZ-19542-A

for all brake applications. The brake

fluid is colored blue for identification.

Do not mix low temperature brake

fluids with the specified fluid for the

brake system.

8. Bleed the dual-master cylinder

and the primary and secondary brake

systems. Centralize the pressure dif-

ferential valve. Refer to Hydraulic

System Bleeding and Centralizing of

the Differential Valve, Part 2-1, Sec-

tion 2 for the proper procedure.

9. Operate the brakes several times,

then check for external hydraulic

leaks.

DUAL MASTER CYLINDER-

POWER BRAKES

REMOVAL

1.

Remove the brake tubes from

the primary and secondary outlet

ports of the master cylinder (Figs. 29

thru 33).

2.

Remove the two nuts and two

lock washers attaching the master cyl-

inder to the brake booster assembly.

3.

Slide the master cylinder forward

and upward from the vehicle.

SHAFT

AUTOMATIC

TRANSMISSION

CLUTCH PEDAL

BUMPER STOP

H1638-A

1.

Before installing the mater cyl-

inder, check the distance t; m the

outer end of the booster ass;. ,ihi\

push rod to the master .>',nder

mounting surface. Turn the nu->h rod

adjusting screw in or out as required

to obtain the specified length. Refer to

Part 2-1, Section 2. Power Brake

Master Cylinder Push Rod Adjust-

ment for the proper procedure.

2.

Position the master cylinder as-

sembly over the booster push rod and

onto the two studs on the booster as-

sembly (Figs. 29 thru 37).

3.

Install the attaching nuts and

lock washers and torque them to spec-

ifications.

4.

Install the front and rear brake

tubes to the master cylinder outlet fit-

tings.

5.

Fill the master cylinder with the

specified brake fluid to within 1/4

inch of the top o\ the dual reservoirs.

Use Ford Brake Fluid Fxtra Heavy

Duty Part Number C6AZ-19542-A

(ESA-M6C25-A) for all brake appli-

cations. The extra htaw duty brake

fluid is colored blue for identification.

Do not mix low temperature brake

fluids with the specified fluids for the

disc brake svstem.

CLIP

W

'0 AIR CONDITIONING

BUSHING

SHAFT

BUSHING

BRAKE PEDAL

SPACER

H 1642-A

FIG. 29—Master Cylinder Installation-

Ford,

Mercury and Meteor

-Power Brake-procarmanuals.com