brakes FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 172 of 413

03-12-01

Wheels

And

Tires

03-12-01

PART

3-12

Wheels

And

Tires

COMPONENT INDEX

FRONT

HUB AND

DRUM ASSEMBLY

Removal

and

Installation

FRONT

HUB AND

ROTOR ASSEMBLY

Removal

and

Installation

FRONT WHEEL ASSEMBLY DESCRIPTION

FRONT WHEEL BEARING ADJUSTMENT

FRONT WHEEL GREASE SEAL

AND

BEARING

Removal, Installation, Repacking

HOISTING INSTRUCTIONS

LIFE GUARD TIRE

Balancing

Correcting Vibration

and

Shake

Description

Repairs

REAR WHEEL ASSEMBLY DESCRIPTION

WHEELS AND TIRES (Conventional)

Removal

and

Installation

MODEL APPLICATION

All

Models

12-07

12-07

12-01

12-02

12-05

12-02

12-01

12-03

Ford

N/A

N/A

N/A

N/A

Mercury

N/A

N/A

N/A

N/A

Meteor

N/A

N/A

N/A

N/A

Cougar

N/A

N/A

N/A

N/A

Fairlane

N/A

N/A

N/A

N/A

Falcon

N/A

N/A

N/A

N/A

Montego

N/A

N/A

N/A

N/A

Mustang

N/A

N/A

N/A

N/A

Lincoln-

Continental

12-03

12-03

12-02

12-08

Thunderbird

12-03

12-03

12-02

12-08

Continental-

Mark

III

12-03

12-03

12-02

12-08

A page number indicates that

the

item

is for the

vehicle listed

at the

head

of the

column.

N/A indicates that

the

item

is not

applicable

to the

vehicle listed.

DESCRIPTION

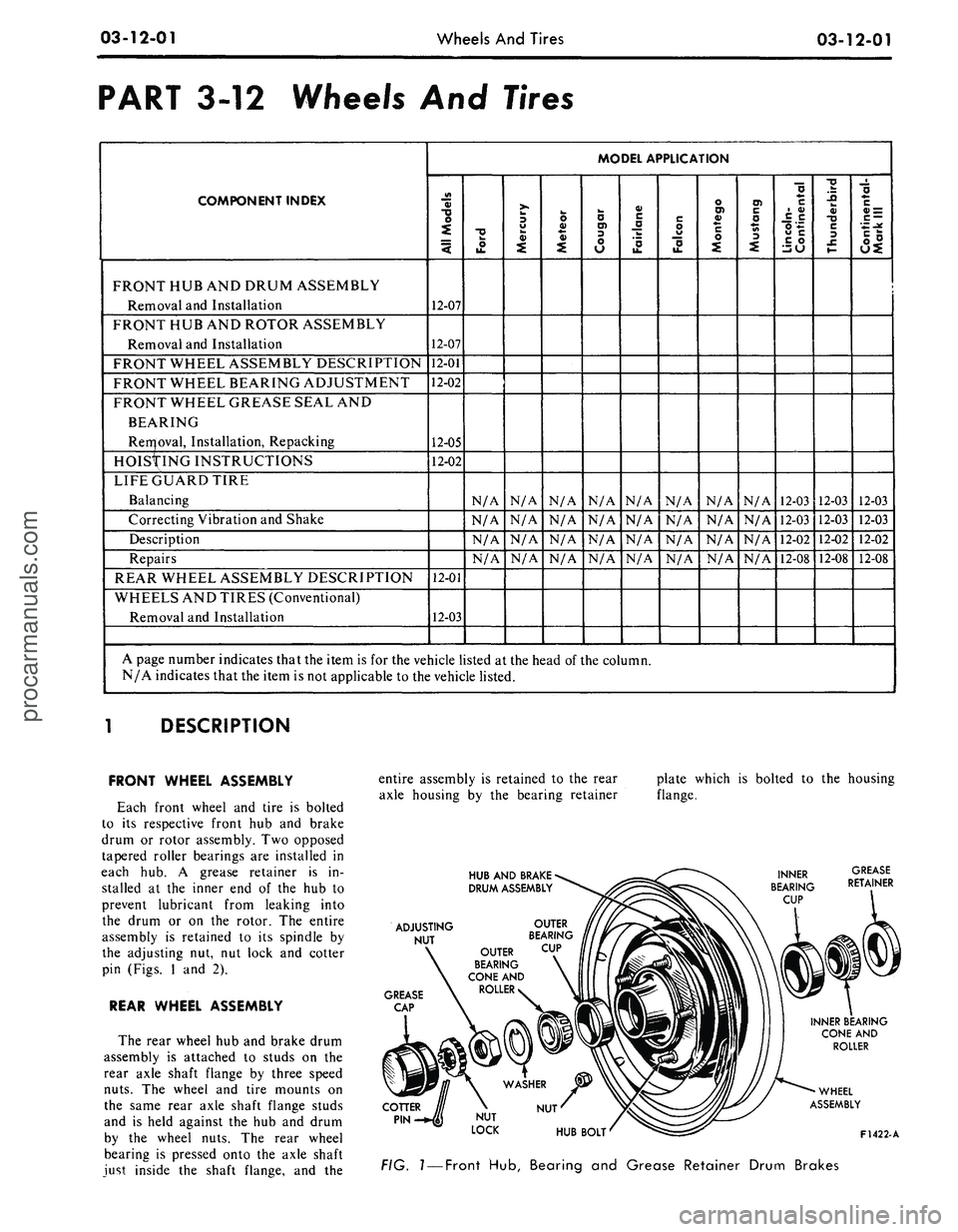

FRONT WHEEL ASSEMBLY

Each front wheel

and

tire

is

bolted

to

its

respective front

hub and

brake

drum

or

rotor assembly.

Two

opposed

tapered roller bearings

are

installed

in

each

hub. A

grease retainer

is in-

stalled

at the

inner

end of the hub to

prevent lubricant from leaking into

the drum

or on the

rotor.

The

entire

assembly

is

retained

to its

spindle

by

the adjusting

nut, nut

lock

and

cotter

pin (Figs.

1 and 2).

REAR WHEEL ASSEMBLY

The rear wheel

hub and

brake drum

assembly

is

attached

to

studs

on the

rear axle shaft flange

by

three speed

nuts.

The

wheel

and

tire mounts

on

the same rear axle shaft flange studs

and

is

held against

the hub and

drum

by

the

wheel nuts.

The

rear wheel

bearing

is

pressed onto

the

axle shaft

just inside

the

shaft flange,

and the

entire assembly

is

retained

to the

rear

axle housing

by the

bearing retainer

HUB

AND

BRAKE

DRUM

ASSEMBLY

plate which

is

bolted

to the

housing

flange.

ADJUSTING

NUT

GREASE

CAP

OUTER

BEARING

OUTER

CUP

BEARING

CONE

AND

ROLLER

NUT

INNER BEARING

CONE

AND

ROLLER

WHEEL

ASSEMBLY

HUB

BOLT'

^£=3^

F1422-A

FIG.

1

—

Front

Hub,

Bearing

and

Grease Retainer Drum Brakes

procarmanuals.com

Page 173 of 413

03-12-02

Wheels

And

Tires

03-12-02

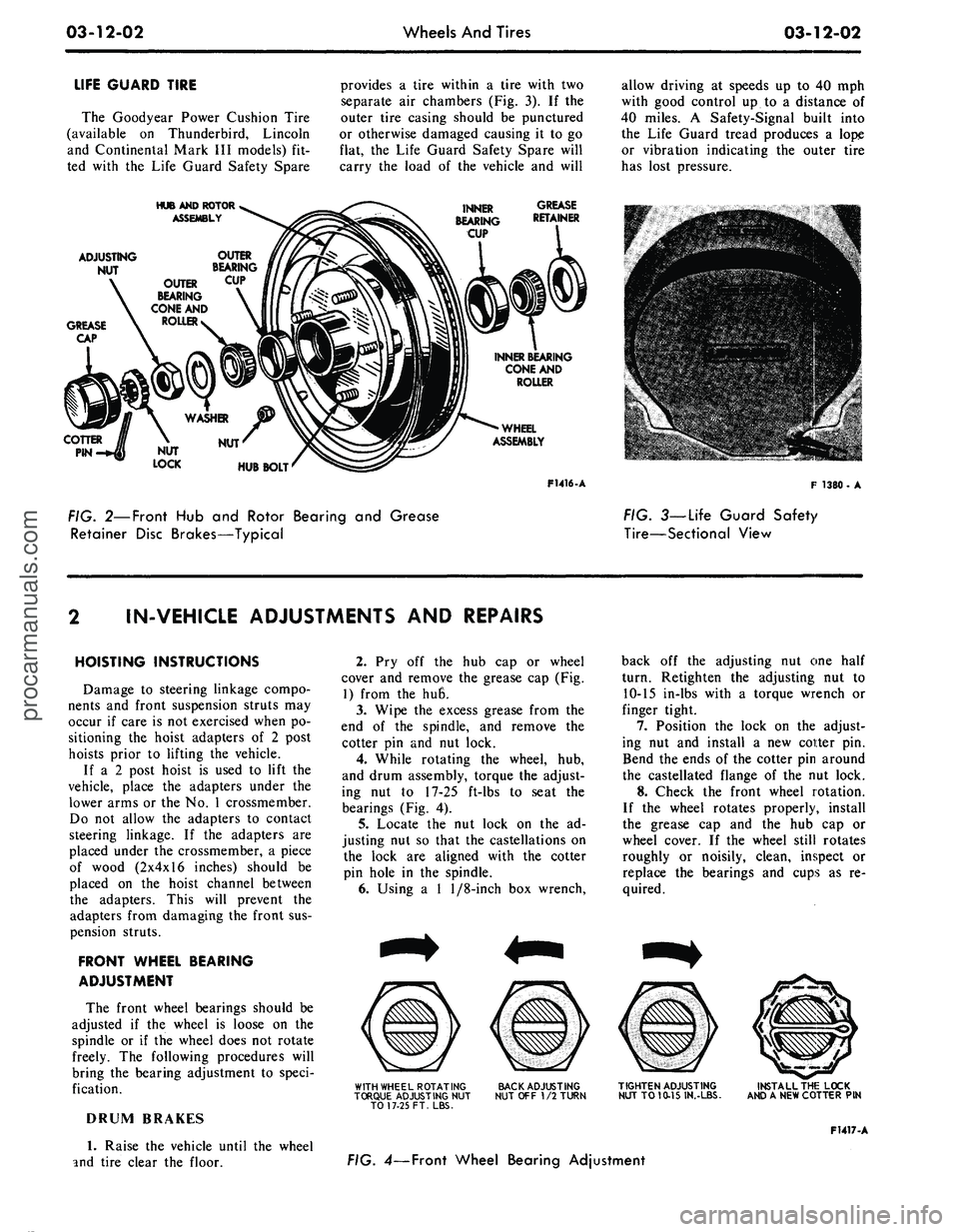

LIFE GUARD TIRE

The Goodyear Power Cushion Tire

(available

on

Thunderbird, Lincoln

and Continental Mark

III

models)

fit-

ted with

the

Life Guard Safety Spare

provides

a

tire within

a

tire with

two

separate

air

chambers

(Fig.

3). If the

outer tire casing should

be

punctured

or otherwise damaged causing

it to go

flat,

the

Life Guard Safety Spare will

carry

the

load

of the

vehicle

and

will

allow driving

at

speeds

up to 40 mph

with good control

up to a

distance

of

40 miles.

A

Safety-Signal built into

the Life Guard tread produces

a

lope

or vibration indicating

the

outer tire

has lost pressure.

HUB AND ROTOR

ASSEMBLY

INNER

BEARING

CUP

GREASE

RETAINER

ADJUSTING

NUT

OUTER

BEARING

CONE

AND

ROLLER

INNER BEARING

CONE

AND

ROLLER

WHEEL

ASSEMBLY

F1416-A

F- 1380 •

A

FIG. 2—Front

Hub and

Rotor Bearing

and

Grease

Retainer Disc Brakes—Typical

FIG. 3—Life Guard Safety

Tire—Sectional View

IN-VEHICLE ADJUSTMENTS AND REPAIRS

HOISTING INSTRUCTIONS

Damage

to

steering linkage compo-

nents

and

front suspension struts

may

occur

if

care

is

not

exercised when

po-

sitioning

the

hoist adapters

of 2

post

hoists prior

to

lifting

the

vehicle.

If

a 2

post hoist

is

used

to

lift

the

vehicle, place

the

adapters under

the

lower arms

or

the No. 1

crossmember.

Do

not

allow

the

adapters

to

contact

steering linkage.

If the

adapters

are

placed under

the

crossmember,

a

piece

of wood (2x4x16 inches) should

be

placed

on the

hoist channel between

the adapters. This will prevent

the

adapters from damaging

the

front

sus-

pension struts.

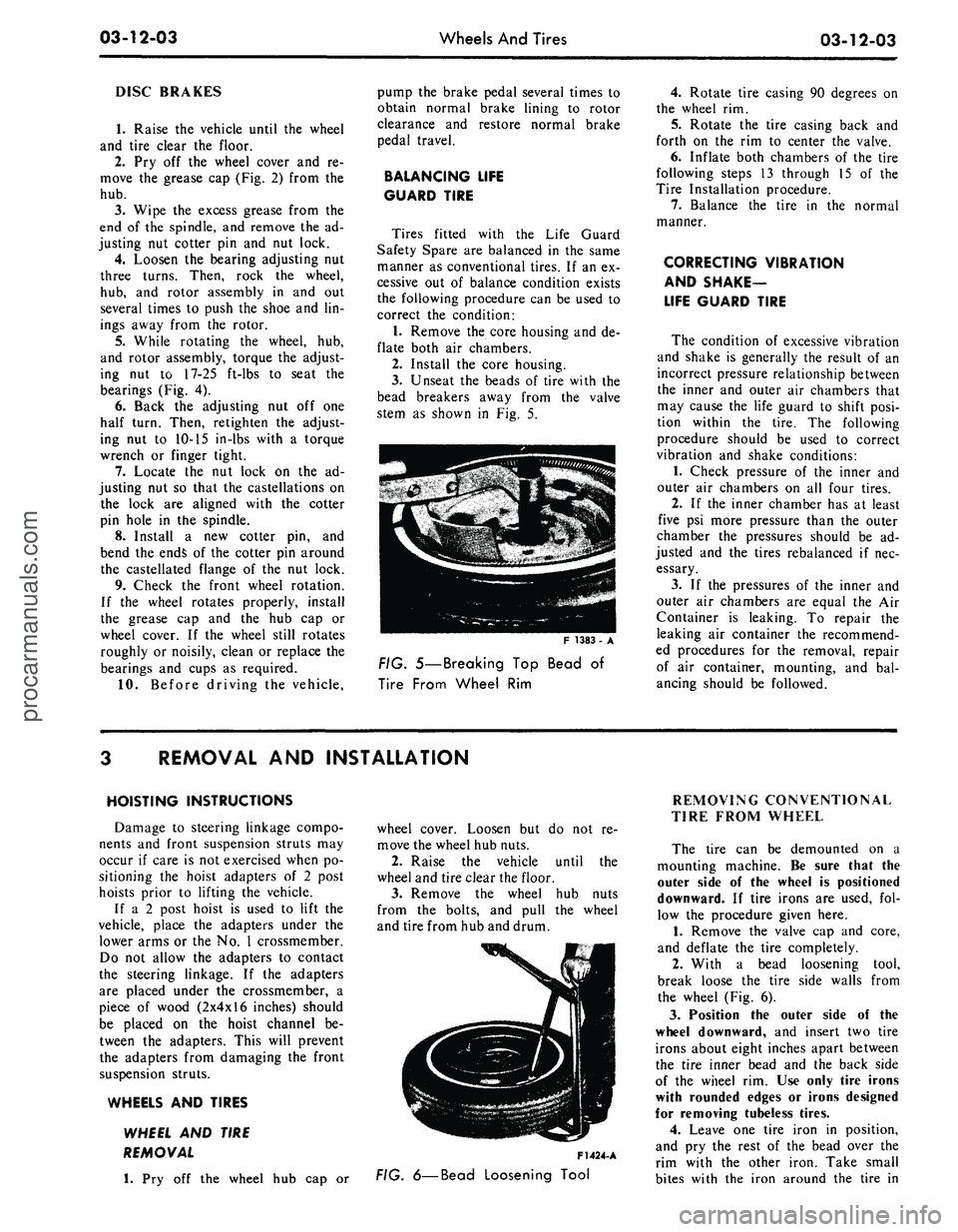

FRONT WHEEL BEARING

ADJUSTMENT

The front wheel bearings should

be

adjusted

if the

wheel

is

loose

on the

spindle

or if the

wheel does

not

rotate

freely.

The

following procedures will

bring

the

bearing adjustment

to

speci-

fication.

DRUM BRAKES

1.

Raise

the

vehicle until

the

wheel

and tire clear

the

floor.

2.

Pry off the hub cap or

wheel

cover

and

remove

the

grease

cap (Fig.

1) from

the hu6.

3.

Wipe

the

excess grease from

the

end

of the

spindle,

and

remove

the

cotter

pin and nut

lock.

4.

While rotating

the

wheel,

hub,

and drum assembly, torque

the

adjust-

ing

nut to 17-25

ft-lbs

to

seat

the

bearings

(Fig.

4).

5.

Locate

the nut

lock

on the ad-

justing

nut so

that

the

castellations

on

the lock

are

aligned with

the

cotter

pin hole

in the

spindle.

6. Using

a 1

1/8-inch

box

wrench,

WITH WHEEL ROTATING

TORQUE ADJUSTING

NUT

TO 17-25 FT. LBS.

BACK ADJUSTING

NUT

OFF

1/2

TURN

back

off the

adjusting

nut one

half

turn. Retighten

the

adjusting

nut to

10-15 in-lbs with

a

torque wrench

or

finger tight.

7.

Position

the

lock

on the

adjust-

ing

nut and

install

a new

cotter

pin.

Bend

the

ends

of

the

cotter

pin

around

the castellated flange

of the nut

lock.

8. Check

the

front wheel rotation.

If

the

wheel rotates properly, install

the grease

cap and the hub cap or

wheel cover.

If the

wheel still rotates

roughly

or

noisily, clean, inspect

or

replace

the

bearings

and

cups

as re-

quired.

TIGHTEN ADJUSTING

NUT

TO

10-15 IN.-LBS.

INSTALL THE LOCK

AND

A

NEW COTTER

PIN

F1417-A

FIG. 4— Front Wheel Bearing Adjustmentprocarmanuals.com

Page 174 of 413

03-12-03

Wheels And Tires

03-12-03

DISC BRAKES

1.

Raise the vehicle until the wheel

and tire clear the floor.

2.

Pry off the wheel cover and re-

move the grease cap (Fig. 2) from the

hub.

3.

Wipe the excess grease from the

end of the spindle, and remove the ad-

justing nut cotter pin and nut lock.

4.

Loosen the bearing adjusting nut

three turns. Then, rock the wheel,

hub,

and rotor assembly in and out

several times to push the shoe and lin-

ings away from the rotor.

5.

While rotating the wheel, hub,

and rotor assembly, torque the adjust-

ing nut to 17-25 ft-lbs to seat the

bearings (Fig. 4).

6. Back the adjusting nut off one

half turn. Then, retighten the adjust-

ing nut to 10-15 in-lbs with a torque

wrench or finger tight.

7.

Locate the nut lock on the ad-

justing nut so that the castellations on

the lock are aligned with the cotter

pin hole in the spindle.

8. Install a new cotter pin, and

bend the ends of the cotter pin around

the castellated flange of the nut lock.

9. Check the front wheel rotation.

If the wheel rotates properly, install

the grease cap and the hub cap or

wheel cover. If the wheel still rotates

roughly or noisily, clean or replace the

bearings and cups as required.

10.

Before driving the vehicle,

pump the brake pedal several times to

obtain normal brake lining to rotor

clearance and restore normal brake

pedal travel.

BALANCING LIFE

GUARD TIRE

Tires fitted with the Life Guard

Safety Spare are balanced in the same

manner as conventional tires. If an ex-

cessive out of balance condition exists

the following procedure can be used to

correct the condition:

1.

Remove the core housing and de-

flate both air chambers.

2.

Install the core housing.

3.

Unseat the beads of tire with the

bead breakers away from the valve

stem as shown in Fig. 5.

F 1383

FIG. 5—Breaking Top Bead of

Tire From Wheel Rim

4.

Rotate tire casing 90 degrees on

the wheel rim.

5.

Rotate the tire casing back and

forth on the rim to center the valve.

6. Inflate both chambers of the tire

following steps 13 through 15 of the

Tire Installation procedure.

7.

Balance the tire in the normal

manner.

CORRECTING VIBRATION

AND SHAKE-

LIFE GUARD TIRE

The condition of excessive vibration

and shake is generally the result of an

incorrect pressure relationship between

the inner and outer air chambers that

may cause the life guard to shift posi-

tion within the tire. The following

procedure should be used to correct

vibration and shake conditions:

1.

Check pressure of the inner and

outer air chambers on all four tires.

2.

If the inner chamber has at least

five psi more pressure than the outer

chamber the pressures should be ad-

justed and the tires rebalanced if nec-

essary.

3.

If the pressures of the inner and

outer air chambers are equal the Air

Container is leaking. To repair the

leaking air container the recommend-

ed procedures for the removal, repair

of air container, mounting, and bal-

ancing should be followed.

REMOVAL AND INSTALLATION

HOISTING INSTRUCTIONS

Damage to steering linkage compo-

nents and front suspension struts may

occur if care is not exercised when po-

sitioning the hoist adapters of 2 post

hoists prior to lifting the vehicle.

If a 2 post hoist is used to lift the

vehicle, place the adapters under the

lower arms or the No. 1 crossmember.

Do not allow the adapters to contact

the steering linkage. If the adapters

are placed under the crossmember, a

piece of wood (2x4x16 inches) should

be placed on the hoist channel be-

tween the adapters. This will prevent

the adapters from damaging the front

suspension struts.

WHEELS AND TIRES

WHEEL AND TIRE

REMOVAL

1.

Pry off the wheel hub cap or

wheel cover. Loosen but do not re-

move the wheel hub nuts.

2.

Raise the vehicle until the

wheel and tire clear the floor.

3.

Remove the wheel hub nuts

from the bolts, and pull the wheel

and tire from hub and drum.

F1424-

A

FIG.

6—Bead

Loosening Tool

REMOVING CONVENTIONAL

TIRE FROM WHEEL

The tire can be demounted on a

mounting machine. Be sure that the

outer side of the wheel is positioned

downward. If tire irons are used, fol-

low the procedure given here.

1.

Remove the valve cap and core,

and deflate the tire completely.

2.

With a bead loosening tool,

break loose the tire side walls from

the wheel (Fig. 6).

3.

Position the outer side of the

wheel downward, and insert two tire

irons about eight inches apart between

the tire inner bead and the back side

of the wheel rim. Use only tire irons

with rounded edges or irons designed

for removing tubeless tires.

4.

Leave one tire iron in position,

and pry the rest of the bead over the

rim with the other iron. Take small

bites with the iron around the tire inprocarmanuals.com

Page 176 of 413

03-12-05

Wheels

And

Tires

03-12-05

and sharp edges from valve hole

in

rim.

8. Mount first tire bead exercising

care

not to

pinch

air

container.

9. Start valve through hole

in rim.

Do

not

pull valve housing into place

at this time.

10.

Mount

the

second bead starting

just past

the

valve

so the

last portion

of

the

bead goes over

the rim at the

valve.

11.

Rotate

the

tire back

and

forth

to center

the

valve housing.

12.

Pull

the

valve housing into

place. Make certain that

the

rubber

valve ridge

is

visible around

thi

valve

housing

(Fig.

12).

13.

Tighten

the

core housing lightly

using pliers.

14.

Thread

the

Inflate-Chek adapt-

er onto

the

core housing.

15.

Inflate

the

inner chamber

to

seat

the

tire beads exercising care

not

to exceed

45 psi

pressure. Adjust this

inner chamber

air

pressure

to 15 psi

higher than

the

recommended tire

pressure.

F 1387

- A

FIG. 12—Valve Installation

16.

Remove

the

Inflate-Chek

adapter

and

adjust tire (outer cham-

ber) pressure

to the

recommended

pressure.

17.

Recheck inner chamber pres-

sure.

18.

Install valve

cap.

WHEEL

AND

TIRE

INSTALLATION

1.

Clean

all

dirt from

the hub and

drum.

2.

Position

the

wheel

and

tire

on

the

hub and

drum. Install

the

wheel

hub nuts

and

tighten them alternately

to draw

the

wheel evenly against

the

hub

and

drum.

3.

Lower

the

vehicle

to the

floor,

and torque

the hub

nuts

to

specifica-

tion.

MAJOR REPAIR OPERATIONS

HOISTING INSTRUCTIONS

Damage

to

steering linkage compo-

nents

and

front suspension struts

may

occur

if

care

is

not

exercised when

po-

sitioning

the

hoist adapters

of 2

post

hoists prior

to

lifting

the

vehicle.

If

a 2

post hoist

is

used

to

lift

the

vehicle, place

the

adapters under

the

lower arms

or the

No.

1

crossmember.

Do

not

allow

the

adapters

to

contact

the steering linkage.

If the

adapters

are placed under

the

crossmember,

a

piece

of

wood (2x4x16 inches) should

be placed

on the

hoist channel

be-

tween

the

adapters. This will prevent

the adapters from damaging

the

front

suspension struts.

FRONT WHEEL GREASE

SEAL

AND

BEARING

REPLACEMENT AND/OR

REPACKING

If bearing adjustment will

not

elimi-

nate looseness

or

rough

and

noisy

op-

eration,

the hub and

bearings should

be cleaned, inspected,

and

repacked

with specified wheel grease.

If the

bearing cups

or the

cone

and

roller

assemblies

are

worn

or

damaged, they

should

be

replaced.

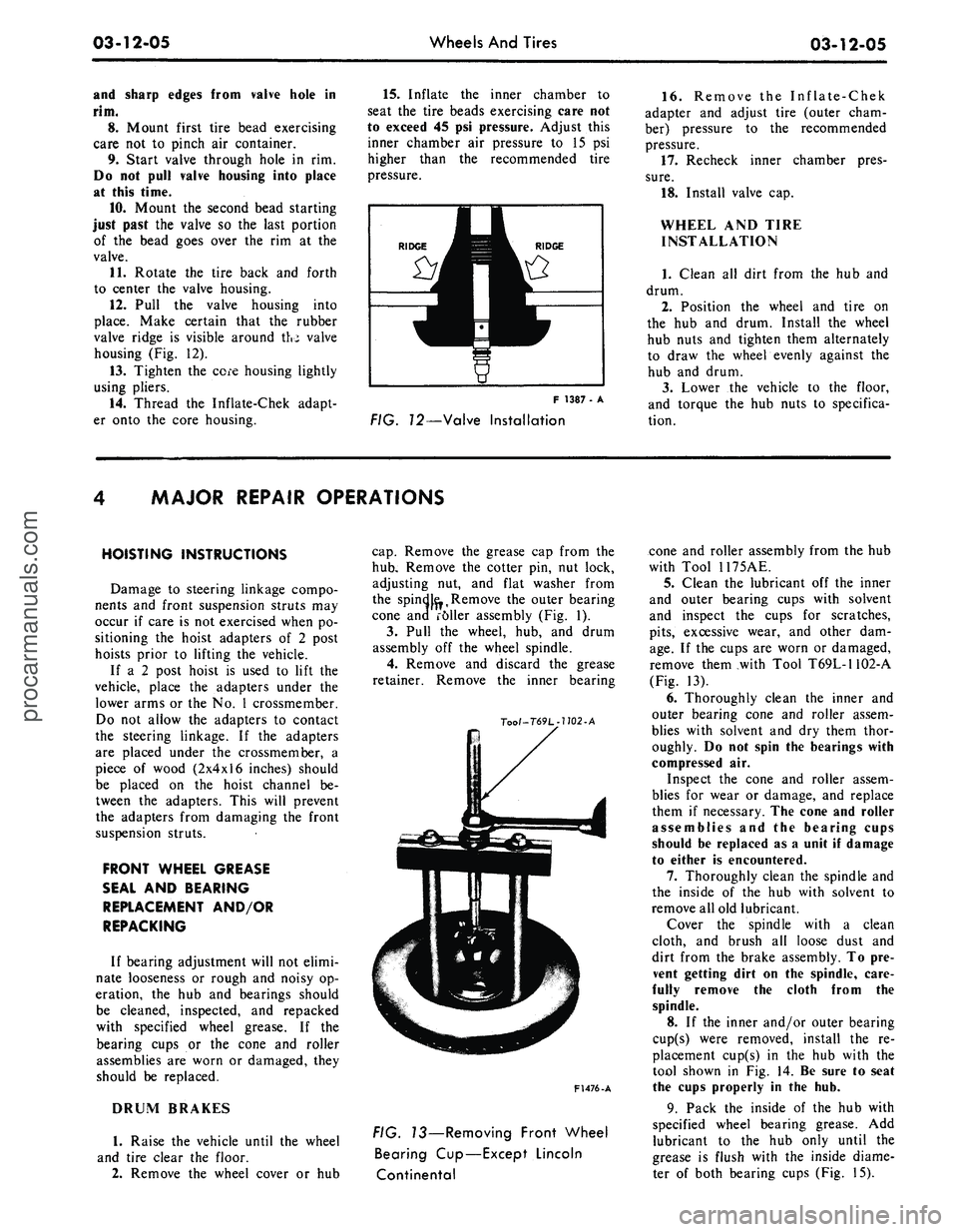

DRUM BRAKES

1.

Raise

the

vehicle until

the

wheel

and tire clear

the

floor.

2.

Remove

the

wheel cover

or hub

cap.

Remove

the

grease

cap

from

the

hub.

Remove

the

cotter

pin,

nut

lock,

adjusting

nut, and

flat washer from

the spindjej, Remove

the

outer bearing

cone

and

roller assembly

(Fig.

1).

3.

Pull

the

wheel,

hub, and

drum

assembly

off the

wheel spindle.

4.

Remove

and

discard

the

grease

retainer. Remove

the

inner bearing

Too/-T69L-J102-A

F1476-A

FIG. 13—Removing Front Wheel

Bearing Cup—Except Lincoln

Continental

cone

and

roller assembly from

the hub

with Tool 1175AE.

5.

Clean

the

lubricant

off the

inner

and outer bearing cups with solvent

and inspect

the

cups

for

scratches,

pits,

excessive wear,

and

other

dam-

age.

If

the

cups

are

worn

or

damaged,

remove them with Tool T69L-1102-A

(Fig.

13).

6. Thoroughly clean

the

inner

and

outer bearing cone

and

roller assem-

blies with solvent

and dry

them thor-

oughly.

Do not

spin

the

bearings with

compressed

air.

Inspect

the

cone

and

roller assem-

blies

for

wear

or

damage,

and

replace

them

if

necessary.

The

cone

and

roller

assemblies

and the

bearing cups

should

be

replaced

as a

unit

if

damage

to either

is

encountered.

7. Thoroughly clean

the

spindle

and

the inside

of the hub

with solvent

to

remove

all old

lubricant.

Cover

the

spindle with

a

clean

cloth,

and

brush

all

loose dust

and

dirt from

the

brake assembly.

To

pre-

vent getting dirt

on the

spindle, care-

fully remove

the

cloth from

the

spindle.

8.

If the

inner and/or outer bearing

cup(s) were removed, install

the re-

placement cup(s)

in the hub

with

the

tool shown

in Fig.

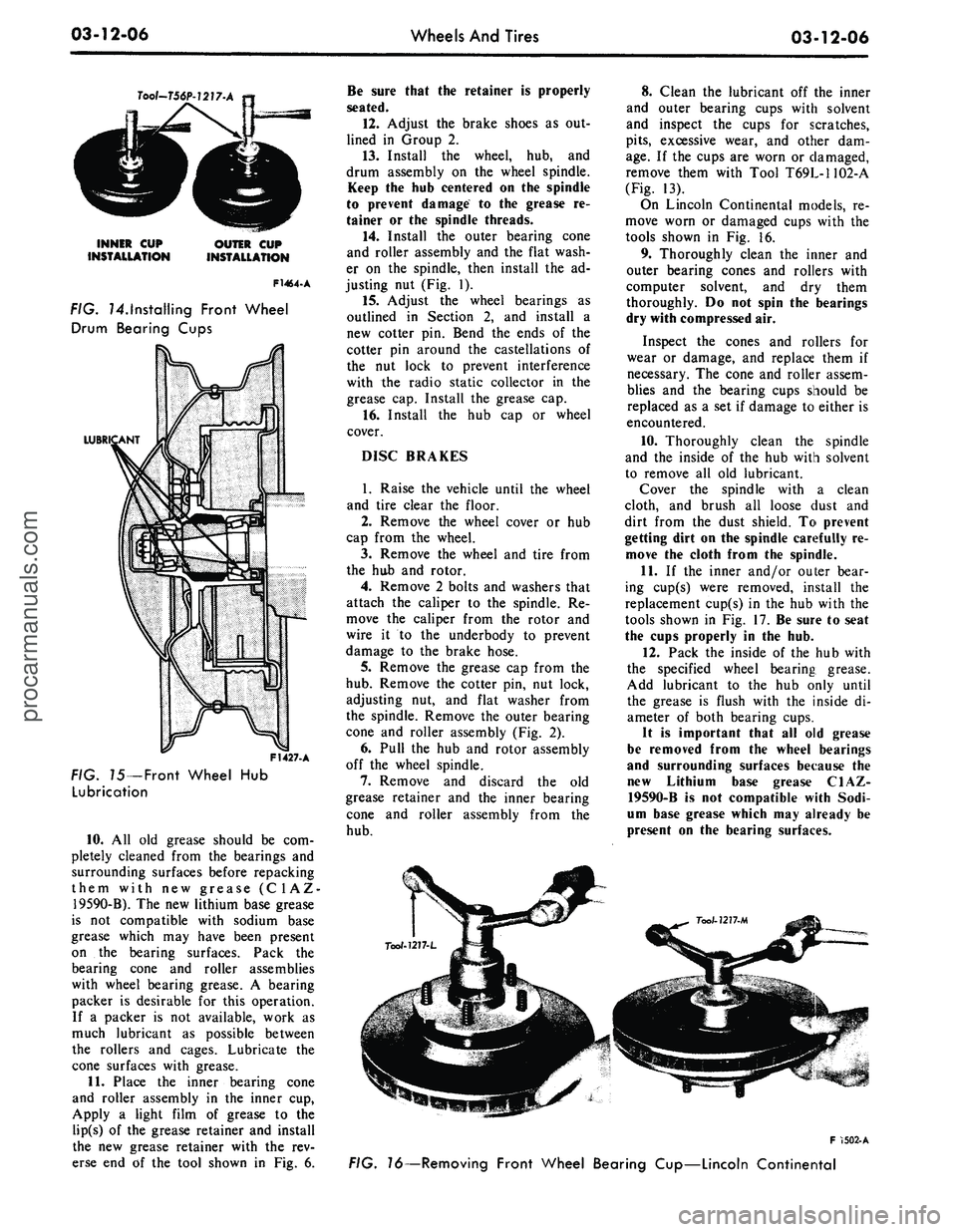

14.

Be

sure

to

seat

the cups properly

in the hub.

9. Pack

the

inside

of the hub

with

specified wheel bearing grease.

Add

lubricant

to the hub

only until

the

grease

is

flush with

the

inside diame-

ter

of

both bearing cups

(Fig.

15).procarmanuals.com

Page 177 of 413

03-12-06

Wheels And Tires

03-12-06

Tool-T56P-1217-A

INNER CUP

INSTALLATION

OUTER CUP

INSTALLATION

F1464-A

FIG. ^.Installing Front Wheel

Drum Bearing Cups

LUBR

F1427. A

FIG. 75—Front Wheel Hub

Lubrication

10.

All old grease should be com-

pletely cleaned from the bearings and

surrounding surfaces before repacking

them with new grease (C1AZ-

19590-B). The new lithium base grease

is not compatible with sodium base

grease which may have been present

on the bearing surfaces. Pack the

bearing cone and roller assemblies

with wheel bearing grease. A bearing

packer is desirable for this operation.

If a packer is not available, work as

much lubricant as possible between

the rollers and cages. Lubricate the

cone surfaces with grease.

11.

Place the inner bearing cone

and roller assembly in the inner cup,

Apply a light film of grease to the

lip(s) of the grease retainer and install

the new grease retainer with the rev-

erse end of the tool shown in Fig. 6.

Be sure that the retainer is properly

seated.

12.

Adjust the brake shoes as out-

lined in Group 2.

13.

Install the wheel, hub, and

drum assembly on the wheel spindle.

Keep the hub centered on the spindle

to prevent damage to the grease re-

tainer or the spindle threads.

14.

Install the outer bearing cone

and roller assembly and the flat wash-

er on the spindle, then install the ad-

justing nut (Fig. 1).

15.

Adjust the wheel bearings as

outlined in Section 2, and install a

new cotter pin. Bend the ends of the

cotter pin around the castellations of

the nut lock to prevent interference

with the radio static collector in the

grease cap. Install the grease cap.

16.

Install the hub cap or wheel

cover.

DISC BRAKES

1.

Raise the vehicle until the wheel

and tire clear the floor.

2.

Remove the wheel cover or hub

cap from the wheel.

3.

Remove the wheel and tire from

the hub and rotor.

4.

Remove 2 bolts and washers that

attach the caliper to the spindle. Re-

move the caliper from the rotor and

wire it to the underbody to prevent

damage to the brake hose.

5.

Remove the grease cap from the

hub.

Remove the cotter pin, nut lock,

adjusting nut, and flat washer from

the spindle. Remove the outer bearing

cone and roller assembly (Fig. 2).

6. Pull the hub and rotor assembly

off the wheel spindle.

7.

Remove and discard the old

grease retainer and the inner bearing

cone and roller assembly from the

hub.

8. Clean the lubricant off the inner

and outer bearing cups with solvent

and inspect the cups for scratches,

pits,

excessive wear, and other dam-

age.

If the cups are worn or damaged,

remove them with Tool T69L-1102-A

(Fig. 13).

On Lincoln Continental models, re-

move worn or damaged cups with the

tools shown in Fig. 16.

9. Thoroughly clean the inner and

outer bearing cones and rollers with

computer solvent, and dry them

thoroughly. Do not spin the bearings

dry with compressed air.

Inspect the cones and rollers for

wear or damage, and replace them if

necessary. The cone and roller assem-

blies and the bearing cups should be

replaced as a set if damage to either is

encountered.

10.

Thoroughly clean the spindle

and the inside of the hub with solvent

to remove all old lubricant.

Cover the spindle with a clean

cloth, and brush all loose dust and

dirt from the dust shield. To prevent

getting dirt on the spindle carefully re-

move the cloth from the spindle.

11.

If the inner and/or outer bear-

ing cup(s) were removed, install the

replacement cup(s) in the hub with the

tools shown in Fig. 17. Be sure to seat

the cups properly in the hub.

12.

Pack the inside of the hub with

the specified wheel bearing grease.

Add lubricant to the hub only until

the grease is flush with the inside di-

ameter of both bearing cups.

It is important that all old grease

be removed from the wheel bearings

and surrounding surfaces because the

new Lithium base grease C1AZ-

19590-B is not compatible with Sodi-

um base grease which may already be

present on the bearing surfaces.

F 1502-A

FIG. 16—Removing Front Wheel Bearing Cup—Lincoln Continentalprocarmanuals.com

Page 205 of 413

04-02-08

Rear Axle — Removable Carrier Type

04-02-08

REMOVAL AND INSTALLATION

CARRIER ASSEMBLY

REMOVAL

1.

Raise the vehicle on a hoist and

remove the two rear wheels and tires.

2.

Remove the two brake drums (3

Tinnerman nuts at each drum) from

the axle shaft flange studs. If diffi-

culty is experienced in removing the

drums, remove the brake adjuster

knockout slug or rubber plug (if so

equipped) and back off the brake

shoes.

3.

Working through the hole pro-

vided in each axle shaft flange, re-

move the nuts that secure the rear

wheel bearing retainer plate. Pull each

axle shaft assembly out of the axle

housing using axle shaft remover,

Tool 4235-C. (Fig. 4). Care must be

exercised to prevent damage to the

production-type synthetic oil seal, if so

equipped. Any roughing or cutting of

the seal element during removal or in-

stallation can result in early seal fail-

ure.

Install a nut on one of the brake

backing plate attaching bolts to hold

the plate to the axle housing after the

shaft has been removed. Whenever a

rear axle shaft is replaced, the wheel

bearing oil seals must be replaced.

Remove the seals with tool 1175AB.

4.

Make scribe marks on the drive

shaft end yoke and the axle U-joint

flange to insure proper position at as-

sembly. Disconnect the drive shaft at

the rear axle U-joint. Hold the cups

on the spider with tape. Mark the

cups so that they will be in their orig-

inal position relative to the flange

when they are assembled. Remove the

drive shaft from the transmission ex-

tension housing. Install an oil seal re-

placer tool in the housing to prevent

transmission leakage. Refer to the

transmission group for the appropriate

tool.

5.

Clean area around carrier to

housing surfaced with a wire brush and

wipe clean, to prevent dirt entry into

the housing. Place a drain pan under

the carrier and housing, remove the

carrier attaching nuts, and drain the

axle.

Remove the carrier assembly

from the axle housing.

INSTALLATION

Synthetic production-type wheel

bearing seals must not be cleaned,

soaked or washed in cleaning solvent.

1.

Clean the axle housing and

shafts using kerosene and swabs. To

avoid contamination of the grease in

the sealed ball bearings, do not allow

any quantity of solvent directly on the

wheel bearings. Clean the mating sur-

faces of the axle housing and carrier.

2.

Position the differential carrier

on the studs in the axle housing using

a new gasket between carrier and

housing. Install the carrier-to-housing

attaching nuts, and torque them to

specifications.

3.

Remove the oil seal replacer tool

from the transmission extension hous-

ing. Position the drive shaft so that

the front U-joint slip yoke splines to

the transmission output shaft.

4.

Connect the drive shaft to the

axle U-joint flange, aligning the scribe

marks made on the drive shaft end

yoke and the axle U-joint flange dur-

ing the removal procedure. Install the

U-bolts and nuts and torque to speci-

fications.

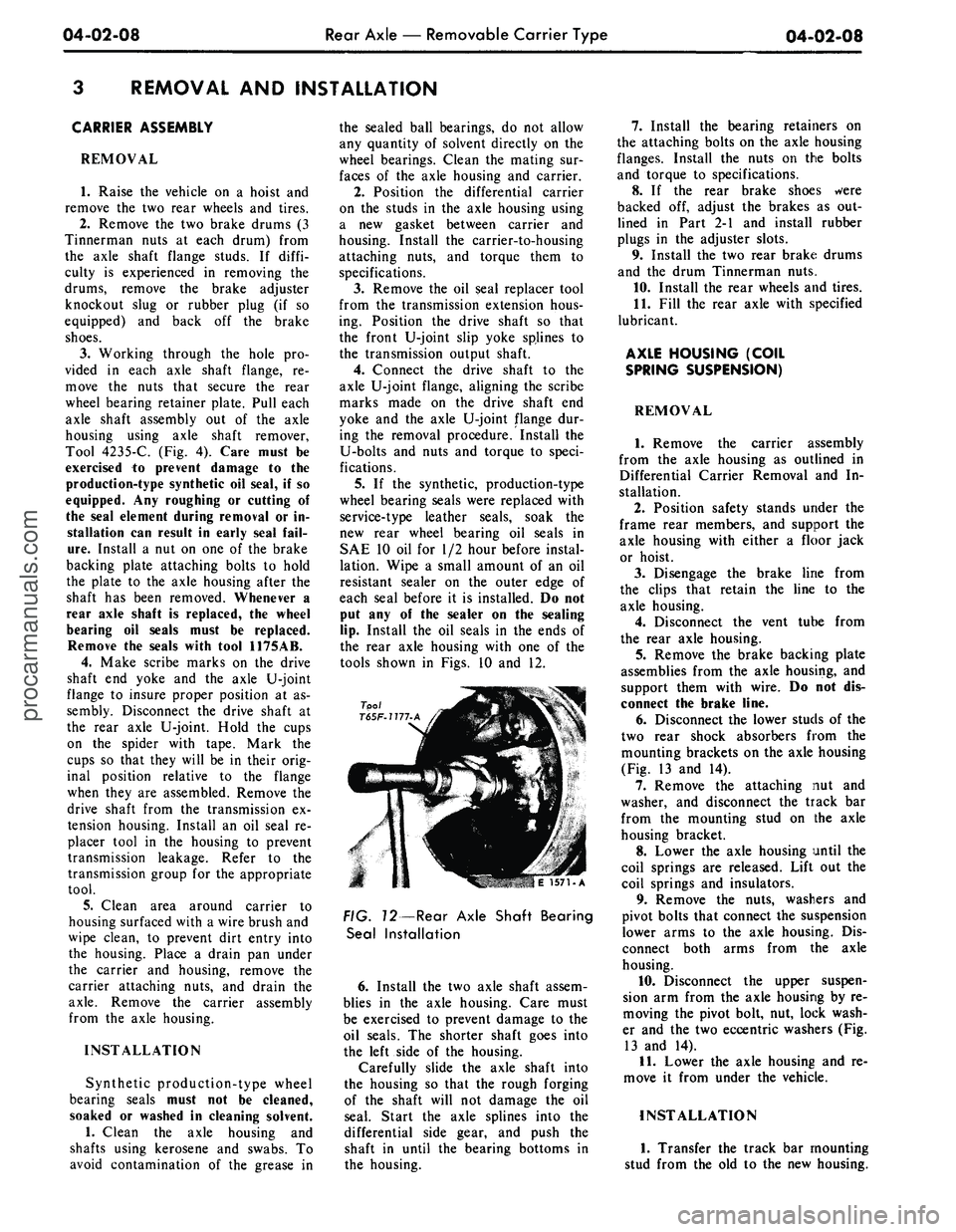

5.

If the synthetic, production-type

wheel bearing seals were replaced with

service-type leather seals, soak the

new rear wheel bearing oil seals in

SAE 10 oil for 1/2 hour before instal-

lation. Wipe a small amount of an oil

resistant sealer on the outer edge of

each seal before it is installed. Do not

put any of the sealer on the sealing

lip.

Install the oil seals in the ends of

the rear axle housing with one of the

tools shown in Figs. 10 and 12.

Tool

T65F-1177.A

E 1571-A

FIG. 12—Rear Axle Shaft Bearing

Seal Installation

6. Install the two axle shaft assem-

blies in the axle housing. Care must

be exercised to prevent damage to the

oil seals. The shorter shaft goes into

the left side of the housing.

Carefully slide the axle shaft into

the housing so that the rough forging

of the shaft will not damage the oil

seal. Start the axle splines into the

differential side gear, and push the

shaft in until the bearing bottoms in

the housing.

7.

Install the bearing retainers on

the attaching bolts on the axle housing

flanges. Install the nuts on the bolts

and torque to specifications.

8. If the rear brake shoes were

backed off, adjust the brakes as out-

lined in Part 2-1 and install rubber

plugs in the adjuster slots.

9. Install the two rear brake drums

and the drum Tinnerman nuts.

10.

Install the rear wheels and tires.

11.

Fill the rear axle with specified

lubricant.

AXLE HOUSING (COIL

SPRING SUSPENSION)

REMOVAL

1.

Remove the carrier assembly

from the axle housing as outlined in

Differential Carrier Removal and In-

stallation.

2.

Position safety stands under the

frame rear members, and support the

axle housing with either a floor jack

or hoist.

3.

Disengage the brake line from

the clips that retain the line to the

axle housing.

4.

Disconnect the vent tube from

the rear axle housing.

5.

Remove the brake backing plate

assemblies from the axle housing, and

support them with wire. Do not dis-

connect the brake line.

6. Disconnect the lower studs of the

two rear shock absorbers from the

mounting brackets on the axle housing

(Fig. 13 and 14).

7.

Remove the attaching nut and

washer, and disconnect the track bar

from the mounting stud on the axle

housing bracket.

8. Lower the axle housing until the

coil springs are released. Lift out the

coil springs and insulators.

9. Remove the nuts, washers and

pivot bolts that connect the suspension

lower arms to the axle housing. Dis-

connect both arms from the axle

housing.

10.

Disconnect the upper suspen-

sion arm from the axle housing by re-

moving the pivot bolt, nut, lock wash-

er and the two eccentric washers (Fig.

13 and 14).

11.

Lower the axle housing and re-

move it from under the vehicle.

INSTALLATION

1.

Transfer the track bar mounting

stud from the old to the new housing.procarmanuals.com

Page 208 of 413

04-02-11

Rear Axle — Removable Carrier Type

04-02-11

If the axle housing is new, install a

new vent. The hose attaching portion

must face toward the front of the ve-

hicle.

2.

If leather-type wheel bearing ser-

vice seals are to be installed, soak the

new rear wheel bearing oil seals in

SAE 10 oil for 1/2 hour before instal-

lation. Wipe a small amount of an oil

resistant sealer on the outer edge of

each seal before it is installed. Do not

put any of the sealer on the sealing

lip.

Install the oil seals in the ends of

the axle housing with one of the tools

shown in Fig. 10 and 12.

3.

Position the replacement axle

housing under the vehicle, and raise

the axle with a hoist or floor jack.

Connect the suspension lower arms to

their mounting brackets on the axle

housing with pivot bolts and nuts. Do

not tighten the bolts and nuts at this

point.

4.

Position the suspension upper

arm in its mounting bracket on the

axle housing, and install the adjusting

bolt, eccentric washers, lock washer

and nut. Leave the bolt and nut loose

at this point.

5.

Position the brake lines to the

axle housing, and secure with the re-

taining clips.

6. Install the brake backing plates

on the axle housing flanges.

7.

Connect the track bar to the

mounting stud, install the washer and

attaching nut, and torque to specifica-

tions.

8. Position the rear coil springs and

insulators in the pockets provided.

9. Connect the lower studs of the

two rear shock absorbers to the

mounting brackets on the axle hous-

ing. Install the attaching nuts, and

torque to specifications.

10.

Connect the vent tube to the

vent on the housing. If axle housing is

new, install a new vent.

11.

Clean the mating surfaces of

the axle housing and differential car-

rier. Position the carrier on the

mounting studs on the housing using a

new gasket between carrier and hous-

ing. Install the copper washers and the

carrier-to-housing attaching nuts, and

torque to specifications.

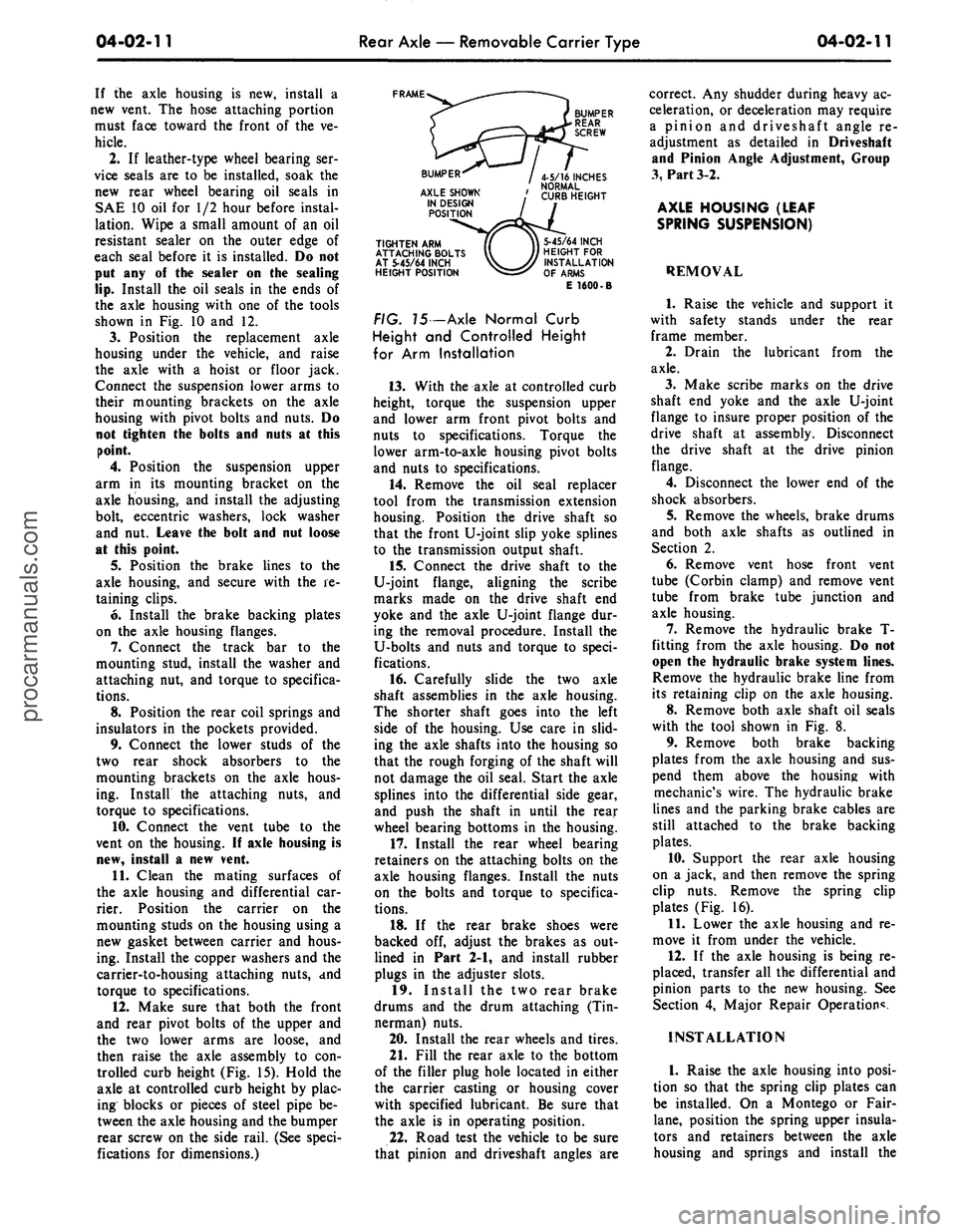

12.

Make sure that both the front

and rear pivot bolts of the upper and

the two lower arms are loose, and

then raise the axle assembly to con-

trolled curb height (Fig. 15). Hold the

axle at controlled curb height by plac-

ing blocks or pieces of steel pipe be-

tween the axle housing and the bumper

rear screw on the side rail. (See speci-

fications for dimensions.)

FRAME

TIGHTEN ARM

ATTACHING BOLTS

AT 5-45/64 INCH

HEIGHT POSITION

5-45/64 INCH

HEIGHT FOR

INSTALLATION

OF ARMS

E 1600-B

FIG. 75 -Axle Normal Curb

Height and Controlled Height

for Arm Installation

13.

With the axle at controlled curb

height, torque the suspension upper

and lower arm front pivot bolts and

nuts to specifications. Torque the

lower arm-to-axle housing pivot bolts

and nuts to specifications.

14.

Remove the oil seal replacer

tool from the transmission extension

housing. Position the drive shaft so

that the front U-joint slip yoke splines

to the transmission output shaft.

15.

Connect the drive shaft to the

U-joint flange, aligning the scribe

marks made on the drive shaft end

yoke and the axle U-joint flange dur-

ing the removal procedure. Install the

U-bolts and nuts and torque to speci-

fications.

16.

Carefully slide the two axle

shaft assemblies in the axle housing.

The shorter shaft goes into the left

side of the housing. Use care in slid-

ing the axle shafts into the housing so

that the rough forging of the shaft will

not damage the oil seal. Start the axle

splines into the differential side gear,

and push the shaft in until the rear

wheel bearing bottoms in the housing.

17.

Install the rear wheel bearing

retainers on the attaching bolts on the

axle housing flanges. Install the nuts

on the bolts and torque to specifica-

tions.

18.

If the rear brake shoes were

backed off, adjust the brakes as out-

lined in Part 2-1, and install rubber

plugs in the adjuster slots.

19.

Install the two rear brake

drums and the drum attaching (Tin-

nerman) nuts.

20.

Install the rear wheels and tires.

21.

Fill the rear axle to the bottom

of the filler plug hole located in either

the carrier casting or housing cover

with specified lubricant. Be sure that

the axle is in operating position.

22.

Road test the vehicle to be sure

that pinion and driveshaft angles are

correct. Any shudder during heavy ac-

celeration, or deceleration may require

a pinion and driveshaft angle re-

adjustment as detailed in Driveshaft

and Pinion Angle Adjustment, Group

3,

Part 3-2.

AXLE HOUSING (LEAF

SPRING SUSPENSION)

REMOVAL

1.

Raise the vehicle and support it

with safety stands under the rear

frame member.

2.

Drain the lubricant from the

axle.

3.

Make scribe marks on the drive

shaft end yoke and the axle U-joint

flange to insure proper position of the

drive shaft at assembly. Disconnect

the drive shaft at the drive pinion

flange.

4.

Disconnect the lower end of the

shock absorbers.

5.

Remove the wheels, brake drums

and both axle shafts as outlined in

Section 2.

6. Remove vent hose front vent

tube (Corbin clamp) and remove vent

tube from brake tube junction and

axle housing.

7.

Remove the hydraulic brake T-

fitting from the axle housing. Do not

open the hydraulic brake system lines.

Remove the hydraulic brake line from

its retaining clip on the axle housing.

8. Remove both axle shaft oil seals

with the tool shown in Fig. 8.

9. Remove both brake backing

plates from the axle housing and sus-

pend them above the housing with

mechanic's wire. The hydraulic brake

lines and the parking brake cables are

still attached to the brake backing

plates.

10.

Support the rear axle housing

on a jack, and then remove the spring

clip nuts. Remove the spring clip

plates (Fig. 16).

11.

Lower the axle housing and re-

move it from under the vehicle.

12.

If the axle housing is being re-

placed, transfer all the differential and

pinion parts to the new housing. See

Section 4, Major Repair Operation*.

INSTALLATION

1.

Raise the axle housing into posi-

tion so that the spring clip plates can

be installed. On a Montego or Fair-

lane,

position the spring upper insula-

tors and retainers between the axle

housing and springs and install theprocarmanuals.com

Page 296 of 413

07-01-05

General Transmission Service

07-01-05

linkage may cause crossleakage and

subsequent transmission failure. Refer

to Linkage Adjustments in Part 7-2,

7-3 or 7-4 for detailed manual linkage

adjustment procedures.

CONTROL PRESSURE

CHECK

When the vacuum diaphragm unit is

operating properly and the downshift

linkage is adjusted properly, all the

transmission shifts (automatic and

kickdown) should occur within the

road speed limits specified in Part 7-5.

If the shifts do not occur within

limits or the transmission slips during

shift point, the following procedure is

suggested to determine engine, trans-

mission, linkage, vacuum diaphragm

unit or valve body problems.

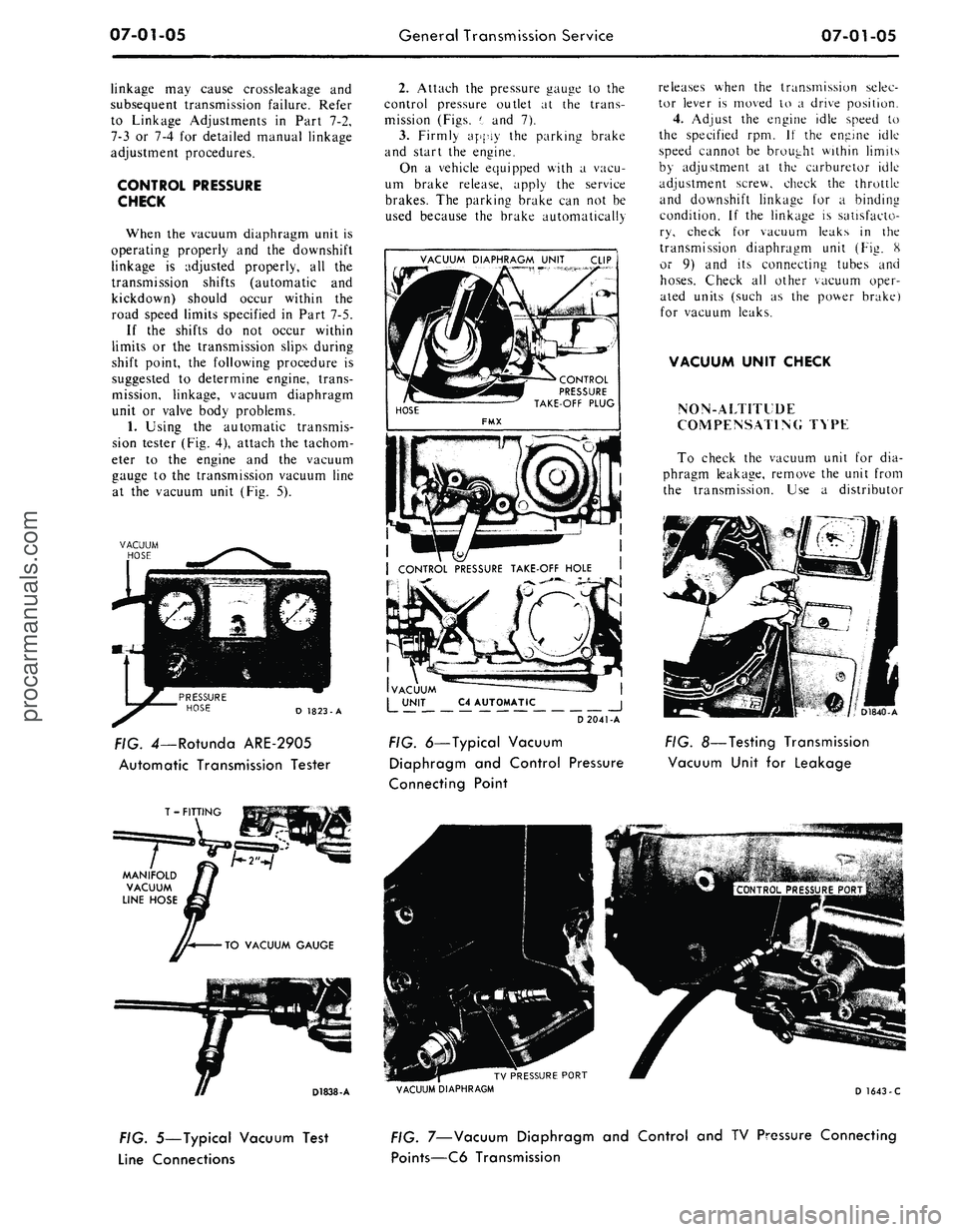

1.

Using the automatic transmis-

sion tester (Fig. 4), attach the tachom-

eter to the engine and the vacuum

gauge to the transmission vacuum line

at the vacuum unit (Fig. 5).

D 1823-A

. 4—Rotunda ARE-2905

Automatic Transmission Tester

T - FITTING

2.

Attach the pressure gauge to the

control pressure outlet at the trans-

mission (Figs. '., and 7).

3.

Firmly apply the parking brake

and start the engine.

On a vehicle equipped with a vacu-

um brake release, apply the service

brakes. The parking brake can not be

used because the brake automatically

VACUUM DIAPHRAGM UNIT

CLIP

I

| CONTROL PRESSURE TAKE-OFF HOLE

D2041-A

FIG. 6—Typical Vacuum

Diaphragm and Control Pressure

Connecting Point

releases when the transmission selec-

tor lever is moved to a drive position.

4.

Adjust the engine idle speed lo

the specified rpm. If the engine idle

speed cannot be brought within limits

by adjustment at the carburetor idle

adjustment screw, check the throttle

and downshift linkage for a binding

condition. If the linkage is satisfacto-

ry, check for vacuum leaks in the

transmission diaphragm unit (Fig. 8

or 9) and its connecting tubes and

hoses.

Check all other vacuum oper-

ated units (such as the power brake)

for vacuum leaks.

VACUUM UNIT CHECK

NON-ALTITIDE

COMPENSATING TYPE

To check the vacuum unit for dia-

phragm leakage, remove the unit from

the transmission. Use a distributor

D1840-A

FIG. 8—Testing Transmission

Vacuum Unit for Leakage

VACUUM DIAPHRAGM

D 1643 -C

FIG. 5—Typical Vacuum Test

Line Connections

FIG.

7—Vacuum

Diaphragm and Control and TV Pressure Connecting

Points—C6 Transmissionprocarmanuals.com